sensor NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 439 of 1033

4 CHECK CHARGE AIR PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 46 and charge air pressure sensor terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 5.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

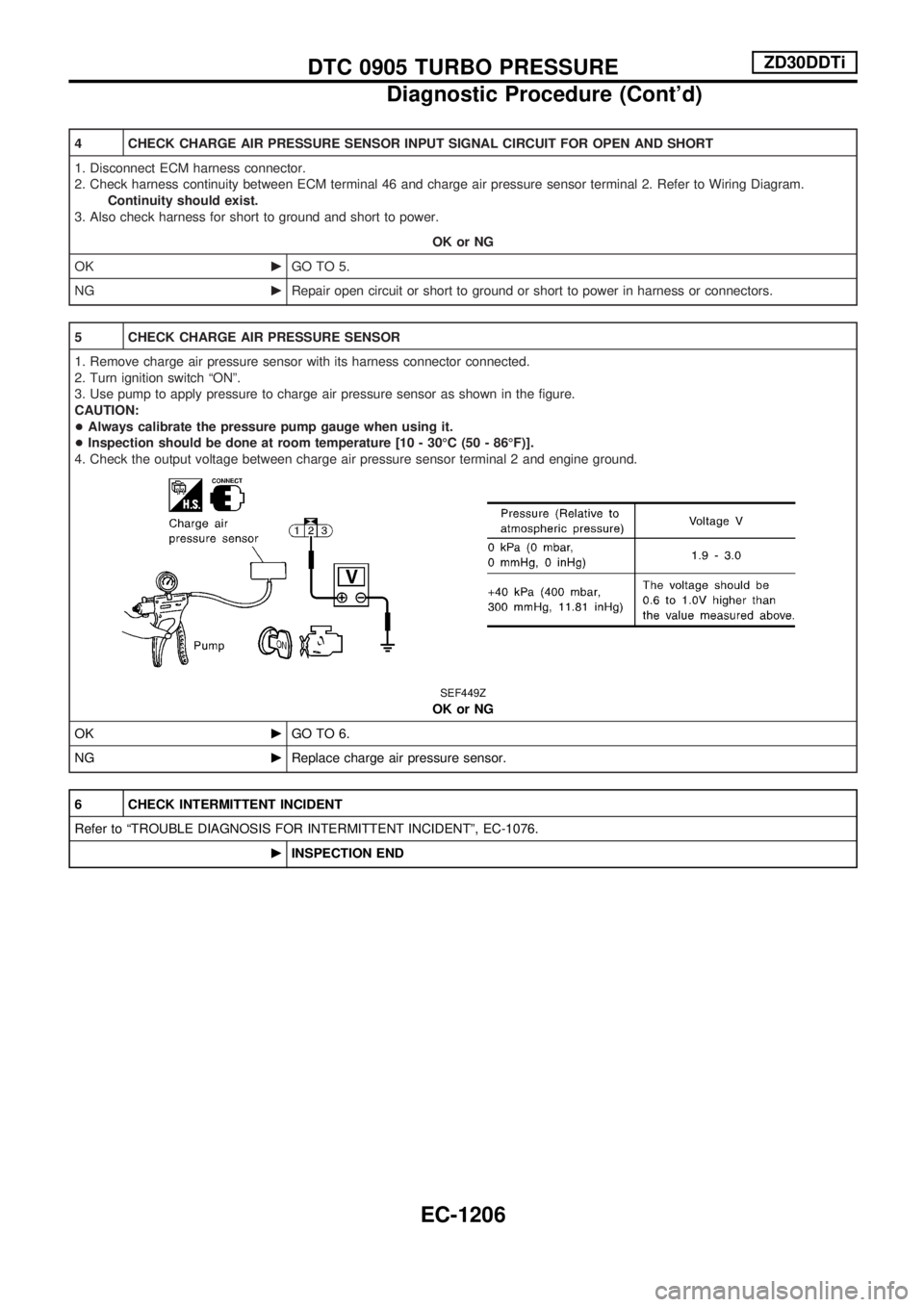

5 CHECK CHARGE AIR PRESSURE SENSOR

1. Remove charge air pressure sensor with its harness connector connected.

2. Turn ignition switch ªONº.

3. Use pump to apply pressure to charge air pressure sensor as shown in the figure.

CAUTION:

+Always calibrate the pressure pump gauge when using it.

+Inspection should be done at room temperature [10 - 30ÉC (50 - 86ÉF)].

4. Check the output voltage between charge air pressure sensor terminal 2 and engine ground.

SEF449Z

OK or NG

OKcGO TO 6.

NGcReplace charge air pressure sensor.

6 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

DTC 0905 TURBO PRESSUREZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1206

Page 440 of 1033

Description

SYSTEM DESCRIPTION

Sensor Input Signal to ECM ECM Function Actuator

Electronic controlled fuel injection pump Fuel injection signal

EGR volume control EGR volume control valve Crankshaft position sensor (TDC) Engine speed

Vehicle speed sensor Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Battery Battery voltage

Mass air flow sensor Amount of intake air

Air conditioner switch Air conditioner operation

Electrical load Electrical load signal

PNP switch Park/Neutral position signal

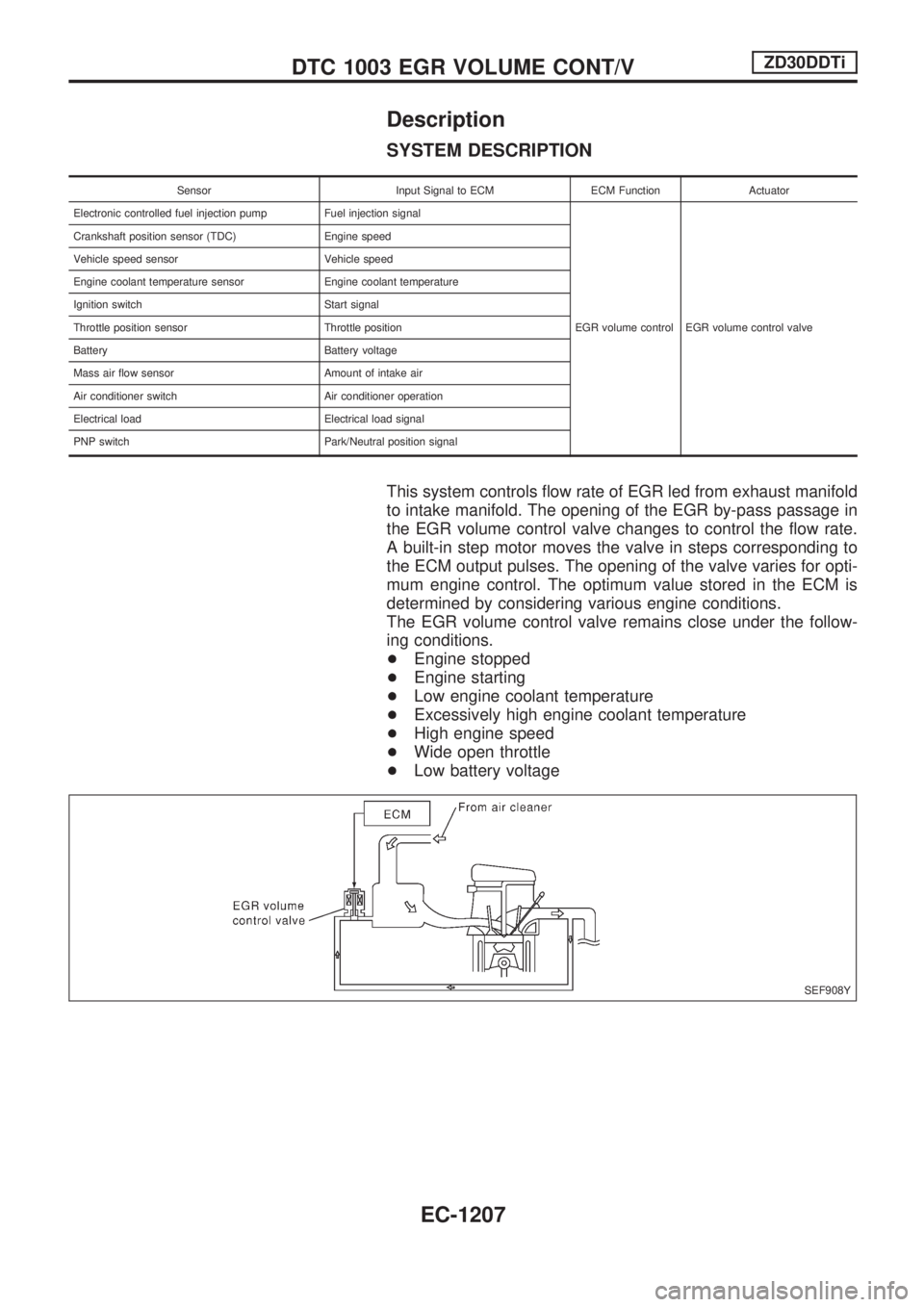

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in

the EGR volume control valve changes to control the flow rate.

A built-in step motor moves the valve in steps corresponding to

the ECM output pulses. The opening of the valve varies for opti-

mum engine control. The optimum value stored in the ECM is

determined by considering various engine conditions.

The EGR volume control valve remains close under the follow-

ing conditions.

+Engine stopped

+Engine starting

+Low engine coolant temperature

+Excessively high engine coolant temperature

+High engine speed

+Wide open throttle

+Low battery voltage

SEF908Y

DTC 1003 EGR VOLUME CONT/VZD30DDTi

EC-1207

Page 448 of 1033

Description

SYSTEM DESCRIPTION

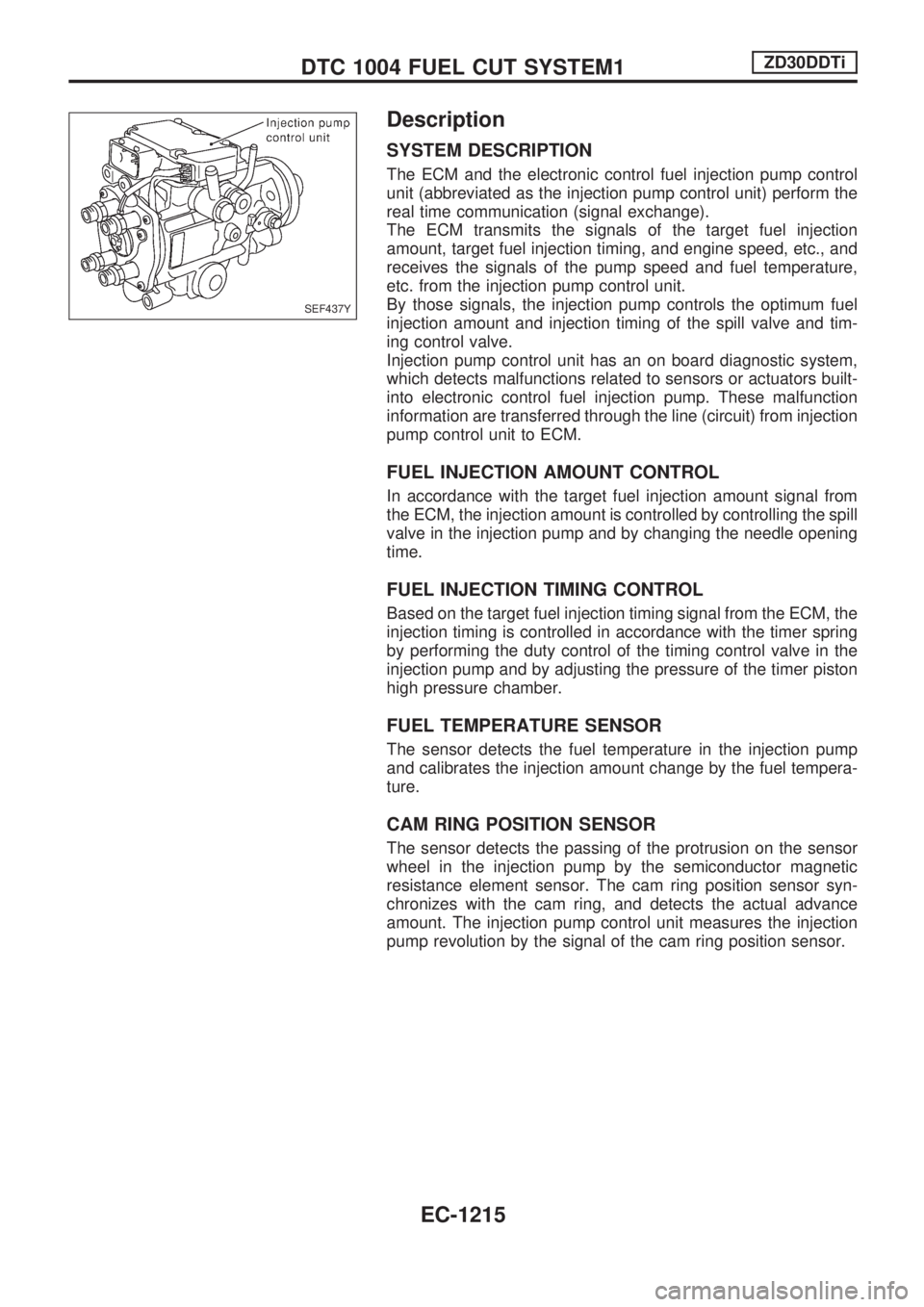

The ECM and the electronic control fuel injection pump control

unit (abbreviated as the injection pump control unit) perform the

real time communication (signal exchange).

The ECM transmits the signals of the target fuel injection

amount, target fuel injection timing, and engine speed, etc., and

receives the signals of the pump speed and fuel temperature,

etc. from the injection pump control unit.

By those signals, the injection pump controls the optimum fuel

injection amount and injection timing of the spill valve and tim-

ing control valve.

Injection pump control unit has an on board diagnostic system,

which detects malfunctions related to sensors or actuators built-

into electronic control fuel injection pump. These malfunction

information are transferred through the line (circuit) from injection

pump control unit to ECM.

FUEL INJECTION AMOUNT CONTROL

In accordance with the target fuel injection amount signal from

the ECM, the injection amount is controlled by controlling the spill

valve in the injection pump and by changing the needle opening

time.

FUEL INJECTION TIMING CONTROL

Based on the target fuel injection timing signal from the ECM, the

injection timing is controlled in accordance with the timer spring

by performing the duty control of the timing control valve in the

injection pump and by adjusting the pressure of the timer piston

high pressure chamber.

FUEL TEMPERATURE SENSOR

The sensor detects the fuel temperature in the injection pump

and calibrates the injection amount change by the fuel tempera-

ture.

CAM RING POSITION SENSOR

The sensor detects the passing of the protrusion on the sensor

wheel in the injection pump by the semiconductor magnetic

resistance element sensor. The cam ring position sensor syn-

chronizes with the cam ring, and detects the actual advance

amount. The injection pump control unit measures the injection

pump revolution by the signal of the cam ring position sensor.

SEF437Y

DTC 1004 FUEL CUT SYSTEM1ZD30DDTi

EC-1215

Page 454 of 1033

Description

SYSTEM DESCRIPTION

Sensor Input Signal to ECMECM

FunctionActuator

Crankshaft position

sensor (TDC)Engine speed

Glow

controlGlow lamp,

Glow relay

¯

Glow plugs Engine coolant tem-

perature sensorEngine coolant tem-

perature

When engine coolant temperature is more than approximately

75ÉC (167ÉF), the glow relay turns off, inactivating the quick-glow

control until coolant temperature drops below approximately

55ÉC (131ÉF).

When coolant temperature is lower than approximately 75ÉC

(167ÉF):

+Ignition switch ON

After ignition switch has turned to ON, the glow relay turns

ON for a certain period of time in relation to engine coolant

temperature, allowing current to flow through glow plug.

+Cranking

The glow relay turns ON, allowing current to flow through

glow plug.

+Starting

After engine has started, current continues to flow through

glow plug (after-glow mode) for a certain period in relation to

engine coolant temperature.

When engine speed exceeds approximately 4,800 rpm, cur-

rent flow through glow plug is interrupted.

The glow indicator lamp turns ON for a certain period of time in

relation to engine coolant temperature at the time glow relay is

turned ON.

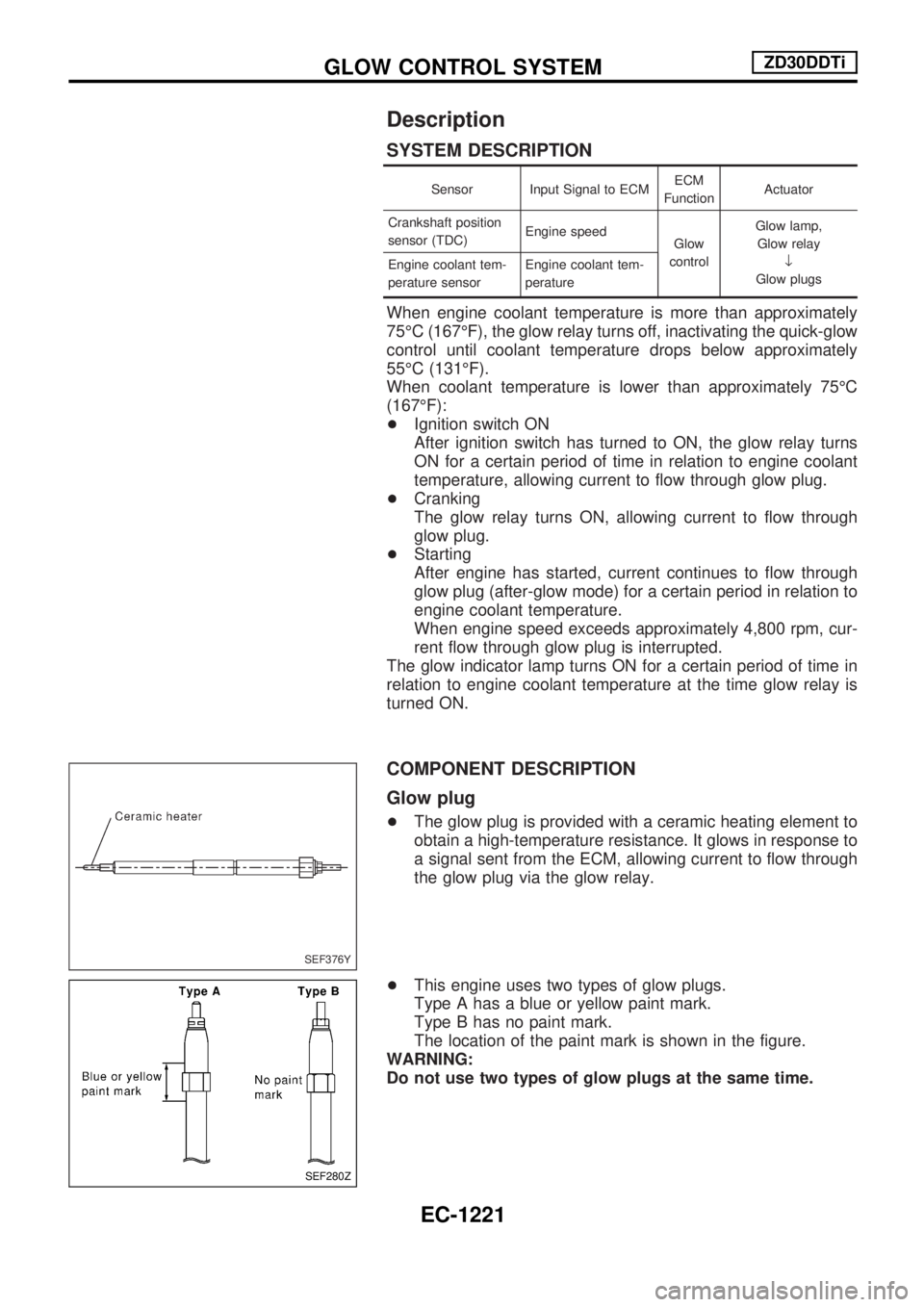

COMPONENT DESCRIPTION

Glow plug

+The glow plug is provided with a ceramic heating element to

obtain a high-temperature resistance. It glows in response to

a signal sent from the ECM, allowing current to flow through

the glow plug via the glow relay.

+This engine uses two types of glow plugs.

Type A has a blue or yellow paint mark.

Type B has no paint mark.

The location of the paint mark is shown in the figure.

WARNING:

Do not use two types of glow plugs at the same time.

SEF376Y

SEF280Z

GLOW CONTROL SYSTEMZD30DDTi

EC-1221

Page 479 of 1033

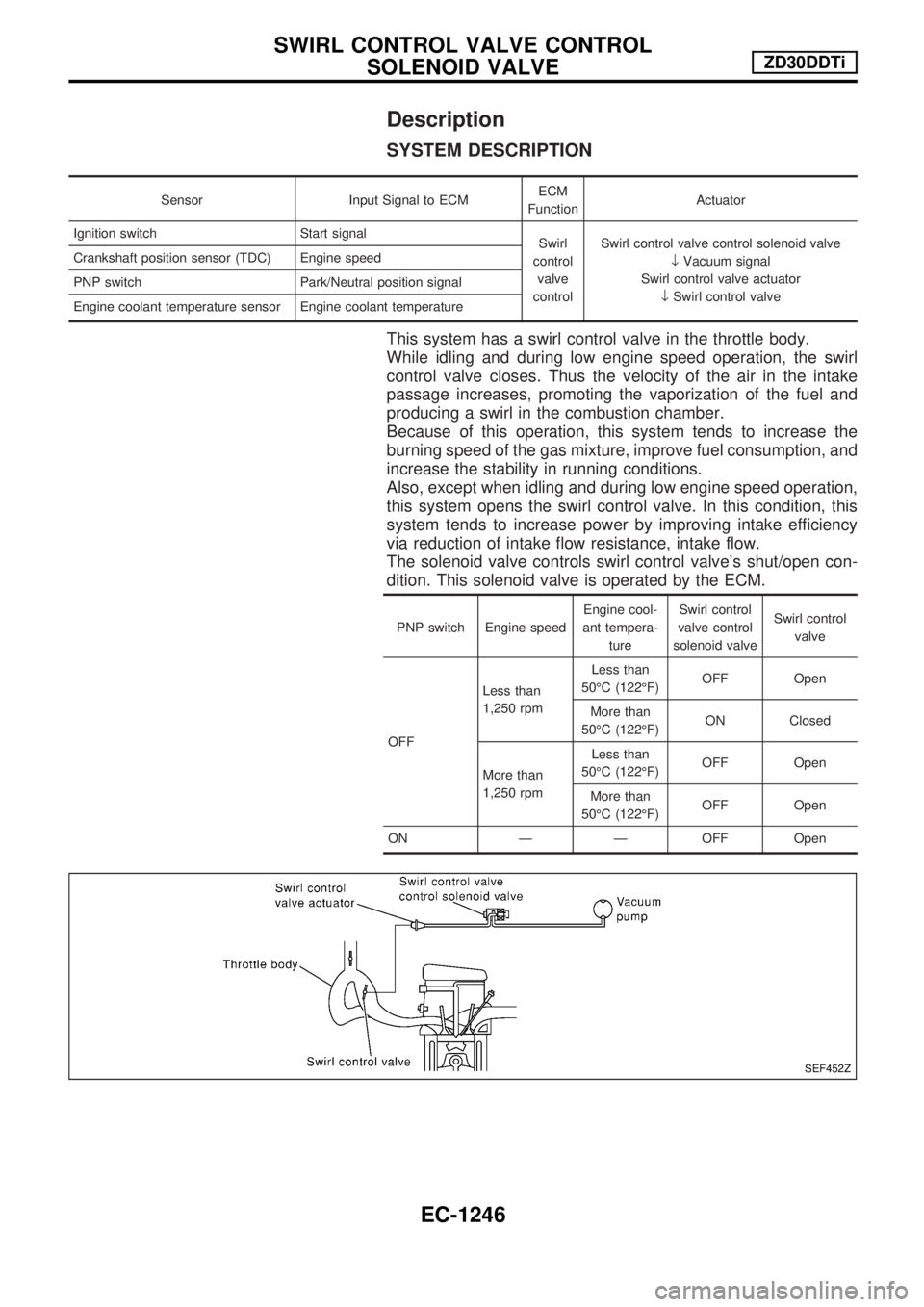

Description

SYSTEM DESCRIPTION

Sensor Input Signal to ECMECM

FunctionActuator

Ignition switch Start signal

Swirl

control

valve

controlSwirl control valve control solenoid valve

¯Vacuum signal

Swirl control valve actuator

¯Swirl control valve Crankshaft position sensor (TDC) Engine speed

PNP switch Park/Neutral position signal

Engine coolant temperature sensor Engine coolant temperature

This system has a swirl control valve in the throttle body.

While idling and during low engine speed operation, the swirl

control valve closes. Thus the velocity of the air in the intake

passage increases, promoting the vaporization of the fuel and

producing a swirl in the combustion chamber.

Because of this operation, this system tends to increase the

burning speed of the gas mixture, improve fuel consumption, and

increase the stability in running conditions.

Also, except when idling and during low engine speed operation,

this system opens the swirl control valve. In this condition, this

system tends to increase power by improving intake efficiency

via reduction of intake flow resistance, intake flow.

The solenoid valve controls swirl control valve's shut/open con-

dition. This solenoid valve is operated by the ECM.

PNP switch Engine speedEngine cool-

ant tempera-

tureSwirl control

valve control

solenoid valveSwirl control

valve

OFFLess than

1,250 rpmLess than

50ÉC (122ÉF)OFF Open

More than

50ÉC (122ÉF)ON Closed

More than

1,250 rpmLess than

50ÉC (122ÉF)OFF Open

More than

50ÉC (122ÉF)OFF Open

ON Ð Ð OFF Open

SEF452Z

SWIRL CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

EC-1246

Page 510 of 1033

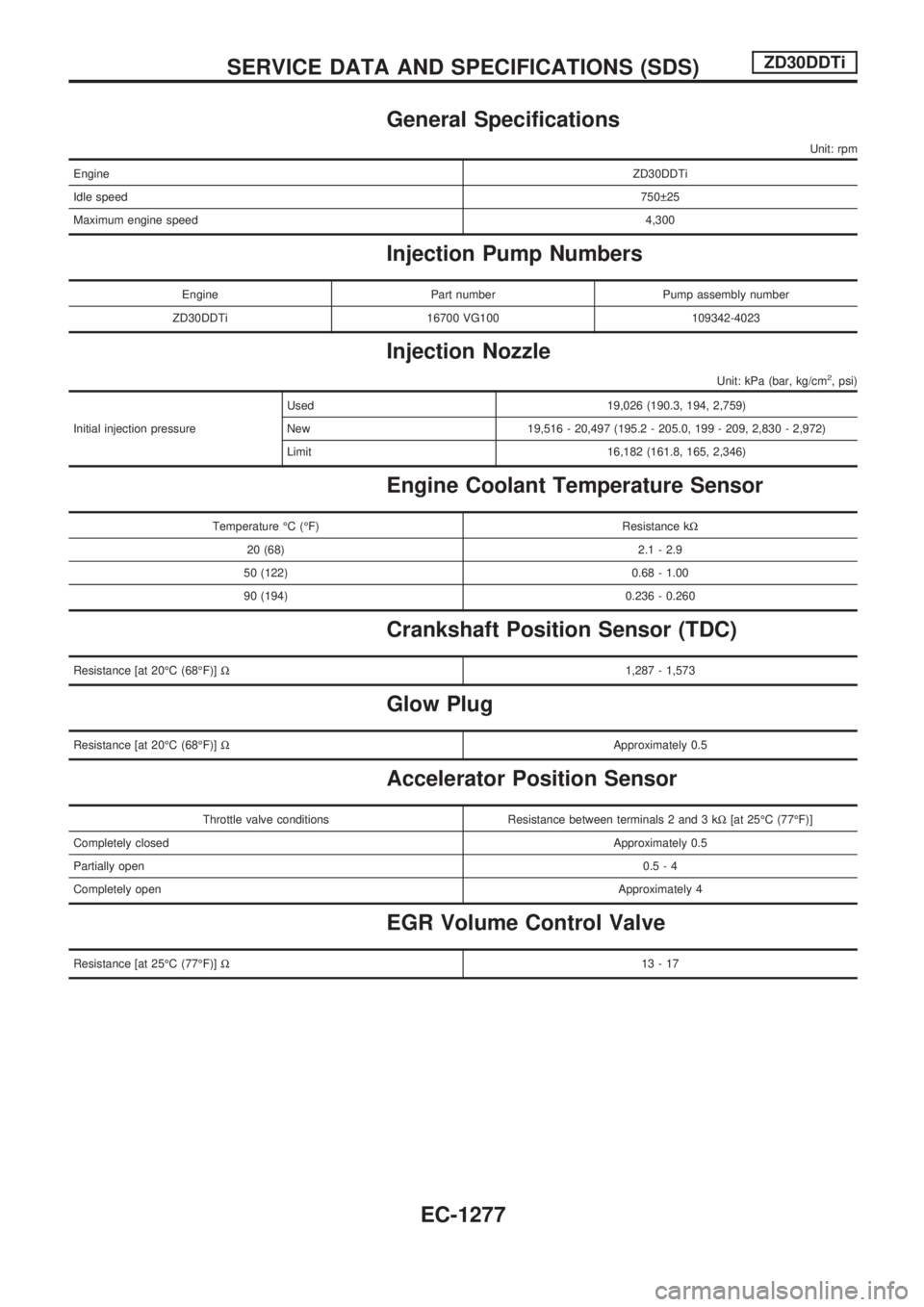

General Specifications

Unit: rpm

EngineZD30DDTi

Idle speed750 25

Maximum engine speed4,300

Injection Pump Numbers

Engine Part number Pump assembly number

ZD30DDTi 16700 VG100 109342-4023

Injection Nozzle

Unit: kPa (bar, kg/cm2, psi)

Initial injection pressureUsed 19,026 (190.3, 194, 2,759)

New 19,516 - 20,497 (195.2 - 205.0, 199 - 209, 2,830 - 2,972)

Limit 16,182 (161.8, 165, 2,346)

Engine Coolant Temperature Sensor

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

Crankshaft Position Sensor (TDC)

Resistance [at 20ÉC (68ÉF)]W1,287 - 1,573

Glow Plug

Resistance [at 20ÉC (68ÉF)]WApproximately 0.5

Accelerator Position Sensor

Throttle valve conditions Resistance between terminals 2 and 3 kW[at 25ÉC (77ÉF)]

Completely closedApproximately 0.5

Partially open0.5-4

Completely openApproximately 4

EGR Volume Control Valve

Resistance [at 25ÉC (77ÉF)]W13-17

SERVICE DATA AND SPECIFICATIONS (SDS)ZD30DDTi

EC-1277

Page 513 of 1033

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The

composition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and

Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS AND PREPARATION

EL-1003

Page 577 of 1033

![NISSAN PATROL 2000 Electronic Repair Manual System Description

POWER SUPPLY AND GROUND

Power is supplied at all times:

+through 10A fuse [No.

20, located in the fuse block (J/B)]

+to front and rear interior room lamp terminal

V1

+through 7.5A f NISSAN PATROL 2000 Electronic Repair Manual System Description

POWER SUPPLY AND GROUND

Power is supplied at all times:

+through 10A fuse [No.

20, located in the fuse block (J/B)]

+to front and rear interior room lamp terminal

V1

+through 7.5A f](/img/5/57367/w960_57367-576.png)

System Description

POWER SUPPLY AND GROUND

Power is supplied at all times:

+through 10A fuse [No.

20, located in the fuse block (J/B)]

+to front and rear interior room lamp terminal

V1

+through 7.5A fuse [No.24, located in the fuse block (J/B)]

+to key switch terminal

V2and

+to super lock control unit terminal

V1.

When the key is removed from ignition key cylinder, power is interrupted:

+through key switch terminal

V1

+to super lock control unit terminalV18.

With the ignition key switch in the ON or START position, power is supplied:

+through 10A fuse [No.

25, located in the fuse block (J/B)]

+to super lock control unit terminal

V17.

Ground is supplied:

+to super lock control unit terminal

V16

+through body grounds terminalsM30andM19(LHD models) orM98(RHD models).

When the front driver side door is opened, ground is supplied:

+through body grounds

B23andM19(LHD models) orM98(RHD models).

+to front door switch (driver side) terminal

V3

+from front door switch (driver side) terminalV1

+to super lock control unit terminalV30.

When any other door is opened, ground is supplied to super lock control unit terminal

V31in the same man-

ner as the driver door switch.

When the front driver side door is unlocked, the super lock control unit receives a ground signal:

+through body grounds terminals

M30andM19(LHD models) orM98(RHD models).

+to front door lock actuator (driver side) (door unlock sensor) terminal

V5

+from front door lock actuator (driver side) (door unlock sensor) terminalV2

+to super lock control unit terminalV28.

When a signal, or combination of signals is received by the super lock control unit, ground is supplied:

+through super lock control unit terminal

V26

+to front interior room lamp terminalV2.

With power and ground supplied, the front interior room lamp illuminates.

INTERIOR ROOM LAMP TIMER OPERATION

When front interior room lamp switch is in the ªDOORº position, the super lock control unit keeps the front

interior room lamp illuminated for about 30 seconds when:

+unlock signal is supplied from driver's door unlock sensor while all doors are closed and key is out of

ignition key cylinder

+key is removed from ignition key cylinder while all doors are closed

+driver's door is opened and then closed while key is out of the ignition key cylinder. (However, if the

driver's door is closed with the key inserted in the ignition key cylinder after the driver's door is opened

with the key removed, the timer is operated.)

The timer is canceled when:

+driver's door is locked or

+ignition switch is turned ON.

ON-OFF CONTROL

When the driver side door, front passenger door, rear LH or RH door, back door LH or RH is opened, the

interior room lamp turns on while the interior room lamp switch is in the ªDOORº position.

INTERIOR ROOM LAMP

EL-1067

Page 601 of 1033

System Description

The warning chime is combined with the super lock control unit.

Both the ignition key and light warning chime will not sound, when ignition switch in the ON or START posi-

tion (when power supply exists at super lock control unit terminal

V17).

IGNITION KEY WARNING CHIME

With the key in the ignition key cylinder, the ignition switch in the OFF or ACC position, and the driver's door

open and locked, the warning chime will sound. Power is supplied

+from key switch terminal

V1

+to super lock control unit terminalV18.

Ground is supplied

+through driver front door switch terminal

V1

+to super lock control unit terminalV30, and

+through front door lock actuator assembly (driver side) (unlock sensor) terminal

V2

+to super lock control unit terminalV28.

LIGHT WARNING CHIME

With ignition switch in the OFF or ACC position, driver's door open, and lighting switch in 1ST or 2ND

position, warning chime will sound. Power is supplied

+from combination switch terminal

V12

+to super lock control unit terminalV19.

Ground is supplied

+through driver front door switch terminal

V1

+to super lock control unit terminalV30.

WARNING CHIME

EL-1091

Page 604 of 1033

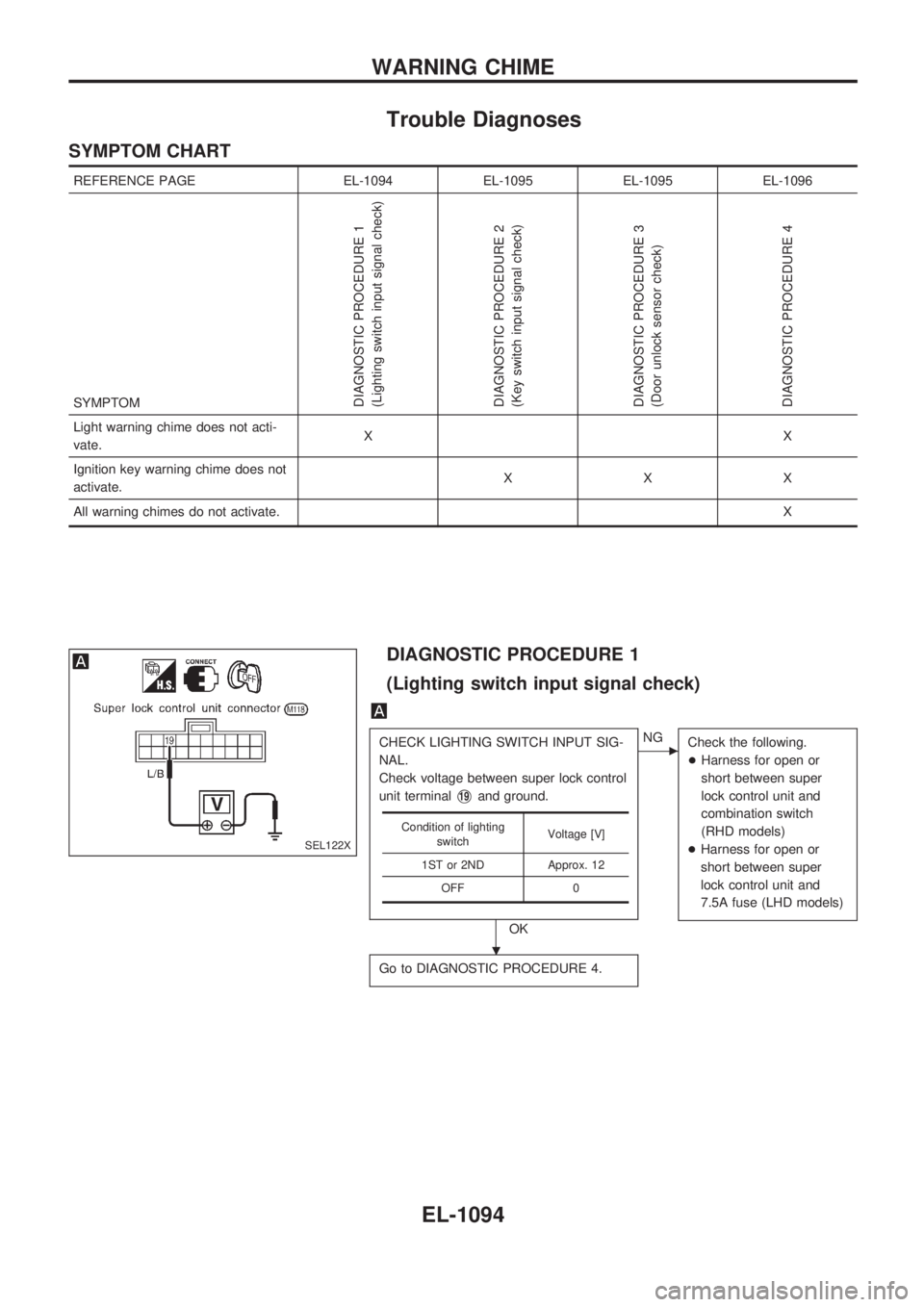

Trouble Diagnoses

SYMPTOM CHART

REFERENCE PAGE EL-1094 EL-1095 EL-1095 EL-1096

SYMPTOM

DIAGNOSTIC PROCEDURE 1

(Lighting switch input signal check)

DIAGNOSTIC PROCEDURE 2

(Key switch input signal check)

DIAGNOSTIC PROCEDURE 3

(Door unlock sensor check)

DIAGNOSTIC PROCEDURE 4

Light warning chime does not acti-

vate.XX

Ignition key warning chime does not

activate.XXX

All warning chimes do not activate.X

DIAGNOSTIC PROCEDURE 1

(Lighting switch input signal check)

CHECK LIGHTING SWITCH INPUT SIG-

NAL.

Check voltage between super lock control

unit terminal

V19and ground.

OK

cNG

Check the following.

+Harness for open or

short between super

lock control unit and

combination switch

(RHD models)

+Harness for open or

short between super

lock control unit and

7.5A fuse (LHD models)

Go to DIAGNOSTIC PROCEDURE 4.

Condition of lighting

switchVoltage [V]

1ST or 2ND Approx. 12

OFF 0

SEL122X

.

WARNING CHIME

EL-1094