door NISSAN PATHFINDER 2023 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2023, Model line: PATHFINDER, Model: NISSAN PATHFINDER 2023Pages: 665, PDF Size: 4.64 MB

Page 574 of 665

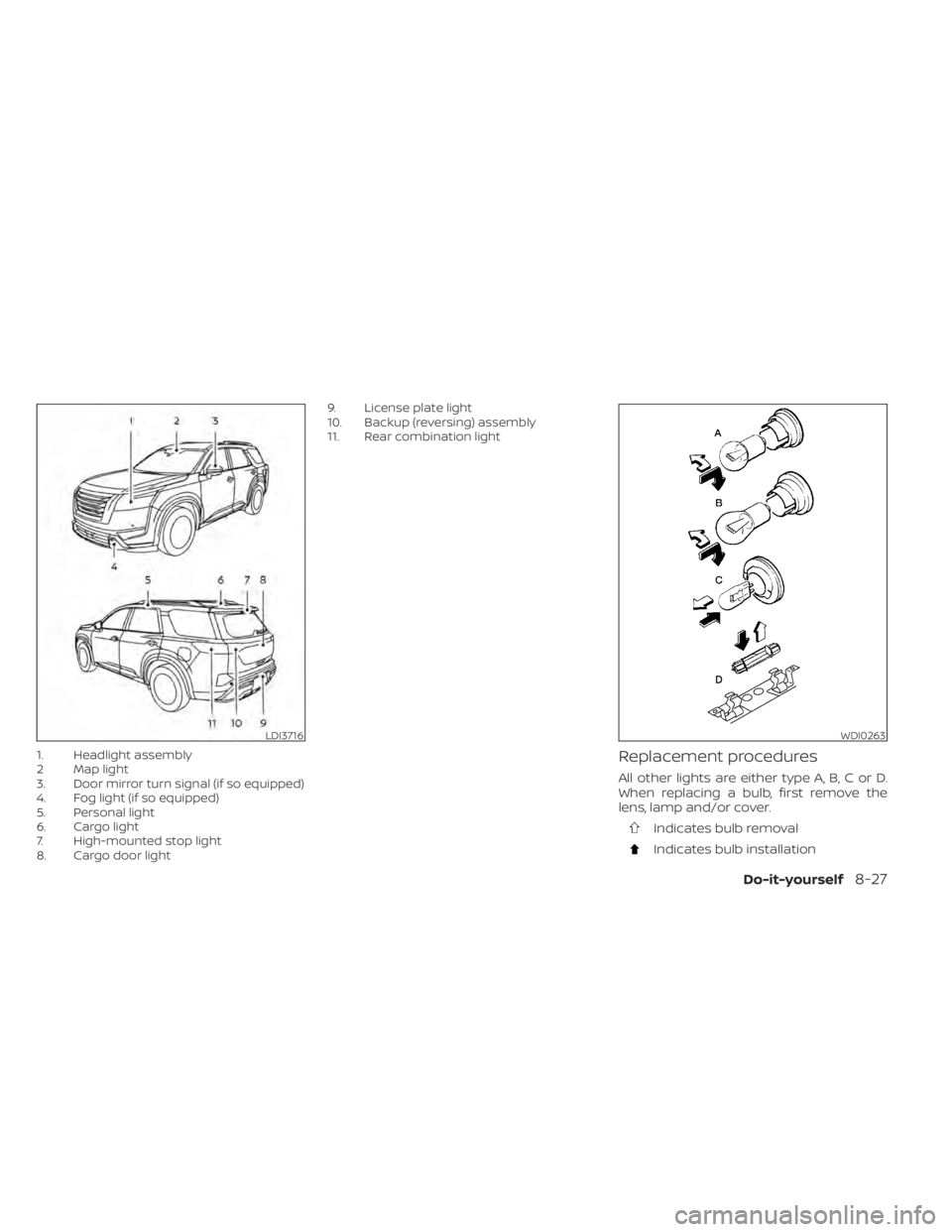

1. Headlight assembly

2 Map light

3. Door mirror turn signal (if so equipped)

4. Fog light (if so equipped)

5. Personal light

6. Cargo light

7. High-mounted stop light

8. Cargo door light9. License plate light

10. Backup (reversing) assembly

11. Rear combination lightReplacement procedures

All other lights are either type A, B, C or D.

When replacing a bulb, first remove the

lens, lamp and/or cover.

Indicates bulb removal

Indicates bulb installation

LDI3716WDI0263

Do-it-yourself8-27

Page 592 of 665

Doors and engine hood:Check that the

doors and engine hood operate properly.

Also ensure that all latches lock securely.

Lubricate hinges, latches, latch pins, rollers

and links if necessary. Make sure that the

secondary latch keeps the hood from

opening when the primary latch is

released.

When driving in areas using road salt or

other corrosive materials, check lubrica-

tion frequently.

Check that the gas stays or struts properly

and securely hold the hood, trunk, or rear

hatch fully open. If the hood, trunk, or rear

hatch is not held open, have the gas stays

or struts replaced.

Lights*: Clean the headlights on a regular

basis. Make sure that the headlights, stop

lights, tail lights, turn signal lights, and other

lights are all operating properly and in-

stalled securely. Also check headlight aim.

Road wheel nuts (lug nuts)*: When check-

ing the tires, make sure no wheel nuts are

missing, and check for any loose wheel

nuts. Tighten if necessary.

Tire rotation*: Rotate tires at the specified

interval shown in the maintenance

schedule. Tires*:

Check the pressure with a gauge

of ten and always prior to long distance

trips. If necessary, adjust the pressure in all

tires, including the spare, to the pressure

specified. Check carefully for damage, cuts

or excessive wear.

Tire Pressure Monitoring System (TPMS)

tire pressure sensor: It is recommended

that you replace the TPMS tire pressure

sensor assembly when the tires are re-

placed due to wear or age.

Wheel alignment and balance: If the ve-

hicle should pull to either side while driving

on a straight and level road, or if you detect

uneven or abnormal tire wear, there may

be a need for wheel alignment. If the steer-

ing wheel or seat vibrates at normal high-

way speeds, wheel balancing may be

needed.

For additional information regarding tires,

refer to “Important Tire Safety Information”

(US) or “Tire Safety Information” (Canada) in

the Warranty Information Booklet.

Windshield: Clean the windshield on a

regular basis. Check the windshield at least

every six months for cracks or other dam-

age. Have a damaged windshield repaired

by a qualified repair facility. It is recom-

mended that you have a damaged wind- shield repaired by a NISSAN dealer, or a

NISSAN Certified Collision Center. To locate

a collision center in your area, refer to

http://collision.nissanusa.com.

Windshield wiper blades*:

Check for

cracks or wear if they do not wipe properly.

Inside the vehicle

The maintenance items listed here should

be checked on a regular basis, such as

when performing scheduled maintenance,

cleaning the vehicle, etc.

Accelerator pedal: Check the pedal for

smooth operation and make sure the

pedal does not catch or require uneven

effort. Keep the floor mat away from the

pedal.

Brake pedal: Check the pedal for smooth

operation. If the brake pedal suddenly goes

down further than normal, the pedal feels

spongy or the vehicle seems to take longer

to stop, have your vehicle checked imme-

diately. It is recommended that you visit a

NISSAN dealer for this service. Keep the

floor mat away from the pedal.

Brakes: Check that the brakes do not pull

the vehicle to one side when applied.

Maintenance and schedules9-3

Page 596 of 665

Steering gear and linkage, axle and sus-

pension parts, drive shaf t boots:Check

for damage, looseness, and leakage of oil

or grease. Under severe driving conditions,

inspect more frequently.

Tire rotation: Rotate tires at the specified

interval shown in the maintenance sched-

ule. When rotating tires, check for damage

and uneven wear. Replace if necessary.

Transmission fluid/oil, differential oil,

transfer case oil and coupling oil: Visually

inspect for signs of leakage at specified

intervals. To help ensure smooth, safe and economi-

cal driving, NISSAN provides two mainte-

nance schedules that may be used, de-

pending upon the conditions in which you

usually drive. These schedules contain

both distance and time intervals, up to

120,000 miles (192,000 km)/96 months. For

most people, the odometer reading will in-

dicate when service is needed. However, if

you drive very little, your vehicle should be

serviced at the regular time intervals

shown in the schedule.

Af ter 120,000 miles (192,000 km)/96

months, continue maintenance at the

same mileage/time intervals.

ADDITIONAL MAINTENANCE ITEMS

FOR SEVERE OPERATING

CONDITIONS

Additional maintenance items for severe

operating conditions

should be per-

formed on vehicles that are driven under

especially demanding conditions. Addi-

tional maintenance items should be per-

formed if you primarily operate your vehicle

under the following conditions:

• Repeated short trips of less than 5 miles (8 km). • Repeated short trips of less than 10 miles

(16 km) with outside temperatures re-

maining below freezing.

• Operating in hot weather in stop-and-go “rush hour” traffic.

• Extensive idling and/or low speed driving for long distances, such as police, taxi or

door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy or salt spread roads.

• Towing a trailer, using a camper or using a car-top carrier.

If your vehicle is mainly operated under the

severe conditions, follow the severe use

maintenance intervals shown in the main-

tenance schedule.OIL CONTROL SYSTEM

Your vehicle is equipped with oil control

system. It calculates engine oil and filter

change intervals based on driving condi-

tions. Driving in the following severe condi-

tions will shorten the engine oil and filter

change interval.

MAINTENANCE SCHEDULES

Maintenance and schedules9-7

Page 597 of 665

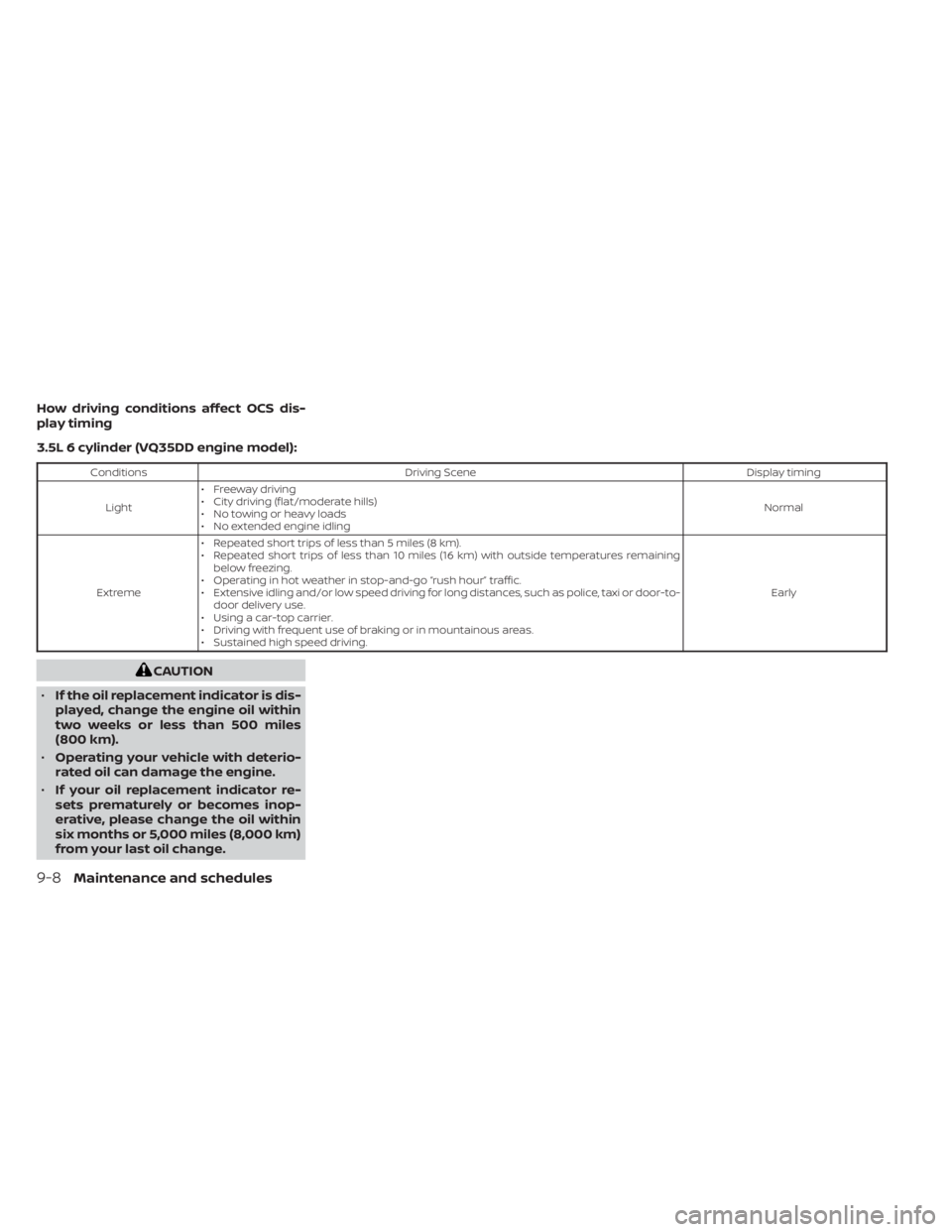

How driving conditions affect OCS dis-

play timing

3.5L 6 cylinder (VQ35DD engine model):

ConditionsDriving Scene Display timing

Light • Freeway driving

• City driving (flat/moderate hills)

• No towing or heavy loads

• No extended engine idling Normal

Extreme • Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) with outside temperatures remaining

below freezing.

• Operating in hot weather in stop-and-go “rush hour” traffic.

• Extensive idling and/or low speed driving for long distances, such as police, taxi or door-to- door delivery use.

• Using a car-top carrier.

• Driving with frequent use of braking or in mountainous areas.

• Sustained high speed driving. Early

CAUTION

• If the oil replacement indicator is dis-

played, change the engine oil within

two weeks or less than 500 miles

(800 km).

• Operating your vehicle with deterio-

rated oil can damage the engine.

• If your oil replacement indicator re-

sets prematurely or becomes inop-

erative, please change the oil within

six months or 5,000 miles (8,000 km)

from your last oil change.

9-8Maintenance and schedules

Page 615 of 665

FUEL RECOMMENDATION

Use unleaded regular gasoline with an oc-

tane rating of at least 87 AKI (Anti-Knock

Index) number (Research octane number

91).

CAUTION

• Only vehicles with the E-85 filler door

label can operate on E-85. Fuel sys-

tem or other damage can occur if

E-85 is used in vehicles that are not

designed to run on E-85.

• Using a fuel other than that specified

could adversely affect the emission

control system, and may also affect

the warranty coverage.

• Under no circumstances should a

leaded gasoline be used, because

this will damage the three-way

catalyst. •

Do not use a fuel containing more

than 15% ethanol in your vehicle. Your

vehicle is not designed to run on a

fuel containing more than 15% etha-

nol. Using a fuel containing more

than 15% ethanol in a vehicle not spe-

cifically designed for a fuel contain-

ing more than 15% ethanol can ad-

versely affect the emission control

devices and systems of the vehicle.

Damage caused by such fuel is not

covered by the NISSAN New Vehicle

Limited Warranty.

• Do not use fuel that contains the oc-

tane booster methylcyclopentadi-

enyl manganese tricarbonyl (MMT).

Using fuel containing MMT may ad-

versely affect vehicle performance

and vehicle emissions. Not all fuel

dispensers are labeled to indicate

MMT content, so you may have to

consult your gasoline retailer for

more details. Note that Federal and

California laws prohibit the use of

MMT in reformulated gasoline. •

U.S. government regulations require

ethanol dispensing pumps to be

identified by a small, square, orange

and black label with the common ab-

breviation or the appropriate per-

centage for that region.Gasoline specifications

NISSAN recommends using gasoline that

meets the World-Wide Fuel Charter (WWFC)

specifications where it is available. Many of

the automobile manufacturers developed

this specification to improve emission con-

trol system and vehicle performance. Ask

your service station manager if the gaso-

line meets the WWFC specifications.

Reformulated gasoline

Some fuel suppliers are now producing re-

formulated gasolines. These gasolines are

specially designed to reduce vehicle emis-

sions. NISSAN supports efforts towards

cleaner air and suggests that you use re-

formulated gasoline when available.

10-4Technical and consumer information

Page 621 of 665

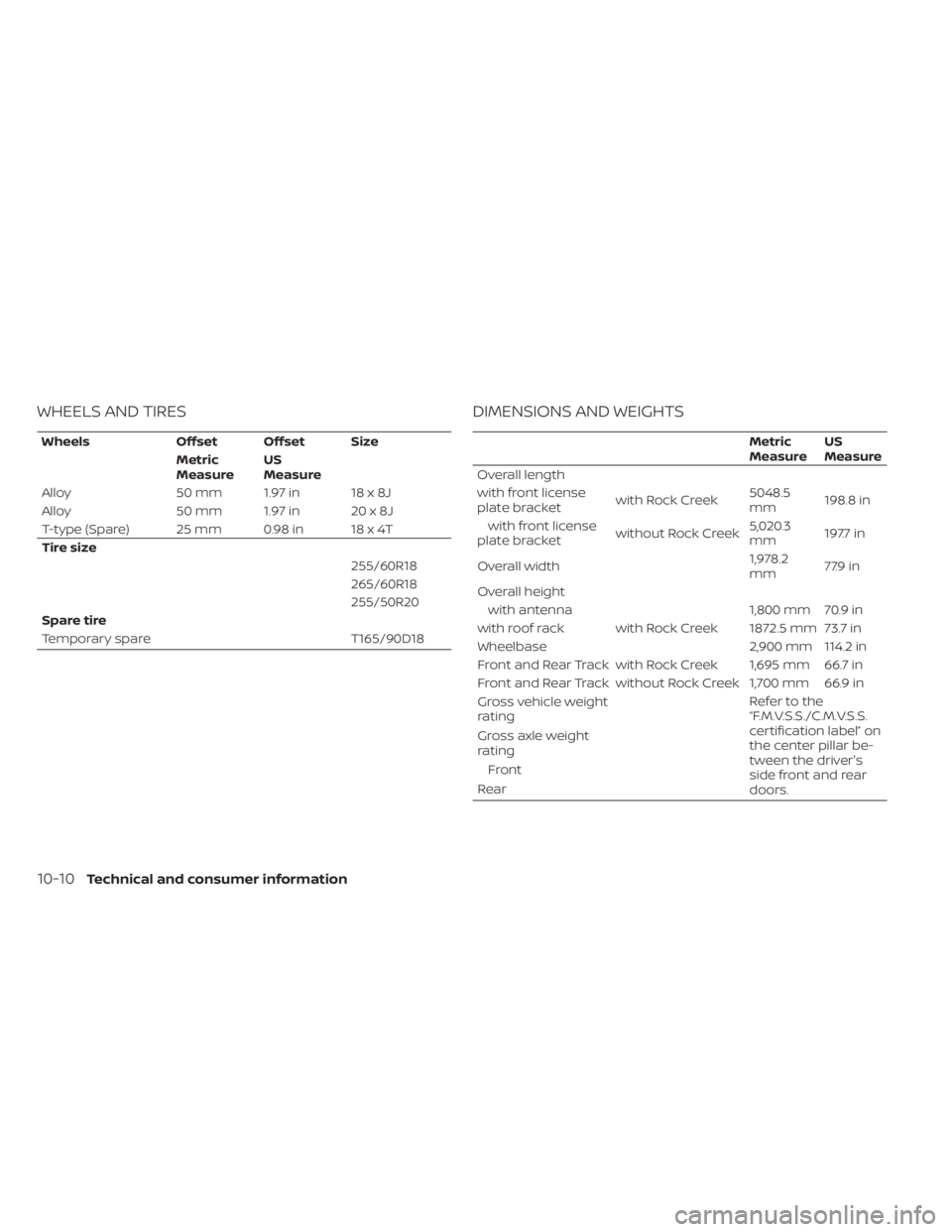

WHEELS AND TIRES

WheelsOffset Offset Size

Metric

Measure US

Measure

Alloy 50mm 1.97in 18x8J

Alloy 50mm 1.97in 20x8J

T-type (Spare) 25 mm 0.98 in 18 x 4T

Tire size 255/60R18

265/60R18

255/50R20

Spare tire

Temporary spare T165/90D18

DIMENSIONS AND WEIGHTS

Metric

MeasureUS

Measure

Overall length

with front license

plate bracket with Rock Creek5048.5

mm198.8 in

with front license

plate bracket without Rock Creek5,020.3

mm197.7 in

Overall width 1,978.2

mm77.9 in

Overall height with antenna 1,800 mm 70.9 in

with roof rack with Rock Creek 1872.5 mm 73.7 in

Wheelbase 2,900 mm 114.2 in

Front and Rear Track with Rock Creek 1,695 mm 66.7 in

Front and Rear Track without Rock Creek 1,700 mm 66.9 in

Gross vehicle weight

rating Refertothe

“F.M.V.S.S./C.M.V.S.S.

certification label” on

the center pillar be-

tween the driver's

side front and rear

doors.

Gross axle weight

rating

Front

Rear

10-10Technical and consumer information

Page 637 of 665

A weight-distributing hitch system (Class

IV) is recommended if you plan to tow trail-

ers with a maximum weight over 5,000 lbs.

(2,268 kg). Check with the trailer and towing

equipment manufacturers to determine if

they recommend the use of a weight-

distributing hitch system.

NOTE:

A weight-distributing hitch system may

affect the operation of trailer surge

brakes. If you are considering use of a

weight-distributing hitch system with a

surge brake-equipped trailer, check with

the surge brake, hitch or trailer manufac-

turer to determine if and how this can be

done.

Follow the instructions provided by the

manufacturer for installing and using the

weight-distributing hitch system.

General set-up instructions are as follows:

1. Park unloaded vehicle on a level surface.With the ignition switch in the ON posi-

tion and the doors closed, allow the ve-

hicle to stand for several minutes so that

it can level.

2. Measure the height of a reference point on the front and rear bumpers at the

center of the vehicle. 3. Attach the trailer to the vehicle and ad-

just the hitch equalizers so that the front

bumper height is within0-.5inches (0 –

13 mm) of the reference height mea-

sured in step 2. The rear bumper should

be no higher than the reference height

measured in step 2.

WARNING

Properly adjust the weight distributing

hitch so the rear of the bumper is no

higher than the measured reference

height when the trailer is attached. If

the rear bumper is higher than the

measured reference height when

loaded, the vehicle may handle unpre-

dictably which could cause a loss of ve-

hicle control and cause serious per-

sonal injury or property damage.

Sway control device

Sudden maneuvers, wind gusts, and buf-

feting caused by other vehicles can affect

trailer handling. Sway control devices may

be used to help control these affects. If you

choose to use one, contact a reputable

trailer hitch supplier to make sure the sway

control device will work with the vehicle,

hitch, trailer and the trailer's brake system.

Follow the instructions provided by the manufacturer for installing and using the

sway control device.

Class I hitch

Class I trailer hitch equipment (receiver, ball

mount and hitch ball) can be used to tow

trailers of a maximum weight of 2,000 lbs.

(907 kg).

Class II hitch

Class II trailer hitch equipment (receiver,

ball mount and hitch ball) can be used to

tow trailers of a maximum weight of 3,500

lbs. (1,587 kg).

Class III hitch

Class III trailer hitch equipment (receiver,

ball mount and hitch ball) can be used to

tow trailers of a maximum weight of 5,000

lbs. (2,268 kg).

Class IV hitch

Class IV trailer hitch equipment (receiver,

ball mount and hitch ball) can be used to

tow trailers of a maximum weight of 10,000

lbs. (4,535 kg). A weight distributing hitch

should be used to tow trailers that weigh

over 5,000 lbs. (2,268 kg).

10-26Technical and consumer information

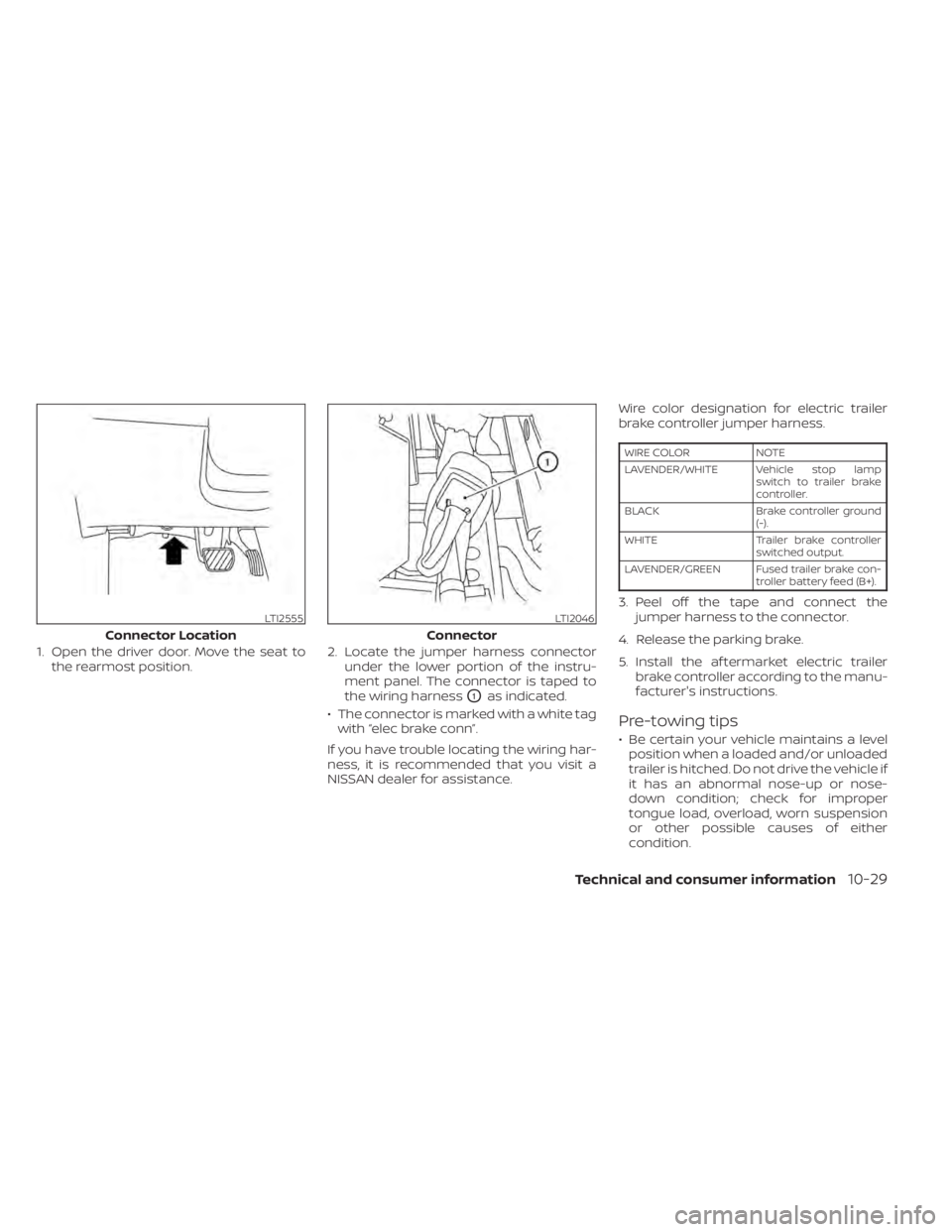

Page 640 of 665

1. Open the driver door. Move the seat tothe rearmost position. 2. Locate the jumper harness connector

under the lower portion of the instru-

ment panel. The connector is taped to

the wiring harness

O1as indicated.

• The connector is marked with a white tag with “elec brake conn”.

If you have trouble locating the wiring har-

ness, it is recommended that you visit a

NISSAN dealer for assistance. Wire color designation for electric trailer

brake controller jumper harness.

WIRE COLOR

NOTE

LAVENDER/WHITE Vehicle stop lamp switch to trailer brake

controller.

BLACK Brake controller ground

(-).

WHITE Trailer brake controller

switched output.

LAVENDER/GREEN Fused trailer brake con- troller battery feed (B+).

3. Peel off the tape and connect thejumper harness to the connector.

4. Release the parking brake.

5. Install the af termarket electric trailer brake controller according to the manu-

facturer's instructions.

Pre-towing tips

• Be certain your vehicle maintains a levelposition when a loaded and/or unloaded

trailer is hitched. Do not drive the vehicle if

it has an abnormal nose-up or nose-

down condition; check for improper

tongue load, overload, worn suspension

or other possible causes of either

condition.

LTI2555

Connector Location

LTI2046

Connector

Technical and consumer information10-29

Page 644 of 665

Automatic transmission

To tow a vehicle equipped with an auto-

matic transmission, an appropriate vehicle

dollyMUST be placed under the towed ve-

hicle's drive wheels. Alwaysfollow the dolly

manufacturer's recommendations when

using their product.

NOTE:

If the battery is completely drained the

transmission will not manually shif t to

other positions. DOT (Department of Transportation) Qual-

ity Grades: All passenger car tires must

conform to federal safety requirements in

addition to these grades.

Quality grades can be found where appli-

cable on the tire sidewall between tread

shoulder and maximum section width. For

example:

Treadwear 200 Traction AA Temperature

A

Treadwear

The treadwear grade is a comparative rat-

ing based on the wear rate of the tire when

tested under controlled conditions on a

specified government test course. For ex-

ample, a tire graded 150 would wear one

and one-half (1 1/2) times as well on the

government course as a tire graded 100.

The relative performance of tires depends

upon the actual conditions of their use,

however, and may depart significantly from

the norm due to variations in driving habits,

service practices and differences in road

characteristics and climate.

Traction AA, A, B and C

The traction grades, from highest to low-

est, are AA, A, B, and C. Those grades repre-

sent the tire's ability to stop on wet pave-ment as measured under controlled

conditions on specified government test

surfaces of asphalt and concrete. A tire

marked C may have poor traction

performance.

WARNING

The traction grade assigned to this tire

is based on straight-ahead braking

traction tests, and does not include ac-

celeration, cornering, hydroplaning, or

peak traction characteristics.

Temperature A, B and C

The temperature grades are A (the high-

est), B, and C, representing the tire’s resis-

tance to the generation of heat, and its

ability to dissipate heat when tested under

controlled conditions on a specified indoor

laboratory test wheel. Sustained high tem-

perature can cause the material of the tire

to degenerate and reduce tire life, and ex-

cessive temperature can lead to sudden

tire failure. The grade C corresponds to a

level of performance which all passenger

car tires must meet under the Federal Mo-

tor Safety Standard No. 109. Grades B and A

represent higher levels of performance on

the laboratory test wheel than the mini-

mum required by law.

UNIFORM TIRE QUALITY GRADING

Technical and consumer information10-33

Page 650 of 665

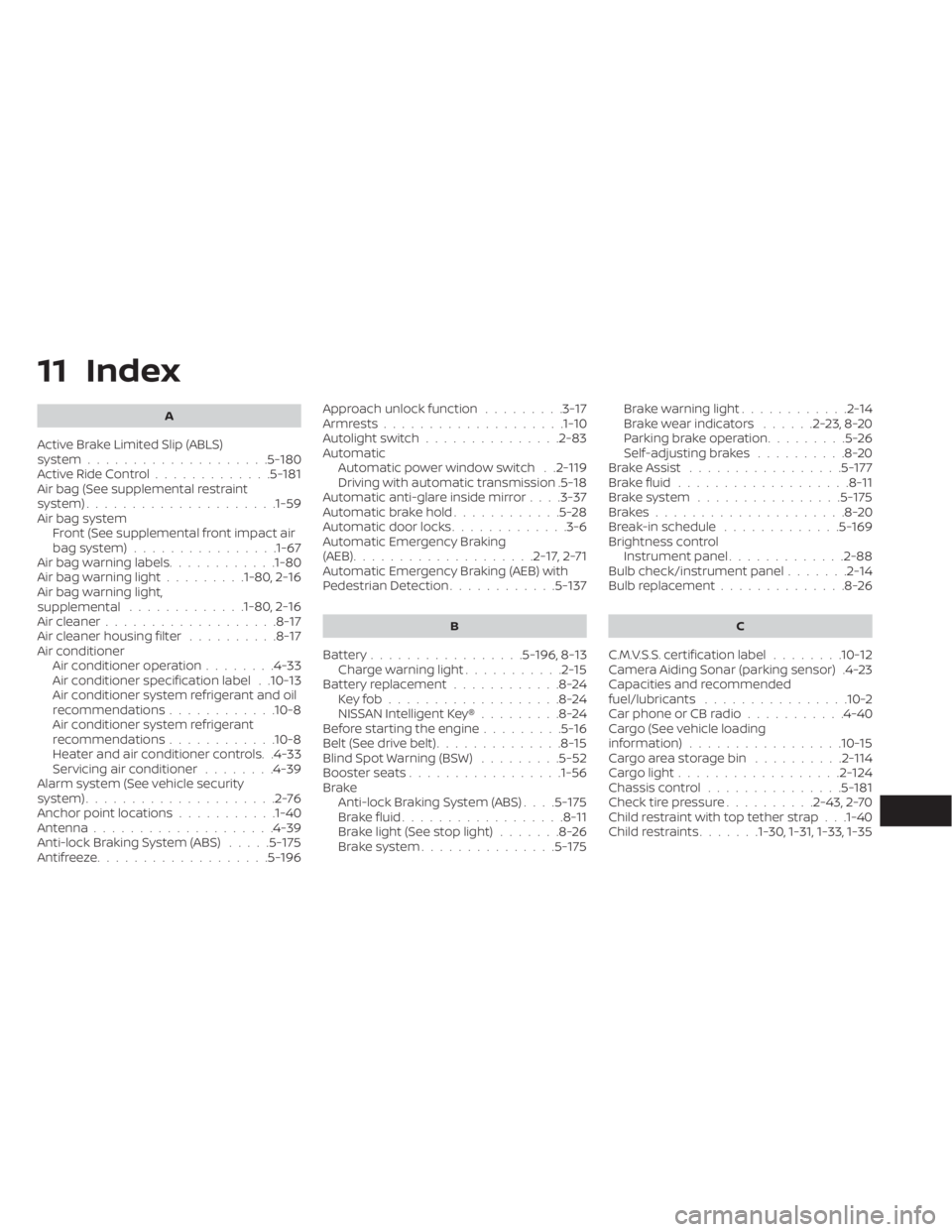

11 Index

A

Active Brake Limited Slip (ABLS)

system....................5-180Active Ride Control.............5-181Air bag (See supplemental restraint

system).....................1-59Air bag system

Front (See supplemental front impact air

bag system)

................1-67Air bag warning labels............1-80Air bag warning light.........1-80, 2-16Air bag warning light,

supplemental.............1-80, 2-16Air cleaner...................8-17Air cleaner housing filter..........8-17Air conditionerAir conditioner operation........4-33Air conditioner specification label. .10-13Air conditioner system refrigerant and oil

recommendations............10-8Air conditioner system refrigerant

recommendations............10-8Heater and air conditioner controls. .4-33Servicing air conditioner........4-39Alarm system (See vehicle security

system).....................2-76Anchor point locations...........1-40Antenna................... .4-39Anti-lock Braking System (ABS).....5-175Antifreeze...................5-196

Approach unlock function.........3-17Armrests....................1-10Autolight switch...............2-83Automatic

Automatic power window switch. .2-119Driving with automatic transmission.5-18Automatic anti-glare inside mirror. . . .3-37Automatic brake hold............5-28Automatic door locks.............3-6Automatic Emergency Braking

(AEB)....................2-17,2-71Automatic Emergency Braking (AEB) with

Pedestrian Detection............5-137

B

Battery.................5- 196, 8-13Charge warning light...........2-15Battery replacement............8-24Key fob...................8-24NISSAN Intelligent Key®.........8-24Before starting the engine.........5-16Belt (See drive belt)..............8-15Blind Spot Warning (BSW).........5-52Booster seats.................1-56Brake

Anti-lock Braking System (ABS). . . .5-175Brake fluid..................8-11Brake light (See stop light).......8-26Brake system...............5-175

Brake warning light............2-14Brake wear indicators......2-23,8-20Parking brake operation.........5-26Self-adjusting brakes..........8-20Brake Assist.................5-177Brake fluid...................8-11Brake system................5-175Brakes.....................8-20Break-in schedule.............5-169Brightness controlInstrument panel.............2-88Bulb check/instrument panel.......2-14Bulb replacement..............8-26

C

C.M.V.S.S. certification label........10-12Camera Aiding Sonar (parking sensor).4-23Capacities and recommended

fuel/lubricants................10-2Car phone or CB radio...........4-40Cargo (See vehicle loading

information)................ .10-15Cargo area storage bin..........2-114Cargo light..................2-124Chassis control...............5-181Check tire pressure..........2-43, 2-70Child restraint with top tether strap. . .1-40Child restraints.......1-30, 1-31, 1-33, 1-35