sensor NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 737 of 1033

Wiring Diagram Codes (Cell Codes)

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (Page number) of each wiring diagram.

Code Section Wiring Diagram Name

A/C,A HA Auto Air Conditioner

A/C,M HA Manual Air Conditioner

A/CCUT EC Air Conditioner Control

A/T AT A/T

ABS BR Anti-lock Brake System

ACC/SW EC Accelerator Switch (FC)

ACL/SW EC Accelerator Position Switch

APS EC Accelerator Position Sensor

ASCD EL Automatic Speed Control Device

AT/C EC A/T Control

BACK/L EL Back-up Lamp

BCDD EC BCDD System

BOOST EC Turbo Charger Boost Sensor

BRK/SW EC Brake Switch Signal

CHARGE EL Charging System

CHIME EL Warning Chime

CHOKE EC Automatic Choke

CKPS EC Crankshaft Position Sensor (OBD)

COOL/B HA Cool Box

COOL/F EC Cooling Fan Control

CORNER EL Cornering Lamp

DEF EL Rear Window Defogger

DIFF/L PD Differential Lock Control System

DTRL ELHeadlamp Ð With Daytime Light

System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGVC/V EC EGR Volume Control Valve

EXH ECExhaust Gas Control Valve Control

Solenoid Valve

F/FOG EL Front Fog Lamp

F/PUMP EC Fuel Pump

FCUT EC Fuel Cut System

FICD EC IACV-FICD Solenoid Valve

FIPOT EC ISC-FI POT

FPCM EC Fuel Pump Control Module

GLOW EC Quick Glow System

HEATER HA Heater System

HEATUP EC Heat up SwitchCode Section Wiring Diagram Name

HLC EL Headlamp Wiper and Washer

HORN EL Horn

IGN EC Ignition Control System

ILL EL Illumination

INJPMP ECElectronic Control Fuel Injection

Pump

INT/V ECIntake Air Control Valve Control

Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN ECMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.,

Oil and Fuel Gauges

MIL/DL EC Mil and Data Link Connectors

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-Theft System

P/ANT EL Power Antenna

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

R/COOL HA Rear Cooler System

R/FOG EL Rear Fog Lamp

R/HEAT HA Rear Heater System

REMOTE EL Audio (Remote Control Switch)

ROOM/L EL Interior Room Lamp

S/LOCK EL Power Door Lock Ð Super Lock

S/SIG EC Start Signal

S/TANK FE Sub Fuel Tank Control System

SHIFT AT A/T Shift Lock System

SRS RS Supplemental Restraint System

STAB RA Stabilizer Release Device

START EL Starting System

STOP/L EL Stop Lamp

SWL/V ECSwirl Control Valve Control Solenoid

Valve

TAIL/L EL Parking, License and Tail Lamps

TURN ELTurn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

WARN EL Warning Lamps

WIRING DIAGRAM CODES (CELL CODES)

EL-1227

Page 766 of 1033

+Vacuum pipe

+Vacuum pump

2. Move the following parts.

+TDC sensor harness

+Power steering oil pump

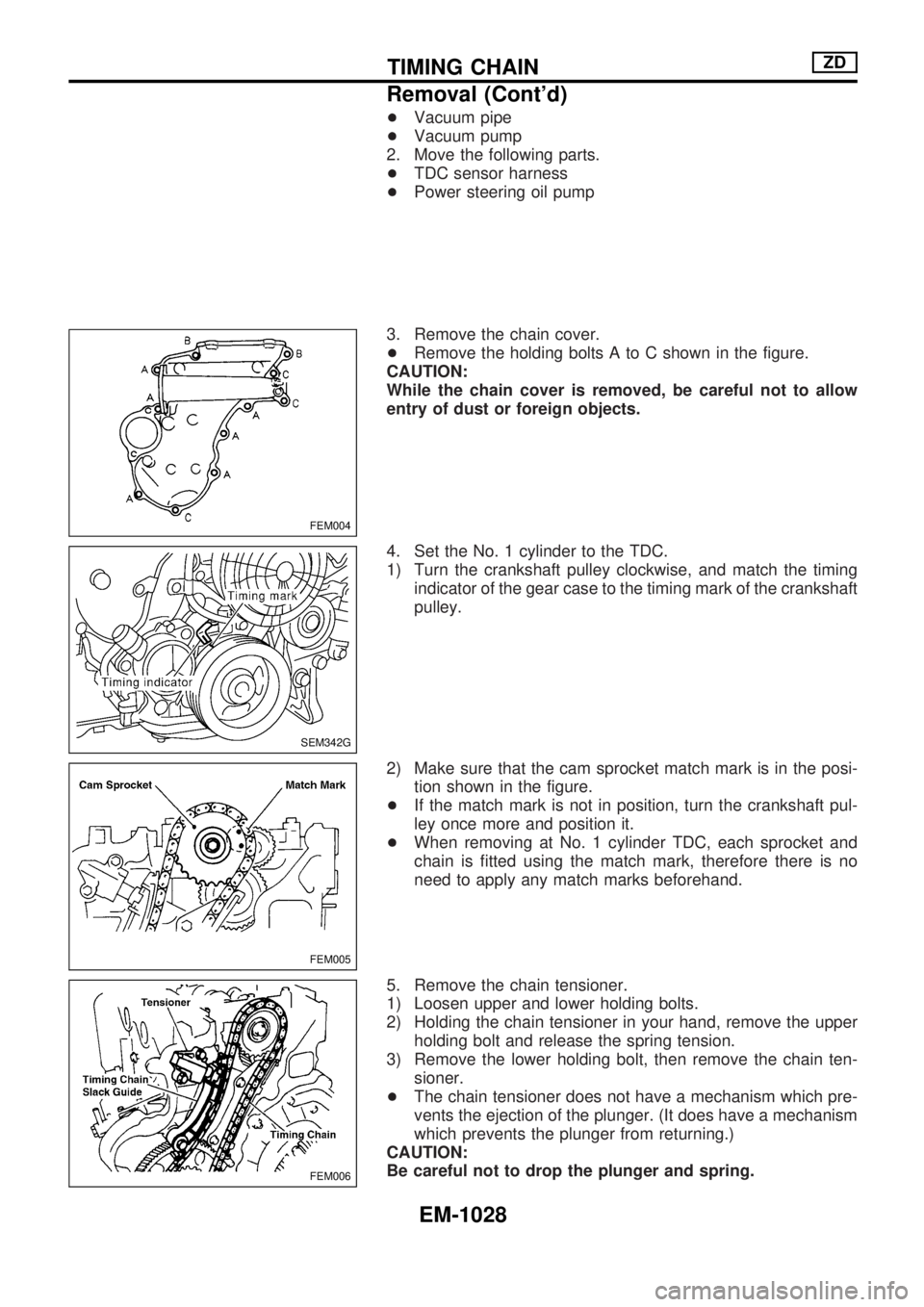

3. Remove the chain cover.

+Remove the holding bolts A to C shown in the figure.

CAUTION:

While the chain cover is removed, be careful not to allow

entry of dust or foreign objects.

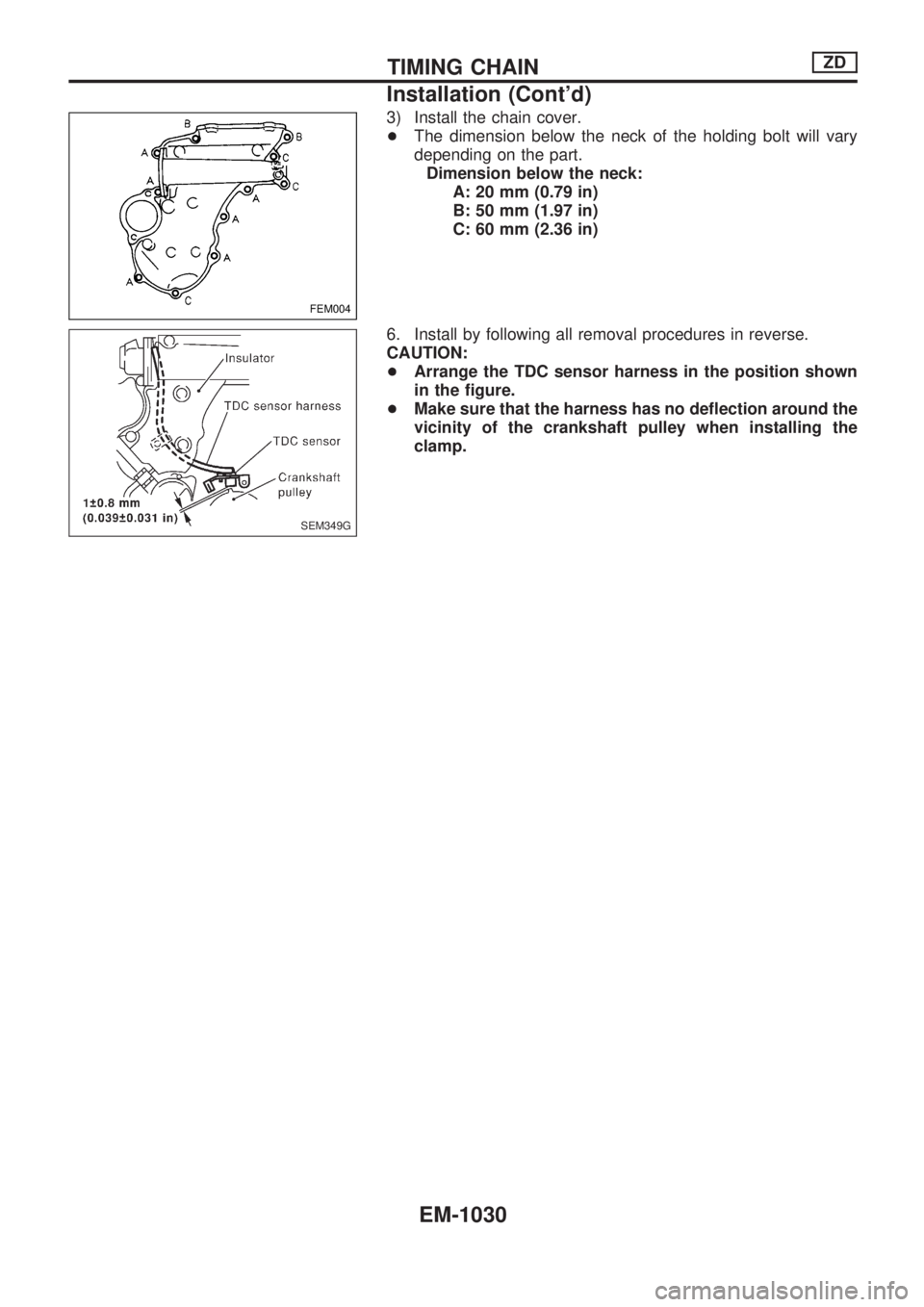

4. Set the No. 1 cylinder to the TDC.

1) Turn the crankshaft pulley clockwise, and match the timing

indicator of the gear case to the timing mark of the crankshaft

pulley.

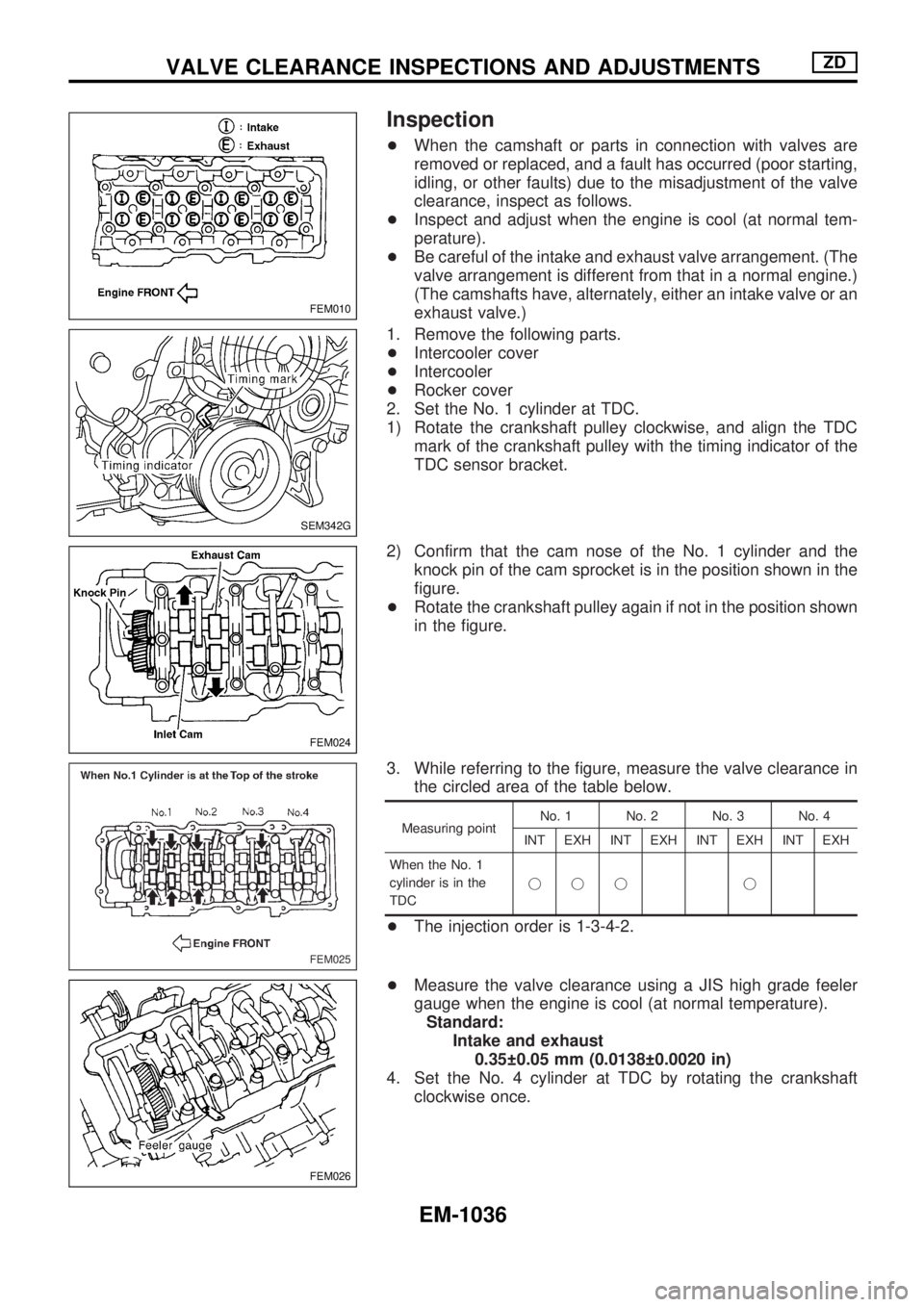

2) Make sure that the cam sprocket match mark is in the posi-

tion shown in the figure.

+If the match mark is not in position, turn the crankshaft pul-

ley once more and position it.

+When removing at No. 1 cylinder TDC, each sprocket and

chain is fitted using the match mark, therefore there is no

need to apply any match marks beforehand.

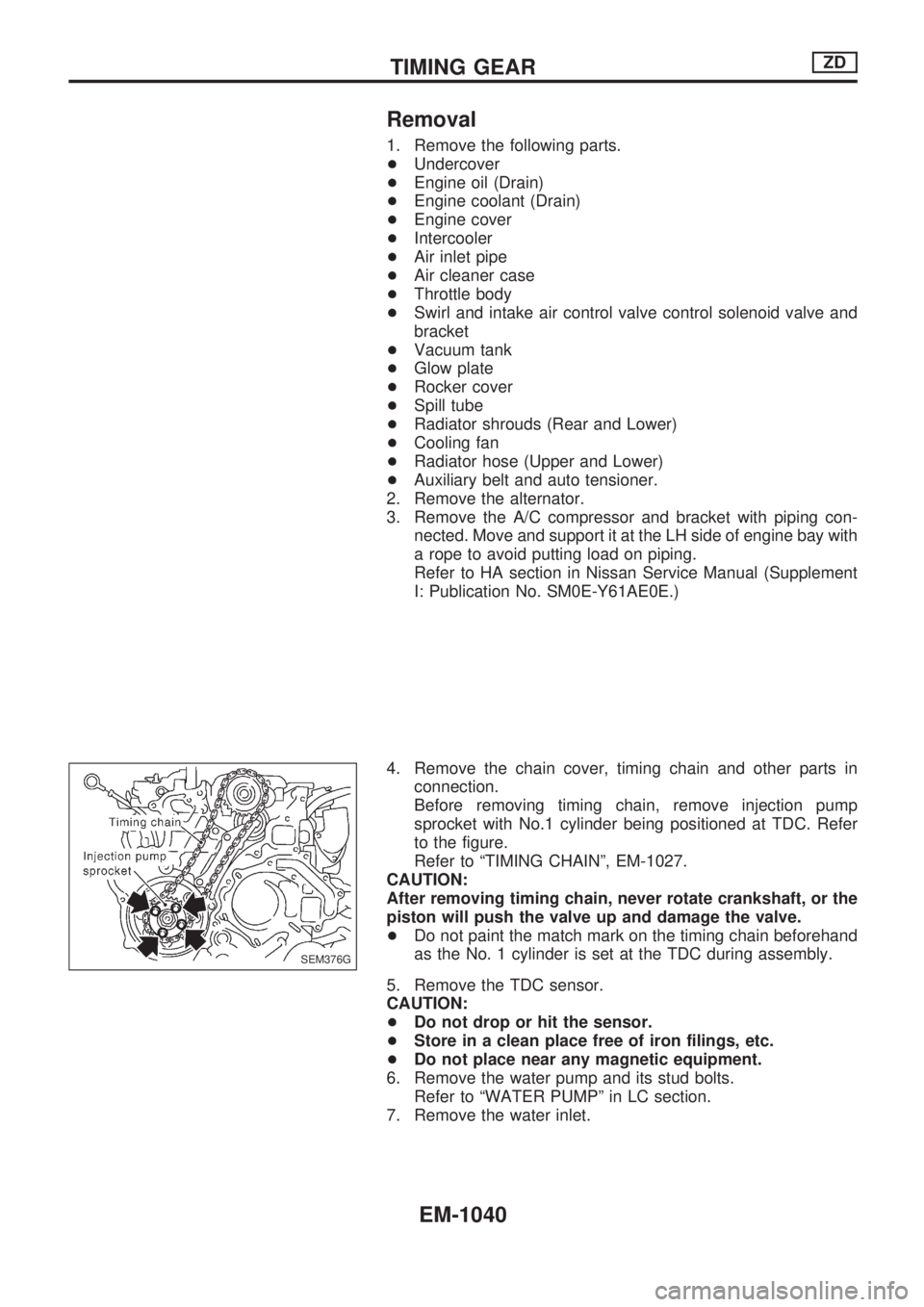

5. Remove the chain tensioner.

1) Loosen upper and lower holding bolts.

2) Holding the chain tensioner in your hand, remove the upper

holding bolt and release the spring tension.

3) Remove the lower holding bolt, then remove the chain ten-

sioner.

+The chain tensioner does not have a mechanism which pre-

vents the ejection of the plunger. (It does have a mechanism

which prevents the plunger from returning.)

CAUTION:

Be careful not to drop the plunger and spring.

FEM004

SEM342G

FEM005

FEM006

TIMING CHAINZD

Removal (Cont'd)

EM-1028

Page 768 of 1033

3) Install the chain cover.

+The dimension below the neck of the holding bolt will vary

depending on the part.

Dimension below the neck:

A: 20 mm (0.79 in)

B: 50 mm (1.97 in)

C: 60 mm (2.36 in)

6. Install by following all removal procedures in reverse.

CAUTION:

+Arrange the TDC sensor harness in the position shown

in the figure.

+Make sure that the harness has no deflection around the

vicinity of the crankshaft pulley when installing the

clamp.

FEM004

SEM349G

TIMING CHAINZD

Installation (Cont'd)

EM-1030

Page 774 of 1033

Inspection

+When the camshaft or parts in connection with valves are

removed or replaced, and a fault has occurred (poor starting,

idling, or other faults) due to the misadjustment of the valve

clearance, inspect as follows.

+Inspect and adjust when the engine is cool (at normal tem-

perature).

+Be careful of the intake and exhaust valve arrangement. (The

valve arrangement is different from that in a normal engine.)

(The camshafts have, alternately, either an intake valve or an

exhaust valve.)

1. Remove the following parts.

+Intercooler cover

+Intercooler

+Rocker cover

2. Set the No. 1 cylinder at TDC.

1) Rotate the crankshaft pulley clockwise, and align the TDC

mark of the crankshaft pulley with the timing indicator of the

TDC sensor bracket.

2) Confirm that the cam nose of the No. 1 cylinder and the

knock pin of the cam sprocket is in the position shown in the

figure.

+Rotate the crankshaft pulley again if not in the position shown

in the figure.

3. While referring to the figure, measure the valve clearance in

the circled area of the table below.

Measuring pointNo. 1 No. 2 No. 3 No. 4

INT EXH INT EXH INT EXH INT EXH

When the No. 1

cylinder is in the

TDCjjj j

+The injection order is 1-3-4-2.

+Measure the valve clearance using a JIS high grade feeler

gauge when the engine is cool (at normal temperature).

Standard:

Intake and exhaust

0.35 0.05 mm (0.0138 0.0020 in)

4. Set the No. 4 cylinder at TDC by rotating the crankshaft

clockwise once.

FEM010

SEM342G

FEM024

FEM025

FEM026

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

EM-1036

Page 778 of 1033

Removal

1. Remove the following parts.

+Undercover

+Engine oil (Drain)

+Engine coolant (Drain)

+Engine cover

+Intercooler

+Air inlet pipe

+Air cleaner case

+Throttle body

+Swirl and intake air control valve control solenoid valve and

bracket

+Vacuum tank

+Glow plate

+Rocker cover

+Spill tube

+Radiator shrouds (Rear and Lower)

+Cooling fan

+Radiator hose (Upper and Lower)

+Auxiliary belt and auto tensioner.

2. Remove the alternator.

3. Remove the A/C compressor and bracket with piping con-

nected. Move and support it at the LH side of engine bay with

a rope to avoid putting load on piping.

Refer to HA section in Nissan Service Manual (Supplement

I: Publication No. SM0E-Y61AE0E.)

4. Remove the chain cover, timing chain and other parts in

connection.

Before removing timing chain, remove injection pump

sprocket with No.1 cylinder being positioned at TDC. Refer

to the figure.

Refer to ªTIMING CHAINº, EM-1027.

CAUTION:

After removing timing chain, never rotate crankshaft, or the

piston will push the valve up and damage the valve.

+Do not paint the match mark on the timing chain beforehand

as the No. 1 cylinder is set at the TDC during assembly.

5. Remove the TDC sensor.

CAUTION:

+Do not drop or hit the sensor.

+Store in a clean place free of iron filings, etc.

+Do not place near any magnetic equipment.

6. Remove the water pump and its stud bolts.

Refer to ªWATER PUMPº in LC section.

7. Remove the water inlet.

SEM376G

TIMING GEARZD

EM-1040

Page 787 of 1033

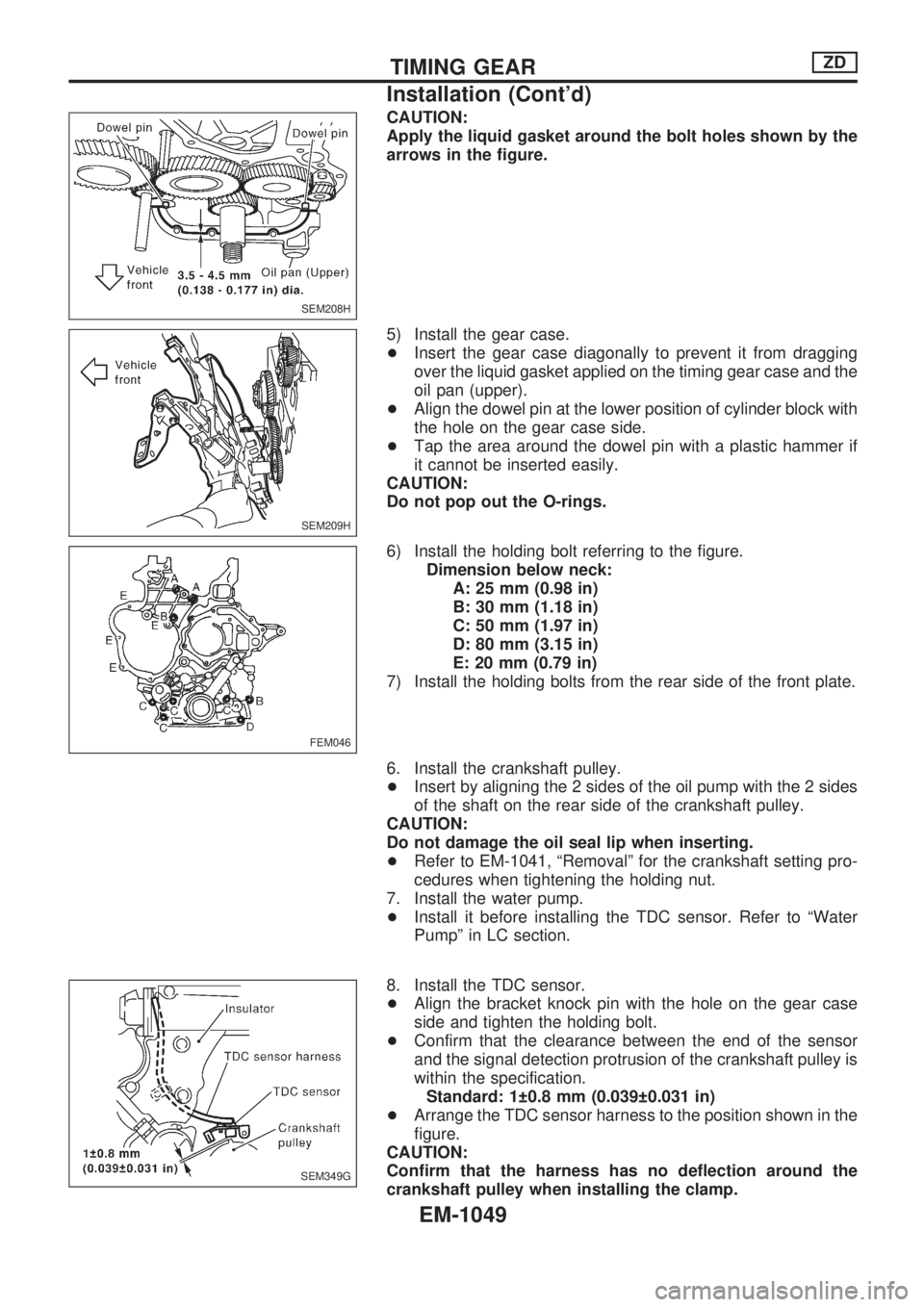

CAUTION:

Apply the liquid gasket around the bolt holes shown by the

arrows in the figure.

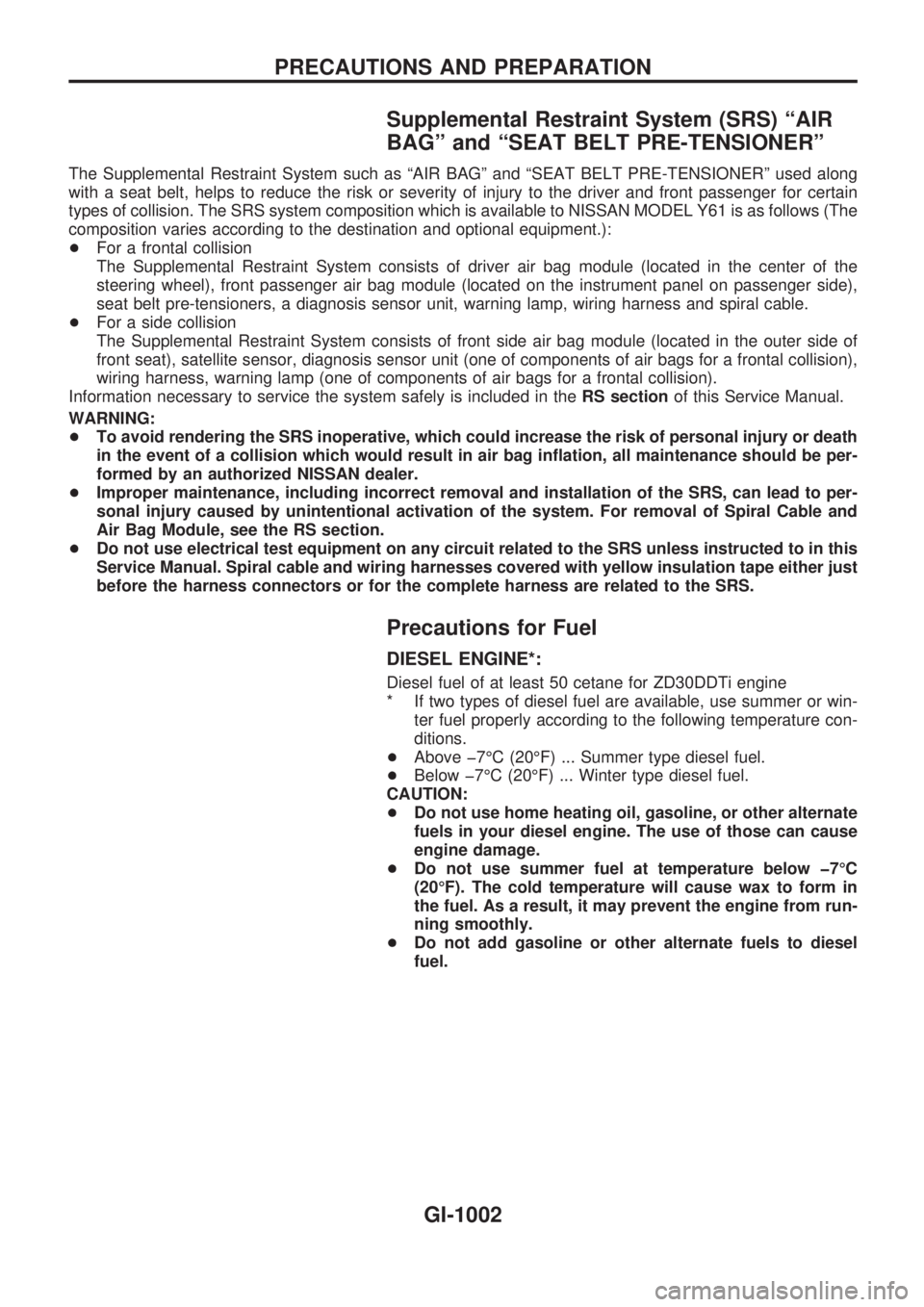

5) Install the gear case.

+Insert the gear case diagonally to prevent it from dragging

over the liquid gasket applied on the timing gear case and the

oil pan (upper).

+Align the dowel pin at the lower position of cylinder block with

the hole on the gear case side.

+Tap the area around the dowel pin with a plastic hammer if

it cannot be inserted easily.

CAUTION:

Do not pop out the O-rings.

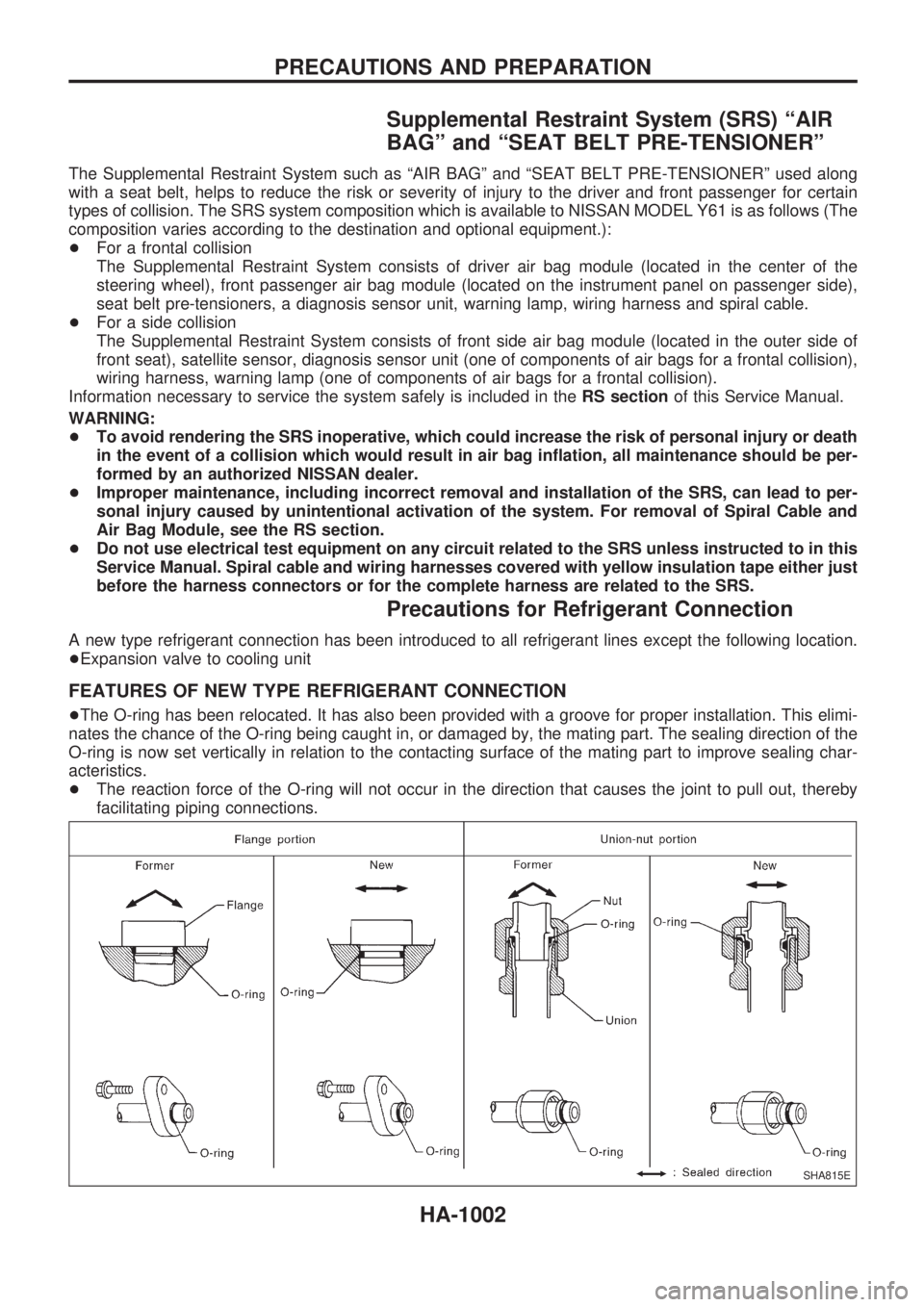

6) Install the holding bolt referring to the figure.

Dimension below neck:

A: 25 mm (0.98 in)

B: 30 mm (1.18 in)

C: 50 mm (1.97 in)

D: 80 mm (3.15 in)

E: 20 mm (0.79 in)

7) Install the holding bolts from the rear side of the front plate.

6. Install the crankshaft pulley.

+Insert by aligning the 2 sides of the oil pump with the 2 sides

of the shaft on the rear side of the crankshaft pulley.

CAUTION:

Do not damage the oil seal lip when inserting.

+Refer to EM-1041, ªRemovalº for the crankshaft setting pro-

cedures when tightening the holding nut.

7. Install the water pump.

+Install it before installing the TDC sensor. Refer to ªWater

Pumpº in LC section.

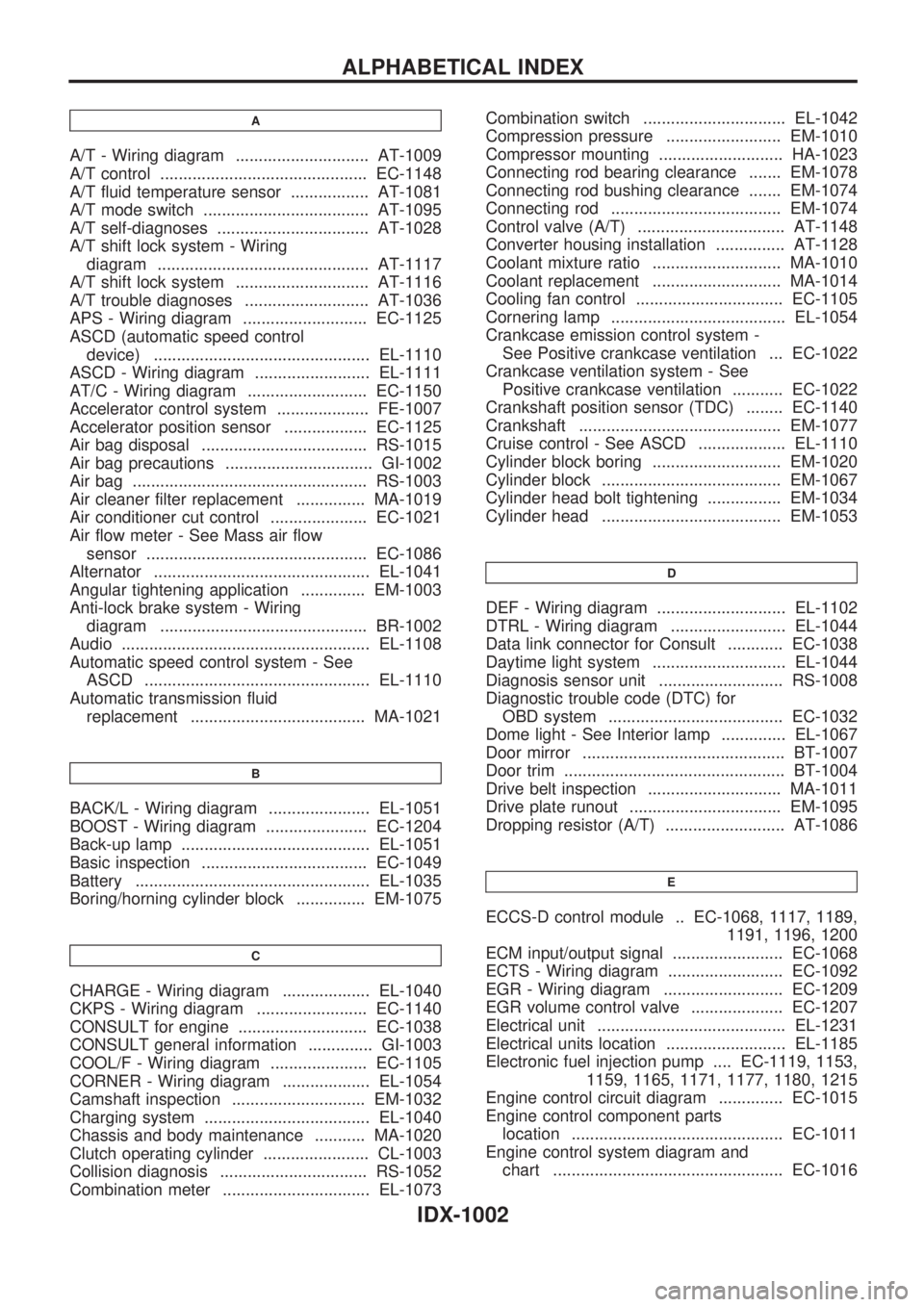

8. Install the TDC sensor.

+Align the bracket knock pin with the hole on the gear case

side and tighten the holding bolt.

+Confirm that the clearance between the end of the sensor

and the signal detection protrusion of the crankshaft pulley is

within the specification.

Standard: 1 0.8 mm (0.039 0.031 in)

+Arrange the TDC sensor harness to the position shown in the

figure.

CAUTION:

Confirm that the harness has no deflection around the

crankshaft pulley when installing the clamp.

SEM208H

SEM209H

FEM046

SEM349G

TIMING GEARZD

Installation (Cont'd)

EM-1049

Page 847 of 1033

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The

composition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and

Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for Fuel

DIESEL ENGINE*:

Diesel fuel of at least 50 cetane for ZD30DDTi engine

* If two types of diesel fuel are available, use summer or win-

ter fuel properly according to the following temperature con-

ditions.

+Above þ7ÉC (20ÉF) ... Summer type diesel fuel.

+Below þ7ÉC (20ÉF) ... Winter type diesel fuel.

CAUTION:

+Do not use home heating oil, gasoline, or other alternate

fuels in your diesel engine. The use of those can cause

engine damage.

+Do not use summer fuel at temperature below þ7ÉC

(20ÉF). The cold temperature will cause wax to form in

the fuel. As a result, it may prevent the engine from run-

ning smoothly.

+Do not add gasoline or other alternate fuels to diesel

fuel.

PRECAUTIONS AND PREPARATION

GI-1002

Page 857 of 1033

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The

composition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and

Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for Refrigerant Connection

A new type refrigerant connection has been introduced to all refrigerant lines except the following location.

+Expansion valve to cooling unit

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

+The O-ring has been relocated. It has also been provided with a groove for proper installation. This elimi-

nates the chance of the O-ring being caught in, or damaged by, the mating part. The sealing direction of the

O-ring is now set vertically in relation to the contacting surface of the mating part to improve sealing char-

acteristics.

+The reaction force of the O-ring will not occur in the direction that causes the joint to pull out, thereby

facilitating piping connections.

SHA815E

PRECAUTIONS AND PREPARATION

HA-1002

Page 880 of 1033

A

A/T - Wiring diagram ............................. AT-1009

A/T control ............................................. EC-1148

A/T fluid temperature sensor ................. AT-1081

A/T mode switch .................................... AT-1095

A/T self-diagnoses ................................. AT-1028

A/T shift lock system - Wiring

diagram .............................................. AT-1117

A/T shift lock system ............................. AT-1116

A/T trouble diagnoses ........................... AT-1036

APS - Wiring diagram ........................... EC-1125

ASCD (automatic speed control

device) ............................................... EL-1110

ASCD - Wiring diagram ......................... EL-1111

AT/C - Wiring diagram .......................... EC-1150

Accelerator control system .................... FE-1007

Accelerator position sensor .................. EC-1125

Air bag disposal .................................... RS-1015

Air bag precautions ................................ GI-1002

Air bag ................................................... RS-1003

Air cleaner filter replacement ............... MA-1019

Air conditioner cut control ..................... EC-1021

Air flow meter - See Mass air flow

sensor ................................................ EC-1086

Alternator ............................................... EL-1041

Angular tightening application .............. EM-1003

Anti-lock brake system - Wiring

diagram ............................................. BR-1002

Audio ...................................................... EL-1108

Automatic speed control system - See

ASCD ................................................. EL-1110

Automatic transmission fluid

replacement ...................................... MA-1021

B

BACK/L - Wiring diagram ...................... EL-1051

BOOST - Wiring diagram ...................... EC-1204

Back-up lamp ......................................... EL-1051

Basic inspection .................................... EC-1049

Battery ................................................... EL-1035

Boring/horning cylinder block ............... EM-1075

C

CHARGE - Wiring diagram ................... EL-1040

CKPS - Wiring diagram ........................ EC-1140

CONSULT for engine ............................ EC-1038

CONSULT general information .............. GI-1003

COOL/F - Wiring diagram ..................... EC-1105

CORNER - Wiring diagram ................... EL-1054

Camshaft inspection ............................. EM-1032

Charging system .................................... EL-1040

Chassis and body maintenance ........... MA-1020

Clutch operating cylinder ....................... CL-1003

Collision diagnosis ................................ RS-1052

Combination meter ................................ EL-1073Combination switch ............................... EL-1042

Compression pressure ......................... EM-1010

Compressor mounting ........................... HA-1023

Connecting rod bearing clearance ....... EM-1078

Connecting rod bushing clearance ....... EM-1074

Connecting rod ..................................... EM-1074

Control valve (A/T) ................................ AT-1148

Converter housing installation ............... AT-1128

Coolant mixture ratio ............................ MA-1010

Coolant replacement ............................ MA-1014

Cooling fan control ................................ EC-1105

Cornering lamp ...................................... EL-1054

Crankcase emission control system -

See Positive crankcase ventilation ... EC-1022

Crankcase ventilation system - See

Positive crankcase ventilation ........... EC-1022

Crankshaft position sensor (TDC) ........ EC-1140

Crankshaft ............................................ EM-1077

Cruise control - See ASCD ................... EL-1110

Cylinder block boring ............................ EM-1020

Cylinder block ....................................... EM-1067

Cylinder head bolt tightening ................ EM-1034

Cylinder head ....................................... EM-1053

D

DEF - Wiring diagram ............................ EL-1102

DTRL - Wiring diagram ......................... EL-1044

Data link connector for Consult ............ EC-1038

Daytime light system ............................. EL-1044

Diagnosis sensor unit ........................... RS-1008

Diagnostic trouble code (DTC) for

OBD system ...................................... EC-1032

Dome light - See Interior lamp .............. EL-1067

Door mirror ............................................ BT-1007

Door trim ................................................ BT-1004

Drive belt inspection ............................. MA-1011

Drive plate runout ................................. EM-1095

Dropping resistor (A/T) .......................... AT-1086

E

ECCS-D control module .. EC-1068, 1117, 1189,

1191, 1196, 1200

ECM input/output signal ........................ EC-1068

ECTS - Wiring diagram ......................... EC-1092

EGR - Wiring diagram .......................... EC-1209

EGR volume control valve .................... EC-1207

Electrical unit ......................................... EL-1231

Electrical units location .......................... EL-1185

Electronic fuel injection pump .... EC-1119, 1153,

1159, 1165, 1171, 1177, 1180, 1215

Engine control circuit diagram .............. EC-1015

Engine control component parts

location .............................................. EC-1011

Engine control system diagram and

chart .................................................. EC-1016

ALPHABETICAL INDEX

IDX-1002

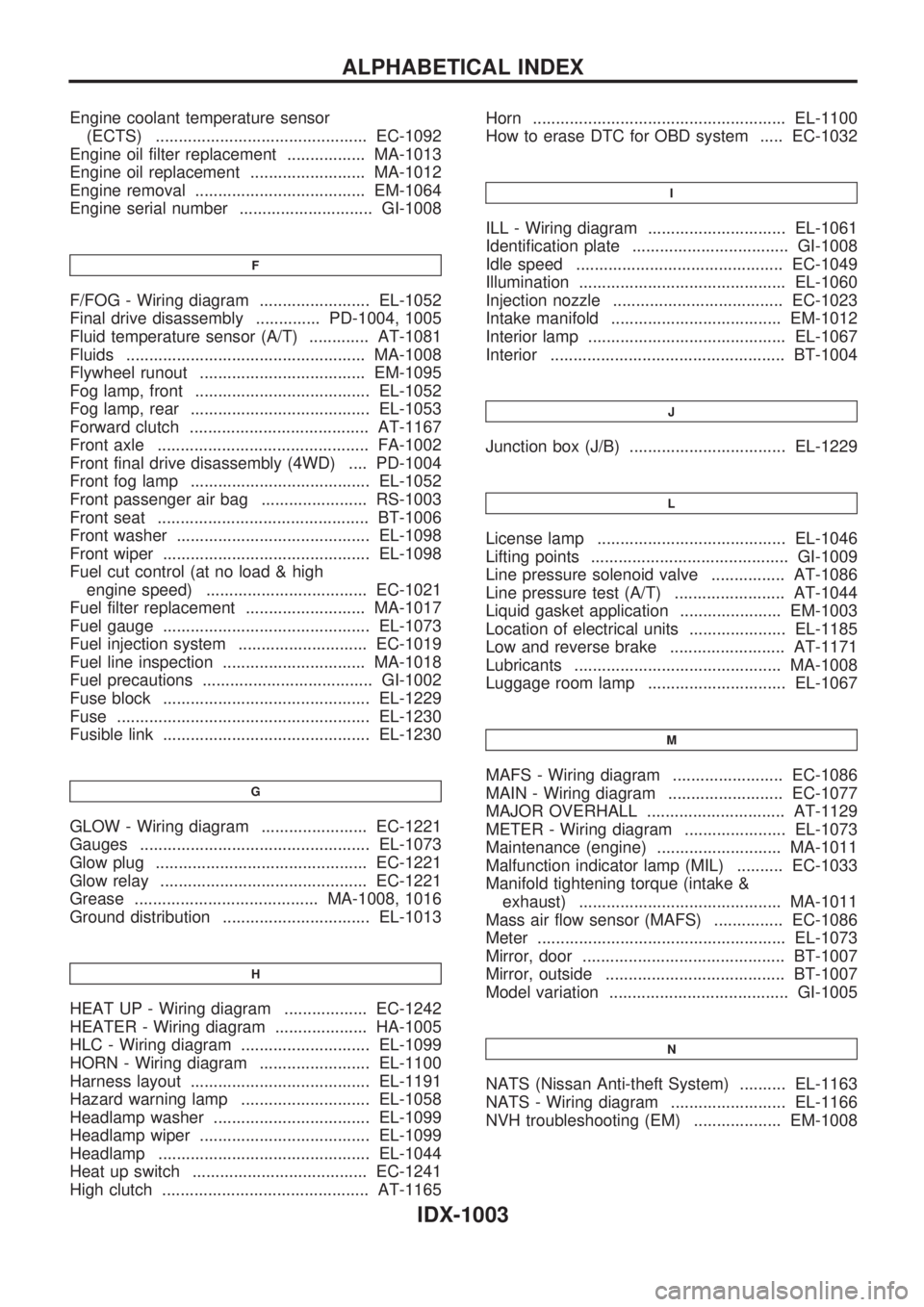

Page 881 of 1033

Engine coolant temperature sensor

(ECTS) .............................................. EC-1092

Engine oil filter replacement ................. MA-1013

Engine oil replacement ......................... MA-1012

Engine removal ..................................... EM-1064

Engine serial number ............................. GI-1008

F

F/FOG - Wiring diagram ........................ EL-1052

Final drive disassembly .............. PD-1004, 1005

Fluid temperature sensor (A/T) ............. AT-1081

Fluids .................................................... MA-1008

Flywheel runout .................................... EM-1095

Fog lamp, front ...................................... EL-1052

Fog lamp, rear ....................................... EL-1053

Forward clutch ....................................... AT-1167

Front axle .............................................. FA-1002

Front final drive disassembly (4WD) .... PD-1004

Front fog lamp ....................................... EL-1052

Front passenger air bag ....................... RS-1003

Front seat .............................................. BT-1006

Front washer .......................................... EL-1098

Front wiper ............................................. EL-1098

Fuel cut control (at no load & high

engine speed) ................................... EC-1021

Fuel filter replacement .......................... MA-1017

Fuel gauge ............................................. EL-1073

Fuel injection system ............................ EC-1019

Fuel line inspection ............................... MA-1018

Fuel precautions ..................................... GI-1002

Fuse block ............................................. EL-1229

Fuse ....................................................... EL-1230

Fusible link ............................................. EL-1230

G

GLOW - Wiring diagram ....................... EC-1221

Gauges .................................................. EL-1073

Glow plug .............................................. EC-1221

Glow relay ............................................. EC-1221

Grease ........................................ MA-1008, 1016

Ground distribution ................................ EL-1013

H

HEAT UP - Wiring diagram .................. EC-1242

HEATER - Wiring diagram .................... HA-1005

HLC - Wiring diagram ............................ EL-1099

HORN - Wiring diagram ........................ EL-1100

Harness layout ....................................... EL-1191

Hazard warning lamp ............................ EL-1058

Headlamp washer .................................. EL-1099

Headlamp wiper ..................................... EL-1099

Headlamp .............................................. EL-1044

Heat up switch ...................................... EC-1241

High clutch ............................................. AT-1165Horn ....................................................... EL-1100

How to erase DTC for OBD system ..... EC-1032

I

ILL - Wiring diagram .............................. EL-1061

Identification plate .................................. GI-1008

Idle speed ............................................. EC-1049

Illumination ............................................. EL-1060

Injection nozzle ..................................... EC-1023

Intake manifold ..................................... EM-1012

Interior lamp ........................................... EL-1067

Interior ................................................... BT-1004

J

Junction box (J/B) .................................. EL-1229

L

License lamp ......................................... EL-1046

Lifting points ........................................... GI-1009

Line pressure solenoid valve ................ AT-1086

Line pressure test (A/T) ........................ AT-1044

Liquid gasket application ...................... EM-1003

Location of electrical units ..................... EL-1185

Low and reverse brake ......................... AT-1171

Lubricants ............................................. MA-1008

Luggage room lamp .............................. EL-1067

M

MAFS - Wiring diagram ........................ EC-1086

MAIN - Wiring diagram ......................... EC-1077

MAJOR OVERHALL .............................. AT-1129

METER - Wiring diagram ...................... EL-1073

Maintenance (engine) ........................... MA-1011

Malfunction indicator lamp (MIL) .......... EC-1033

Manifold tightening torque (intake &

exhaust) ............................................ MA-1011

Mass air flow sensor (MAFS) ............... EC-1086

Meter ...................................................... EL-1073

Mirror, door ............................................ BT-1007

Mirror, outside ....................................... BT-1007

Model variation ....................................... GI-1005

N

NATS (Nissan Anti-theft System) .......... EL-1163

NATS - Wiring diagram ......................... EL-1166

NVH troubleshooting (EM) ................... EM-1008

ALPHABETICAL INDEX

IDX-1003