battery NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2350 of 3641

CHASSIS AND BODY MAINTENANCEMA-35

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

BRAKE FLUID

BRAKE FLUID : InspectionINFOID:0000000012432280

BRAKE FLUID LEVEL

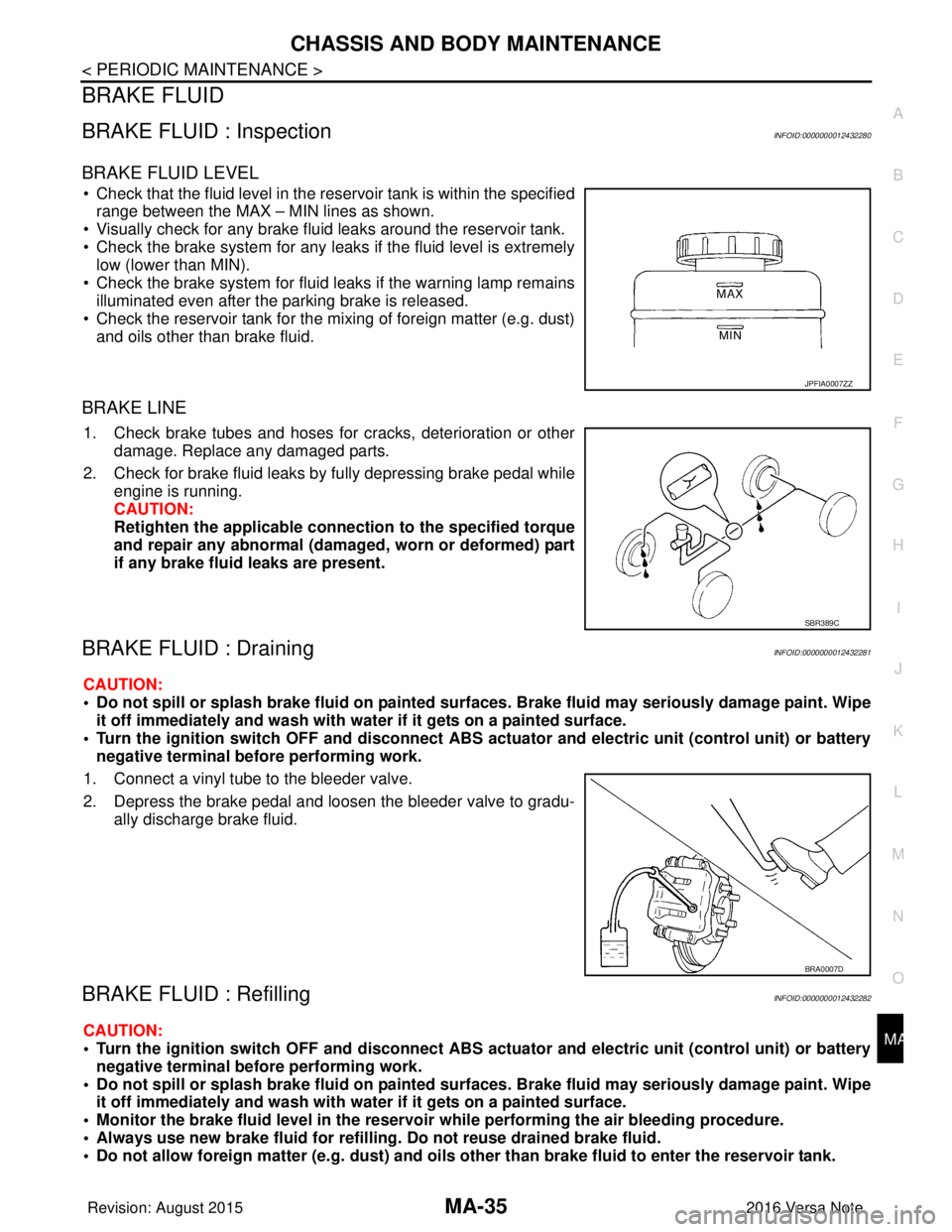

• Check that the fluid level in the re

servoir tank is within the specified

range between the MAX – MIN lines as shown.

• Visually check for any brake fluid leaks around the reservoir tank.

• Check the brake system for any leak s if the fluid level is extremely

low (lower than MIN).

• Check the brake system for fluid leaks if the warning lamp remains

illuminated even after the parking brake is released.

• Check the reservoir tank for the mixing of foreign matter (e.g. dust) and oils other than brake fluid.

BRAKE LINE

1. Check brake tubes and hoses for cracks, deterioration or other

damage. Replace any damaged parts.

2. Check for brake fluid leaks by fully depressing brake pedal while engine is running.

CAUTION:

Retighten the applicable conn ection to the specified torque

and repair any abnormal (damag ed, worn or deformed) part

if any brake fluid leaks are present.

BRAKE FLUID : DrainingINFOID:0000000012432281

CAUTION:

• Do not spill or splash brake fluid on painted su rfaces. Brake fluid may seriously damage paint. Wipe

it off immediately and wash with wa ter if it gets on a painted surface.

• Turn the ignition switch OFF an d disconnect ABS actuator and electric unit (control unit) or battery

negative terminal before performing work.

1. Connect a vinyl tube to the bleeder valve.

2. Depress the brake pedal and loosen the bleeder valve to gradu- ally discharge brake fluid.

BRAKE FLUID : RefillingINFOID:0000000012432282

CAUTION:

• Turn the ignition switch OFF an d disconnect ABS actuator and electric unit (control unit) or battery

negative terminal before performing work.

• Do not spill or splash brake fluid on painted su rfaces. Brake fluid may seriously damage paint. Wipe

it off immediately and wash with wa ter if it gets on a painted surface.

• Monitor the brake fluid level in the reservoir while performing the air bleeding procedure.

• Always use new brake fluid for refillin g. Do not reuse drained brake fluid.

• Do not allow foreign matter (e.g. dust) and oils ot her than brake fluid to enter the reservoir tank.

JPFIA0007ZZ

SBR389C

BRA0007D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2351 of 3641

MA-36

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

1. Check that there is no foreign material in the reservoir tank, andrefill with new brake fluid. Refer to MA-11, "

Fluids and Lubri-

cants".

2. Loosen the bleeder valve, slowly depress the brake pedal to the full stroke, and then release the pedal. Repeat this operation at

intervals of 2 or 3 seconds until new brake fluid is discharged.

Then close the bleeder valve with the brake pedal depressed.

Repeat the same work on each wheel.

3. Perform the air bleeding procedure. Refer to MA-36, "

BRAKE

FLUID : Bleeding Brake System".

BRAKE FLUID : Bleeding Brake SystemINFOID:0000000012432283

CAUTION:

• Turn the ignition switch OFF and disconnect ABS act uator and electric unit (control unit) or battery

negative terminal before performing the work.

• Monitor the fluid level in the reservoir tank while performing the air bleeding.

• Do not spill or splash brake fluid on painted su rfaces. Brake fluid may seriously damage paint. Wipe

it off immediately and wash with wa ter if it gets on a painted surface.

• Always use new brake fluid for refilling. Do not reuse drained brake fluid.

• Do not allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

1. Connect a vinyl tube to the bleeder valve.

2. Fully depress the brake pedal 4 to 5 times.

3. Loosen the bleeder valve and bleed air with the br ake pedal depressed, and then quickly tighten the

bleeder valve.

4. Repeat steps 2 and 3 until all of the air is out of the brake line.

5. Tighten the bleeder valve to the specified torque. • Front disc brake: Refer to BR-36, "

BRAKE CALIPER ASSEMBLY : Exploded View".

• Rear drum brake: Refer to BR-41, "

Exploded View".

6. Perform steps 1 to 5 in the following order: Front (RH) brake → front (LH) brake → rear (RH) brake → rear

(LH) brake.

7. Check that the fluid level in the reservoir tank is within the specified range after air bleeding. Refer to MA-

35, "BRAKE FLUID : Inspection".

8. Add brake fluid as necessary to keep the brake fluid level within the specified range. Refer to MA-11, "

Flu-

ids and Lubricants".

9. Inspect the brake pedal height and play. Adjust it if the measurement value is not the standard. Refer to

BR-9, "

Inspection and Adjustment".

DISC BRAKE

DISC BRAKE : InspectionINFOID:0000000012432284

INSPECTION

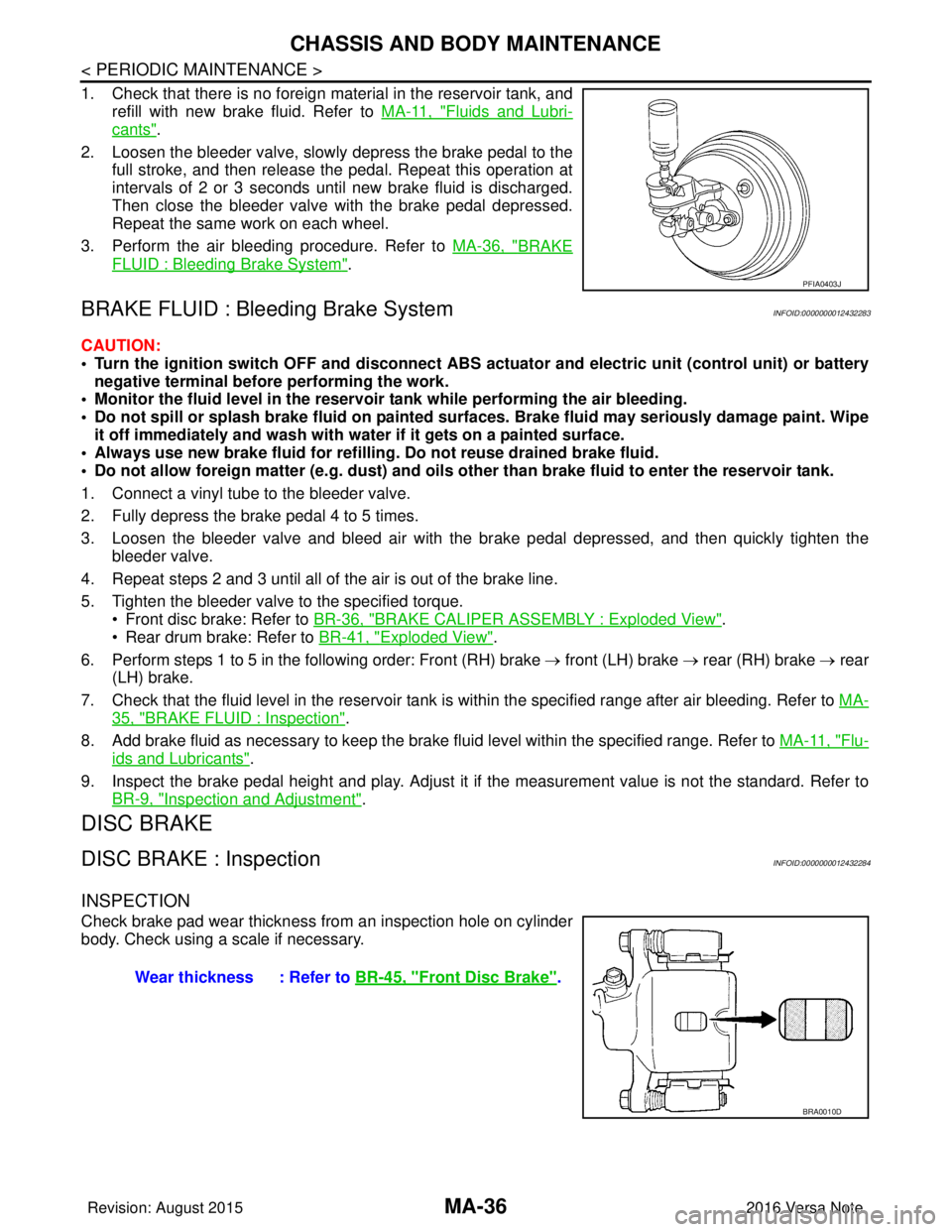

Check brake pad wear thickness from an inspection hole on cylinder

body. Check using a scale if necessary.

PFIA0403J

Wear thickness : Refer to BR-45, "Front Disc Brake".

BRA0010D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2364 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI-6

< PRECAUTION >[TYPE A]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432539

The Supplemental Re NISSAN NOTE 2016 Service Repair Manual MWI-6

< PRECAUTION >[TYPE A]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432539

The Supplemental Re](/img/5/57363/w960_57363-2363.png)

MWI-6

< PRECAUTION >[TYPE A]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432539

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2381 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI

COMBINATION METERMWI-23

< ECU DIAGNOSIS INFORMATION > [TYPE A]

C

D

E

F

G H

I

J

K L

M B A

O P

*1:For Canada

Fail-safeINFOID:0000000012432555

The combination meter activates the fail-safe contro l i NISSAN NOTE 2016 Service Repair Manual MWI

COMBINATION METERMWI-23

< ECU DIAGNOSIS INFORMATION > [TYPE A]

C

D

E

F

G H

I

J

K L

M B A

O P

*1:For Canada

Fail-safeINFOID:0000000012432555

The combination meter activates the fail-safe contro l i](/img/5/57363/w960_57363-2380.png)

MWI

COMBINATION METERMWI-23

< ECU DIAGNOSIS INFORMATION > [TYPE A]

C

D

E

F

G H

I

J

K L

M B A

O P

*1:For Canada

Fail-safeINFOID:0000000012432555

The combination meter activates the fail-safe contro l if CAN communication with each unit is malfunctioning.

Te r m i n a l

No. Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation or condition

1 L CAN high —— —

2 P CAN low —— —

3SB2P/R — — —

4LG8P/R — — —

6 W Fuel level sensor signal (+) — —Refer to MWI-46, "

Component Inspec-

tion".

7VAir bag — — —

8 P O/D OFF switch ONO/D OFF switch pressed

0

O/D OFF switch released Battery voltage

9 V Seat belt buckle switch LH ON Unfastened (ON)

0

Fastened (OFF) Battery voltage

10 SB Parking Brake switch ONParking brake is inactive

Battery voltage

Parking brake is active 0

11 BR Brake fluid level switch ON Brake fluid level low

0

Brake fluid level normal Battery voltage

13 B Illumination control —— —

15 R Ignition switch ON or ACC — —Battery voltage

17

*1V Washer fluid level switch ON Washer fluid level low 0

Washer fluid level normal

Battery voltage

18 GR Security —— —

21 B Ground —— 0

22 B

23 B

24 GR Fuel level sensor ground (-) ON —0

27 R/W Battery power supply OFF— Battery voltage

28 GR Ignition switch ON or START ON —Battery voltage

29 G Seat belt buckle switch RH ON Unfastened (ON)

0

Fastened (OFF) Battery voltage

38 Y Generator ONGenerator voltage low

0

Generator voltage normal Battery voltage

Function Specifications

Speedometer Reset to zero by suspending communication.

Tachometer

Illumination control When suspending communication, changes to nighttime mode.

Shift position indicator When suspending communication, not indicate.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2401 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI

POWER SUPPLY AND GROUND CIRCUITMWI-43

< DTC/CIRCUIT DIAGNOSIS > [TYPE A]

C

D

E

F

G H

I

J

K L

M B A

O P

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

COMBINATION METER : Diagnosis ProcedureINFO NISSAN NOTE 2016 Service Repair Manual MWI

POWER SUPPLY AND GROUND CIRCUITMWI-43

< DTC/CIRCUIT DIAGNOSIS > [TYPE A]

C

D

E

F

G H

I

J

K L

M B A

O P

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

COMBINATION METER : Diagnosis ProcedureINFO](/img/5/57363/w960_57363-2400.png)

MWI

POWER SUPPLY AND GROUND CIRCUITMWI-43

< DTC/CIRCUIT DIAGNOSIS > [TYPE A]

C

D

E

F

G H

I

J

K L

M B A

O P

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

COMBINATION METER : Diagnosis ProcedureINFOID:0000000012432574

Regarding Wiring Diagram information, refer to MWI-26, "Wiring Diagram".

1.CHECK FUSE

Check that the following fuses are not blown.

Is the fuse blown?

YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

2.POWER SUPPLY CIRCUIT CHECK

1. Disconnect combination meter connector.

2. Check voltage between combination meter harness connector M82, terminals 27, 28, 15 and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connector.

3.GROUND CIRCUIT CHECK

1. Turn ignition switch OFF.

2. Disconnect combination meter connector.

3. Check continuity between combination meter harness connector M82, terminals 21, 22, 23 and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair or replace harness or connector.

BCM (BODY CONTROL MODULE)

Power source Fuse No.

Battery 8

Ignition switch ON or START 3

Ignition switch ACC or ON 18

TerminalsIgnition switch position

(+) (–)OFF ACC ONSTART

Connector Terminal

M82 27

GroundBattery voltage Battery voltage Battery voltage Battery voltage

28 0V0VBattery voltage Battery voltage

15 0V Battery voltage Battery voltage 0V

Te r m i n a l s

Continuity

(+)

(–)

Connector Terminal

M82 21

Ground Yes

22

23

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2402 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI-44

< DTC/CIRCUIT DIAGNOSIS >[TYPE A]

POWER SUPPLY AND GROUND CIRCUIT

BCM (BODY CONTROL MODULE) : Diagnosis Procedure

INFOID:0000000012542950

Regarding Wiring Diagram information, refer to BCS-11 NISSAN NOTE 2016 Service Repair Manual MWI-44

< DTC/CIRCUIT DIAGNOSIS >[TYPE A]

POWER SUPPLY AND GROUND CIRCUIT

BCM (BODY CONTROL MODULE) : Diagnosis Procedure

INFOID:0000000012542950

Regarding Wiring Diagram information, refer to BCS-11](/img/5/57363/w960_57363-2401.png)

MWI-44

< DTC/CIRCUIT DIAGNOSIS >[TYPE A]

POWER SUPPLY AND GROUND CIRCUIT

BCM (BODY CONTROL MODULE) : Diagnosis Procedure

INFOID:0000000012542950

Regarding Wiring Diagram information, refer to BCS-117, "Wiring Diagram".

1.CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connectors.

3. Check voltage between BCM connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM connector and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

Terminal No. Signal nameFuses and fusible link No.

37 Battery power supply 8 (10A)

42 12 (10A)

50 G (40A)

11 Ignition switch ACC or ON 18 (10A)

38 Ignition switch ON or START 2 (10A)

BCMGround Ignition switch position

Connector Terminal

—OFF

ACC ON

M18 11

0 V

Battery voltage

Battery voltage

37

Battery voltage

38 0 V0 V

M19 42

Battery voltage Battery voltage

50

BCM GroundContinuity

Connector Terminal

M19 55—Yes

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2412 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI-54

< REMOVAL AND INSTALLATION >[TYPE A]

COMBINATION METER

REMOVAL AND INSTALLATION

COMBINATION METER

Removal and InstallationINFOID:0000000012432595

REMOVAL

1. Disconnect negative battery terminal NISSAN NOTE 2016 Service Repair Manual MWI-54

< REMOVAL AND INSTALLATION >[TYPE A]

COMBINATION METER

REMOVAL AND INSTALLATION

COMBINATION METER

Removal and InstallationINFOID:0000000012432595

REMOVAL

1. Disconnect negative battery terminal](/img/5/57363/w960_57363-2411.png)

MWI-54

< REMOVAL AND INSTALLATION >[TYPE A]

COMBINATION METER

REMOVAL AND INSTALLATION

COMBINATION METER

Removal and InstallationINFOID:0000000012432595

REMOVAL

1. Disconnect negative battery terminal. Refer to

PG-70, "Removal and Installation (Battery)".

2. Remove cluster lid A. Refer to IP-21, "

Removal and Installation".

3. Remove combination meter screws (A).

4. Pull the combination meter straight out to release clips. NOTE:

Back side of the combination meter shown for clip position ( )

clarity.

5. Disconnect the harness connector from the combination meter.

INSTALLATION

Installation is in the reverse order of removal.

ALNIA1519ZZ

JSNIA3895ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2414 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI-56

< PRECAUTION >[TYPE B]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432597

The Supplemental R NISSAN NOTE 2016 Service Repair Manual MWI-56

< PRECAUTION >[TYPE B]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432597

The Supplemental R](/img/5/57363/w960_57363-2413.png)

MWI-56

< PRECAUTION >[TYPE B]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432597

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2434 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI-76

< ECU DIAGNOSIS INFORMATION >[TYPE B]

COMBINATION METER

TERMINAL LAYOUT

PHYSICAL VALUES

JSNIA5390ZZ

Te r m i n a l

No. Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch NISSAN NOTE 2016 Service Repair Manual MWI-76

< ECU DIAGNOSIS INFORMATION >[TYPE B]

COMBINATION METER

TERMINAL LAYOUT

PHYSICAL VALUES

JSNIA5390ZZ

Te r m i n a l

No. Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch](/img/5/57363/w960_57363-2433.png)

MWI-76

< ECU DIAGNOSIS INFORMATION >[TYPE B]

COMBINATION METER

TERMINAL LAYOUT

PHYSICAL VALUES

JSNIA5390ZZ

Te r m i n a l

No. Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation or condition

1 L CAN high —— —

2 P CAN low —— —

4LG8P/R — — —

6 W Fuel level sensor signal (+) — —Refer to

MWI-102, "

Component Inspec-

tion".

7VAir bag — — —

8 P O/D OFF switch ONO/D OFF switch pressed

0

O/D OFF switch released Battery voltage

9 V Seat belt buckle switch LH ON Unfastened (ON)

0

Fastened (OFF) Battery voltage

10 SB Parking Brake switch ONParking brake is inactive

Battery voltage

Parking brake is active 0

11 BR Brake fluid level switch ON Brake fluid level low

0

Brake fluid level normal Battery voltage

15 R Ignition switch ON or ACC — —Battery voltage

16 B Illumination control switch (-) — ——

17

*1V Washer fluid level switch ON Washer fluid level low 0

Washer fluid level normal

Battery voltage

18 GR Security —— —

19 V Ambient sensor signal (+) ON ——

20 R Ambient sensor ground (-) — —0

21 B Ground —— 0

22 B

23 B

24 GR Fuel level sensor ground (-) ON —0

27 R/W Battery power supply OFF— Battery voltage

28 GR Ignition switch ON or START ON —Battery voltage

29 G Seat belt buckle switch RH ON Unfastened (ON)

0

Fastened (OFF) Battery voltage

36 LG Steering switch

(meter control switch)

——

—

38 Y Generator ONGenerator voltage low

0

Generator voltage no rmalBattery voltage

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2456 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI-98

< DTC/CIRCUIT DIAGNOSIS >[TYPE B]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

COMBINATION METER : Diagnosis ProcedureINFOID:0000000012432633

Regarding Wiri NISSAN NOTE 2016 Service Repair Manual MWI-98

< DTC/CIRCUIT DIAGNOSIS >[TYPE B]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

COMBINATION METER : Diagnosis ProcedureINFOID:0000000012432633

Regarding Wiri](/img/5/57363/w960_57363-2455.png)

MWI-98

< DTC/CIRCUIT DIAGNOSIS >[TYPE B]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

COMBINATION METER : Diagnosis ProcedureINFOID:0000000012432633

Regarding Wiring Diagram information, refer to

MWI-79, "Wiring Diagram".

1.CHECK FUSE

Check that the following fuses are not blown.

Is the fuse blown?

YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

2.POWER SUPPLY CIRCUIT CHECK

1. Disconnect combination meter connector.

2. Check voltage between combination meter harne ss connector M24, terminals 27, 28, 15 and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connector.

3.GROUND CIRCUIT CHECK

1. Turn ignition switch OFF.

2. Disconnect combination meter connector.

3. Check continuity between combination meter har ness connector M24, terminals 21, 22, 23 and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair or replace harness or connector.

BCM (BODY CONTROL SYSTEM) (WIT HOUT INTELLIGENT KEY SYSTEM)

BCM (BODY CONTROL SYSTEM) (WITHOUT INTELLIGENT KEY SYSTEM) : Diag-

Power source Fuse No.

Battery 8

Ignition switch ON or START 3

Ignition switch ACC or ON 18

TerminalsIgnition switch position

(+) (–)OFF ACC ONSTART

Connector Terminal

M24 27

GroundBattery voltage Battery voltage Battery voltage Battery voltage

28 0V0VBattery voltage Battery voltage

15 0V Battery voltage Battery voltage 0V

Te r m i n a l s

Continuity

(+)

(–)

Connector Terminal

M24 21

Ground Yes

22

23

Revision: August 2015 2016 Versa Note

cardiagn.com