sensor NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 882 of 1033

O

Oil change (capacity) ............................ MA-1008

Oil pan (engine) .................................... EM-1022

Oil pump (A/T) ....................................... AT-1144

Oil seal replacement (engine) .............. EM-1051

On board diagnostic system ................. EC-1032

Operating cylinder (clutch) .................... CL-1003

Outside mirror ........................................ BT-1007

Overdrive control switch ........................ AT-1095

Overrun clutch solenoid valve ............... AT-1075

Overrun clutch ....................................... AT-1167

Oversize piston ..................................... EM-1075

P

P/ANT - Wiring diagram ........................ EL-1109

PCV (positive crankcase ventilation) .... EC-1022

PNP/SW - Wiring diagram .................... EC-1233

POWER - Wiring diagram ..................... EL-1005

Park/Neutral position switch ................. EC-1233

Park/neutral position switch (A/T) ......... AT-1095

Parking lamp .......................................... EL-1046

Pilot bushing replacement - See Pilot

converter ........................................... EM-1083

Piston pin inspection ............................ EM-1072

Piston ring inspection ........................... EM-1073

Piston to bore clearance ...................... EM-1076

Power antenna ...................................... EL-1109

Power supply routing ............................. EL-1004

Power window ....................................... EL-1115

Pressure test (A/T) ................................ AT-1044

Priming pump ........................................ EC-1049

Propeller shaft on vehicle service ......... PD-1003

Propeller shaft vibration ........................ PD-1003

Propeller shaft ....................................... PD-1002

Q

Quick-glow system ................................ EC-1221

R

R/COOL - Wiring diagram

(front auto A/C) ....................... HA-1013, 1017

R/COOL - Wiring diagram (front

manual A/C) ...................................... HA-1019

R/HEAT - Wiring diagram ..................... HA-1006

ROOM/L - Wiring diagram ..................... EL-1068

Radio - See Audio ................................. EL-1108

Rear cooler - Wiring diagram (front

auto A/C) ................................. HA-1013, 1017

Rear cooler - Wiring diagram (front

manual A/C) ...................................... HA-1019

Rear fog lamp ........................................ EL-1053

Rear heater - Wiring diagram ............... HA-1006Rear window defogger .......................... EL-1101

Refrigerant lines .................................... HA-1021

Removal and installation (A/T) .............. AT-1127

Reverse clutch ....................................... AT-1161

Revolution sensor (A/T) ........................ AT-1065

Room lamp - See Interior lamp ............. EL-1067

S

S/LOCK - Wiring diagram ...................... EL-1128

S/TANK - Wiring diagram ...................... FE-1003

SHIFT - Wiring diagram ........................ AT-1117

SRS - See Supplemental Restraint

System .............................................. RS-1003

STAB - Wiring diagram ......................... RA-1002

START - Wiring diagram ....................... EL-1036

SWL/V - Wiring diagram ....................... EC-1248

Screw jack .............................................. GI-1009

Seat belt pre-tensioner disposal ........... RS-1015

Seat belt pre-tensioner ......................... RS-1003

Seat, front .............................................. BT-1006

Self-diagnostic results ........................... EC-1034

Shift lock system ................................... AT-1116

Shift schedule ........................................ AT-1206

Shift solenoid valve A (A/T) .................. AT-1071

Shift solenoid valve B (A/T) .................. AT-1073

Side air bag ........................................... RS-1003

Speedometer ......................................... EL-1073

Spiral cable ........................................... RS-1009

Stabilizer release device - Wiring

diagram ............................................. RA-1002

Stabilizer release device ....................... RA-1002

Stall test (A/T) ....................................... AT-1041

Start signal ............................................ EC-1230

Starter .................................................... EL-1039

Starting system ...................................... EL-1036

Steering switch ...................................... EL-1043

Stop lamp .............................................. EL-1050

Super lock ................................... EL-1124, 1159

Supplemental Restraint System ........... RS-1003

Supplemental restraint system - Wiring

diagram ................................... RS-1024, 1028

Swirl control valve control solenoid

valve .................................................. EC-1246

Symptom matrix chart ........................... EC-1055

T

TCM circuit diagram .............................. AT-1008

TCM inspection table ............................ AT-1060

Tachometer ............................................ EL-1073

Tail lamp ................................................ EL-1046

Throttle position switch .......................... AT-1096

Timing chain ......................................... EM-1027

Timing gear ........................................... EM-1039

Torque converter clutch solenoid

valve .................................................. AT-1078

Torque converter installation ................. AT-1128

ALPHABETICAL INDEX

IDX-1004

Page 883 of 1033

Tow truck towing .......................... GI-1009, 1010

Towing point ........................................... GI-1010

Trim ....................................................... BT-1004

Turbocharger charge air cooler ............ EM-1011

Turbocharger ........................................ EM-1014

Turn signal lamp .................................... EL-1058

V

VSS - Wiring diagram ........................... EC-1096

Vacuum hose drawing (Engine

control) ............................................... EC-1017

Valve clearance .................................... EM-1036

Valve guide ........................................... EM-1060

Valve lifter ............................................. EM-1033

Valve seat ............................................. EM-1061Valve spring .......................................... EM-1062

Vehicle identification number ....... GI-1005, 1007

Vehicle speed sensor (VSS) ................. EC-1096

W

WARN - Wiring diagram ........................ EL-1080

WINDOW - Wiring diagram ................... EL-1117

WIPER - Wiring diagram ....................... EL-1098

Warning chime ....................................... EL-1091

Warning lamps ....................................... EL-1078

Washer, front ......................................... EL-1098

Water temperature gauge ..................... EL-1073

Wiper, front ............................................ EL-1098

ALPHABETICAL INDEX

IDX-1005

Page 893 of 1033

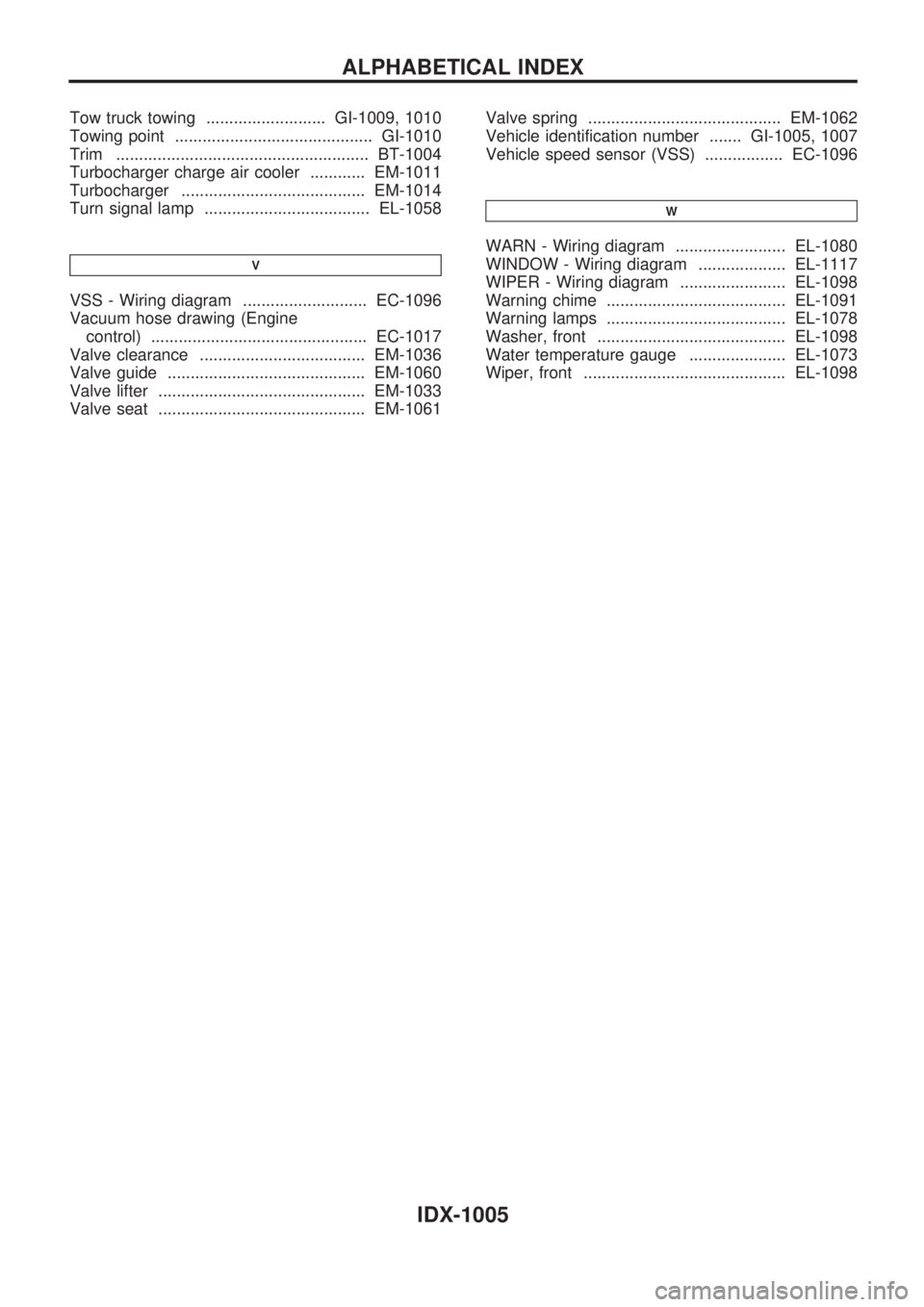

Water Pump

CAUTION:

+When removing water pump assembly, be careful not to

get coolant on drive belt.

+Water pump cannot be disassembled and should be

replaced as a unit.

+Always replace with new gasket.

+After installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

Refer to MA section.

REMOVAL AND INSTALLATION

1. Drain coolant from radiator and cylinder block.

Refer to MA section (ªChanging Engine Coolantº, ªENGINE

MAINTENANCEº).

2. Remove radiator upper hose.

3. Remove radiator shroud.

4. Remove cooling fan.

5. Remove drive belt. Refer to MA section, ªChecking Drive

Beltº.

6. Remove insulator.

7. Remove vacuum pipe.

8. Remove TDC sensor. Refer to TDC sensor removal and

installation in ªTIMING GEARº.

9. Remove fan coupling with water pump.

10. Install in the reverse order of removal.

JLC373B

ENGINE COOLING SYSTEMZD

LC-1010

Page 915 of 1033

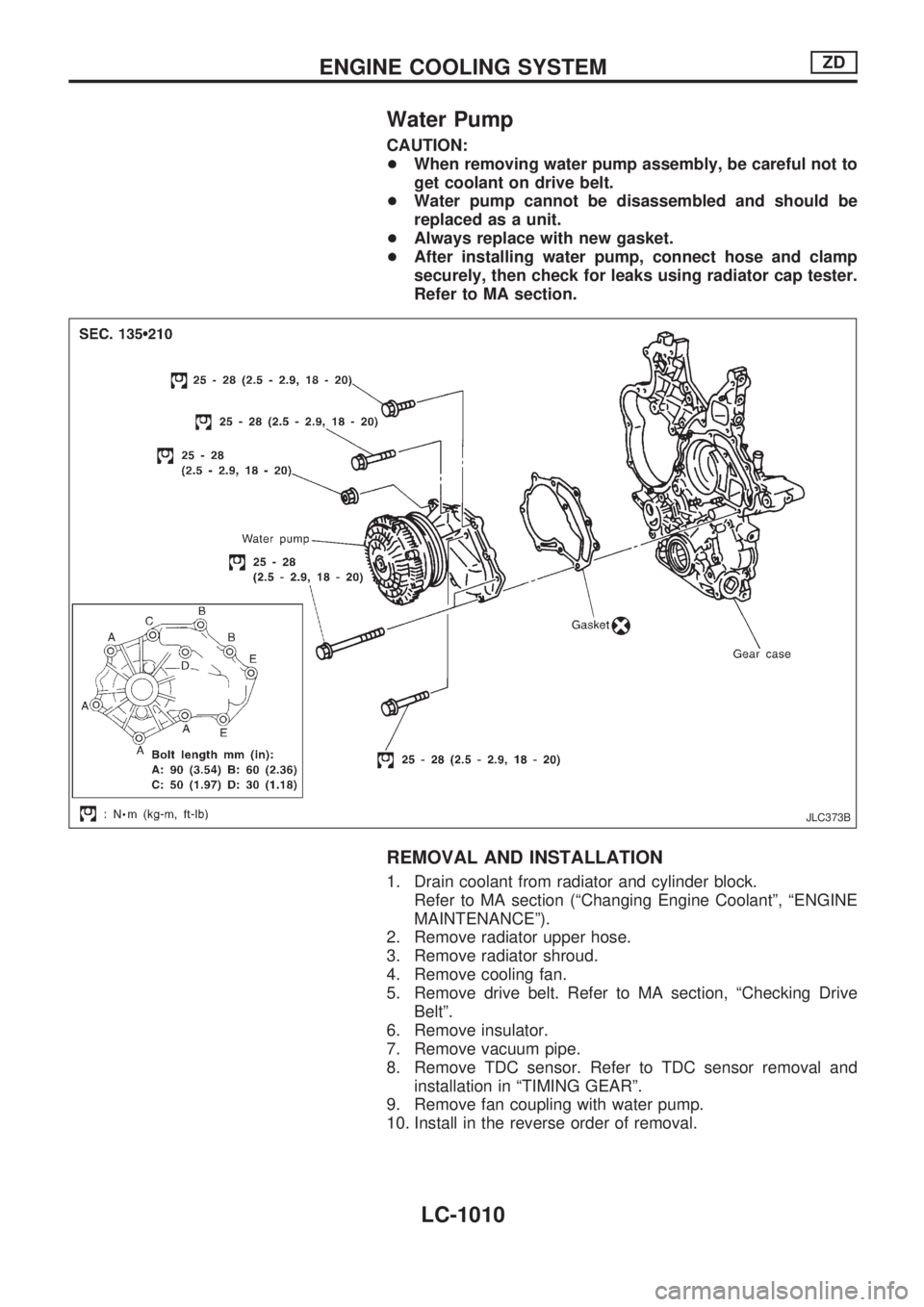

Pull the negative-pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system with cap tester to check for

leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Use of higher pressure than the specified value may cause

damage to radiator.

Checking and Replacing Fuel Filter and

Draining Water

Be careful not to spill fuel in engine compartment. Place a

rag to absorb fuel.

CHECKING FUEL FILTER

Check fuel filter for fuel leakage, damage and other abnormal

signs.

REPLACING FUEL FILTER

1. Disconnect harness connector and drain fuel.

2. Remove fuel filter using band-type filter wrench.

3. Remove fuel filter and fuel filter sensor.

CAUTION:

Remove fuel filter without spilling fuel. If spilt, wipe off

immediately. Be specially careful not to spill fuel on engine

mount insulator.

SMA871B

JMA109D

JMA110D

DMA011

SMA111D

ENGINE MAINTENANCEZD

Checking Cooling System (Cont'd)

MA-1017

Page 916 of 1033

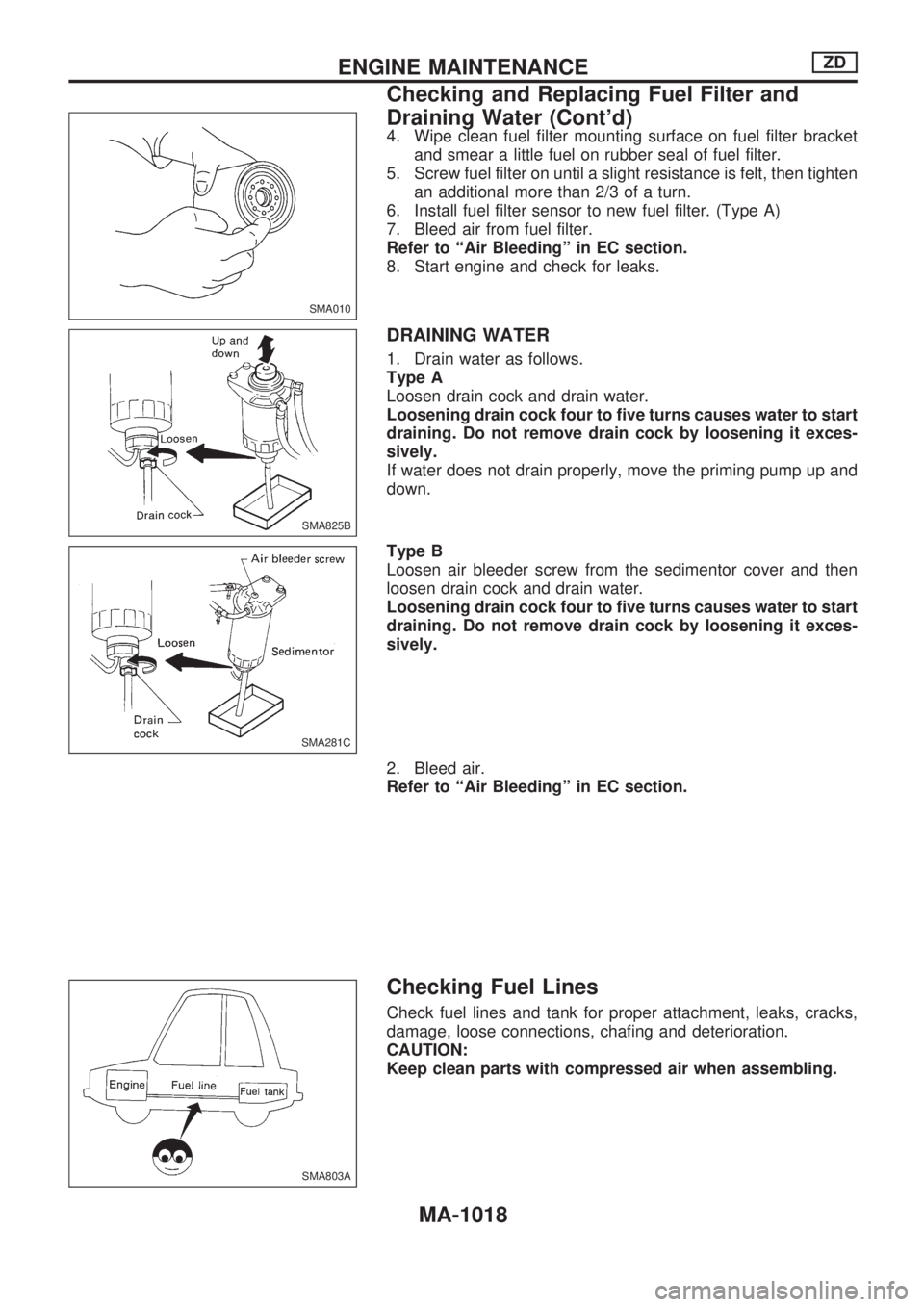

4. Wipe clean fuel filter mounting surface on fuel filter bracket

and smear a little fuel on rubber seal of fuel filter.

5. Screw fuel filter on until a slight resistance is felt, then tighten

an additional more than 2/3 of a turn.

6. Install fuel filter sensor to new fuel filter. (Type A)

7. Bleed air from fuel filter.

Refer to ªAir Bleedingº in EC section.

8. Start engine and check for leaks.

DRAINING WATER

1. Drain water as follows.

Type A

Loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

If water does not drain properly, move the priming pump up and

down.

Type B

Loosen air bleeder screw from the sedimentor cover and then

loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

2. Bleed air.

Refer to ªAir Bleedingº in EC section.

Checking Fuel Lines

Check fuel lines and tank for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CAUTION:

Keep clean parts with compressed air when assembling.

SMA010

SMA825B

SMA281C

SMA803A

ENGINE MAINTENANCEZD

Checking and Replacing Fuel Filter and

Draining Water (Cont'd)

MA-1018

Page 927 of 1033

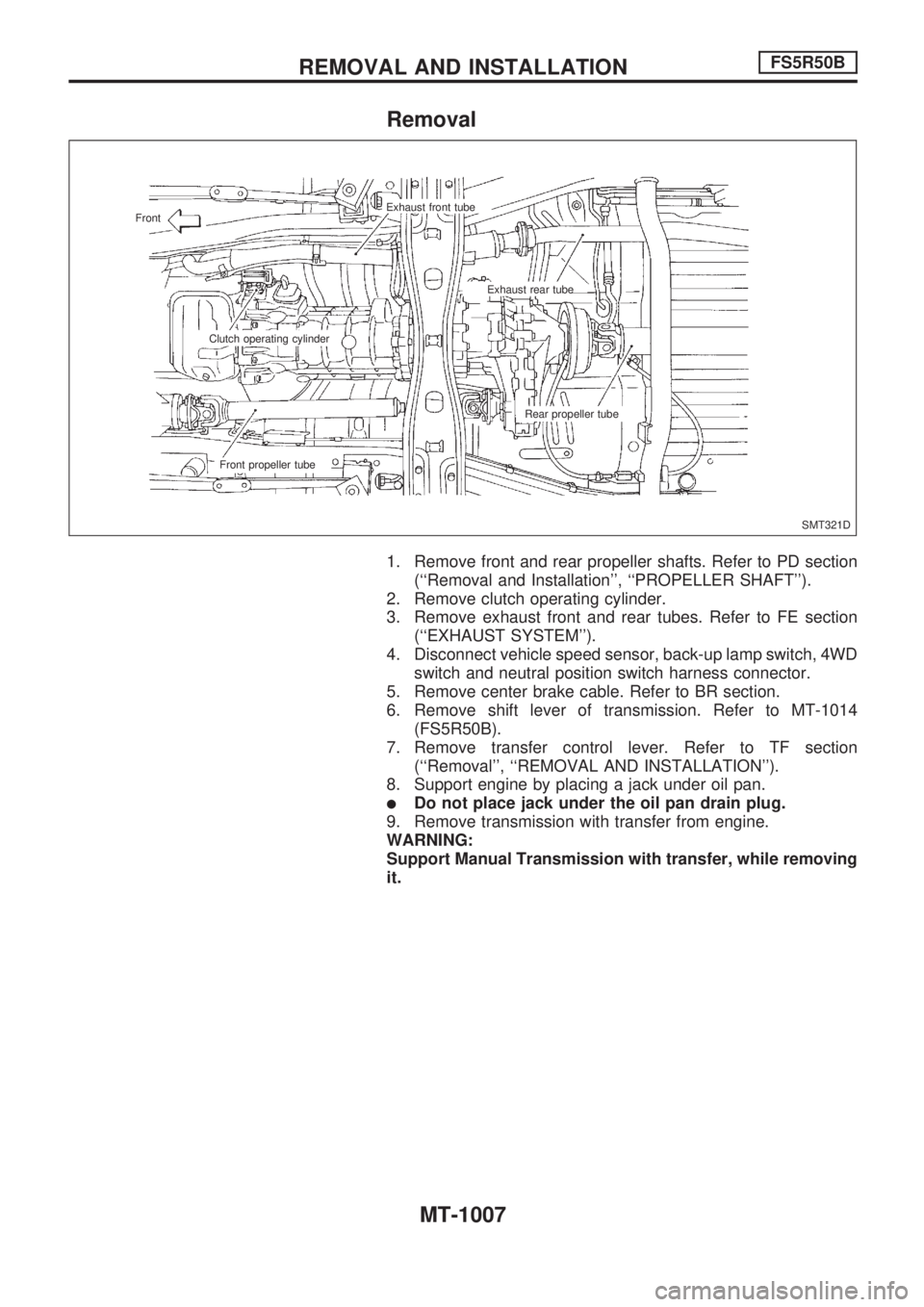

Removal

1. Remove front and rear propeller shafts. Refer to PD section

(``Removal and Installation'', ``PROPELLER SHAFT'').

2. Remove clutch operating cylinder.

3. Remove exhaust front and rear tubes. Refer to FE section

(``EXHAUST SYSTEM'').

4. Disconnect vehicle speed sensor, back-up lamp switch, 4WD

switch and neutral position switch harness connector.

5. Remove center brake cable. Refer to BR section.

6. Remove shift lever of transmission. Refer to MT-1014

(FS5R50B).

7. Remove transfer control lever. Refer to TF section

(``Removal'', ``REMOVAL AND INSTALLATION'').

8. Support engine by placing a jack under oil pan.

lDo not place jack under the oil pan drain plug.

9. Remove transmission with transfer from engine.

WARNING:

Support Manual Transmission with transfer, while removing

it.

SMT321D Exhaust front tube

Front

Exhaust rear tube

Clutch operating cylinder

Rear propeller tube

Front propeller tube

REMOVAL AND INSTALLATIONFS5R50B

MT-1007

Page 973 of 1033

RESTRAINT SYSTEM

SECTION

RS

MODIFICATION NOTICE:

+Side air bag has been adopted as optional equipment.

+Diagnosis sensor unit has been changed.

+Seat belt pre-tensioner with load limiter has been added.

+Deployment procedure of seat belt pre-tensioner has been changed.

CONTENTS

PRECAUTION...................................................... 1002

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº ... 1002

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)1003

Precautions for SRS ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº Service ................... 1003

Special Service Tools ...................................... 1003

Description ....................................................... 1004

Built-in Type Side Air Bag ............................... 1004

Seat Belt Pre-tensioner with Load Limiter ....... 1005

SRS Component Parts Location...................... 1005

Maintenance Items........................................... 1006

Removal and Installation Ð Diagnosis Sensor

Unit, Seat Belt Pre-tensioner with Load Limiter

and Satellite Sensor......................................... 1008

Removal Ð Driver Air Bag Module and Spiral

Cable ................................................................ 1009Installation Ð Driver Air Bag Module and

Spiral Cable ..................................................... 1011

Removal Ð Side Air Bag Module.................... 1012

Installation Ð Side Air Bag Module................. 1013

Disposal of Air Bag Module and Seat Belt

Pre-tensioner.................................................... 1015

TROUBLE DIAGNOSES Ð Supplemental

Restraint System (SRS)..................................... 1019

Trouble Diagnoses Introduction ....................... 1019

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ........................................ 1021

Schematic ........................................................ 1023

Wiring Diagram Ð SRS Ð/LHD Models ......... 1024

Wiring Diagram Ð SRS Ð/RHD Models ........ 1028

Self-diagnosis................................................... 1032

Trouble Diagnoses for Air Bag Warning Lamp1050

COLLISION DIAGNOSIS..................................... 1052

RS

Page 974 of 1033

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS composition which is available to NISSAN MODEL Y61 is as follows (The com-

position varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTION

RS-1002

Page 975 of 1033

Precautions for SRS ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº Service

+Do not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

+Before servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt pre-

tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes have passed.

+Diagnosis sensor unit must always be installed with their arrow marks ªSº pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

+The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt

to turn steering wheel or column after removal of steering gear.

+Handle air bag module carefully. Always place driver and passenger air bag modules with the pad side

facing upward and front side air bag modules (built-in type) with the stud bolt side facing down.

+Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

+After air bag inflates, the front instrument panel assembly should be replaced if damaged.

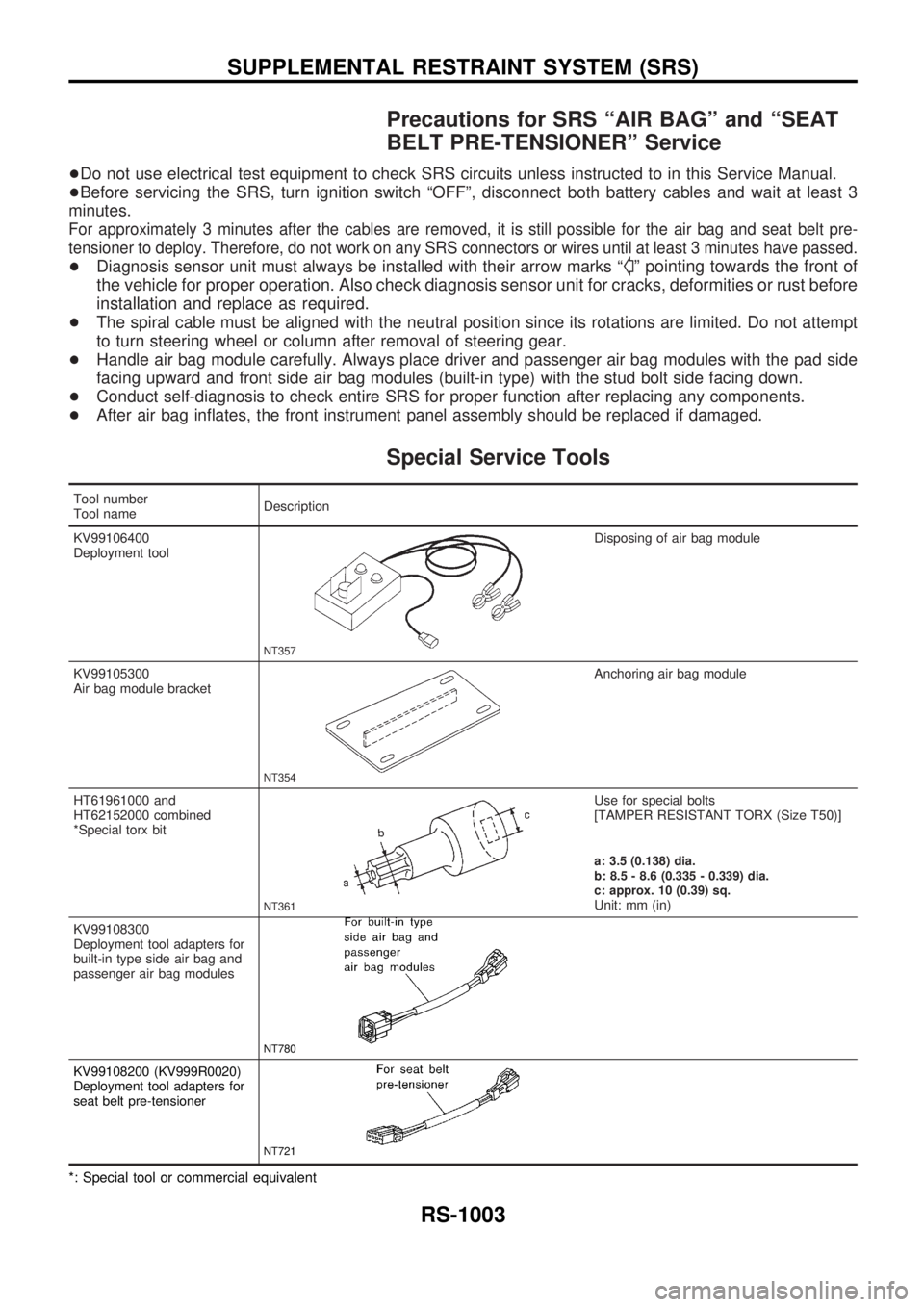

Special Service Tools

Tool number

Tool nameDescription

KV99106400

Deployment tool

NT357

Disposing of air bag module

KV99105300

Air bag module bracket

NT354

Anchoring air bag module

HT61961000 and

HT62152000 combined

*Special torx bit

NT361

Use for special bolts

[TAMPER RESISTANT TORX (Size T50)]

a: 3.5 (0.138) dia.

b: 8.5 - 8.6 (0.335 - 0.339) dia.

c: approx. 10 (0.39) sq.

Unit: mm (in)

KV99108300

Deployment tool adapters for

built-in type side air bag and

passenger air bag modules

NT780

KV99108200 (KV999R0020)

Deployment tool adapters for

seat belt pre-tensioner

NT721

*: Special tool or commercial equivalent

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-1003

Page 976 of 1033

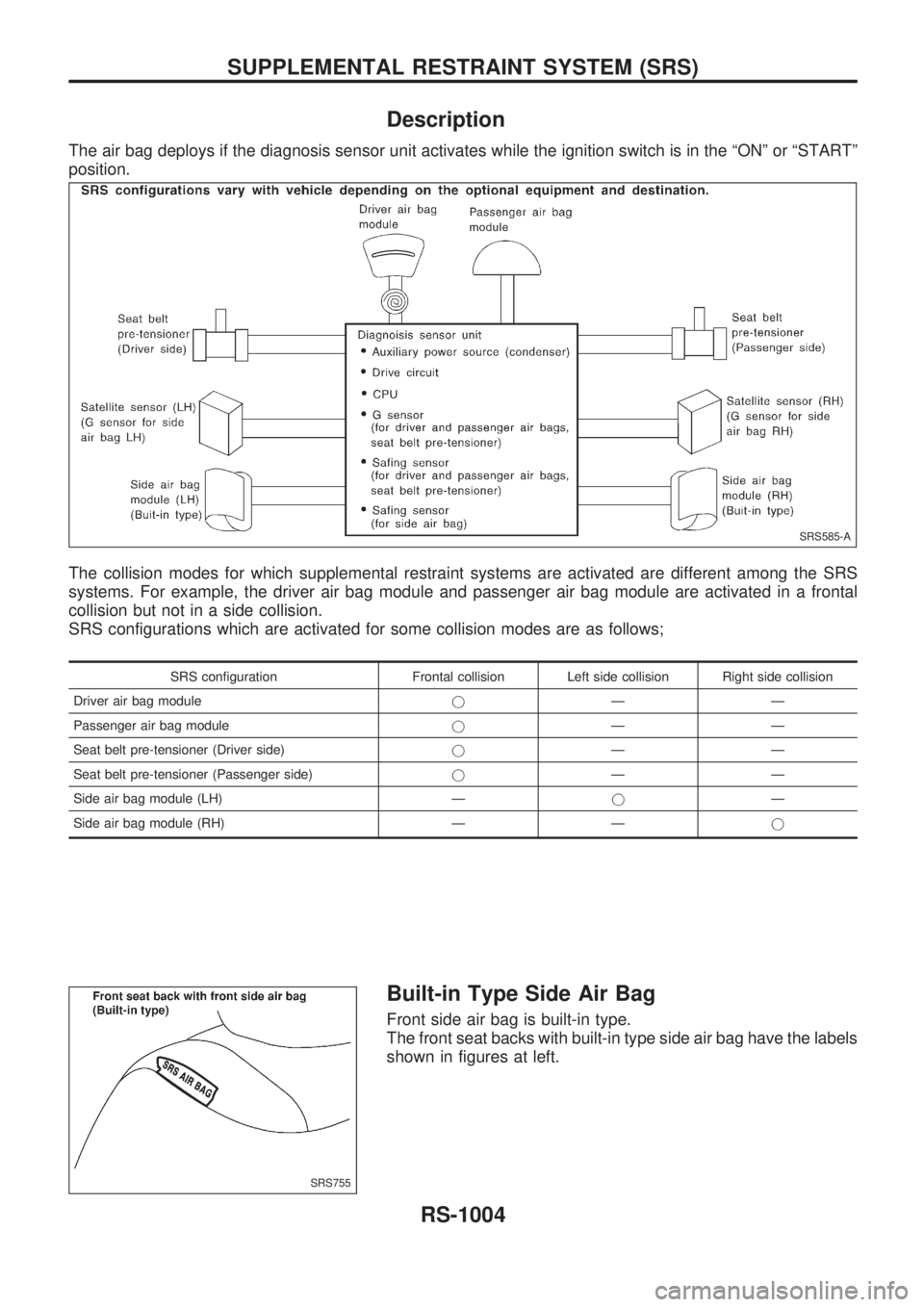

Description

The air bag deploys if the diagnosis sensor unit activates while the ignition switch is in the ªONº or ªSTARTº

position.

The collision modes for which supplemental restraint systems are activated are different among the SRS

systems. For example, the driver air bag module and passenger air bag module are activated in a frontal

collision but not in a side collision.

SRS configurations which are activated for some collision modes are as follows;

SRS configuration Frontal collision Left side collision Right side collision

Driver air bag modulejÐÐ

Passenger air bag modulejÐÐ

Seat belt pre-tensioner (Driver side)jÐÐ

Seat belt pre-tensioner (Passenger side)jÐÐ

Side air bag module (LH) ÐjÐ

Side air bag module (RH) Ð Ðj

Built-in Type Side Air Bag

Front side air bag is built-in type.

The front seat backs with built-in type side air bag have the labels

shown in figures at left.

SRS585-A

SRS755

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-1004