brake system NISSAN PATROL 2000 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 213 of 1033

BRAKE SYSTEM

SECTION

BR

MODIFICATION NOTICE:

+CONSULT-II is available for all models.

+Service Data and Specifications (SDS) have been changed.

+Wiring Diagrams have been changed.

CONTENTS

TROUBLE DIAGNOSES..................................... 1002

Schematic ........................................................ 1002

Wiring Diagram Ð ABS Ð .............................. 1003Self-diagnosis................................................... 1008

SERVICE DATA AND SPECIFICATIONS (SDS)1010

General Specifications ..................................... 1010

BR

Page 273 of 1033

![NISSAN PATROL 2000 Electronic User Guide Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

VHCL SPEED SE

[km/h] or [mph]jj+The vehicle speed computed from the

vehicle speed sensor signal is displayed.

FUEL TEMP SEN

[ÉC] NISSAN PATROL 2000 Electronic User Guide Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

VHCL SPEED SE

[km/h] or [mph]jj+The vehicle speed computed from the

vehicle speed sensor signal is displayed.

FUEL TEMP SEN

[ÉC]](/img/5/57367/w960_57367-272.png)

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

VHCL SPEED SE

[km/h] or [mph]jj+The vehicle speed computed from the

vehicle speed sensor signal is displayed.

FUEL TEMP SEN

[ÉC] or [ÉF]jj+The fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ACCEL POS SEN [V]

jj+The accelerator position sensor signal

voltage is displayed.

FULL ACCEL SW

[ON/OFF]jj+Indicates [ON/OFF] condition from the

accelerator position switch signal.

ACCEL SW (FC)

[OPEN/CLOSE]jj+Indicates [OPEN/CLOSE] condition from

the accelerator switch (FC) signal.

OFF ACCEL SW

[ON/OFF]jj+Indicates [ON/OFF] condition from the

accelerator position switch signal.

SPILL/V [ÉCA]

j+The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT [V]

jj+The power supply voltage of ECM is dis-

played.

P/N POSI SW

[ON/OFF]jj+Indicates [ON/OFF] condition from the

park/neutral position switch signal.

START SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition from the

starter signal.+After starting the engine, [OFF] is dis-

played regardless of the starter signal.

AIR COND SIG

[ON/OFF]jj+Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

BRAKE SW [ON/OFF]

jj+Indicates [ON/OFF] condition from the

stop lamp switch signal.

IGN SW

[ON/OFF]jj+Indicates [ON/OFF] condition from igni-

tion switch signal.

WARM UP SW

[ON/OFF]j+Indicates [ON/OFF] condition from the

heat up switch signal.

MAS AIR/FL SE [V]

jj+The signal voltage of the mass air flow

sensor is displayed.+When the engine is stopped, a certain

value is indicated.

DECELER F/CUT

[ON/OFF]j+The [ON/OFF] condition from decelera-

tion fuel cut signal (sent from electronic

control fuel injection pump) is displayed.

INJ TIMG C/V [%]

j+The duty ratio of fuel injection timing

control valve (sent from electronic con-

trol fuel injection pump) is displayed.

AIR COND RLY

[ON/OFF]j+Indicates the control condition of the air

conditioner relay (determined by ECM

according to the input signals).

GLOW RLY [ON/OFF]

j+The glow relay control condition (deter-

mined by ECM according to the input

signal) is displayed.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

CONSULT-II (Cont'd)

EC-1040

Page 424 of 1033

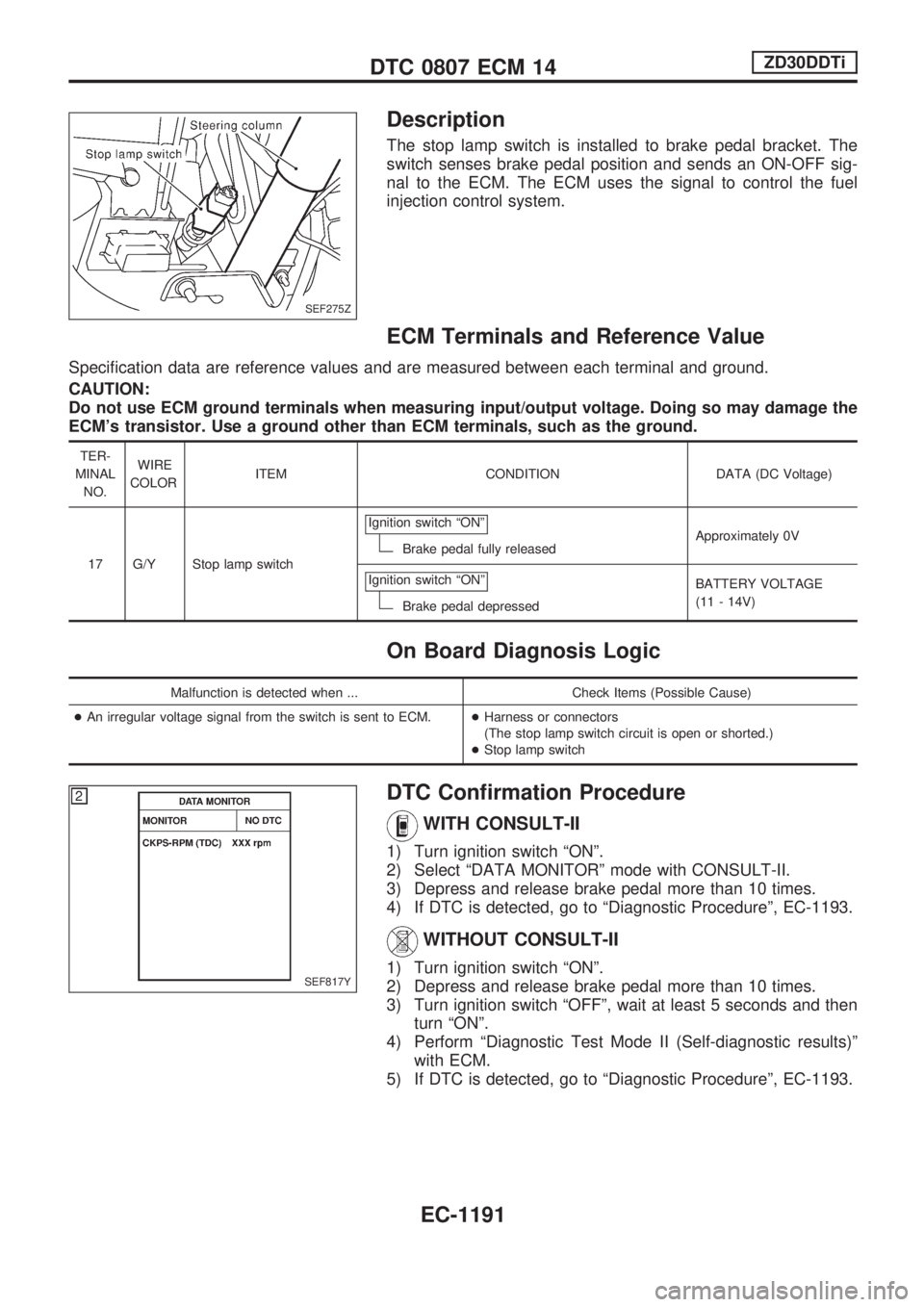

Description

The stop lamp switch is installed to brake pedal bracket. The

switch senses brake pedal position and sends an ON-OFF sig-

nal to the ECM. The ECM uses the signal to control the fuel

injection control system.

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

17 G/Y Stop lamp switchIgnition switch ªONº

Brake pedal fully releasedApproximately 0V

Ignition switch ªONº

Brake pedal depressedBATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

+An irregular voltage signal from the switch is sent to ECM.+Harness or connectors

(The stop lamp switch circuit is open or shorted.)

+Stop lamp switch

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Depress and release brake pedal more than 10 times.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1193.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº.

2) Depress and release brake pedal more than 10 times.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-1193.

SEF275Z

SEF817Y

DTC 0807 ECM 14ZD30DDTi

EC-1191

Page 737 of 1033

Wiring Diagram Codes (Cell Codes)

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (Page number) of each wiring diagram.

Code Section Wiring Diagram Name

A/C,A HA Auto Air Conditioner

A/C,M HA Manual Air Conditioner

A/CCUT EC Air Conditioner Control

A/T AT A/T

ABS BR Anti-lock Brake System

ACC/SW EC Accelerator Switch (FC)

ACL/SW EC Accelerator Position Switch

APS EC Accelerator Position Sensor

ASCD EL Automatic Speed Control Device

AT/C EC A/T Control

BACK/L EL Back-up Lamp

BCDD EC BCDD System

BOOST EC Turbo Charger Boost Sensor

BRK/SW EC Brake Switch Signal

CHARGE EL Charging System

CHIME EL Warning Chime

CHOKE EC Automatic Choke

CKPS EC Crankshaft Position Sensor (OBD)

COOL/B HA Cool Box

COOL/F EC Cooling Fan Control

CORNER EL Cornering Lamp

DEF EL Rear Window Defogger

DIFF/L PD Differential Lock Control System

DTRL ELHeadlamp Ð With Daytime Light

System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGVC/V EC EGR Volume Control Valve

EXH ECExhaust Gas Control Valve Control

Solenoid Valve

F/FOG EL Front Fog Lamp

F/PUMP EC Fuel Pump

FCUT EC Fuel Cut System

FICD EC IACV-FICD Solenoid Valve

FIPOT EC ISC-FI POT

FPCM EC Fuel Pump Control Module

GLOW EC Quick Glow System

HEATER HA Heater System

HEATUP EC Heat up SwitchCode Section Wiring Diagram Name

HLC EL Headlamp Wiper and Washer

HORN EL Horn

IGN EC Ignition Control System

ILL EL Illumination

INJPMP ECElectronic Control Fuel Injection

Pump

INT/V ECIntake Air Control Valve Control

Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN ECMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.,

Oil and Fuel Gauges

MIL/DL EC Mil and Data Link Connectors

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-Theft System

P/ANT EL Power Antenna

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

R/COOL HA Rear Cooler System

R/FOG EL Rear Fog Lamp

R/HEAT HA Rear Heater System

REMOTE EL Audio (Remote Control Switch)

ROOM/L EL Interior Room Lamp

S/LOCK EL Power Door Lock Ð Super Lock

S/SIG EC Start Signal

S/TANK FE Sub Fuel Tank Control System

SHIFT AT A/T Shift Lock System

SRS RS Supplemental Restraint System

STAB RA Stabilizer Release Device

START EL Starting System

STOP/L EL Stop Lamp

SWL/V ECSwirl Control Valve Control Solenoid

Valve

TAIL/L EL Parking, License and Tail Lamps

TURN ELTurn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

WARN EL Warning Lamps

WIRING DIAGRAM CODES (CELL CODES)

EL-1227

Page 880 of 1033

A

A/T - Wiring diagram ............................. AT-1009

A/T control ............................................. EC-1148

A/T fluid temperature sensor ................. AT-1081

A/T mode switch .................................... AT-1095

A/T self-diagnoses ................................. AT-1028

A/T shift lock system - Wiring

diagram .............................................. AT-1117

A/T shift lock system ............................. AT-1116

A/T trouble diagnoses ........................... AT-1036

APS - Wiring diagram ........................... EC-1125

ASCD (automatic speed control

device) ............................................... EL-1110

ASCD - Wiring diagram ......................... EL-1111

AT/C - Wiring diagram .......................... EC-1150

Accelerator control system .................... FE-1007

Accelerator position sensor .................. EC-1125

Air bag disposal .................................... RS-1015

Air bag precautions ................................ GI-1002

Air bag ................................................... RS-1003

Air cleaner filter replacement ............... MA-1019

Air conditioner cut control ..................... EC-1021

Air flow meter - See Mass air flow

sensor ................................................ EC-1086

Alternator ............................................... EL-1041

Angular tightening application .............. EM-1003

Anti-lock brake system - Wiring

diagram ............................................. BR-1002

Audio ...................................................... EL-1108

Automatic speed control system - See

ASCD ................................................. EL-1110

Automatic transmission fluid

replacement ...................................... MA-1021

B

BACK/L - Wiring diagram ...................... EL-1051

BOOST - Wiring diagram ...................... EC-1204

Back-up lamp ......................................... EL-1051

Basic inspection .................................... EC-1049

Battery ................................................... EL-1035

Boring/horning cylinder block ............... EM-1075

C

CHARGE - Wiring diagram ................... EL-1040

CKPS - Wiring diagram ........................ EC-1140

CONSULT for engine ............................ EC-1038

CONSULT general information .............. GI-1003

COOL/F - Wiring diagram ..................... EC-1105

CORNER - Wiring diagram ................... EL-1054

Camshaft inspection ............................. EM-1032

Charging system .................................... EL-1040

Chassis and body maintenance ........... MA-1020

Clutch operating cylinder ....................... CL-1003

Collision diagnosis ................................ RS-1052

Combination meter ................................ EL-1073Combination switch ............................... EL-1042

Compression pressure ......................... EM-1010

Compressor mounting ........................... HA-1023

Connecting rod bearing clearance ....... EM-1078

Connecting rod bushing clearance ....... EM-1074

Connecting rod ..................................... EM-1074

Control valve (A/T) ................................ AT-1148

Converter housing installation ............... AT-1128

Coolant mixture ratio ............................ MA-1010

Coolant replacement ............................ MA-1014

Cooling fan control ................................ EC-1105

Cornering lamp ...................................... EL-1054

Crankcase emission control system -

See Positive crankcase ventilation ... EC-1022

Crankcase ventilation system - See

Positive crankcase ventilation ........... EC-1022

Crankshaft position sensor (TDC) ........ EC-1140

Crankshaft ............................................ EM-1077

Cruise control - See ASCD ................... EL-1110

Cylinder block boring ............................ EM-1020

Cylinder block ....................................... EM-1067

Cylinder head bolt tightening ................ EM-1034

Cylinder head ....................................... EM-1053

D

DEF - Wiring diagram ............................ EL-1102

DTRL - Wiring diagram ......................... EL-1044

Data link connector for Consult ............ EC-1038

Daytime light system ............................. EL-1044

Diagnosis sensor unit ........................... RS-1008

Diagnostic trouble code (DTC) for

OBD system ...................................... EC-1032

Dome light - See Interior lamp .............. EL-1067

Door mirror ............................................ BT-1007

Door trim ................................................ BT-1004

Drive belt inspection ............................. MA-1011

Drive plate runout ................................. EM-1095

Dropping resistor (A/T) .......................... AT-1086

E

ECCS-D control module .. EC-1068, 1117, 1189,

1191, 1196, 1200

ECM input/output signal ........................ EC-1068

ECTS - Wiring diagram ......................... EC-1092

EGR - Wiring diagram .......................... EC-1209

EGR volume control valve .................... EC-1207

Electrical unit ......................................... EL-1231

Electrical units location .......................... EL-1185

Electronic fuel injection pump .... EC-1119, 1153,

1159, 1165, 1171, 1177, 1180, 1215

Engine control circuit diagram .............. EC-1015

Engine control component parts

location .............................................. EC-1011

Engine control system diagram and

chart .................................................. EC-1016

ALPHABETICAL INDEX

IDX-1002

Page 881 of 1033

Engine coolant temperature sensor

(ECTS) .............................................. EC-1092

Engine oil filter replacement ................. MA-1013

Engine oil replacement ......................... MA-1012

Engine removal ..................................... EM-1064

Engine serial number ............................. GI-1008

F

F/FOG - Wiring diagram ........................ EL-1052

Final drive disassembly .............. PD-1004, 1005

Fluid temperature sensor (A/T) ............. AT-1081

Fluids .................................................... MA-1008

Flywheel runout .................................... EM-1095

Fog lamp, front ...................................... EL-1052

Fog lamp, rear ....................................... EL-1053

Forward clutch ....................................... AT-1167

Front axle .............................................. FA-1002

Front final drive disassembly (4WD) .... PD-1004

Front fog lamp ....................................... EL-1052

Front passenger air bag ....................... RS-1003

Front seat .............................................. BT-1006

Front washer .......................................... EL-1098

Front wiper ............................................. EL-1098

Fuel cut control (at no load & high

engine speed) ................................... EC-1021

Fuel filter replacement .......................... MA-1017

Fuel gauge ............................................. EL-1073

Fuel injection system ............................ EC-1019

Fuel line inspection ............................... MA-1018

Fuel precautions ..................................... GI-1002

Fuse block ............................................. EL-1229

Fuse ....................................................... EL-1230

Fusible link ............................................. EL-1230

G

GLOW - Wiring diagram ....................... EC-1221

Gauges .................................................. EL-1073

Glow plug .............................................. EC-1221

Glow relay ............................................. EC-1221

Grease ........................................ MA-1008, 1016

Ground distribution ................................ EL-1013

H

HEAT UP - Wiring diagram .................. EC-1242

HEATER - Wiring diagram .................... HA-1005

HLC - Wiring diagram ............................ EL-1099

HORN - Wiring diagram ........................ EL-1100

Harness layout ....................................... EL-1191

Hazard warning lamp ............................ EL-1058

Headlamp washer .................................. EL-1099

Headlamp wiper ..................................... EL-1099

Headlamp .............................................. EL-1044

Heat up switch ...................................... EC-1241

High clutch ............................................. AT-1165Horn ....................................................... EL-1100

How to erase DTC for OBD system ..... EC-1032

I

ILL - Wiring diagram .............................. EL-1061

Identification plate .................................. GI-1008

Idle speed ............................................. EC-1049

Illumination ............................................. EL-1060

Injection nozzle ..................................... EC-1023

Intake manifold ..................................... EM-1012

Interior lamp ........................................... EL-1067

Interior ................................................... BT-1004

J

Junction box (J/B) .................................. EL-1229

L

License lamp ......................................... EL-1046

Lifting points ........................................... GI-1009

Line pressure solenoid valve ................ AT-1086

Line pressure test (A/T) ........................ AT-1044

Liquid gasket application ...................... EM-1003

Location of electrical units ..................... EL-1185

Low and reverse brake ......................... AT-1171

Lubricants ............................................. MA-1008

Luggage room lamp .............................. EL-1067

M

MAFS - Wiring diagram ........................ EC-1086

MAIN - Wiring diagram ......................... EC-1077

MAJOR OVERHALL .............................. AT-1129

METER - Wiring diagram ...................... EL-1073

Maintenance (engine) ........................... MA-1011

Malfunction indicator lamp (MIL) .......... EC-1033

Manifold tightening torque (intake &

exhaust) ............................................ MA-1011

Mass air flow sensor (MAFS) ............... EC-1086

Meter ...................................................... EL-1073

Mirror, door ............................................ BT-1007

Mirror, outside ....................................... BT-1007

Model variation ....................................... GI-1005

N

NATS (Nissan Anti-theft System) .......... EL-1163

NATS - Wiring diagram ......................... EL-1166

NVH troubleshooting (EM) ................... EM-1008

ALPHABETICAL INDEX

IDX-1003

Page 901 of 1033

![NISSAN PATROL 2000 Electronic User Guide Chassis and Body Maintenance

Abbreviations: R = Replace, I = Inspect: Correct or replace if necessary, L = Lubricate, T = Tighten, [ ] = At the specified mileage only

MAINTENANCE OPERATIONMAINTENANCE NISSAN PATROL 2000 Electronic User Guide Chassis and Body Maintenance

Abbreviations: R = Replace, I = Inspect: Correct or replace if necessary, L = Lubricate, T = Tighten, [ ] = At the specified mileage only

MAINTENANCE OPERATIONMAINTENANCE](/img/5/57367/w960_57367-900.png)

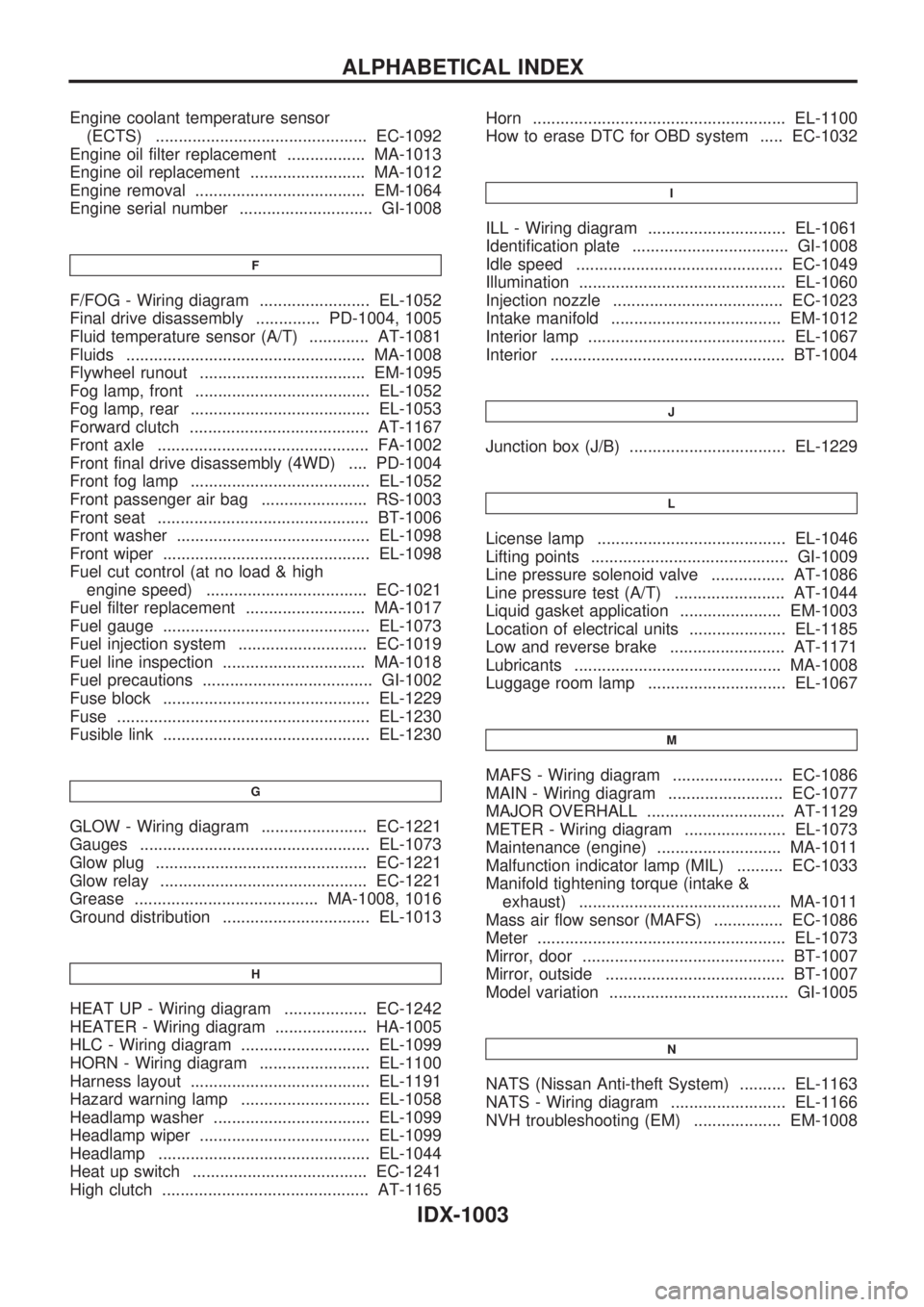

Chassis and Body Maintenance

Abbreviations: R = Replace, I = Inspect: Correct or replace if necessary, L = Lubricate, T = Tighten, [ ] = At the specified mileage only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform on a kilometer basis, but on an annual basis

when driving less than 15,000 km (9,000 miles) per

year.km x 1,000 15 30 45 60 75 90

(miles x 1,000) (9) (18) (27) (36) (45) (54)

Months 12 24 36 48 60 72

Underhood and under vehicleReference

pages

Headlamp aimingIIIIII Ð

When alignment (if necessary, balance & rotate wheels)IIIIII Ð

Brake pads, rotors & other brake componentsHIIIIII Ð

Foot brake, parking brake & clutch (for free play, stroke & operation)IIIIII Ð

Brake booster vacuum hoses, connections & check valve I I I Ð

Brake & clutch, systems and fluid (for level and leaks)IIIIII Ð

Brake fluidHRRRÐ

Power steering fluid and lines (for level and leaks)IIIIII Ð

Supplemental air bag systems See NOTE (1)RS-1007

Ventilation air filterHRRRÐ

Manual transmission oil (Inspect for leaks. Replace if leaks are found.)IIIII[R] Ð

Automatic transmission fluid (for level and leaks)HIIIIII Ð

Greasing point of propeller shaft See NOTE (2)LLLLLL Ð

Transfer fluid and limited-slip differential (LSD) gear oil (for

level & leaks or replace)HSee NOTE (3) I I I R I I Ð

Drive shafts & steering damperHIIIIII Ð

Front wheel bearing greaseHIRIRIR Ð

Front axle joint in knuckle flangeLLLÐ

Free-running hub greaseHIIIIII Ð

Body mounting bolts & nutsTTTTTT Ð

Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust systemHIIIIII Ð

Body corrosion See NOTE (4)Ð

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) The propeller shaft should be re-greased after being immersed in water.

(3) Including differential gear with differential lock.

(4) Inspect once per year.

HMaintenance items with ªHº should be performed more frequently according to ªMaintenance under severe driv-

ing conditionsº.

PERIODIC MAINTENANCE

MA-1003

Page 902 of 1033

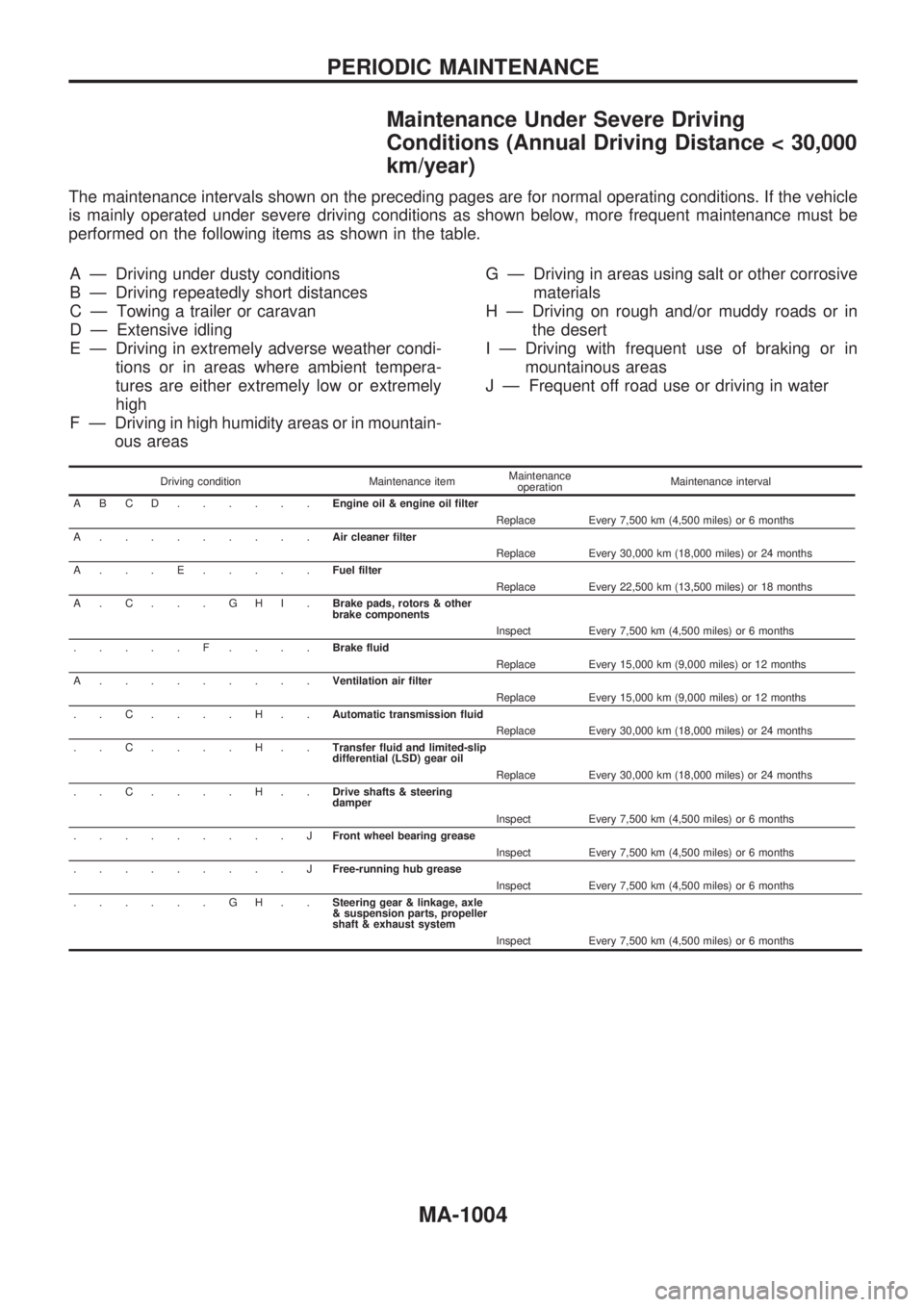

Maintenance Under Severe Driving

Conditions (Annual Driving Distance < 30,000

km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be

performed on the following items as shown in the table.

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather condi-

tions or in areas where ambient tempera-

tures are either extremely low or extremely

high

F Ð Driving in high humidity areas or in mountain-

ous areasG Ð Driving in areas using salt or other corrosive

materials

H Ð Driving on rough and/or muddy roads or in

the desert

I Ð Driving with frequent use of braking or in

mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance itemMaintenance

operationMaintenance interval

ABCD......Engine oil & engine oil filter

Replace Every 7,500 km (4,500 miles) or 6 months

A.........Air cleaner filter

Replace Every 30,000 km (18,000 miles) or 24 months

A...E.....Fuel filter

Replace Every 22,500 km (13,500 miles) or 18 months

A.C...GHI.Brake pads, rotors & other

brake components

Inspect Every 7,500 km (4,500 miles) or 6 months

.....F....Brake fluid

Replace Every 15,000 km (9,000 miles) or 12 months

A.........Ventilation air filter

Replace Every 15,000 km (9,000 miles) or 12 months

..C....H..Automatic transmission fluid

Replace Every 30,000 km (18,000 miles) or 24 months

..C....H..Transfer fluid and limited-slip

differential (LSD) gear oil

Replace Every 30,000 km (18,000 miles) or 24 months

..C....H..Drive shafts & steering

damper

Inspect Every 7,500 km (4,500 miles) or 6 months

.........JFront wheel bearing grease

Inspect Every 7,500 km (4,500 miles) or 6 months

.........JFree-running hub grease

Inspect Every 7,500 km (4,500 miles) or 6 months

......GH..Steering gear & linkage, axle

& suspension parts, propeller

shaft & exhaust system

Inspect Every 7,500 km (4,500 miles) or 6 months

PERIODIC MAINTENANCE

MA-1004

Page 904 of 1033

Chassis and Body Maintenance

Abbreviations: R = Replace, I = Inspect: Correct or replace if necessary, L = Lubricate, T = Tighten

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform on a kilometer

basis onlykm x 1,000 10 20 30 40 50 60 70 80 90 100 110 120

(miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72)

Underhood and under vehicleReference

pages

Headlamp aimingIIIIÐ

When alignment (if necessary, balance & rotate wheels)IIIIÐ

Brake pads, rotors & other brake componentsHIIIIÐ

Foot brake, parking brake & clutch (for free play, stroke & operation)IIIIÐ

Brake booster vacuum hoses, connections & check valve I I Ð

Brake & clutch, systems and fluid (for level and leaks)IIIIÐ

Brake fluidHRRÐ

Power steering fluid and lines (for level and leaks)IIIIÐ

Supplemental air bag systems See NOTE (1)RS-1007

Ventilation air filterHRRRRÐ

Manual transmission oil (Inspect for leaks. Replace if leaks are found.) I I R I Ð

Automatic transmission fluid (for level and leaks)HIIIIÐ

Greasing point of propeller shaft See NOTE (2)LLLLÐ

Transfer fluid and limited-slip differential (LSD) gear oil

(for level & leaks or replace)HSee NOTE (3) I R I R Ð

Drive shafts & steering damperHIIIIÐ

Front wheel bearing greaseHIRIRÐ

Front axle joint in knuckle flangeLLÐ

Free-running hub greaseHIIIIÐ

Body mounting bolts & nutsTTTTÐ

Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust systemHIIIIÐ

Body corrosion See NOTE (4)Ð

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) The propeller shaft should be re-greased after being immersed in water.

(3) Including differential gear with differential lock.

(4) Inspect once per year.

HMaintenance items with ªHº should be performed more frequently according to ªMaintenance under severe driv-

ing conditionsº.

PERIODIC MAINTENANCE

MA-1006

Page 905 of 1033

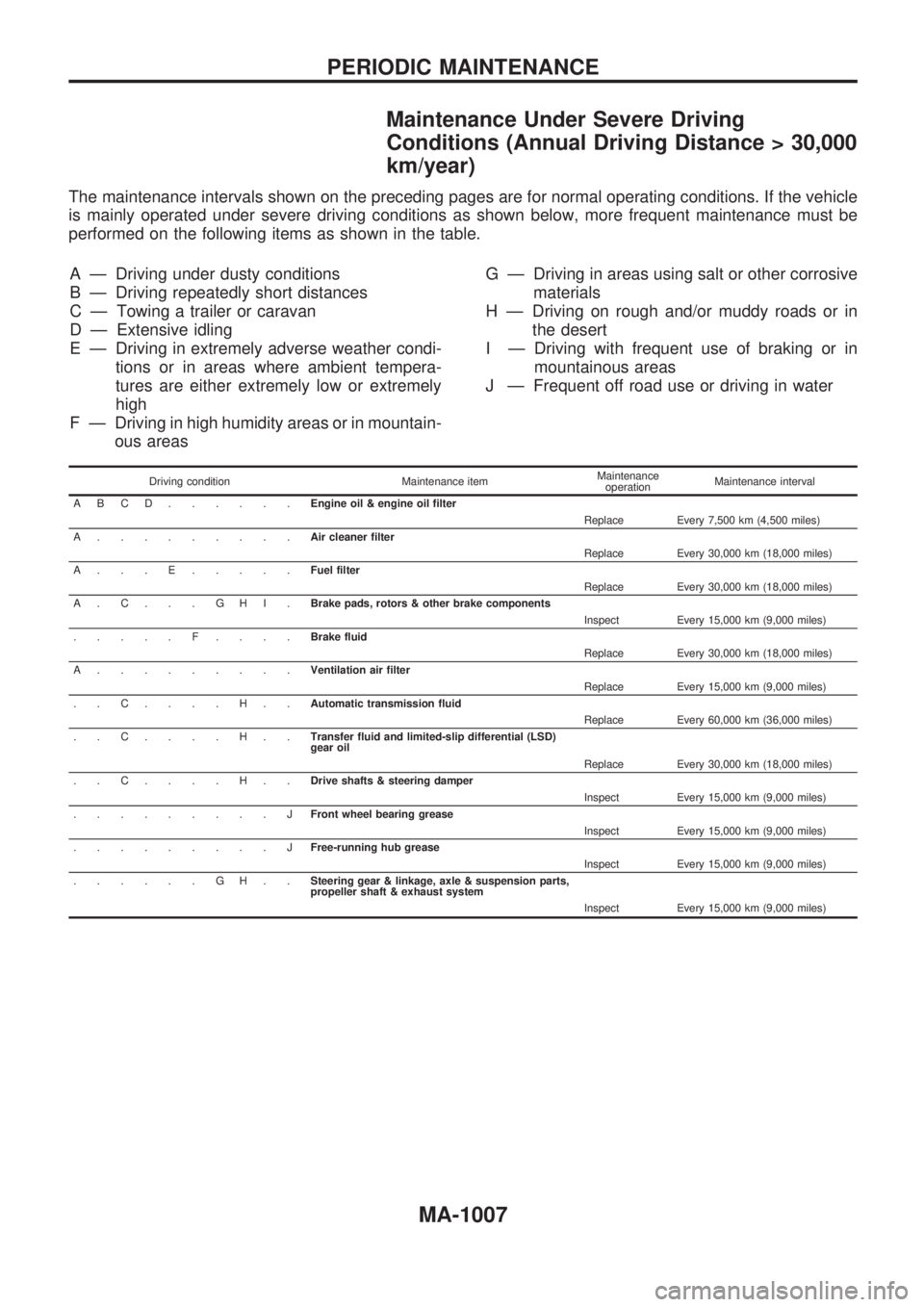

MaintenanceUnderSevereDriving

Conditions (Annual Driving Distance > 30,000

km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be

performed on the following items as shown in the table.

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather condi- tions or in areas where ambient tempera-

tures are either extremely low or extremely

high

F Ð Driving in high humidity areas or in mountain- ous areas G Ð Driving in areas using salt or other corrosive

materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance item Maintenance

operation Maintenance interval

ABCD...... Engine oil & engine oil filter

Replace Every 7,500 km (4,500 miles)

A......... Air cleaner filter

Replace Every 30,000 km (18,000 miles)

A...E..... Fuel filter

Replace Every 30,000 km (18,000 miles)

A.C...GHI. Brake pads, rotors & other brake components

Inspect Every 15,000 km (9,000 miles)

.....F.... Brake fluid

Replace Every 30,000 km (18,000 miles)

A......... Ventilation air filter

Replace Every 15,000 km (9,000 miles)

..C....H.. Automatic transmission fluid

Replace Every 60,000 km (36,000 miles)

..C....H.. Transfer fluid and limited-slip differential (LSD)

gear oil

Replace Every 30,000 km (18,000 miles)

..C....H.. Drive shafts & steering damper

Inspect Every 15,000 km (9,000 miles)

.........J Front wheel bearing grease

Inspect Every 15,000 km (9,000 miles)

.........J Free-running hub grease

Inspect Every 15,000 km (9,000 miles)

......GH.. Steering gear & linkage, axle & suspension parts,

propeller shaft & exhaust system

Inspect Every 15,000 km (9,000 miles)

PERIODIC MAINTENANCE

MA-1007