battery NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2573 of 3641

![NISSAN NOTE 2016 Service Repair Manual PCS-70

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

PUSH-BUTTON IGNITION SWITCH

PUSH-BUTTON IGNITION SWITCH

Component Function CheckINFOID:0000000012433317

1.CHECK FUNCTION

1. Select PUSH SW i NISSAN NOTE 2016 Service Repair Manual PCS-70

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

PUSH-BUTTON IGNITION SWITCH

PUSH-BUTTON IGNITION SWITCH

Component Function CheckINFOID:0000000012433317

1.CHECK FUNCTION

1. Select PUSH SW i](/img/5/57363/w960_57363-2572.png)

PCS-70

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

PUSH-BUTTON IGNITION SWITCH

PUSH-BUTTON IGNITION SWITCH

Component Function CheckINFOID:0000000012433317

1.CHECK FUNCTION

1. Select PUSH SW in Data Monitor of BCM with CONSULT.

2. Check the push-button ignition switch signal under the following conditions.

Is the indication normal?

YES >> Inspection End.

NO >> Go to PCS-70, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012433318

Regarding Wiring Diagram information, refer to PCS-42, "Wiring Diagram".

1. CHECK PUSH-BUTTON IGNITION SWITCH OUTPUT SIGNAL (PUSH-BUTTON IGNITION SWITCH)

1. Turn ignition switch OFF.

2. Disconnect push-button ignition switch connector and IPDM E/R connector E47.

3. Check voltage between push-button ignition switch connector M25 terminal 8 and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2. CHECK PUSH-BUTTON IGNI TION SWITCH CIRCUIT (BCM)

1. Disconnect BCM connector M98.

2. Check continuity between BCM connector M98 terminal 76 and push-button ignition switch connector M25 terminal 8.

3. Check continuity between BCM connector M98 terminal 76 and ground.

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-74, "Removal and Installation".

NO >> Repair or replace harness or connectors.

3. CHECK IGNITION SWITCH OU TPUT SIGNAL (IPDM E/R)

Check voltage between IPDM E/R connector E47 terminal 81 and ground.

Test item ConditionStatus

PUSH SW Push-button ignition switch is pressed

On

Push-button ignition switch is not pressed Off

Push-button ignition switch

GroundVo l ta g e

(Approx.)

Connector Terminal

M25 8—Battery voltage

BCM Push-button ignition switch

Continuity

Connector TerminalConnector Terminal

M 987 6M 25 8 Y es

BCM

Ground Continuity

Connector Terminal

M98 76 — No

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2574 of 3641

![NISSAN NOTE 2016 Service Repair Manual PCS

PUSH-BUTTON IGNITION SWITCHPCS-71

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4. CHECK PUSH- NISSAN NOTE 2016 Service Repair Manual PCS

PUSH-BUTTON IGNITION SWITCHPCS-71

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4. CHECK PUSH-](/img/5/57363/w960_57363-2573.png)

PCS

PUSH-BUTTON IGNITION SWITCHPCS-71

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4. CHECK PUSH-BUTTON IGNITION SWITCH CIRCUIT (IPDM E/R)

1. Disconnect BCM connector M98.

2. Check continuity between IPDM E/R connector E47 terminal 81 and push-button ignition switch connector

M25 terminal 8.

3. Check continuity between IPDM E/R connector E47 terminal 81 and ground.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation".

NO >> Repair or replace harness or connectors.

5.CHECK PUSH-BUTTON IGNITION SWITCH GROUND CIRCUIT

Check continuity between push-button igniti on switch connector M25 terminal 4 and ground.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace harness or connectors.

6.CHECK PUSH-BUTTON IGNITION SWITCH

Refer to PCS-71, "

Component Inspection".

Is the inspection result normal?

YES >> Refer to GI-42, "Intermittent Incident".

NO >> Replace push-button ignition switch. Refer to PCS-77, "

Removal and Installation".

Component InspectionINFOID:0000000012433319

1.CHECK PUSH-BUTTON IGNITION SWITCH

1. Turn ignition switch OFF.

2. Disconnect push-button ignition switch connector.

3. Check continuity between push-button ignition switch terminals.

Is the inspection result normal?

IPDM E/R GroundVo l ta g e

(Approx.)

Connector Terminal

E47 81—Battery voltage

IPDM E/R Push-button ignition switch

Continuity

Connector TerminalConnector Terminal

E47 81M25 8Yes

IPDM E/R

Ground Continuity

Connector Terminal

E47 81 — No

Push-button ignition switch GroundContinuity

Connector Terminal

M25 4— Yes

Push-button ignition switch terminals ConditionContinuity

4 – 8 Pressed

Yes

Not pressed No

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2576 of 3641

![NISSAN NOTE 2016 Service Repair Manual PCS

POWER SUPPLY AND GROUND CIRCUITPCS-73

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:000000 NISSAN NOTE 2016 Service Repair Manual PCS

POWER SUPPLY AND GROUND CIRCUITPCS-73

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:000000](/img/5/57363/w960_57363-2575.png)

PCS

POWER SUPPLY AND GROUND CIRCUITPCS-73

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000012542520

Regarding Wiring Diagram information, refer to

BCS-52, "Wiring Diagram".

1.CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Disconnect BCM connector M99.

2. Check voltage between BCM connector M99 and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM connector M99 and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

IPDM E/R (INTELLIGENT POWER DIST RIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000012542521

Regarding Wiring Diagram information, refer to PCS-21, "Wiring Diagram".

1. CHECK FUSE AND FUSIBLE LINKS

Check that the following IPDM E/R fuse or fusible links are not blown.

Terminal No. Signal nameFuses and fusible link No.

57 Battery power supply 12 (10A)

70 G (40A)

BCM

Ground Voltage

Connector Terminal

M99 57

— Battery voltage

70

BCM GroundContinuity

Connector Terminal

M99 67—Yes

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2577 of 3641

![NISSAN NOTE 2016 Service Repair Manual PCS-74

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> NISSAN NOTE 2016 Service Repair Manual PCS-74

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >>](/img/5/57363/w960_57363-2576.png)

PCS-74

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2.

2. CHECK BATTERY POWER SUPPLY CIRCUIT

1. Disconnect IPDM E/R connector E42.

2. Check voltage between IPDM E/R connector E42 and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connectors.

3. CHECK GROUND CIRCUIT

1. Disconnect IPDM E/R connectors E45, E46 and E47.

2. Check continuity between IPDM E/R connectors and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair or replace harness or connectors.

Terminal No. Signal nameFuse and fusible link Nos.

1 Battery power supply A (120A), E (80A)

2 B (60A)

IPDM E/R

GroundVol tag e

(Approx.)

Connector Terminal

E42 1

—Battery voltage

2

IPDM E/R

GroundContinuity

Connector Terminal

E45 19

Ye s

E46 60

E47 89

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2582 of 3641

PWO-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432097

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for WorkINFOID:0000000012432098

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2588 of 3641

PG

PG-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION PG

A

O P

N

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

PRECAUTION .......

........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Power Generation Voltage Variable

Control System ..........................................................

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tools .......................................... ......4

Commercial Service Tool ..........................................4

SYSTEM DESCRIPTION ..............................5

ELECTRICAL UNITS LOCATION .................. .....5

Electrical Units Location ...................................... ......5

COMPONENT PARTS ........................................9

Circuit Breaker (Built Into BCM) .......................... ......9

Harness Connector ...................................................9

Standardized Relay ............................................. ....12

WIRING DIAGRAM ......................................15

POWER SUPPLY ROUTING CIRCUIT .......... ....15

Wiring Diagram — Battery Power Supply — ....... ....15

Wiring Diagram — Accessory Power Supply — .....23

Wiring Diagram — Ignition Power Supply — ..........27

GROUND ............................................................35

Ground Distribution ............................................. ....35

HARNESS ...................................................... ....42

Harness Layout ................................................... ....42

FUSE BLOCK - JUNCTION BOX (J/B) .............58

Terminal Arrangement ............................................58

FUSE AND FUSIBLE LINK BOX ................... ....59

Terminal Arrangement ............................................59

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

60

IPDM E/R Terminal Arrangement ........................ ....60

BASIC INSPECTION ...................................61

BATTERY ..........................................................61

How to Handle Battery ......................................... ....61

Work Flow ................................................................61

INSPECTION AND ADJUSTMENT ..................64

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ............................... ....

64

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Special Re-

pair Requirement .....................................................

64

FUSE INSPECTION ..........................................65

How To Check .........................................................65

FUSIBLE LINK INSPECTION ...........................69

Fusible Link .............................................................69

REMOVAL AND INSTALLATION ...............70

BATTERY ..........................................................70

Exploded View ..................................................... ....70

Removal and Installation (Battery) ..........................70

Removal and Installation (Battery Tray) ..................71

BATTERY TERMINAL WITH FUSIBLE LINK ...72

Exploded View .........................................................72

Removal and Installation .........................................72

BATTERY CURRENT SENSOR .......................73

Exploded View .........................................................73

Removal and Installation .........................................73

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

74

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2589 of 3641

PG-2

SERVICE DATA AND SPECIFICATIONS

(SDS) ..................................................................

74

Battery .................................................................. ...74

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2590 of 3641

PG

PRECAUTIONSPG-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

B A

O P

N

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012433111

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for Power Generation Voltage Variable Control SystemINFOID:0000000012433112

CAUTION:

For this model, the battery current sensor that is in stalled to the battery cable at the negative terminal

measures the charging/discharging current of the battery, and performs various controls. If the electri-

cal component or the ground wire is connected direct ly to the battery terminal, the current other than

that being measured with the battery current sensor is charging to or discharging from the battery.

This condition causes the malfunction of the control, and then the battery discharge may occur. Do

not connect the electrical component or the gr ound wire directly to the battery terminal.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2591 of 3641

PG-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000012433113

The actual shape of the tools may differ from those illustrated here.

Commercial Service ToolINFOID:0000000012433114

Tool number

(TechMate No.)

Tool nameDescription

—

(—) Model GR8-1200 NI

Multitasking battery and electrical diag-

nostic station Tests batteries, starting and charging

systems and charges batteries.

For operating instructions, refer to diag-

nostic station instruction manual.

—

(—) Model EXP-800 NI

Battery and electrical diagnostic analyzer Tests batteries and charging systems.

For operating instructions, refer to diag-

nostic analyzer instruction manual.

AWIIA1239ZZ

JSMIA0806ZZ

Tool name

Description

Power tool Loosening nuts, screws and bolts

PIIB1407E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2602 of 3641

PG

POWER SUPPLY ROUTING CIRCUITPG-15

< WIRING DIAGRAM >

C

DE

F

G H

I

J

K L

B A

O P

N

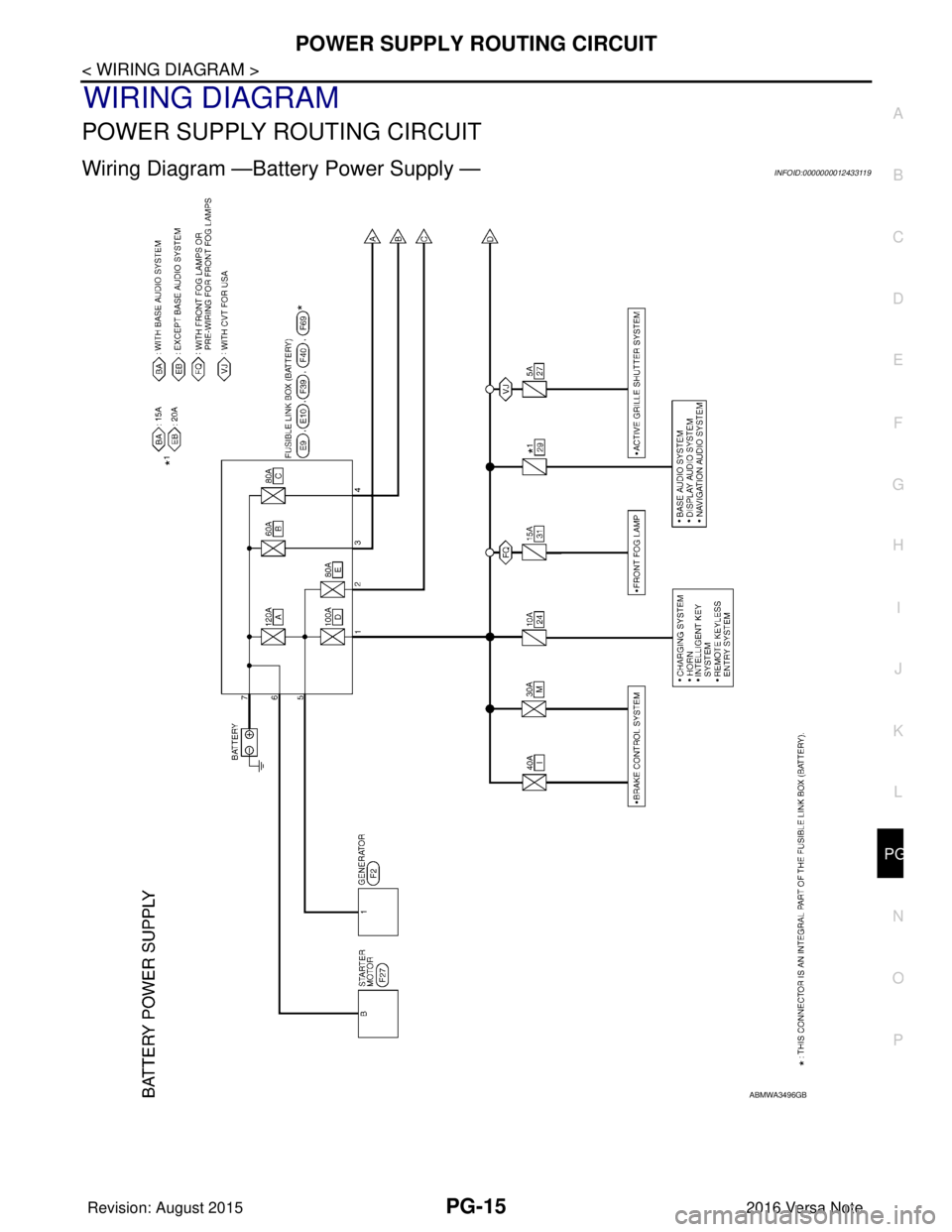

WIRING DIAGRAM

POWER SUPPLY ROUTING CIRCUIT

Wiring Diagram —Battery Power Supply —INFOID:0000000012433119

ABMWA3496GB

Revision: August 2015

2016 Versa Note

cardiagn.com