EGR valve NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 456 of 3641

![NISSAN NOTE 2016 Service Repair Manual BRC-8

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

COMPONENT PARTS

Component Description

INFOID:0000000012430827

ABS Actuator and Electric Unit (Control Unit)INFOID:0000000012430828

Electric unit (control uni NISSAN NOTE 2016 Service Repair Manual BRC-8

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

COMPONENT PARTS

Component Description

INFOID:0000000012430827

ABS Actuator and Electric Unit (Control Unit)INFOID:0000000012430828

Electric unit (control uni](/img/5/57363/w960_57363-455.png)

BRC-8

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

COMPONENT PARTS

Component Description

INFOID:0000000012430827

ABS Actuator and Electric Unit (Control Unit)INFOID:0000000012430828

Electric unit (control unit) is integrated with actuator and comprehensively controls VDC function, TCS func-

tion, ABS function and EBD function.

ELECTRIC UNIT (CONTROL UNIT)

• Brake fluid pressure is controlled according to signals from each sensor.

• If malfunction is detected, the system enters fail-safe mode.

ACTUATOR

The following components are integrated with ABS actuator:

Pump

Returns the brake fluid reserved in reservoir to master cylinder by reducing pressure.

Motor

Activates the pump according to signals from ABS actuator and electric unit (control unit).

Motor Relay

Operates the motor ON/OFF according to signals fr om ABS actuator and electric unit (control unit).

Actuator Relay (Main Relay)

Operates each valve ON/OFF according to signals fr om ABS actuator and electric unit (control unit).

ABS IN Valve

A. View with steering wheel and spiral

cable removed B. Left side of instrument panel C. Left side of engine compartment

D. Left side of engine compartment E. Right side of engine compartment F. Left front wheel assembly

G. Near brake pedal area H. Left side of instrument panel I. Center of front seats (view with cen-

ter console removed)

J. Left rear wheel assembly

ALFIA0482ZZ

Component Reference/Function

1 Steering angle sensor BRC-9, "

Steering Angle Sensor"

2 VDC OFF switchBRC-10, "VDC OFF Switch"

3 IPDM E/RPCS-4, "Component Parts Location"

4 Brake fluid level switchBRC-10, "Brake Fluid Level Switch"

5 ABS actuator and electric unit (control unit)BRC-8, "ABS Actuator and Electric Unit (Control Unit)"

6 Front wheel sensorBRC-9, "Wheel Sensor and Sensor Rotor"

7 Stop lamp switchBRC-9, "Sto p La mp Sw itc h"

8 Combination meter (type A)MWI-9, "METER SYSTEM : Combination Meter"

9 Combination meter (type B)MWI-9, "METER SYSTEM : Combination Meter"

10 Parking brake switch BRC-10, "Parking Brake Switch"

11. Rear wheel sensor BRC-9, "Wheel Sensor and Sensor Rotor"

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 457 of 3641

![NISSAN NOTE 2016 Service Repair Manual COMPONENT PARTSBRC-9

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Switches the fluid pressure line to increase or hold according to signals from control unit.

ABS OUT Valve

S NISSAN NOTE 2016 Service Repair Manual COMPONENT PARTSBRC-9

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Switches the fluid pressure line to increase or hold according to signals from control unit.

ABS OUT Valve

S](/img/5/57363/w960_57363-456.png)

COMPONENT PARTSBRC-9

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Switches the fluid pressure line to increase or hold according to signals from control unit.

ABS OUT Valve

Switches the fluid pressure line to increase, hold or decrease according to signals from control unit.

Cut Valve 1, Cut Valve 2

Shuts off the ordinary brake line from master cylinder, when VDC function and TCS function are activated.

Suction Valve 1, Suction Valve 2

Supplies the brake fluid from master cylinder to the pump, when VDC function and TCS function are activated.

Return Check Valve

Returns the brake fluid from brake caliper and wheel cyli nder to master cylinder by bypassing orifice of each

valve when brake is released.

Reservoir

Temporarily reserves the brake fluid drained from brake caliper, so that pressure efficiently decreases when

decreasing pressure of brake caliper and wheel cylinder.

Yaw rate/side/decel G sensor

Calculates the following information that affects the v ehicle, and transmits a signal to ABS actuator and elec-

tric unit (control unit) via communication lines:

• Vehicle rotation angular velocity (yaw rate signal)

• Vehicle lateral acceleration (side G signal) and longitudinal acceleration (decel G signal)

Pressure Sensor

Detects the brake fluid pressure and transmits signal to ABS actuator and electric unit (control unit).

Wheel Sensor and Sensor RotorINFOID:0000000012430829

NOTE:

• Wheel sensor of front wheel is installed on steering knuckle.

• Sensor rotor of front wheel is integrated in wheel hub assembly.

• Wheel sensor of rear wheel is installed on back plate of rear brake.

• Sensor rotor of rear wheel is installed on rear brake drum.

• Never measure resistance and voltage value using a tester because sensor is active sensor.

• Downsize and weight reduction is aimed. IC for detection portion

and magnet for sensor rotor are adopted.

• Power supply is supplied to detection portion so that magnetic field

line is read. Magnetic field that is detected is converted to current

signal.

• When sensor rotor rotates, magnetic field changes. Magnetic field

change is converted to current signals (rectangular wave) and is

transmitted to ABS actuator and electric unit (control unit). Change

of magnetic field is pr oportional to wheel speed.

Stop Lamp SwitchINFOID:0000000012430830

Detects the operation status of brake pedal and transmits converted electric signal to ABS actuator and elec-

tric unit (control unit).

Steering Angle SensorINFOID:0000000012430831

Detects the following information and transmits steering angle signal to ABS actuator and electric unit (control

unit) via CAN communication:

• Steering wheel rotation amount

• Steering wheel rotation angular velocity

• Steering wheel rotation direction

JPFIC0131GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1011 of 3641

![NISSAN NOTE 2016 Service Repair Manual EM-10

< BASIC INSPECTION >[HR16DE]

CAMSHAFT VALVE CLEARANCE

BASIC INSPECTION

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000012431690

INSPECTION

Perform inspection as follows after re NISSAN NOTE 2016 Service Repair Manual EM-10

< BASIC INSPECTION >[HR16DE]

CAMSHAFT VALVE CLEARANCE

BASIC INSPECTION

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000012431690

INSPECTION

Perform inspection as follows after re](/img/5/57363/w960_57363-1010.png)

EM-10

< BASIC INSPECTION >[HR16DE]

CAMSHAFT VALVE CLEARANCE

BASIC INSPECTION

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000012431690

INSPECTION

Perform inspection as follows after removal, replacement or installation of camshaft or valve-related parts, or if

there are unusual engine conditions regarding valve clearance.

1. Remove rocker cover. Refer to

EM-48, "

Removal and Installation".

2. Measure the valve clearance with the following procedure:

a. Set No. 1 cylinder at TDC of its compression stroke. • Rotate crankshaft pulley (2) clockwise and align TDC mark (no

paint) (A) to timing indicator (1) on front cover.

• At the same time, check that both intake and exhaust cam lobes of No. 1 cylinder face inside ( ) as shown.

• If the lobes do not face inside, rotate the crankshaft pulley 360 degrees to align as shown.

b. Using suitable tool (A) measure the clearance between the valve lifter and camshaft.

(B) : White paint mark (Not used for service)

PBIC3673E

(1) : Camshaft (INT)

(2) : Camshaft (EXH)

: Engine front

JPBIA4738ZZ

Valve clearance : Refer to EM-117, "Camshaft".

JPBIA4116ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1012 of 3641

![NISSAN NOTE 2016 Service Repair Manual CAMSHAFT VALVE CLEARANCEEM-11

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Measure the valve clearances at locations marked “

×” [loca-

tions indicated with ( )] as shown usi NISSAN NOTE 2016 Service Repair Manual CAMSHAFT VALVE CLEARANCEEM-11

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Measure the valve clearances at locations marked “

×” [loca-

tions indicated with ( )] as shown usi](/img/5/57363/w960_57363-1011.png)

CAMSHAFT VALVE CLEARANCEEM-11

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Measure the valve clearances at locations marked “

×” [loca-

tions indicated with ( )] as shown using suitable tool.

c. Set No. 4 cylinder at TDC of its compression stroke. • Rotate crankshaft pulley (2) one revolution (360 degrees) andalign TDC mark (no paint) (A) to timing indicator (1) on front

cover.

• Measure the valve clearances at locations marked “ ×” [loca-

tions indicated with ( )] as shown using suitable tool.

3. If out of the specifications, adjust as necessary. Refer to “ADJUSTMENT”.

ADJUSTMENT

NOTE:

Proper valve clearance is obtained by selecting the correct valve lifter head thickness.

1. Remove camshaft. Refer to EM-60, "

Exploded View".

2. Remove valve lifters from the loca tions that are out of the standard.

(A) : No. 1 cylinder

(B) : No. 2 cylinder

(C) : No. 3 cylinder

(D) : No. 4 cylinder

JPBIA4117ZZ

Measuring position No. 1 CYL. No. 2 CYL. No. 3 CYL. No. 4 CYL.

No. 1 cylinder at compression TDC EXH

× ×

INT × ×

(B) : White paint mark (Not use for service)

PBIC3673E

(A) : No. 1 cylinder

(B) : No. 2 cylinder

(C) : No. 3 cylinder

(D) : No. 4 cylinder

JPBIA4118ZZ

Measuring position No. 1 CYL. No. 2 CYL. No. 3 CYL. No. 4 CYL.

No. 4 cylinder at compression TDC EXH

× ×

INT × ×

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1117 of 3641

![NISSAN NOTE 2016 Service Repair Manual EM-116

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:00 NISSAN NOTE 2016 Service Repair Manual EM-116

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:00](/img/5/57363/w960_57363-1116.png)

EM-116

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000012431742

GENERAL SPECIFICATIONS

Va l v e Ti m i n g

Unit: degree

( ): Valve timing control “ON”

Drive BeltINFOID:0000000012431743

DRIVE BELT

Belt Deflection

*: When engine is cold.Engine type

HR16DE

Cylinder arrangement In-line 4

Displacement cm

3 (cu in)1,598 (97.51)

Bore and stro ke mm (in)78.0× 83.6 (3.071 × 3.291)

Valve arrangement DOHC

Firing order 1-3-4-2

Number of piston rings Compression

2

Oil 1

Compression ratio 9.8:1

Compression pressure

kPa (kg/cm

2, psi) / 200 rpm Standard 1,510 (15.4, 219)

Minimum

1,270 (12.95, 184)

Differential limit between cylinders 100 (1.0, 14.5)

Va l v e t i m i n g

: Intake valve

: Exhaust valve

ab c d e f

216 228 11 (

−27)

AT D C 59 (-21)

ABDC -1 (49)

AT D C 37 (-13)

BBDC

JPBIA4228ZZ

Location Deflection adjustment *

Unit: mm (in)

Used belt New belt

Limit After adjusted

Drive belt With A/C

10.0 (0.39) 4.9 - 5.2 (0.19 - 0.20) 4.1 - 4.4 (0.16 - 0.17)

Without A/C 9.1 (0.36)4.3 - 4.7 (0.17 - 0.19) 3.7 - 3.9 (0.146 - 0.154)

Applied pushing force 98.1 N (10.0 kg-f, 22.0 lb-f)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1211 of 3641

![NISSAN NOTE 2016 Service Repair Manual EC-84

< ECU DIAGNOSIS INFORMATION >[HR16DE]

ECM

P0014 Exhaust valve timing control The signal is not energized to the exhaust valve timing control solenoid valve and the valve

control does not fun NISSAN NOTE 2016 Service Repair Manual EC-84

< ECU DIAGNOSIS INFORMATION >[HR16DE]

ECM

P0014 Exhaust valve timing control The signal is not energized to the exhaust valve timing control solenoid valve and the valve

control does not fun](/img/5/57363/w960_57363-1210.png)

EC-84

< ECU DIAGNOSIS INFORMATION >[HR16DE]

ECM

P0014 Exhaust valve timing control The signal is not energized to the exhaust valve timing control solenoid valve and the valve

control does not function.

P0101

P0102

P0103 Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0117

P0118 Engine coolant temperature

sensor circuit Engine coolant temperature will be determined by ECM based on the following conditions.

CONSULT displays the engine coolant temperature decided by ECM.

Condition Engine coolant temperature decided

(CONSULT display)

Just as ignition switch is turned ON or START 40°C (104 °F)

Approx. 4 minutes or more after engine starting 80°C (176 °F)

Except as shown above 40 - 80

°C (104 - 176 °F)

(Depends on the time)

• When the fail safe system for engine coolant temperature sensor is activated, the cool- ing fan operates while engine is running.

• ECM operates active grille shutter to fully-open position.

P0116

P0125 Engine coolant temperature

sensor ECM operates active grille shutter to fully-open position.

P0122

P0123

P0222

P0223

P2135 Throttle position sensor ECM controls the electric throttle control actuator in regulating the throttle opening in order

for the idle position to be within +10 degrees.

ECM regulates the opening speed of the throttle valve to be slower than the normal con-

dition.

So, the acceleration will be poor.

P0196

P0197

P0198 Engine oil temperature sensor • Exhaust valve timing control does not function.

• ECM operates active grille shutter to fully-open position.

P0500 Vehicle speed sensor • The cooling fan operates (Highest) while engine is running.

• ECM operates active grille shutter to fully-open position.

P0524 Engine oil pressure • ECM illuminates oil pressure warning lamp on the combination meter.

• Engine speed will not rise more than 4,000 rpm due to the fuel cut.

• Fail-safe is canceled when ignition switch OFF → ON.

P059F Active grille shutter • When a voltage and temperature related malfunction is detected, the active grille shutter

stops at the position of detection.

• Except for the above case, operates the active grille shutter to fully opened position.

P0603

P0607 ECM

Engine torque may be limited.

P0604

ECM • ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (Approx. 5 decrees) by the return spring.

• The position of the following commponents is fixed.

- Intake valve timing control solenoid valve

- Exhaust valve timing control solenoid valve

• ASCD operation may be deactivated.

P0605

P0606

P060B

ECM NOTE:

Fail-safe may not occur depending on malfunction type.

• ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (Approx. 5 decrees) by the return spring.

• The position of the following commponents is fixed.

- Intake valve timing control solenoid valve

- Exhaust valve timing control solenoid valve

• ASCD operation may be deactivated.

DTC No. Detected items

Engine operating condition in fail safe mode

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1212 of 3641

![NISSAN NOTE 2016 Service Repair Manual ECM

EC-85

< ECU DIAGNOSIS INFORMATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC Inspection Priority ChartINFOID:0000000012431344

If some DTCs are displayed at the same time, perform inspections o NISSAN NOTE 2016 Service Repair Manual ECM

EC-85

< ECU DIAGNOSIS INFORMATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC Inspection Priority ChartINFOID:0000000012431344

If some DTCs are displayed at the same time, perform inspections o](/img/5/57363/w960_57363-1211.png)

ECM

EC-85

< ECU DIAGNOSIS INFORMATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC Inspection Priority ChartINFOID:0000000012431344

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

P060A

ECM NOTE:

Fail-safe may not occur depending on malfunction type.

• ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (Approx. 5 decrees) by the return spring.

• The position of the following commponents is fixed.

- Intake valve timing control solenoid valve

- Exhaust valve timing control solenoid valve

• Engine torque may be limited.

• ASCD operation may be deactivated.

P0643

ECM • ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (Approx. 5 decrees) by the return spring.

• The position of the following commponents is fixed.

- Intake valve timing control solenoid valve

- Exhaust valve timing control solenoid valve

P0643 Sensor power supply ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P1720 Vehicle speed sensor ECM operates active grille shutter to fully-open position.

P1805 Brake switch ECM controls the electric throttle control actuator by regulating the throttle opening to a

small range.

Therefore, acceleration will be poor.

Vehicle condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

P2100

P2103 Throttle control motor relay ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2101 Electric throttle control function ECM stops the electric thro ttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2118 Throttle control motor ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2119 Electric throttle control actuator (When electric throttle control actuator does not function properly due to the return sp ring

malfunction:)

ECM controls the electric throttle actuator by regulating the throttle opening around the

idle position. The engine speed will not rise more than 2,000 rpm.

(When throttle valve opening angle in fail safe mode is not in specified range:)

ECM controls the electric throttle control actuator by regulating the throttle opening to 20

degrees or less.

(When ECM detects the throttle valve is stuck open:)

While the vehicle is driving, it slows down gradually by fuel cut. After the vehicle stops, the

engine stalls.

The engine can restart in the Neutral position, and engine speed will not exceed 1,000 rpm

or more.

P2122

P2123

P2127

P2128

P2138 Accelerator pedal position sen-

sor

The ECM controls the electric throttle control actuator in regulating the throttle opening in

order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

DTC No. Detected items

Engine operating condition in fail safe mode

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1294 of 3641

![NISSAN NOTE 2016 Service Repair Manual P0011 IVT CONTROLEC-167

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0011 IVT CONTROL

DTC LogicINFOID:0000000012431384

DTC DETECTION LOGIC

NOTE:

If DTC P0011 is displayed with D NISSAN NOTE 2016 Service Repair Manual P0011 IVT CONTROLEC-167

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0011 IVT CONTROL

DTC LogicINFOID:0000000012431384

DTC DETECTION LOGIC

NOTE:

If DTC P0011 is displayed with D](/img/5/57363/w960_57363-1293.png)

P0011 IVT CONTROLEC-167

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0011 IVT CONTROL

DTC LogicINFOID:0000000012431384

DTC DETECTION LOGIC

NOTE:

If DTC P0011 is displayed with DTC P0075, first perform the trouble diagnosis for DTC P0075. Refer to

EC-180, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is between 10 V and 16 V at

idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE-I

With CONSULT

1. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT.

2. Start engine and warm it up to the normal operating temperature.

3. Maintain the following conditions for at least 6 c onsecutive seconds. Hold the accelerator pedal as steady

as possible.

4. Let engine idle for 10 seconds.

5. Check 1st trip DTC. With GST

Follow the procedure “With CONSULT” above.

Is 1st trip DTC detected?

YES >> Go to EC-168, "Diagnosis Procedure"

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-II

With CONSULT

1. Maintain the following conditions for at least 20 consecutive seconds.

DTC No. Trouble diagnosis content Detecting condition Possible cause

P0011 Intake valve timing control

performance There is a gap between angle of

target and phase-control angle

degree. • Crankshaft position sensor

• Camshaft position sensor

• Intake valve timing control solenoid valve

• Accumulation of debris to the signal pick-up portion of

the camshaft

• Timing chain installation

• Foreign matter caught in the oil groove for intake valve timing control

ENG SPEED 500 - 2,000 rpm

COOLAN TEMP/S More than 60 °C (140 °F)

Shift lever P or N position (CVT)

Neutral position (M/T)

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1298 of 3641

![NISSAN NOTE 2016 Service Repair Manual P0014 EVT CONTROLEC-171

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0014 EVT CONTROL

DTC LogicINFOID:0000000012431387

DTC DETECTION LOGIC

NOTE:

If DTC P0014 is displayed with D NISSAN NOTE 2016 Service Repair Manual P0014 EVT CONTROLEC-171

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0014 EVT CONTROL

DTC LogicINFOID:0000000012431387

DTC DETECTION LOGIC

NOTE:

If DTC P0014 is displayed with D](/img/5/57363/w960_57363-1297.png)

P0014 EVT CONTROLEC-171

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0014 EVT CONTROL

DTC LogicINFOID:0000000012431387

DTC DETECTION LOGIC

NOTE:

If DTC P0014 is displayed with DTC P0078, first pe

rform trouble diagnosis for DTC P0078. Refer to EC-

182, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is between 10 V and 16 V at

idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE-I

With CONSULT

1. Turn ignition switch ON and select “DATA MONITOR” mode of “ENGINE” using CONSULT.

2. Start engine and warm it up to the normal operating temperature.

3. Maintain the following conditions for at least 6 c onsecutive seconds. Hold the accelerator pedal as steady

as possible.

4. Let engine idle for 10 seconds.

5. Check 1st trip DTC. With GST

Follow the procedure “With CONSULT” above.

Is 1st trip DTC detected?

YES >> Proceed to EC-172, "Diagnosis Procedure"

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-II

With CONSULT

1. Select “DATA MONITOR” mode of “ENGINE” using CONSULT.

2. Maintain the following conditions for at least 20 consecutive seconds.

DTC No. CONSULT screen terms

(Trouble diagnosis content) DTC detecting condition

Possible cause

P0014 EXH/V TIM CONT-B1

(Exhaust valve timing control

performance) There is a gap between angle of

target and phase-control angle

degree. • Crankshaft position sensor

• Exhaust valve timing control position sensor

• Exhaust valve timing control solenoid valve

• Accumulation of debris to the signal pick-up portion of

the camshaft

• Timing chain installation

• Foreign matter caught in the oil groove for exhaust valve timing control

ENG SPEED 1,200 - 2,000 rpm (A constant rotation is maintained.)

COOLAN TEMP/S More than 60° C (140°F)

Selector lever P or N position (CVT)

Neutral position (M/T)

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1903 of 3641

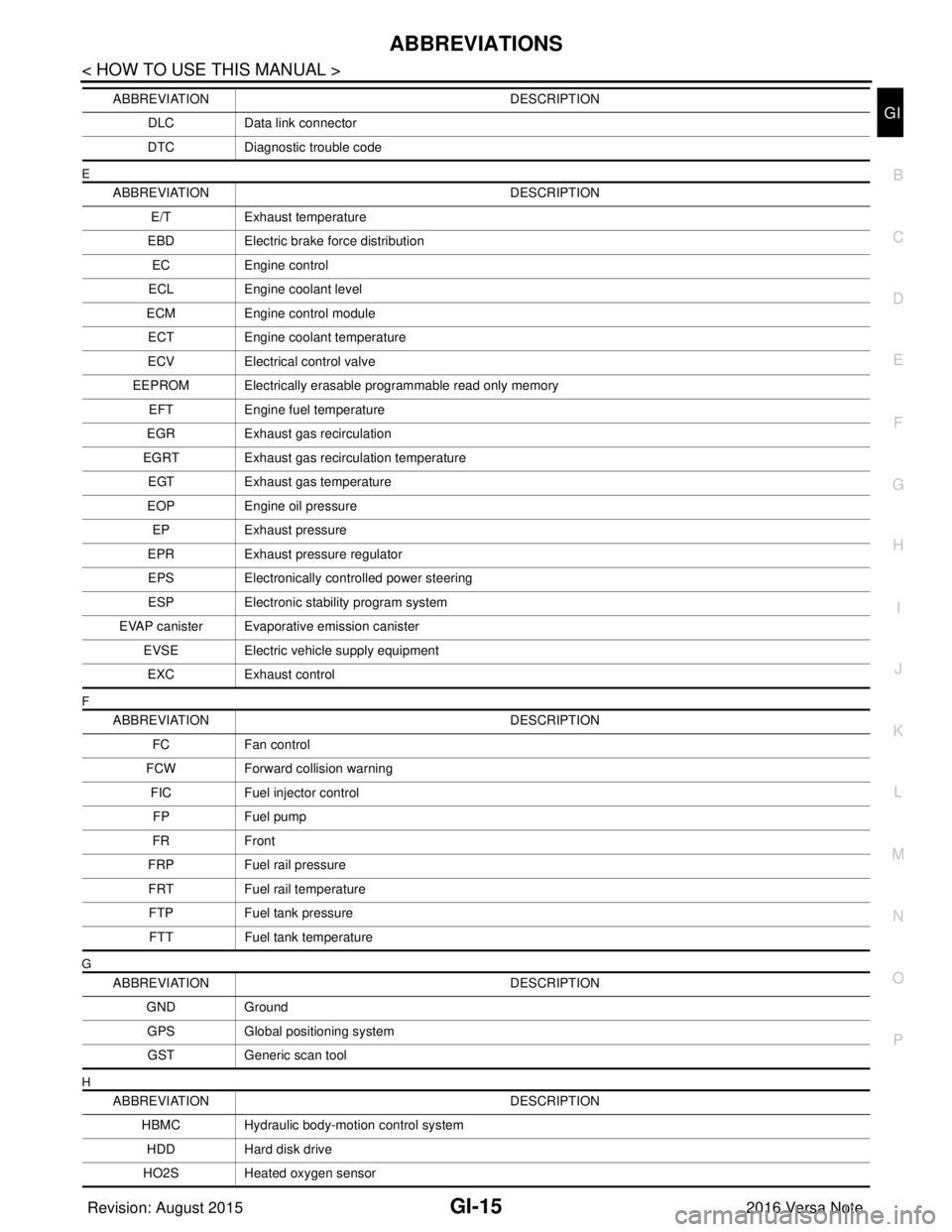

ABBREVIATIONSGI-15

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

E

F

G

H

DLC Data link connector

DTC Diagnostic trouble code

ABBREVIATION DESCRIPTION

E/T Exhaust temperature

EBD Electric brake force distribution

EC Engine control

ECL Engine coolant level

ECM Engine control module

ECT Engine coolant temperature

ECV Electrical control valve

EEPROM Electrically erasable programmable read only memory EFT Engine fuel temperature

EGR Exhaust gas recirculation

EGRT Exhaust gas recirculation temperature EGT Exhaust gas temperature

EOP Engine oil pressure

EP Exhaust pressure

EPR Exhaust pressure regulator

EPS Electronically controlled power steering

ESP Electronic stability program system

EVAP canister Evaporative emission canister EVSE Electric vehicle supply equipment

EXC Exhaust control

ABBREVIATION DESCRIPTION

FC Fan control

FCW Forward collision warning

FIC Fuel injector control

FP Fuel pump

FR Front

FRP Fuel rail pressure

FRT Fuel rail temperature

FTP Fuel tank pressure

FTT Fuel tank temperature

ABBREVIATION DESCRIPTION

GND Ground

GPS Global positioning system

GST Generic scan tool

ABBREVIATION DESCRIPTION

HBMC Hydraulic body-motion control system HDD Hard disk drive

HO2S Heated oxygen sensor

ABBREVIATION

DESCRIPTION

Revision: August 2015 2016 Versa Note

cardiagn.com