light NISSAN PATROL 1998 Y61 / 5.G General Information Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 47, PDF Size: 1.07 MB

Page 11 of 47

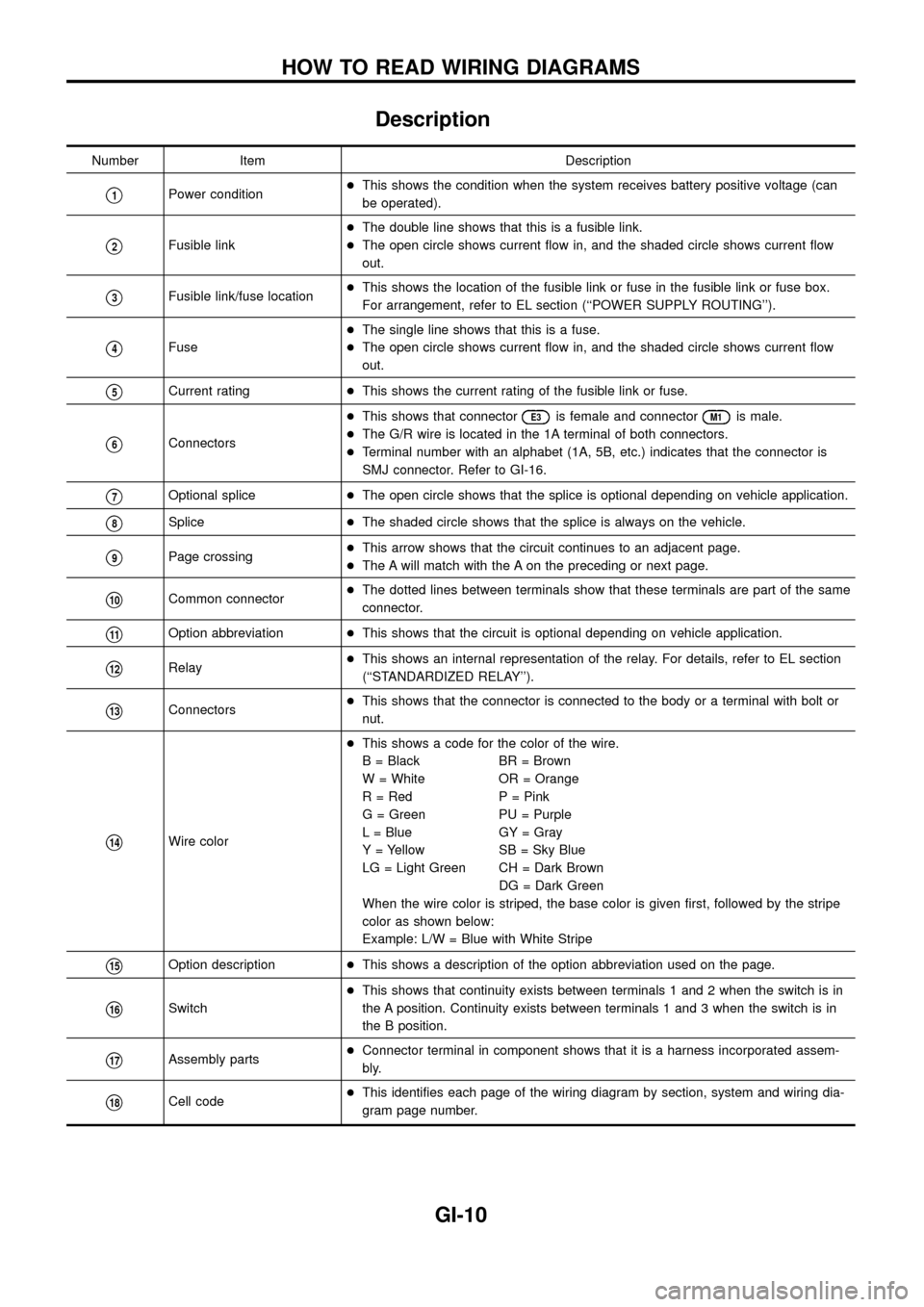

Description

Number Item Description

V1Power condition+This shows the condition when the system receives battery positive voltage (can

be operated).

V2Fusible link+The double line shows that this is a fusible link.

+The open circle shows current ¯ow in, and the shaded circle shows current ¯ow

out.

V3Fusible link/fuse location+This shows the location of the fusible link or fuse in the fusible link or fuse box.

For arrangement, refer to EL section (``POWER SUPPLY ROUTING'').

V4Fuse+The single line shows that this is a fuse.

+The open circle shows current ¯ow in, and the shaded circle shows current ¯ow

out.

V5Current rating+This shows the current rating of the fusible link or fuse.

V6Connectors+This shows that connector

E3is female and connectorM1is male.

+The G/R wire is located in the 1A terminal of both connectors.

+Terminal number with an alphabet (1A, 5B, etc.) indicates that the connector is

SMJ connector. Refer to GI-16.

V7Optional splice+The open circle shows that the splice is optional depending on vehicle application.

V8Splice+The shaded circle shows that the splice is always on the vehicle.

V9Page crossing+This arrow shows that the circuit continues to an adjacent page.

+The A will match with the A on the preceding or next page.

V10Common connector+The dotted lines between terminals show that these terminals are part of the same

connector.

V11Option abbreviation+This shows that the circuit is optional depending on vehicle application.

V12Relay+This shows an internal representation of the relay. For details, refer to EL section

(``STANDARDIZED RELAY'').

V13Connectors+This shows that the connector is connected to the body or a terminal with bolt or

nut.

V14Wire color+This shows a code for the color of the wire.

B = Black BR = Brown

W = White OR = Orange

R = Red P = Pink

G = Green PU = Purple

L = Blue GY = Gray

Y = Yellow SB = Sky Blue

LG = Light Green CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given ®rst, followed by the stripe

color as shown below:

Example: L/W = Blue with White Stripe

V15Option description+This shows a description of the option abbreviation used on the page.

V16Switch+This shows that continuity exists between terminals 1 and 2 when the switch is in

the A position. Continuity exists between terminals 1 and 3 when the switch is in

the B position.

V17Assembly parts+Connector terminal in component shows that it is a harness incorporated assem-

bly.

V18Cell code+This identi®es each page of the wiring diagram by section, system and wiring dia-

gram page number.

HOW TO READ WIRING DIAGRAMS

GI-10

Page 22 of 47

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

+Vehicle vibration

+Heat sensitive

+Freezing

+Water intrusion

+Electrical load

+Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

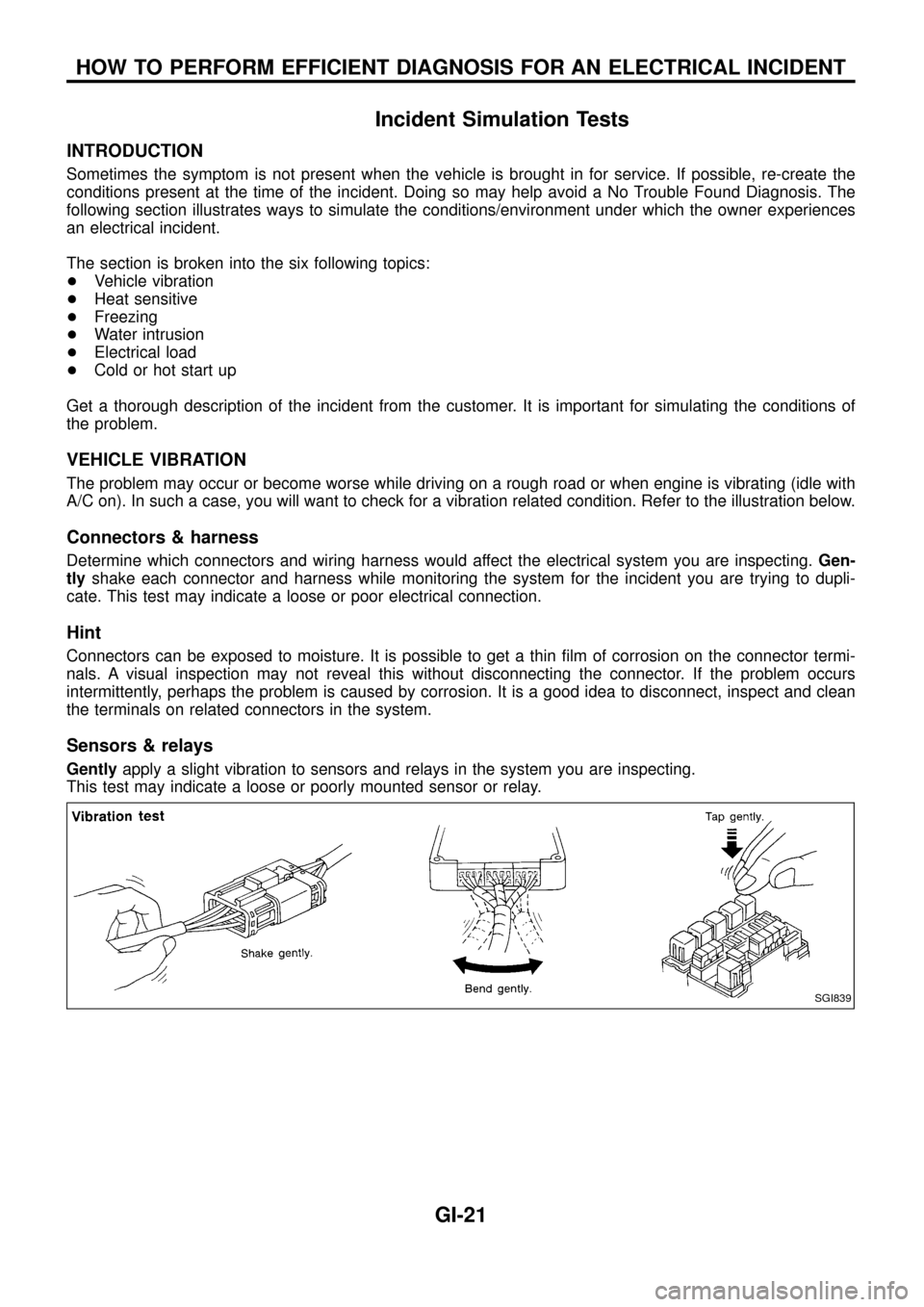

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustration below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting.Gen-

tlyshake each connector and harness while monitoring the system for the incident you are trying to dupli-

cate. This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin ®lm of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-21

Page 28 of 47

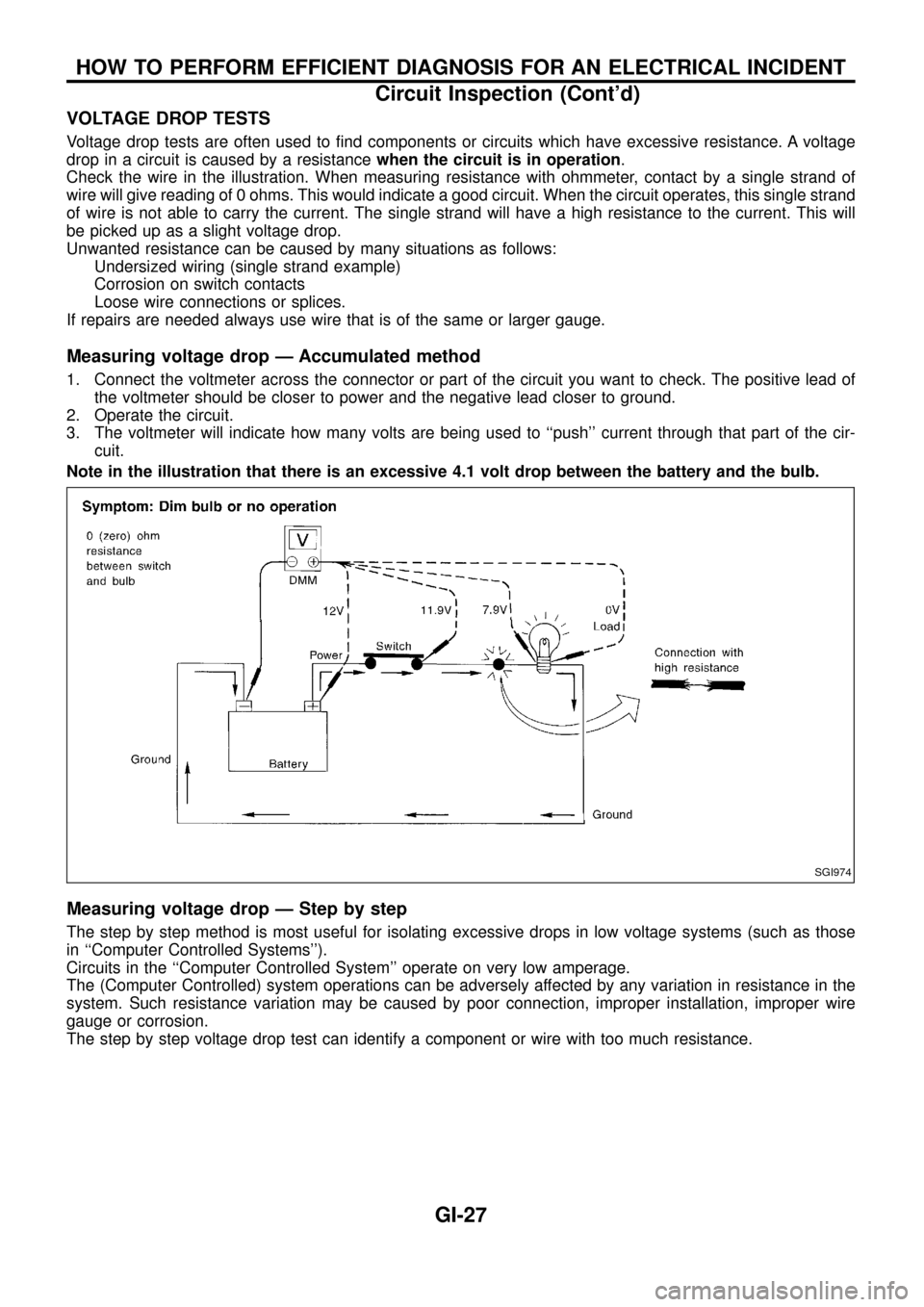

VOLTAGE DROP TESTS

Voltage drop tests are often used to ®nd components or circuits which have excessive resistance. A voltage

drop in a circuit is caused by a resistancewhen the circuit is in operation.

Check the wire in the illustration. When measuring resistance with ohmmeter, contact by a single strand of

wire will give reading of 0 ohms. This would indicate a good circuit. When the circuit operates, this single strand

of wire is not able to carry the current. The single strand will have a high resistance to the current. This will

be picked up as a slight voltage drop.

Unwanted resistance can be caused by many situations as follows:

Undersized wiring (single strand example)

Corrosion on switch contacts

Loose wire connections or splices.

If repairs are needed always use wire that is of the same or larger gauge.

Measuring voltage drop Ð Accumulated method

1. Connect the voltmeter across the connector or part of the circuit you want to check. The positive lead of

the voltmeter should be closer to power and the negative lead closer to ground.

2. Operate the circuit.

3. The voltmeter will indicate how many volts are being used to ``push'' current through that part of the cir-

cuit.

Note in the illustration that there is an excessive 4.1 volt drop between the battery and the bulb.

Measuring voltage drop Ð Step by step

The step by step method is most useful for isolating excessive drops in low voltage systems (such as those

in ``Computer Controlled Systems'').

Circuits in the ``Computer Controlled System'' operate on very low amperage.

The (Computer Controlled) system operations can be adversely affected by any variation in resistance in the

system. Such resistance variation may be caused by poor connection, improper installation, improper wire

gauge or corrosion.

The step by step voltage drop test can identify a component or wire with too much resistance.

SGI974

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-27

Page 30 of 47

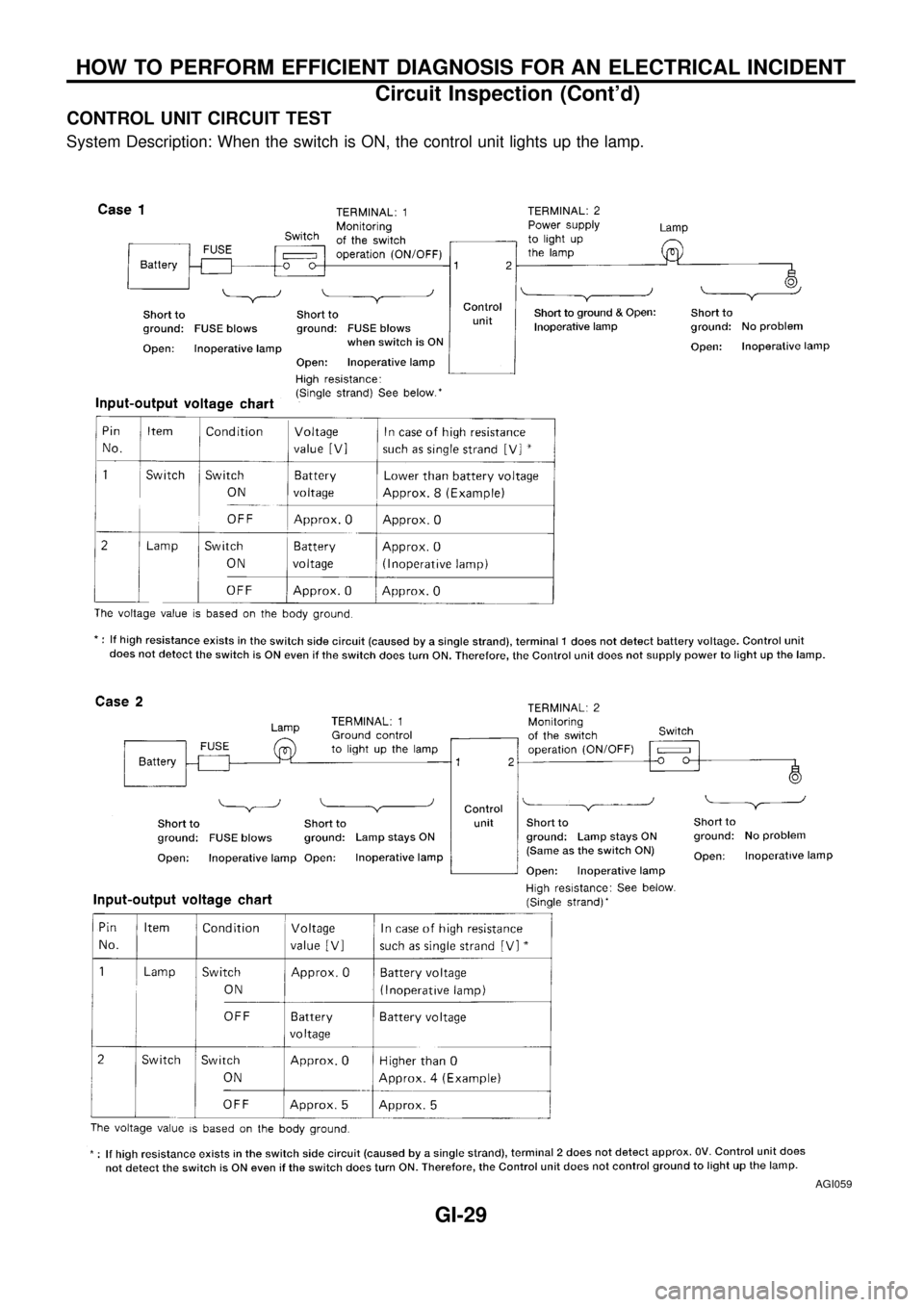

CONTROL UNIT CIRCUIT TEST

System Description: When the switch is ON, the control unit lights up the lamp.

AGI059

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-29

Page 45 of 47

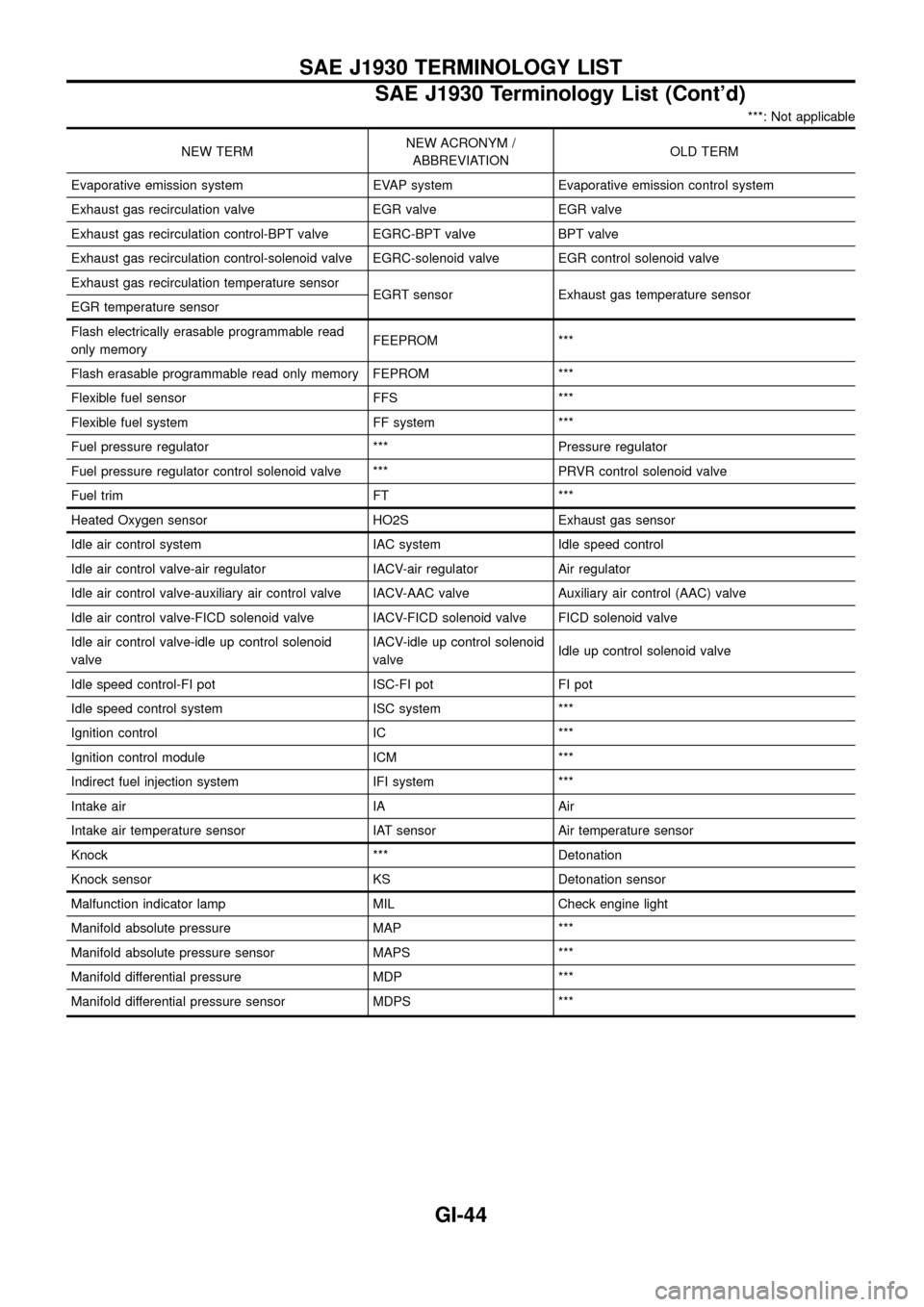

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Evaporative emission system EVAP system Evaporative emission control system

Exhaust gas recirculation valve EGR valve EGR valve

Exhaust gas recirculation control-BPT valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid valve EGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sensor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable read

only memoryFEEPROM ***

Flash erasable programmable read only memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid valve *** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control valve IACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control solenoid

valveIACV-idle up control solenoid

valveIdle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

SAE J1930 TERMINOLOGY LIST

SAE J1930 Terminology List (Cont'd)

GI-44