exhaust NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 416 of 3641

CORROSION PROTECTIONBRM-17

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

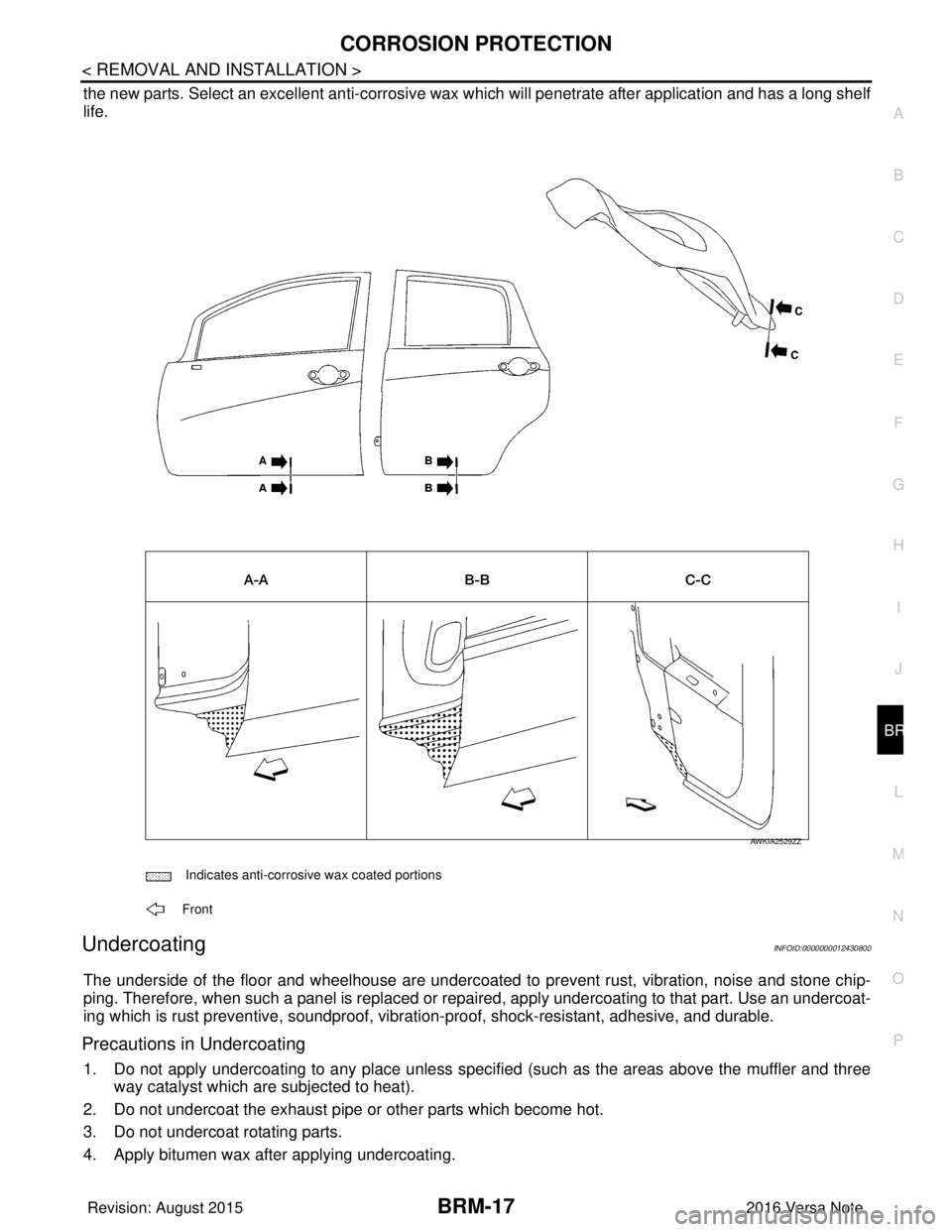

the new parts. Select an excellent anti-corrosive wax which will penetrate after application and has a long shelf

life.

UndercoatingINFOID:0000000012430800

The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chip-

ping. Therefore, when such a panel is replaced or re paired, apply undercoating to that part. Use an undercoat-

ing which is rust preventive, soundproof, vibr ation-proof, shock-resistant, adhesive, and durable.

Precautions in Undercoating

1. Do not apply undercoating to any place unless specif ied (such as the areas above the muffler and three

way catalyst which are subjected to heat).

2. Do not undercoat the exhaust pipe or other parts which become hot.

3. Do not undercoat rotating parts.

4. Apply bitumen wax after applying undercoating.

Indicates anti-corrosive wax coated portions

Front

AWKIA2529ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1002 of 3641

EM-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EM

A

EM

N

O P

CONTENTS

ENGINE MECHANICAL

HR16DE

PRECAUTION ....... ........................................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Procedure without Cowl Top Cover ......3

Draining Engine Coolant ...........................................3

Disconnecting Fuel Piping .........................................3

Removal and Disassembly ........................................3

Inspection, Repair and Replacement ........................4

Assembly and Installation .........................................4

Parts Requiring Angle Tightening ....................... ......4

Precaution for Liquid Gasket .....................................4

PREPARATION ............................................6

PREPARATION .............................................. .....6

Special Service Tools .......................................... ......6

Commercial Service Tools ........................................7

BASIC INSPECTION ...................................10

CAMSHAFT VALVE CLEARANCE ............... ....10

Inspection and Adjustment .................................. ....10

COMPRESSION PRESSURE ............................13

Inspection ............................................................ ....13

SYMPTOM DIAGNOSIS ..............................14

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ ....

14

NVH troubleshooting Chart ................................. ....14

PERIODIC MAINTENANCE .........................16

DRIVE BELT ................................................... ....16

Exploded View .................................................... ....16

Removal and Installation .........................................16

Inspection ............................................................ ....17

Adjustment ...............................................................17

AIR CLEANER FILTER .....................................19

Exploded View .........................................................19

Removal and Installation .........................................19

SPARK PLUG ...................................................21

Exploded View .........................................................21

Removal and Installation .........................................21

REMOVAL AND INSTALLATION ...............24

DRIVE BELT IDLER PULLEY ..........................24

Exploded View ..................................................... ....24

Removal and Installation .........................................24

AIR CLEANER AND AIR DUCT .......................26

Exploded View .........................................................26

Removal and Installation .........................................26

INTAKE MANIFOLD .........................................28

Exploded View .........................................................28

Removal and Installation .........................................28

EXHAUST MANIFOLD ......................................31

Exploded View .........................................................31

Removal and Installation .........................................31

OIL PAN AND OIL STRAINER .........................34

Exploded View .........................................................34

Removal and Installation (Lower Oil Pan) ...............34

Removal and Installation (Upper Oil Pan) ........... ....37

FUEL INJECTOR AND FUEL TUBE ................40

Exploded View .........................................................40

Removal and Installation .........................................40

IGNITION COIL .................................................47

Exploded View .........................................................47

Removal and Installation .........................................47

ROCKER COVER .............................................48

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1003 of 3641

EM-2

Exploded View ........................................................48

Removal and Installation ........................................48

TIMING CHAIN ............................................... ...51

Exploded View ..................................................... ...51

Removal and Installation ........................................51

CAMSHAFT .......................................................60

Exploded View ..................................................... ...60

Removal and Installation ........................................60

Inspection ...............................................................68

OIL SEAL ...........................................................73

VALVE OIL SEAL .................................................. ...73

VALVE OIL SEAL : Removal and Installation .........73

FRONT OIL SEAL .................................................. ...74

FRONT OIL SEAL : Removal and Installation ........74

REAR OIL SEAL .................................................... ...74

REAR OIL SEAL : Removal and Installation ..........74

CYLINDER HEAD ........................................... ...76

Exploded View ..................................................... ...76

Removal and Installation ........................................76

Exploded View ........................................................78

Disassembly and Assembly ....................................78

Inspection ...............................................................80

UNIT REMOVAL AND INSTALLATION .....86

ENGINE ASSEMBLY ...................................... ...86

Exploded View ..................................................... ...86

Removal and Installation ........................................87

UNIT DISASSEMBLY AND ASSEMBLY ...91

ENGINE UNIT ....................................................91

Setting .................................................................. ...91

Disassembly ............................................................92

Assembly ................................................................92

CYLINDER BLOCK ...........................................93

Exploded View ........................................................93

Disassembly and Assembly ....................................94

Inspection ..............................................................102

HOW TO SELECT PISTON AND BEARING ...111

Description ........................................................... .111

Connecting Rod Bearing .......................................111

Main Bearing ........................................................113

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

116

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

116

General Specification ........................................... .116

Drive Belt ..............................................................116

Spark Plug ............................................................117

Exhaust Manifold ..................................................117

Camshaft ...............................................................117

Cylinder head ........................................................119

Cylinder Block .......................................................121

Main Bearing .........................................................124

Connecting Rod Bearing .......................................125

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1005 of 3641

![NISSAN NOTE 2016 Service Repair Manual EM-4

< PRECAUTION >[HR16DE]

PRECAUTIONS

• Dowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

check that dowel pins are installed in the original NISSAN NOTE 2016 Service Repair Manual EM-4

< PRECAUTION >[HR16DE]

PRECAUTIONS

• Dowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

check that dowel pins are installed in the original](/img/5/57363/w960_57363-1004.png)

EM-4

< PRECAUTION >[HR16DE]

PRECAUTIONS

• Dowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

check that dowel pins are installed in the original position.

• Cover openings of engine system with a tape or equival ent, if necessary, to seal out foreign materials.

• Mark and arrange disassembly parts in an organi zed way for easy troubleshooting and reassembly.

• When loosening nuts and bolts, start with the one furthest outside, then the one diagonally opposite, and so on. If the order of loosening is specified, do exactl y as specified. Power tools may be used in the step.

Inspection, Repair and ReplacementINFOID:0000000012431684

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Assembly and InstallationINFOID:0000000012431685

• Use torque wrench to tighten bolts or nuts to specification.

• Tighten nuts and bolts in order exactly as specified in the procedure. If a tightening order or procedure is not

specified, tighten nuts and bolts equally in several differ ent steps. Start with the nuts or bolts in the center

and then tighten diagonally starting with the inside and moving to the outside in a spiral pattern.

• Replace with new gasket, packing, oil seal or O-ring.

• Thoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for restrictions and blockages.

• Avoid damaging sliding or mating surfaces. Before assembling, completely remove foreign materials such as cloth lint or dust, and oil the sliding surfaces.

• After refilling engine coolant, bleed the air from the cooling system.

• After repairing, start the engine and increase engine s peed to check for engine coolant leaks, fuel leaks,

engine oil leaks, and exhaust gas leaks.

Parts Requiring Angle TighteningINFOID:0000000012431686

• For the final tightening of the following engine parts use Tool:

- Camshaft sprocket (INT) bolt

- Cylinder head bolts

- Main bearing cap bolts

- Connecting rod cap bolts

- Crankshaft pulley bolt (Note an angle wrench is required as bolt flange is provided with notches for angle tightening)

• Do not use a torque value for final tightening.

• The torque value for these parts are for a preliminary step.

• Ensure thread and seat surfaces are clean and coated with engine oil.

Precaution for Liquid GasketINFOID:0000000012431687

REMOVAL OF LIQUID GASKET SEALING

• After removing the bolts and nuts, separate the mating surface and remove the liquid gasket using Tool (A).

CAUTION:

Be careful not to damage the mating surfaces.

• In areas where the cutter is difficult to use, use a plastic hammer to lightly tap (1) the cutter where the liquid gasket is applied. Use a

plastic hammer to slide (2) the cutter by tapping on the side.

CAUTION:

Do not damage the mating surfaces. Tool number : KV10112100 (BT-8653-A)

Tool Number (A) : KV10111100 (J-37228)

AWBIA1249GB

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1009 of 3641

![NISSAN NOTE 2016 Service Repair Manual EM-8

< PREPARATION >[HR16DE]

PREPARATION

Spark plug wrench

Removing and installing spark plug

a: 14 mm (0.55 in)

Pulley holder Crankshaft pulley removing and installing

Valve seat cutter set Finishing NISSAN NOTE 2016 Service Repair Manual EM-8

< PREPARATION >[HR16DE]

PREPARATION

Spark plug wrench

Removing and installing spark plug

a: 14 mm (0.55 in)

Pulley holder Crankshaft pulley removing and installing

Valve seat cutter set Finishing](/img/5/57363/w960_57363-1008.png)

EM-8

< PREPARATION >[HR16DE]

PREPARATION

Spark plug wrench

Removing and installing spark plug

a: 14 mm (0.55 in)

Pulley holder Crankshaft pulley removing and installing

Valve seat cutter set Finishing valve seat dimensions

Piston ring expander Removing and installing piston ring

Valve guide drift Removing and installing valve guide

Valve guide reamer (1): Reaming valve guide inner hole

(2): Reaming hole for oversize valve guide

(J-43897-18)

(J-43897-12)

Oxygen sensor thread cleaner Reconditioning the exhaust system threads

before installing a new air fuel ratio sensor

(Use with anti-seize lubricant shown below.)

A: [18 mm (0.71 in) dia.] for zirconia heated

oxygen sensor

B: [12 mm (0.47 in) dia.] for titania heated

oxygen sensor

C: Mating surface shave cylinder

D: Flutes

Tool name

Description

JPBIA0399ZZ

NT035

S-NT048

S-NT030

PBIC4012E

PBIC4013E

JPBIA0238ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1010 of 3641

![NISSAN NOTE 2016 Service Repair Manual PREPARATIONEM-9

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Acoustic tension gauge

Checking drive belt tension

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL specifica-

t NISSAN NOTE 2016 Service Repair Manual PREPARATIONEM-9

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Acoustic tension gauge

Checking drive belt tension

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL specifica-

t](/img/5/57363/w960_57363-1009.png)

PREPARATIONEM-9

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Acoustic tension gauge

Checking drive belt tension

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL specifica-

tion MIL-A-907) Lubricating oxygen sensor thread cleaning

tool when reconditioning exhaust system

threads

Manual lift table caddy Removing and installing engine

1. Compression gauge

2. Adapter Checking compression pressure

Tube presser Pressing the tube of liquid gasket

Tool name

Description

PBIC3881E

AEM489

ZZA1210D

ZZA0008D

S-NT052

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1011 of 3641

![NISSAN NOTE 2016 Service Repair Manual EM-10

< BASIC INSPECTION >[HR16DE]

CAMSHAFT VALVE CLEARANCE

BASIC INSPECTION

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000012431690

INSPECTION

Perform inspection as follows after re NISSAN NOTE 2016 Service Repair Manual EM-10

< BASIC INSPECTION >[HR16DE]

CAMSHAFT VALVE CLEARANCE

BASIC INSPECTION

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000012431690

INSPECTION

Perform inspection as follows after re](/img/5/57363/w960_57363-1010.png)

EM-10

< BASIC INSPECTION >[HR16DE]

CAMSHAFT VALVE CLEARANCE

BASIC INSPECTION

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000012431690

INSPECTION

Perform inspection as follows after removal, replacement or installation of camshaft or valve-related parts, or if

there are unusual engine conditions regarding valve clearance.

1. Remove rocker cover. Refer to

EM-48, "

Removal and Installation".

2. Measure the valve clearance with the following procedure:

a. Set No. 1 cylinder at TDC of its compression stroke. • Rotate crankshaft pulley (2) clockwise and align TDC mark (no

paint) (A) to timing indicator (1) on front cover.

• At the same time, check that both intake and exhaust cam lobes of No. 1 cylinder face inside ( ) as shown.

• If the lobes do not face inside, rotate the crankshaft pulley 360 degrees to align as shown.

b. Using suitable tool (A) measure the clearance between the valve lifter and camshaft.

(B) : White paint mark (Not used for service)

PBIC3673E

(1) : Camshaft (INT)

(2) : Camshaft (EXH)

: Engine front

JPBIA4738ZZ

Valve clearance : Refer to EM-117, "Camshaft".

JPBIA4116ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1013 of 3641

![NISSAN NOTE 2016 Service Repair Manual EM-12

< BASIC INSPECTION >[HR16DE]

CAMSHAFT VALVE CLEARANCE

3. Measure the center thickness of the removed valve lifters using

a suitable tool (A).

4. Use the equation below to calculate valve lifter NISSAN NOTE 2016 Service Repair Manual EM-12

< BASIC INSPECTION >[HR16DE]

CAMSHAFT VALVE CLEARANCE

3. Measure the center thickness of the removed valve lifters using

a suitable tool (A).

4. Use the equation below to calculate valve lifter](/img/5/57363/w960_57363-1012.png)

EM-12

< BASIC INSPECTION >[HR16DE]

CAMSHAFT VALVE CLEARANCE

3. Measure the center thickness of the removed valve lifters using

a suitable tool (A).

4. Use the equation below to calculate valve lifter thickness for replacement.

• Crown surface thickness of new valve lifter (B) can be identi-fied by stamp mark (A) on the under side of the lifter.

NOTE:

Available thickness of valve lifter: 26 sizes range 3.00 to 3.50

mm (0.1181 to 0.1378 in) in increments of 0.02 mm (0.0008 in)

when manufactured at factory. Refer to EM-117, "

Camshaft".

• Stamp mark “302” indicates 3.02 mm (0.1189 in) in thickness.

5. Install the correct thickness valve lifter.

6. Install camshaft. Refer to EM-60, "

Exploded View".

7. Install timing chain. Refer to EM-51, "

Exploded View".

8. Manually rotate crankshaft pulley a few rotations.

9. Check that valve clearances are within specification. Refer to “INSPECTION”.

10. Installation of remaining components is in the reverse order of removal.

11. Warm up the engine, and check for unusual noise and vibration.

PBIC3195J

Valve lifter thickness calculation: t = t1 + (C1 – C2)

t = Valve lifter thickness to be replaced

t

1 = Removed valve lifter thickness

C

1= Measured valve clearance

C

2= Standard valve clearance at 20° C (68°F):

Intake : 0.30 mm (0.012 in)

Exhaust : 0.33 mm (0.013 in)

PBIC3196J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1032 of 3641

![NISSAN NOTE 2016 Service Repair Manual EXHAUST MANIFOLDEM-31

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

EXHAUST MANIFOLD

Exploded ViewINFOID:0000000012431707

Removal and InstallationINFOID:0000000012431708

REMOVA NISSAN NOTE 2016 Service Repair Manual EXHAUST MANIFOLDEM-31

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

EXHAUST MANIFOLD

Exploded ViewINFOID:0000000012431707

Removal and InstallationINFOID:0000000012431708

REMOVA](/img/5/57363/w960_57363-1031.png)

EXHAUST MANIFOLDEM-31

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

EXHAUST MANIFOLD

Exploded ViewINFOID:0000000012431707

Removal and InstallationINFOID:0000000012431708

REMOVAL

1. Remove air duct (inlet), air duct and air cleaner assembly. Refer to

EM-26, "Exploded View".

2. Remove exhaust front tube. Refer to EX-5, "

Exploded View".

3. Remove harness bracket from the cylinder head on the right rear side.

4. Remove exhaust manifold upper and lower covers.

5. Disconnect air fuel ratio sensor 1 harness connector.

AWBIA1603ZZ

1. Exhaust manifold cover (upper) 2. Harness bracket 3. Air-fuel ratio sensor 1

4. Exhaust manifold stay 5. Heat insulator6. Exhaust manifold

7. Exhaust manifold cover (lower) 8. Exhaust maifold gasket Engine front

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1033 of 3641

![NISSAN NOTE 2016 Service Repair Manual EM-32

< REMOVAL AND INSTALLATION >[HR16DE]

EXHAUST MANIFOLD

6. Use Tool (A) to remove the air-fuel ratio sensor 1 with exhaust

manifold installed on vehicle (if necessary).

CAUTION:

• Handle air-fue NISSAN NOTE 2016 Service Repair Manual EM-32

< REMOVAL AND INSTALLATION >[HR16DE]

EXHAUST MANIFOLD

6. Use Tool (A) to remove the air-fuel ratio sensor 1 with exhaust

manifold installed on vehicle (if necessary).

CAUTION:

• Handle air-fue](/img/5/57363/w960_57363-1032.png)

EM-32

< REMOVAL AND INSTALLATION >[HR16DE]

EXHAUST MANIFOLD

6. Use Tool (A) to remove the air-fuel ratio sensor 1 with exhaust

manifold installed on vehicle (if necessary).

CAUTION:

• Handle air-fuel ratio sensor 1 carefully and avoid impacts.

• Before installing a new air-fu el ratio sensor 1, clean the

exhaust tube threads using suitable tool and approved

anti-seize lubricant.

• If air-fuel ratio sensor is dropped onto a hard surface, such as a concrete floor, from a height of 0.5 m or more,

discard the sensor and use a new one.

7. Remove exhaust manifold side bolt of exhaust manifold stay.

8. Remove exhaust manifold. • Loosen nuts in reverse order as shown.

9. Remove exhaust manifold gasket.

10. Remove stud bolt using suitable tool from cylinder head (if necessary).

INSPECTION AFTER REMOVAL

Mounting Surface Distortion

• Using suitable tools (A) and (B), check the surface distortion of the exhaust manifold mating surface as shown.

• Replace exhaust manifold if it exceeds the limit.

INSTALLATION

Installation is in the reverse order of removal.

Exhaust manifold

1. Install new exhaust manifold gasket. CAUTION:Tool number (A) : KV10117100 ( — )

Oxygen sensor thread cleaner : — (J-43897-12)

: — (J-43897-18)

JPBIA4126ZZ

JPBIA4127ZZ

Limit : Refer to EM-117, "Exhaust Manifold".

PBIC3530J

Revision: August 2015 2016 Versa Note

cardiagn.com