start NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 3205 of 3641

C1604 TORQUE SENSORSTC-21

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

C1604 TORQUE SENSOR

DTC LogicINFOID:0000000012431955

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”.

Is DTC

“C1604” detected?

YES >> Proceed to diagnosis procedure. Refer to STC-21, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000012431956

Regarding Wiring Diagram information, refer to STC-11, "Wiring Diagram".

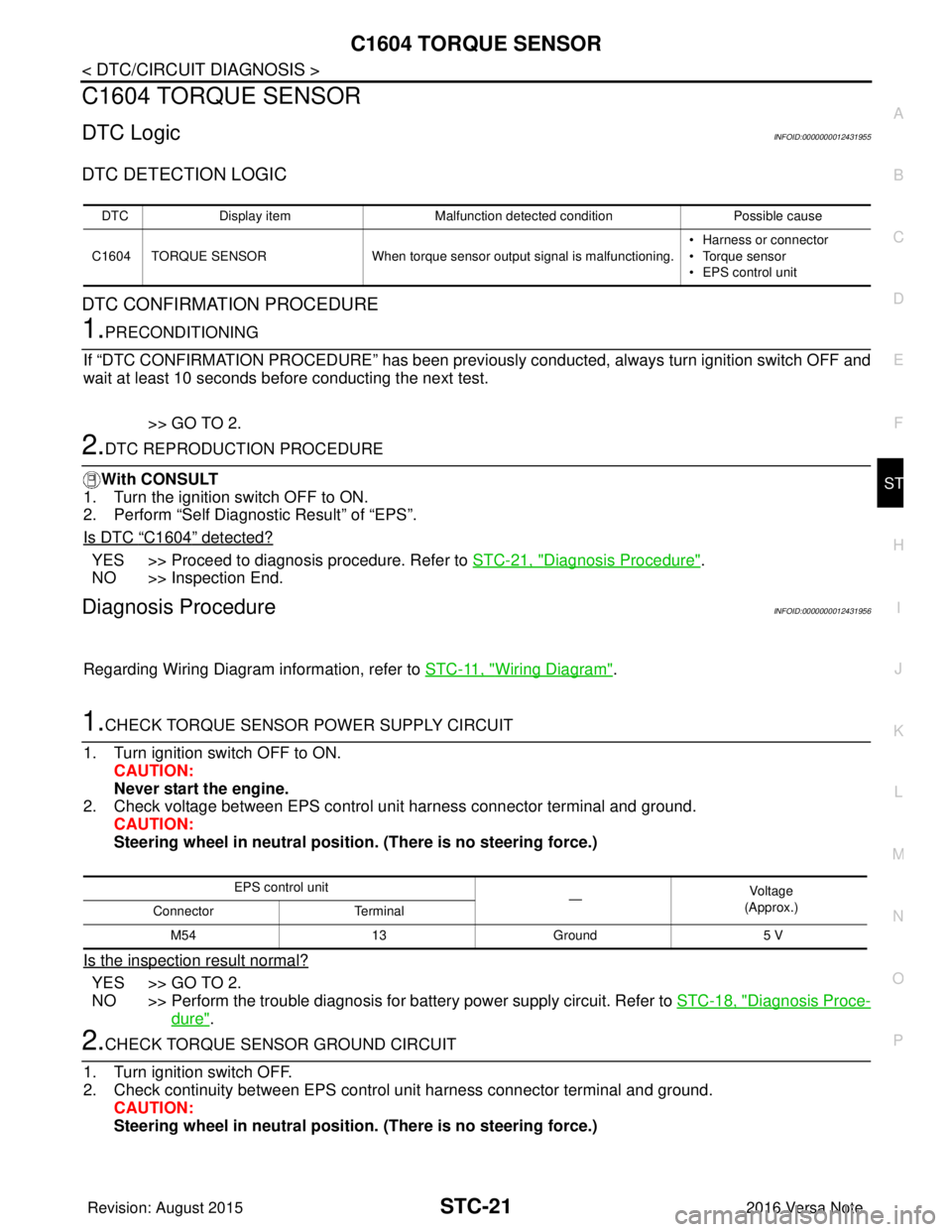

1.CHECK TORQUE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF to ON. CAUTION:

Never start the engine.

2. Check voltage between EPS control unit harness connector terminal and ground.

CAUTION:

Steering wheel in neutral position . (There is no steering force.)

Is the inspection result normal?

YES >> GO TO 2.

NO >> Perform the trouble diagnosis for battery power supply circuit. Refer to STC-18, "

Diagnosis Proce-

dure".

2.CHECK TORQUE SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between EPS control unit harness connector terminal and ground. CAUTION:

Steering wheel in neutral position . (There is no steering force.)

DTCDisplay item Malfunction detected condition Possible cause

C1604 TORQUE SENSOR When torque sensor output signal is malfunctioning. • Harness or connector

• Torque sensor

• EPS control unit

EPS control unit

—Vo l ta g e

(Approx.)

Connector Terminal

M54 13Ground 5 V

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3206 of 3641

STC-22

< DTC/CIRCUIT DIAGNOSIS >

C1604 TORQUE SENSOR

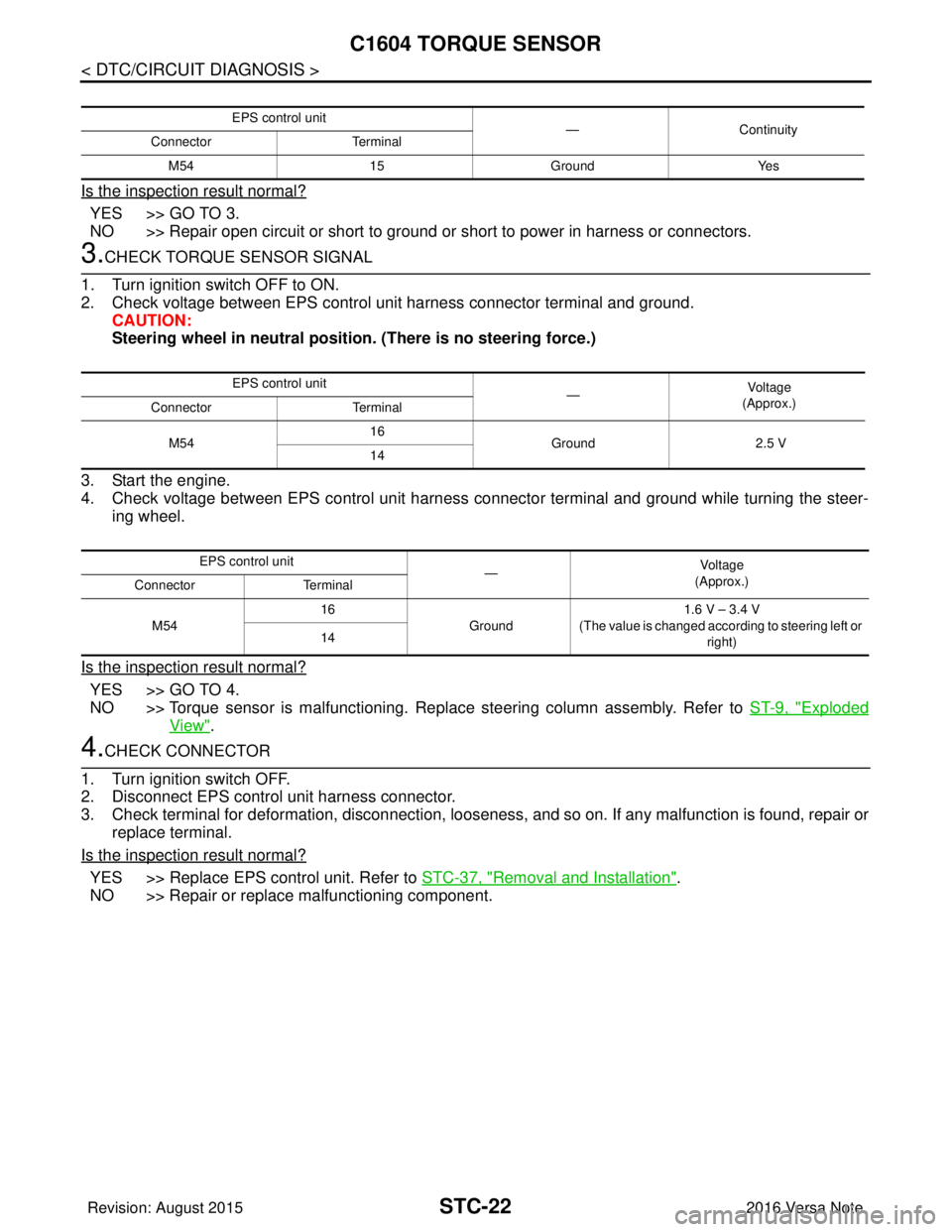

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK TORQUE SENSOR SIGNAL

1. Turn ignition switch OFF to ON.

2. Check voltage between EPS control unit harness connector terminal and ground. CAUTION:

Steering wheel in neutral position. (There is no steering force.)

3. Start the engine.

4. Check voltage between EPS control unit harness connector terminal and ground while turning the steer- ing wheel.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Torque sensor is malfunctioning. Repl ace steering column assembly. Refer to ST-9, "

Exploded

View".

4.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect EPS control unit harness connector.

3. Check terminal for deformation, disconnection, looseness, and so on. If any malfunction is found, repair or replace terminal.

Is the inspection result normal?

YES >> Replace EPS control unit. Refer to STC-37, "Removal and Installation".

NO >> Repair or replace malfunctioning component.

EPS control unit —Continuity

Connector Terminal

M54 15Ground Yes

EPS control unit

—Vo l ta g e

(Approx.)

Connector Terminal

M54 16

Ground 2.5 V

14

EPS control unit —Voltag e

(Approx.)

Connector Terminal

M54 16

Ground 1.6 V – 3.4 V

(The value is changed according to steering left or right)

14

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 3213 of 3641

EPS WARNING LAMPSTC-29

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

EPS WARNING LAMP

Component Function CheckINFOID:0000000012431971

1.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check that the EPS warning lamp turns ON when igni tion switch turns ON. Then, EPS warning lamp turns

OFF after the engine is started.

Is the inspection result normal?

YES >> Inspection End.

NO >> Perform trouble diagnosis. Refer to STC-29, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012431972

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”.

Is any DTC detected?

YES >> Check the DTC. Refer to STC-10, "DTC Index".

NO >> GO TO 2.

2.CHECK EPS WARNING LAMP SIGNAL

With CONSULT

1. Turn the ignition switch ON.

CAUTION:

Never start the engine.

2. Select “Data Monitor” of “ EPS” and select “WARNING LAMP”.

3. Check that the EPS warning lamp is turned ON.

4. Start the engine. CAUTION:

Never drive the vehicle.

5. Check that the EPS warning lamp is turned OFF.

Is the inspection result normal?

YES >> Perform the trouble diagnosis for combination meter power supply circuit. Refer to MWI-43,

"COMBINATION METER : Diagnosis Procedure" (Type A) or MWI-98, "COMBINATION METER :

Diagnosis Procedure" (Type B).

NO >> Replace the EPS control unit. Refer to STC-37, "

Removal and Installation".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3215 of 3641

EPS WARNING LAMP DOES NOT TURN OFFSTC-31

< SYMPTOM DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

EPS WARNING LAMP DOES NOT TURN OFF

DescriptionINFOID:0000000012431975

EPS warning lamp does not turn OFF several seconds after engine started.

Diagnosis ProcedureINFOID:0000000012431976

1.PERFORM SELF-DIAGNOSIS

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”.

Is any DTC detected?

YES >> Check the DTC. Refer to STC-10, "DTC Index".

NO >> GO TO 2.

2.CHECK EPS WARNING LAMP

Perform the trouble diagnosis of EPS warning lamp. Refer to STC-29, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace the specific malfunctioning part.

3.CHECK EPS CONTROL UNIT POWE R SUPPLY AND GROUND CIRCUIT

Perform the trouble diagnosis of EPS cont rol unit power supply and ground. Refer to STC-18, "

Diagnosis Pro-

cedure".

Is the inspection result normal?

YES >> Check that there is no malfunction in eac h harness connector pin terminal or disconnection.

NO >> Repair or replace the specific malfunctioning part.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3216 of 3641

STC-32

< SYMPTOM DIAGNOSIS >

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHT

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHT

DescriptionINFOID:0000000012431977

Steering wheel turning force is heavy or light.

Diagnosis ProcedureINFOID:0000000012431978

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”.

Is any DTC detected?

YES >> Check the DTC. Refer to STC-10, "DTC Index".

NO >> GO TO 2.

2.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check that the EPS warning lamp turns ON when igni tion switch turns ON. Then, EPS warning lamp turns

OFF after the engine is started.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Perform trouble diagnosis of EPS warning lamp. Refer to STC-29, "

Diagnosis Procedure".

3.CHECK EPS CONTROL UNIT SIGNAL (1)

With CONSULT

1. Start the engine. CAUTION:

Never drive the vehicle.

2. Select “ASSIST LEVEL” in “Data Monitor” of “EPS”.

Does the item in

“Data Monitor” indicate 100%?

YES >> GO TO 6.

NO >> GO TO 4.

4.CHECK EPS CONTROL UNIT SIGNAL (2)

With CONSULT

Select “BATTERY VOLT” in “Data Monitor” of “EPS”.

Does the item in

“Data Monitor” indicate 10 V or more?

YES >> GO TO 5.

NO >> Perform trouble diagnosis of EPS control unit power supply and ground. Refer to STC-18, "

Diag-

nosis Procedure".

5.CHECK EPS CONTROL UNIT SIGNAL (3)

With CONSULT

1. Select “ASSIST LEVEL” in “Data Monitor” of “EPS”.

2. Stop the EPS system until the item in “Data Monitor” becomes “100%”.

NOTE:

While stopping the EPS system, do not turn steering wheel.

3. Check that the symptom continues.

Does the symptom continue?

YES >> GO TO 6.

NO >> The assist torque decreases because of protection function. This is not malfunction. Inspection End.

6.CHECK EPS CONTROL UNIT SIGNAL (4)

With CONSULT

1. Start the engine. CAUTION:

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3218 of 3641

STC-34

< SYMPTOM DIAGNOSIS >

UNBALANCE STEERING WHEEL TURNING FORCE AND RETURN BETWEEN RIGHT AND LEFT

UNBALANCE STEERING WHEEL TU RNING FORCE AND RETURN BE-

TWEEN RIGHT AND LEFT

DescriptionINFOID:0000000012431979

Unbalance steering wheel turning force and return between right and left.

Diagnosis ProcedureINFOID:0000000012431980

1.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check the EPS warning lamp while engine is running.

Does the EPS warning lamp turn OFF?

YES >> GO TO 2.

NO >> Refer to STC-29, "

Diagnosis Procedure".

2.CHECK WHEEL ALIGNMENT

1. Check the wheel alignment. Refer to FSU-7, "

Inspection".

2. Perform “Self Diagnostic Result” of “EPS”.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Adjustment of wheel alignment. Refer to FSU-8, "

Adjustment".

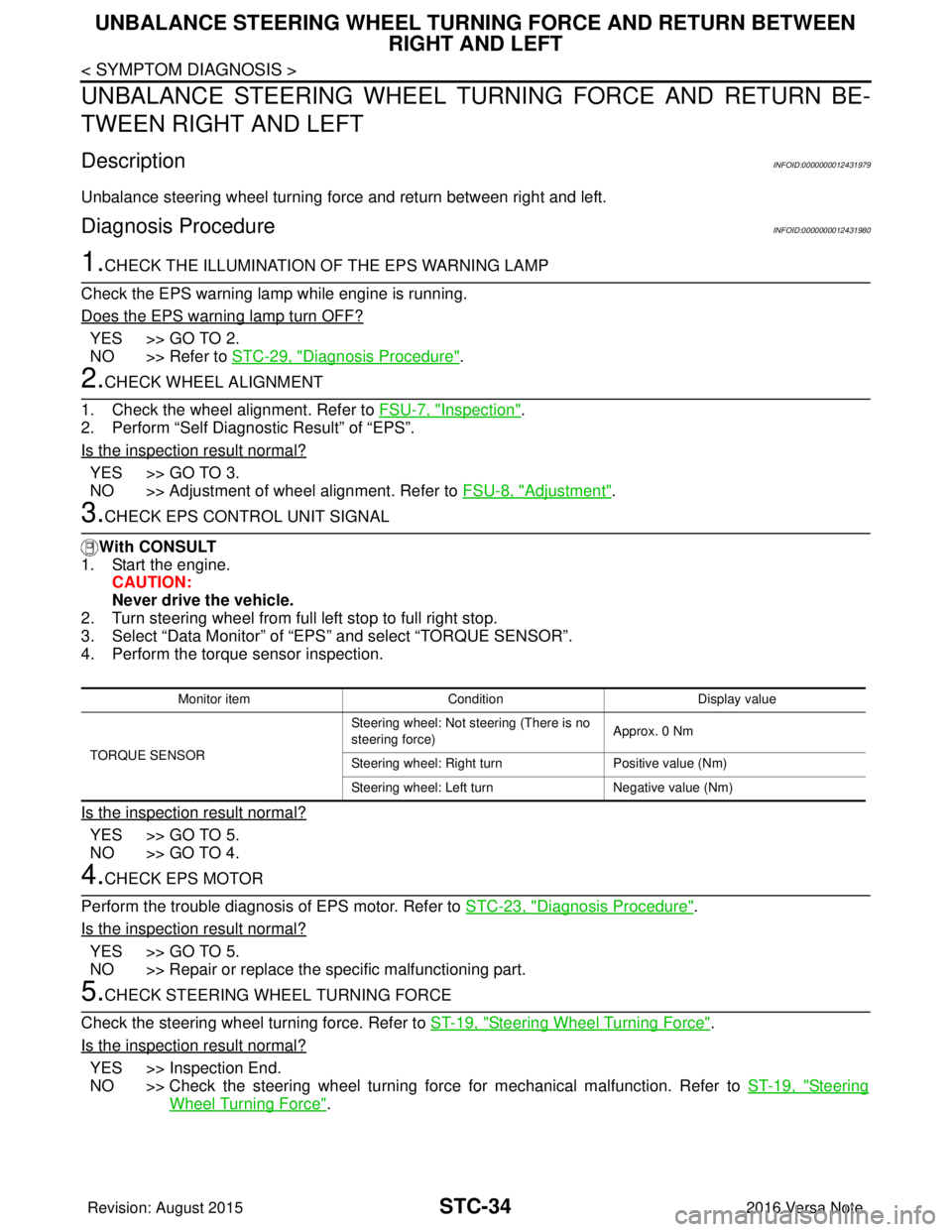

3.CHECK EPS CONTROL UNIT SIGNAL

With CONSULT

1. Start the engine.

CAUTION:

Never drive the vehicle.

2. Turn steering wheel from full left stop to full right stop.

3. Select “Data Monitor” of “EPS” and select “TORQUE SENSOR”.

4. Perform the torque sensor inspection.

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK EPS MOTOR

Perform the trouble diagnosis of EPS motor. Refer to STC-23, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace the specific malfunctioning part.

5.CHECK STEERING WHEEL TURNING FORCE

Check the steering wheel turning force. Refer to ST-19, "

Steering Wheel Turning Force".

Is the inspection result normal?

YES >> Inspection End.

NO >> Check the steering wheel turning force for mechanical malfunction. Refer to ST-19, "

Steering

Wheel Turning Force".

Monitor item ConditionDisplay value

TORQUE SENSOR Steering wheel: Not st

eering (There is no

steering force) Approx. 0 Nm

Steering wheel: Right turn Positive value (Nm)

Steering wheel: Left turn Negative value (Nm)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3219 of 3641

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

STC-35

< SYMPTOM DIAGNOSIS >

C

D E

F

H I

J

K L

M A

B

STC

N

O P

UNBALANCE STEERING WHEEL TU RNING FORCE (TORQUE VARIA-

TION)

DescriptionINFOID:0000000012431981

Unbalance steering wheel turning force (torque variation).

Diagnosis ProcedureINFOID:0000000012431982

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”.

Is any DTC detected?

YES >> Check the DTC. Refer to STC-10, "DTC Index".

NO >> GO TO 2.

2.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check the EPS warning lamp while the engine is started.

Does the EPS warning lamp turn OFF?

YES >> GO TO 3.

NO >> Refer to STC-29, "

Diagnosis Procedure".

3.CHECK STEERING COLU MN AND STEERING GEAR

Check the steering column assembly and steering gear assembly.

• Steering column assembly. Refer to ST-9, "

Exploded View".

• Steering gear assembly. Refer to ST-14, "

Exploded View".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace the specific malfunctioning part.

4.CHECK EPS CONTROL UNIT SIGNAL (1)

With CONSULT

1. Start the engine. CAUTION:

Never drive the vehicle.

2. Turn steering wheel from full left stop to full right stop.

3. Select “ASSIST LEVEL” in “Data Monitor” of “EPS”.

Does the item in

“Data Monitor” maintain “100%”?

YES >> GO TO 7.

NO >> GO TO 5.

5.CHECK EPS CONTROL UNIT SIGNAL (2)

With CONSULT

Select “BATTERY VOLT” in “Data Monitor” of “EPS”.

Does the item in

“Data Monitor” indicate 10 V or more?

YES >> GO TO 6.

NO >> Perform trouble diagnosis of EPS control unit power supply and ground. Refer to STC-18, "

Diag-

nosis Procedure".

6.CHECK EPS CONTROL UNIT SIGNAL (3)

With CONSULT

1. Select “ASSIST LEVEL” in “Data Monitor” of “EPS”.

2. Stop the EPS system until the item in “Data Monitor” becomes “100%”. NOTE:

While stopping the EPS system, do not turn steering wheel.

3. Check that the symptom continues.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3220 of 3641

STC-36

< SYMPTOM DIAGNOSIS >

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

Does the symptom continue?

YES >> GO TO 7.

NO >> The assist torque decreases because of protection function. This is not malfunction. Inspection

End.

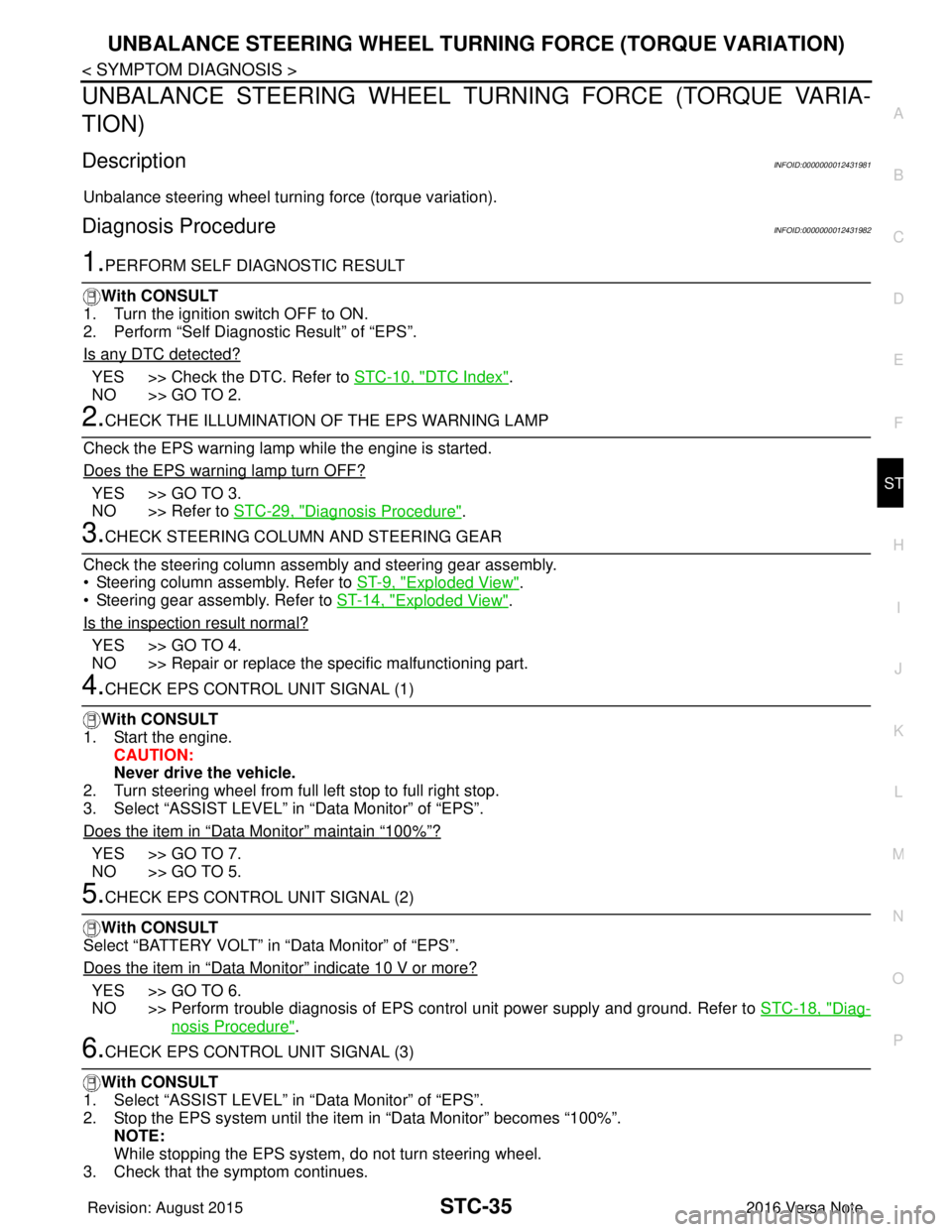

7.CHECK EPS CONTROL UNIT SIGNAL (4)

With CONSULT

1. Start the engine.

CAUTION:

Never drive the vehicle.

2. Turn steering wheel from full left stop to full right stop.

3. Select “TORQUE SENSOR” in “Data Monitor” of “EPS”.

4. Perform the torque sensor inspection.

Is the inspection result normal?

YES >> GO TO 9.

NO >> GO TO 8.

8.CHECK EPS MOTOR

Perform the trouble diagnosis of EPS motor. Refer to STC-23, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace the specific malfunctioning part.

9.CHECK STEERING WHEEL TURNING FORCE

Check the steering wheel turning force. Refer to ST-19, "

Steering Wheel Turning Force".

Is the inspection result normal?

YES >> Inspection End.

NO >> Check the steering wheel turning force for mechanical malfunction. Refer to ST-19, "

Steering

Wheel Turning Force".

Monitor item ConditionDisplay value

TORQUE SENSOR Steering wheel: Not steering (There is no

steering force)

Approx. 0 Nm

Steering wheel: Right turn Positive value (Nm)

Steering wheel: Left turn Negative value (Nm)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3226 of 3641

STEERING WHEELST-5

< BASIC INSPECTION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

BASIC INSPECTION

STEERING WHEEL

InspectionINFOID:0000000012430497

CONDITION OF INSTALLATION

• Check installation conditions of steering gear, front suspension, axle and steering column.

• Check if movement exists when steering wheel is mo ved up and down, to the left and right and to the axial

direction.

• Verify that the steering gear nuts are tightened to specification. Refer to ST-14, "

Exploded View".

STEERING WHEEL PLAY

1. Set the front wheels and tires in the straight-ahead position, start engine, then lightly turn steering wheel

to the left and right until the front wheels start to move. Measure steering wheel movement on the outer

circumference.

2. When the measurement value is outside the standard va lue, check backlash for each joint of steering col-

umn and installation condition of steering gear.

STEERING WHEEL NEUTRAL POSITION

Check steering wheel neutral position using the following procedure:

1. Confirm that front wheel alignment is correct. Refer to FSU-8, "

Adjustment".

2. Set the front wheels and tires in the straight-ahead posit ion, check if steering wheel is in the neutral posi-

tion.

3. If it is not in the neutral position, remo ve steering wheel and reinstall it correctly.

4. If the neutral position cannot be attained by repositi oning the steering wheel two teeth or less on steering

stem, loosen the steering gear outer socket lock nuts, then adjust the inner sockets by the same amount

in the opposite direction.

5. Re-check the front wheel alignment. Refer to FSU-8, "

Adjustment".

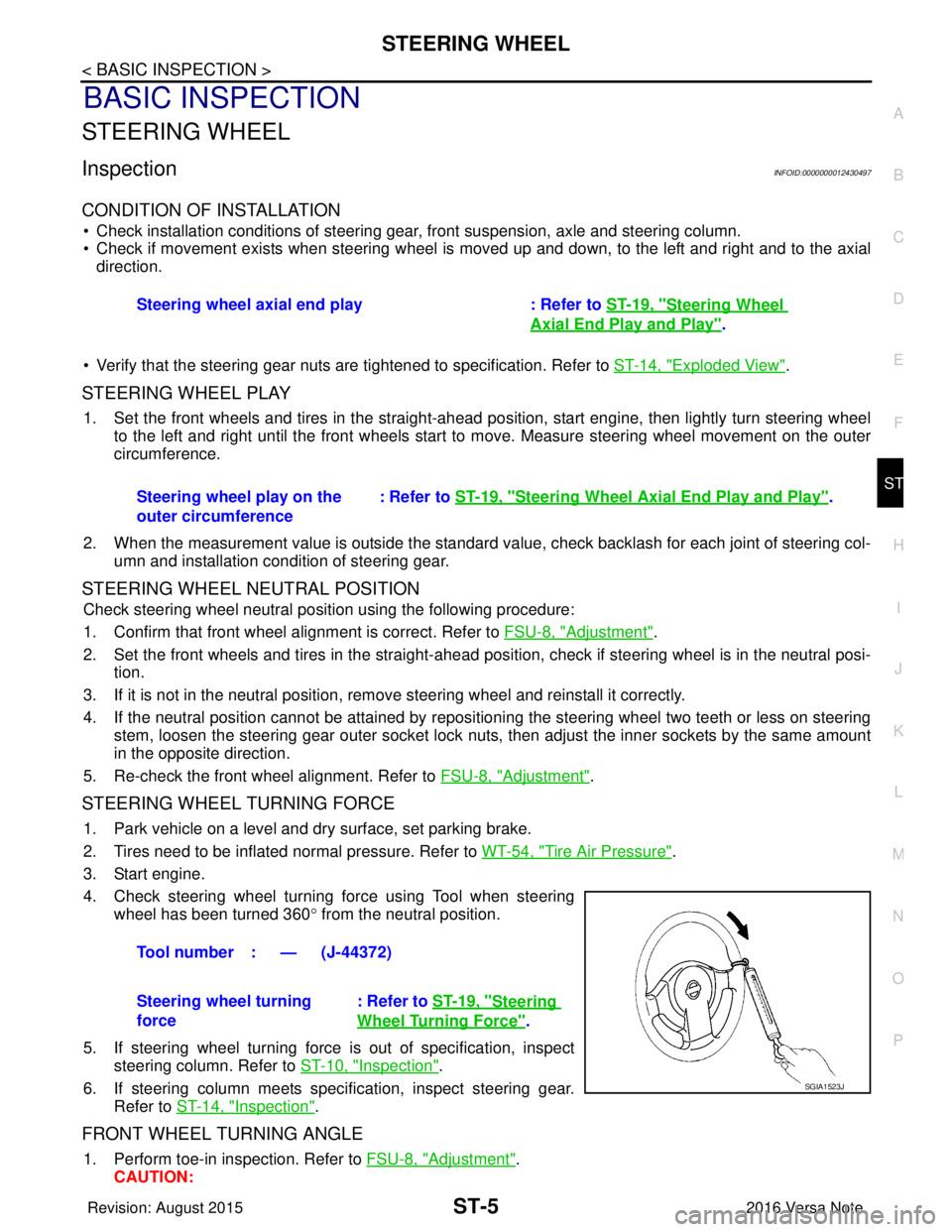

STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Tires need to be inflated normal pressure. Refer to WT-54, "

Tire Air Pressure".

3. Start engine.

4. Check steering wheel turning force using Tool when steering wheel has been turned 360 ° from the neutral position.

5. If steering wheel turning force is out of specification, inspect steering column. Refer to ST-10, "

Inspection".

6. If steering column meets specification, inspect steering gear. Refer to ST-14, "

Inspection".

FRONT WHEEL TURNING ANGLE

1. Perform toe-in inspection. Refer to FSU-8, "Adjustment".

CAUTION: Steering wheel axial end play : Refer to

ST-19, "

Steering Wheel

Axial End Play and Play".

Steering wheel play on the

outer circumference : Refer to

ST-19, "

Steering Wheel Axia l End Play and Play".

Tool number : — (J-44372)

Steering wheel turning

force : Refer to

ST-19, "

Steering

Wheel Turning Force".

SGIA1523J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3239 of 3641

ST-18

< UNIT DISASSEMBLY AND ASSEMBLY >

STEERING GEAR AND LINKAGE

When tightening outer socket lock nut (1), be sure to hold

outer socket (2) using a suitable tool to prevent ball joint

from contacting knuckle.

InspectionINFOID:0000000012430512

INSPECTION AFTER DISASSEMBLY

Boot

• Check boot for cracks and replace it if damage exists.

Steering gear

• Check steering gear for damage and scratches to the inner wall. Replace if there are any abnormal condi- tions.

Outer Socket and Inner Socket

Check the following items and replace the component if outside specification:

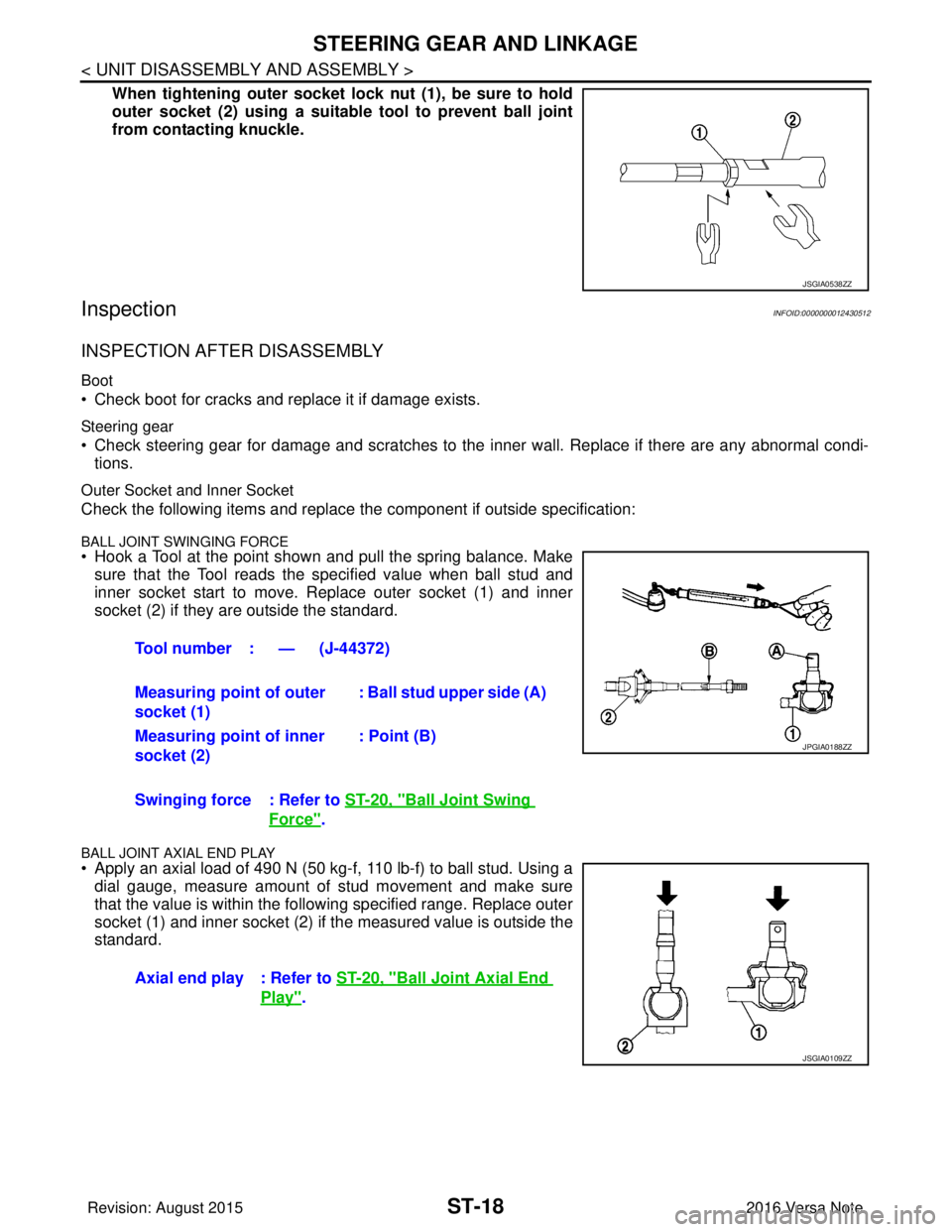

BALL JOINT SWINGING FORCE• Hook a Tool at the point shown and pull the spring balance. Make

sure that the Tool reads the specified value when ball stud and

inner socket start to move. Replace outer socket (1) and inner

socket (2) if they are outside the standard.

BALL JOINT AXIAL END PLAY

• Apply an axial load of 490 N (50 kg-f, 110 lb-f) to ball stud. Using adial gauge, measure amount of stud movement and make sure

that the value is within the following specified range. Replace outer

socket (1) and inner socket (2) if the measured value is outside the

standard.

JSGIA0538ZZ

Tool number : — (J-44372)

Measuring point of outer

socket (1) : Ball stud upper side (A)

Measuring point of inner

socket (2) : Point (B)

Swinging force : Refer to ST-20, "

Ball Joint Swing

Force".

Axial end play : Refer to ST-20, "

Ball Joint Axial End

Play".

JPGIA0188ZZ

JSGIA0109ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com