battery NISSAN PATROL 2000 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 124 of 1033

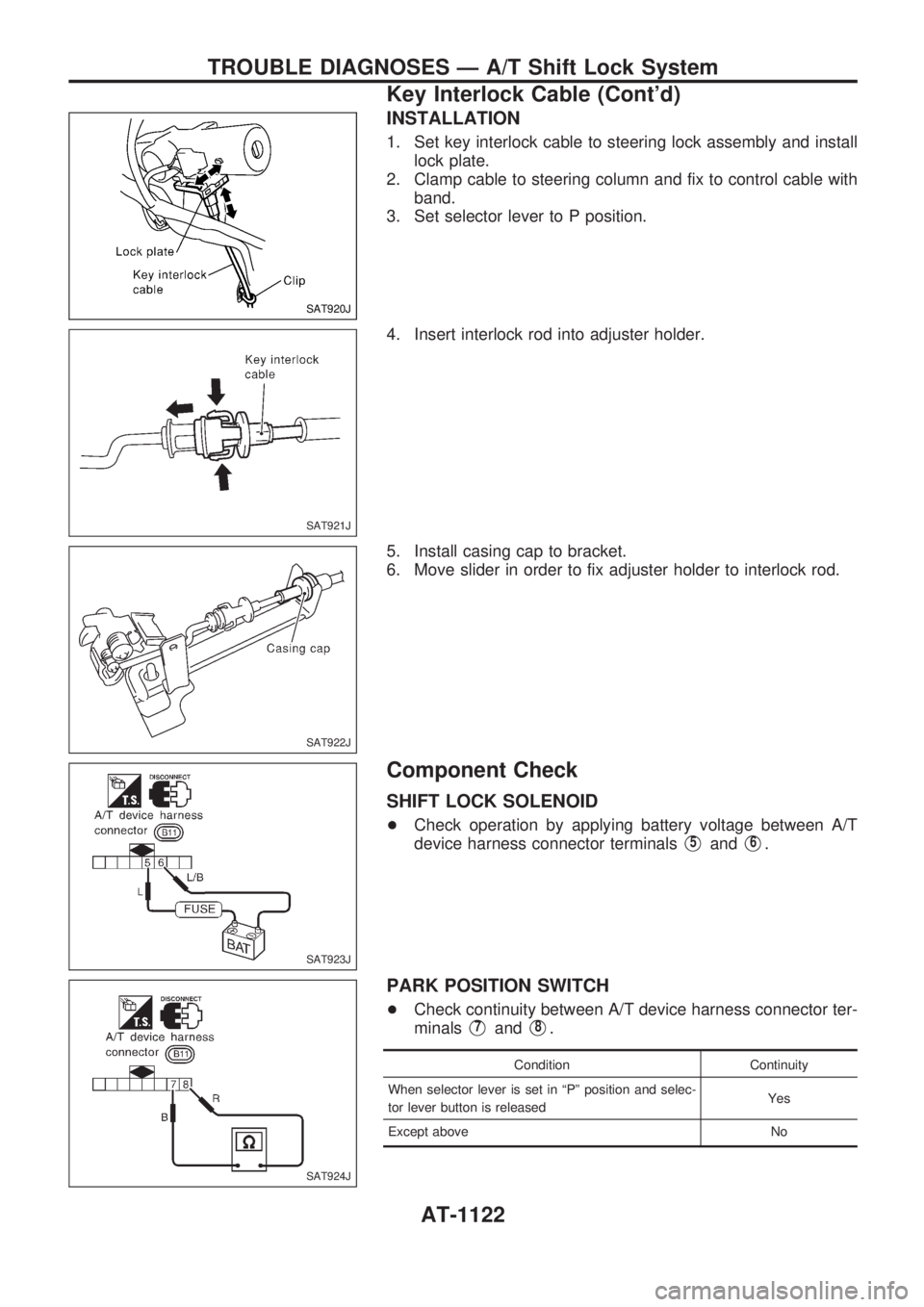

INSTALLATION

1. Set key interlock cable to steering lock assembly and install

lock plate.

2. Clamp cable to steering column and fix to control cable with

band.

3. Set selector lever to P position.

4. Insert interlock rod into adjuster holder.

5. Install casing cap to bracket.

6. Move slider in order to fix adjuster holder to interlock rod.

Component Check

SHIFT LOCK SOLENOID

+Check operation by applying battery voltage between A/T

device harness connector terminals

V5andV6.

PARK POSITION SWITCH

+Check continuity between A/T device harness connector ter-

minals

V7andV8.

Condition Continuity

When selector lever is set in ªPº position and selec-

tor lever button is releasedYes

Except above No

SAT920J

SAT921J

SAT922J

SAT923J

SAT924J

TROUBLE DIAGNOSES Ð A/T Shift Lock System

Key Interlock Cable (Cont'd)

AT-1122

Page 129 of 1033

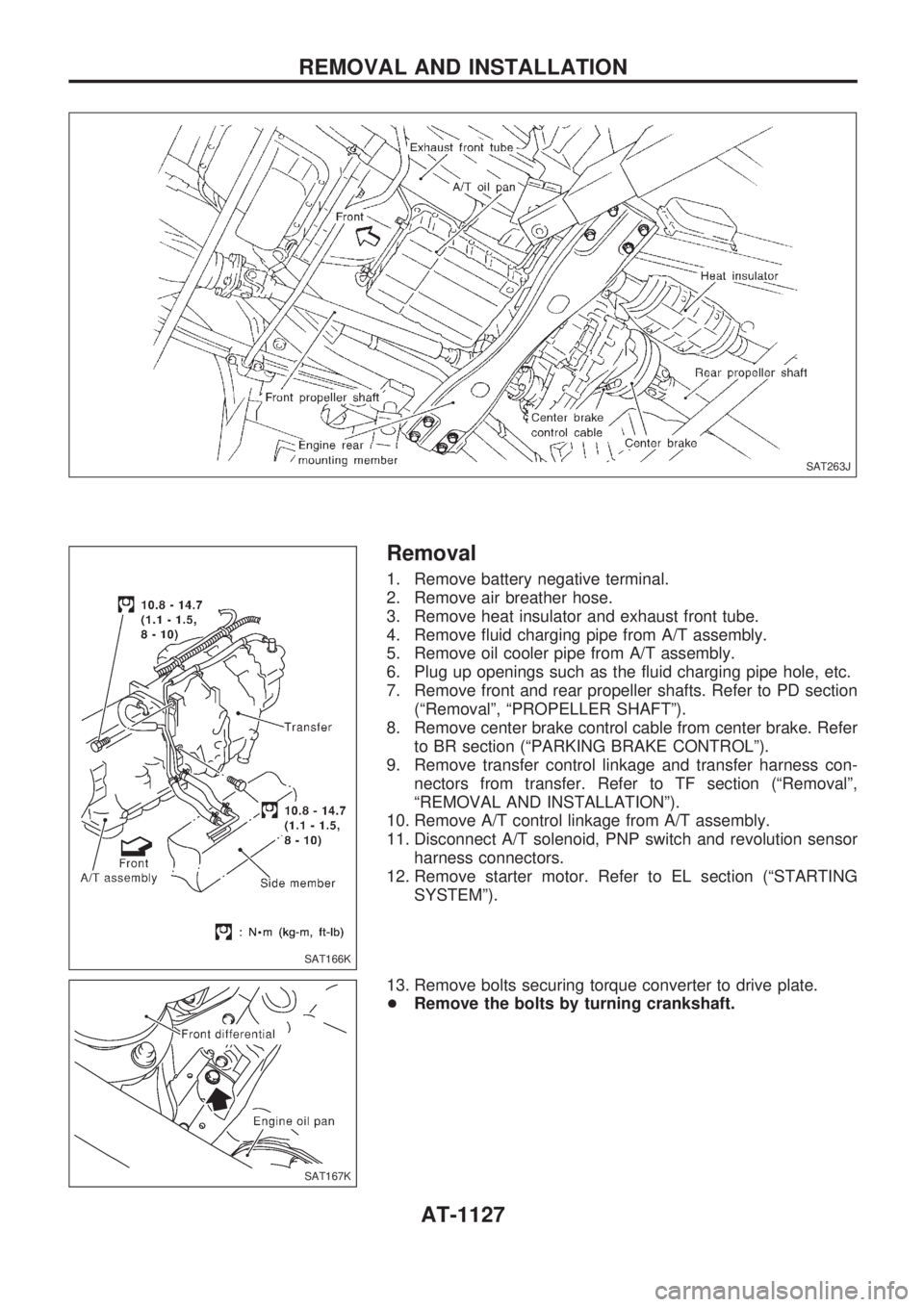

Removal

1. Remove battery negative terminal.

2. Remove air breather hose.

3. Remove heat insulator and exhaust front tube.

4. Remove fluid charging pipe from A/T assembly.

5. Remove oil cooler pipe from A/T assembly.

6. Plug up openings such as the fluid charging pipe hole, etc.

7. Remove front and rear propeller shafts. Refer to PD section

(ªRemovalº, ªPROPELLER SHAFTº).

8. Remove center brake control cable from center brake. Refer

to BR section (ªPARKING BRAKE CONTROLº).

9. Remove transfer control linkage and transfer harness con-

nectors from transfer. Refer to TF section (ªRemovalº,

ªREMOVAL AND INSTALLATIONº).

10. Remove A/T control linkage from A/T assembly.

11. Disconnect A/T solenoid, PNP switch and revolution sensor

harness connectors.

12. Remove starter motor. Refer to EL section (ªSTARTING

SYSTEMº).

13. Remove bolts securing torque converter to drive plate.

+Remove the bolts by turning crankshaft.

SAT263J

SAT166K

SAT167K

REMOVAL AND INSTALLATION

AT-1127

Page 235 of 1033

On Board Diagnosis Logic ............................... 1092

DTC Confirmation Procedure .......................... 1092

Wiring Diagram ................................................ 1093

Diagnostic Procedure....................................... 1094

DTC 0104 VEHICLE SPEED SEN...................... 1096

Description ....................................................... 1096

ECM Terminals and Reference Value ............. 1096

On Board Diagnosis Logic ............................... 1096

Overall Function Check ................................... 1097

Wiring Diagram ................................................ 1098

Diagnostic Procedure....................................... 1099

DTC 0203 ACCEL POS SW (F/C)...................... 1100

Description ....................................................... 1100

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1100

ECM Terminals and Reference Value ............. 1100

On Board Diagnosis Logic ............................... 1100

DTC Confirmation Procedure .......................... 1101

Wiring Diagram ................................................ 1102

Diagnostic Procedure....................................... 1103

DTC 0208 OVER HEAT....................................... 1105

Description ....................................................... 1105

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1105

ECM Terminals and Reference Value ............. 1106

On Board Diagnosis Logic ............................... 1106

Overall Function Check ................................... 1107

Wiring Diagram ................................................ 1108

Diagnostic Procedure....................................... 1109

Main 12 Causes of Overheating ...................... 1116

DTC 0301 ECM 2, DTC 0901 ECM 12............... 1117

Description ....................................................... 1117

On Board Diagnosis Logic ............................... 1117

DTC Confirmation Procedure .......................... 1117

Diagnostic Procedure....................................... 1118

DTC 0402 P9zFUEL TEMP SEN......................... 1119

Description ....................................................... 1119

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1120

ECM Terminals and Reference Value ............. 1120

On Board Diagnosis Logic ............................... 1120

DTC Confirmation Procedure .......................... 1121

Wiring Diagram ................................................ 1122

Diagnostic Procedure....................................... 1123

DTC 0403 ACCEL POS SENSOR...................... 1125

Description ....................................................... 1125

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1125

ECM Terminals and Reference Value ............. 1126

On Board Diagnosis Logic ............................... 1126

DTC Confirmation Procedure .......................... 1127

Wiring Diagram ................................................ 1128

Diagnostic Procedure....................................... 1130

DTC 0406 INT AIR VOL...................................... 1138On Board Diagnosis Logic ............................... 1138

DTC Confirmation Procedure .......................... 1138

Diagnostic Procedure....................................... 1139

DTC 0407 CRANK POS SEN (TDC).................. 1140

Description ....................................................... 1140

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1140

ECM Terminals and Reference Value ............. 1140

On Board Diagnosis Logic ............................... 1141

DTC Confirmation Procedure .......................... 1141

Wiring Diagram ................................................ 1142

Diagnostic Procedure....................................... 1143

DTC 0502 BATTERY VOLTAGE........................ 1146

On Board Diagnosis Logic ............................... 1146

DTC Confirmation Procedure .......................... 1146

Diagnostic Procedure....................................... 1146

DTC 0504 A/T COMM LINE................................ 1148

System Description .......................................... 1148

ECM Terminals and Reference Value ............. 1148

On Board Diagnosis Logic ............................... 1148

DTC Confirmation Procedure .......................... 1149

Overall Function Check ................................... 1149

Wiring Diagram ................................................ 1150

Diagnostic Procedure....................................... 1151

DTC 0701 P1zCAM POS SEN............................. 1153

Description ....................................................... 1153

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1154

ECM Terminals and Reference Value ............. 1154

On Board Diagnosis Logic ............................... 1154

DTC Confirmation Procedure .......................... 1155

Wiring Diagram ................................................ 1156

Diagnostic Procedure....................................... 1157

DTC 0702 P2zTDC PULSE SIG........................... 1159

Description ....................................................... 1159

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1160

ECM Terminals and Reference Value ............. 1160

On Board Diagnosis Logic ............................... 1160

DTC Confirmation Procedure .......................... 1161

Wiring Diagram ................................................ 1162

Diagnostic Procedure....................................... 1163

DTC 0703 P3zPUMP COMM LINE...................... 1165

Description ....................................................... 1165

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1166

ECM Terminals and Reference Value ............. 1166

On Board Diagnosis Logic ............................... 1166

DTC Confirmation Procedure .......................... 1167

Wiring Diagram ................................................ 1168

Diagnostic Procedure....................................... 1169

DTC 0704 P4zSPILL/V CIRC, DTC 0706

P6zSPILL VALVE................................................. 1171

Description ....................................................... 1171

EC-1002

Page 241 of 1033

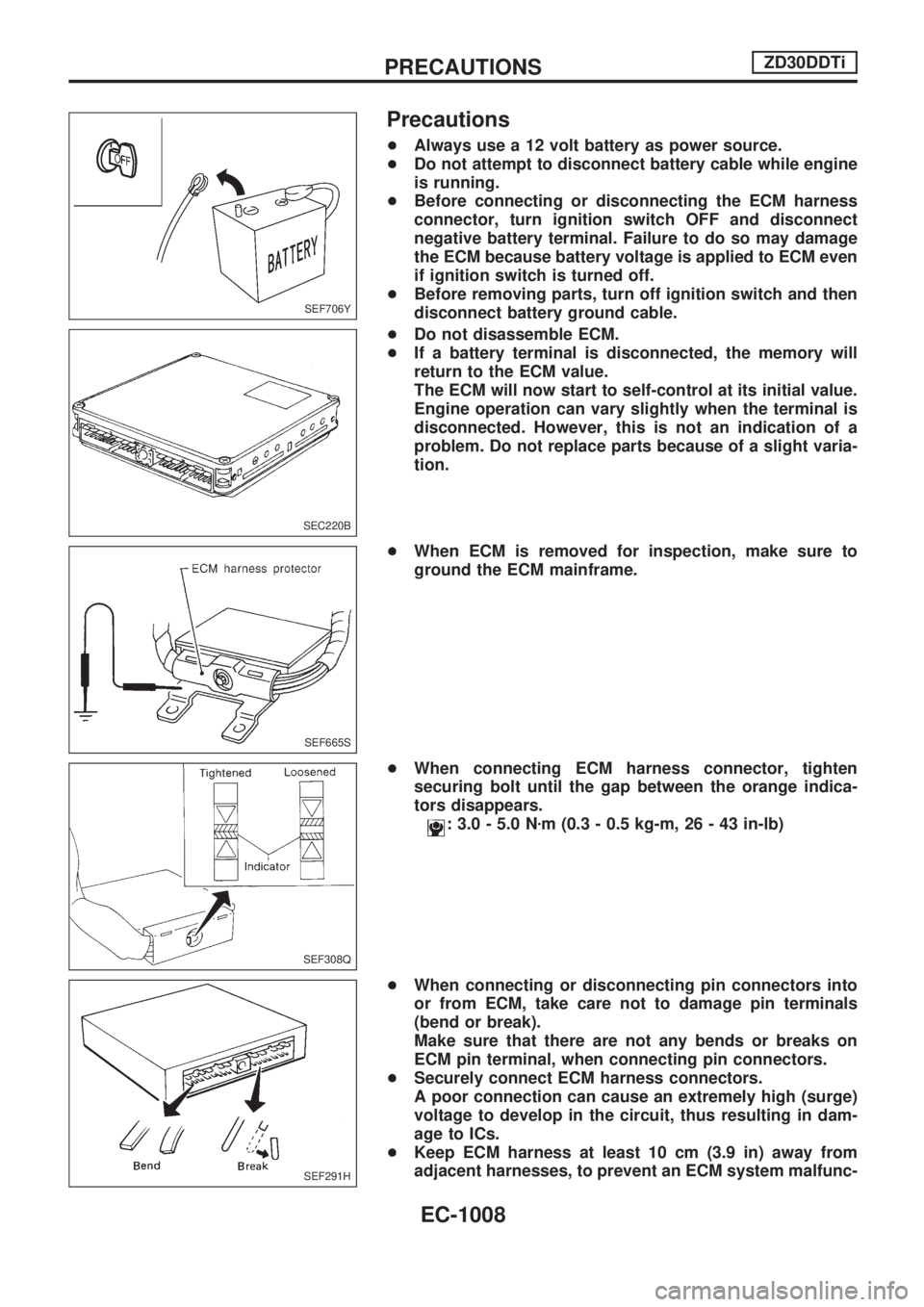

Precautions

+Always use a 12 volt battery as power source.

+Do not attempt to disconnect battery cable while engine

is running.

+Before connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect

negative battery terminal. Failure to do so may damage

the ECM because battery voltage is applied to ECM even

if ignition switch is turned off.

+Before removing parts, turn off ignition switch and then

disconnect battery ground cable.

+Do not disassemble ECM.

+If a battery terminal is disconnected, the memory will

return to the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is

disconnected. However, this is not an indication of a

problem. Do not replace parts because of a slight varia-

tion.

+When ECM is removed for inspection, make sure to

ground the ECM mainframe.

+When connecting ECM harness connector, tighten

securing bolt until the gap between the orange indica-

tors disappears.

: 3.0 - 5.0 Nzm (0.3 - 0.5 kg-m, 26 - 43 in-lb)

+When connecting or disconnecting pin connectors into

or from ECM, take care not to damage pin terminals

(bend or break).

Make sure that there are not any bends or breaks on

ECM pin terminal, when connecting pin connectors.

+Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in the circuit, thus resulting in dam-

age to ICs.

+Keep ECM harness at least 10 cm (3.9 in) away from

adjacent harnesses, to prevent an ECM system malfunc-

SEF706Y

SEC220B

SEF665S

SEF308Q

SEF291H

PRECAUTIONSZD30DDTi

EC-1008

Page 251 of 1033

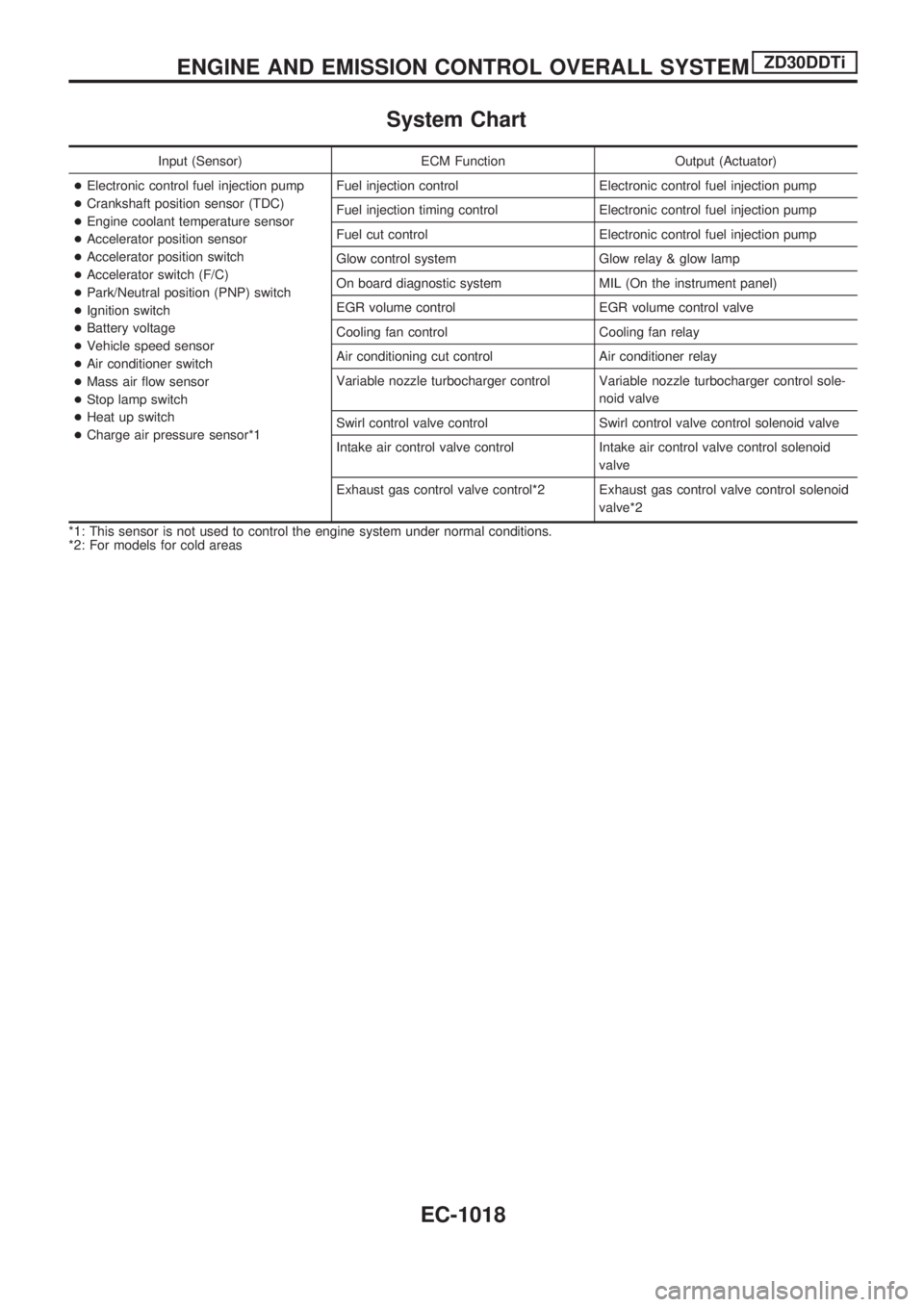

System Chart

Input (Sensor) ECM Function Output (Actuator)

+Electronic control fuel injection pump

+Crankshaft position sensor (TDC)

+Engine coolant temperature sensor

+Accelerator position sensor

+Accelerator position switch

+Accelerator switch (F/C)

+Park/Neutral position (PNP) switch

+Ignition switch

+Battery voltage

+Vehicle speed sensor

+Air conditioner switch

+Mass air flow sensor

+Stop lamp switch

+Heat up switch

+Charge air pressure sensor*1Fuel injection control Electronic control fuel injection pump

Fuel injection timing control Electronic control fuel injection pump

Fuel cut control Electronic control fuel injection pump

Glow control system Glow relay & glow lamp

On board diagnostic system MIL (On the instrument panel)

EGR volume control EGR volume control valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Variable nozzle turbocharger control Variable nozzle turbocharger control sole-

noid valve

Swirl control valve control Swirl control valve control solenoid valve

Intake air control valve control Intake air control valve control solenoid

valve

Exhaust gas control valve control*2 Exhaust gas control valve control solenoid

valve*2

*1: This sensor is not used to control the engine system under normal conditions.

*2: For models for cold areas

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

EC-1018

Page 252 of 1033

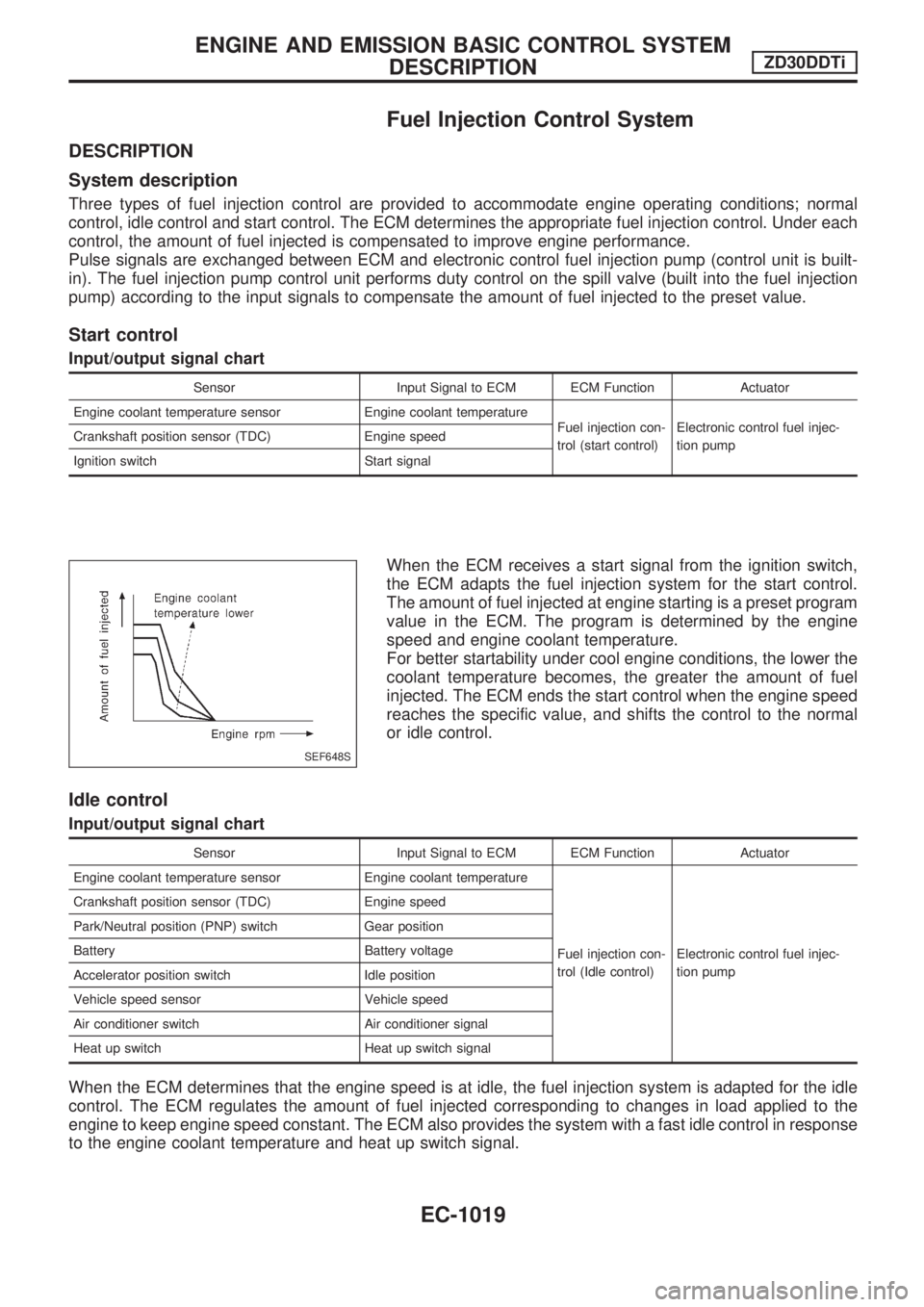

Fuel Injection Control System

DESCRIPTION

System description

Three types of fuel injection control are provided to accommodate engine operating conditions; normal

control, idle control and start control. The ECM determines the appropriate fuel injection control. Under each

control, the amount of fuel injected is compensated to improve engine performance.

Pulse signals are exchanged between ECM and electronic control fuel injection pump (control unit is built-

in). The fuel injection pump control unit performs duty control on the spill valve (built into the fuel injection

pump) according to the input signals to compensate the amount of fuel injected to the preset value.

Start control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (start control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Ignition switch Start signal

When the ECM receives a start signal from the ignition switch,

the ECM adapts the fuel injection system for the start control.

The amount of fuel injected at engine starting is a preset program

value in the ECM. The program is determined by the engine

speed and engine coolant temperature.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches the specific value, and shifts the control to the normal

or idle control.

Idle control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (Idle control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Park/Neutral position (PNP) switch Gear position

Battery Battery voltage

Accelerator position switch Idle position

Vehicle speed sensor Vehicle speed

Air conditioner switch Air conditioner signal

Heat up switch Heat up switch signal

When the ECM determines that the engine speed is at idle, the fuel injection system is adapted for the idle

control. The ECM regulates the amount of fuel injected corresponding to changes in load applied to the

engine to keep engine speed constant. The ECM also provides the system with a fast idle control in response

to the engine coolant temperature and heat up switch signal.

SEF648S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-1019

Page 266 of 1033

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See

EC-1035.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

+If the battery is disconnected, the emission-related diagnostic information will be lost after

approx. 24 hours.

+Erasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

NATS (Nissan Anti-Theft System)

+If the security indicator lights up with the ignition switch

in the ªONº position or ªNATS MALFUNCTIONº is dis-

played on ªSELF-DIAG RESULTSº screen, perform self-

diagnostic results mode with CONSULT-II using NATS

program card. Refer to ªNATS (Nissan Anti-Theft Sys-

tem)º in EL section.

+Confirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº

mode with CONSULT-II.

+When replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried

out with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle

owner. Regarding the procedures of NATS initialization

and NATS ignition key ID registration, refer to CON-

SULT-II operation manual, NATS.

Malfunction Indicator (MI)

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON

without the engine running. This is a bulb check.

+If the MI does not light up, refer to EL section (ªWARNING

LAMPS AND CHIMEº) or see EC-1276.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter. Refer to MA section.

SEF252Z

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Diagnostic Trouble Code (DTC) (Cont'd)

EC-1033

Page 269 of 1033

Diagnostic test mode I Ð Bulb check

In this mode, the MI on the instrument panel should stay ON. If it remains OFF, check the bulb. Refer to EL

section, ªWARNING LAMPS AND CHIMEº or see EC-1276.

Diagnostic test mode I Ð Malfunction warning

MI Condition

ON When the malfunction is detected or the ECM's CPU is malfunctioning.

OFF No malfunction.

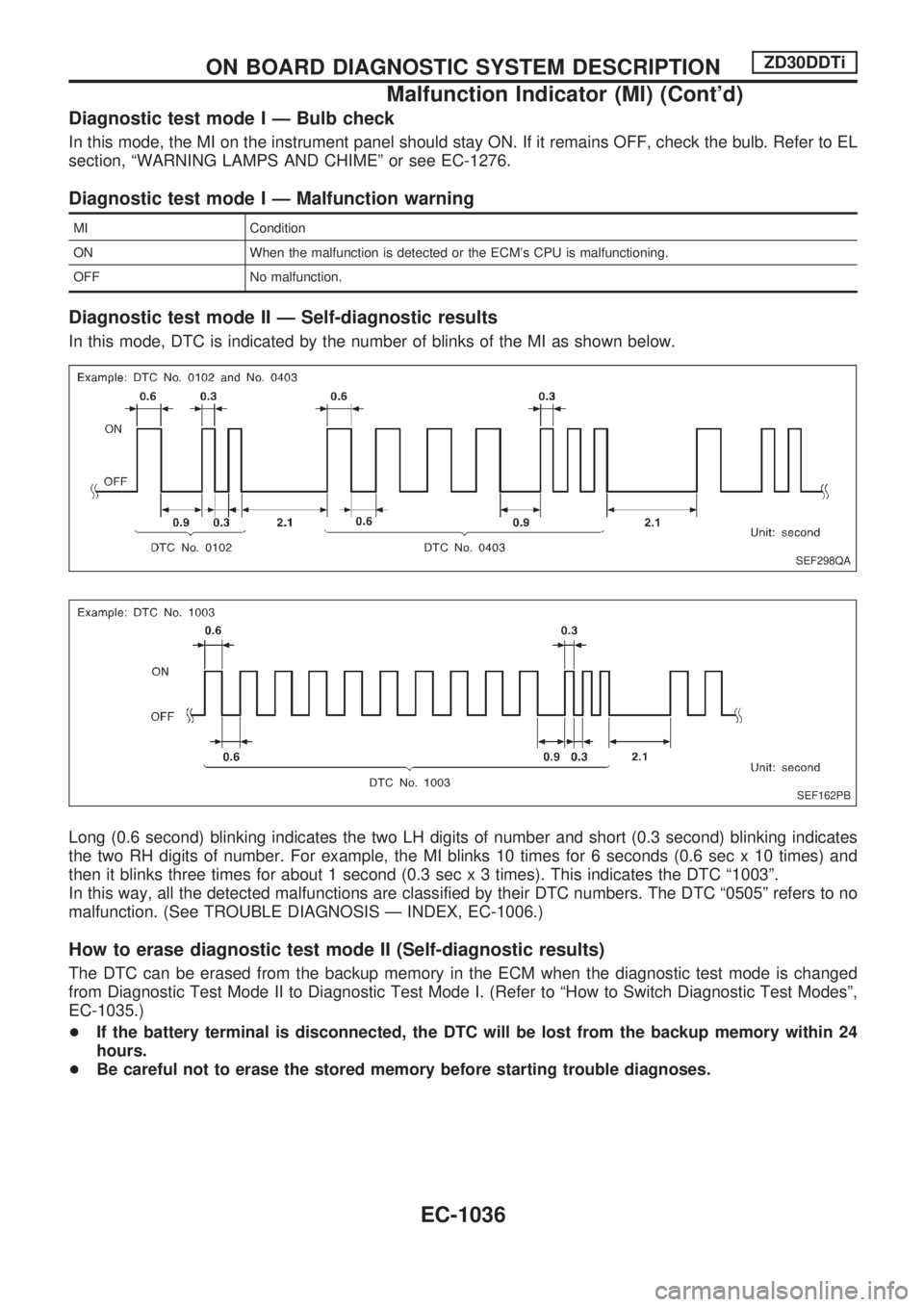

Diagnostic test mode II Ð Self-diagnostic results

In this mode, DTC is indicated by the number of blinks of the MI as shown below.

Long (0.6 second) blinking indicates the two LH digits of number and short (0.3 second) blinking indicates

the two RH digits of number. For example, the MI blinks 10 times for 6 seconds (0.6 sec x 10 times) and

then it blinks three times for about 1 second (0.3 sec x 3 times). This indicates the DTC ª1003º.

In this way, all the detected malfunctions are classified by their DTC numbers. The DTC ª0505º refers to no

malfunction. (See TROUBLE DIAGNOSIS Ð INDEX, EC-1006.)

How to erase diagnostic test mode II (Self-diagnostic results)

The DTC can be erased from the backup memory in the ECM when the diagnostic test mode is changed

from Diagnostic Test Mode II to Diagnostic Test Mode I. (Refer to ªHow to Switch Diagnostic Test Modesº,

EC-1035.)

+If the battery terminal is disconnected, the DTC will be lost from the backup memory within 24

hours.

+Be careful not to erase the stored memory before starting trouble diagnoses.

SEF298QA

SEF162PB

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-1036

Page 272 of 1033

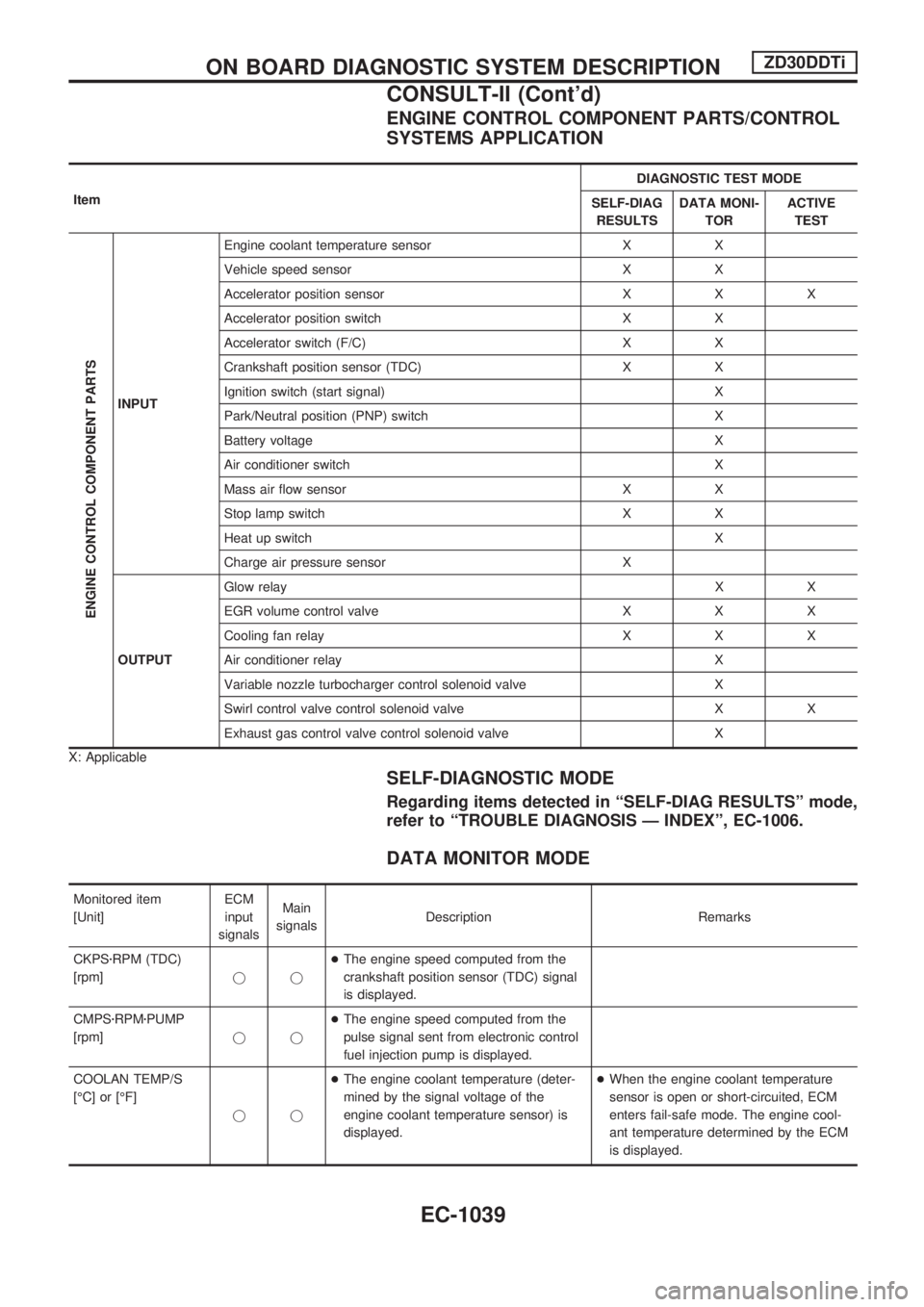

ENGINE CONTROL COMPONENT PARTS/CONTROL

SYSTEMS APPLICATION

ItemDIAGNOSTIC TEST MODE

SELF-DIAG

RESULTSDATA MONI-

TORACTIVE

TEST

ENGINE CONTROL COMPONENT PARTS

INPUTEngine coolant temperature sensor X X

Vehicle speed sensor X X

Accelerator position sensor X X X

Accelerator position switch X X

Accelerator switch (F/C) X X

Crankshaft position sensor (TDC) X X

Ignition switch (start signal) X

Park/Neutral position (PNP) switch X

Battery voltage X

Air conditioner switch X

Mass air flow sensor X X

Stop lamp switch X X

Heat up switch X

Charge air pressure sensor X

OUTPUTGlow relayXX

EGR volume control valve X X X

Cooling fan relay X X X

Air conditioner relay X

Variable nozzle turbocharger control solenoid valve X

Swirl control valve control solenoid valve X X

Exhaust gas control valve control solenoid valve X

X: Applicable

SELF-DIAGNOSTIC MODE

Regarding items detected in ªSELF-DIAG RESULTSº mode,

refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-1006.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

CKPSzRPM (TDC)

[rpm]jj+The engine speed computed from the

crankshaft position sensor (TDC) signal

is displayed.

CMPSzRPMzPUMP

[rpm]jj+The engine speed computed from the

pulse signal sent from electronic control

fuel injection pump is displayed.

COOLAN TEMP/S

[ÉC] or [ÉF]

jj+The engine coolant temperature (deter-

mined by the signal voltage of the

engine coolant temperature sensor) is

displayed.+When the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the ECM

is displayed.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

CONSULT-II (Cont'd)

EC-1039

Page 273 of 1033

![NISSAN PATROL 2000 Electronic Owners Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

VHCL SPEED SE

[km/h] or [mph]jj+The vehicle speed computed from the

vehicle speed sensor signal is displayed.

FUEL TEMP SEN

[ÉC] NISSAN PATROL 2000 Electronic Owners Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

VHCL SPEED SE

[km/h] or [mph]jj+The vehicle speed computed from the

vehicle speed sensor signal is displayed.

FUEL TEMP SEN

[ÉC]](/img/5/57367/w960_57367-272.png)

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

VHCL SPEED SE

[km/h] or [mph]jj+The vehicle speed computed from the

vehicle speed sensor signal is displayed.

FUEL TEMP SEN

[ÉC] or [ÉF]jj+The fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ACCEL POS SEN [V]

jj+The accelerator position sensor signal

voltage is displayed.

FULL ACCEL SW

[ON/OFF]jj+Indicates [ON/OFF] condition from the

accelerator position switch signal.

ACCEL SW (FC)

[OPEN/CLOSE]jj+Indicates [OPEN/CLOSE] condition from

the accelerator switch (FC) signal.

OFF ACCEL SW

[ON/OFF]jj+Indicates [ON/OFF] condition from the

accelerator position switch signal.

SPILL/V [ÉCA]

j+The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT [V]

jj+The power supply voltage of ECM is dis-

played.

P/N POSI SW

[ON/OFF]jj+Indicates [ON/OFF] condition from the

park/neutral position switch signal.

START SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition from the

starter signal.+After starting the engine, [OFF] is dis-

played regardless of the starter signal.

AIR COND SIG

[ON/OFF]jj+Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

BRAKE SW [ON/OFF]

jj+Indicates [ON/OFF] condition from the

stop lamp switch signal.

IGN SW

[ON/OFF]jj+Indicates [ON/OFF] condition from igni-

tion switch signal.

WARM UP SW

[ON/OFF]j+Indicates [ON/OFF] condition from the

heat up switch signal.

MAS AIR/FL SE [V]

jj+The signal voltage of the mass air flow

sensor is displayed.+When the engine is stopped, a certain

value is indicated.

DECELER F/CUT

[ON/OFF]j+The [ON/OFF] condition from decelera-

tion fuel cut signal (sent from electronic

control fuel injection pump) is displayed.

INJ TIMG C/V [%]

j+The duty ratio of fuel injection timing

control valve (sent from electronic con-

trol fuel injection pump) is displayed.

AIR COND RLY

[ON/OFF]j+Indicates the control condition of the air

conditioner relay (determined by ECM

according to the input signals).

GLOW RLY [ON/OFF]

j+The glow relay control condition (deter-

mined by ECM according to the input

signal) is displayed.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

CONSULT-II (Cont'd)

EC-1040