brake system NISSAN PATROL 2000 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 906 of 1033

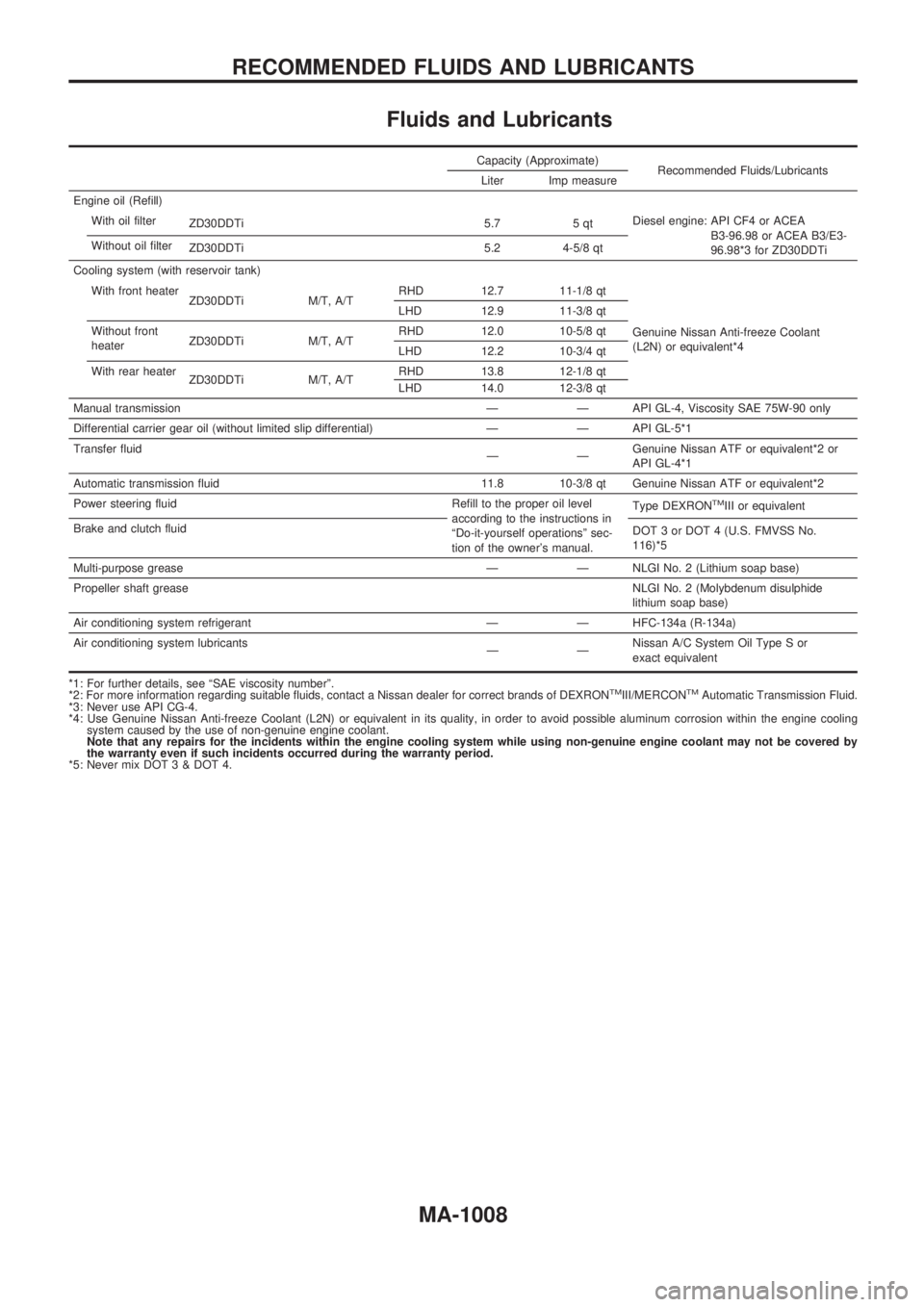

Fluids and Lubricants

Capacity (Approximate)

Recommended Fluids/Lubricants

Liter Imp measure

Engine oil (Refill)

With oil filter

ZD30DDTi 5.7 5 qtDiesel engine: API CF4 or ACEA

B3-96.98 or ACEA B3/E3-

96.98*3 for ZD30DDTi Without oil filter

ZD30DDTi 5.2 4-5/8 qt

Cooling system (with reservoir tank)

With front heater

ZD30DDTi M/T, A/TRHD 12.7 11-1/8 qt

Genuine Nissan Anti-freeze Coolant

(L2N) or equivalent*4 LHD 12.9 11-3/8 qt

Without front

heaterZD30DDTi M/T, A/TRHD 12.0 10-5/8 qt

LHD 12.2 10-3/4 qt

With rear heater

ZD30DDTi M/T, A/TRHD 13.8 12-1/8 qt

LHD 14.0 12-3/8 qt

Manual transmission Ð Ð API GL-4, Viscosity SAE 75W-90 only

Differential carrier gear oil (without limited slip differential) Ð Ð API GL-5*1

Transfer fluid

ÐÐGenuine Nissan ATF or equivalent*2 or

API GL-4*1

Automatic transmission fluid 11.8 10-3/8 qt Genuine Nissan ATF or equivalent*2

Power steering fluid Refill to the proper oil level

according to the instructions in

ªDo-it-yourself operationsº sec-

tion of the owner's manual.Type DEXRON

TMIII or equivalent

Brake and clutch fluid

DOT 3 or DOT 4 (U.S. FMVSS No.

116)*5

Multi-purpose grease Ð Ð NLGI No. 2 (Lithium soap base)

Propeller shaft greaseNLGI No. 2 (Molybdenum disulphide

lithium soap base)

Air conditioning system refrigerant Ð Ð HFC-134a (R-134a)

Air conditioning system lubricants

ÐÐNissan A/C System Oil Type S or

exact equivalent

*1: For further details, see ªSAE viscosity numberº.

*2: For more information regarding suitable fluids, contact a Nissan dealer for correct brands of DEXRON

TMIII/MERCONTMAutomatic Transmission Fluid.

*3: Never use API CG-4.

*4: Use Genuine Nissan Anti-freeze Coolant (L2N) or equivalent in its quality, in order to avoid possible aluminum corrosion within the engine cooling

system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be covered by

the warranty even if such incidents occurred during the warranty period.

*5: Never mix DOT 3 & DOT 4.

RECOMMENDED FLUIDS AND LUBRICANTS

MA-1008

Page 918 of 1033

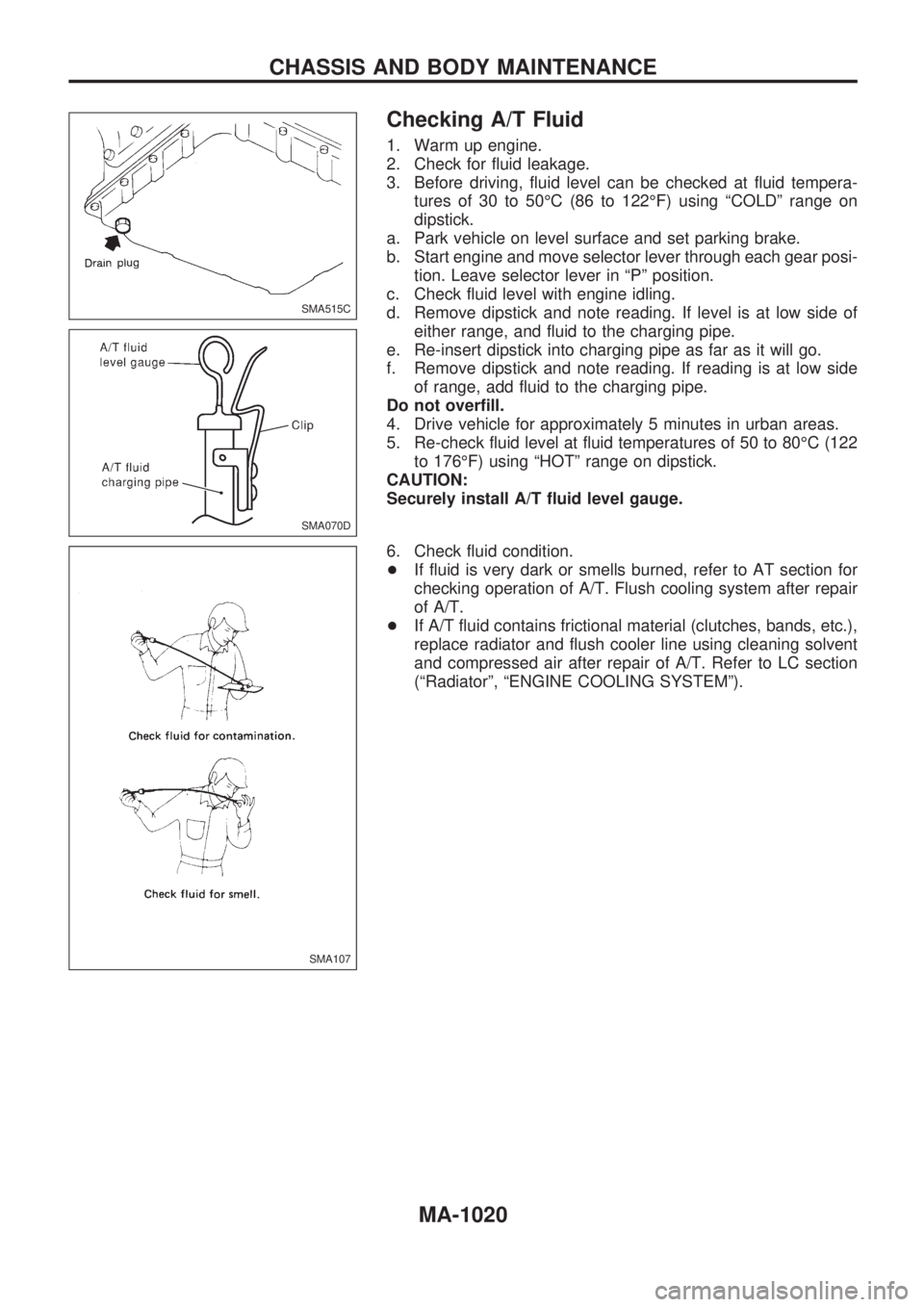

Checking A/T Fluid

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid tempera-

tures of 30 to 50ÉC (86 to 122ÉF) using ªCOLDº range on

dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in ªPº position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of

either range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side

of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80ÉC (122

to 176ÉF) using ªHOTº range on dipstick.

CAUTION:

Securely install A/T fluid level gauge.

6. Check fluid condition.

+If fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair

of A/T.

+If A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to LC section

(ªRadiatorº, ªENGINE COOLING SYSTEMº).

SMA515C

SMA070D

SMA107

CHASSIS AND BODY MAINTENANCE

MA-1020

Page 927 of 1033

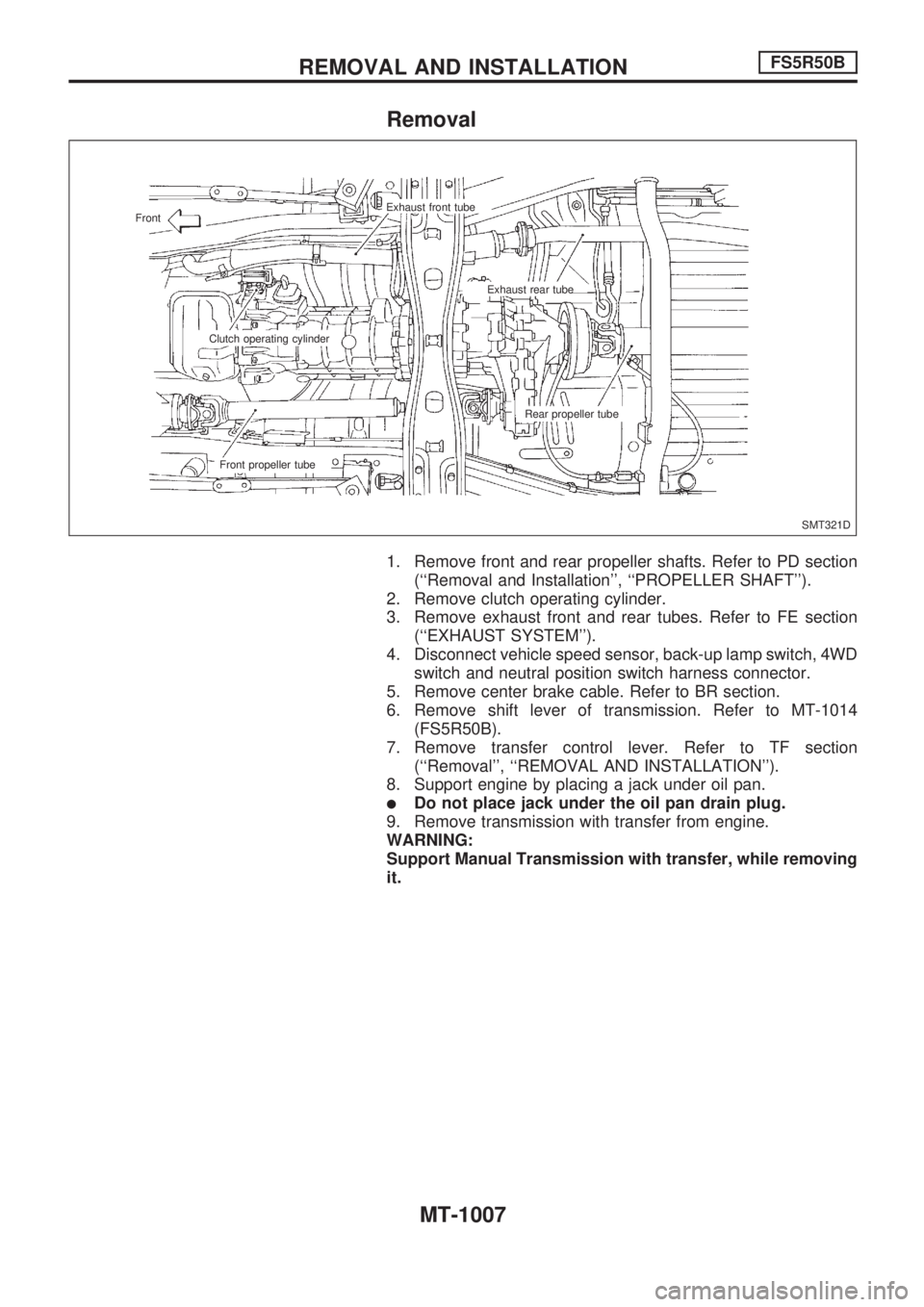

Removal

1. Remove front and rear propeller shafts. Refer to PD section

(``Removal and Installation'', ``PROPELLER SHAFT'').

2. Remove clutch operating cylinder.

3. Remove exhaust front and rear tubes. Refer to FE section

(``EXHAUST SYSTEM'').

4. Disconnect vehicle speed sensor, back-up lamp switch, 4WD

switch and neutral position switch harness connector.

5. Remove center brake cable. Refer to BR section.

6. Remove shift lever of transmission. Refer to MT-1014

(FS5R50B).

7. Remove transfer control lever. Refer to TF section

(``Removal'', ``REMOVAL AND INSTALLATION'').

8. Support engine by placing a jack under oil pan.

lDo not place jack under the oil pan drain plug.

9. Remove transmission with transfer from engine.

WARNING:

Support Manual Transmission with transfer, while removing

it.

SMT321D Exhaust front tube

Front

Exhaust rear tube

Clutch operating cylinder

Rear propeller tube

Front propeller tube

REMOVAL AND INSTALLATIONFS5R50B

MT-1007