battery NISSAN NOTE 2016 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 374 of 3641

![NISSAN NOTE 2016 Service Manual PDF BCS

BCM

BCS-113

< ECU DIAGNOSIS INFORMATION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

53

(G) Ground Door unlock output

signal

OutputFront door lock

actuator RH,

rear door loc NISSAN NOTE 2016 Service Manual PDF BCS

BCM

BCS-113

< ECU DIAGNOSIS INFORMATION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

53

(G) Ground Door unlock output

signal

OutputFront door lock

actuator RH,

rear door loc](/img/5/57363/w960_57363-373.png)

BCS

BCM

BCS-113

< ECU DIAGNOSIS INFORMATION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

53

(G) Ground Door unlock output

signal

OutputFront door lock

actuator RH,

rear door lock

actuator RH,

rear door lock

actuator LH and

back door lock

actuator Actuated to UNLOCK po-

sition

Battery voltage

Other than actuated to

UNLOCK position 0 V

54

(SB) Ground Door lock output sig-

nal

OutputAll door lock ac-

tuators Actuated to LOCK posi-

tion

Battery voltage

Other than actuated to

LOCK position 0 V

55

(B) Ground Gnd

Output Ignition switch ON 0 V

56

(LG) Ground Rear wiper auto stop

switch Input Rear wiper OFF (stopped)

0V

ON (activated) Battery voltage

57

(BR) Ground Door sw (RR) signal Input Rear door

switch RHOFF (rear door RH

closed)

7.0 - 8.0 V

ON (rear door RH open) 0 V

58

(W) Ground Door sw (RL) signal Input Rear door

switch LHOFF (rear door LH closed)

7.0 - 8.0 V

ON (rear door LH open) 0 V

59

(SB) Ground Door sw (DR) signal Input Front door

switch LHOFF (front door LH

closed)

7.0 - 8.0 V

ON (front door LH open) 0 V

Terminal No.

(Wire color) Description

Condition Va l u e

(Approx.)

Signal name Input/

Output

+ −

PKIB4960J

PKIB4960J

PKIB4960J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 375 of 3641

![NISSAN NOTE 2016 Service Manual PDF BCS-114

< ECU DIAGNOSIS INFORMATION >[WITHOUT INTELLIGENT KEY SYSTEM]

BCM

1: With variable intermittent wipers

2: Without variable intermittent wipers60

(BG) Ground Door sw (AS) signal Input Front doo NISSAN NOTE 2016 Service Manual PDF BCS-114

< ECU DIAGNOSIS INFORMATION >[WITHOUT INTELLIGENT KEY SYSTEM]

BCM

1: With variable intermittent wipers

2: Without variable intermittent wipers60

(BG) Ground Door sw (AS) signal Input Front doo](/img/5/57363/w960_57363-374.png)

BCS-114

< ECU DIAGNOSIS INFORMATION >[WITHOUT INTELLIGENT KEY SYSTEM]

BCM

1: With variable intermittent wipers

2: Without variable intermittent wipers60

(BG) Ground Door sw (AS) signal Input Front door

switch RHOFF (front door RH

closed)

7.0 - 8.0 V

ON (front door RH open) 0 V

62

(P) Ground Door switch (Back)

signal InputBack door

switch OFF (back door closed)

7.0 - 8.0 V

ON (back door open) 0 V

63

(W) Ground Flasher output

(RIGHT) signal

OutputIgnition switch

ON Turn signal switch OFF

0 V

Turn signal switch RH 6.5 V

(Turn signal lamp turn on: 9 - 16

V)

64

(V) Ground

Flasher output

(LEFT) signal Output

Ignition switch

ON Turn signal switch OFF

0 V

Turn signal switch LH 6.5 V

(Turn signal lamp turn on: 9 - 16 V)

68

(R) Ground Rear wiper motor

output 1

OutputPush-button ig-

nition switch ON Rear wiper stop position

Battery voltage

Any position other than

rear wiper stop position 0V

70

(L) Ground

Cargo lamp output

signal Output Back door Closed (cargo lamp OFF)

Battery voltage

Open (cargo lamp ON) 0 – 1 V

Te r m i n a l N o .

(Wire color) Description

Condition Va l u e

(Approx.)

Signal name Input/

Output

+ −

PKIB4960J

PKIB4960J

PKIC6370E

PKIC6370E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 376 of 3641

![NISSAN NOTE 2016 Service Manual PDF BCS

BCM

BCS-115

< ECU DIAGNOSIS INFORMATION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

Fail-safeINFOID:0000000012432390

FAIL-SAFE CONTROL BY DTC

BCM performs fail-safe control wh NISSAN NOTE 2016 Service Manual PDF BCS

BCM

BCS-115

< ECU DIAGNOSIS INFORMATION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

Fail-safeINFOID:0000000012432390

FAIL-SAFE CONTROL BY DTC

BCM performs fail-safe control wh](/img/5/57363/w960_57363-375.png)

BCS

BCM

BCS-115

< ECU DIAGNOSIS INFORMATION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

Fail-safeINFOID:0000000012432390

FAIL-SAFE CONTROL BY DTC

BCM performs fail-safe control when any DTC are detected.

FAIL-SAFE CONTROL OF COMBINATION SWIT

CH READING FUNCTION CAUSED BY LOW

POWER SUPPLY VOLTAGE

If voltage of battery power supply lower, BCM maintains combination switch reading to the status when input

voltage is less than approximately 9 V.

NOTE:

When voltage of battery power supply is approximately 9 V or more, combination switch reading function

returns to normal operation.

DTC Inspection Priority ChartINFOID:0000000012432391

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

DTC IndexINFOID:0000000012432392

NOTE: Details of time display

• CRNT: Displays when there is a malfunction now or after returning to the normal condition until turning igni- tion switch OFF → ON again.

• 1 - 39: Displayed if any previous ma lfunction is present when current conditi on is normal. It increases like 1

→ 2 → 3...38 → 39 after returning to the normal condition whenever ignition switch OFF → ON. The counter

remains at 39 even if the number of cycles exceeds it. It is counted from 1 again when turning ignition switch

OFF → ON after returning to the normal condi tion if the malfunction is detected again.

Display contents of CONSULT Fail-safe Cancellation

B2190: NATS ANTENNA AMP Inhibit engine cranking Erase DTC

B2191: DIFFERENCE OF KEY Inhibit engine cranking Erase DTC

B2192: ID DISCORD BCM-ECM Inhibit engine cranking Erase DTC

B2193: CHAIN OF BCM-ECM Inhibit engine cranking Erase DTC

B2195: ANTI SCANNING Inhibit engine cranking Ignition switch ON → OFF

B2196: DONGLE NG Inhibit engine cranking Erase DTC

Priority DTC

1 • U1000: CAN COMM

• U1010: CONTROL UNIT (CAN)

2 • B2190: NATS ANTENNA AMP

• B2191: DIFFERENCE OF KEY

• B2192: ID DISCORD BCM-ECM

• B2193: CHAIN OF BCM-ECM

• B2195: ANTI SCANNING

• B2196: DONGLE NG

3 • C1704: LOW PRESSURE FL

• C1705: LOW PRESSURE FR

• C1706: LOW PRESSURE RR

• C1707: LOW PRESSURE RL

• C1708: [NO DATA] FL

• C1709: [NO DATA] FR

• C1710: [NO DATA] RR

• C1711: [NO DATA] RL

• C1716: [PRESS DATA ERR] FL

• C1717: [PRESS DATA ERR] FR

• C1718: [PRESS DATA ERR] RR

• C1719: [PRESS DATA ERR] RL

• C1729: VHCL SPEED SIG ERR

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 390 of 3641

![NISSAN NOTE 2016 Service Manual PDF BCS

POWER SUPPLY AND GROUND CIRCUITBCS-129

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000012 NISSAN NOTE 2016 Service Manual PDF BCS

POWER SUPPLY AND GROUND CIRCUITBCS-129

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000012](/img/5/57363/w960_57363-389.png)

BCS

POWER SUPPLY AND GROUND CIRCUITBCS-129

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000012432406

Regarding Wiring Diagram information, refer to

BCS-117, "Wiring Diagram".

1.CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connectors.

3. Check voltage between BCM connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM connector and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

Terminal No. Signal nameFuses and fusible link No.

37 Battery power supply 8 (10A)

42 12 (10A)

50 G (40A)

11 Ignition switch ACC or ON 18 (10A)

38 Ignition switch ON or START 2 (10A)

BCMGround Ignition switch position

Connector Terminal

—OFF

ACC ON

M18 11

0 V

Battery voltage

Battery voltage

37

Battery voltage

38 0 V0 V

M19 42

Battery voltage Battery voltage

50

BCM GroundContinuity

Connector Terminal

M19 55—Yes

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 397 of 3641

![NISSAN NOTE 2016 Service Manual PDF BCS-136

< SYMPTOM DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000012432410

SHIPPING MODE

• Shipping mode inhibits battery NISSAN NOTE 2016 Service Manual PDF BCS-136

< SYMPTOM DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000012432410

SHIPPING MODE

• Shipping mode inhibits battery](/img/5/57363/w960_57363-396.png)

BCS-136

< SYMPTOM DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000012432410

SHIPPING MODE

• Shipping mode inhibits battery power consumption duri

ng transportation or storage of the vehicle. Vehicle is

set to shipping mode before being shipped from the factory.

• When ignition switch is OFF, BCM operates shipping mode.

• BCM control function is limited in shipping mode. Re mote keyless entry function does not operate in ship-

ping mode.

• For shipping mode cancel operation, refer to BCS-125, "

Work Procedure".

NOTE:

Do not cancel shipping mode during storage of the v ehicle. Shipping mode should not be canceled until just

prior to customer delivery.

TRANSIT MODE

• BCM is in transit mode if turn signal indicators in combination meter illuminate for 1 minute when ignition

switch is turned from OFF to ON.

• In this case, cancel operation must be performed.

• For transit mode cancel operation, refer to BCS-126, "

Work Procedure".

NOTE:

Do not cancel transit mode during storage of the vehicle. Transit mode s hould not be canceled until just prior

to customer delivery.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 398 of 3641

![NISSAN NOTE 2016 Service Manual PDF BCS

BCM (BODY CONTROL MODULE)BCS-137

< REMOVAL AND INSTALLATION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

REMOVAL AND INSTALLATION

BCM (BODY CONTROL MODULE)

Removal and Installa NISSAN NOTE 2016 Service Manual PDF BCS

BCM (BODY CONTROL MODULE)BCS-137

< REMOVAL AND INSTALLATION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

REMOVAL AND INSTALLATION

BCM (BODY CONTROL MODULE)

Removal and Installa](/img/5/57363/w960_57363-397.png)

BCS

BCM (BODY CONTROL MODULE)BCS-137

< REMOVAL AND INSTALLATION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

REMOVAL AND INSTALLATION

BCM (BODY CONTROL MODULE)

Removal and InstallationINFOID:0000000012432411

REMOVAL

CAUTION:

Before replacing BCM, perform “READ CONFIGURAT

ION” to save or print current vehicle specifica-

tion. Refer to BCS-123, "

Description".

1. Disconnect negative and positive battery terminals, then wait at least three minutes. Refer to PG-70,

"Removal and Installation (Battery)".

2. Remove instrument lower panel LH. Refer to IP-24, "

Removal and Installation".

3. Remove screws (A) and remove the BCM (1) from the steering member and position aside.

: Front

4. Disconnect the harness connectors from the BCM.

5. Remove relays from relay bracket.

6. Remove relay bracket from BCM to transfer to new BCM.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Perform “CONFIGURATION (BCM)” when replacing BCM. Refer to BCS-123, "

Description".

• Make sure to perform the system initialization (N ATS) (if equipped) when replacing BCM. Refer to

BCS-121, "

Description".

• When replacing BCM, if new BCM does not come with keyfobs attached, all existing keyfobs must be

re-registered.

• For initialization and registration of Intelligent Key, refer to CONSULT Immobilizer mode and fol- lowthe on-screen instructions.

ALMIA0656ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 399 of 3641

![NISSAN NOTE 2016 Service Manual PDF BCS-138

< REMOVAL AND INSTALLATION >[WITHOUT INTELLIGENT KEY SYSTEM]

COMBINATION SWITCH

COMBINATION SWITCH

Removal and InstallationINFOID:0000000012432412

CAUTION:

• Before servicing, turn the ignit NISSAN NOTE 2016 Service Manual PDF BCS-138

< REMOVAL AND INSTALLATION >[WITHOUT INTELLIGENT KEY SYSTEM]

COMBINATION SWITCH

COMBINATION SWITCH

Removal and InstallationINFOID:0000000012432412

CAUTION:

• Before servicing, turn the ignit](/img/5/57363/w960_57363-398.png)

BCS-138

< REMOVAL AND INSTALLATION >[WITHOUT INTELLIGENT KEY SYSTEM]

COMBINATION SWITCH

COMBINATION SWITCH

Removal and InstallationINFOID:0000000012432412

CAUTION:

• Before servicing, turn the ignition switch OFF, disconnect both battery terminals and wait at least

three minutes.

• Do not use air or electric tools when remo ving or installing the combination switch.

REMOVAL

1. Disconnect the negative and positive battery terminals, then wait at least three minutes. Refer to PG-70,

"Removal and Installation (Battery)".

2. Remove the steering column covers. Refer to IP-17, "

Removal and Installation".

3. Rotate steering wheel clockwise to access first combination switch screw (A) and remove.

4. Rotate steering wheel counter-c lockwise to access second com-

bination switch screw (A) and remove.

5. Disconnect the harness connector (B) from the combination switch (1) and remove.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• After the work is completed, make sure no system malfunction is detected by air bag warning lamp.

• In case a malfunction is detected by the air bag wa rning lamp, reset with the self-diagnosis function

and delete the memory with CONSULT.

• If a malfunction is still detected after the above operation, perform self-diagnosis to repair malfunc-

tions. Refer to BCS-121, "

Description".

ALMIA0648ZZ

ALMIA0649ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 402 of 3641

PRECAUTIONSBRM-3

< PRECAUTION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012562862

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for Heating MetalINFOID:0000000012430791

• Normal Steel (coated and non-coated)

390 MPa - 590MPa

• High Tensile (coated and non-coated) above 590 MPa

• Maximum temperature for heating both steel types is: 550 degrees Celsius

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 403 of 3641

BRM-4

< PRECAUTION >

HANDLING PRECAUTIONS FOR PLASTICS

HANDLING PRECAUTIONS FOR PLASTICS

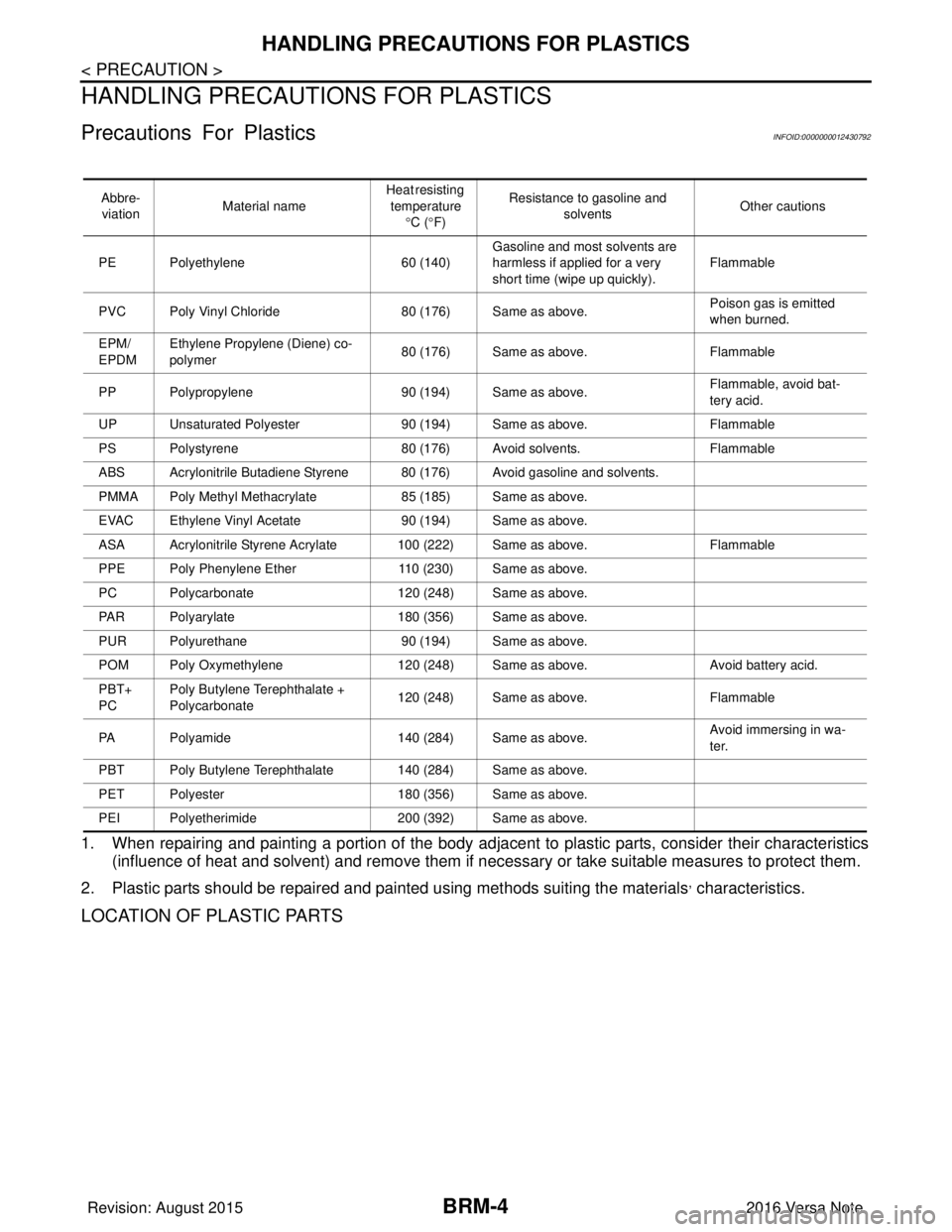

Precautions For PlasticsINFOID:0000000012430792

1. When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics

(influence of heat and solvent) and remove them if neces sary or take suitable measures to protect them.

2. Plastic parts should be repaired and painted using methods suiting the materials

, characteristics.

LOCATION OF PLASTIC PARTS

Abbre- viation Material name Heat resisting

temperature °C ( °F) Resistance to gasoline and

solvents Other cautions

PE Polyethylene 60 (140)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly). Flammable

PVC Poly Vinyl Chloride 80 (176) Same as above. Poison gas is emitted

when burned.

EPM/

EPDM Ethylene Propylene (Diene) co-

polymer

80 (176) Same as above.

Flammable

PP Polypropylene 90 (194) Same as above. Flammable, avoid bat-

tery acid.

UP Unsaturated Polyester 90 (194) Same as above. Flammable

PS Polystyrene 80 (176) Avoid solvents. Flammable

ABS Acrylonitrile Butadiene Styrene 80 (176) Avoid gasoline and solvents.

PMMA Poly Methyl Methacrylate 85 (185) Same as above.

EVAC Ethylene Vinyl Acetate 90 (194) Same as above.

ASA Acrylonitrile Styrene Acrylate 100 (222) Same as above. Flammable

PPE Poly Phenylene Ether 110 (230) Same as above.

PC Polycarbonate 120 (248) Same as above.

PAR Polyarylate 180 (356) Same as above.

PUR Polyurethane 90 (194) Same as above.

POM Poly Oxymethylene 120 (248) Same as above. Avoid battery acid.

PBT+

PC Poly Butylene Terephthalate +

Polycarbonate

120 (248) Same as above.

Flammable

PA Polyamide 140 (284) Same as above. Avoid immersing in wa-

ter.

PBT Poly Butylene Terephthalate 140 (284) Same as above.

PET Polyester 180 (356) Same as above.

PEI Polyetherimide 200 (392) Same as above.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 452 of 3641

![NISSAN NOTE 2016 Service Manual PDF BRC-4

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430820

The Supplement NISSAN NOTE 2016 Service Manual PDF BRC-4

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430820

The Supplement](/img/5/57363/w960_57363-451.png)

BRC-4

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430820

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Brake SystemINFOID:0000000012430821

WARNING:

Clean any dust from the front brake and rear brake using a vacuum dust collector. Do not blow by

compressed air.

• Brake fluid use refer to MA-11, "

Fluids and Lubricants".

• Do not reuse drained brake fluid.

• Do not spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

• Always confirm the specified tightening torque when installing the brake pipes.

• After pressing the brake pedal more deeply or harder t han normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

• Do not use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

• Always loosen the brake tube flare nut with a flare nut wrench.

• Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

• Always connect the battery terminal when moving the vehicle.

• Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) harness connector or the battery negative

terminal before performing the work.

• Check that no brake fluid leakage is present after replacing the parts.

JPFIA0001ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com