sensor NISSAN PATROL 1998 Y61 / 5.G General Information Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 47, PDF Size: 1.07 MB

Page 2 of 47

Observe the following precautions to ensure safe and proper

servicing. These precautions are not described in each indi-

vidual section.

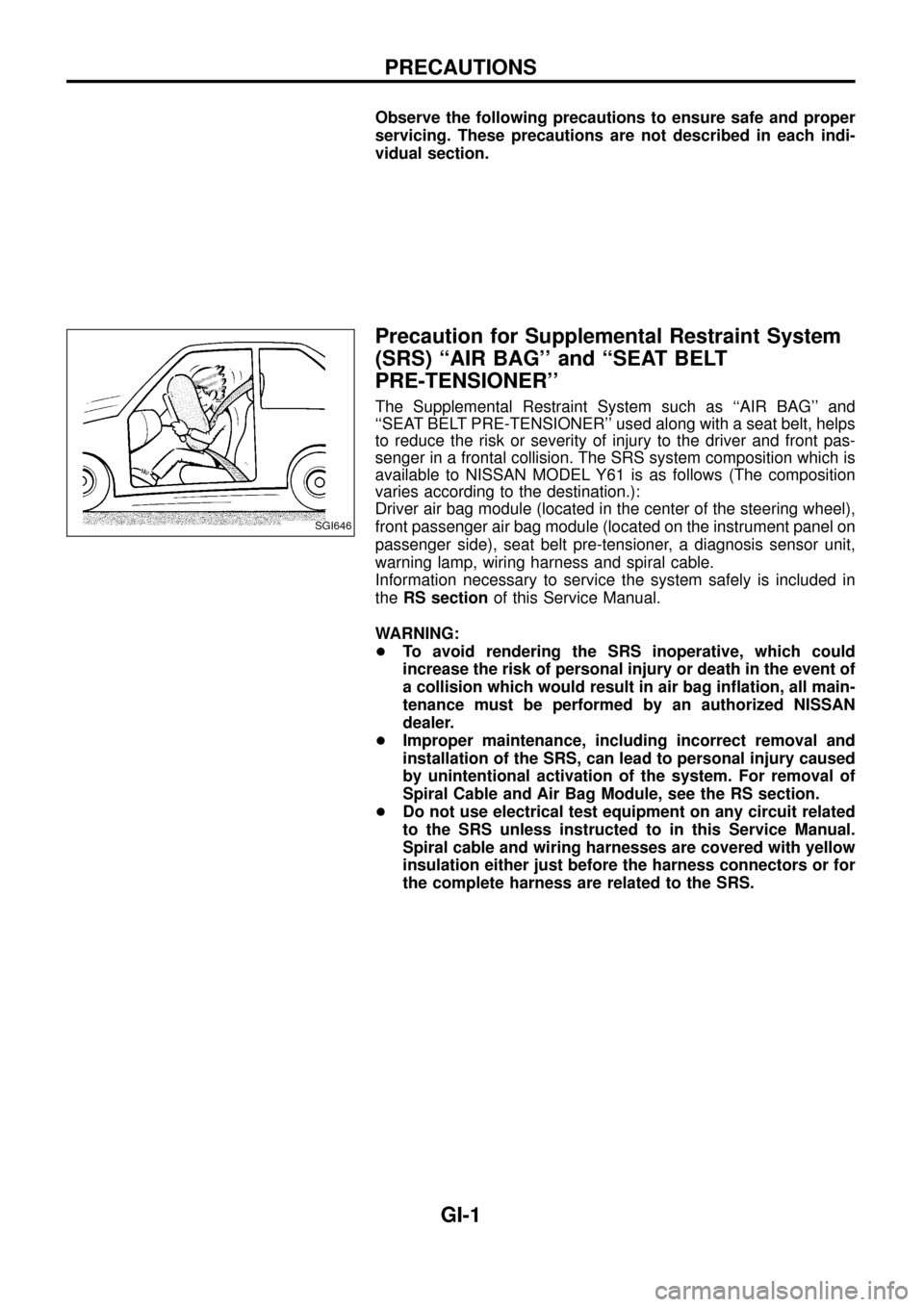

Precaution for Supplemental Restraint System

(SRS) ``AIR BAG'' and ``SEAT BELT

PRE-TENSIONER''

The Supplemental Restraint System such as ``AIR BAG'' and

``SEAT BELT PRE-TENSIONER'' used along with a seat belt, helps

to reduce the risk or severity of injury to the driver and front pas-

senger in a frontal collision. The SRS system composition which is

available to NISSAN MODEL Y61 is as follows (The composition

varies according to the destination.):

Driver air bag module (located in the center of the steering wheel),

front passenger air bag module (located on the instrument panel on

passenger side), seat belt pre-tensioner, a diagnosis sensor unit,

warning lamp, wiring harness and spiral cable.

Information necessary to service the system safely is included in

theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could

increase the risk of personal injury or death in the event of

a collision which would result in air bag in¯ation, all main-

tenance must be performed by an authorized NISSAN

dealer.

+Improper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury caused

by unintentional activation of the system. For removal of

Spiral Cable and Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related

to the SRS unless instructed to in this Service Manual.

Spiral cable and wiring harnesses are covered with yellow

insulation either just before the harness connectors or for

the complete harness are related to the SRS.

SGI646

PRECAUTIONS

GI-1

Page 4 of 47

+Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

+Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

+Replace inner and outer races of tapered roller bearings and

needle bearings as a set.

+Arrange the disassembled parts in accordance with their

assembled locations and sequence.

+Do not touch the terminals of electrical components which use

microcomputers (such as ECMs).

Static electricity may damage internal electronic components.

+After disconnecting vacuum or air hoses, attach a tag to indi-

cate the proper connection.

+Use only the ¯uids and lubricants speci®ed in this manual.

+Use approved bonding agent, sealants or their equivalents

when required.

+Use tools and recommended special tools where speci®ed for

safe and efficient service repairs.

+When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

+Dispose of drained oil or the solvent used for cleaning parts in

an appropriate manner.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do

not carelessly disconnect the harness connectors which are

related to the ECCS system and TCM (Transmission Control

Module) system. The connectors should be disconnected only

when working according to the WORK FLOW of TROUBLE

DIAGNOSES in EC and AT sections.

Precautions for Multiport Fuel Injection System

or ECCS Engine

+Before connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM (Engine Control

Module):

Turn ignition switch to ``OFF'' position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

+

Before disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

+Be careful not to jar components such as ECM and mass air

¯ow sensor.SGI787

PRECAUTIONS

General Precautions (Cont'd)

GI-3

Page 22 of 47

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

+Vehicle vibration

+Heat sensitive

+Freezing

+Water intrusion

+Electrical load

+Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

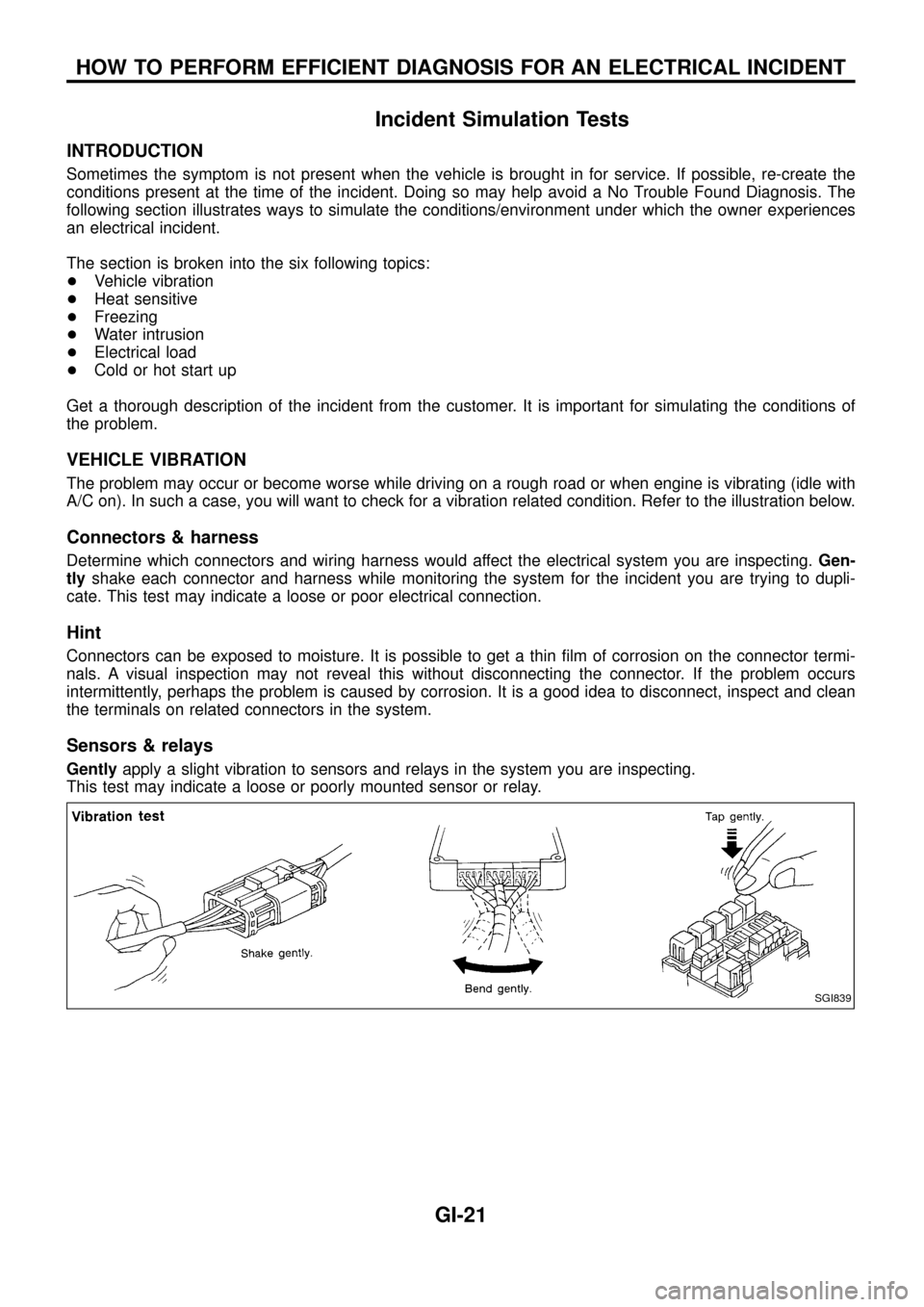

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustration below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting.Gen-

tlyshake each connector and harness while monitoring the system for the incident you are trying to dupli-

cate. This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin ®lm of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-21

Page 44 of 47

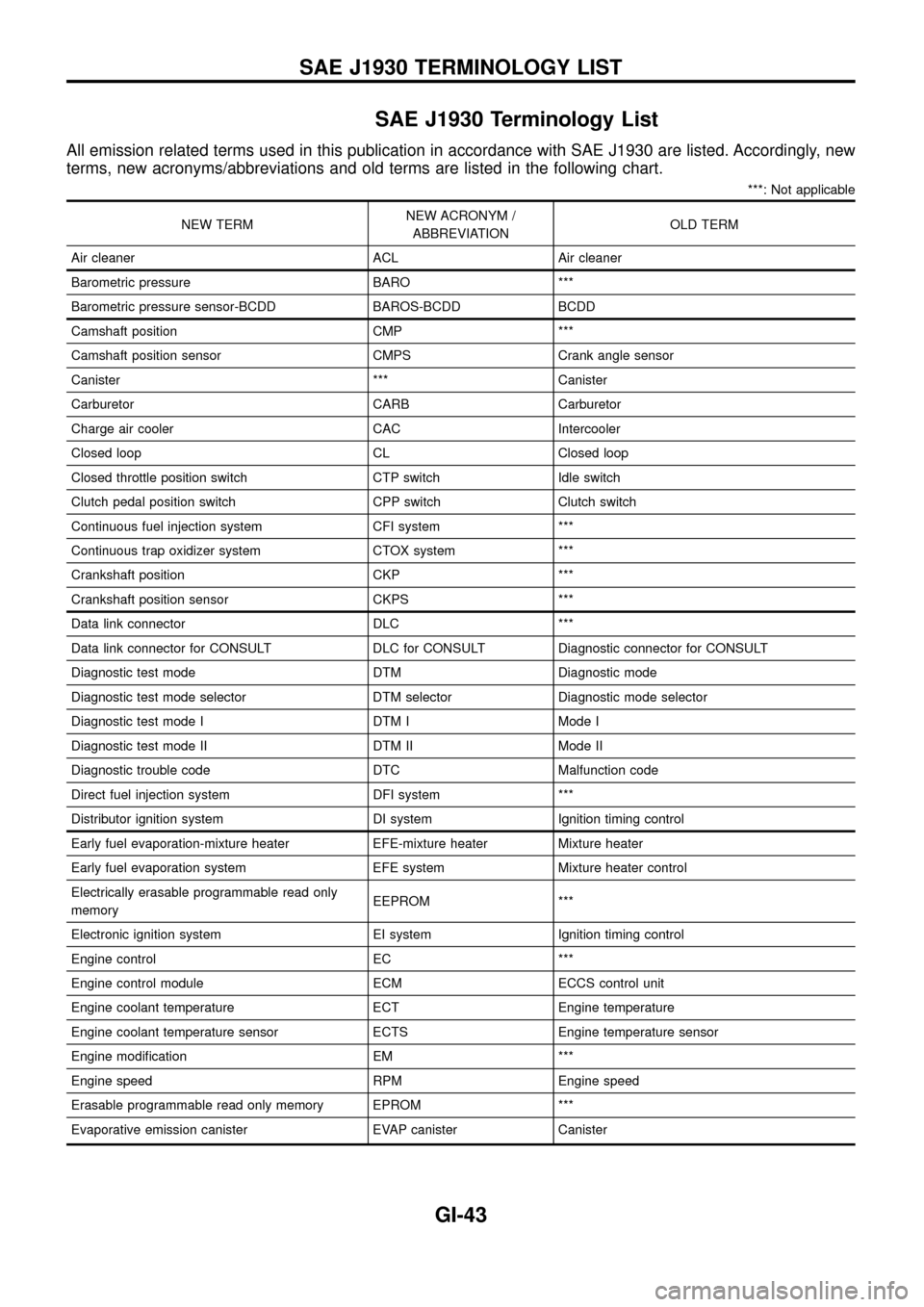

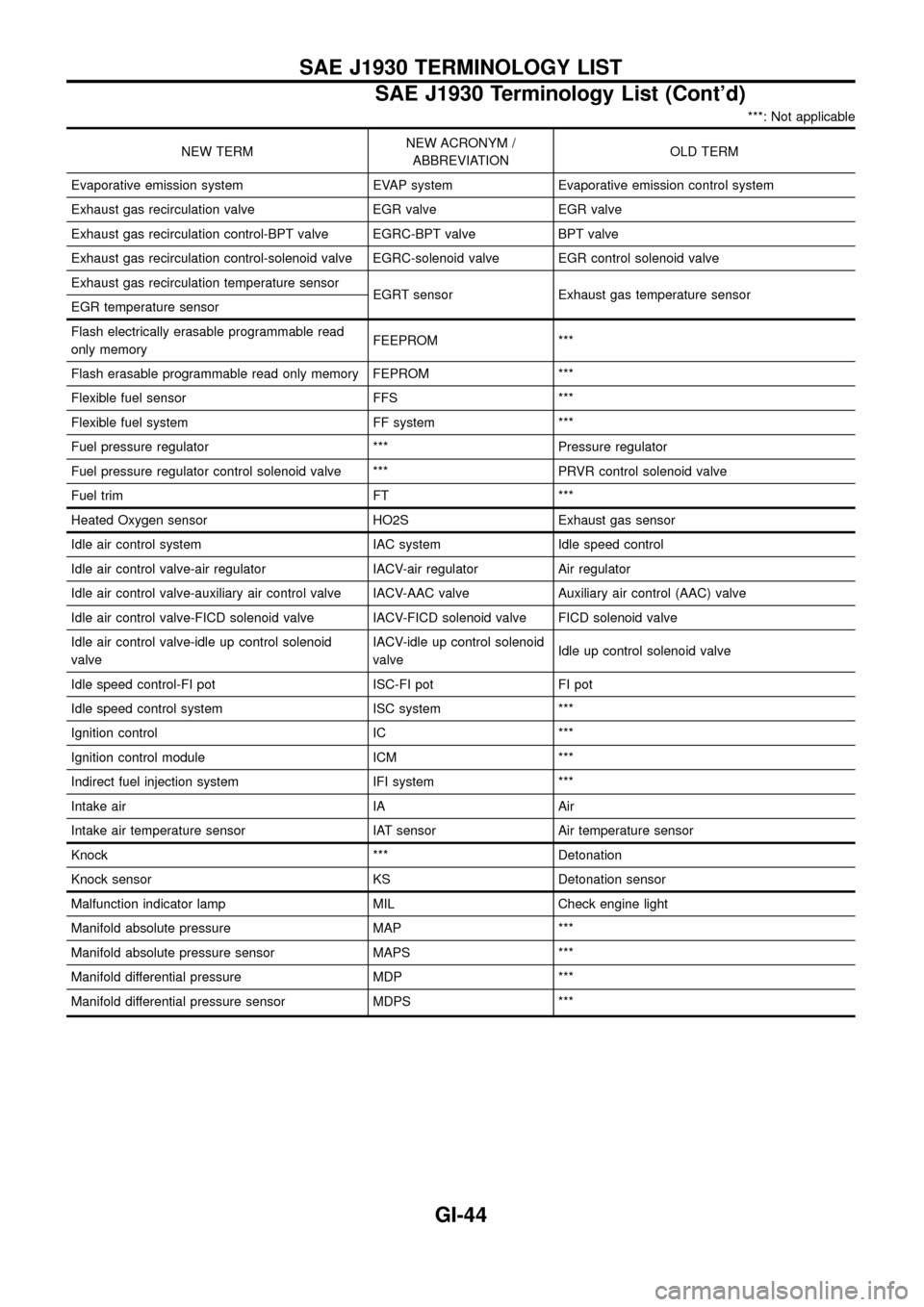

SAE J1930 Terminology List

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Data link connector for CONSULT DLC for CONSULT Diagnostic connector for CONSULT

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read only

memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modi®cation EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

SAE J1930 TERMINOLOGY LIST

GI-43

Page 45 of 47

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Evaporative emission system EVAP system Evaporative emission control system

Exhaust gas recirculation valve EGR valve EGR valve

Exhaust gas recirculation control-BPT valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid valve EGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sensor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable read

only memoryFEEPROM ***

Flash erasable programmable read only memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid valve *** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control valve IACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control solenoid

valveIACV-idle up control solenoid

valveIdle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

SAE J1930 TERMINOLOGY LIST

SAE J1930 Terminology List (Cont'd)

GI-44

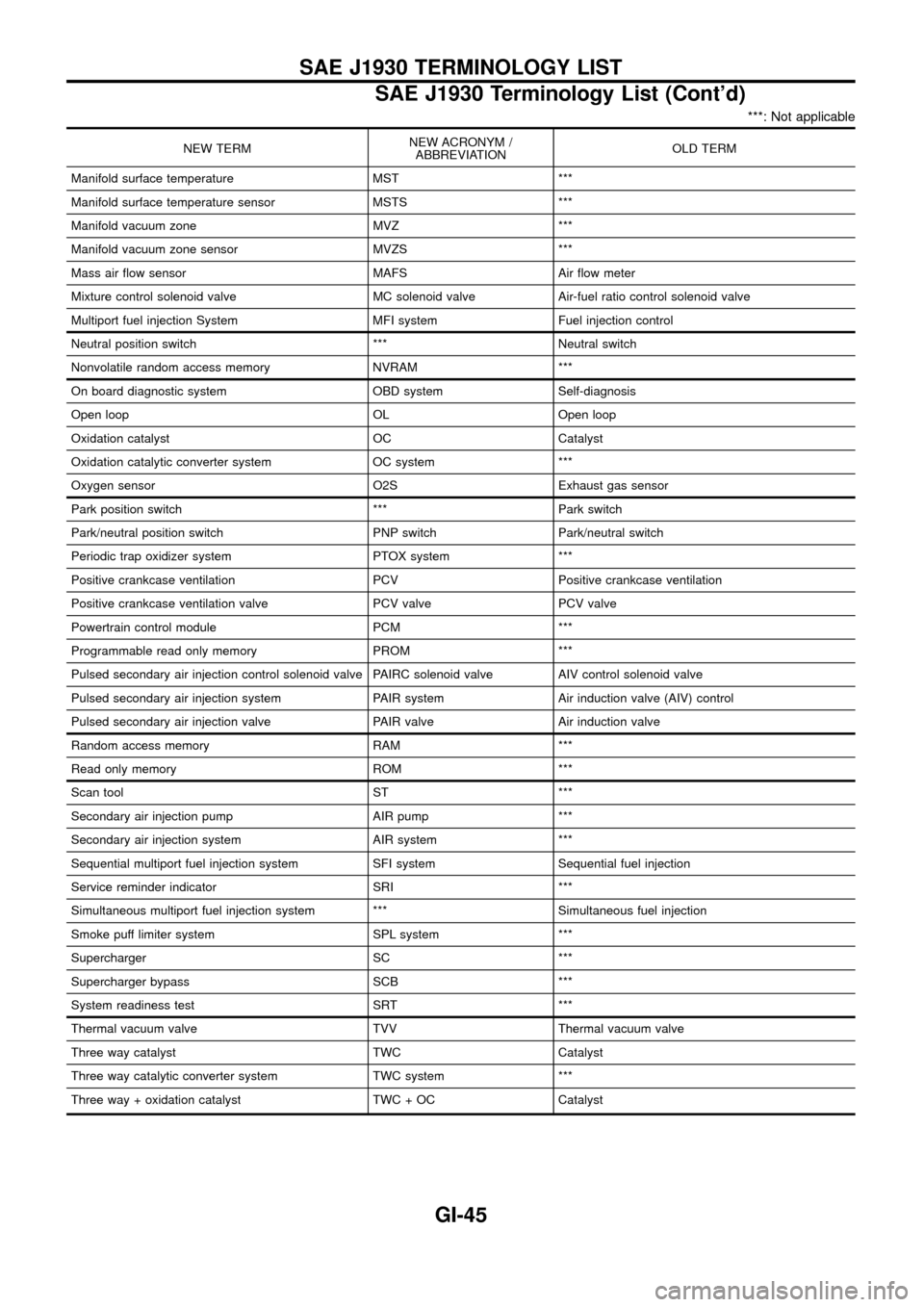

Page 46 of 47

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air ¯ow sensor MAFS Air ¯ow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection System MFI system Fuel injection control

Neutral position switch *** Neutral switch

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switch Park/neutral switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control solenoid valve PAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

Simultaneous multiport fuel injection system *** Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

SAE J1930 TERMINOLOGY LIST

SAE J1930 Terminology List (Cont'd)

GI-45

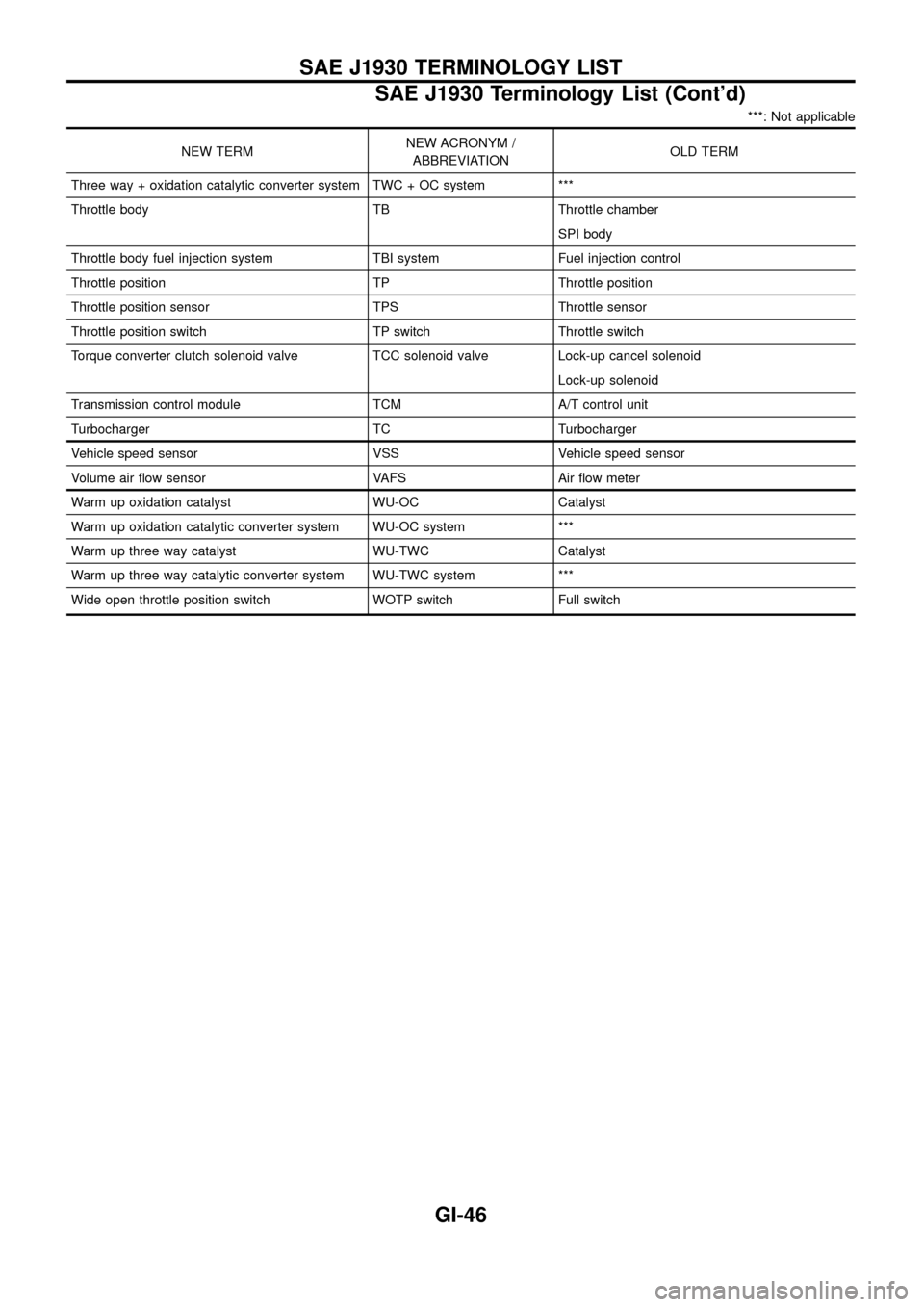

Page 47 of 47

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Three way + oxidation catalytic converter system TWC + OC system ***

Throttle body TB Throttle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valve Lock-up cancel solenoid

Lock-up solenoid

Transmission control module TCM A/T control unit

Turbocharger TC Turbocharger

Vehicle speed sensor VSS Vehicle speed sensor

Volume air ¯ow sensor VAFS Air ¯ow meter

Warm up oxidation catalyst WU-OC Catalyst

Warm up oxidation catalytic converter system WU-OC system ***

Warm up three way catalyst WU-TWC Catalyst

Warm up three way catalytic converter system WU-TWC system ***

Wide open throttle position switch WOTP switch Full switch

SAE J1930 TERMINOLOGY LIST

SAE J1930 Terminology List (Cont'd)

GI-46