radiator cap NISSAN NOTE 2016 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2332 of 3641

ENGINE MAINTENANCEMA-17

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

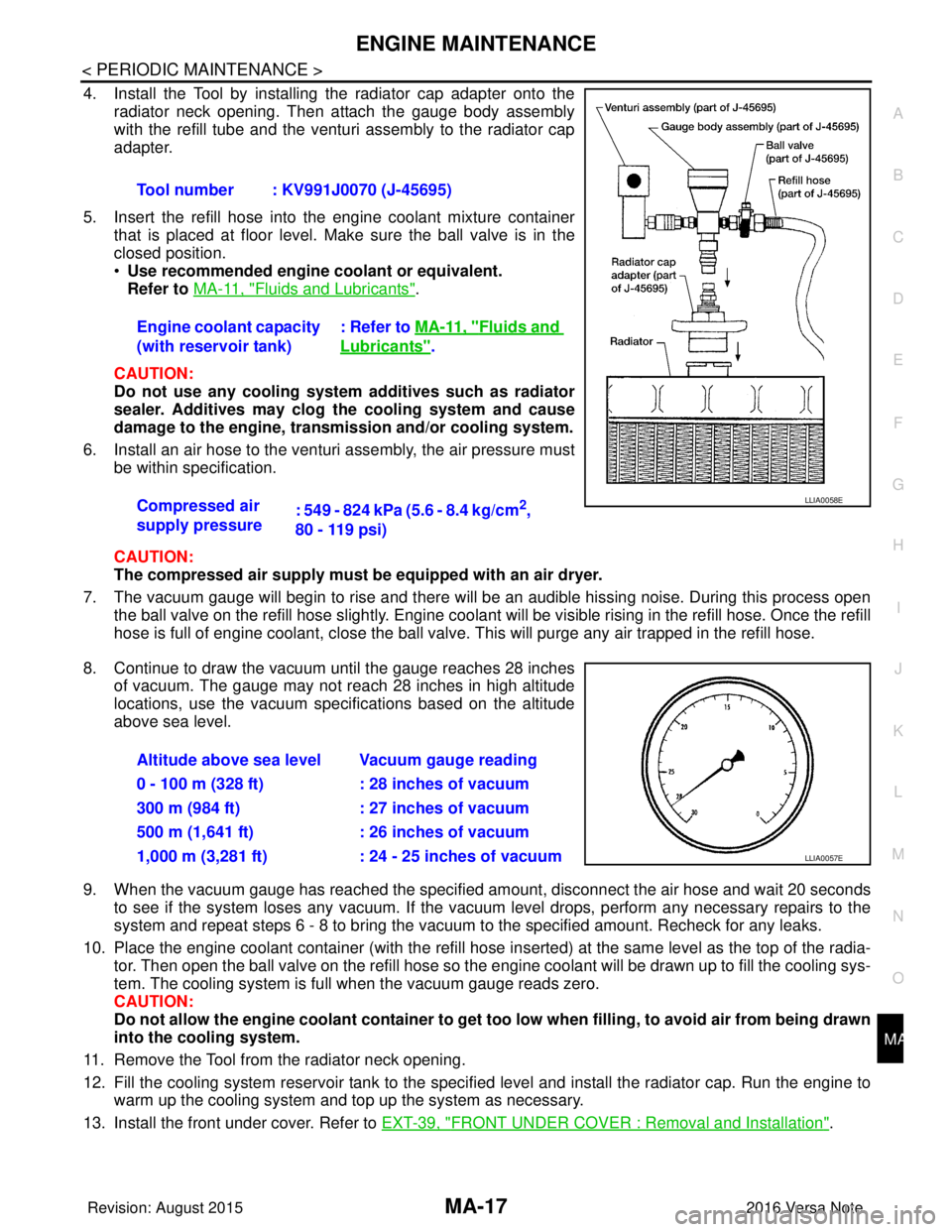

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the engine coolant mixture container that is placed at floor level. Make sure the ball valve is in the

closed position.

•Use recommended engine coolant or equivalent.

Refer to MA-11, "

Fluids and Lubricants".

CAUTION:

Do not use any cooling system additives such as radiator

sealer. Additives may clog the cooling system and cause

damage to the engine, transmission and/or cooling system.

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Engine coolant will be visible rising in the refill hose. Once the refill

hose is full of engine coolant, close the ball valve. This will purge any air trapped in the refill hose.

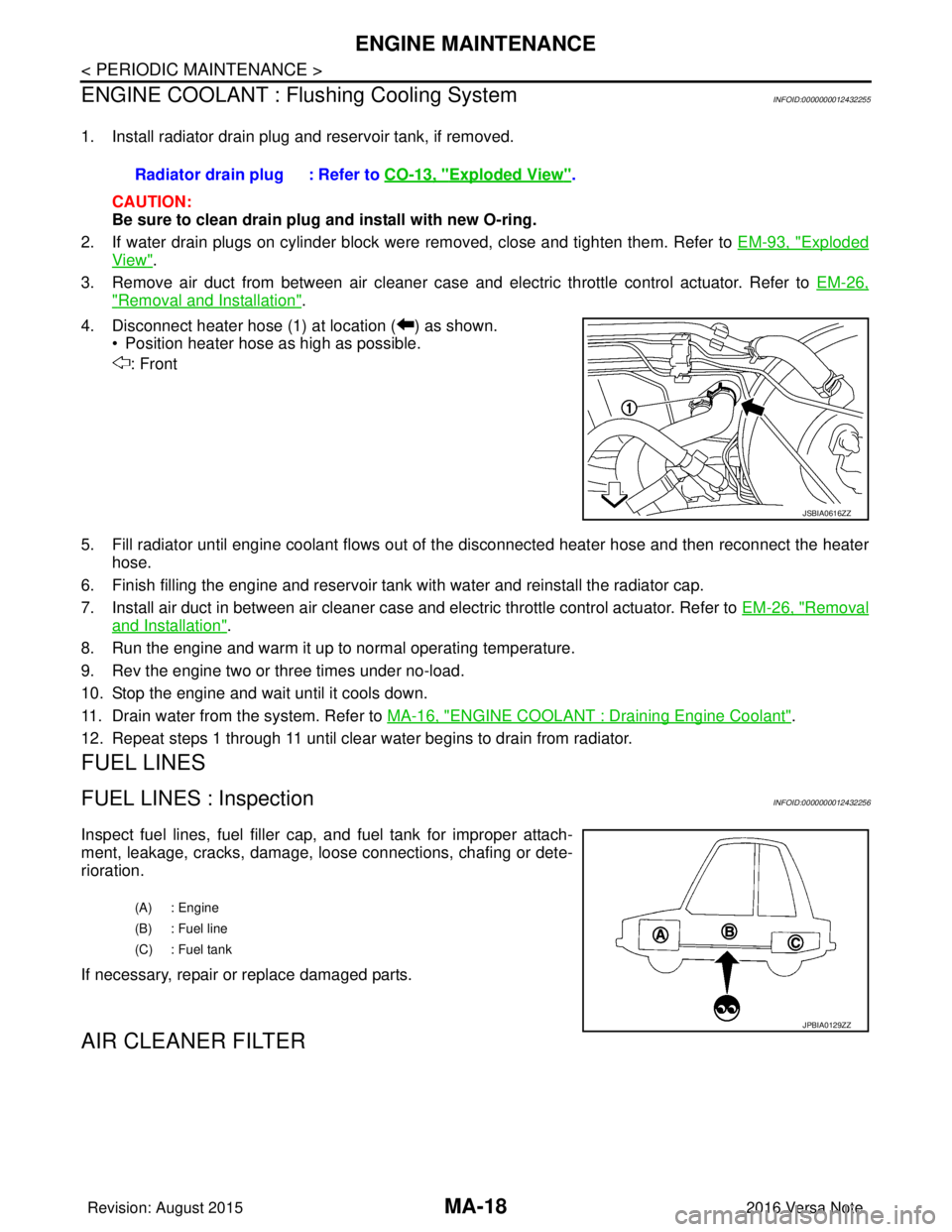

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specified amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to br ing the vacuum to the specified amount. Recheck for any leaks.

10. Place the engine coolant container (with the refill hose in serted) at the same level as the top of the radia-

tor. Then open the ball valve on the refill hose so the engine coolant will be drawn up to fill the cooling sys-

tem. The cooling system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the engine coolant co ntainer to get too low when filling, to avoid air from being drawn

into the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specif ied level and install the radiator cap. Run the engine to

warm up the cooling system and top up the system as necessary.

13. Install the front under cover. Refer to EXT-39, "

FRONT UNDER COVER : Removal and Installation".

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank)

: Refer to

MA-11, "

Fluids and

Lubricants".

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2333 of 3641

MA-18

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

ENGINE COOLANT : Flushing Cooling System

INFOID:0000000012432255

1. Install radiator drain plug and reservoir tank, if removed.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

2. If water drain plugs on cylinder block were removed, close and tighten them. Refer to EM-93, "

Exploded

View".

3. Remove air duct from between air cleaner case and electric throttle control actuator. Refer to EM-26,

"Removal and Installation".

4. Disconnect heater hose (1) at location ( ) as shown. • Position heater hose as high as possible.

: Front

5. Fill radiator until engine coolant flows out of the disconnected heater hose and then reconnect the heater

hose.

6. Finish filling the engine and reservoir tank with water and reinstall the radiator cap.

7. Install air duct in between air cleaner case and electric throttle control actuator. Refer to EM-26, "

Removal

and Installation".

8. Run the engine and warm it up to normal operating temperature.

9. Rev the engine two or three times under no-load.

10. Stop the engine and wait until it cools down.

11. Drain water from the system. Refer to MA-16, "

ENGINE COOLANT : Draining Engine Coolant".

12. Repeat steps 1 through 11 until clear water begins to drain from radiator.

FUEL LINES

FUEL LINES : InspectionINFOID:0000000012432256

Inspect fuel lines, fuel filler cap, and fuel tank for improper attach-

ment, leakage, cracks, damage, l oose connections, chafing or dete-

rioration.

If necessary, repair or replace damaged parts.

AIR CLEANER FILTER

Radiator drain plug : Refer to CO-13, "Exploded View".

JSBIA0616ZZ

(A) : Engine

(B) : Fuel line

(C) : Fuel tank

JPBIA0129ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3265 of 3641

![NISSAN NOTE 2016 Service Owners Guide TM-24

< UNIT REMOVAL AND INSTALLATION >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

UNIT REMOVAL AND INSTALLATION

TRANSAXLE ASSEMBLY

Exploded ViewINFOID:0000000012430961

Removal and InstallationINFOID:0000000012 NISSAN NOTE 2016 Service Owners Guide TM-24

< UNIT REMOVAL AND INSTALLATION >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

UNIT REMOVAL AND INSTALLATION

TRANSAXLE ASSEMBLY

Exploded ViewINFOID:0000000012430961

Removal and InstallationINFOID:0000000012](/img/5/57363/w960_57363-3264.png)

TM-24

< UNIT REMOVAL AND INSTALLATION >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

UNIT REMOVAL AND INSTALLATION

TRANSAXLE ASSEMBLY

Exploded ViewINFOID:0000000012430961

Removal and InstallationINFOID:0000000012430962

WARNING:

Do not remove the radiator cap when the engine is

hot. Serious burns could occur from high pressure

coolant escaping from the radiator. Wrap a thick clot h around the cap. Slowly turn it a quarter turn to

allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

CAUTION:

Do not reuse CSC (Concentric Slave Cylinder). The CSC slides back to the orig inal position every time

the transaxle assembly is removed. This action may allow dust or contaminants to gather on the slid-

ing parts and damage a seal of CSC causing clutch fluid leakage.

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove the engine and transaxle assembly. Refer to EM-87, "Removal and Installation".

2. Disconnect the reverse lamp switch harness connector.

3. Remove the bolts that fasten the transaxle assembly and engine assembly.

4. Remove transaxle assembly from the engine assembly.

5. Remove engine mounting bracket (LH). Refer to EM-86, "

Exploded View".

6. Remove CSC (Concentric Slave Cylinder). Refer to CL-17, "

Removal and Installation".

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Secure transaxle assembly to a suitable jack.

• The transaxle assembly must not interfere with the wire harnesses and clutch tube.

• When installing transaxle assembly, do not bring input shaft into contact with clutch cover.

• Bolt hole is not threaded on new clutch housing. Self-tapping bolt is used to attach lock plate to

clutch housing.

1. Transaxle assembly

: Refer to "INSTALLATION" in TM-24, "

Removal and Installation" for the locations and tightening torque.

JPDIC0478ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3492 of 3641

![NISSAN NOTE 2016 Service Owners Guide WATER HOSETM-251

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

WATER HOSE

Exploded ViewINFOID:0000000012431207

Removal and InstallationINFOID:0000000012431208

REMOVAL

WAR NISSAN NOTE 2016 Service Owners Guide WATER HOSETM-251

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

WATER HOSE

Exploded ViewINFOID:0000000012431207

Removal and InstallationINFOID:0000000012431208

REMOVAL

WAR](/img/5/57363/w960_57363-3491.png)

WATER HOSETM-251

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

WATER HOSE

Exploded ViewINFOID:0000000012431207

Removal and InstallationINFOID:0000000012431208

REMOVAL

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CAUTION:

Perform these steps after the engine cool ant temperature has cooled sufficiently.

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

1. Remove the hose clamp and pull out the water hose A.

2. Remove the hose clamp and pull out the water hose B.

3. Remove the hose clamp and pull out the water hose C.

4. Pull out the heater hose and remove the water bypass pipe.

5. Remove the heater thermostat assembly.

1. Hose clamp 2. Water hose A3. Clip

4. Bracket A 5. Bracket B6. CVT oil warner

7. Water hose B 8. Water bypass pipe9. Hose clamp

10. Water hose C 11. Water outlet

A. To heater core : Always replace after every disassembly.

: N·m (kg-m, in-lb)

JSDIA4111GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3497 of 3641

![NISSAN NOTE 2016 Service Owners Guide TM-256

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

CVT OIL WARMER

CVT OIL WARMER

Exploded ViewINFOID:0000000012431217

Removal and InstallationINFOID:0000000012431218

REMOVAL

WARNING:

Never remove the r NISSAN NOTE 2016 Service Owners Guide TM-256

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

CVT OIL WARMER

CVT OIL WARMER

Exploded ViewINFOID:0000000012431217

Removal and InstallationINFOID:0000000012431218

REMOVAL

WARNING:

Never remove the r](/img/5/57363/w960_57363-3496.png)

TM-256

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

CVT OIL WARMER

CVT OIL WARMER

Exploded ViewINFOID:0000000012431217

Removal and InstallationINFOID:0000000012431218

REMOVAL

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns coul

d occur from high pressure

engine coolant escaping from the radiator. Wrap a thick cloth ar ound the cap. Slowly turn it a quarter

turn to allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

CAUTION:

Perform these steps after the coolant temperature has cooled sufficiently.

1. Pull out water hose from CVT oil warmer. Refer to TM-251, "

Removal and Installation".

2. Pull out fluid cooler hose from CVT oil warmer. Refer to TM-254, "

Removal and Installation".

3. Remove CVT oil warmer.

4. Remove O-ring from CVT oil warmer.

INSTALLATION

Note the followings and install in the reverse order of removal.

CAUTION:

• Never reuse O-ring.

• Apply CVT fluid to O-ring.

InspectionINFOID:0000000012431219

INSPECTION AFTER INSTALLATION

Start the engine and check visually that ther e is no leakage of CVT fluid and engine coolant.

ADJUSTMENT AFTER INSTALLATION

Adjust CVT fluid level. Refer to TM-229, "Adjustment".

1. Transaxle assembly 2. CVT oil warmer 3. O-ring

: Always replace after every disassembly.

: N·m (kg-m, in-lb)

: Apply CVT fluid

JSDIA5447GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3500 of 3641

![NISSAN NOTE 2016 Service Owners Guide TRANSMISSION ASSEMBLYTM-259

< UNIT REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

UNIT REMOVAL AND INSTALLATION

TRANSMISSION ASSEMBLY

Exploded ViewINFOID:0000000012431223

Re NISSAN NOTE 2016 Service Owners Guide TRANSMISSION ASSEMBLYTM-259

< UNIT REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

UNIT REMOVAL AND INSTALLATION

TRANSMISSION ASSEMBLY

Exploded ViewINFOID:0000000012431223

Re](/img/5/57363/w960_57363-3499.png)

TRANSMISSION ASSEMBLYTM-259

< UNIT REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

UNIT REMOVAL AND INSTALLATION

TRANSMISSION ASSEMBLY

Exploded ViewINFOID:0000000012431223

Removal and InstallationINFOID:0000000012431224

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CAUTION:

• Perform these steps after the coolant temperature has cooled sufficiently.

• When replacing the transaxle, perform "ADDI TIONAL SERVICE WHEN REPLACING TRANSAXLE

ASSEMBLY". Refer to TM-127, "

Description".

NOTE:

When removing components such as hoses, tubes/line, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove the engine and transaxle assembly. Refer to EM-87, "Removal and Installation".

2. Disconnect the harness connectors and harnesses. • For CVT unit harness connector.

• Transmission position switch harness connector

1. Transaxle assembly

A : For the tightening torque, refer to TM-259, "

Removal and Installation".

JSDIA1890ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com