width NISSAN PATROL 1998 Y61 / 5.G Engine Mechanical Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 65, PDF Size: 2.4 MB

Page 2 of 65

Parts Requiring Angular Tightening

+Some important engine parts are tightened using an angular-

tightening method rather than a torque setting method.

+If these parts are tightened using a torque setting method, dis-

persal of the tightening force (axial bolt force) will be two or

three times that of the dispersal produced by using the correct

angular-tightening method.

+Although the torque setting values (described in this manual)

are equivalent to those used when bolts and nuts are tightened

with an angular-tightening method, they should be used for

reference only.

+To assure the satisfactory maintenance of the engine, bolts and

nuts must be tightened using an angular-tightening method.

+Before tightening the bolts and nuts, ensure that the thread and

seating surfaces are clean and then coated with engine oil.

+The bolts and nuts which require the angular-tightening method

are cylinder head bolts.

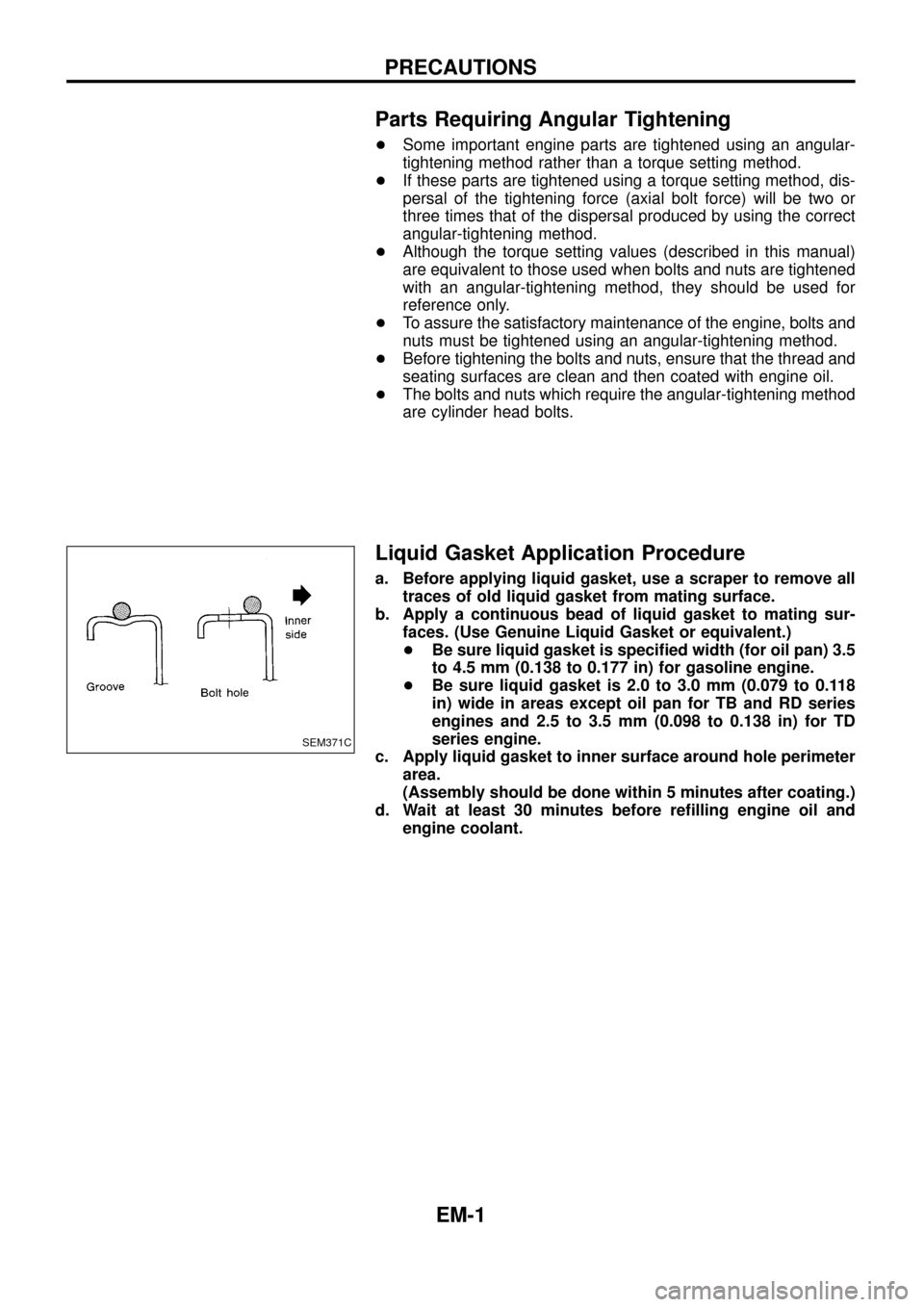

Liquid Gasket Application Procedure

a. Before applying liquid gasket, use a scraper to remove all

traces of old liquid gasket from mating surface.

b. Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine Liquid Gasket or equivalent.)

+Be sure liquid gasket is speci®ed width (for oil pan) 3.5

to 4.5 mm (0.138 to 0.177 in) for gasoline engine.

+Be sure liquid gasket is 2.0 to 3.0 mm (0.079 to 0.118

in) wide in areas except oil pan for TB and RD series

engines and 2.5 to 3.5 mm (0.098 to 0.138 in) for TD

series engine.

c. Apply liquid gasket to inner surface around hole perimeter

area.

(Assembly should be done within 5 minutes after coating.)

d. Wait at least 30 minutes before re®lling engine oil and

engine coolant.

SEM371C

PRECAUTIONS

EM-1

Page 64 of 65

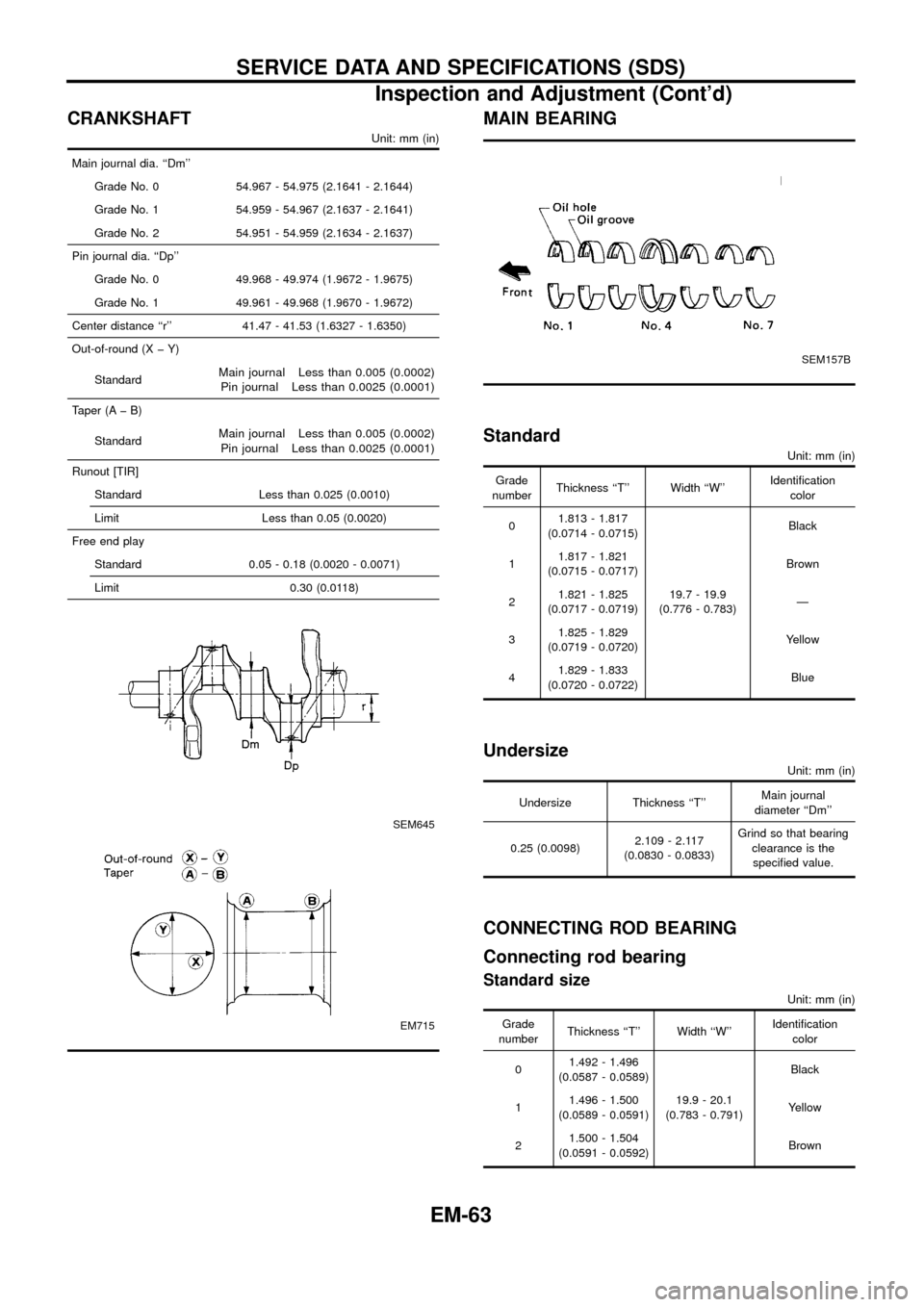

CRANKSHAFT

Unit: mm (in)

Main journal dia. ``Dm''

Grade No. 0 54.967 - 54.975 (2.1641 - 2.1644)

Grade No. 1 54.959 - 54.967 (2.1637 - 2.1641)

Grade No. 2 54.951 - 54.959 (2.1634 - 2.1637)

Pin journal dia. ``Dp''

Grade No. 0 49.968 - 49.974 (1.9672 - 1.9675)

Grade No. 1 49.961 - 49.968 (1.9670 - 1.9672)

Center distance ``r'' 41.47 - 41.53 (1.6327 - 1.6350)

Out-of-round (X þ Y)

Standard

Main journal Less than 0.005 (0.0002)

Pin journal Less than 0.0025 (0.0001)

Taper (A þ B)

Standard

Main journal Less than 0.005 (0.0002)

Pin journal Less than 0.0025 (0.0001)

Runout [TIR]

Standard Less than 0.025 (0.0010)

Limit Less than 0.05 (0.0020)

Free end play

Standard 0.05 - 0.18 (0.0020 - 0.0071)

Limit 0.30 (0.0118)

SEM645

EM715

MAIN BEARING

SEM157B

Standard

Unit: mm (in)

Grade

numberThickness ``T'' Width ``W''Identi®cation

color

01.813 - 1.817

(0.0714 - 0.0715)

19.7 - 19.9

(0.776 - 0.783)Black

11.817 - 1.821

(0.0715 - 0.0717)Brown

21.821 - 1.825

(0.0717 - 0.0719)Ð

31.825 - 1.829

(0.0719 - 0.0720)Yellow

41.829 - 1.833

(0.0720 - 0.0722)Blue

Undersize

Unit: mm (in)

Undersize Thickness ``T''Main journal

diameter ``Dm''

0.25 (0.0098)2.109 - 2.117

(0.0830 - 0.0833)Grind so that bearing

clearance is the

speci®ed value.

CONNECTING ROD BEARING

Connecting rod bearing

Standard size

Unit: mm (in)

Grade

numberThickness ``T'' Width ``W''Identi®cation

color

01.492 - 1.496

(0.0587 - 0.0589)

19.9 - 20.1

(0.783 - 0.791)Black

11.496 - 1.500

(0.0589 - 0.0591)Yellow

21.500 - 1.504

(0.0591 - 0.0592)Brown

SERVICE DATA AND SPECIFICATIONS (SDS)

Inspection and Adjustment (Cont'd)

EM-63