battery NISSAN PATROL 2000 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 77 of 1033

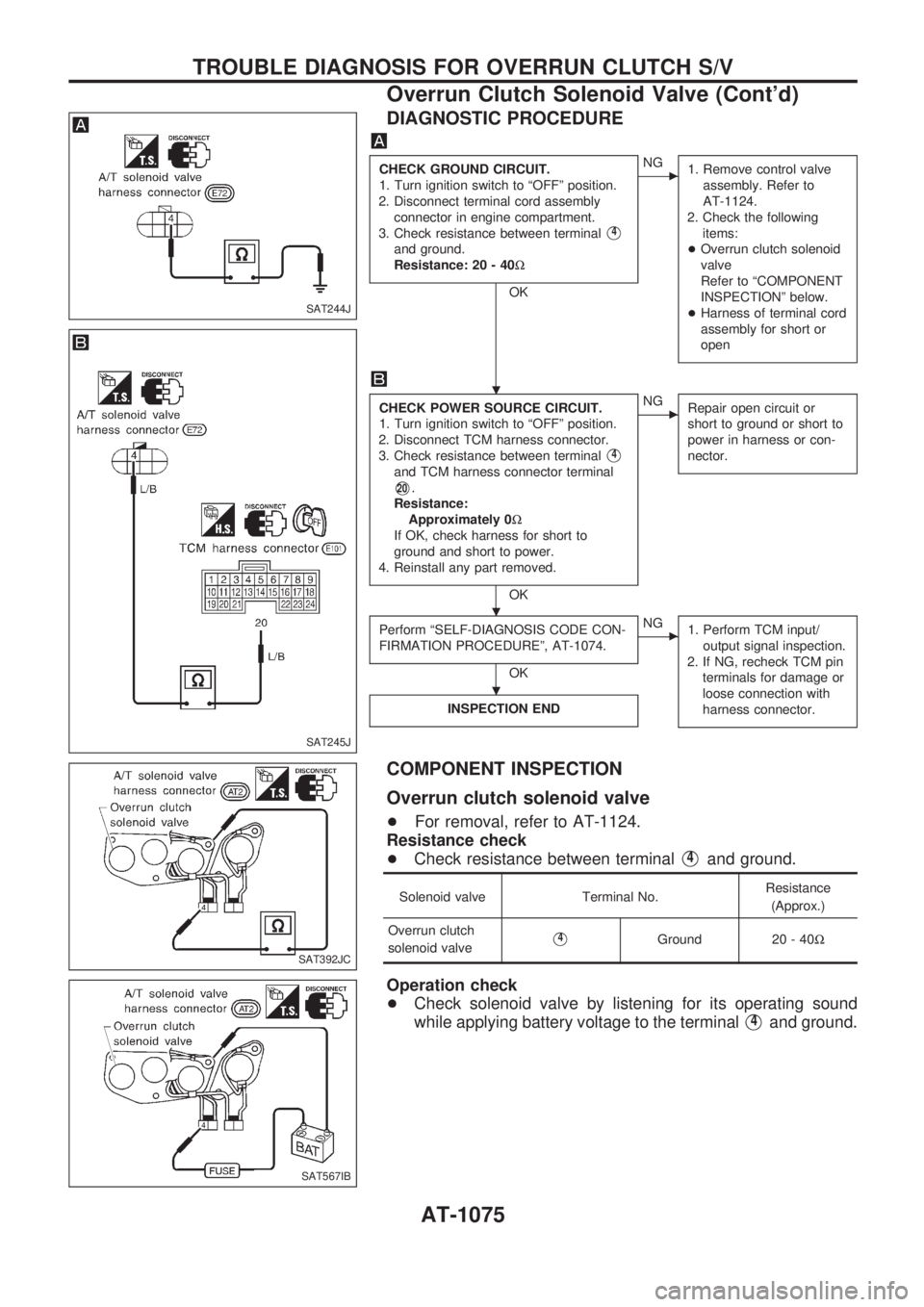

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminal

V4

and ground.

Resistance: 20 - 40W

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Overrun clutch solenoid

valve

Refer to ªCOMPONENT

INSPECTIONº below.

+Harness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal

V4

and TCM harness connector terminal

V20.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

cNG

Repair open circuit or

short to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1074.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

Overrun clutch solenoid valve

+For removal, refer to AT-1124.

Resistance check

+Check resistance between terminal

V4and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Overrun clutch

solenoid valve

V4Ground 20 - 40W

Operation check

+Check solenoid valve by listening for its operating sound

while applying battery voltage to the terminal

V4and ground.

SAT244J

SAT245J

SAT392JC

SAT567IB

.

.

.

TROUBLE DIAGNOSIS FOR OVERRUN CLUTCH S/V

Overrun Clutch Solenoid Valve (Cont'd)

AT-1075

Page 80 of 1033

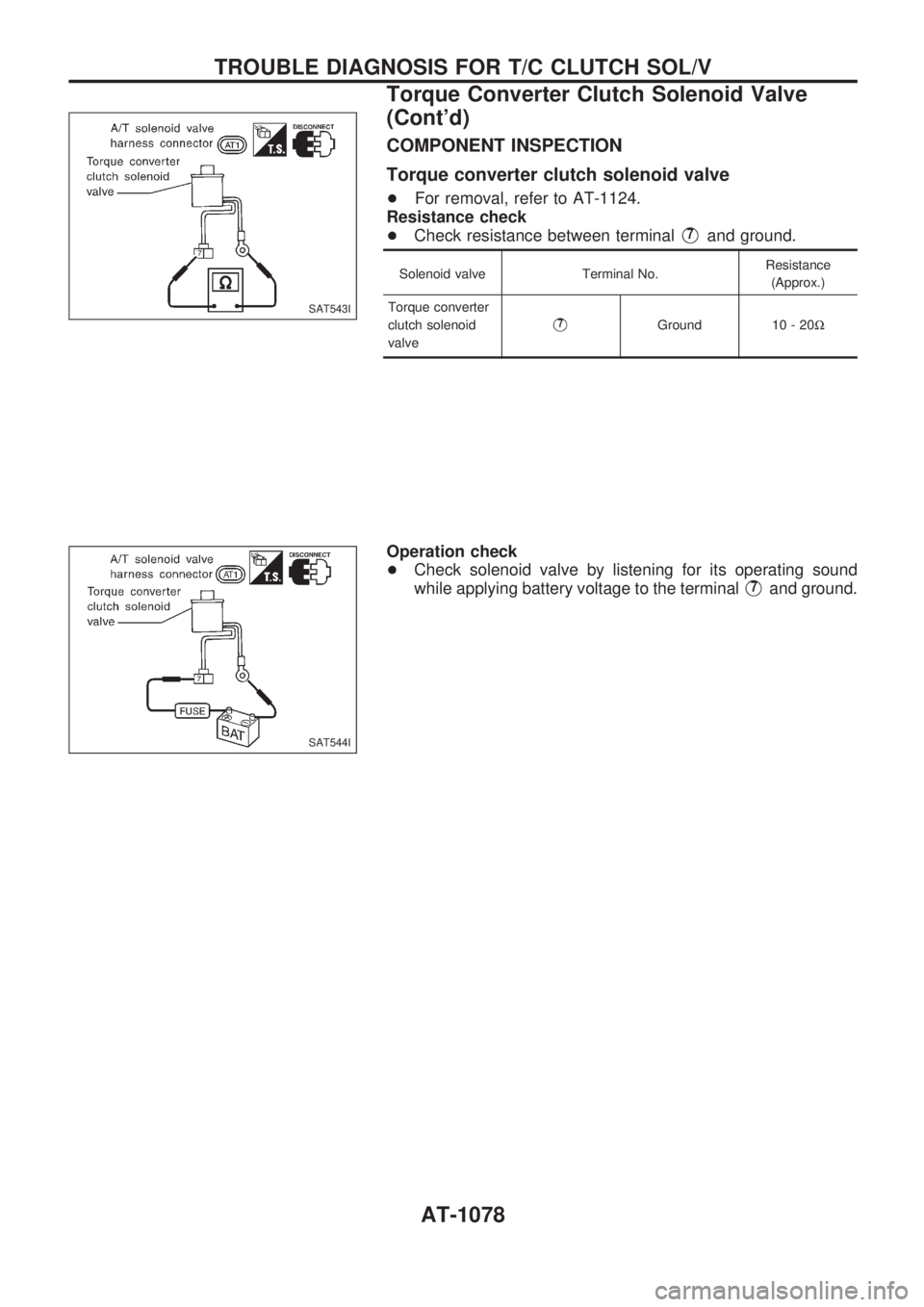

COMPONENT INSPECTION

Torque converter clutch solenoid valve

+For removal, refer to AT-1124.

Resistance check

+Check resistance between terminal

V7and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Torque converter

clutch solenoid

valve

V7Ground 10 - 20W

Operation check

+Check solenoid valve by listening for its operating sound

while applying battery voltage to the terminal

V7and ground.

SAT543I

SAT544I

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V

Torque Converter Clutch Solenoid Valve

(Cont'd)

AT-1078

Page 82 of 1033

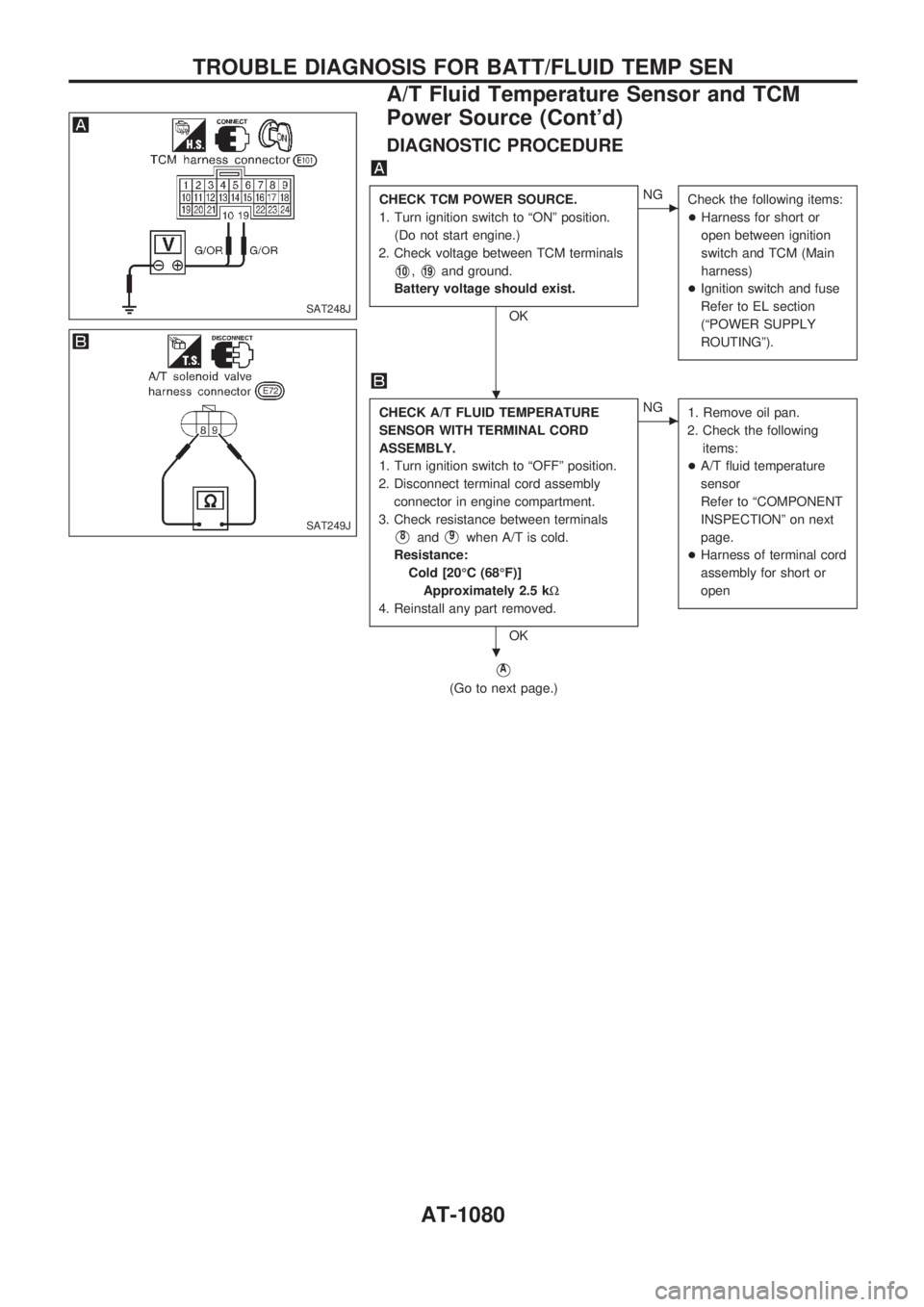

DIAGNOSTIC PROCEDURE

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals

V10,V19and ground.

Battery voltage should exist.

OK

cNG

Check the following items:

+Harness for short or

open between ignition

switch and TCM (Main

harness)

+Ignition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK A/T FLUID TEMPERATURE

SENSOR WITH TERMINAL CORD

ASSEMBLY.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminals

V8andV9when A/T is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

4. Reinstall any part removed.

OK

cNG

1. Remove oil pan.

2. Check the following

items:

+A/T fluid temperature

sensor

Refer to ªCOMPONENT

INSPECTIONº on next

page.

+Harness of terminal cord

assembly for short or

open

VA

(Go to next page.)

SAT248J

SAT249J

.

.

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

A/T Fluid Temperature Sensor and TCM

Power Source (Cont'd)

AT-1080

Page 88 of 1033

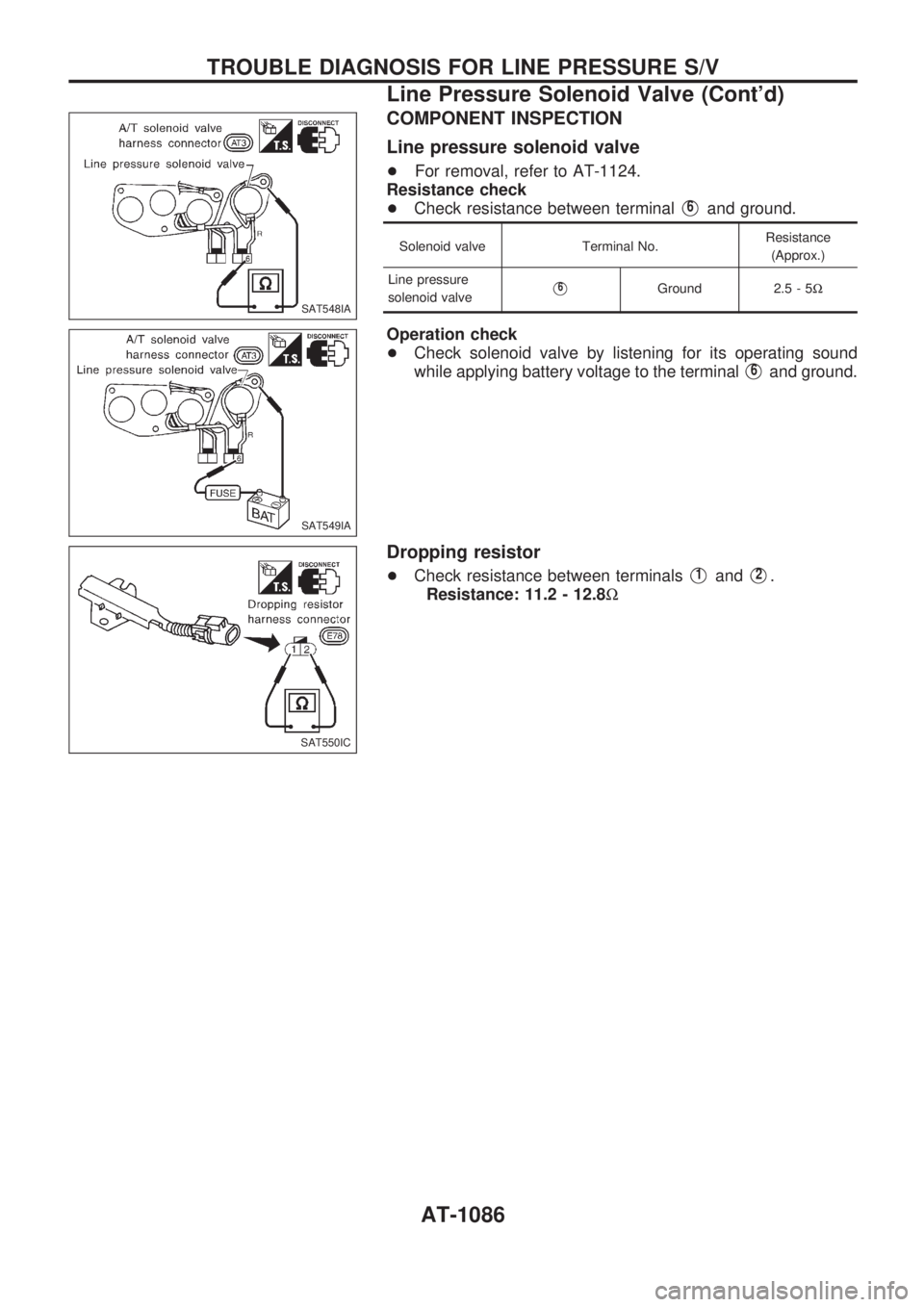

COMPONENT INSPECTION

Line pressure solenoid valve

+For removal, refer to AT-1124.

Resistance check

+Check resistance between terminal

V6and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Line pressure

solenoid valve

V6Ground 2.5 - 5W

Operation check

+Check solenoid valve by listening for its operating sound

while applying battery voltage to the terminal

V6and ground.

Dropping resistor

+Check resistance between terminalsV1andV2.

Resistance: 11.2 - 12.8W

SAT548IA

SAT549IA

SAT550IC

TROUBLE DIAGNOSIS FOR LINE PRESSURE S/V

Line Pressure Solenoid Valve (Cont'd)

AT-1086

Page 94 of 1033

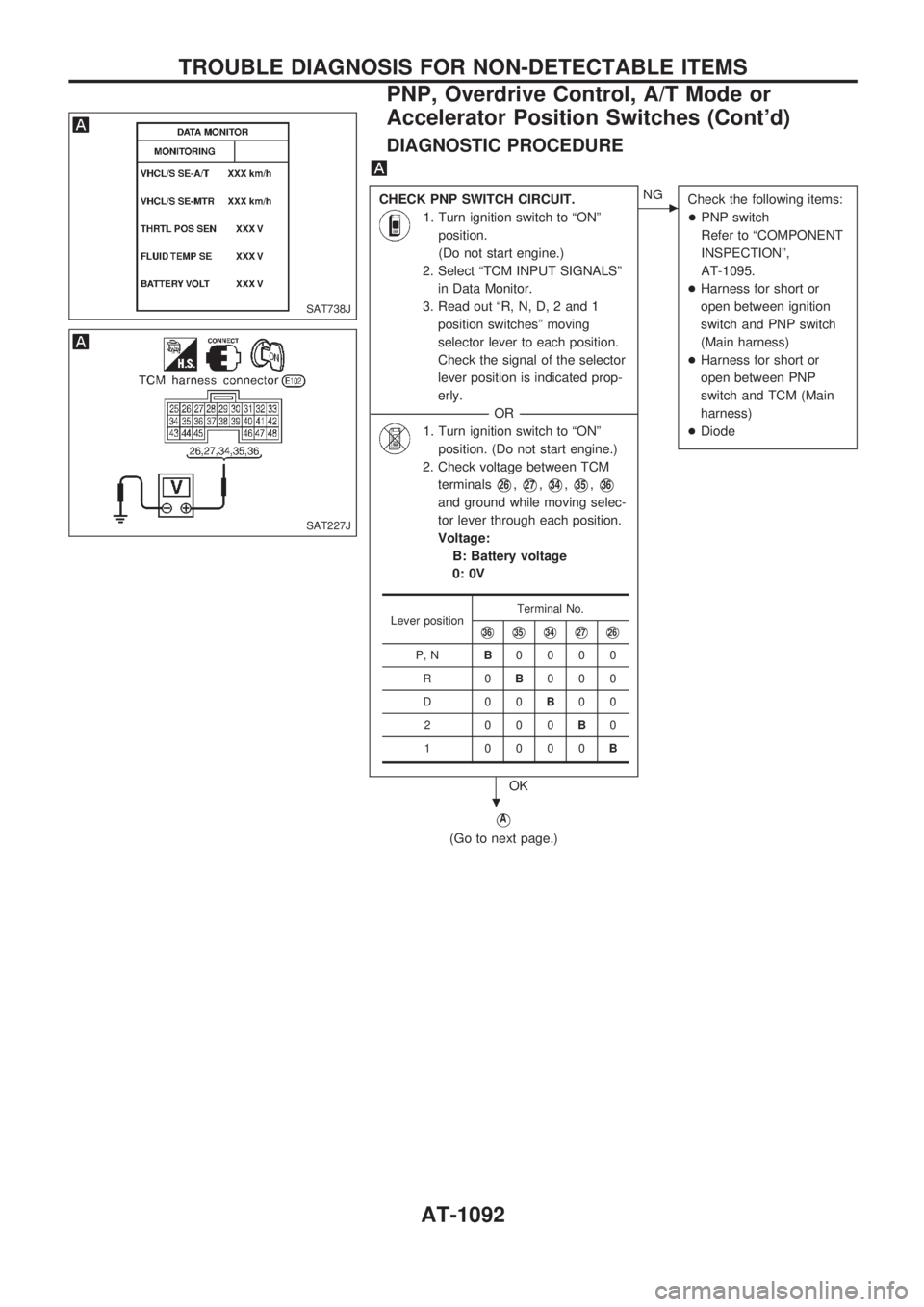

DIAGNOSTIC PROCEDURE

CHECK PNP SWITCH CIRCUIT.

1. Turn ignition switch to ªONº

position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out ªR, N, D, 2 and 1

position switchesº moving

selector lever to each position.

Check the signal of the selector

lever position is indicated prop-

erly.

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº

position. (Do not start engine.)

2. Check voltage between TCM

terminals

V26,V27,V34,V35,V36

and ground while moving selec-

tor lever through each position.

Voltage:

B: Battery voltage

0: 0V

OK

cNG

Check the following items:

+PNP switch

Refer to ªCOMPONENT

INSPECTIONº,

AT-1095.

+Harness for short or

open between ignition

switch and PNP switch

(Main harness)

+Harness for short or

open between PNP

switch and TCM (Main

harness)

+Diode

VA

(Go to next page.)

Lever positionTerminal No.V36V35V34V27V26

P, NB0000

R0B000

D00B00

2 000B0

1 0000B

SAT738J

SAT227J

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

PNP, Overdrive Control, A/T Mode or

Accelerator Position Switches (Cont'd)

AT-1092

Page 95 of 1033

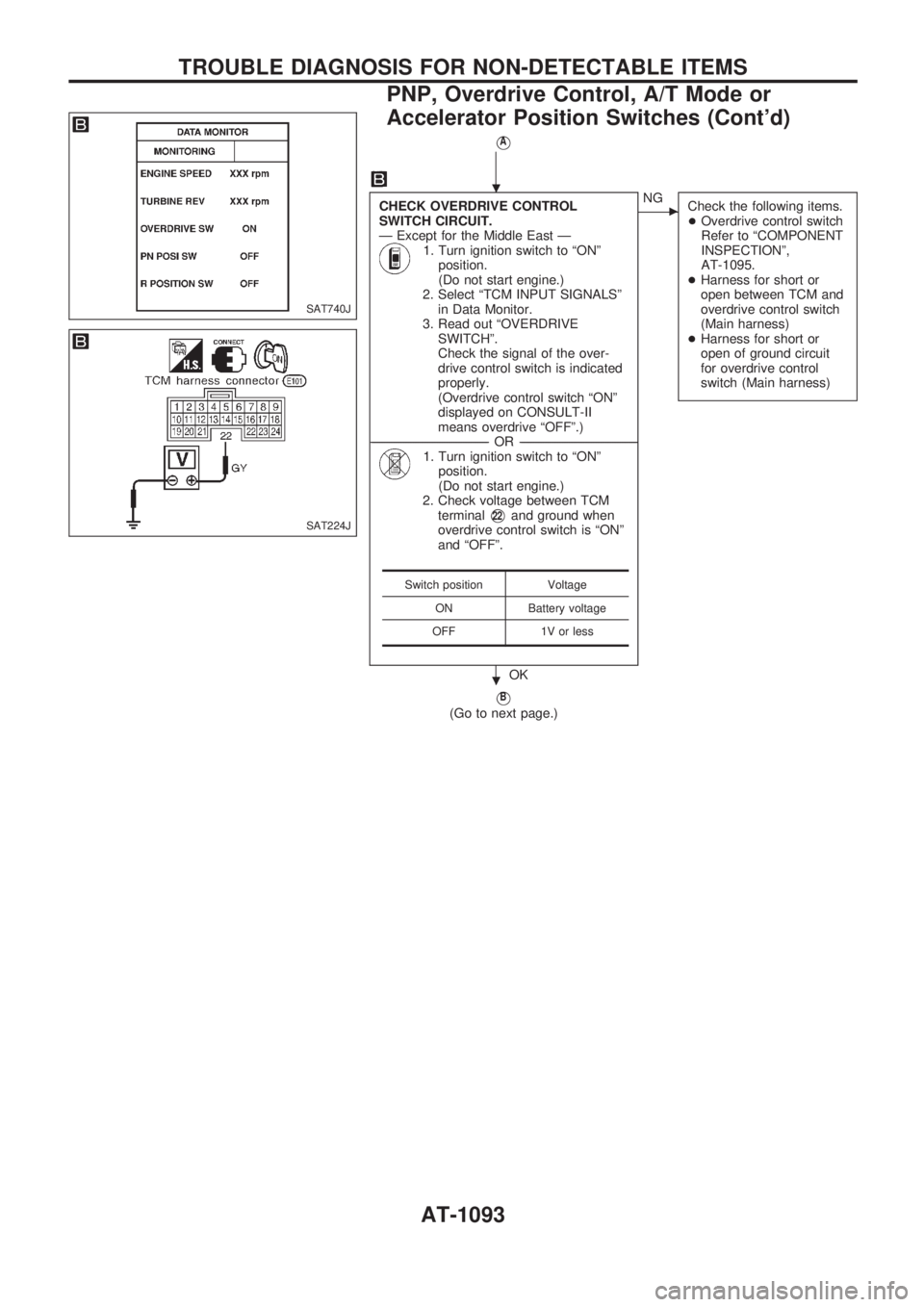

VA

CHECK OVERDRIVE CONTROL

SWITCH CIRCUIT.

Ð Except for the Middle East Ð

1. Turn ignition switch to ªONº

position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out ªOVERDRIVE

SWITCHº.

Check the signal of the over-

drive control switch is indicated

properly.

(Overdrive control switch ªONº

displayed on CONSULT-II

means overdrive ªOFFº.)

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº

position.

(Do not start engine.)

2. Check voltage between TCM

terminal

V22and ground when

overdrive control switch is ªONº

and ªOFFº.

OK

cNG

Check the following items.

+Overdrive control switch

Refer to ªCOMPONENT

INSPECTIONº,

AT-1095.

+Harness for short or

open between TCM and

overdrive control switch

(Main harness)

+Harness for short or

open of ground circuit

for overdrive control

switch (Main harness)

VB

(Go to next page.)

Switch position Voltage

ON Battery voltage

OFF 1V or less

SAT740J

SAT224J

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

PNP, Overdrive Control, A/T Mode or

Accelerator Position Switches (Cont'd)

AT-1093

Page 96 of 1033

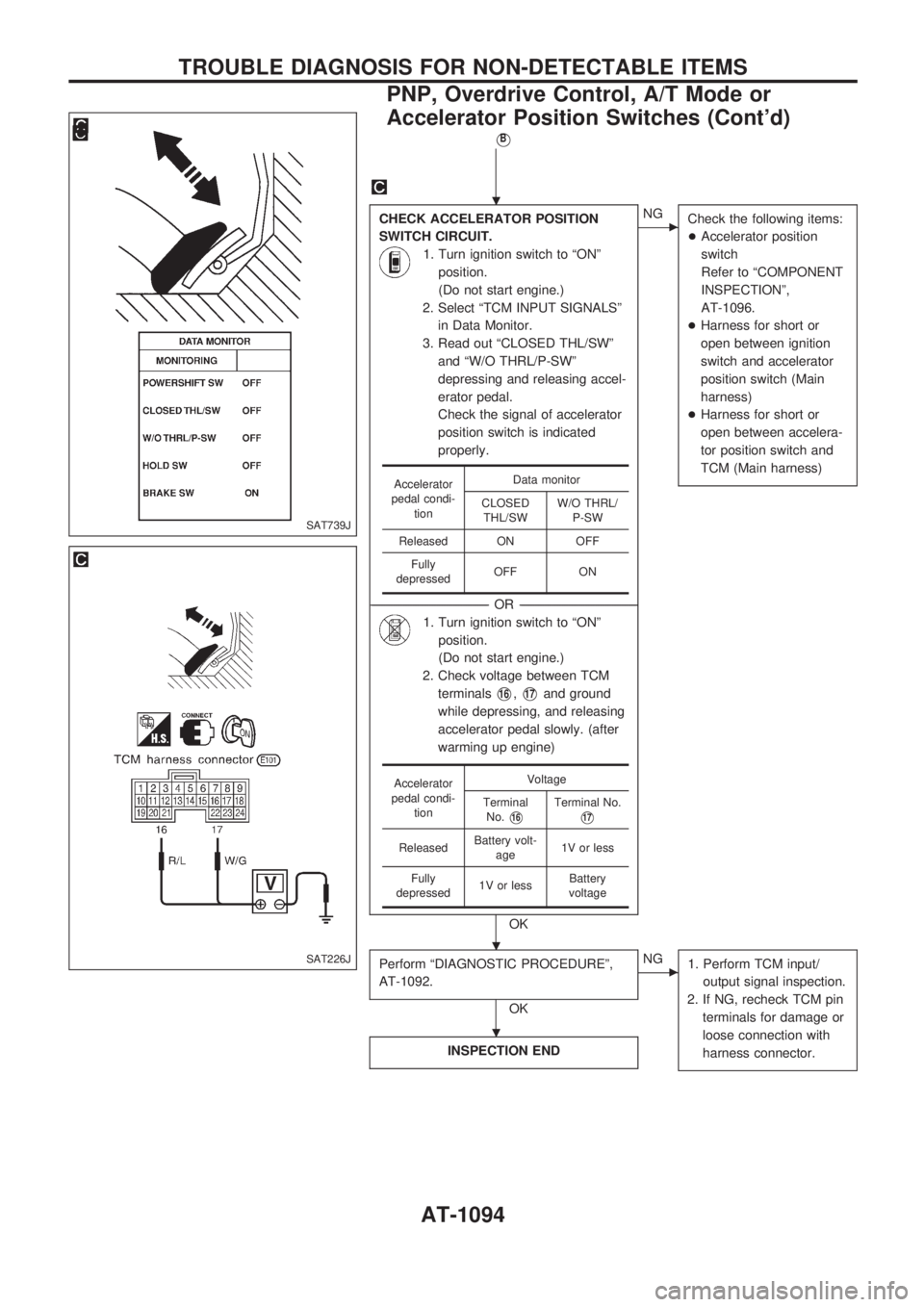

VB

CHECK ACCELERATOR POSITION

SWITCH CIRCUIT.

1. Turn ignition switch to ªONº

position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out ªCLOSED THL/SWº

and ªW/O THRL/P-SWº

depressing and releasing accel-

erator pedal.

Check the signal of accelerator

position switch is indicated

properly.

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº

position.

(Do not start engine.)

2. Check voltage between TCM

terminals

V16,V17and ground

while depressing, and releasing

accelerator pedal slowly. (after

warming up engine)

OK

cNG

Check the following items:

+Accelerator position

switch

Refer to ªCOMPONENT

INSPECTIONº,

AT-1096.

+Harness for short or

open between ignition

switch and accelerator

position switch (Main

harness)

+Harness for short or

open between accelera-

tor position switch and

TCM (Main harness)

Perform ªDIAGNOSTIC PROCEDUREº,

AT-1092.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

Accelerator

pedal condi-

tionData monitor

CLOSED

THL/SWW/O THRL/

P-SW

Released ON OFF

Fully

depressedOFF ON

Accelerator

pedal condi-

tionVoltage

Terminal

No.

V16Terminal No.

V17

ReleasedBattery volt-

age1V or less

Fully

depressed1V or lessBattery

voltage

SAT739J

SAT226J

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

PNP, Overdrive Control, A/T Mode or

Accelerator Position Switches (Cont'd)

AT-1094

Page 99 of 1033

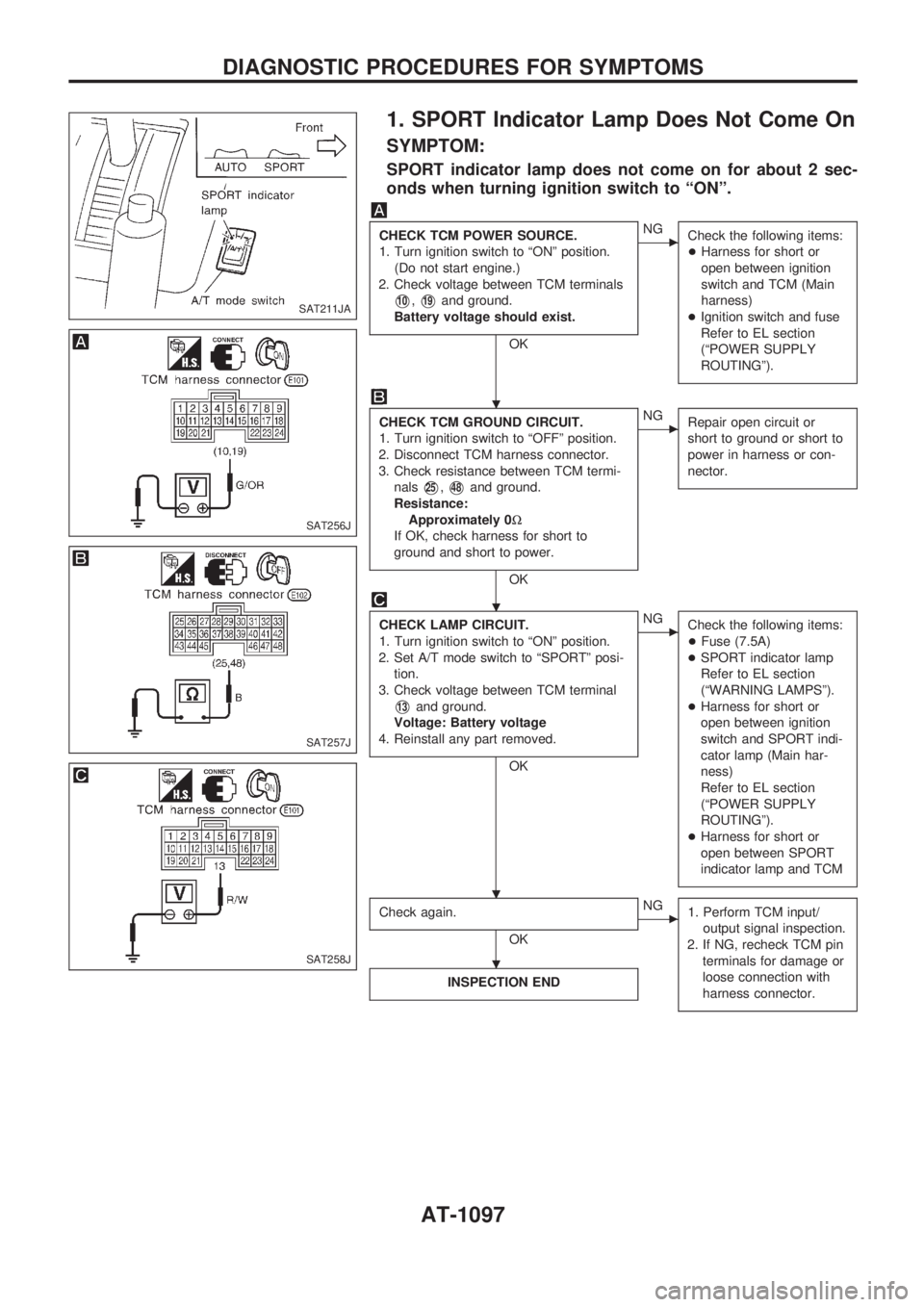

1. SPORT Indicator Lamp Does Not Come On

SYMPTOM:

SPORT indicator lamp does not come on for about 2 sec-

onds when turning ignition switch to ªONº.

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals

V10,V19and ground.

Battery voltage should exist.

OK

cNG

Check the following items:

+Harness for short or

open between ignition

switch and TCM (Main

harness)

+Ignition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK TCM GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between TCM termi-

nals

V25,V48and ground.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

OK

cNG

Repair open circuit or

short to ground or short to

power in harness or con-

nector.

CHECK LAMP CIRCUIT.

1. Turn ignition switch to ªONº position.

2. Set A/T mode switch to ªSPORTº posi-

tion.

3. Check voltage between TCM terminal

V13and ground.

Voltage: Battery voltage

4. Reinstall any part removed.

OK

cNG

Check the following items:

+Fuse (7.5A)

+SPORT indicator lamp

Refer to EL section

(ªWARNING LAMPSº).

+Harness for short or

open between ignition

switch and SPORT indi-

cator lamp (Main har-

ness)

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

+Harness for short or

open between SPORT

indicator lamp and TCM

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT211JA

SAT256J

SAT257J

SAT258J

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1097

Page 120 of 1033

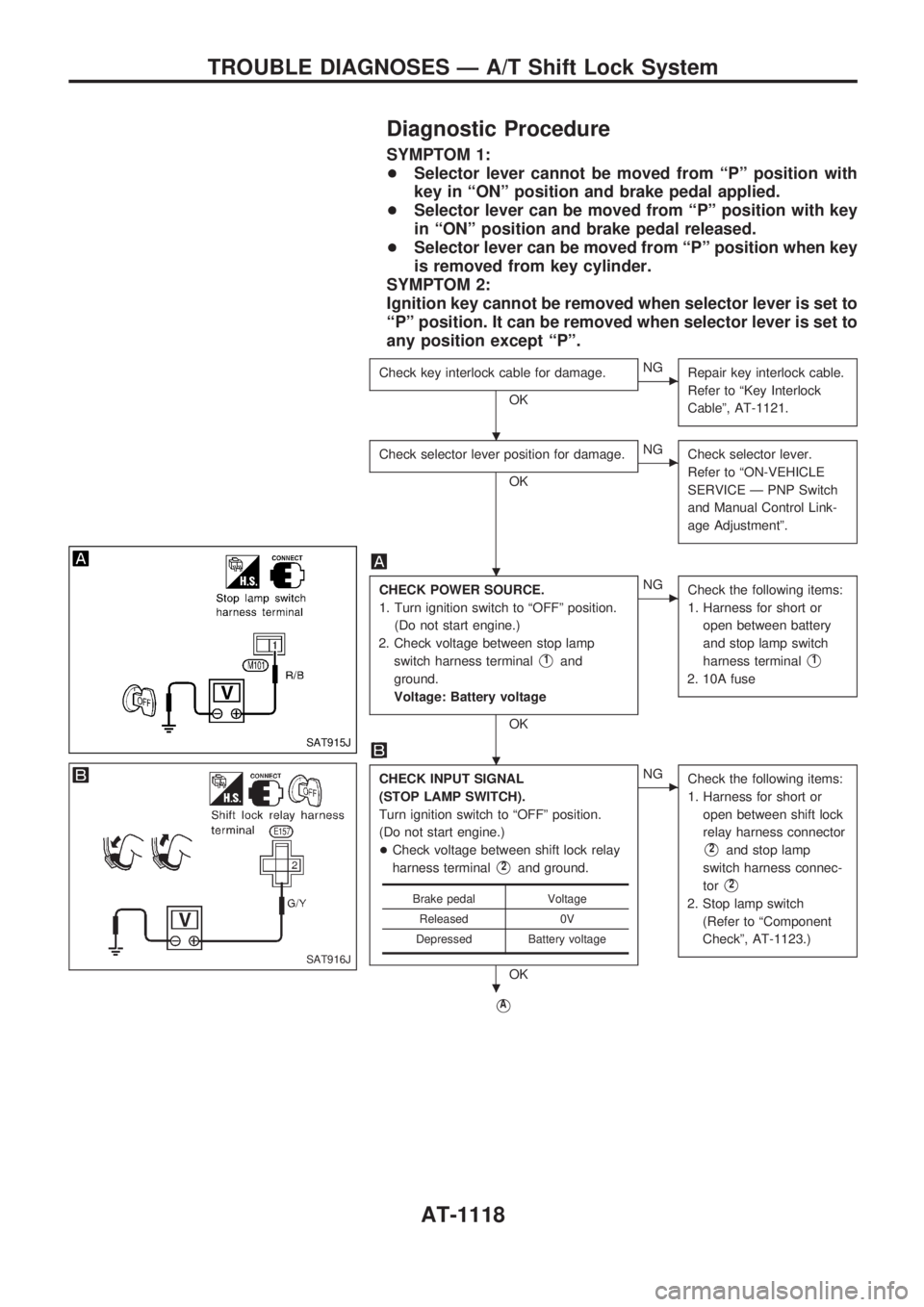

Diagnostic Procedure

SYMPTOM 1:

+Selector lever cannot be moved from ªPº position with

key in ªONº position and brake pedal applied.

+Selector lever can be moved from ªPº position with key

in ªONº position and brake pedal released.

+Selector lever can be moved from ªPº position when key

is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to

ªPº position. It can be removed when selector lever is set to

any position except ªPº.

Check key interlock cable for damage.

OK

cNG

Repair key interlock cable.

Refer to ªKey Interlock

Cableº, AT-1121.

Check selector lever position for damage.

OK

cNG

Check selector lever.

Refer to ªON-VEHICLE

SERVICE Ð PNP Switch

and Manual Control Link-

age Adjustmentº.

CHECK POWER SOURCE.

1. Turn ignition switch to ªOFFº position.

(Do not start engine.)

2. Check voltage between stop lamp

switch harness terminal

V1and

ground.

Voltage: Battery voltage

OK

cNG

Check the following items:

1. Harness for short or

open between battery

and stop lamp switch

harness terminal

V1

2. 10A fuse

CHECK INPUT SIGNAL

(STOP LAMP SWITCH).

Turn ignition switch to ªOFFº position.

(Do not start engine.)

+Check voltage between shift lock relay

harness terminal

V2and ground.

OK

cNG

Check the following items:

1. Harness for short or

open between shift lock

relay harness connector

V2and stop lamp

switch harness connec-

tor

V2

2. Stop lamp switch

(Refer to ªComponent

Checkº, AT-1123.)

VA

Brake pedal Voltage

Released 0V

Depressed Battery voltage

SAT915J

SAT916J

.

.

.

.

TROUBLE DIAGNOSES Ð A/T Shift Lock System

AT-1118

Page 121 of 1033

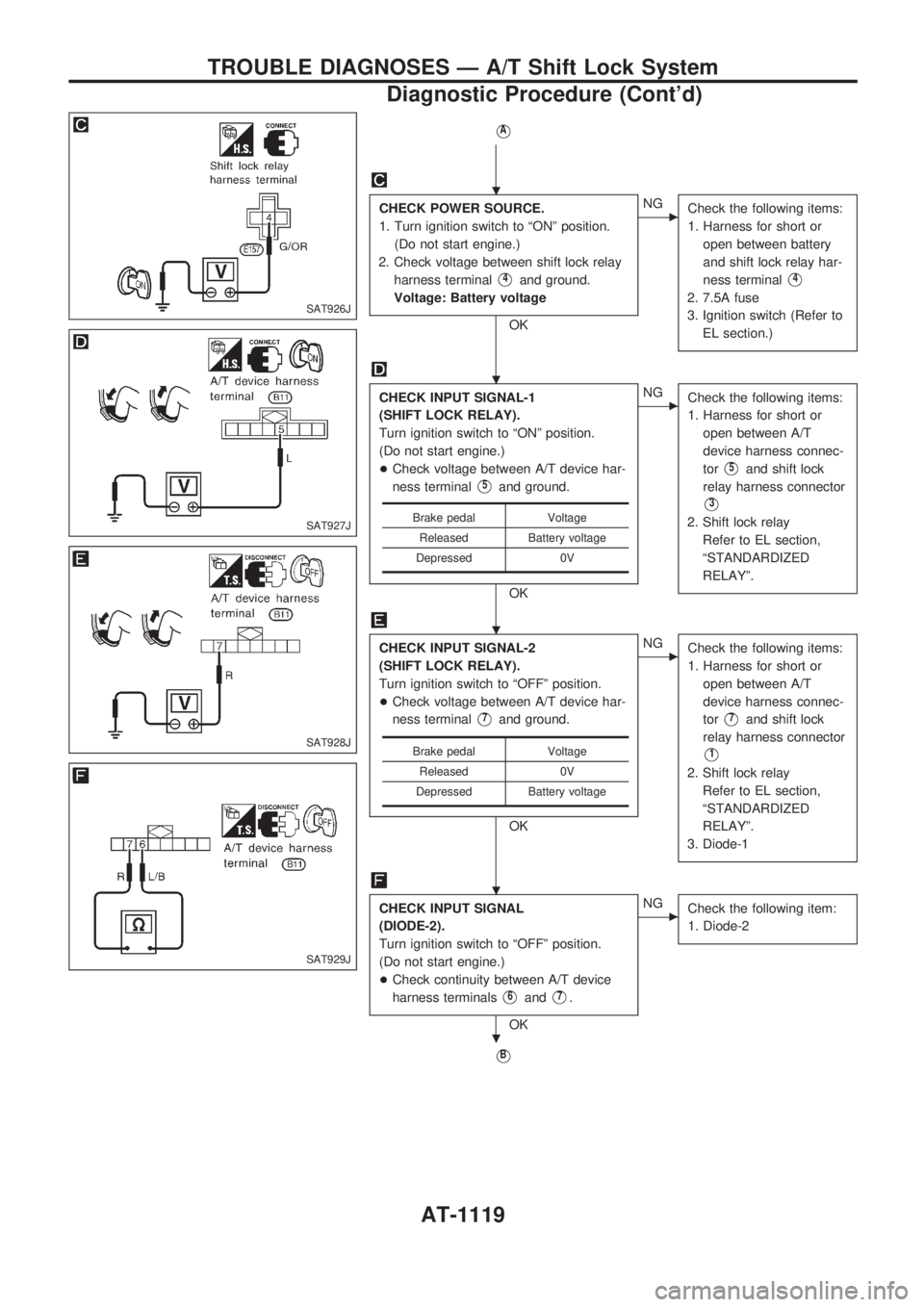

VA

CHECK POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between shift lock relay

harness terminal

V4and ground.

Voltage: Battery voltage

OK

cNG

Check the following items:

1. Harness for short or

open between battery

and shift lock relay har-

ness terminal

V4

2. 7.5A fuse

3. Ignition switch (Refer to

EL section.)

CHECK INPUT SIGNAL-1

(SHIFT LOCK RELAY).

Turn ignition switch to ªONº position.

(Do not start engine.)

+Check voltage between A/T device har-

ness terminal

V5and ground.

OK

cNG

Check the following items:

1. Harness for short or

open between A/T

device harness connec-

tor

V5and shift lock

relay harness connector

V3

2. Shift lock relay

Refer to EL section,

ªSTANDARDIZED

RELAYº.

CHECK INPUT SIGNAL-2

(SHIFT LOCK RELAY).

Turn ignition switch to ªOFFº position.

+Check voltage between A/T device har-

ness terminal

V7and ground.

OK

cNG

Check the following items:

1. Harness for short or

open between A/T

device harness connec-

tor

V7and shift lock

relay harness connector

V1

2. Shift lock relay

Refer to EL section,

ªSTANDARDIZED

RELAYº.

3. Diode-1

CHECK INPUT SIGNAL

(DIODE-2).

Turn ignition switch to ªOFFº position.

(Do not start engine.)

+Check continuity between A/T device

harness terminals

V6andV7.

OK

cNG

Check the following item:

1. Diode-2

VB

Brake pedal Voltage

Released Battery voltage

Depressed 0V

Brake pedal Voltage

Released 0V

Depressed Battery voltage

SAT926J

SAT927J

SAT928J

SAT929J

.

.

.

.

.

TROUBLE DIAGNOSES Ð A/T Shift Lock System

Diagnostic Procedure (Cont'd)

AT-1119