battery NISSAN PATROL 2000 Electronic Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 306 of 1033

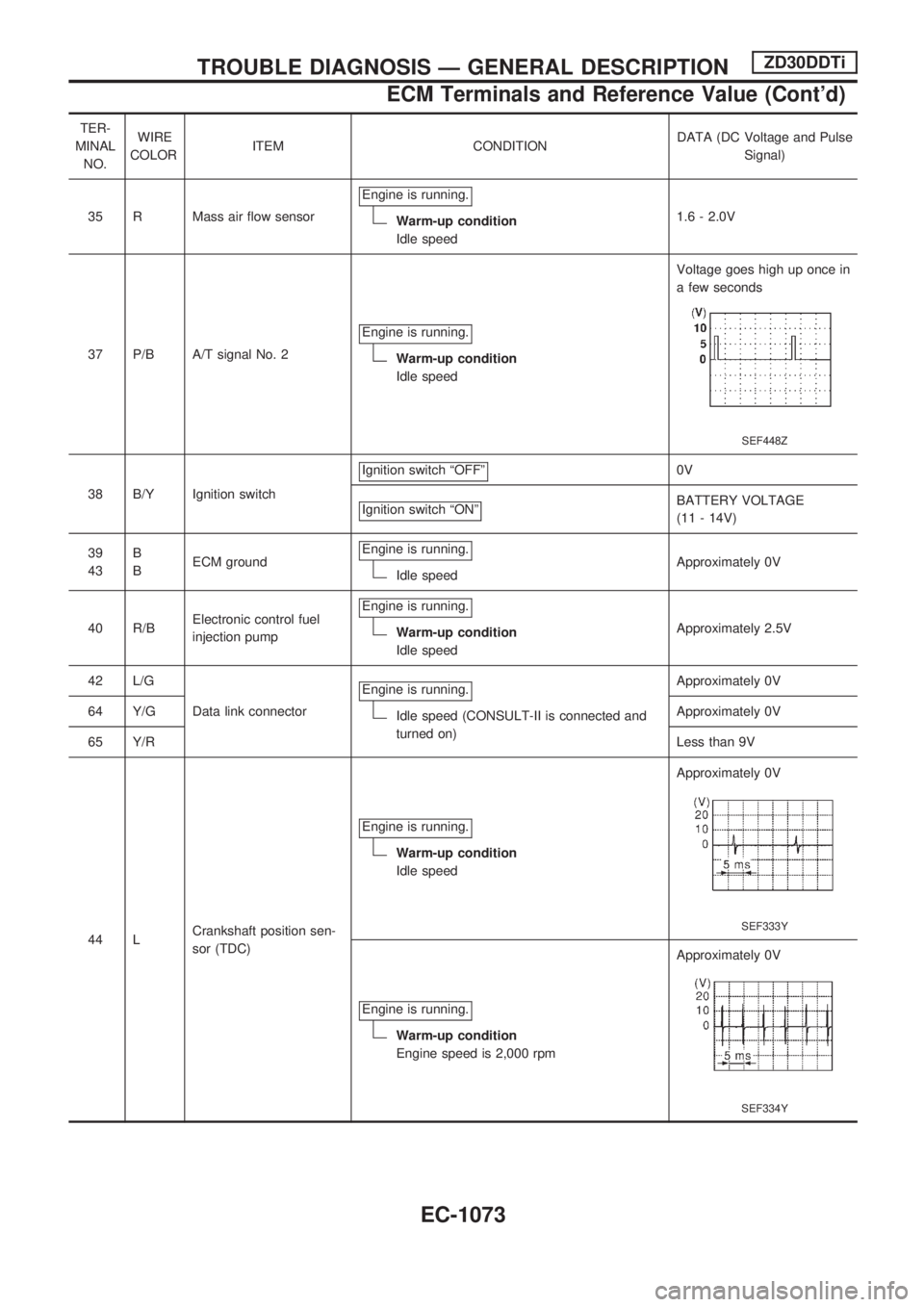

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

35 R Mass air flow sensorEngine is running.

Warm-up condition

Idle speed1.6 - 2.0V

37 P/B A/T signal No. 2Engine is running.

Warm-up condition

Idle speedVoltage goes high up once in

a few seconds

SEF448Z

38 B/Y Ignition switchIgnition switch ªOFFº

0V

Ignition switch ªONº

BATTERY VOLTAGE

(11 - 14V)

39

43B

BECM groundEngine is running.

Idle speedApproximately 0V

40 R/BElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.5V

42 L/G

Data link connectorEngine is running.

Idle speed (CONSULT-II is connected and

turned on)Approximately 0V

64 Y/GApproximately 0V

65 Y/RLess than 9V

44 LCrankshaft position sen-

sor (TDC)Engine is running.

Warm-up condition

Idle speedApproximately 0V

SEF333Y

Engine is running.

Warm-up condition

Engine speed is 2,000 rpmApproximately 0V

SEF334Y

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-1073

Page 307 of 1033

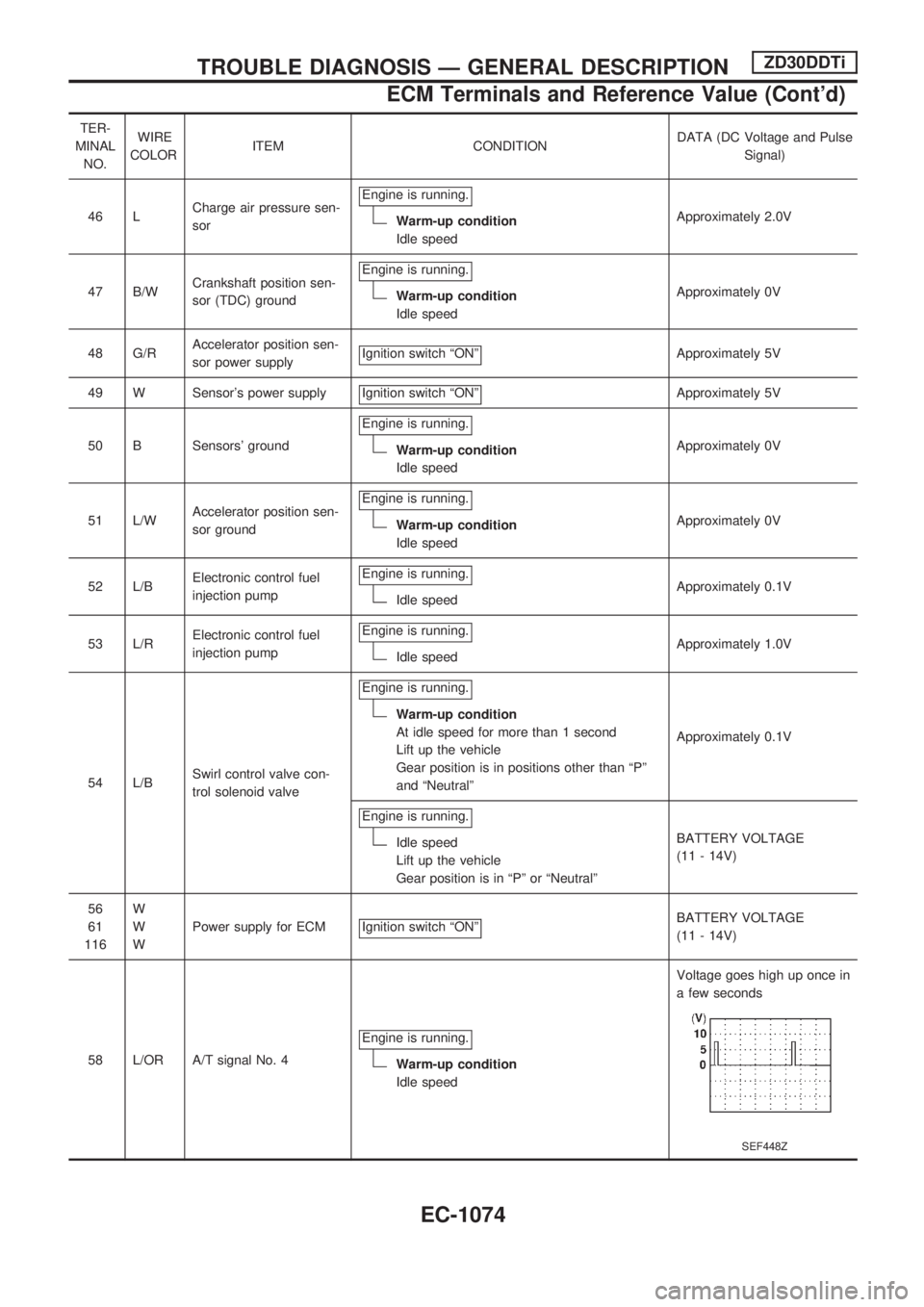

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

46 LCharge air pressure sen-

sorEngine is running.

Warm-up condition

Idle speedApproximately 2.0V

47 B/WCrankshaft position sen-

sor (TDC) groundEngine is running.

Warm-up condition

Idle speedApproximately 0V

48 G/RAccelerator position sen-

sor power supplyIgnition switch ªONº

Approximately 5V

49 W Sensor's power supply Ignition switch ªONº

Approximately 5V

50 B Sensors' groundEngine is running.

Warm-up condition

Idle speedApproximately 0V

51 L/WAccelerator position sen-

sor groundEngine is running.

Warm-up condition

Idle speedApproximately 0V

52 L/BElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.1V

53 L/RElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 1.0V

54 L/BSwirl control valve con-

trol solenoid valveEngine is running.

Warm-up condition

At idle speed for more than 1 second

Lift up the vehicle

Gear position is in positions other than ªPº

and ªNeutralºApproximately 0.1V

Engine is running.

Idle speed

Lift up the vehicle

Gear position is in ªPº or ªNeutralºBATTERY VOLTAGE

(11 - 14V)

56

61

116W

W

WPower supply for ECM Ignition switch ªONº

BATTERY VOLTAGE

(11 - 14V)

58 L/OR A/T signal No. 4Engine is running.

Warm-up condition

Idle speedVoltage goes high up once in

a few seconds

SEF448Z

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-1074

Page 308 of 1033

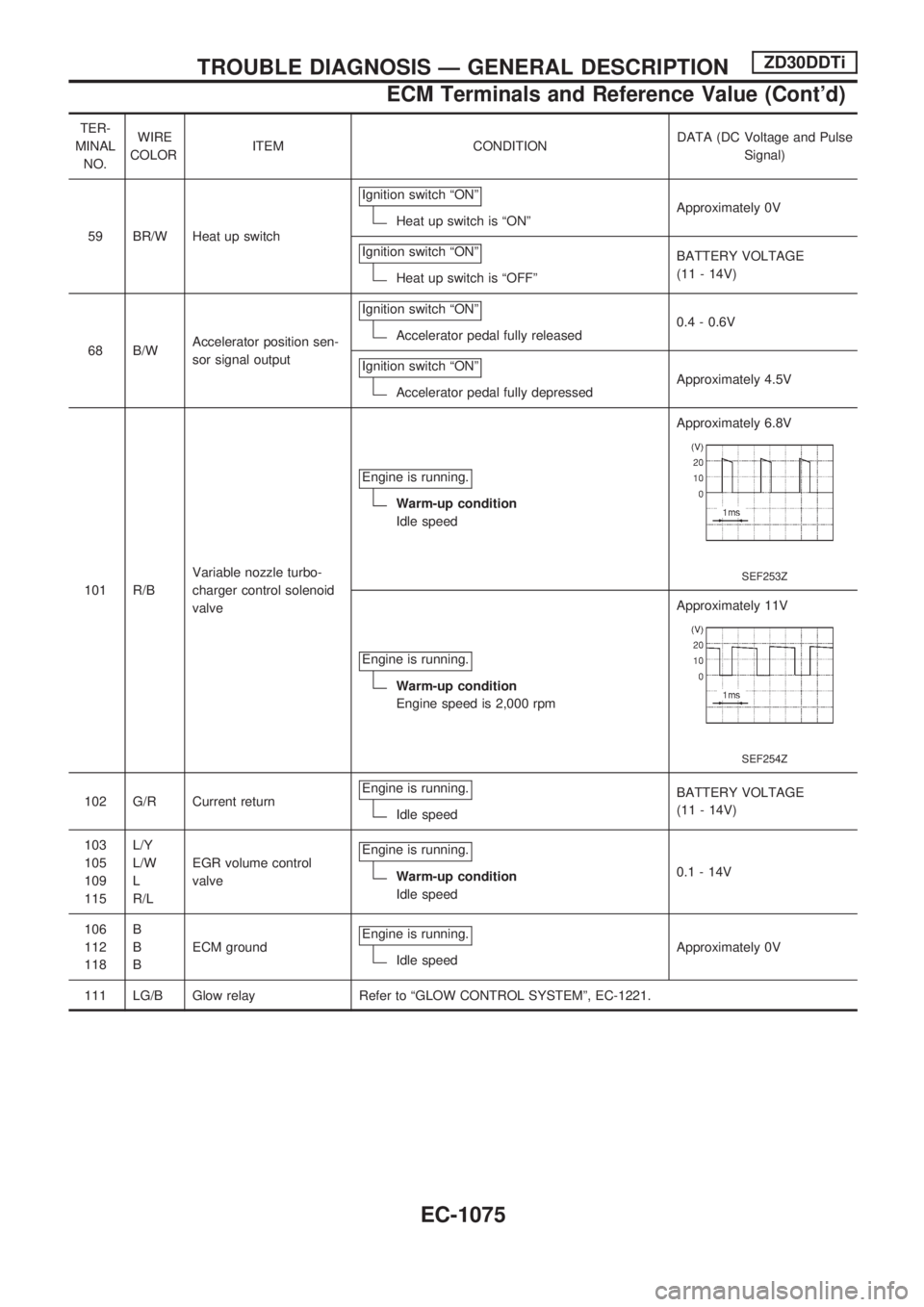

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

59 BR/W Heat up switchIgnition switch ªONº

Heat up switch is ªONºApproximately 0V

Ignition switch ªONº

Heat up switch is ªOFFºBATTERY VOLTAGE

(11 - 14V)

68 B/WAccelerator position sen-

sor signal outputIgnition switch ªONº

Accelerator pedal fully released0.4 - 0.6V

Ignition switch ªONº

Accelerator pedal fully depressedApproximately 4.5V

101 R/BVariable nozzle turbo-

charger control solenoid

valveEngine is running.

Warm-up condition

Idle speedApproximately 6.8V

SEF253Z

Engine is running.

Warm-up condition

Engine speed is 2,000 rpmApproximately 11V

SEF254Z

102 G/R Current returnEngine is running.Idle speedBATTERY VOLTAGE

(11 - 14V)

103

105

109

115L/Y

L/W

L

R/LEGR volume control

valveEngine is running.

Warm-up condition

Idle speed0.1 - 14V

106

112

118B

B

BECM groundEngine is running.

Idle speedApproximately 0V

111 LG/B Glow relay Refer to ªGLOW CONTROL SYSTEMº, EC-1221.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-1075

Page 310 of 1033

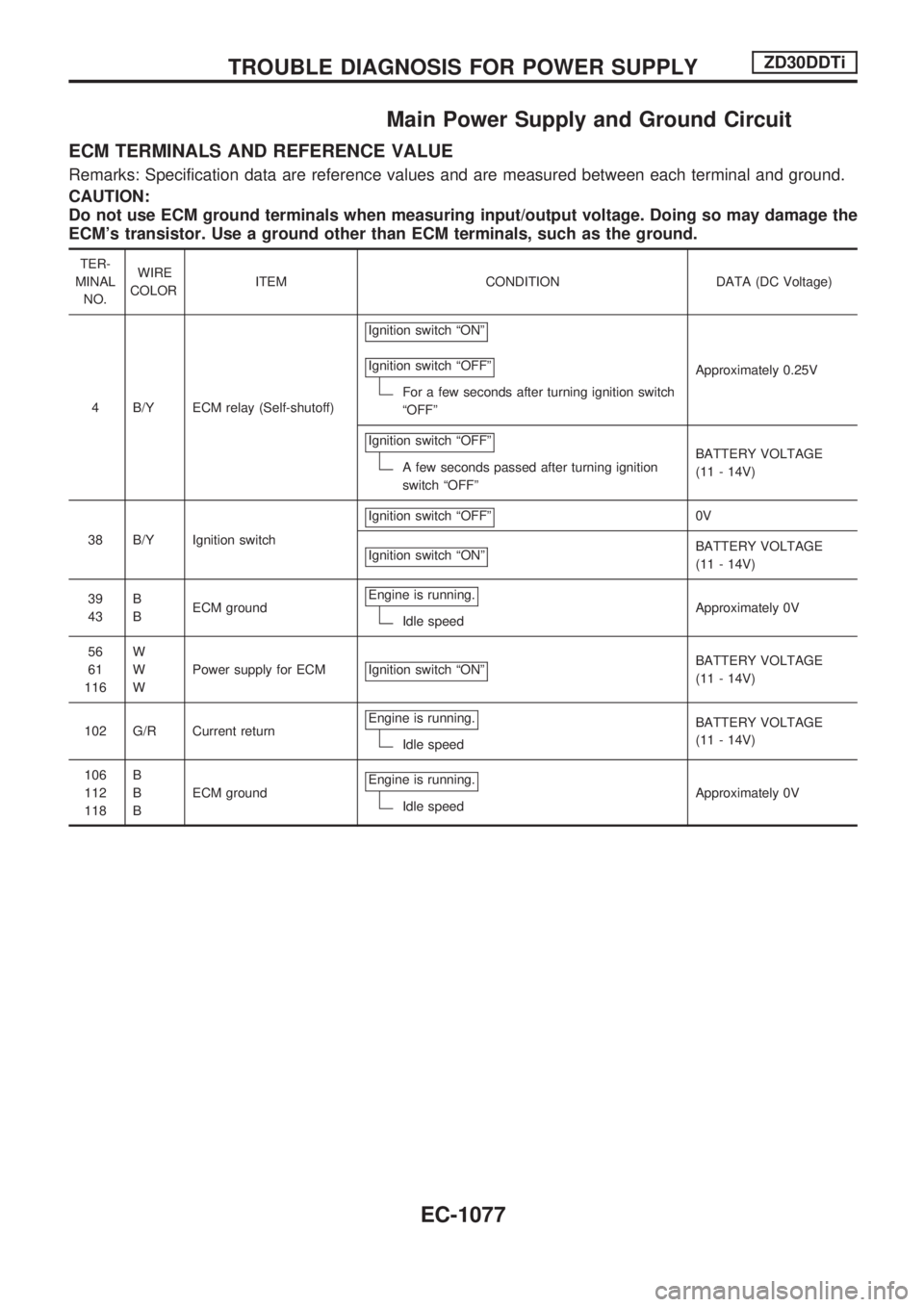

Main Power Supply and Ground Circuit

ECM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

4 B/Y ECM relay (Self-shutoff)Ignition switch ªONº

Ignition switch ªOFFº

For a few seconds after turning ignition switch

ªOFFºApproximately 0.25V

Ignition switch ªOFFº

A few seconds passed after turning ignition

switch ªOFFºBATTERY VOLTAGE

(11 - 14V)

38 B/Y Ignition switchIgnition switch ªOFFº

0V

Ignition switch ªONº

BATTERY VOLTAGE

(11 - 14V)

39

43B

BECM groundEngine is running.

Idle speedApproximately 0V

56

61

116W

W

WPower supply for ECM Ignition switch ªONº

BATTERY VOLTAGE

(11 - 14V)

102 G/R Current returnEngine is running.

Idle speedBATTERY VOLTAGE

(11 - 14V)

106

112

118B

B

BECM groundEngine is running.

Idle speedApproximately 0V

TROUBLE DIAGNOSIS FOR POWER SUPPLYZD30DDTi

EC-1077

Page 314 of 1033

5 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-3

+Harness for open or short between ECM and engine ground

cRepair open circuit or short to ground or short to power in harness or connectors.

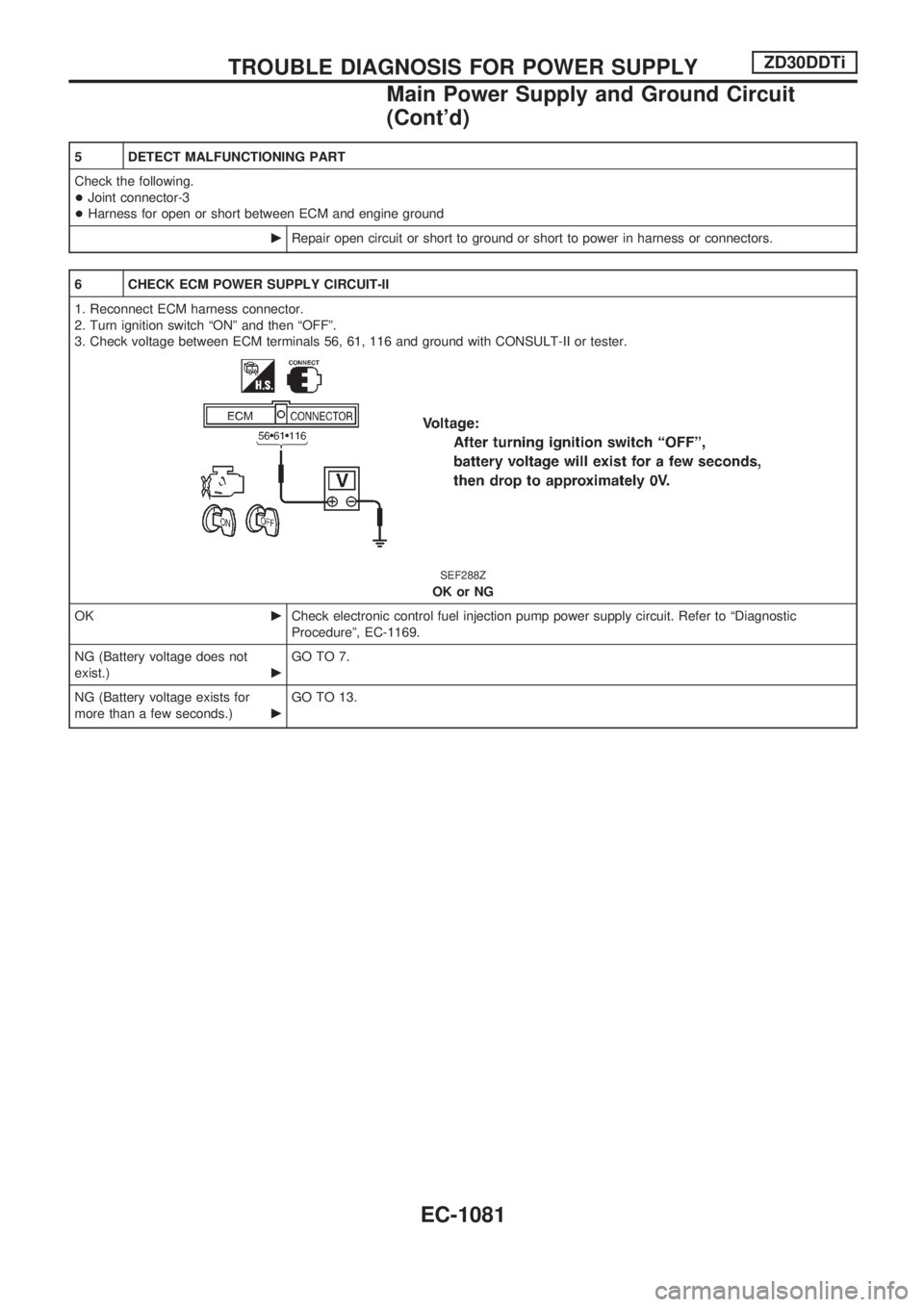

6 CHECK ECM POWER SUPPLY CIRCUIT-II

1. Reconnect ECM harness connector.

2. Turn ignition switch ªONº and then ªOFFº.

3. Check voltage between ECM terminals 56, 61, 116 and ground with CONSULT-II or tester.

SEF288Z

OK or NG

OKcCheck electronic control fuel injection pump power supply circuit. Refer to ªDiagnostic

Procedureº, EC-1169.

NG (Battery voltage does not

exist.)cGO TO 7.

NG (Battery voltage exists for

more than a few seconds.)cGO TO 13.

TROUBLE DIAGNOSIS FOR POWER SUPPLYZD30DDTi

Main Power Supply and Ground Circuit

(Cont'd)

EC-1081

Page 315 of 1033

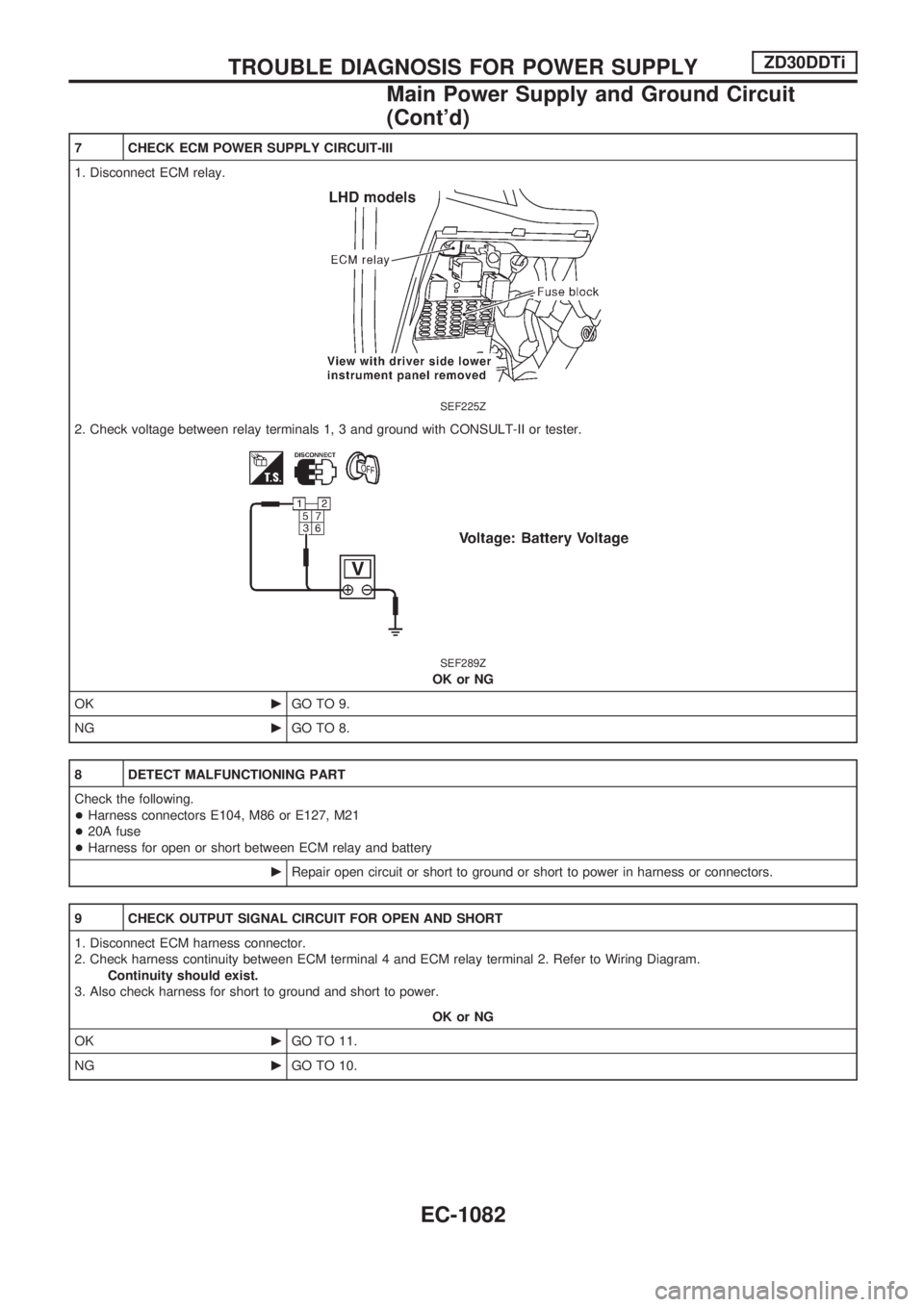

7 CHECK ECM POWER SUPPLY CIRCUIT-III

1. Disconnect ECM relay.

SEF225Z

2. Check voltage between relay terminals 1, 3 and ground with CONSULT-II or tester.

SEF289Z

OK or NG

OKcGO TO 9.

NGcGO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E104, M86 or E127, M21

+20A fuse

+Harness for open or short between ECM relay and battery

cRepair open circuit or short to ground or short to power in harness or connectors.

9 CHECK OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 4 and ECM relay terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 11.

NGcGO TO 10.

TROUBLE DIAGNOSIS FOR POWER SUPPLYZD30DDTi

Main Power Supply and Ground Circuit

(Cont'd)

EC-1082

Page 333 of 1033

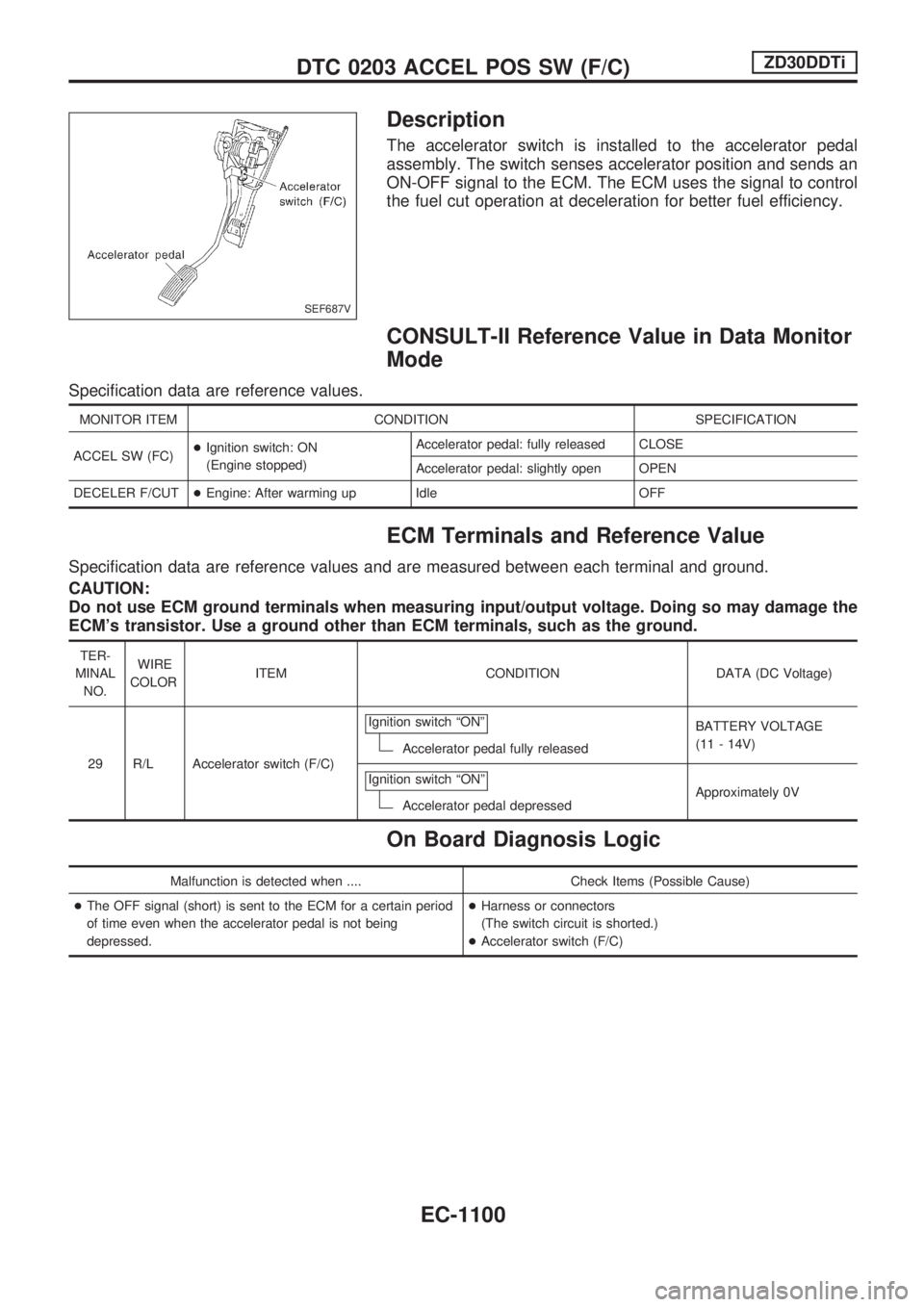

Description

The accelerator switch is installed to the accelerator pedal

assembly. The switch senses accelerator position and sends an

ON-OFF signal to the ECM. The ECM uses the signal to control

the fuel cut operation at deceleration for better fuel efficiency.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

ACCEL SW (FC)+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released CLOSE

Accelerator pedal: slightly open OPEN

DECELER F/CUT+Engine: After warming up Idle OFF

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

29 R/L Accelerator switch (F/C)Ignition switch ªONº

Accelerator pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

Ignition switch ªONº

Accelerator pedal depressedApproximately 0V

On Board Diagnosis Logic

Malfunction is detected when .... Check Items (Possible Cause)

+The OFF signal (short) is sent to the ECM for a certain period

of time even when the accelerator pedal is not being

depressed.+Harness or connectors

(The switch circuit is shorted.)

+Accelerator switch (F/C)

SEF687V

DTC 0203 ACCEL POS SW (F/C)ZD30DDTi

EC-1100

Page 339 of 1033

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

14 L Cooling fan relayEngine is running.

Cooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

Engine is running.

Cooling fan is operatingApproximately 0.1V

On Board Diagnosis Logic

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Malfunction is detected when ... Check Items (Possible Cause)

+Cooling fan does not operate properly (Overheat).

+Cooling fan system does not operate properly (Overheat).

+Engine coolant was not added to the system using the proper

filling method.+Harness or connectors

(The cooling fan circuit is open or shorted.)

+Cooling fan

+Radiator hose

+Radiator

+Radiator cap

+Water pump

+Thermostat

+Fan belt

+Engine coolant temperature sensor

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-1116.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure

to use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture

Ratioº, ªRECOMMENDED LUBRICANTS AND FLUIDSº).

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC 0208 OVER HEATZD30DDTi

EC-1106

Page 344 of 1033

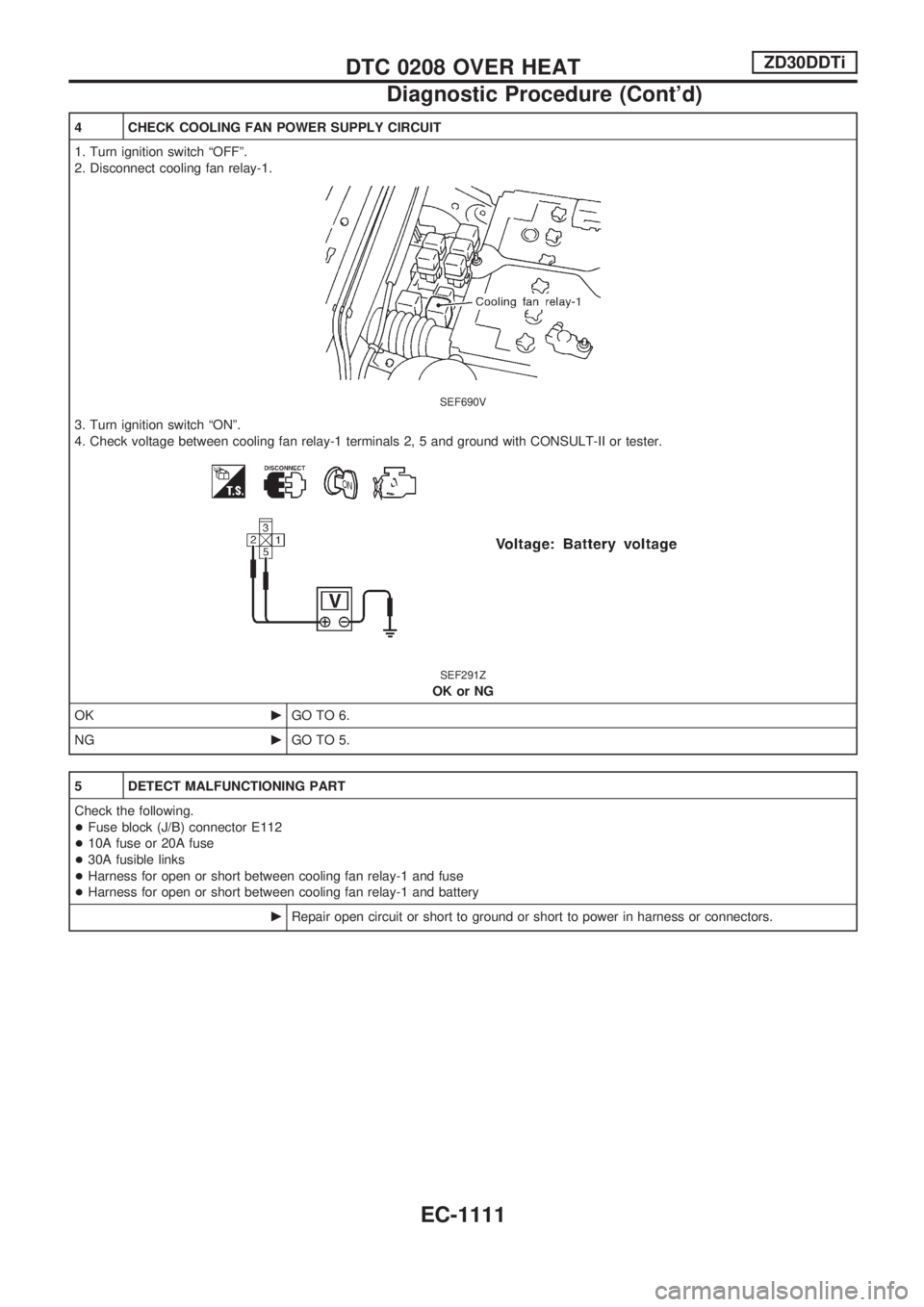

4 CHECK COOLING FAN POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan relay-1.

SEF690V

3. Turn ignition switch ªONº.

4. Check voltage between cooling fan relay-1 terminals 2, 5 and ground with CONSULT-II or tester.

SEF291Z

OK or NG

OKcGO TO 6.

NGcGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Fuse block (J/B) connector E112

+10A fuse or 20A fuse

+30A fusible links

+Harness for open or short between cooling fan relay-1 and fuse

+Harness for open or short between cooling fan relay-1 and battery

cRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1111

Page 346 of 1033

9 CHECK COOLING FAN RELAY-1

Check continuity between cooling fan relay-1 terminals 3 and 5 under the following conditions.

SEF608X

OK or NG

OKcGO TO 10.

NGcReplace cooling fan relay.

10 CHECK COOLING FAN MOTOR-1

Supply battery voltage between the following terminals and check operation.

SEF292Z

OK or NG

OKcGO TO 11.

NGcReplace cooling fan motor.

11 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1113