Engine harness NISSAN PATROL 1998 Y61 / 5.G Electrical System User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 326, PDF Size: 11.36 MB

Page 57 of 326

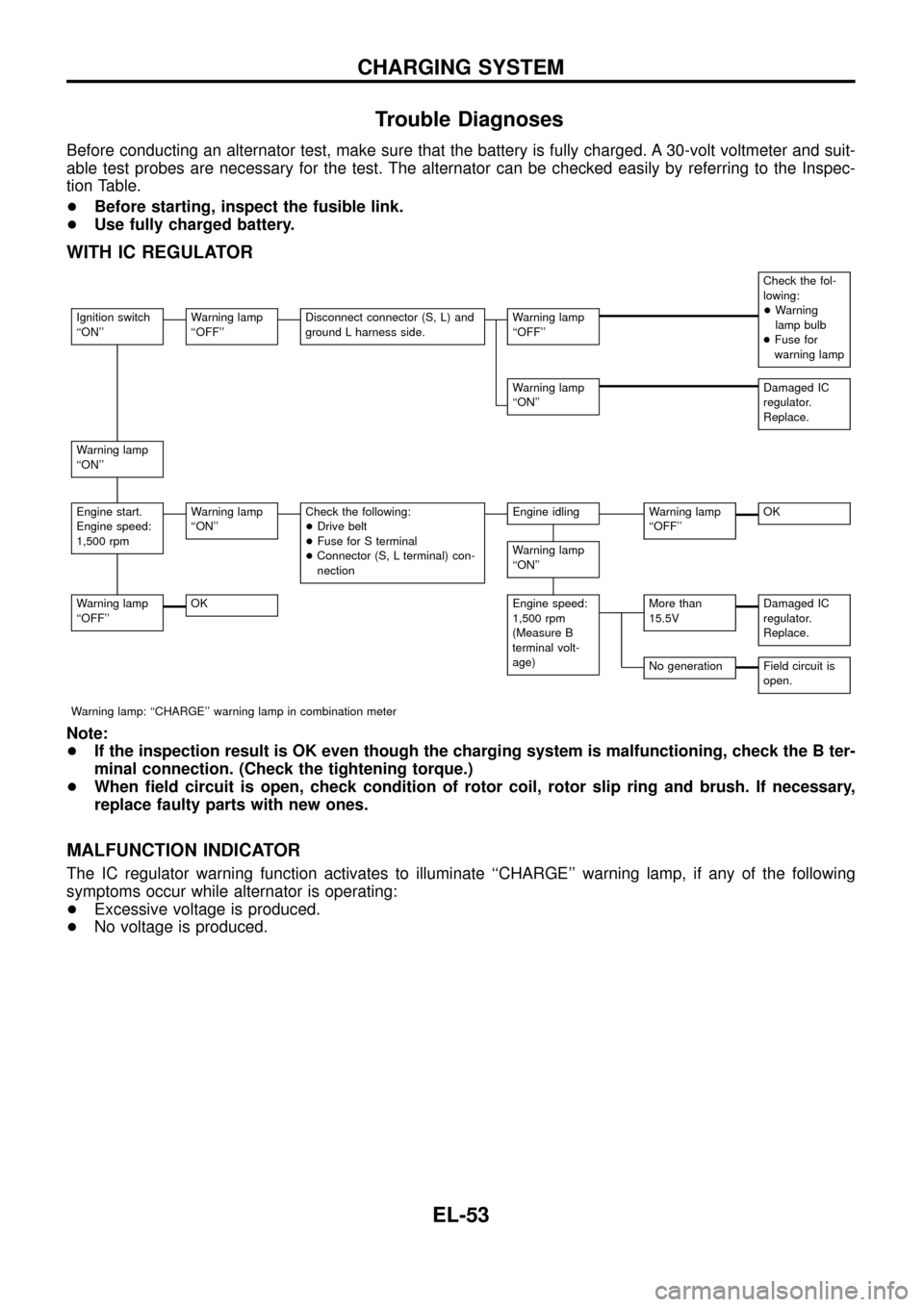

Trouble Diagnoses

Before conducting an alternator test, make sure that the battery is fully charged. A 30-volt voltmeter and suit-

able test probes are necessary for the test. The alternator can be checked easily by referring to the Inspec-

tion Table.

+Before starting, inspect the fusible link.

+Use fully charged battery.

WITH IC REGULATOR

Check the fol-

lowing:

+Warning

lamp bulb

+Fuse for

warning lamp

Ignition switch

``ON''Warning lamp

``OFF''Disconnect connector (S, L) and

ground L harness side.Warning lamp

``OFF''

Warning lamp

``ON''Damaged IC

regulator.

Replace.

Warning lamp

``ON''

Engine start.

Engine speed:

1,500 rpmWarning lamp

``ON''Check the following:

+Drive belt

+Fuse for S terminal

+Connector (S, L terminal) con-

nectionEngine idlingWarning lamp

``OFF''OK

Warning lamp

``ON''

Warning lamp

``OFF''OKEngine speed:

1,500 rpm

(Measure B

terminal volt-

age)More than

15.5VDamaged IC

regulator.

Replace.

No generationField circuit is

open.

Warning lamp: ``CHARGE'' warning lamp in combination meter

Note:

+If the inspection result is OK even though the charging system is malfunctioning, check the B ter-

minal connection. (Check the tightening torque.)

+When ®eld circuit is open, check condition of rotor coil, rotor slip ring and brush. If necessary,

replace faulty parts with new ones.

MALFUNCTION INDICATOR

The IC regulator warning function activates to illuminate ``CHARGE'' warning lamp, if any of the following

symptoms occur while alternator is operating:

+Excessive voltage is produced.

+No voltage is produced.

CHARGING SYSTEM

EL-53

Page 67 of 326

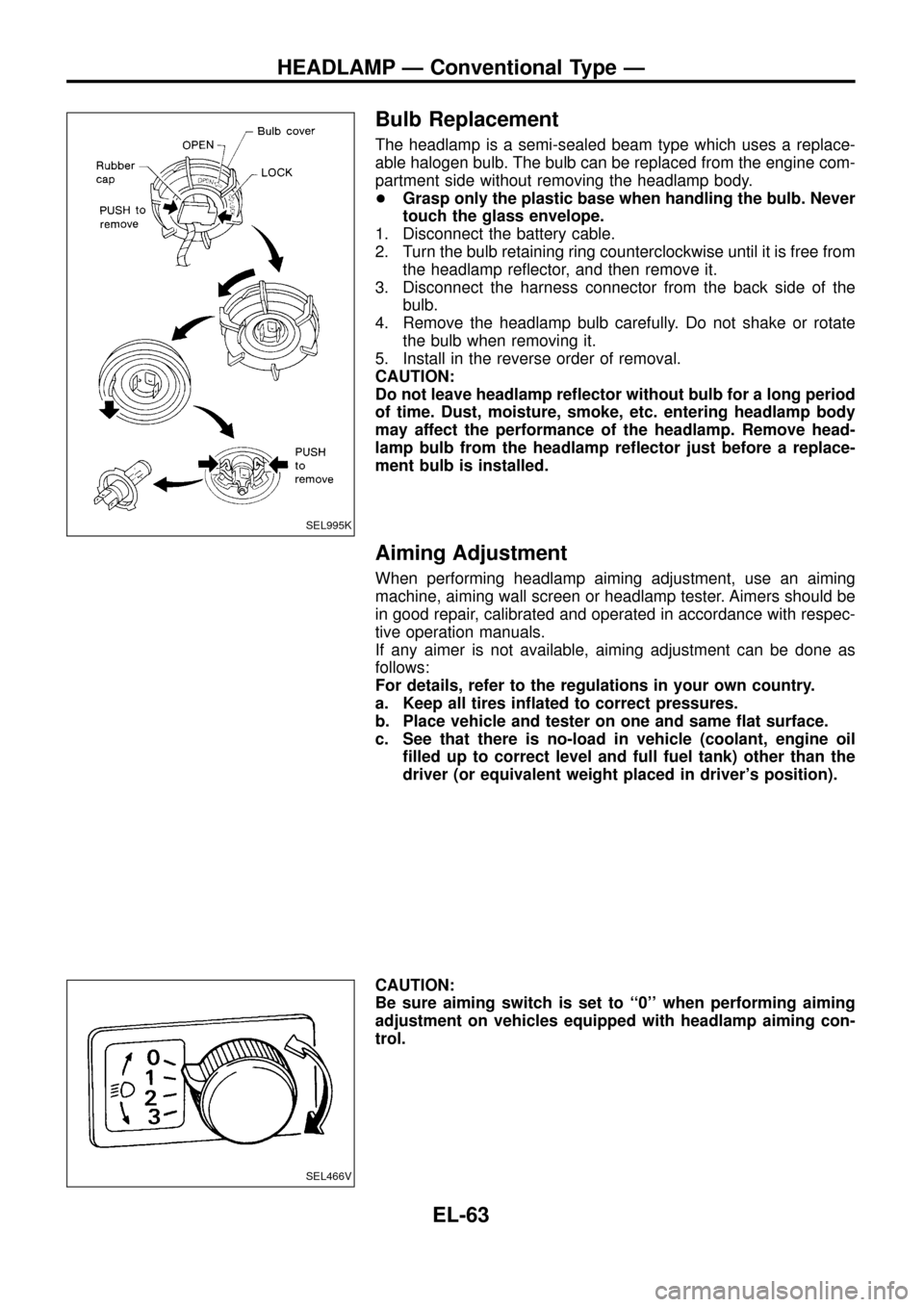

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replace-

able halogen bulb. The bulb can be replaced from the engine com-

partment side without removing the headlamp body.

+Grasp only the plastic base when handling the bulb. Never

touch the glass envelope.

1. Disconnect the battery cable.

2. Turn the bulb retaining ring counterclockwise until it is free from

the headlamp re¯ector, and then remove it.

3. Disconnect the harness connector from the back side of the

bulb.

4. Remove the headlamp bulb carefully. Do not shake or rotate

the bulb when removing it.

5. Install in the reverse order of removal.

CAUTION:

Do not leave headlamp re¯ector without bulb for a long period

of time. Dust, moisture, smoke, etc. entering headlamp body

may affect the performance of the headlamp. Remove head-

lamp bulb from the headlamp re¯ector just before a replace-

ment bulb is installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. Aimers should be

in good repair, calibrated and operated in accordance with respec-

tive operation manuals.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

a. Keep all tires in¯ated to correct pressures.

b. Place vehicle and tester on one and same ¯at surface.

c. See that there is no-load in vehicle (coolant, engine oil

®lled up to correct level and full fuel tank) other than the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ``0'' when performing aiming

adjustment on vehicles equipped with headlamp aiming con-

trol.

SEL995K

SEL466V

HEADLAMP Ð Conventional Type Ð

EL-63

Page 115 of 326

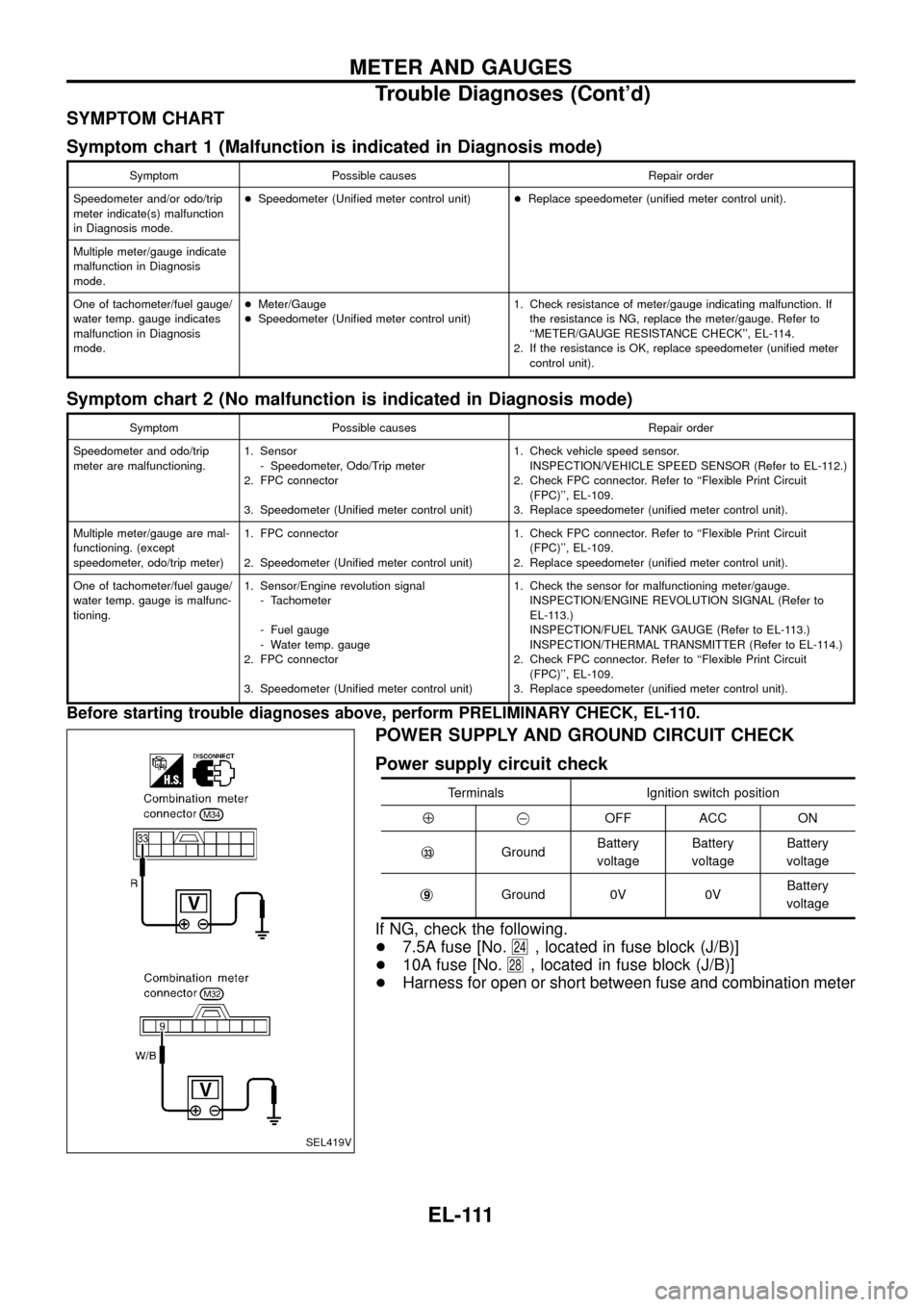

SYMPTOM CHART

Symptom chart 1 (Malfunction is indicated in Diagnosis mode)

Symptom Possible causes Repair order

Speedometer and/or odo/trip

meter indicate(s) malfunction

in Diagnosis mode.+Speedometer (Uni®ed meter control unit)+Replace speedometer (uni®ed meter control unit).

Multiple meter/gauge indicate

malfunction in Diagnosis

mode.

One of tachometer/fuel gauge/

water temp. gauge indicates

malfunction in Diagnosis

mode.+Meter/Gauge

+Speedometer (Uni®ed meter control unit)1. Check resistance of meter/gauge indicating malfunction. If

the resistance is NG, replace the meter/gauge. Refer to

``METER/GAUGE RESISTANCE CHECK'', EL-114.

2. If the resistance is OK, replace speedometer (uni®ed meter

control unit).

Symptom chart 2 (No malfunction is indicated in Diagnosis mode)

Symptom Possible causes Repair order

Speedometer and odo/trip

meter are malfunctioning.1. Sensor

- Speedometer, Odo/Trip meter

2. FPC connector

3. Speedometer (Uni®ed meter control unit)1. Check vehicle speed sensor.

INSPECTION/VEHICLE SPEED SENSOR (Refer to EL-112.)

2. Check FPC connector. Refer to ``Flexible Print Circuit

(FPC)'', EL-109.

3. Replace speedometer (uni®ed meter control unit).

Multiple meter/gauge are mal-

functioning. (except

speedometer, odo/trip meter)1. FPC connector

2. Speedometer (Uni®ed meter control unit)1. Check FPC connector. Refer to ``Flexible Print Circuit

(FPC)'', EL-109.

2. Replace speedometer (uni®ed meter control unit).

One of tachometer/fuel gauge/

water temp. gauge is malfunc-

tioning.1. Sensor/Engine revolution signal

- Tachometer

- Fuel gauge

- Water temp. gauge

2. FPC connector

3. Speedometer (Uni®ed meter control unit)1. Check the sensor for malfunctioning meter/gauge.

INSPECTION/ENGINE REVOLUTION SIGNAL (Refer to

EL-113.)

INSPECTION/FUEL TANK GAUGE (Refer to EL-113.)

INSPECTION/THERMAL TRANSMITTER (Refer to EL-114.)

2. Check FPC connector. Refer to ``Flexible Print Circuit

(FPC)'', EL-109.

3. Replace speedometer (uni®ed meter control unit).

Before starting trouble diagnoses above, perform PRELIMINARY CHECK, EL-110.

POWER SUPPLY AND GROUND CIRCUIT CHECK

Power supply circuit check

Terminals Ignition switch position

Å@OFF ACC ON

j

33GroundBattery

voltageBattery

voltageBattery

voltage

j

9Ground 0V 0VBattery

voltage

If NG, check the following.

+7.5A fuse [No.

24, located in fuse block (J/B)]

+10A fuse [No.

28, located in fuse block (J/B)]

+Harness for open or short between fuse and combination meter

SEL419V

METER AND GAUGES

Trouble Diagnoses (Cont'd)

EL-111

Page 117 of 326

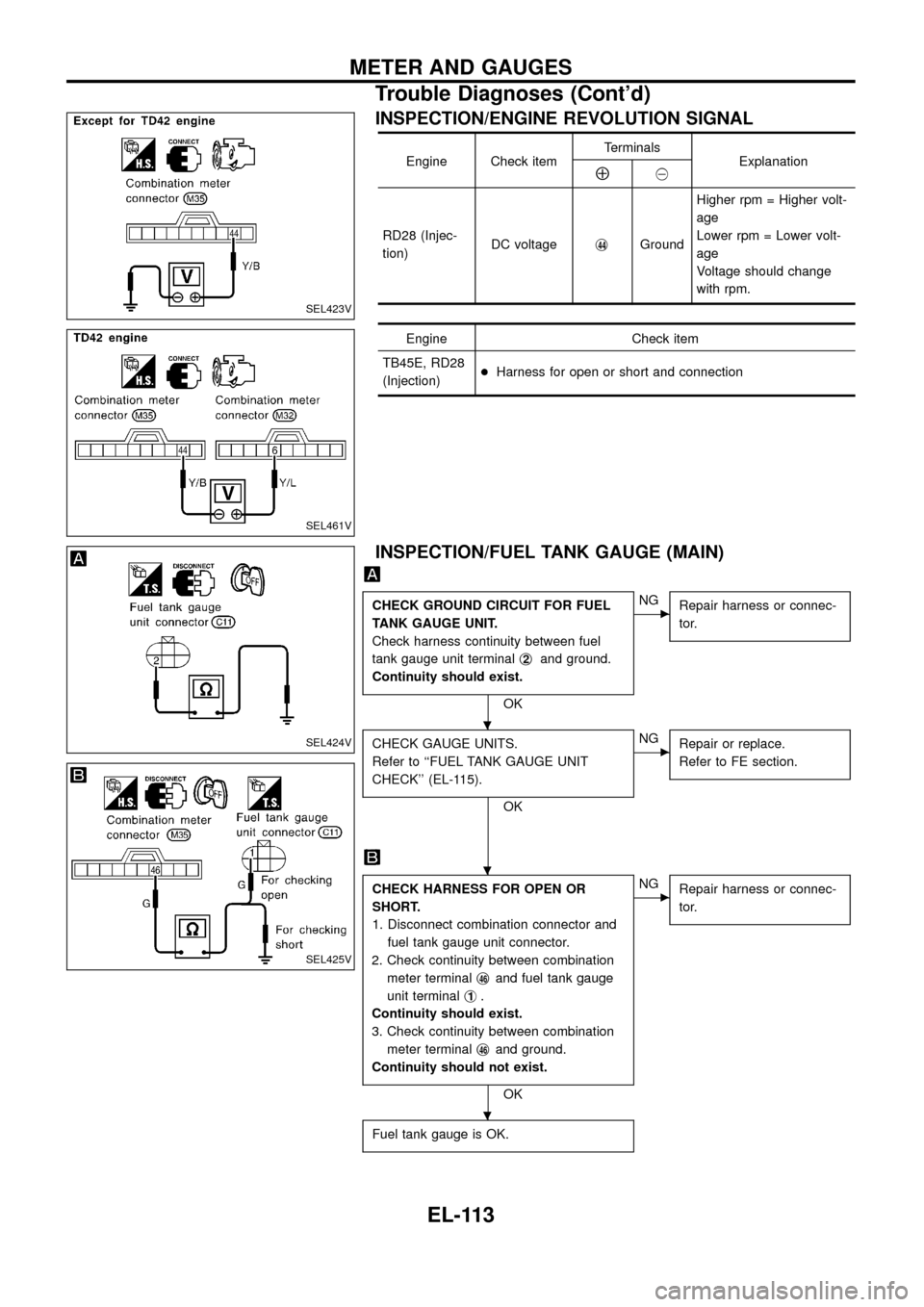

INSPECTION/ENGINE REVOLUTION SIGNAL

Engine Check itemTerminals

ExplanationÅ@

RD28 (Injec-

tion)DC voltagej

44GroundHigher rpm = Higher volt-

age

Lower rpm = Lower volt-

age

Voltage should change

with rpm.

Engine Check item

TB45E, RD28

(Injection)+Harness for open or short and connection

INSPECTION/FUEL TANK GAUGE (MAIN)

CHECK GROUND CIRCUIT FOR FUEL

TANK GAUGE UNIT.

Check harness continuity between fuel

tank gauge unit terminalj

2and ground.

Continuity should exist.

OK

cNG

Repair harness or connec-

tor.

CHECK GAUGE UNITS.

Refer to ``FUEL TANK GAUGE UNIT

CHECK'' (EL-115).

OK

cNG

Repair or replace.

Refer to FE section.

CHECK HARNESS FOR OPEN OR

SHORT.

1. Disconnect combination connector and

fuel tank gauge unit connector.

2. Check continuity between combination

meter terminalj

46and fuel tank gauge

unit terminalj

1.

Continuity should exist.

3. Check continuity between combination

meter terminalj

46and ground.

Continuity should not exist.

OK

cNG

Repair harness or connec-

tor.

Fuel tank gauge is OK.

SEL423V

SEL461V

SEL424V

SEL425V

.

.

.

METER AND GAUGES

Trouble Diagnoses (Cont'd)

EL-113

Page 122 of 326

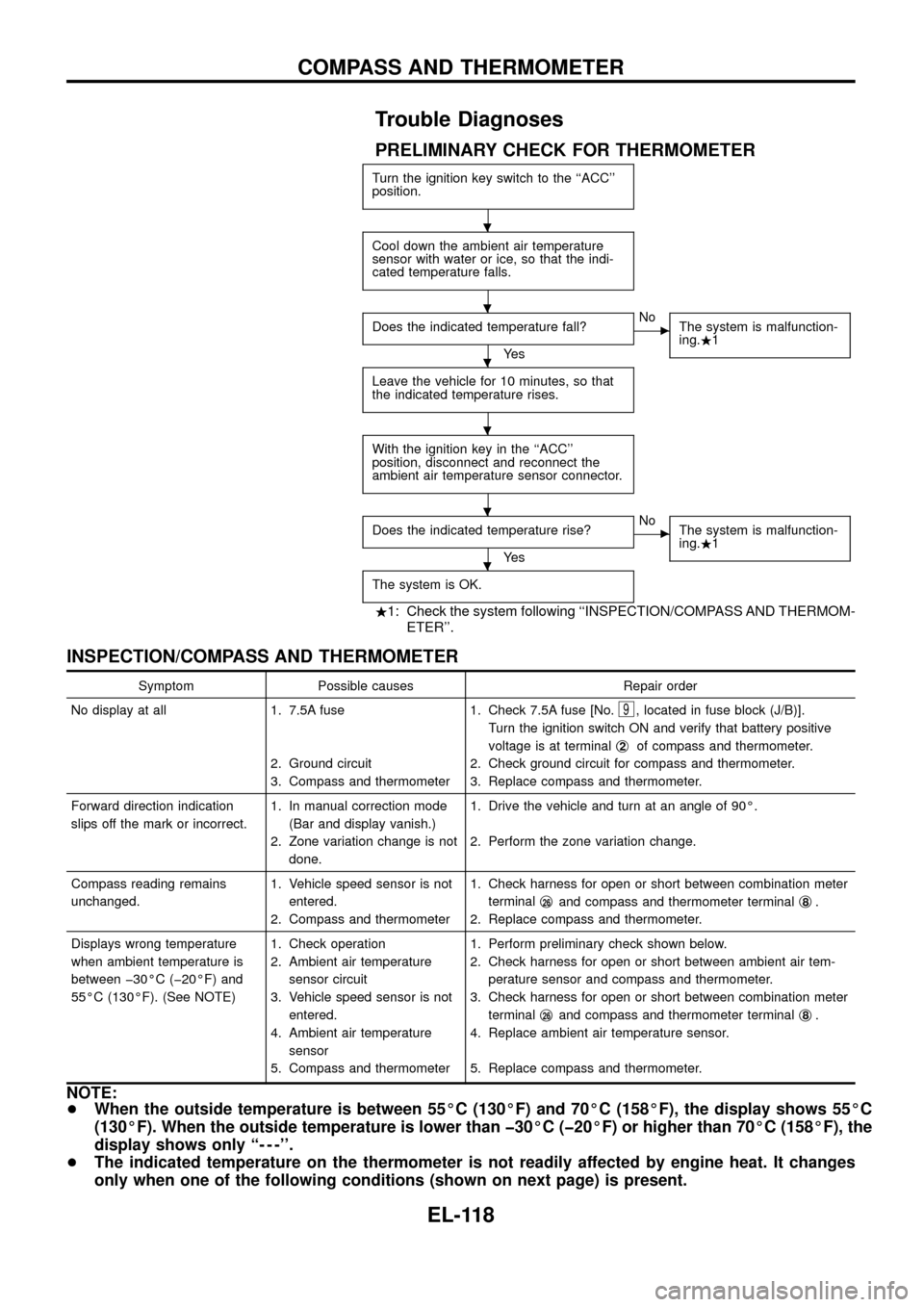

Trouble Diagnoses

PRELIMINARY CHECK FOR THERMOMETER

Turn the ignition key switch to the ``ACC''

position.

Cool down the ambient air temperature

sensor with water or ice, so that the indi-

cated temperature falls.

Does the indicated temperature fall?

Ye s

cNo

The system is malfunction-

ing..1

Leave the vehicle for 10 minutes, so that

the indicated temperature rises.

With the ignition key in the ``ACC''

position, disconnect and reconnect the

ambient air temperature sensor connector.

Does the indicated temperature rise?

Ye s

cNo

The system is malfunction-

ing..1

The system is OK.

.1: Check the system following ``INSPECTION/COMPASS AND THERMOM-

ETER''.

INSPECTION/COMPASS AND THERMOMETER

Symptom Possible causes Repair order

No display at all 1. 7.5A fuse

2. Ground circuit

3. Compass and thermometer1. Check 7.5A fuse [No.

9, located in fuse block (J/B)].

Turn the ignition switch ON and verify that battery positive

voltage is at terminalj

2of compass and thermometer.

2. Check ground circuit for compass and thermometer.

3. Replace compass and thermometer.

Forward direction indication

slips off the mark or incorrect.1. In manual correction mode

(Bar and display vanish.)

2. Zone variation change is not

done.1. Drive the vehicle and turn at an angle of 90É.

2. Perform the zone variation change.

Compass reading remains

unchanged.1. Vehicle speed sensor is not

entered.

2. Compass and thermometer1. Check harness for open or short between combination meter

terminalj

26and compass and thermometer terminalj8.

2. Replace compass and thermometer.

Displays wrong temperature

when ambient temperature is

between þ30ÉC (þ20ÉF) and

55ÉC (130ÉF). (See NOTE)1. Check operation

2. Ambient air temperature

sensor circuit

3. Vehicle speed sensor is not

entered.

4. Ambient air temperature

sensor

5. Compass and thermometer1. Perform preliminary check shown below.

2. Check harness for open or short between ambient air tem-

perature sensor and compass and thermometer.

3. Check harness for open or short between combination meter

terminalj

26and compass and thermometer terminalj8.

4. Replace ambient air temperature sensor.

5. Replace compass and thermometer.

NOTE:

+When the outside temperature is between 55ÉC (130ÉF) and 70ÉC (158ÉF), the display shows 55ÉC

(130ÉF). When the outside temperature is lower than þ30ÉC (þ20ÉF) or higher than 70ÉC (158ÉF), the

display shows only ``- - -''.

+The indicated temperature on the thermometer is not readily affected by engine heat. It changes

only when one of the following conditions (shown on next page) is present.

.

.

.

.

.

.

COMPASS AND THERMOMETER

EL-118

Page 176 of 326

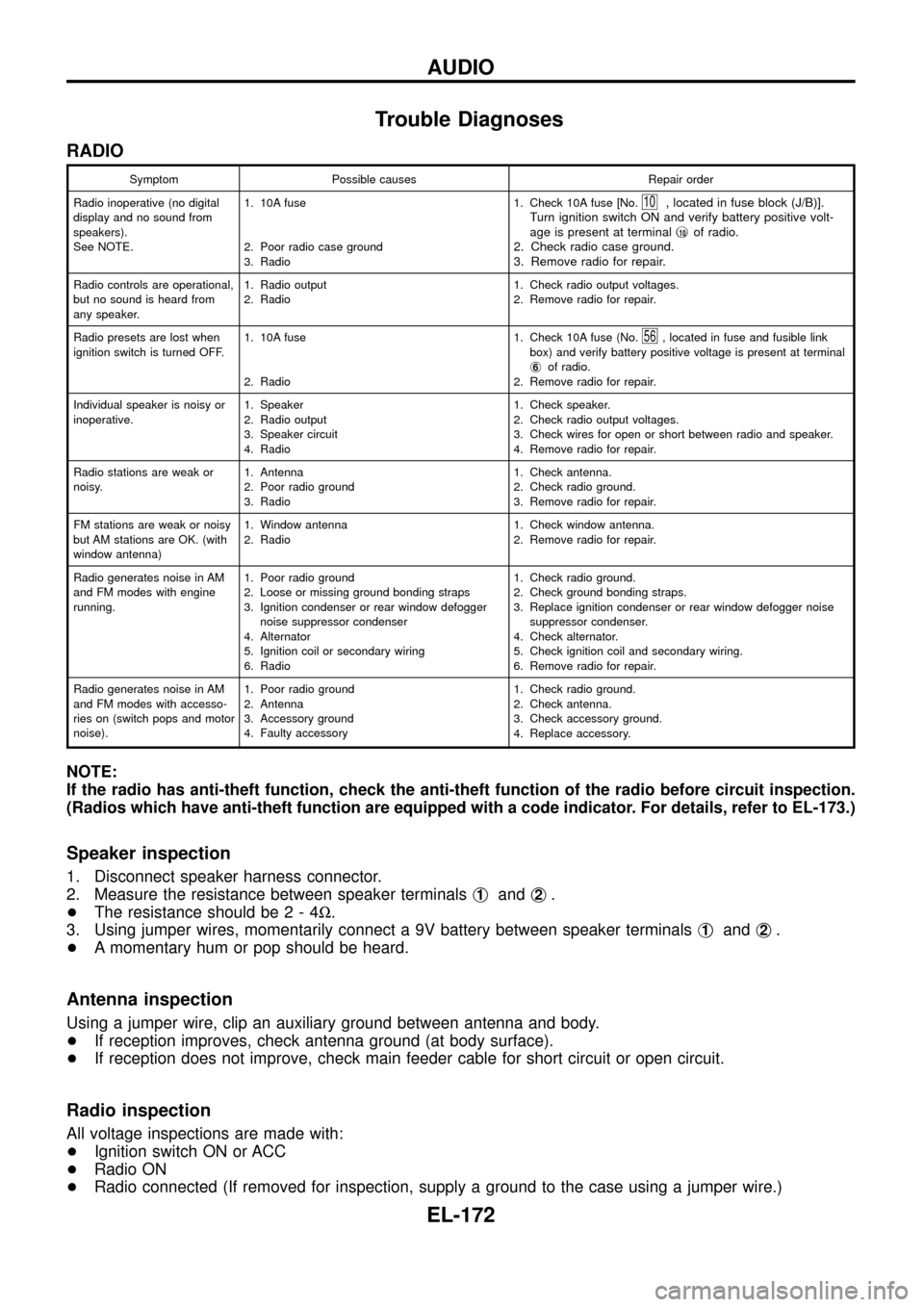

Trouble Diagnoses

RADIO

Symptom Possible causes Repair order

Radio inoperative (no digital

display and no sound from

speakers).

See NOTE.1. 10A fuse

2. Poor radio case ground

3. Radio1. Check 10A fuse [No.

10, located in fuse block (J/B)].

Turn ignition switch ON and verify battery positive volt-

age is present at terminalj

10of radio.

2. Check radio case ground.

3. Remove radio for repair.

Radio controls are operational,

but no sound is heard from

any speaker.1. Radio output

2. Radio1. Check radio output voltages.

2. Remove radio for repair.

Radio presets are lost when

ignition switch is turned OFF.1. 10A fuse

2. Radio1. Check 10A fuse (No.

56, located in fuse and fusible link

box) and verify battery positive voltage is present at terminal

j

6of radio.

2. Remove radio for repair.

Individual speaker is noisy or

inoperative.1. Speaker

2. Radio output

3. Speaker circuit

4. Radio1. Check speaker.

2. Check radio output voltages.

3. Check wires for open or short between radio and speaker.

4. Remove radio for repair.

Radio stations are weak or

noisy.1. Antenna

2. Poor radio ground

3. Radio1. Check antenna.

2. Check radio ground.

3. Remove radio for repair.

FM stations are weak or noisy

but AM stations are OK. (with

window antenna)1. Window antenna

2. Radio1. Check window antenna.

2. Remove radio for repair.

Radio generates noise in AM

and FM modes with engine

running.1. Poor radio ground

2. Loose or missing ground bonding straps

3. Ignition condenser or rear window defogger

noise suppressor condenser

4. Alternator

5. Ignition coil or secondary wiring

6. Radio1. Check radio ground.

2. Check ground bonding straps.

3. Replace ignition condenser or rear window defogger noise

suppressor condenser.

4. Check alternator.

5. Check ignition coil and secondary wiring.

6. Remove radio for repair.

Radio generates noise in AM

and FM modes with accesso-

ries on (switch pops and motor

noise).1. Poor radio ground

2. Antenna

3. Accessory ground

4. Faulty accessory1. Check radio ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

NOTE:

If the radio has anti-theft function, check the anti-theft function of the radio before circuit inspection.

(Radios which have anti-theft function are equipped with a code indicator. For details, refer to EL-173.)

Speaker inspection

1. Disconnect speaker harness connector.

2. Measure the resistance between speaker terminalsj

1andj2.

+The resistance should be2-4W.

3. Using jumper wires, momentarily connect a 9V battery between speaker terminalsj

1andj2.

+A momentary hum or pop should be heard.

Antenna inspection

Using a jumper wire, clip an auxiliary ground between antenna and body.

+If reception improves, check antenna ground (at body surface).

+If reception does not improve, check main feeder cable for short circuit or open circuit.

Radio inspection

All voltage inspections are made with:

+Ignition switch ON or ACC

+Radio ON

+Radio connected (If removed for inspection, supply a ground to the case using a jumper wire.)

AUDIO

EL-172

Page 235 of 326

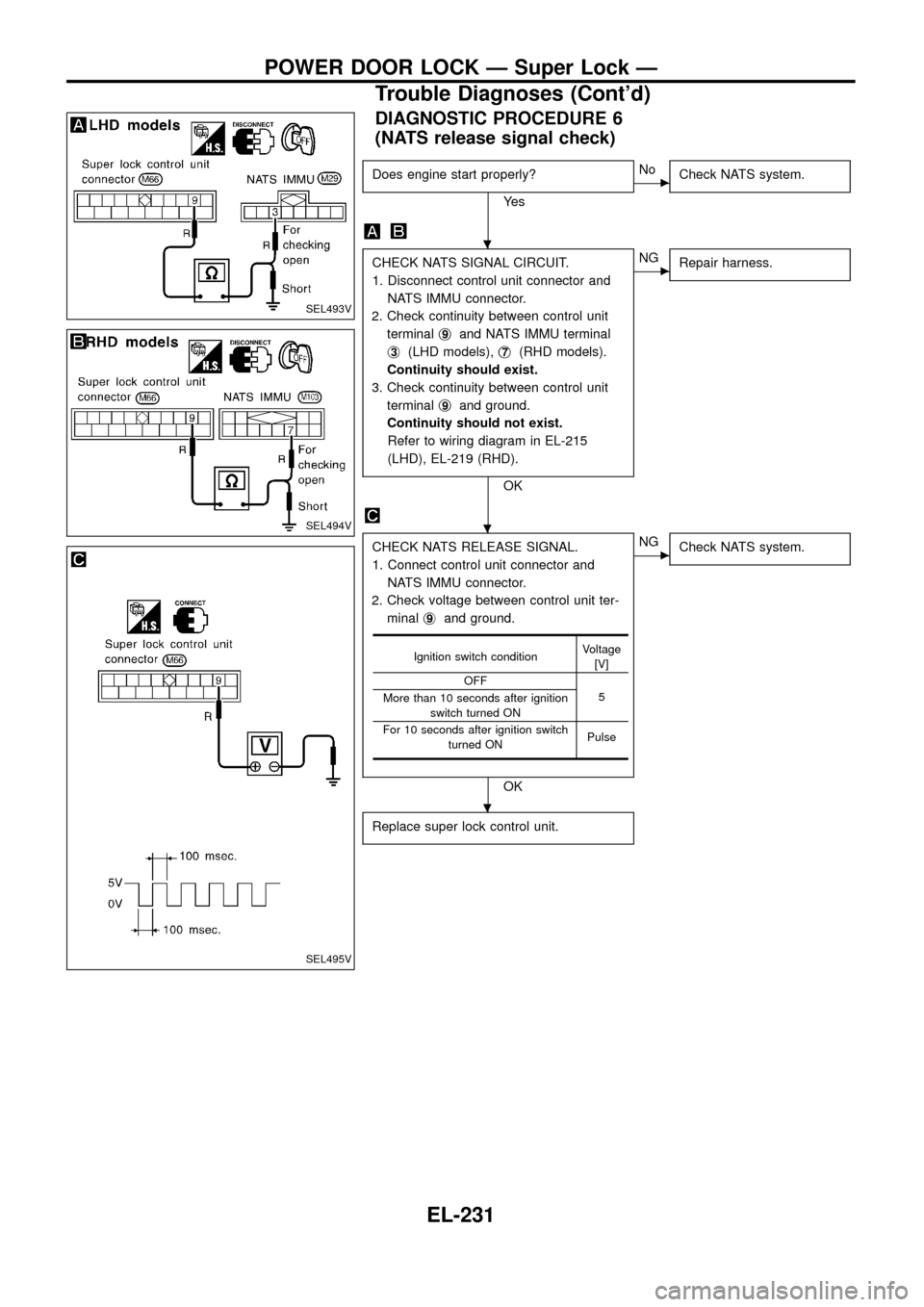

DIAGNOSTIC PROCEDURE 6

(NATS release signal check)

Does engine start properly?

Ye s

cNo

Check NATS system.

CHECK NATS SIGNAL CIRCUIT.

1. Disconnect control unit connector and

NATS IMMU connector.

2. Check continuity between control unit

terminalj

9and NATS IMMU terminal

j

3(LHD models),j7(RHD models).

Continuity should exist.

3. Check continuity between control unit

terminalj

9and ground.

Continuity should not exist.

Refer to wiring diagram in EL-215

(LHD), EL-219 (RHD).

OK

cNG

Repair harness.

CHECK NATS RELEASE SIGNAL.

1. Connect control unit connector and

NATS IMMU connector.

2. Check voltage between control unit ter-

minalj

9and ground.

OK

cNG

Check NATS system.

Replace super lock control unit.

Ignition switch conditionVoltage

[V]

OFF

5

More than 10 seconds after ignition

switch turned ON

For 10 seconds after ignition switch

turned ONPulse

SEL493V

SEL494V

SEL495V

.

.

.

POWER DOOR LOCK Ð Super Lock Ð

Trouble Diagnoses (Cont'd)

EL-231

Page 251 of 326

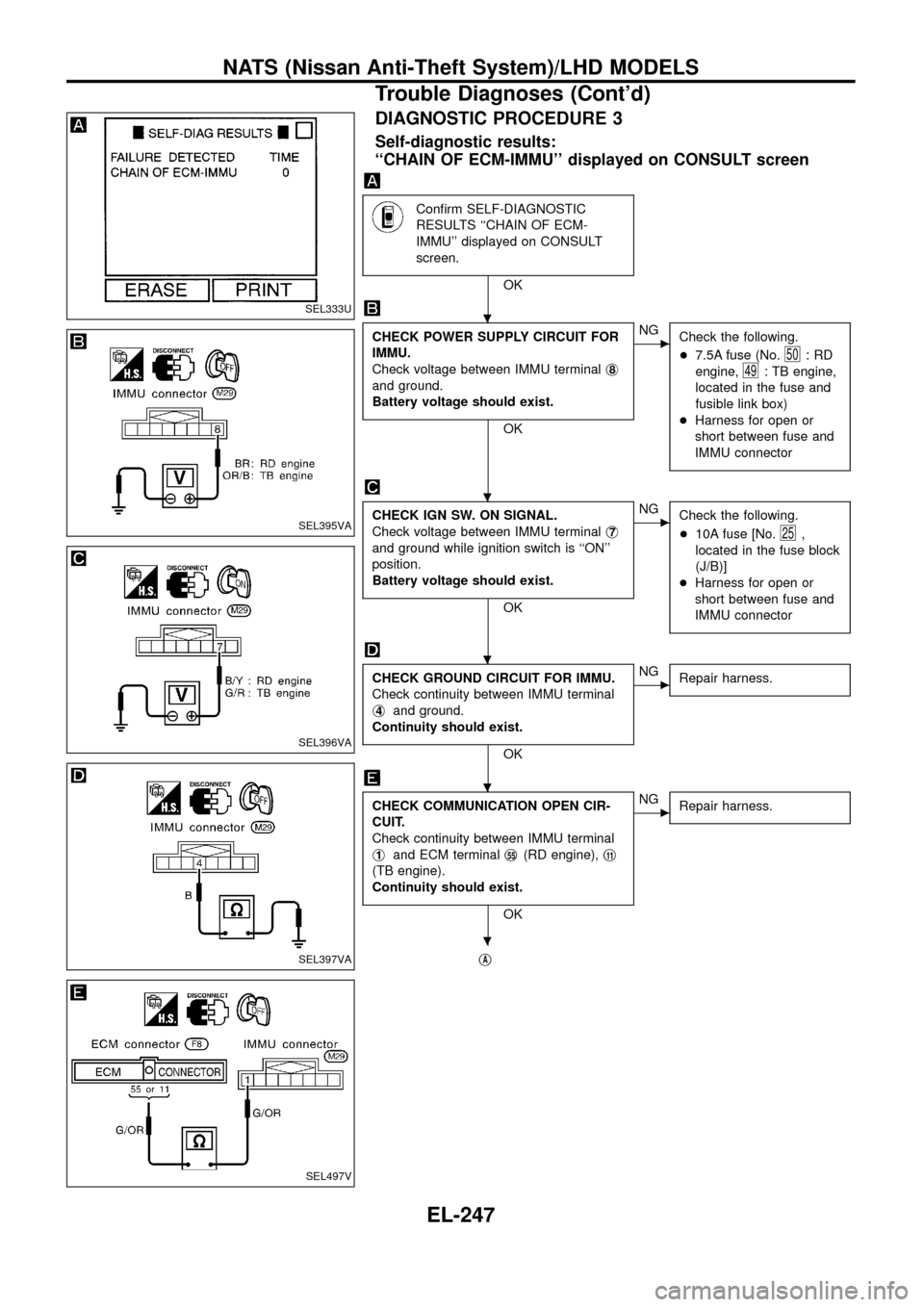

DIAGNOSTIC PROCEDURE 3

Self-diagnostic results:

``CHAIN OF ECM-IMMU'' displayed on CONSULT screen

Con®rm SELF-DIAGNOSTIC

RESULTS ``CHAIN OF ECM-

IMMU'' displayed on CONSULT

screen.

OK

CHECK POWER SUPPLY CIRCUIT FOR

IMMU.

Check voltage between IMMU terminalj

8

and ground.

Battery voltage should exist.

OK

cNG

Check the following.

+7.5A fuse (No.

50:RD

engine,

49: TB engine,

located in the fuse and

fusible link box)

+Harness for open or

short between fuse and

IMMU connector

CHECK IGN SW. ON SIGNAL.

Check voltage between IMMU terminalj

7

and ground while ignition switch is ``ON''

position.

Battery voltage should exist.

OK

cNG

Check the following.

+10A fuse [No.

25,

located in the fuse block

(J/B)]

+Harness for open or

short between fuse and

IMMU connector

CHECK GROUND CIRCUIT FOR IMMU.

Check continuity between IMMU terminal

j

4and ground.

Continuity should exist.

OK

cNG

Repair harness.

CHECK COMMUNICATION OPEN CIR-

CUIT.

Check continuity between IMMU terminal

j

1and ECM terminalj55(RD engine),j11

(TB engine).

Continuity should exist.

OK

cNG

Repair harness.

jA

SEL333U

SEL395VA

SEL396VA

SEL397VA

SEL497V

.

.

.

.

.

NATS (Nissan Anti-Theft System)/LHD MODELS

Trouble Diagnoses (Cont'd)

EL-247

Page 269 of 326

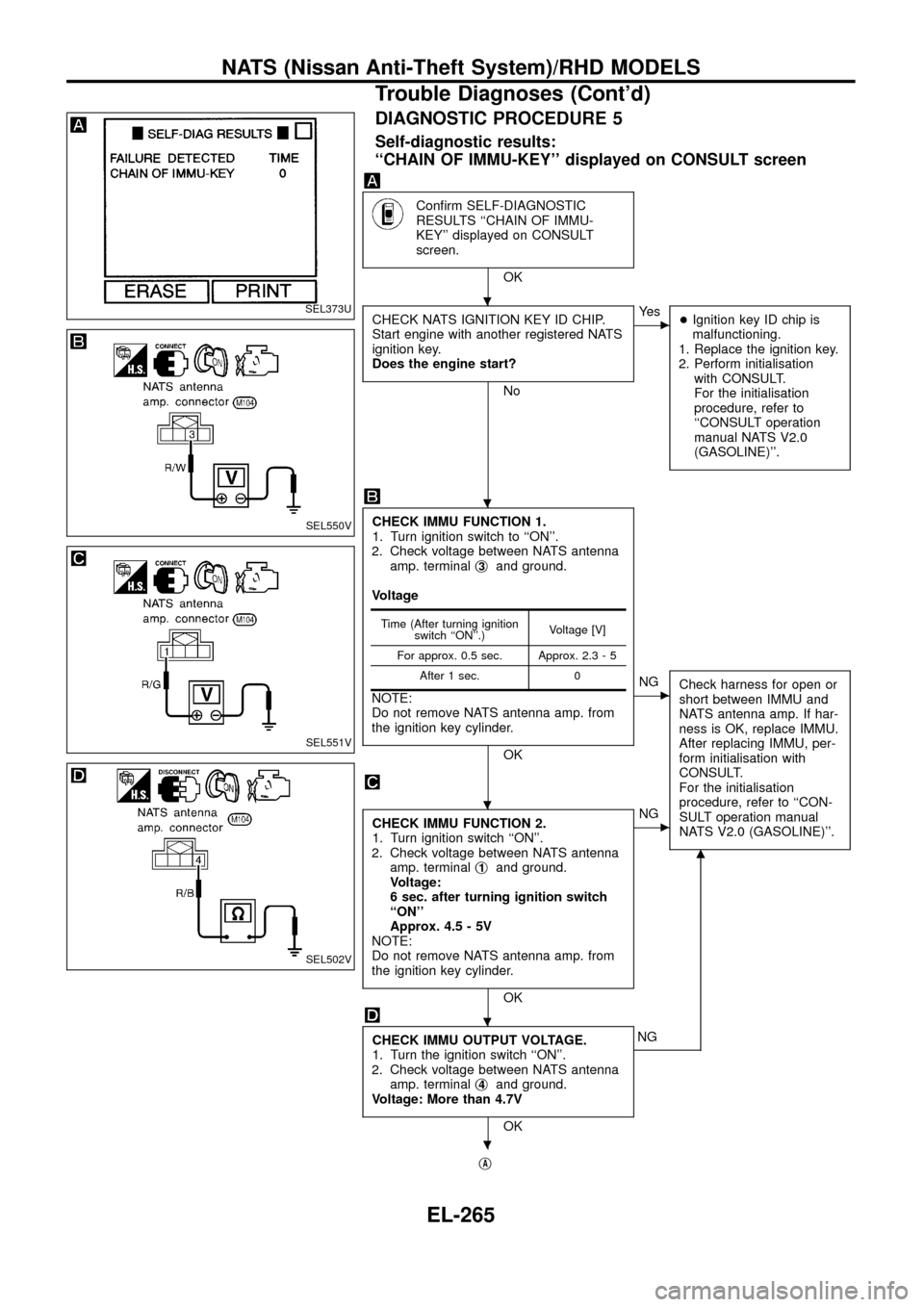

DIAGNOSTIC PROCEDURE 5

Self-diagnostic results:

``CHAIN OF IMMU-KEY'' displayed on CONSULT screen

Con®rm SELF-DIAGNOSTIC

RESULTS ``CHAIN OF IMMU-

KEY'' displayed on CONSULT

screen.

OK

CHECK NATS IGNITION KEY ID CHIP.

Start engine with another registered NATS

ignition key.

Does the engine start?

No

cYe s

+Ignition key ID chip is

malfunctioning.

1. Replace the ignition key.

2. Perform initialisation

with CONSULT.

For the initialisation

procedure, refer to

``CONSULT operation

manual NATS V2.0

(GASOLINE)''.

CHECK IMMU FUNCTION 1.

1. Turn ignition switch to ``ON''.

2. Check voltage between NATS antenna

amp. terminalj

3and ground.

Voltage

NOTE:

Do not remove NATS antenna amp. from

the ignition key cylinder.

OK

cNG

Check harness for open or

short between IMMU and

NATS antenna amp. If har-

ness is OK, replace IMMU.

After replacing IMMU, per-

form initialisation with

CONSULT.

For the initialisation

procedure, refer to ``CON-

SULT operation manual

NATS V2.0 (GASOLINE)''.

CHECK IMMU FUNCTION 2.

1. Turn ignition switch ``ON''.

2. Check voltage between NATS antenna

amp. terminalj

1and ground.

Voltage:

6 sec. after turning ignition switch

``ON''

Approx. 4.5 - 5V

NOTE:

Do not remove NATS antenna amp. from

the ignition key cylinder.

OK

cNG

CHECK IMMU OUTPUT VOLTAGE.

1. Turn the ignition switch ``ON''.

2. Check voltage between NATS antenna

amp. terminalj

4and ground.

Voltage: More than 4.7V

OK

m

NG

j

A

Time (After turning ignition

switch ``ON''.)Voltage [V]

For approx. 0.5 sec. Approx. 2.3 - 5

After 1 sec. 0

SEL373U

SEL550V

SEL551V

SEL502V

.

.

.

.

.

NATS (Nissan Anti-Theft System)/RHD MODELS

Trouble Diagnoses (Cont'd)

EL-265

Page 271 of 326

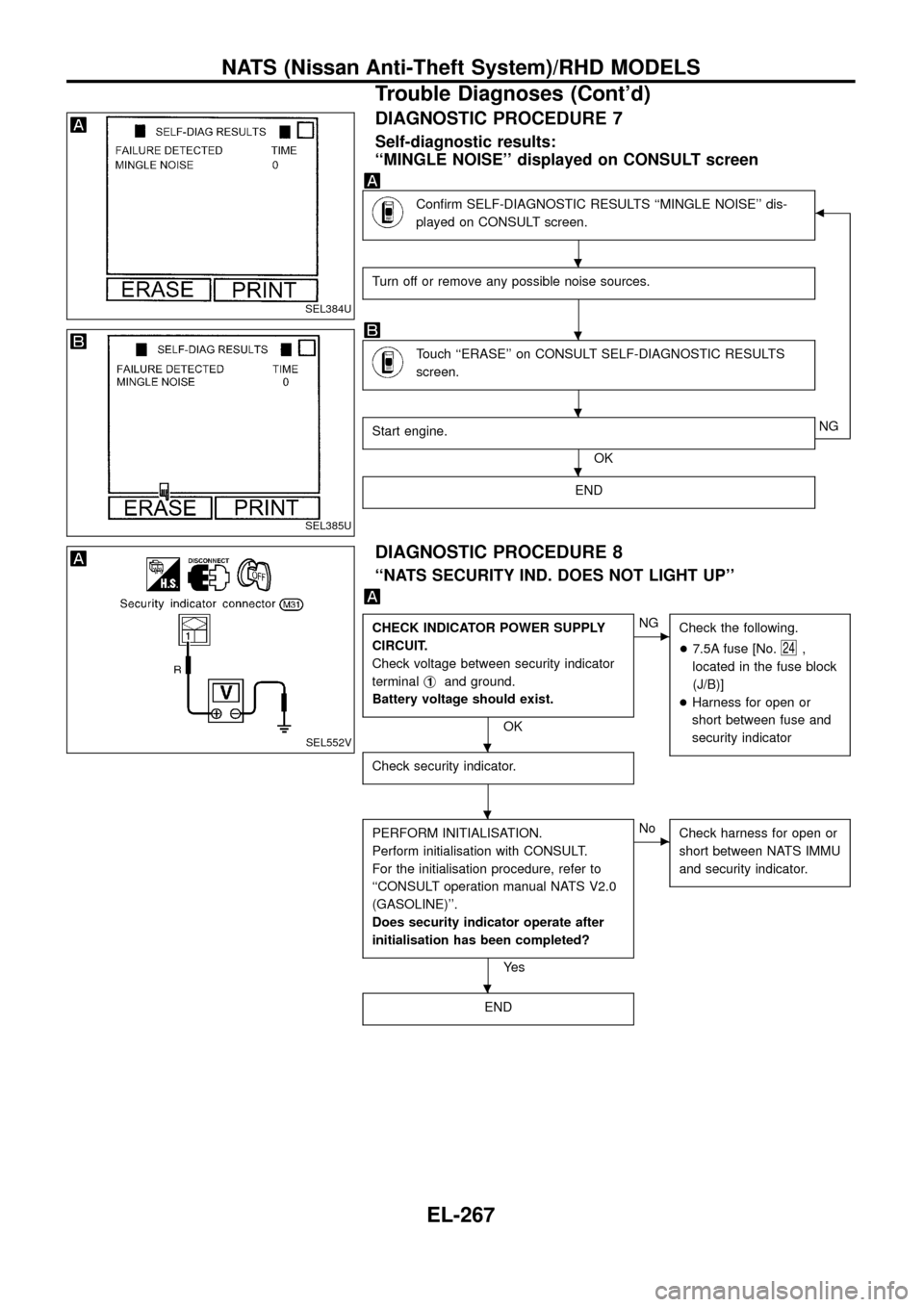

DIAGNOSTIC PROCEDURE 7

Self-diagnostic results:

``MINGLE NOISE'' displayed on CONSULT screen

Con®rm SELF-DIAGNOSTIC RESULTS ``MINGLE NOISE'' dis-

played on CONSULT screen.b

Turn off or remove any possible noise sources.

Touch ``ERASE'' on CONSULT SELF-DIAGNOSTIC RESULTS

screen.

Start engine.

OKNG

END

DIAGNOSTIC PROCEDURE 8

``NATS SECURITY IND. DOES NOT LIGHT UP''

CHECK INDICATOR POWER SUPPLY

CIRCUIT.

Check voltage between security indicator

terminalj

1and ground.

Battery voltage should exist.

OK

cNG

Check the following.

+7.5A fuse [No.

24,

located in the fuse block

(J/B)]

+Harness for open or

short between fuse and

security indicator

Check security indicator.

PERFORM INITIALISATION.

Perform initialisation with CONSULT.

For the initialisation procedure, refer to

``CONSULT operation manual NATS V2.0

(GASOLINE)''.

Does security indicator operate after

initialisation has been completed?

Ye s

cNo

Check harness for open or

short between NATS IMMU

and security indicator.

END

SEL384U

SEL385U

SEL552V

.

.

.

.

.

.

.

NATS (Nissan Anti-Theft System)/RHD MODELS

Trouble Diagnoses (Cont'd)

EL-267