lock NISSAN PATROL 1998 Y61 / 5.G Electrical System User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 326, PDF Size: 11.36 MB

Page 113 of 326

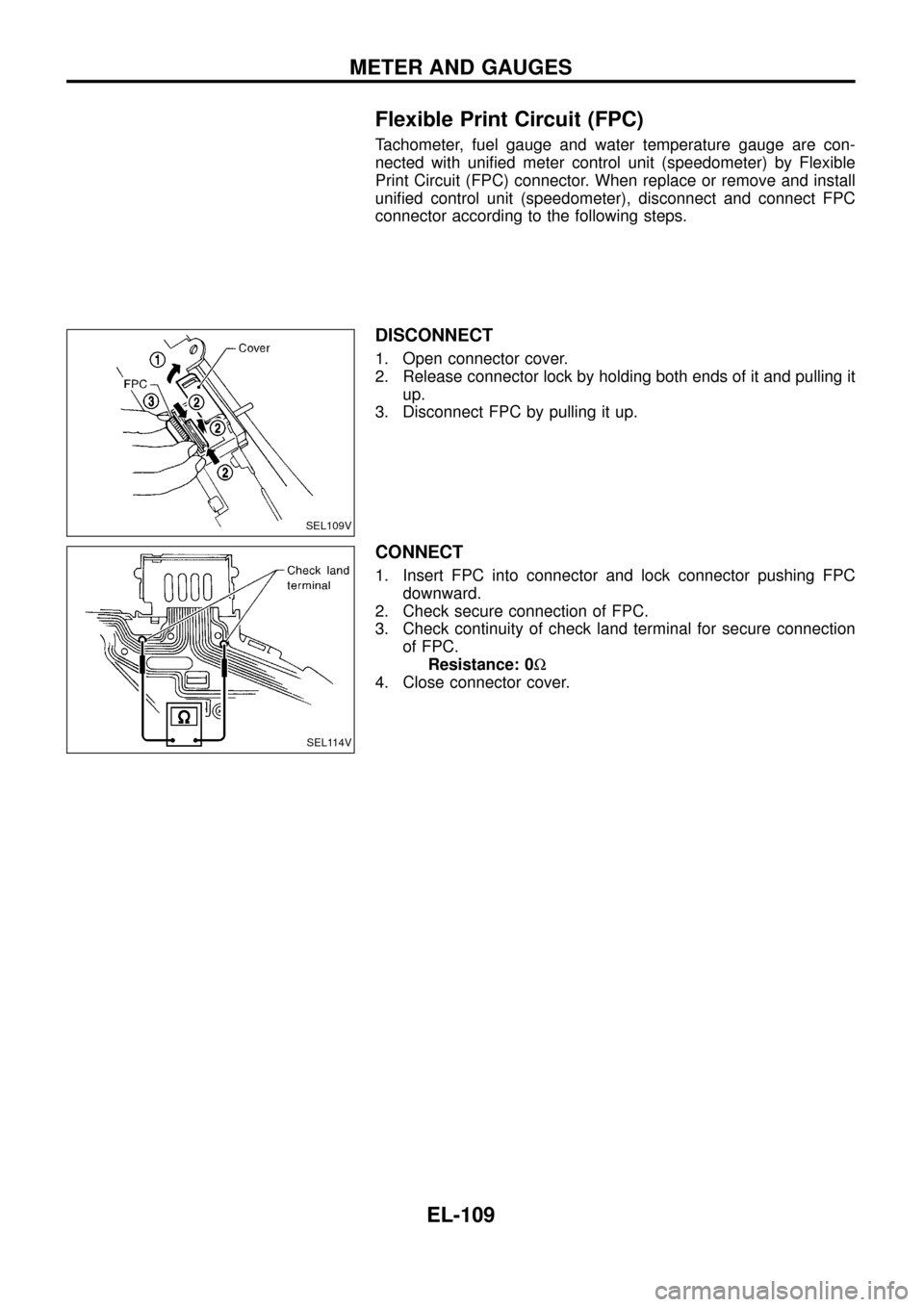

Flexible Print Circuit (FPC)

Tachometer, fuel gauge and water temperature gauge are con-

nected with uni®ed meter control unit (speedometer) by Flexible

Print Circuit (FPC) connector. When replace or remove and install

uni®ed control unit (speedometer), disconnect and connect FPC

connector according to the following steps.

DISCONNECT

1. Open connector cover.

2. Release connector lock by holding both ends of it and pulling it

up.

3. Disconnect FPC by pulling it up.

CONNECT

1. Insert FPC into connector and lock connector pushing FPC

downward.

2. Check secure connection of FPC.

3. Check continuity of check land terminal for secure connection

of FPC.

Resistance: 0W

4. Close connector cover.

SEL109V

SEL114V

METER AND GAUGES

EL-109

Page 115 of 326

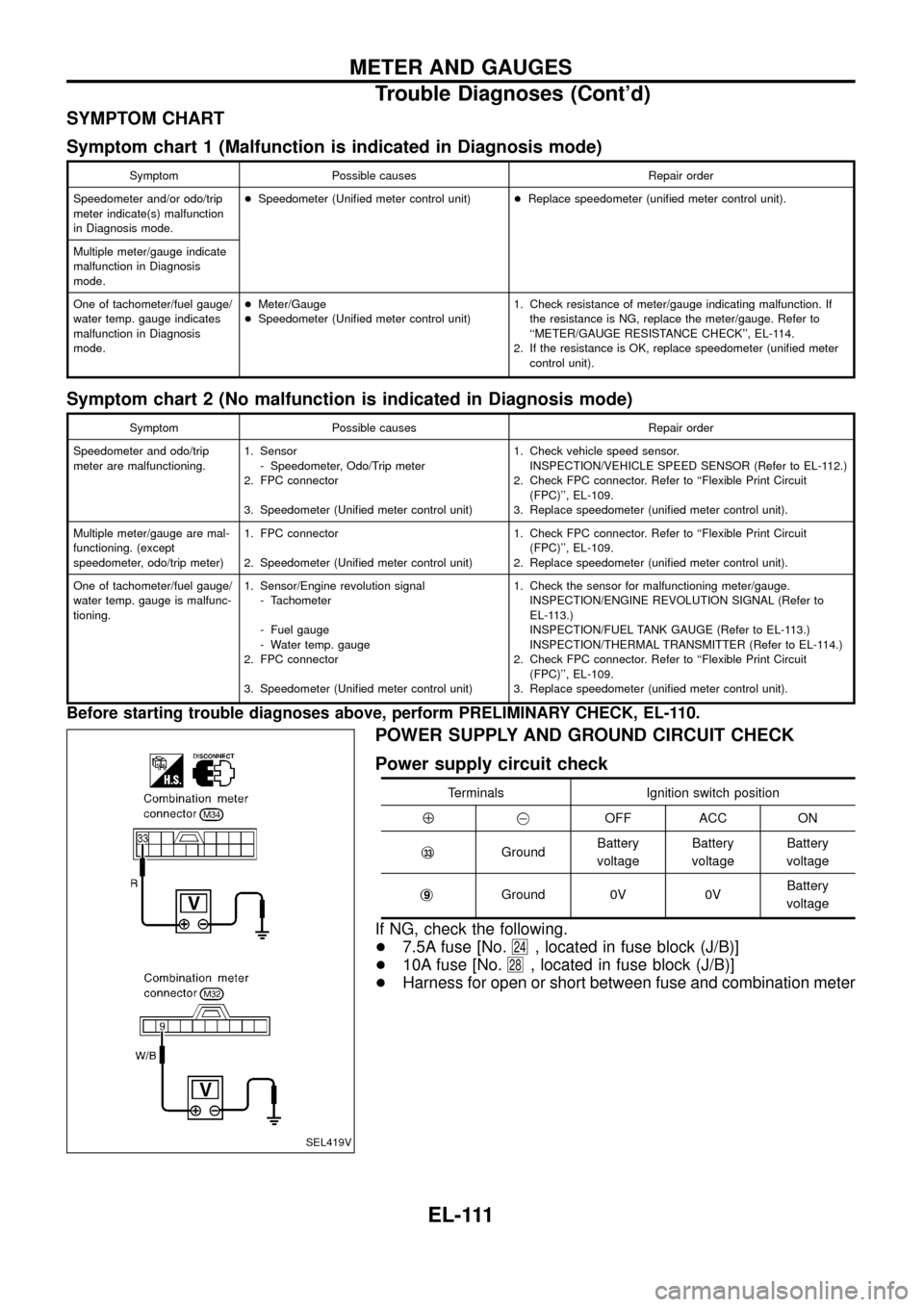

SYMPTOM CHART

Symptom chart 1 (Malfunction is indicated in Diagnosis mode)

Symptom Possible causes Repair order

Speedometer and/or odo/trip

meter indicate(s) malfunction

in Diagnosis mode.+Speedometer (Uni®ed meter control unit)+Replace speedometer (uni®ed meter control unit).

Multiple meter/gauge indicate

malfunction in Diagnosis

mode.

One of tachometer/fuel gauge/

water temp. gauge indicates

malfunction in Diagnosis

mode.+Meter/Gauge

+Speedometer (Uni®ed meter control unit)1. Check resistance of meter/gauge indicating malfunction. If

the resistance is NG, replace the meter/gauge. Refer to

``METER/GAUGE RESISTANCE CHECK'', EL-114.

2. If the resistance is OK, replace speedometer (uni®ed meter

control unit).

Symptom chart 2 (No malfunction is indicated in Diagnosis mode)

Symptom Possible causes Repair order

Speedometer and odo/trip

meter are malfunctioning.1. Sensor

- Speedometer, Odo/Trip meter

2. FPC connector

3. Speedometer (Uni®ed meter control unit)1. Check vehicle speed sensor.

INSPECTION/VEHICLE SPEED SENSOR (Refer to EL-112.)

2. Check FPC connector. Refer to ``Flexible Print Circuit

(FPC)'', EL-109.

3. Replace speedometer (uni®ed meter control unit).

Multiple meter/gauge are mal-

functioning. (except

speedometer, odo/trip meter)1. FPC connector

2. Speedometer (Uni®ed meter control unit)1. Check FPC connector. Refer to ``Flexible Print Circuit

(FPC)'', EL-109.

2. Replace speedometer (uni®ed meter control unit).

One of tachometer/fuel gauge/

water temp. gauge is malfunc-

tioning.1. Sensor/Engine revolution signal

- Tachometer

- Fuel gauge

- Water temp. gauge

2. FPC connector

3. Speedometer (Uni®ed meter control unit)1. Check the sensor for malfunctioning meter/gauge.

INSPECTION/ENGINE REVOLUTION SIGNAL (Refer to

EL-113.)

INSPECTION/FUEL TANK GAUGE (Refer to EL-113.)

INSPECTION/THERMAL TRANSMITTER (Refer to EL-114.)

2. Check FPC connector. Refer to ``Flexible Print Circuit

(FPC)'', EL-109.

3. Replace speedometer (uni®ed meter control unit).

Before starting trouble diagnoses above, perform PRELIMINARY CHECK, EL-110.

POWER SUPPLY AND GROUND CIRCUIT CHECK

Power supply circuit check

Terminals Ignition switch position

Å@OFF ACC ON

j

33GroundBattery

voltageBattery

voltageBattery

voltage

j

9Ground 0V 0VBattery

voltage

If NG, check the following.

+7.5A fuse [No.

24, located in fuse block (J/B)]

+10A fuse [No.

28, located in fuse block (J/B)]

+Harness for open or short between fuse and combination meter

SEL419V

METER AND GAUGES

Trouble Diagnoses (Cont'd)

EL-111

Page 122 of 326

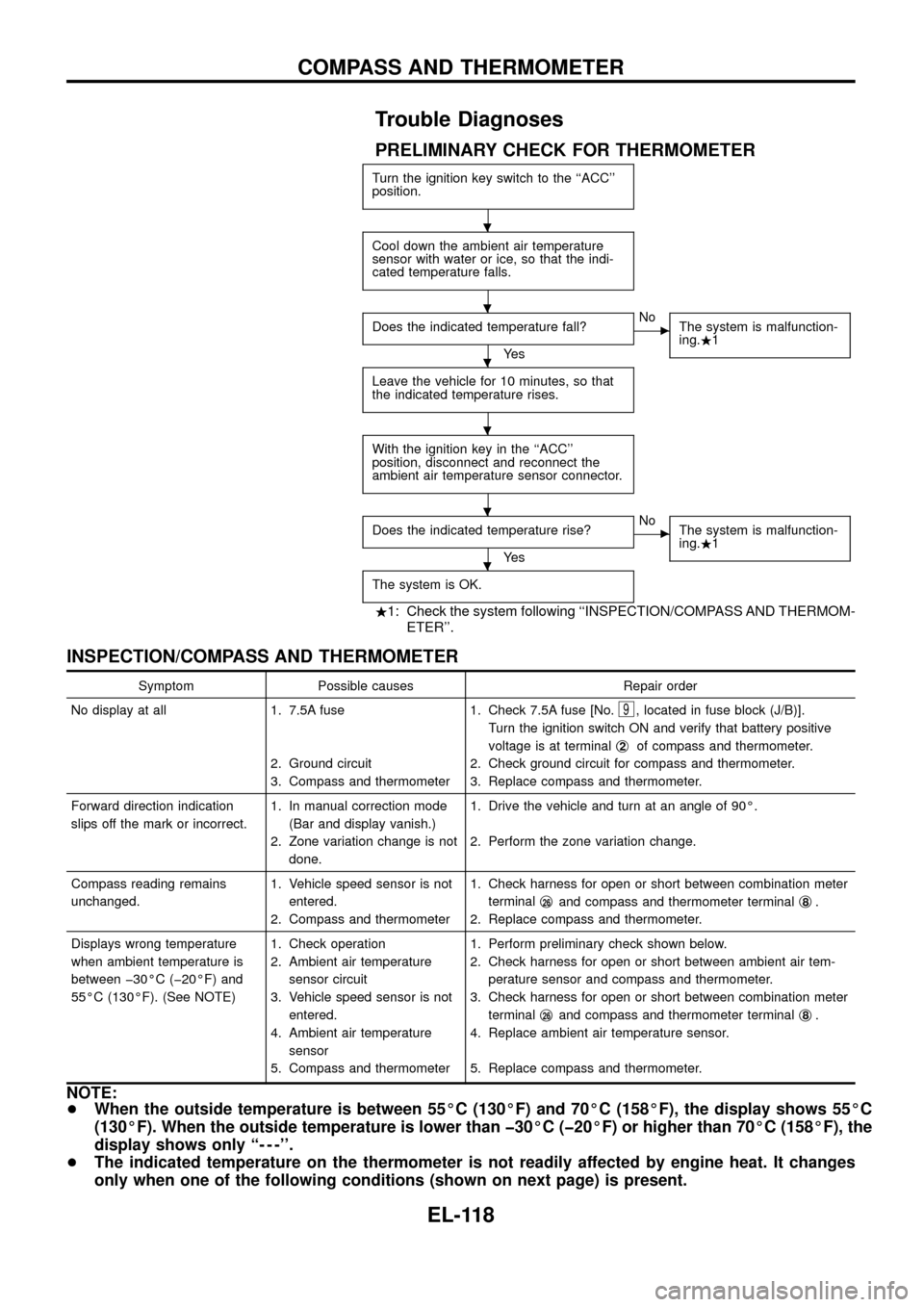

Trouble Diagnoses

PRELIMINARY CHECK FOR THERMOMETER

Turn the ignition key switch to the ``ACC''

position.

Cool down the ambient air temperature

sensor with water or ice, so that the indi-

cated temperature falls.

Does the indicated temperature fall?

Ye s

cNo

The system is malfunction-

ing..1

Leave the vehicle for 10 minutes, so that

the indicated temperature rises.

With the ignition key in the ``ACC''

position, disconnect and reconnect the

ambient air temperature sensor connector.

Does the indicated temperature rise?

Ye s

cNo

The system is malfunction-

ing..1

The system is OK.

.1: Check the system following ``INSPECTION/COMPASS AND THERMOM-

ETER''.

INSPECTION/COMPASS AND THERMOMETER

Symptom Possible causes Repair order

No display at all 1. 7.5A fuse

2. Ground circuit

3. Compass and thermometer1. Check 7.5A fuse [No.

9, located in fuse block (J/B)].

Turn the ignition switch ON and verify that battery positive

voltage is at terminalj

2of compass and thermometer.

2. Check ground circuit for compass and thermometer.

3. Replace compass and thermometer.

Forward direction indication

slips off the mark or incorrect.1. In manual correction mode

(Bar and display vanish.)

2. Zone variation change is not

done.1. Drive the vehicle and turn at an angle of 90É.

2. Perform the zone variation change.

Compass reading remains

unchanged.1. Vehicle speed sensor is not

entered.

2. Compass and thermometer1. Check harness for open or short between combination meter

terminalj

26and compass and thermometer terminalj8.

2. Replace compass and thermometer.

Displays wrong temperature

when ambient temperature is

between þ30ÉC (þ20ÉF) and

55ÉC (130ÉF). (See NOTE)1. Check operation

2. Ambient air temperature

sensor circuit

3. Vehicle speed sensor is not

entered.

4. Ambient air temperature

sensor

5. Compass and thermometer1. Perform preliminary check shown below.

2. Check harness for open or short between ambient air tem-

perature sensor and compass and thermometer.

3. Check harness for open or short between combination meter

terminalj

26and compass and thermometer terminalj8.

4. Replace ambient air temperature sensor.

5. Replace compass and thermometer.

NOTE:

+When the outside temperature is between 55ÉC (130ÉF) and 70ÉC (158ÉF), the display shows 55ÉC

(130ÉF). When the outside temperature is lower than þ30ÉC (þ20ÉF) or higher than 70ÉC (158ÉF), the

display shows only ``- - -''.

+The indicated temperature on the thermometer is not readily affected by engine heat. It changes

only when one of the following conditions (shown on next page) is present.

.

.

.

.

.

.

COMPASS AND THERMOMETER

EL-118

Page 143 of 326

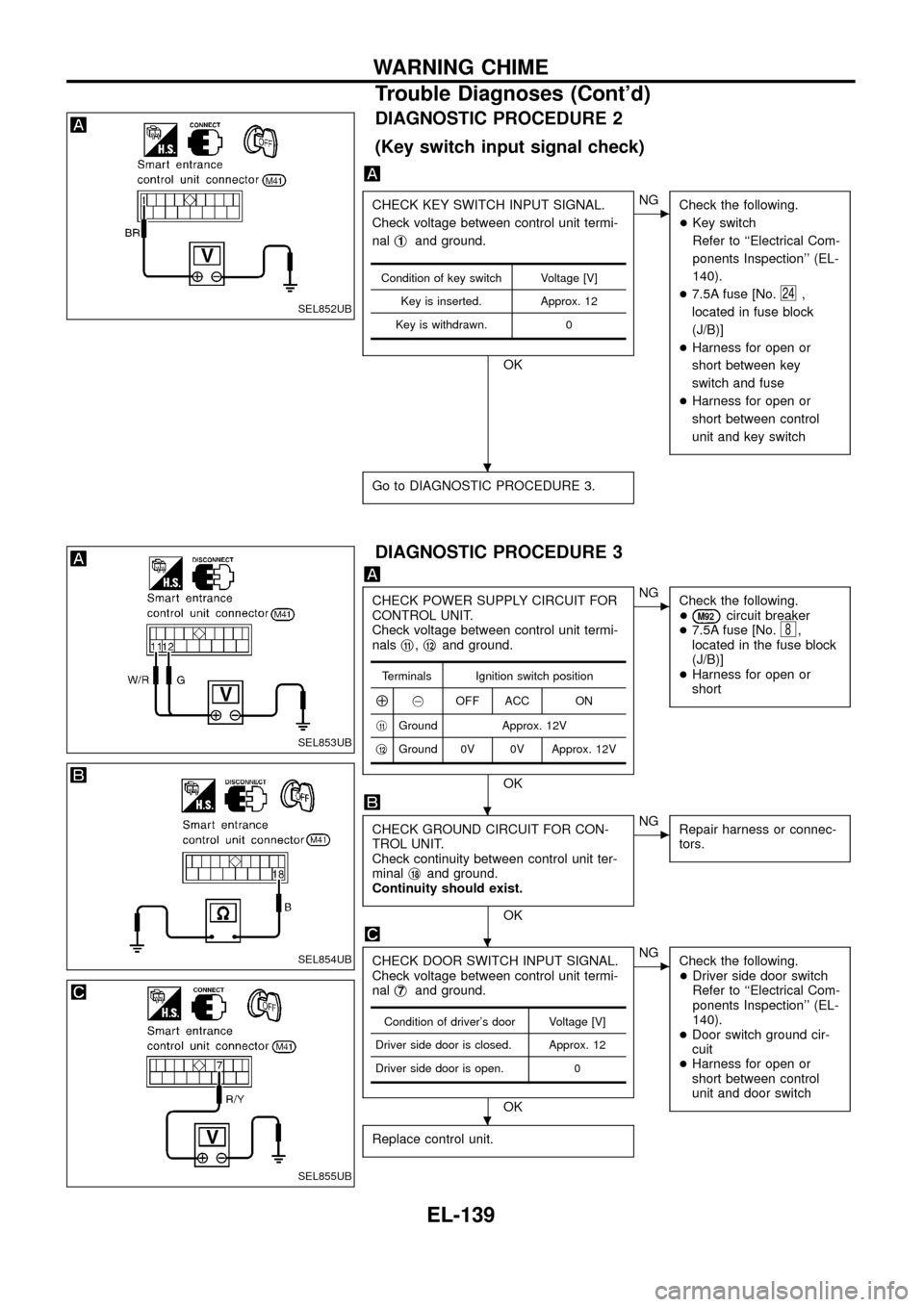

DIAGNOSTIC PROCEDURE 2

(Key switch input signal check)

CHECK KEY SWITCH INPUT SIGNAL.

Check voltage between control unit termi-

nalj

1and ground.

OK

cNG

Check the following.

+Key switch

Refer to ``Electrical Com-

ponents Inspection'' (EL-

140).

+7.5A fuse [No.

24,

located in fuse block

(J/B)]

+Harness for open or

short between key

switch and fuse

+Harness for open or

short between control

unit and key switch

Go to DIAGNOSTIC PROCEDURE 3.

Condition of key switch Voltage [V]

Key is inserted. Approx. 12

Key is withdrawn. 0

DIAGNOSTIC PROCEDURE 3

CHECK POWER SUPPLY CIRCUIT FOR

CONTROL UNIT.

Check voltage between control unit termi-

nalsj

11,j12and ground.

OK

cNG

Check the following.

+

M92circuit breaker

+7.5A fuse [No.8,

located in the fuse block

(J/B)]

+Harness for open or

short

CHECK GROUND CIRCUIT FOR CON-

TROL UNIT.

Check continuity between control unit ter-

minalj

18and ground.

Continuity should exist.

OK

cNG

Repair harness or connec-

tors.

CHECK DOOR SWITCH INPUT SIGNAL.

Check voltage between control unit termi-

nalj

7and ground.

OK

cNG

Check the following.

+Driver side door switch

Refer to ``Electrical Com-

ponents Inspection'' (EL-

140).

+Door switch ground cir-

cuit

+Harness for open or

short between control

unit and door switch

Replace control unit.

Terminals Ignition switch position

Å@OFF ACC ON

j

11Ground Approx. 12V

j

12Ground 0V 0V Approx. 12V

Condition of driver's door Voltage [V]

Driver side door is closed. Approx. 12

Driver side door is open. 0

SEL852UB

SEL853UB

SEL854UB

SEL855UB

.

.

.

.

WARNING CHIME

Trouble Diagnoses (Cont'd)

EL-139

Page 145 of 326

System Description

WIPER OPERATION

The wiper switch is controlled by a lever built into the combination switch.

There are three wiper switch positions:

+LO speed

+HI speed

+INT (Intermittent)

With the ignition switch in the ACC or ON position, power is supplied

+through 20A fuse [No.

, located in the fuse block (J/B)]

+to wiper motor terminalj

4.

Low and high speed wiper operation

Ground is supplied to wiper switch terminalj

17through body grounds.

When the wiper switch is placed in the LO position, ground is supplied

+through terminalj

14of the wiper switch

+to wiper motor terminalj

2.

With power and ground supplied, the wiper motor operates at low speed.

When the wiper switch is placed in the HI position, ground is supplied

+through terminalj

16of the wiper switch

+to wiper motor terminalj

3.

With power and ground supplied, the wiper motor operates at high speed.

Auto stop operation

With wiper switch turned OFF, wiper motor will continue to operate until wiper arms reach windshield base.

When wiper arms are not located at base of windshield with wiper switch OFF, ground is provided

+from terminalj

14of the wiper switch

+to wiper motor terminalj

2, in order to continue wiper motor operation at low speed.

+through wiper ampli®er (OUTPUT) combined with wiper switch and (with intermittent wiper)

+through terminalj

13of wiper switch

+to wiper motor terminalj

5

+through terminalj6of the wiper motor, and

+through body grounds.

When wiper arms reach base of windshield, wiper motor terminalsj

4andj5are connected instead of ter-

minalsj

5andj6. Wiper motor will then stop wiper arms at the PARK position.

Intermittent operation

The wiper motor operates the wiper arms one time at low speed at a set interval of approximately 3 to 13

seconds. This feature is controlled by the wiper ampli®er (INT SW) combined with wiper switch.

When the wiper switch is placed in the INT position, ground is supplied to wiper ampli®er.

The desired interval time is input to wiper ampli®er (INT VR) from wiper volume switch combined with wiper

switch.

Then intermittent ground is supplied

+to wiper motor terminalj

2

+from terminalj14of wiper switch

+through wiper ampli®er (OUTPUT).

The wiper motor operates at low speed at the desired interval.

WASHER OPERATION

With the ignition switch in the ACC or ON position, power is supplied

+through 20A fuse [No.

, located in the fuse block (J/B)]

+to washer motor terminalj

2.

When the lever is pulled to the WASH position, ground is supplied through wiper switch

+to washer motor terminalj

1, and

+to wiper ampli®er (WASH SW) combined with wiper switch.

With power and ground supplied, the washer motor operates.

When the lever is pulled to the WASH position for one second or more, the wiper motor operates at low speed

for approximately 3 seconds to clean windshield. This feature is controlled by the wiper ampli®er in the same

manner as the intermittent operation.

FRONT WIPER AND WASHER

EL-141

Page 149 of 326

System Description

WIPER OPERATION

The rear wiper switch is controlled by a ring built into the combination switch.

There are two wiper switch positions:

+ON (LO speed)

+INT (Intermittent)

With the ignition switch in the ON position, power is supplied

+through 10A fuse (No.

18, located in the fuse block)

+to rear wiper motor terminalj

4, and

+to rear wiper ampli®er terminalj

5.

Low speed wiper operation

Ground is supplied to rear wiper switch terminalj24through body grounds.

When the rear wiper is placed in the ON position, ground is supplied

+through rear wiper switch terminalj

22

+to rear wiper relay terminalj6.

Then ground is supplied

+to rear wiper motor terminalj

1

+through rear wiper ampli®er terminalsj2andj3.

With power and ground supplied, the wiper motor operates.

Auto stop operation

With the rear wiper switch turned OFF, rear wiper motor will continue to operate until wiper arm reaches rear

window base.

When wiper arm is not located at base of rear window with rear wiper switch OFF, ground is supplied

+to rear wiper motor terminalj

1

+through rear wiper ampli®er terminalsj2,j7and

+through rear wiper motor terminalj

3, in order to continue rear wiper motor operation at low speed.

Ground is also supplied

+to rear wiper motor terminalj

2

+through body grounds.

When wiper arm reaches base of rear window, rear wiper motor terminalsj

3andj4are connected instead

of terminalsj

2andj3. Rear wiper motor will then stop wiper arm at the PARK position.

Intermittent operation

The rear wiper motor operates the wiper arm one time at low speed at an interval of approximately 7 sec-

onds.

When the rear wiper switch is placed in the INT position, ground is supplied

+to rear wiper ampli®er terminalj

1

+through rear wiper switch terminalj21.

Then the rear wiper motor operates intermittently in the same manner as the low speed wiper operation.

WASHER OPERATION

With the ignition switch in the ACC or ON position, power is supplied

+through 10A fuse (No.

18, located in the fuse block)

+to rear washer motor terminalj

2.

When the ring is turned WASH position, ground is supplied

+to rear washer motor terminalj

1, and

+to rear wiper ampli®er terminalj

4

+through terminalj23of rear wiper switch.

With power and ground is supplied, the rear washer motor operates.

The rear wiper motor operates when the ring is turned to WASH position for one second or more and for

approximately 3 seconds after the ring is released. This feature is controlled by the rear wiper ampli®er in the

same manner as the low speed wiper operation.

REAR WIPER AND WASHER

EL-145

Page 158 of 326

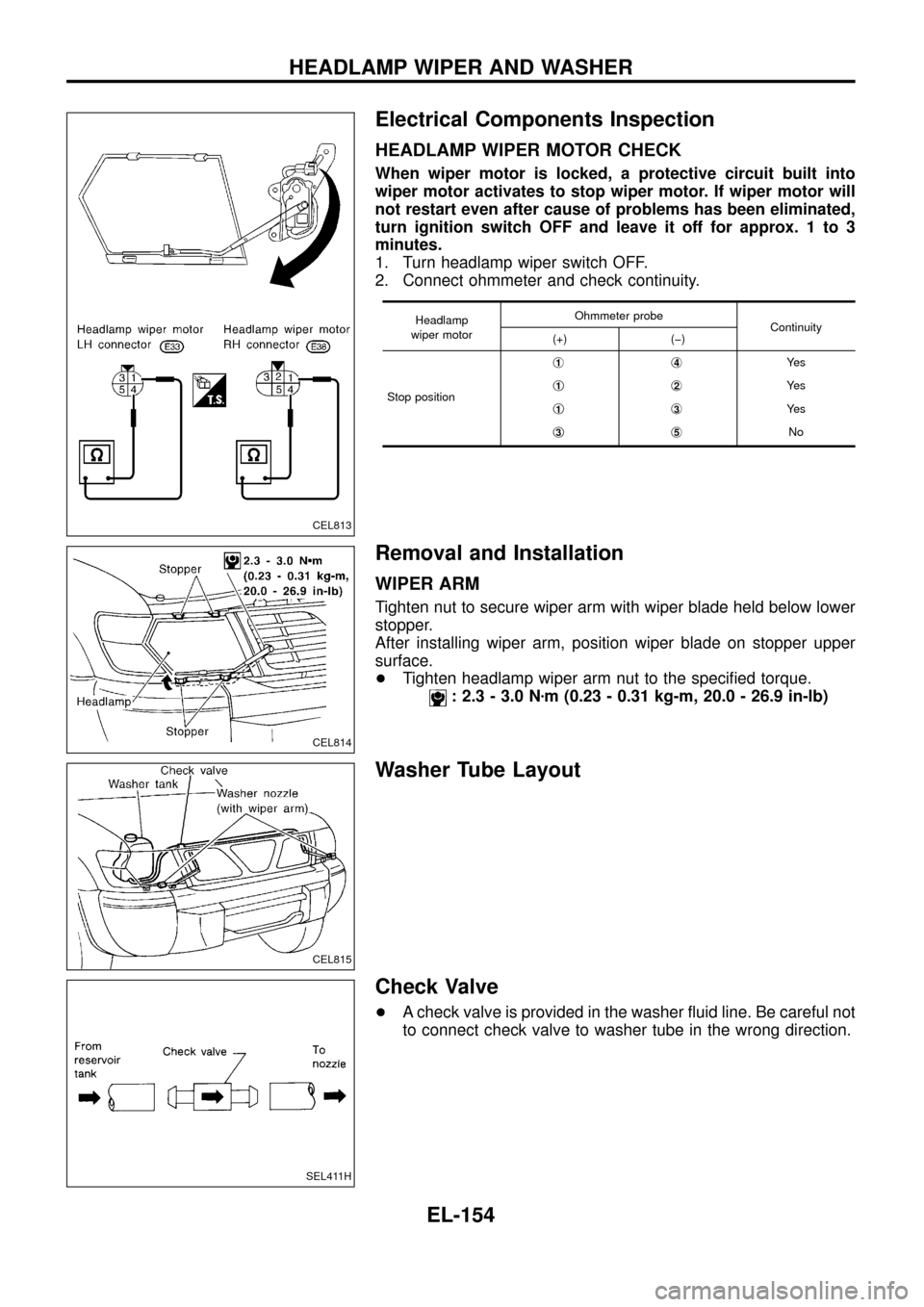

Electrical Components Inspection

HEADLAMP WIPER MOTOR CHECK

When wiper motor is locked, a protective circuit built into

wiper motor activates to stop wiper motor. If wiper motor will

not restart even after cause of problems has been eliminated,

turn ignition switch OFF and leave it off for approx. 1 to 3

minutes.

1. Turn headlamp wiper switch OFF.

2. Connect ohmmeter and check continuity.

Headlamp

wiper motorOhmmeter probe

Continuity

(+) (þ)

Stop positionj

1j4Ye s

j

1j2Ye s

j

1j3Ye s

j

3j5No

Removal and Installation

WIPER ARM

Tighten nut to secure wiper arm with wiper blade held below lower

stopper.

After installing wiper arm, position wiper blade on stopper upper

surface.

+Tighten headlamp wiper arm nut to the speci®ed torque.

: 2.3 - 3.0 Nzm (0.23 - 0.31 kg-m, 20.0 - 26.9 in-lb)

Washer Tube Layout

Check Valve

+A check valve is provided in the washer ¯uid line. Be careful not

to connect check valve to washer tube in the wrong direction.

CEL813

CEL814

CEL815

SEL411H

HEADLAMP WIPER AND WASHER

EL-154

Page 161 of 326

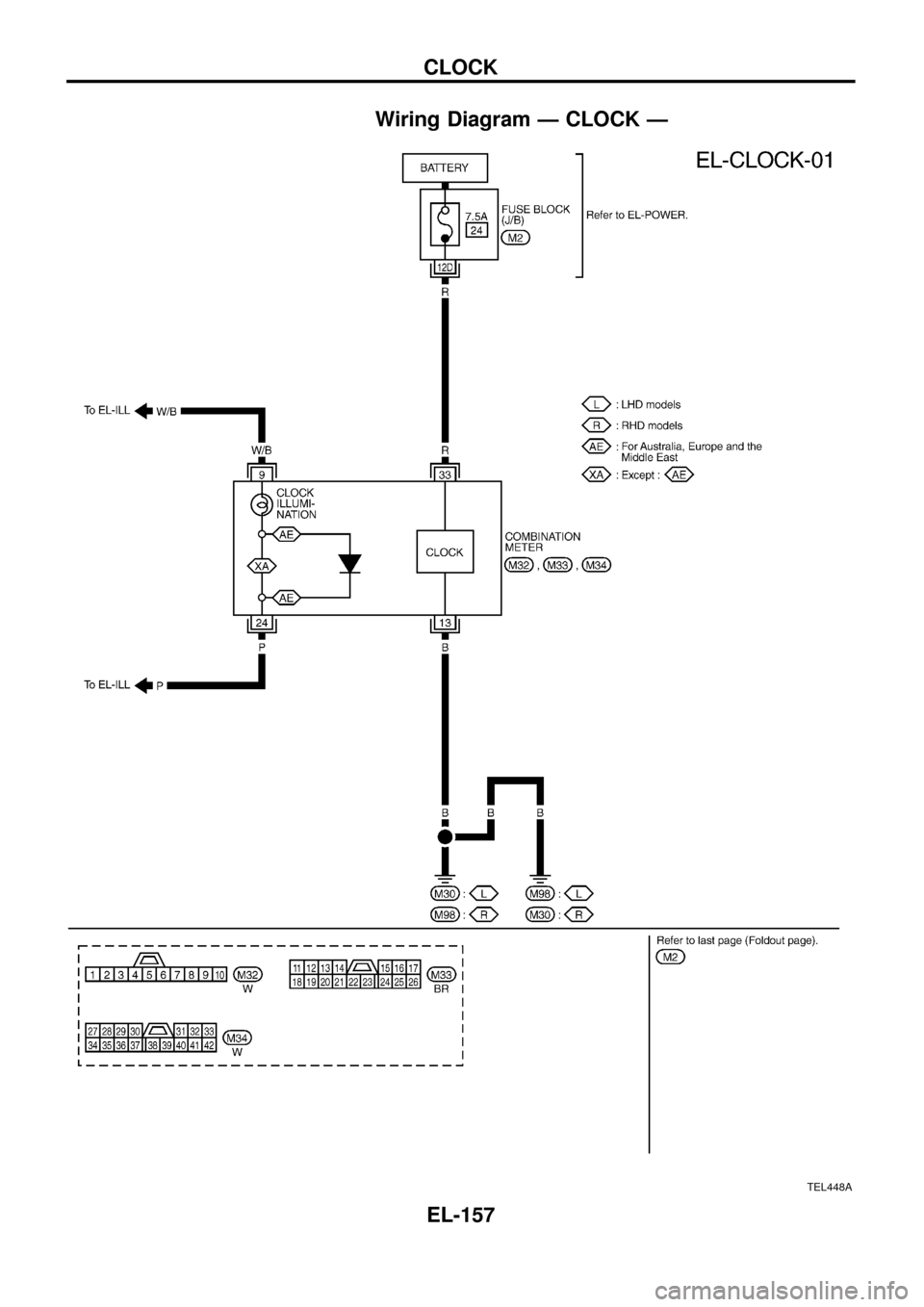

Wiring Diagram Ð CLOCK Ð

TEL448A

CLOCK

EL-157

Page 162 of 326

System Description

The rear window defogger system is controlled by the smart entrance control unit. The rear window defogger

operates only for approximately 15 minutes.

Power is supplied at all times

+to rear window defogger relay terminalj

3

+through 15A fuse (No.43, located in the fuse and fusible link box) and

+to rear window defogger relay terminalj

6

+through 20A fuse (No.44, located in the fuse and fusible link box).

With the ignition switch in the ON or START position, power is supplied

+to the rear window defogger relay terminalj

1and

+to smart entrance control unit terminalj

12

+through 7.5A fuse [No.8, located in the fuse block (J/B)].

Ground is supplied to terminalj

2of the rear window defogger switch through body grounds.

When the rear window defogger switch is turned ON, ground is supplied

+through terminalj

1of the rear window defogger switch

+to smart entrance control unit terminalj

8.

Terminalj

9of the smart entrance control unit then supplies ground to the rear window defogger relay termi-

nalj

2.

With power and ground supplied, the rear window defogger relay is energized.

Power is supplied

+through terminalsj

5andj7of the rear window defogger relay

+to the rear window defogger.

The rear window defogger has an independent ground.

With power and ground supplied, the rear window defogger ®laments heat and defog the rear window.

When the system is activated, the rear window defogger indicator illuminates in the rear window defogger

switch.

Power is supplied

+to terminalj

3of the rear window defogger switch

+from terminalj

5of the rear window defogger relay.

Terminalj

4of the rear window defogger switch is grounded through body grounds.

REAR WINDOW DEFOGGER

EL-158

Page 167 of 326

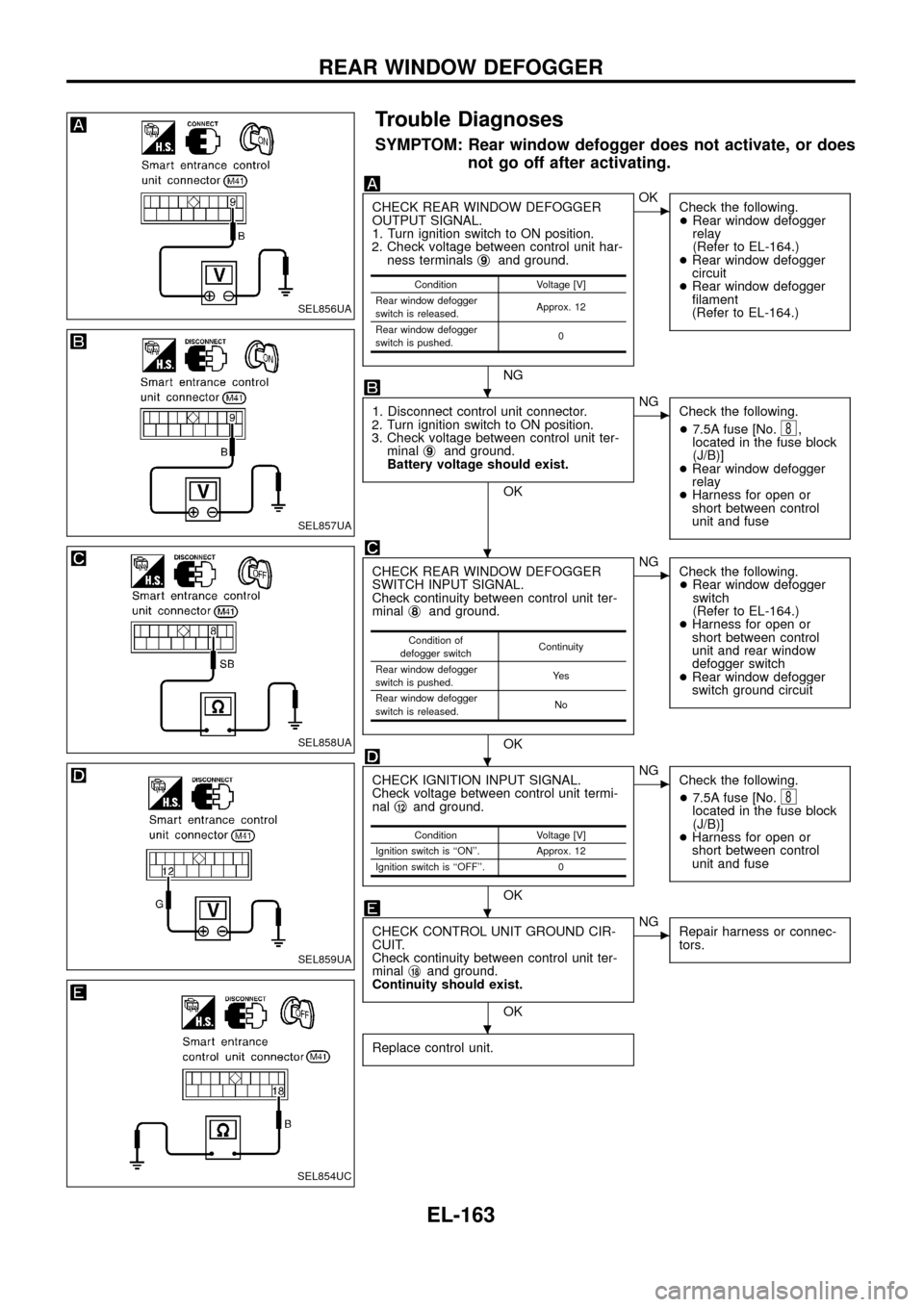

Trouble Diagnoses

SYMPTOM: Rear window defogger does not activate, or does

not go off after activating.

CHECK REAR WINDOW DEFOGGER

OUTPUT SIGNAL.

1. Turn ignition switch to ON position.

2. Check voltage between control unit har-

ness terminalsj

9and ground.

NG

cOK

Check the following.

+Rear window defogger

relay

(Refer to EL-164.)

+Rear window defogger

circuit

+Rear window defogger

®lament

(Refer to EL-164.)

1. Disconnect control unit connector.

2. Turn ignition switch to ON position.

3. Check voltage between control unit ter-

minalj

9and ground.

Battery voltage should exist.

OK

cNG

Check the following.

+7.5A fuse [No.

8,

located in the fuse block

(J/B)]

+Rear window defogger

relay

+Harness for open or

short between control

unit and fuse

CHECK REAR WINDOW DEFOGGER

SWITCH INPUT SIGNAL.

Check continuity between control unit ter-

minalj

8and ground.

OK

cNG

Check the following.

+Rear window defogger

switch

(Refer to EL-164.)

+Harness for open or

short between control

unit and rear window

defogger switch

+Rear window defogger

switch ground circuit

CHECK IGNITION INPUT SIGNAL.

Check voltage between control unit termi-

nalj

12and ground.

OK

cNG

Check the following.

+7.5A fuse [No.

8located in the fuse block

(J/B)]

+Harness for open or

short between control

unit and fuse

CHECK CONTROL UNIT GROUND CIR-

CUIT.

Check continuity between control unit ter-

minalj

18and ground.

Continuity should exist.

OK

cNG

Repair harness or connec-

tors.

Replace control unit.

Condition Voltage [V]

Rear window defogger

switch is released.Approx. 12

Rear window defogger

switch is pushed.0

Condition of

defogger switchContinuity

Rear window defogger

switch is pushed.Ye s

Rear window defogger

switch is released.No

Condition Voltage [V]

Ignition switch is ``ON''. Approx. 12

Ignition switch is ``OFF''. 0

SEL856UA

SEL857UA

SEL858UA

SEL859UA

SEL854UC

.

.

.

.

.

REAR WINDOW DEFOGGER

EL-163