start NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 3177 of 3641

DIAGNOSIS AND REPAIR WORKFLOWSTR-25

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

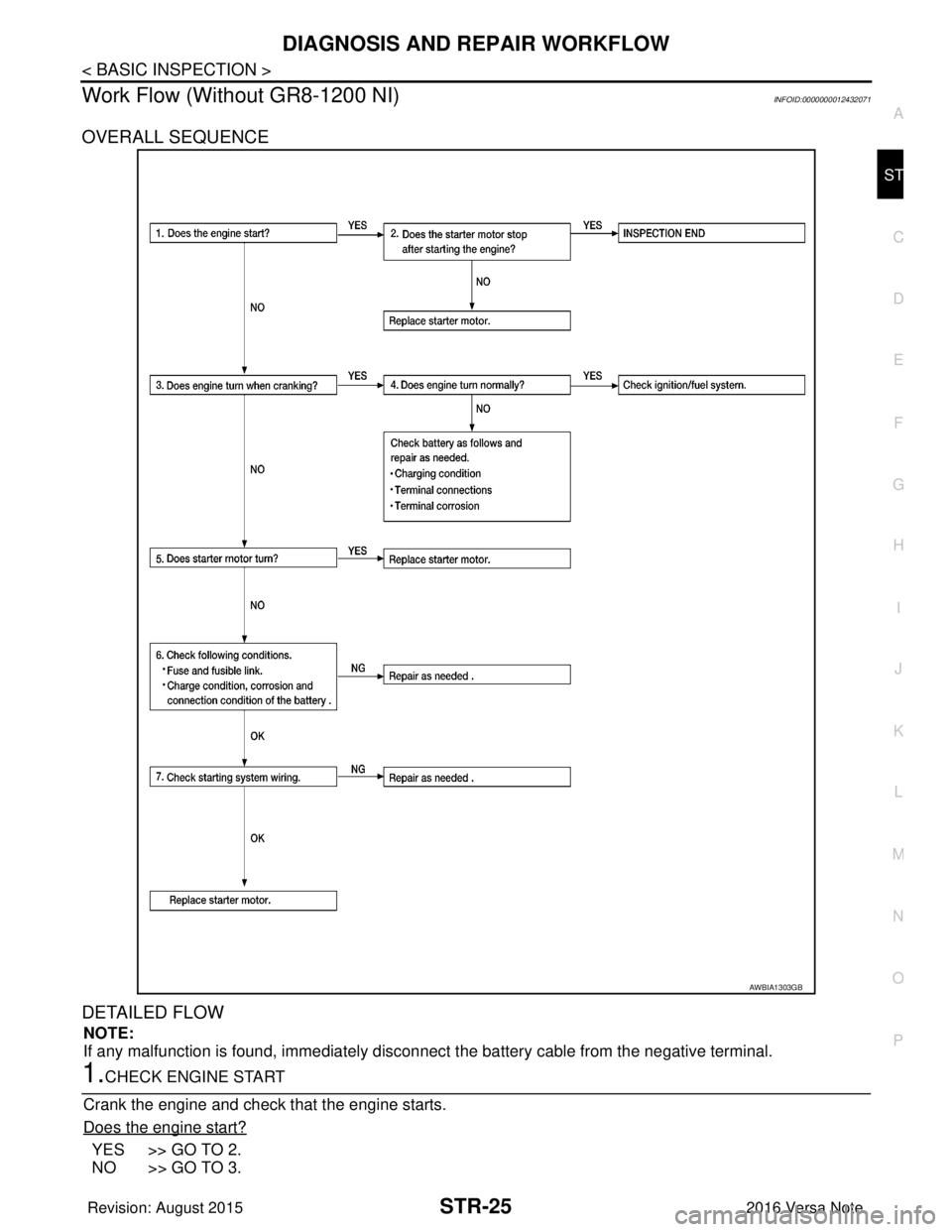

Work Flow (Without GR8-1200 NI)INFOID:0000000012432071

OVERALL SEQUENCE

DETAILED FLOW

NOTE:

If any malfunction is found, immediately disconnec

t the battery cable from the negative terminal.

1.CHECK ENGINE START

Crank the engine and check that the engine starts.

Does the engine start?

YES >> GO TO 2.

NO >> GO TO 3.

AWBIA1303GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3178 of 3641

STR-26

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

2.CHECK THAT THE STARTER MOTOR STOPS

Check that the starter motor stops after starting the engine.

Does the starter motor stop?

YES >> Inspection End.

NO >> Replace starter motor. Refer to STR-31, "

Removal and Installation".

3.CHECK THAT THE ENGINE TURNS WHEN CRANKING

Check that the engine turns when cranking.

Does engine turn when cranking?

YES >> GO TO 4.

NO >> GO TO 5.

4.CHECK THE ENGINE SPEED WHEN CRANKING

Check that the engine speed is not low when cranking.

Does engine turn normally?

YES >> Check ignition/fuel system.

NO >> Check charge condition, corrosion and connection condition of the battery. Refer to PG-61, "

How

to Handle Battery".

5.CHECK STARTER MOTOR ACTIVATION

Check that the starter motor runs at cranking.

Does starter motor turn?

YES >> Replace starter motor. Refer to STR-31, "Removal and Installation".

NO >> GO TO 6.

6.CHECK POWER SUPPLY CIRCUIT

Check the following conditions:

• Fuse and fusible link

• Charge condition, corrosion and connection of the battery.

Are these inspection results normal?

YES >> GO TO 7.

NO >> Repair as needed.

7.CHECK STARTING SYSTEM WIRING

Check the following:

• “B” terminal circuit. Refer to STR-27, "

Diagnosis Procedure".

• “S” terminal circuit. Refer to STR-29, "

Diagnosis Procedure".

Are the inspection results normal?

YES >> Replace starter motor. Refer to STR-31, "Removal and Installation".

NO >> Repair as needed.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3179 of 3641

B TERMINAL CIRCUITSTR-27

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

DTC/CIRCUIT DIAGNOSIS

B TERMINAL CIRCUIT

DescriptionINFOID:0000000012432072

Terminal “B” is constantly supplied with battery power.

Diagnosis ProcedureINFOID:0000000012432073

Regarding Wiring Diagram information, refer to

STR-10, "Wiring Diagram - With Intelligent Key System" or

STR-16, "

Wiring Diagram - Without Intelligent Key System".

CAUTION:

Perform diagnosis under the cond ition that the engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possi ble) until the fuel pressure is released.

1.CHECK “B” TERMINAL CIRCUIT

1. Turn ignition switch OFF.

2. Check that starter motor B” terminal connection is clean and tight.

3. Check voltage between starter motor connector F27 and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check harness between battery and starter motor for open circuit.

2.CHECK BATTERY CABLE CONNECTION STATUS (VOLTAGE DROP TEST)

1. Shift selector lever to P (P ark) or N (Neutral) position.

2. Check voltage between battery positive terminal and starter motor B terminal.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check harness between the battery and starter motor for continuity.

3.CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

1. Shift selector lever to P (P ark) or N (Neutral) position.

2. Check voltage between starter motor case and battery negative terminal.

Is the inspection result normal?

Te r m i n a l s

Voltage

(Approx.)

(+)

(-)

Starter motor “B” terminal Terminal

F27 BGround Battery voltage

Te r m i n a l s

ConditionVoltage

(Approx.)

(+) (-)

Starter motor “B“ terminal Terminal

Battery positive terminal F27 B When the ignition switch is in START position Less than 0.5V

Te r m i n a l s

ConditionVoltage

(Approx.)

(+) (-)

Starter motor case Battery negative terminal When the ignition switch is in

START position Less than 0.2V

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 3180 of 3641

STR-28

< DTC/CIRCUIT DIAGNOSIS >

B TERMINAL CIRCUIT

YES >> “B” terminal circuit is OK. Further inspection is necessary. Refer to STR-21, "Work Flow (With

GR8-1200 NI)" or STR-25, "Work Flow (Without GR8-1200 NI)".

NO >> Check the starter motor case to engine mounting for high resistance.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3181 of 3641

S CONNECTOR CIRCUITSTR-29

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

S CONNECTOR CIRCUIT

DescriptionINFOID:0000000012432074

The starter motor magnetic switch is supplied with power when the ignition switch is turned to the START posi-

tion while the selector lever is in the P (Park) or N (Neutral) position.

Diagnosis ProcedureINFOID:0000000012432075

Regarding Wiring Diagram information, refer to

STR-10, "Wiring Diagram - With Intelligent Key System" or

STR-16, "

Wiring Diagram - Without Intelligent Key System".

CAUTION:

Perform diagnosis under the cond ition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possi ble) until the fuel pressure is released.

1.CHECK “S” CONNECTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector.

3. Shift selector lever to “P” (Park) or “N” (Neutral) position.

4. Check voltage between starter motor harness connector F28 and ground.

Is the inspection result normal?

YES >> “S” circuit is OK. Further inspection is necessary. Refer to STR-21, "Work Flow (With GR8-1200

NI)" or STR-25, "Work Flow (Without GR8-1200 NI)".

NO >> GO TO 2.

2.CHECK HARNESS CONTINUI TY (OPEN CIRCUIT)

1. Disconnect IPDM E/R connector.

2. Check continuity between starter motor harnes s connector F28 and the IPDM E/R harness connector

E43.

3. Check continuity between starter motor connector F28 terminal S and ground.

Is the inspection result normal?

YES >> Further inspection is necessary. Refer to STR-21, "Work Flow (With GR8-1200 NI)" or STR-25,

"Work Flow (Without GR8-1200 NI)".

NO >> Repair or replace the harness or connectors.

(+) (-)

Condition Voltage

(Approx.)

Connector Terminal

F28 SGround When the ignition switch is in START position Battery voltage

Starter motor harness connector IPDM E/R harness connector

Continuity

Connector TerminalConnector Terminal

F28 SE43 6Yes

Connector Terminal –Continuity

F28 SGround No

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3182 of 3641

STR-30

< SYMPTOM DIAGNOSIS >

STARTING SYSTEM

SYMPTOM DIAGNOSIS

STARTING SYSTEM

Symptom TableINFOID:0000000012432076

SymptomReference

No normal cranking Refer to STR-21, "

Work Flow (With GR8-1200 NI)" or STR-25,

"Work Flow (Without GR8-1200 NI)".

Starter motor does not rotate

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3183 of 3641

STARTER MOTORSTR-31

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

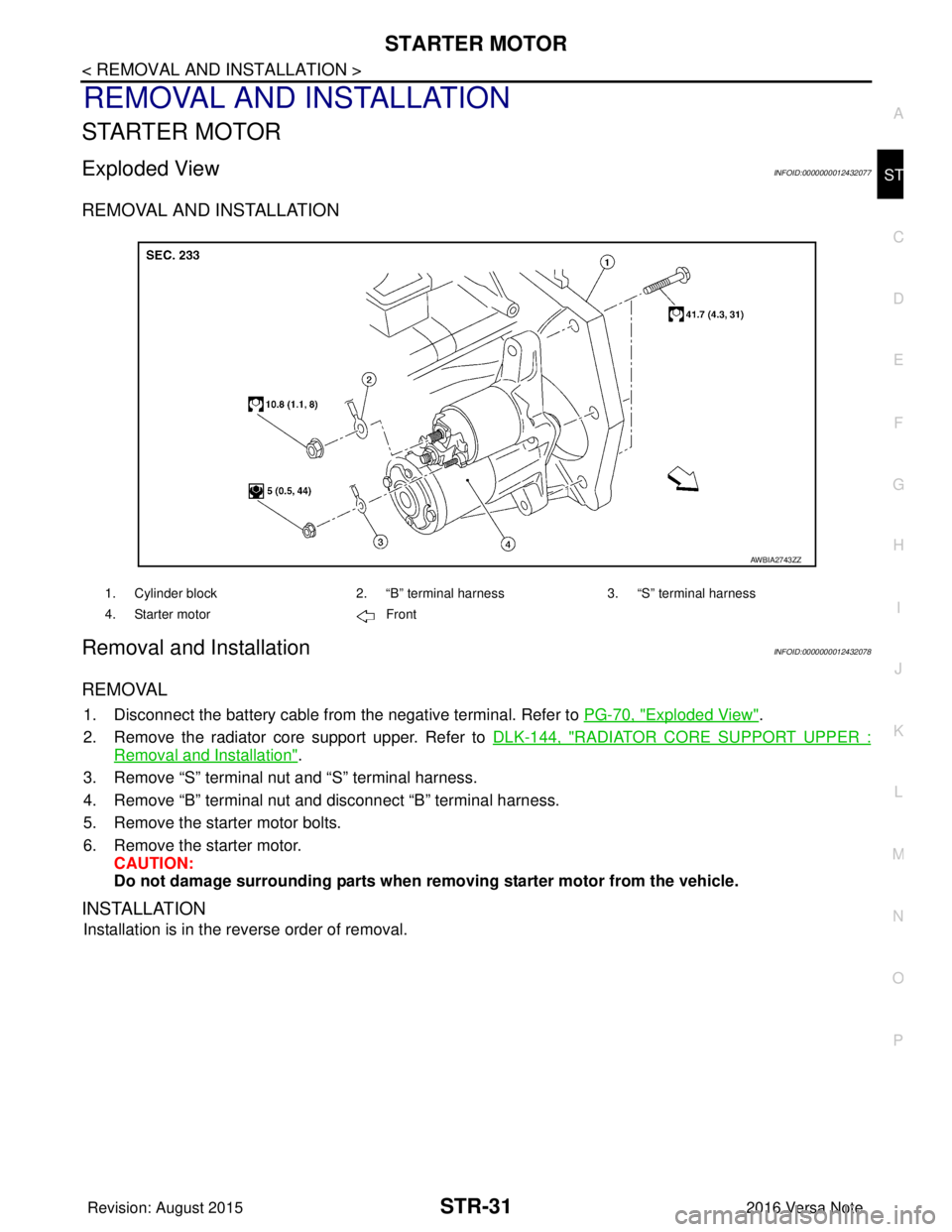

REMOVAL AND INSTALLATION

STARTER MOTOR

Exploded ViewINFOID:0000000012432077

REMOVAL AND INSTALLATION

Removal and InstallationINFOID:0000000012432078

REMOVAL

1. Disconnect the battery cable from

the negative terminal. Refer to PG-70, "Exploded View".

2. Remove the radiator core support upper. Refer to DLK-144, "

RADIATOR CORE SUPPORT UPPER :

Removal and Installation".

3. Remove “S” terminal nut and “S” terminal harness.

4. Remove “B” terminal nut and disconnect “B” terminal harness.

5. Remove the starter motor bolts.

6. Remove the starter motor. CAUTION:

Do not damage surrounding parts when re moving starter motor from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

1. Cylinder block2. “B” terminal harness3. “S” terminal harness

4. Starter motor Front

AWBIA2743ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3184 of 3641

STR-32

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Starter MotorINFOID:0000000012432079

*: Always check with the Parts Department for the latest parts information.Manufacturer

HITACHI

Model number* S114-954B

Typ e Reduction gear type

System voltage 12V

No-load Terminal voltage

11V

Current Less than 110A

Revolution More than 3,000 rpm

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3200 of 3641

STC-16

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

YES >> GO TO 7.

NO >> Check harness and connectors based on the information obtained by interview. Refer to GI-42,

"Intermittent Incident".

7.FINAL CHECK

With CONSULT

1. Check the reference value for EPS control unit.

2. Recheck the symptom and check that sympto m is not reproduced on the same conditions.

Is the symptom reproduced?

YES >> GO TO 3.

NO >> Inspection End.

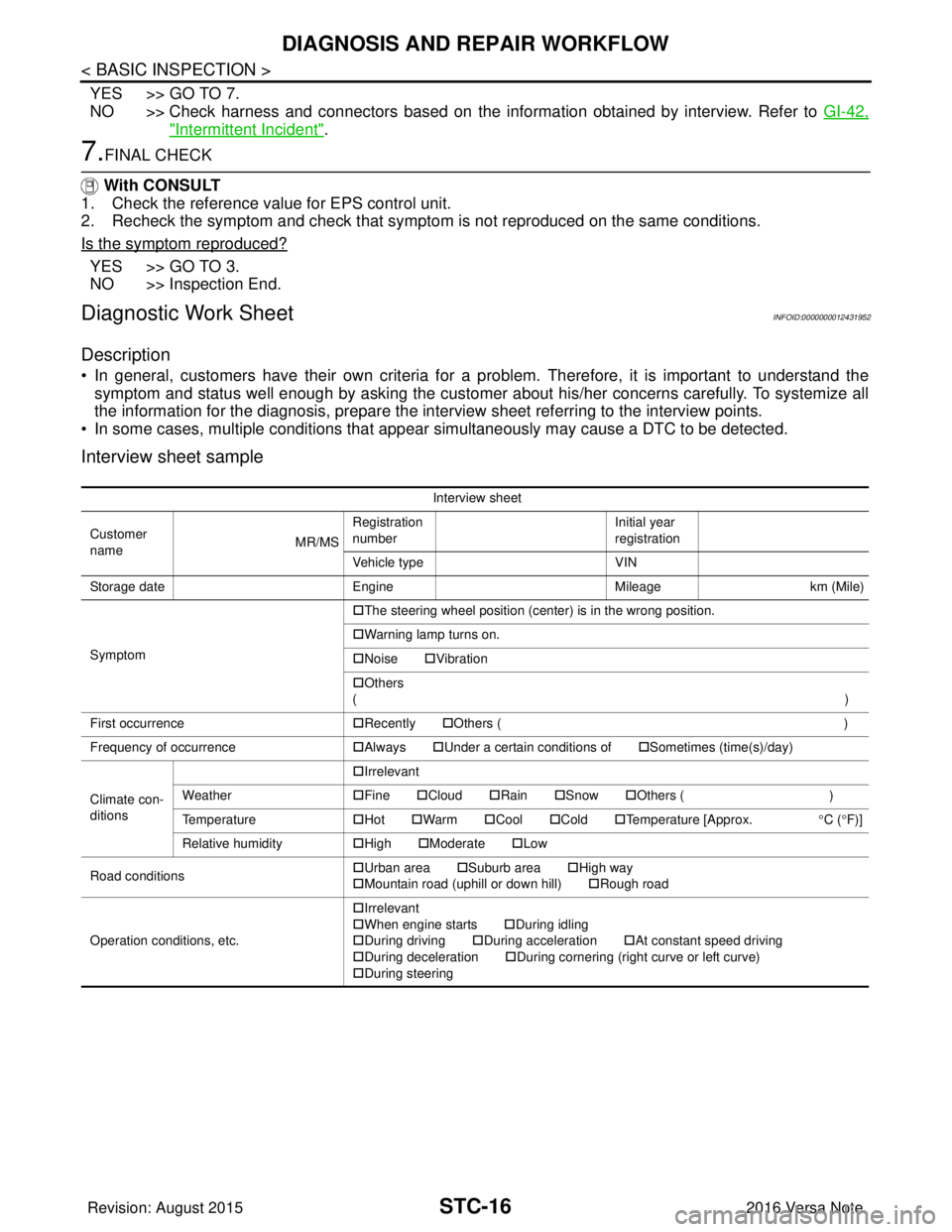

Diagnostic Work SheetINFOID:0000000012431952

Description

• In general, customers have their own criteria for a pr oblem. Therefore, it is important to understand the

symptom and status well enough by asking the customer about his/her concerns carefully. To systemize all

the information for the diagnosis, prepare the interview sheet referring to the interview points.

• In some cases, multiple conditions that appear simultaneously may cause a DTC to be detected.

Interview sheet sample

Interview sheet

Customer

name MR/MSRegistration

number

Initial year

registration

Vehicle type VIN

Storage date EngineMileagekm (Mile)

Symptom �†

The steering wheel position (center) is in the wrong position.

�† Warning lamp turns on.

�† Noise �†Vibration

�† Others

( )

First occurrence �†Recently �†Others ( )

Frequency of occurrence �†Always �†Under a certain conditions of �†Sometimes (time(s)/day)

Climate con-

ditions �†

Irrelevant

Weather �†Fine �†Cloud �†Rain �†Snow �†Others ( )

Temperature �†Hot �†Warm �†Cool �†Cold �†Temperature [Approx. °C ( °F)]

Relative humidity �†High �†Moderate �†Low

Road conditions �†

Urban area �†Suburb area �†High way

�† Mountain road (uphill or down hill) �†Rough road

Operation conditions, etc. �†

Irrelevant

�† When engine starts �†During idling

�† During driving �†During acceleration �†At constant speed driving

�† During deceleration �†During cornerin g (right curve or left curve)

�† During steering

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3203 of 3641

C1601 BATTERY POWER SUPPLYSTC-19

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

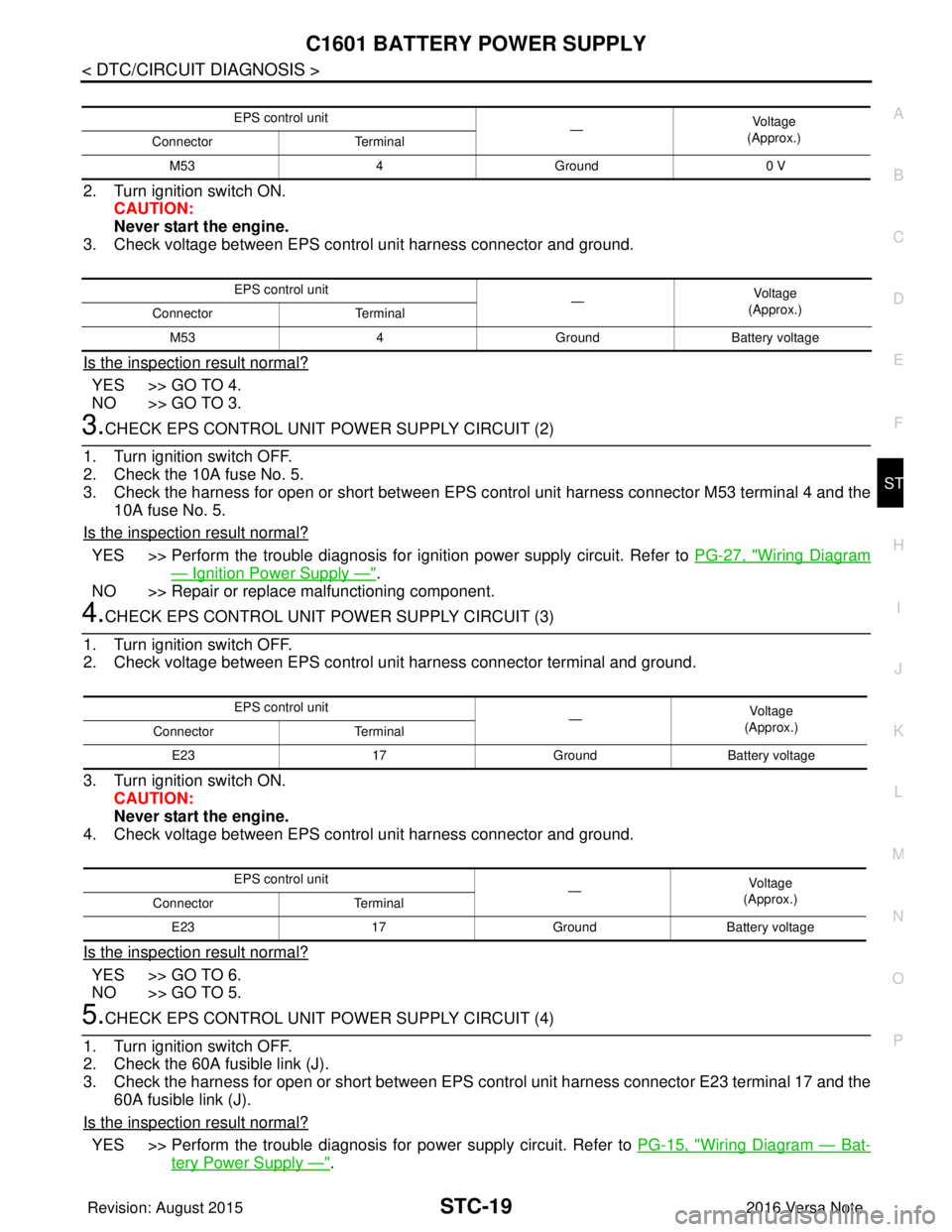

2. Turn ignition switch ON. CAUTION:

Never start the engine.

3. Check voltage between EPS control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK EPS CONTROL UNIT POWER SUPPLY CIRCUIT (2)

1. Turn ignition switch OFF.

2. Check the 10A fuse No. 5.

3. Check the harness for open or short between EPS c ontrol unit harness connector M53 terminal 4 and the

10A fuse No. 5.

Is the inspection result normal?

YES >> Perform the trouble diagnosis for i gnition power supply circuit. Refer to PG-27, "Wiring Diagram

— Ignition Power Supply —".

NO >> Repair or replace malfunctioning component.

4.CHECK EPS CONTROL UNIT POWER SUPPLY CIRCUIT (3)

1. Turn ignition switch OFF.

2. Check voltage between EPS control unit harness connector terminal and ground.

3. Turn ignition switch ON. CAUTION:

Never start the engine.

4. Check voltage between EPS control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 5.

5.CHECK EPS CONTROL UNIT POWER SUPPLY CIRCUIT (4)

1. Turn ignition switch OFF.

2. Check the 60A fusible link (J).

3. Check the harness for open or short between EPS c ontrol unit harness connector E23 terminal 17 and the

60A fusible link (J).

Is the inspection result normal?

YES >> Perform the trouble diagnosis fo r power supply circuit. Refer to PG-15, "Wiring Diagram — Bat-

tery Power Supply —".

EPS control unit

—Vol tag e

(Approx.)

Connector Terminal

M53 4Ground 0 V

EPS control unit

—Voltage

(Approx.)

Connector Terminal

M53 4GroundBattery voltage

EPS control unit

—Vo l ta g e

(Approx.)

Connector Terminal

E23 17GroundBattery voltage

EPS control unit —Vol tag e

(Approx.)

Connector Terminal

E23 17GroundBattery voltage

Revision: August 2015 2016 Versa Note

cardiagn.com