ECO mode NISSAN PATROL 1998 Y61 / 5.G Engine Control Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 192, PDF Size: 4.28 MB

Page 133 of 192

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble

Code No.Malfunction is detected when ...Check Items

(Possible Cause)

36, 37, 38+Fuel cut solenoid valve circuit is malfunctioning.+Main power supply circuit (ECM terminals

11 6,11 7)

and fuse

+Harness or connectors

(The solenoid valve circuit is open or shorted.)

+Fuel cut solenoid valve

+ECM

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON''.

2) Select ``DATA MONITOR'' mode with CONSULT.

3) Start engine.

4) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

SEF748V

TROUBLE DIAGNOSIS FOR ``FUEL CUT S/V 1'' (DTC 36),

``FCV SHORT'' (DTC 37), ``FUEL CUT S/V 2'' (DTC 38)

Fuel Cut Solenoid Valve (Cont'd)

EC-131

Page 135 of 192

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK POWER SUPPLY FOR ECM.

Check power supply circuit. Refer to

EC-63.

OK

CHECK OUTPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``ON''.

2. Select ``FUEL CUT SOL/V'' in

``ACTIVE TEST'' mode with

CONSULT.

3. Touch ``ON'' and ``OFF'' alter-

nately.

4. Check that operating sound is

emitted.

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness con-

nector and electronic fuel injec-

tion pump harness connector.

3. Check harness continuity

between terminal

V4and ECM

terminals

11 3,11 5.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Repair open circuit or short

to ground or short to power

in harness or connectors.

CHECK COMPONENT

(Fuel cut solenoid valve).

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace fuel cut solenoid

valve.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

SEF860S

SEF682VA

SEF768V

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``FUEL CUT S/V 1'' (DTC 36),

``FCV SHORT'' (DTC 37), ``FUEL CUT S/V 2'' (DTC 38)

Fuel Cut Solenoid Valve (Cont'd)

EC-133

Page 137 of 192

Fuel Temperature Sensor (FTS)

The fuel temperature sensor is used to detect the fuel temperature

in the injection pump. The sensor modi®es a voltage signal from the

ECM. The modi®ed signal returns to the ECM as the fuel tempera-

ture input. The sensor uses a thermistor which is sensitive to the

change in temperature. The electrical resistance of the thermistor

decreases as temperature increases.

Engine coolant tempera-

ture

ÉC (ÉF)Voltage

(V)Resistance

(kW)

þ20 (þ4) 4.6 13.67 - 16.37

20 (68) 3.5 2.306 - 2.568

60 (140) 1.8 0.538 - 0.624

80 (176) 1.2 0.289 - 0.344

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

10 P Fuel temperature sensor Engine is running.

Approximately 0 - 4.8V

Output voltage varies with

fuel temperature.

50 B Sensors' groundEngine is running.

(Warm-up condition)

Idle speedApproximately 0V

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ...Check Items

(Possible Cause)

42+An excessively high or low voltage from the sensor is

detected by ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Fuel temperature sensor

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON''.

2) Select ``DATA MONITOR'' mode with CONSULT.

3) Wait at least 5 seconds.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Turn ignition switch ``ON'' and wait at least 5 seconds.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

SEF666S

SEF012P

SEF748V

TROUBLE DIAGNOSIS FOR ``FUEL TEMP SENSOR'' (DTC 42)

EC-135

Page 142 of 192

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble

Code No.Malfunction is detected when ...Check Items

(Possible Cause)

43+An excessively low or high voltage from the sensor is

detected by the ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Accelerator position sensor

+Accelerator position switch

+Accelerator switch (F/C)

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON''.

2) Select ``DATA MONITOR'' mode with CONSULT.

3) Wait at least 2 seconds.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Turn ignition switch ``ON'' and wait at least 2 seconds.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

SEF748V

TROUBLE DIAGNOSIS FOR ``ACCEL POS SENSOR'' (DTC 43)

Accelerator Position Sensor (Cont'd)

EC-140

Page 147 of 192

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

Before performing the following procedure, con®rm that bat-

tery voltage is more than 10V.

1) Turn ignition switch ``ON'' and select ``DATA MONITOR''

mode with CONSULT.

2) Crank engine for at least 1 second.

3) Start engine and run it for at least 2 seconds at idle

speed.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Crank engine for at least 1 second.

2) Start engine and run it for at least 2 seconds at idle

speed.

3) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

4) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.SEF714V

TROUBLE DIAGNOSIS FOR ``CRANK POS SEN (TDC)'' (DTC 47)

Crankshaft Position Sensor (TDC) (Cont'd)

EC-145

Page 151 of 192

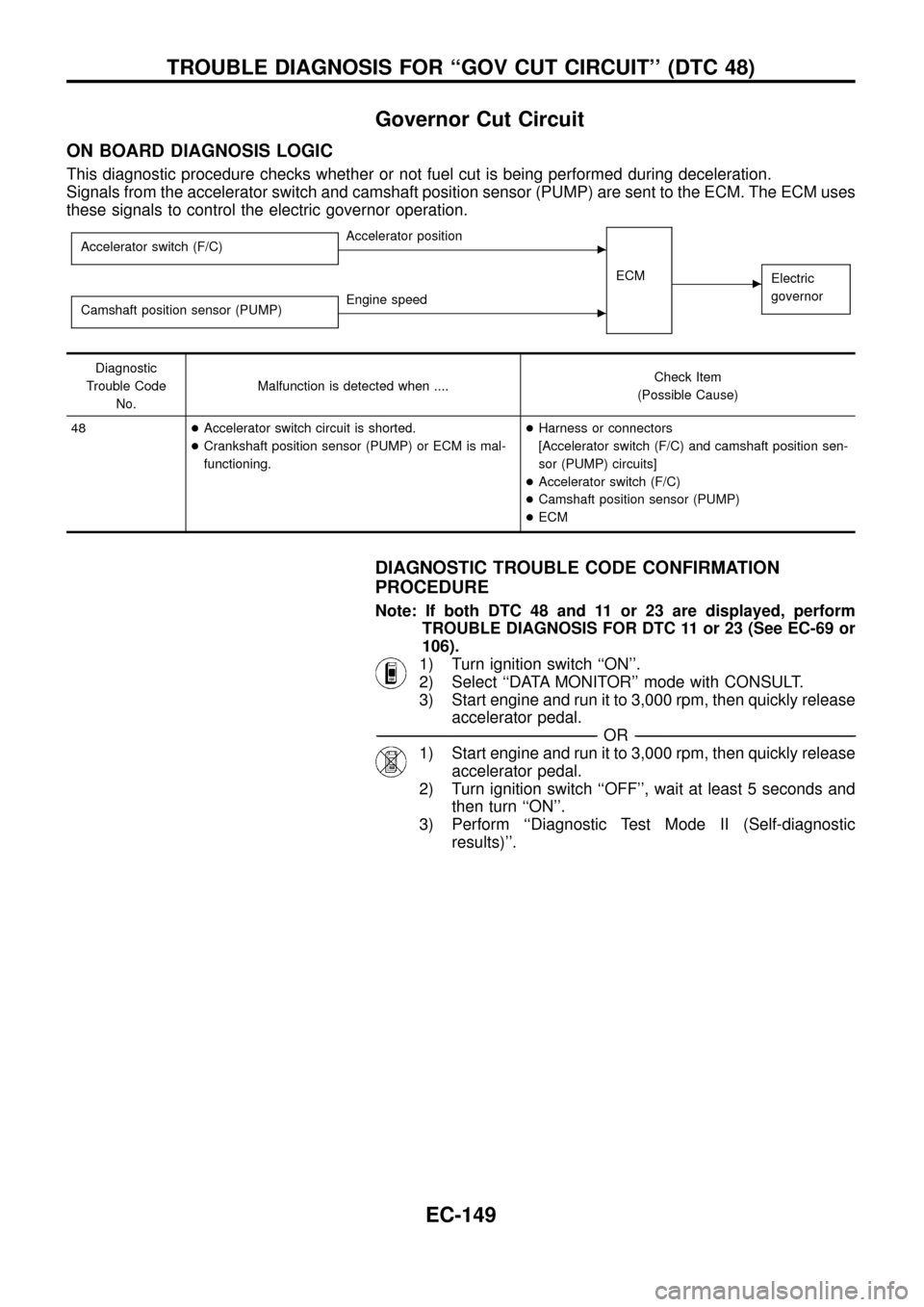

Governor Cut Circuit

ON BOARD DIAGNOSIS LOGIC

This diagnostic procedure checks whether or not fuel cut is being performed during deceleration.

Signals from the accelerator switch and camshaft position sensor (PUMP) are sent to the ECM. The ECM uses

these signals to control the electric governor operation.

Accelerator switch (F/C)cAccelerator position

ECM

cElectric

governor

Camshaft position sensor (PUMP)cEngine speed

Diagnostic

Trouble Code

No.Malfunction is detected when ....Check Item

(Possible Cause)

48+Accelerator switch circuit is shorted.

+Crankshaft position sensor (PUMP) or ECM is mal-

functioning.+Harness or connectors

[Accelerator switch (F/C) and camshaft position sen-

sor (PUMP) circuits]

+Accelerator switch (F/C)

+Camshaft position sensor (PUMP)

+ECM

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

Note: If both DTC 48 and 11 or 23 are displayed, perform

TROUBLE DIAGNOSIS FOR DTC 11 or 23 (See EC-69 or

106).

1) Turn ignition switch ``ON''.

2) Select ``DATA MONITOR'' mode with CONSULT.

3) Start engine and run it to 3,000 rpm, then quickly release

accelerator pedal.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine and run it to 3,000 rpm, then quickly release

accelerator pedal.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)''.

TROUBLE DIAGNOSIS FOR ``GOV CUT CIRCUIT'' (DTC 48)

EC-149

Page 166 of 192

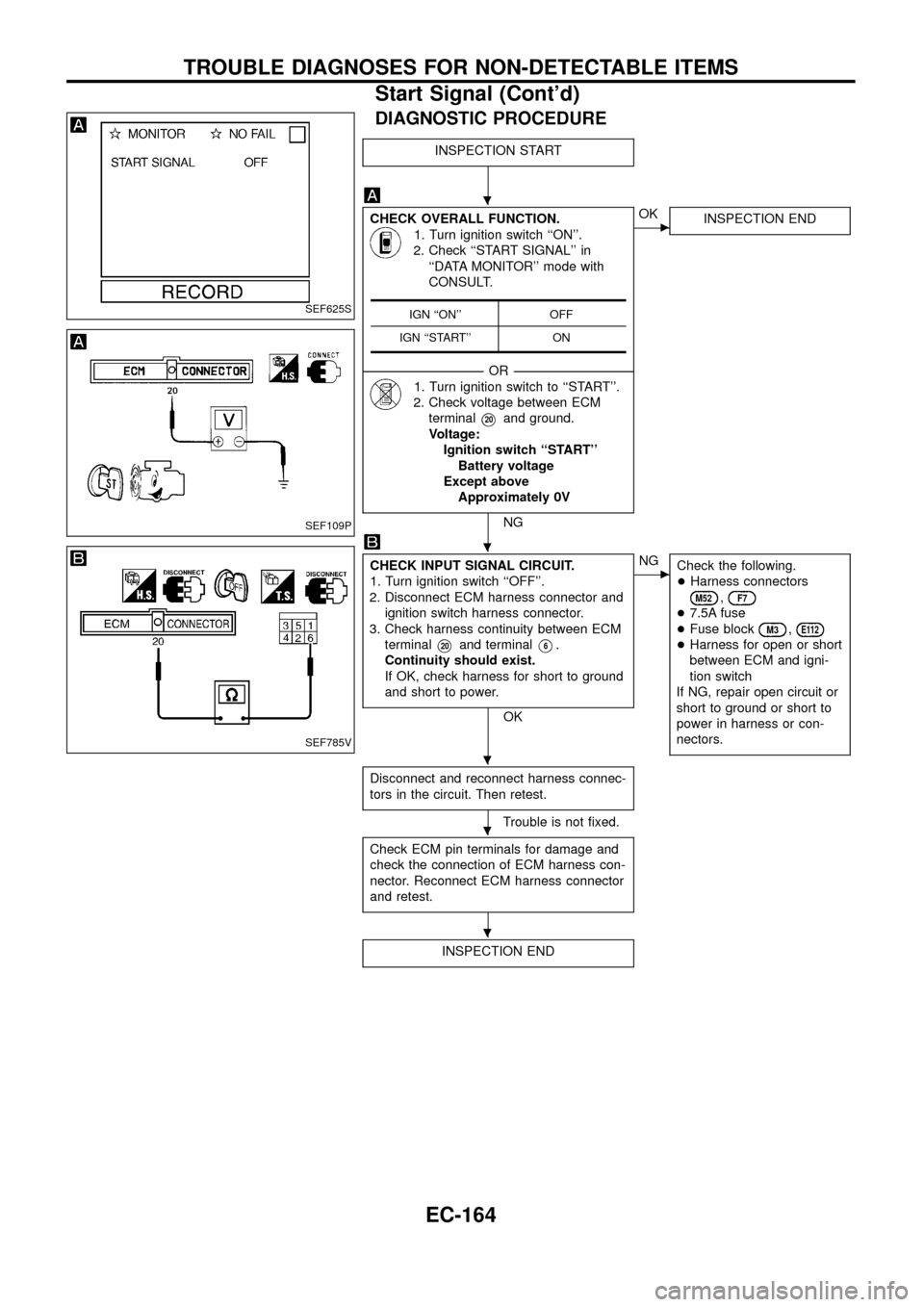

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``ON''.

2. Check ``START SIGNAL'' in

``DATA MONITOR'' mode with

CONSULT.

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ``START''.

2. Check voltage between ECM

terminal

V20and ground.

Voltage:

Ignition switch ``START''

Battery voltage

Except above

Approximately 0V

NG

cOK

INSPECTION END

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector and

ignition switch harness connector.

3. Check harness continuity between ECM

terminal

V20and terminalV6.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Check the following.

+Harness connectors

M52,F7

+7.5A fuse

+Fuse block

M3,E112

+Harness for open or short

between ECM and igni-

tion switch

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

IGN ``ON'' OFF

IGN ``START'' ONSEF625S

SEF109P

SEF785V

.

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Start Signal (Cont'd)

EC-164