brake system NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 1 of 1033

Edition: February 2000

Release: February 2000 (01)

Publication No.: SM0E-Y61AE0E

Reference No.: 7711346024GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL,

FUEL & EXHAUST SYSTEMFE

CLUTCHCL

MANUAL TRANSMISSIONMT

AUTOMATIC TRANSMISSIONAT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

PATROL GR

MODEL Y61 SERIES

NISSAN EUROPE S.A.S.

2000 NISSAN EUROPE S.A.S.

Produced in The Netherlands

Not to be reproduced in whole or in part

without the prior written permission of

Nissan Europe S.A.S., Paris, France.

QUICK REFERENCE INDEX

Page 4 of 1033

Diagnostic Procedure....................................... 1088

TROUBLE DIAGNOSIS FOR CONTROL UNIT

(EFP ROM)........................................................... 1089

Description ....................................................... 1089

Diagnostic Procedure....................................... 1090

TROUBLE DIAGNOSIS FOR

NON-DETECTABLE ITEMS................................ 1091

PNP, Overdrive Control, A/T Mode or

Accelerator Position Switches ......................... 1091

DIAGNOSTIC PROCEDURES FOR

SYMPTOMS......................................................... 1097

1. SPORT Indicator Lamp Does Not

Come On.......................................................... 1097

2. SPORT Indicator Lamp Does Not

Come On.......................................................... 1098

3. O/D OFF Indicator Lamp Does Not Come

On .................................................................... 1098

4. SPORT Indicator Lamp Does Not

Come On.......................................................... 1099

5. Engine Cannot Be Started In ªPº and ªNº

Position ............................................................ 1100

6. In ªPº Position, Vehicle Moves Forward Or

Backward When Pushed ................................. 1100

7. In ªNº Position, Vehicle Moves .................... 1101

8. Large Shock. ªNº®ªRº Position ................ 1102

9. Vehicle Does Not Creep Backward In ªRº

Position ............................................................ 1103

10. Vehicle Does Not Creep Forward In ªDº,

ª2º Or ª1º Position ............................................ 1104

11. Vehicle Cannot Be Started From D

1......... 1105

12. A/T Does Not Shift: D

1®D2Or Does Not

Kickdown: D

4®D2......................................... 1106

13. A/T Does Not Shift: D

2®D3.................... 1107

14. A/T Does Not Shift: D

3®D4.................... 1108

15. A/T Does Not Perform Lock-up ................. 1109

16. A/T Does Not Hold Lock-up Condition ...... 1110

17. Lock-up Is Not Released ........................... 1110

18. Engine Speed Does Not Return To Idle

(Light Braking D

4®D3) .................................. 1111

19. Vehicle Does Not Start From D

1............... 1112

20. A/T Does Not Shift: D

2®D1When

Depressing Accelerator Pedal ......................... 1113

21. A/T Does Not Shift: D

4®D3, When

Overdrive Control Switch ªONº®ªOFFº ........ 1114

22. A/T Does Not Shift: D

3®22, When

Selector Lever ªDº®ª2º Position ................... 1114

23. A/T Does Not Shift: 2

2®11, WhenSelector Lever ª2º®ª1º Position .................... 1115

24. Vehicle Does Not Decelerate By Engine

Brake ................................................................ 1115

TROUBLE DIAGNOSES Ð A/T Shift Lock

System................................................................. 1116

Description ....................................................... 1116

Wiring Diagram Ð SHIFT Ð ........................... 1117

Diagnostic Procedure....................................... 1118

Key Interlock Cable.......................................... 1121

Component Check ........................................... 1122

ON-VEHICLE SERVICE...................................... 1124

Control Valve Assembly and Accumulators .... 1124

Revolution Sensor Replacement ..................... 1125

Rear Oil Seal Replacement ............................. 1125

Parking Pawl Components Inspection ............. 1125

PNP Switch Adjustment ................................... 1125

Manual Control Linkage Adjustment................ 1126

REMOVAL AND INSTALLATION....................... 1127

Removal ........................................................... 1127

Installation ........................................................ 1128

MAJOR OVERHAUL........................................... 1129

Oil Channel ...................................................... 1131

Locations of Needle Bearings, Thrust Washers

and Snap Rings ............................................... 1132

DISASSEMBLY.................................................... 1133

REPAIR FOR COMPONENT PARTS................. 1144

Oil Pump .......................................................... 1144

Control Valve Assembly................................... 1148

Control Valve Upper Body ............................... 1154

Control Valve Lower Body ............................... 1159

Reverse Clutch ................................................ 1161

High Clutch ...................................................... 1165

Forward and Overrun Clutches ....................... 1167

Low & Reverse Brake ...................................... 1171

Forward Clutch Drum Assembly ...................... 1175

Rear Internal Gear and Forward Clutch Hub .. 1177

Band Servo Piston Assembly .......................... 1180

Parking Pawl Components .............................. 1184

ASSEMBLY.......................................................... 1186

Assembly (1) .................................................... 1186

Adjustment ....................................................... 1190

Assembly (2) .................................................... 1195

A/T FLUID COOLER SYSTEM........................... 1205

A/T Fluid Cooler ............................................... 1205

SERVICE DATA AND SPECIFICATIONS (SDS)1206

General Specifications ..................................... 1206

Specifications and Adjustment......................... 1206

When you read wiring diagrams:

+Read GI section, ªHOW TO READ WIRING DIAGRAMSº.

+See EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSESº.

AT-1002

Page 26 of 1033

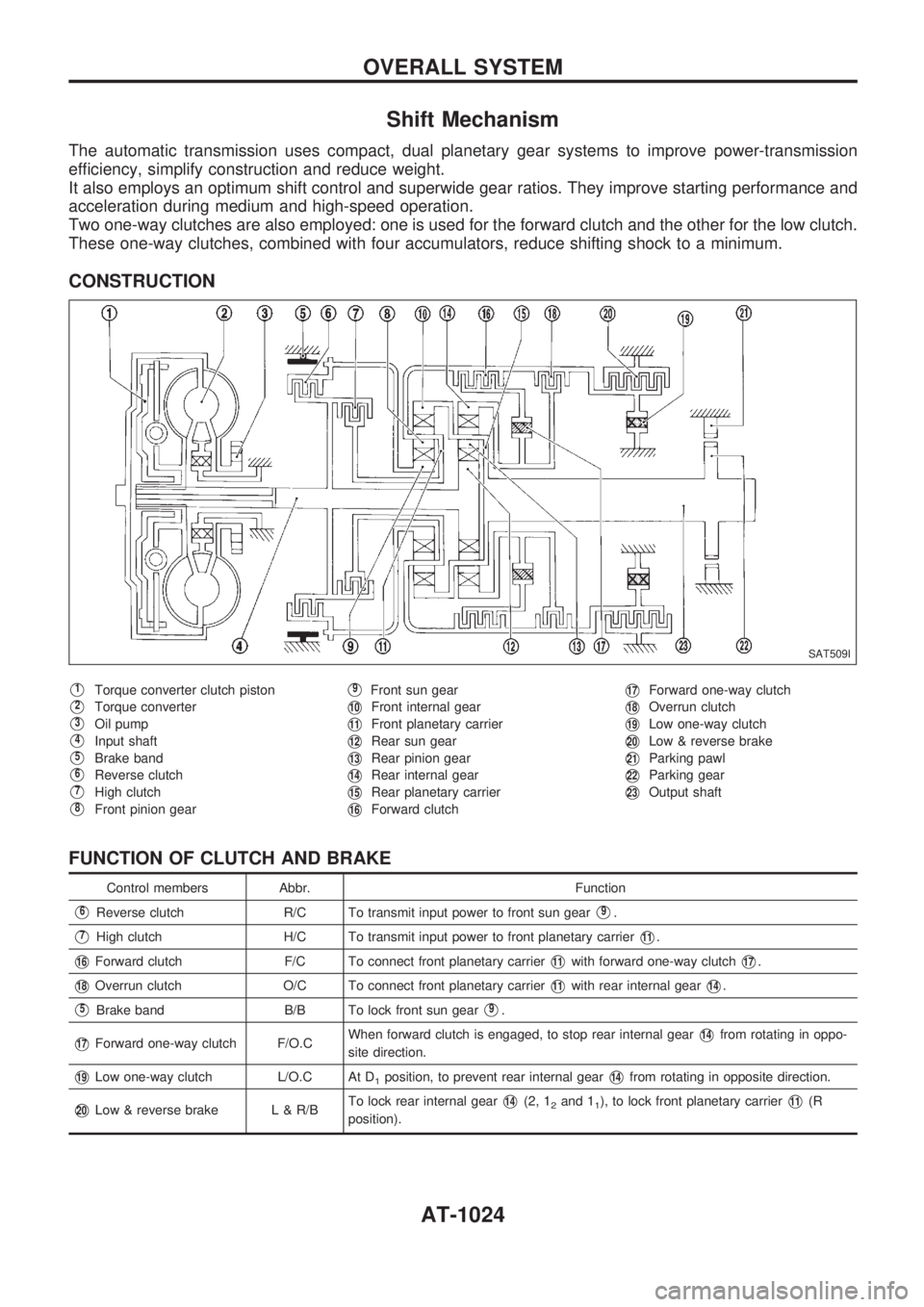

Shift Mechanism

The automatic transmission uses compact, dual planetary gear systems to improve power-transmission

efficiency, simplify construction and reduce weight.

It also employs an optimum shift control and superwide gear ratios. They improve starting performance and

acceleration during medium and high-speed operation.

Two one-way clutches are also employed: one is used for the forward clutch and the other for the low clutch.

These one-way clutches, combined with four accumulators, reduce shifting shock to a minimum.

CONSTRUCTION

V1Torque converter clutch piston

V2Torque converter

V3Oil pump

V4Input shaft

V5Brake band

V6Reverse clutch

V7High clutch

V8Front pinion gear

V9Front sun gear

V10Front internal gear

V11Front planetary carrier

V12Rear sun gear

V13Rear pinion gear

V14Rear internal gear

V15Rear planetary carrier

V16Forward clutch

V17Forward one-way clutch

V18Overrun clutch

V19Low one-way clutch

V20Low & reverse brake

V21Parking pawl

V22Parking gear

V23Output shaft

FUNCTION OF CLUTCH AND BRAKE

Control members Abbr. Function

V6Reverse clutch R/C To transmit input power to front sun gearV9.

V7High clutch H/C To transmit input power to front planetary carrierV11.

V16Forward clutch F/C To connect front planetary carrierV11with forward one-way clutchV17.

V18Overrun clutch O/C To connect front planetary carrierV11with rear internal gearV14.

V5Brake band B/B To lock front sun gearV9.

V17Forward one-way clutch F/O.CWhen forward clutch is engaged, to stop rear internal gearV14from rotating in oppo-

site direction.

V19Low one-way clutch L/O.C At D1position, to prevent rear internal gearV14from rotating in opposite direction.

V20Low & reverse brake L & R/BTo lock rear internal gearV14(2, 12and 11), to lock front planetary carrierV11(R

position).

SAT509I

OVERALL SYSTEM

AT-1024

Page 27 of 1033

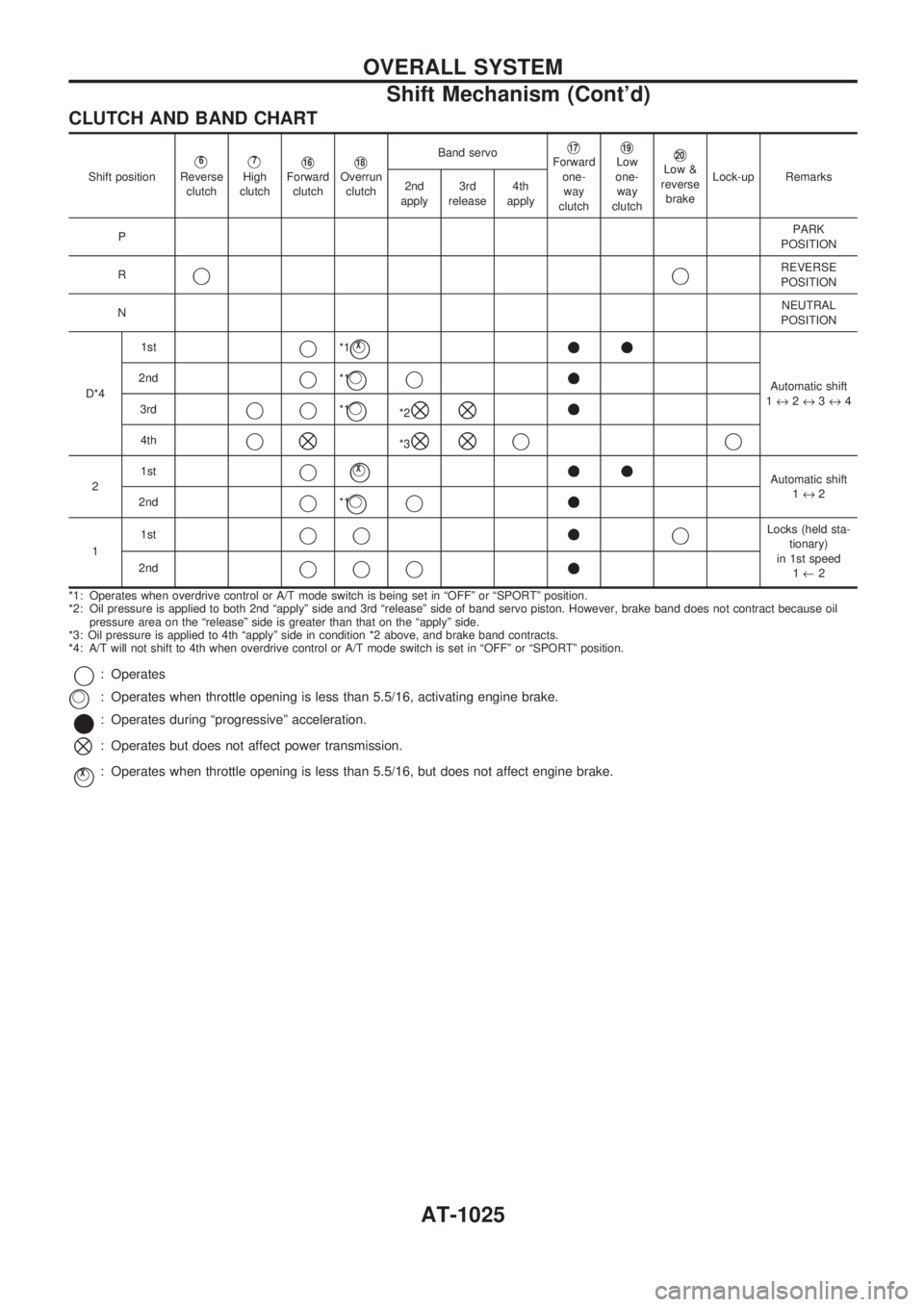

CLUTCH AND BAND CHART

Shift positionV6

Reverse

clutchV7

High

clutchV16Forward

clutchV18Overrun

clutchBand servo

V17Forward

one-

way

clutchV19Low

one-

way

clutchV20Low &

reverse

brakeLock-up Remarks

2nd

apply3rd

release4th

apply

PPARK

POSITION

R

jjREVERSE

POSITION

NNEUTRAL

POSITION

D*41st

j*1jVX++

Automatic shift

1«2«3«4 2ndj*1jVj+

3rdjj*1jV*2^^+

4thj^*3^^jj

21stjjVX++Automatic shift

1«2

2nd

j*1jVj+

11stjj+jLocks (held sta-

tionary)

in 1st speed

1¬2 2nd

jjj+

*1: Operates when overdrive control or A/T mode switch is being set in ªOFFº or ªSPORTº position.

*2: Oil pressure is applied to both 2nd ªapplyº side and 3rd ªreleaseº side of band servo piston. However, brake band does not contract because oil

pressure area on the ªreleaseº side is greater than that on the ªapplyº side.

*3: Oil pressure is applied to 4th ªapplyº side in condition *2 above, and brake band contracts.

*4: A/T will not shift to 4th when overdrive control or A/T mode switch is set in ªOFFº or ªSPORTº position.

j: Operates

: Operates when throttle opening is less than 5.5/16, activating engine brake.

*: Operates during ªprogressiveº acceleration.

^: Operates but does not affect power transmission.

jVX: Operates when throttle opening is less than 5.5/16, but does not affect engine brake.

jV

OVERALL SYSTEM

Shift Mechanism (Cont'd)

AT-1025

Page 29 of 1033

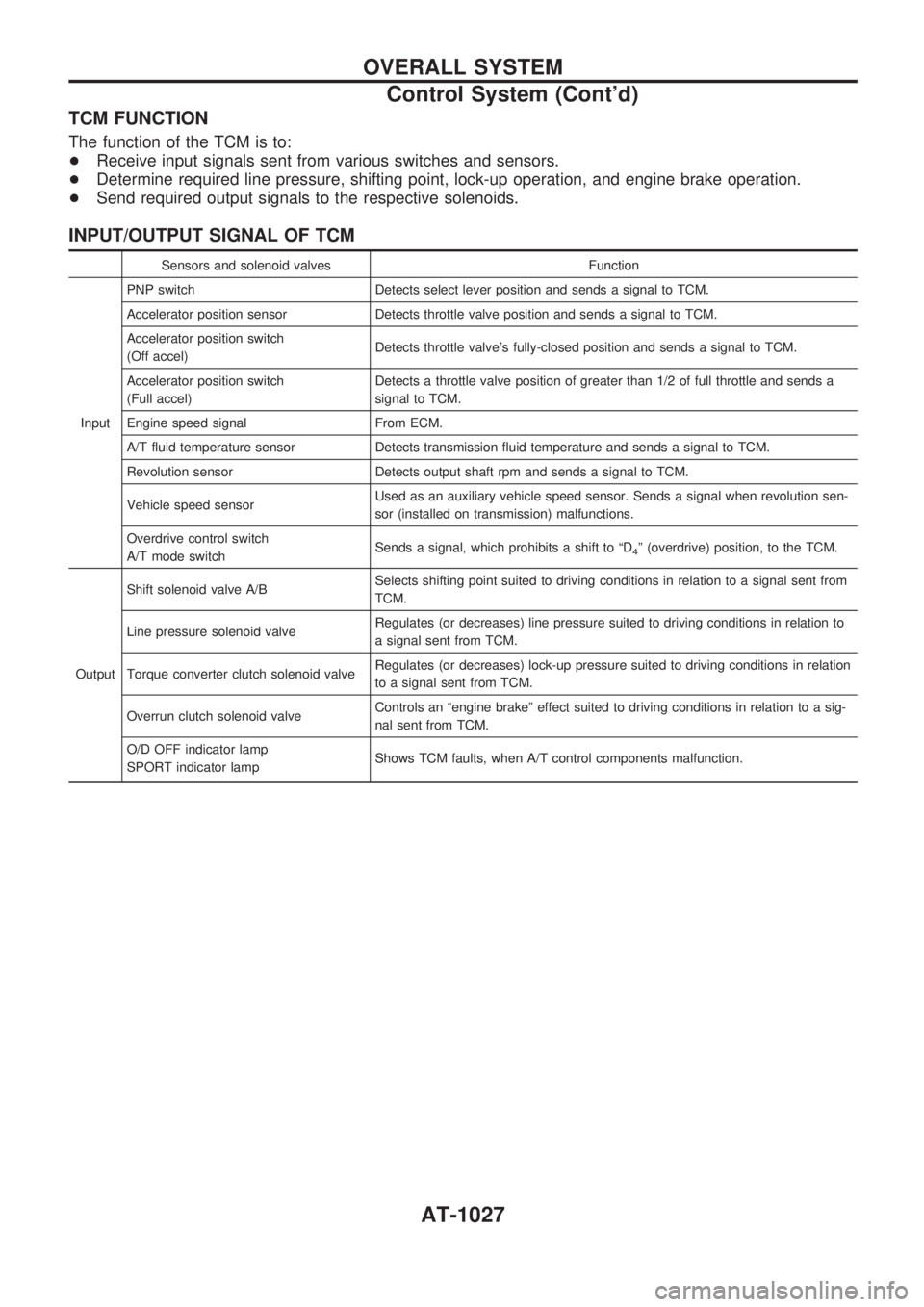

TCM FUNCTION

The function of the TCM is to:

+Receive input signals sent from various switches and sensors.

+Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

+Send required output signals to the respective solenoids.

INPUT/OUTPUT SIGNAL OF TCM

Sensors and solenoid valves Function

InputPNP switch Detects select lever position and sends a signal to TCM.

Accelerator position sensor Detects throttle valve position and sends a signal to TCM.

Accelerator position switch

(Off accel)Detects throttle valve's fully-closed position and sends a signal to TCM.

Accelerator position switch

(Full accel)Detects a throttle valve position of greater than 1/2 of full throttle and sends a

signal to TCM.

Engine speed signal From ECM.

A/T fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

Revolution sensor Detects output shaft rpm and sends a signal to TCM.

Vehicle speed sensorUsed as an auxiliary vehicle speed sensor. Sends a signal when revolution sen-

sor (installed on transmission) malfunctions.

Overdrive control switch

A/T mode switchSends a signal, which prohibits a shift to ªD

4º (overdrive) position, to the TCM.

OutputShift solenoid valve A/BSelects shifting point suited to driving conditions in relation to a signal sent from

TCM.

Line pressure solenoid valveRegulates (or decreases) line pressure suited to driving conditions in relation to

a signal sent from TCM.

Torque converter clutch solenoid valveRegulates (or decreases) lock-up pressure suited to driving conditions in relation

to a signal sent from TCM.

Overrun clutch solenoid valveControls an ªengine brakeº effect suited to driving conditions in relation to a sig-

nal sent from TCM.

O/D OFF indicator lamp

SPORT indicator lampShows TCM faults, when A/T control components malfunction.

OVERALL SYSTEM

Control System (Cont'd)

AT-1027

Page 118 of 1033

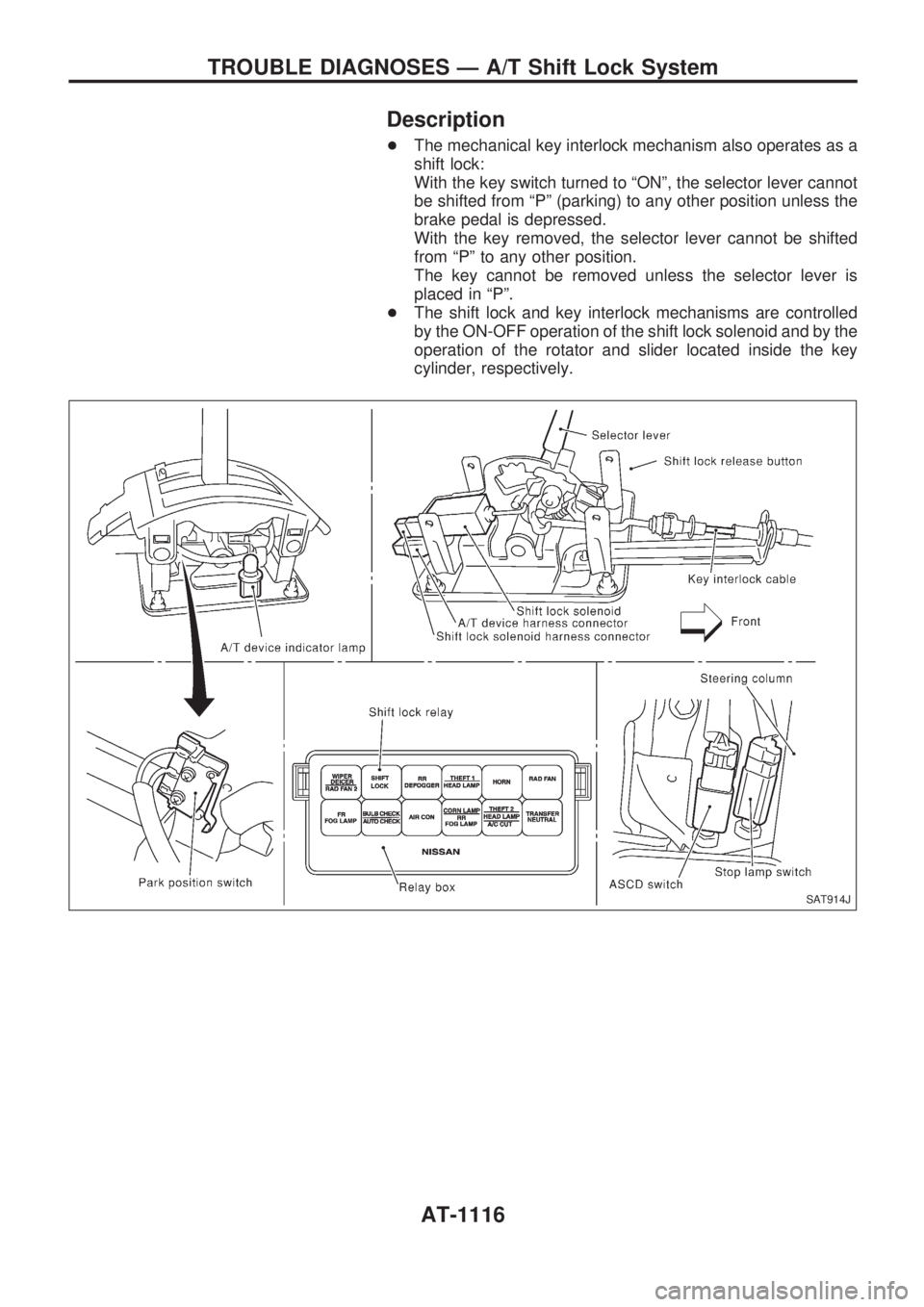

Description

+The mechanical key interlock mechanism also operates as a

shift lock:

With the key switch turned to ªONº, the selector lever cannot

be shifted from ªPº (parking) to any other position unless the

brake pedal is depressed.

With the key removed, the selector lever cannot be shifted

from ªPº to any other position.

The key cannot be removed unless the selector lever is

placed in ªPº.

+The shift lock and key interlock mechanisms are controlled

by the ON-OFF operation of the shift lock solenoid and by the

operation of the rotator and slider located inside the key

cylinder, respectively.

SAT914J

TROUBLE DIAGNOSES Ð A/T Shift Lock System

AT-1116

Page 120 of 1033

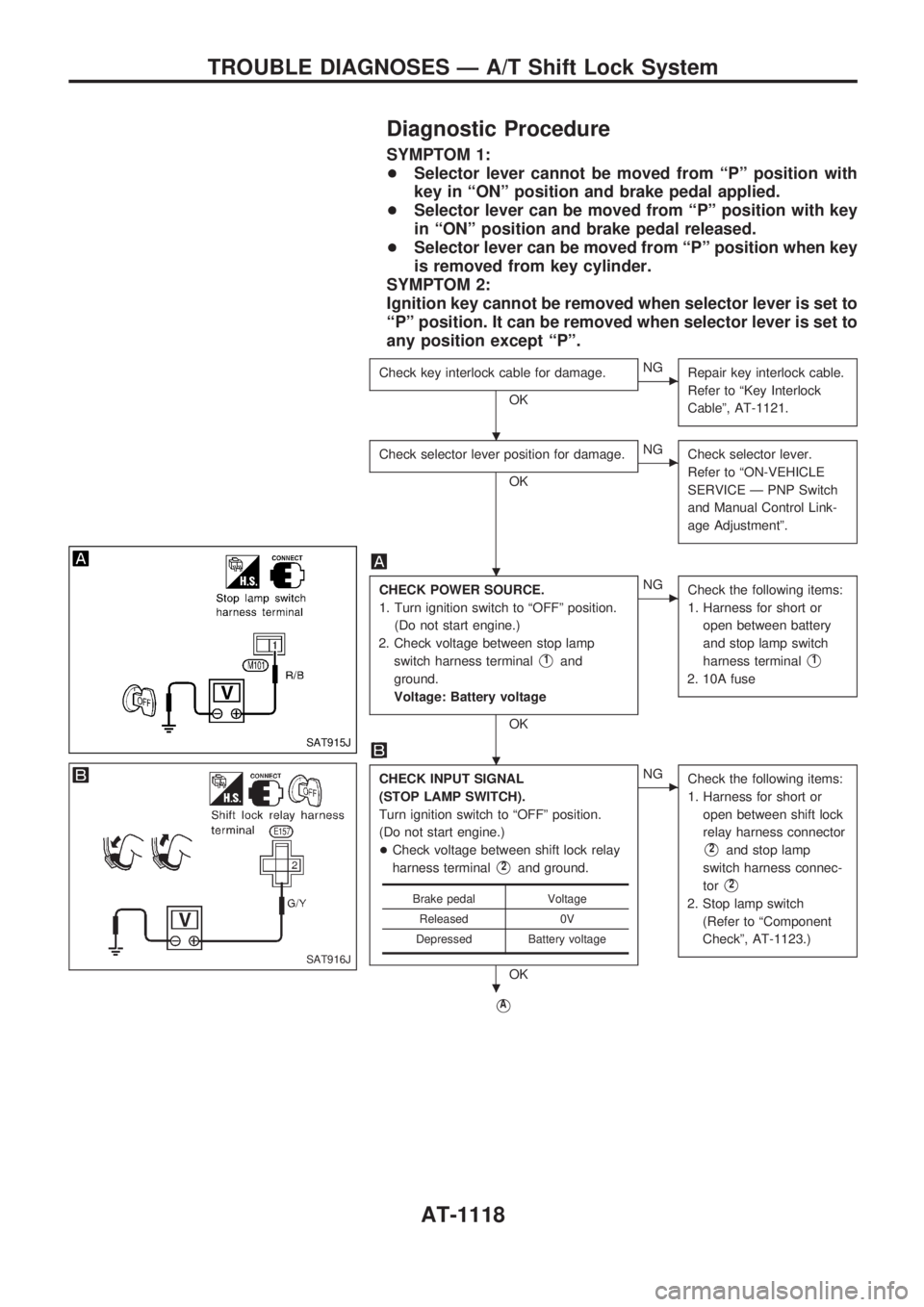

Diagnostic Procedure

SYMPTOM 1:

+Selector lever cannot be moved from ªPº position with

key in ªONº position and brake pedal applied.

+Selector lever can be moved from ªPº position with key

in ªONº position and brake pedal released.

+Selector lever can be moved from ªPº position when key

is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to

ªPº position. It can be removed when selector lever is set to

any position except ªPº.

Check key interlock cable for damage.

OK

cNG

Repair key interlock cable.

Refer to ªKey Interlock

Cableº, AT-1121.

Check selector lever position for damage.

OK

cNG

Check selector lever.

Refer to ªON-VEHICLE

SERVICE Ð PNP Switch

and Manual Control Link-

age Adjustmentº.

CHECK POWER SOURCE.

1. Turn ignition switch to ªOFFº position.

(Do not start engine.)

2. Check voltage between stop lamp

switch harness terminal

V1and

ground.

Voltage: Battery voltage

OK

cNG

Check the following items:

1. Harness for short or

open between battery

and stop lamp switch

harness terminal

V1

2. 10A fuse

CHECK INPUT SIGNAL

(STOP LAMP SWITCH).

Turn ignition switch to ªOFFº position.

(Do not start engine.)

+Check voltage between shift lock relay

harness terminal

V2and ground.

OK

cNG

Check the following items:

1. Harness for short or

open between shift lock

relay harness connector

V2and stop lamp

switch harness connec-

tor

V2

2. Stop lamp switch

(Refer to ªComponent

Checkº, AT-1123.)

VA

Brake pedal Voltage

Released 0V

Depressed Battery voltage

SAT915J

SAT916J

.

.

.

.

TROUBLE DIAGNOSES Ð A/T Shift Lock System

AT-1118

Page 121 of 1033

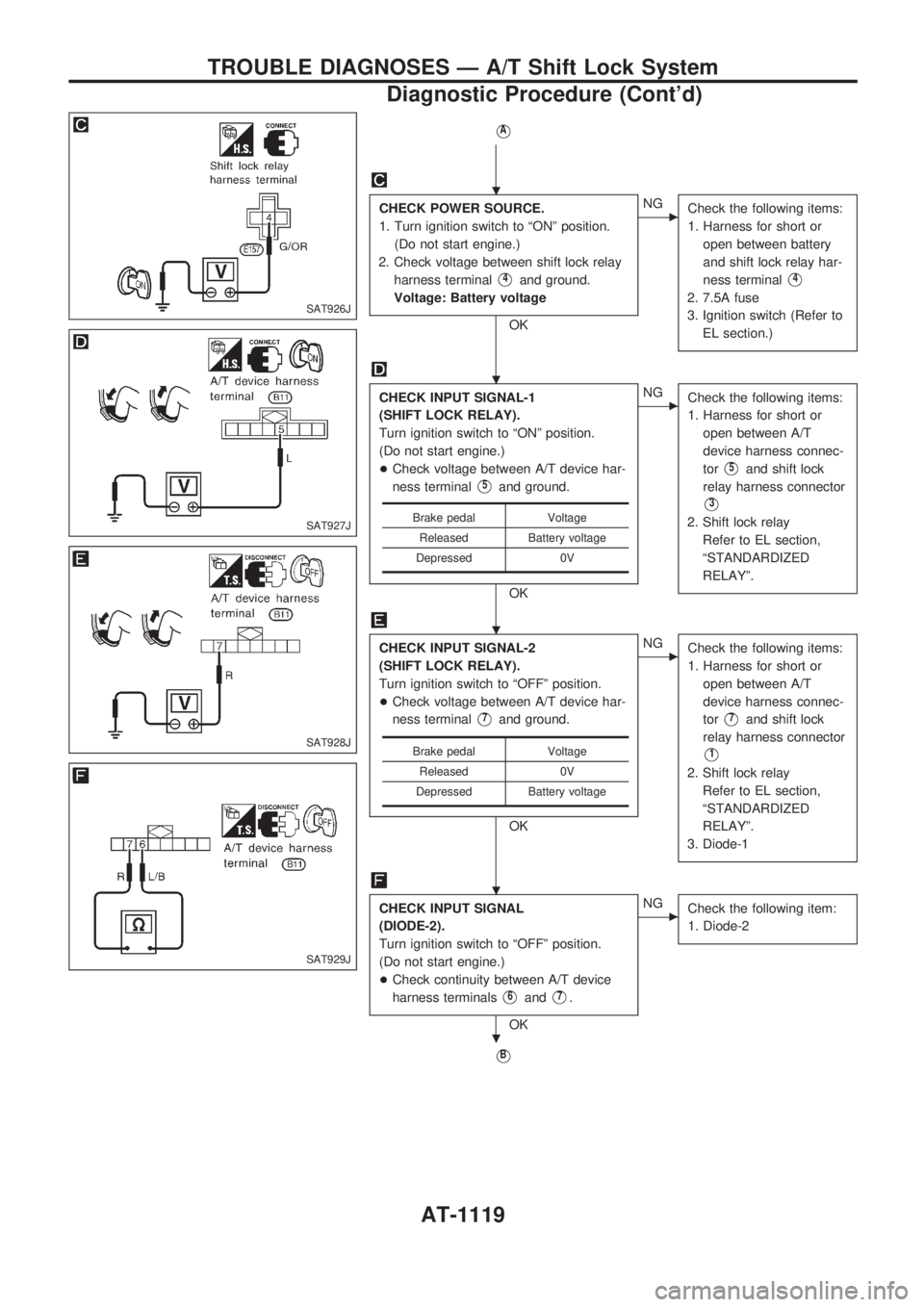

VA

CHECK POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between shift lock relay

harness terminal

V4and ground.

Voltage: Battery voltage

OK

cNG

Check the following items:

1. Harness for short or

open between battery

and shift lock relay har-

ness terminal

V4

2. 7.5A fuse

3. Ignition switch (Refer to

EL section.)

CHECK INPUT SIGNAL-1

(SHIFT LOCK RELAY).

Turn ignition switch to ªONº position.

(Do not start engine.)

+Check voltage between A/T device har-

ness terminal

V5and ground.

OK

cNG

Check the following items:

1. Harness for short or

open between A/T

device harness connec-

tor

V5and shift lock

relay harness connector

V3

2. Shift lock relay

Refer to EL section,

ªSTANDARDIZED

RELAYº.

CHECK INPUT SIGNAL-2

(SHIFT LOCK RELAY).

Turn ignition switch to ªOFFº position.

+Check voltage between A/T device har-

ness terminal

V7and ground.

OK

cNG

Check the following items:

1. Harness for short or

open between A/T

device harness connec-

tor

V7and shift lock

relay harness connector

V1

2. Shift lock relay

Refer to EL section,

ªSTANDARDIZED

RELAYº.

3. Diode-1

CHECK INPUT SIGNAL

(DIODE-2).

Turn ignition switch to ªOFFº position.

(Do not start engine.)

+Check continuity between A/T device

harness terminals

V6andV7.

OK

cNG

Check the following item:

1. Diode-2

VB

Brake pedal Voltage

Released Battery voltage

Depressed 0V

Brake pedal Voltage

Released 0V

Depressed Battery voltage

SAT926J

SAT927J

SAT928J

SAT929J

.

.

.

.

.

TROUBLE DIAGNOSES Ð A/T Shift Lock System

Diagnostic Procedure (Cont'd)

AT-1119

Page 125 of 1033

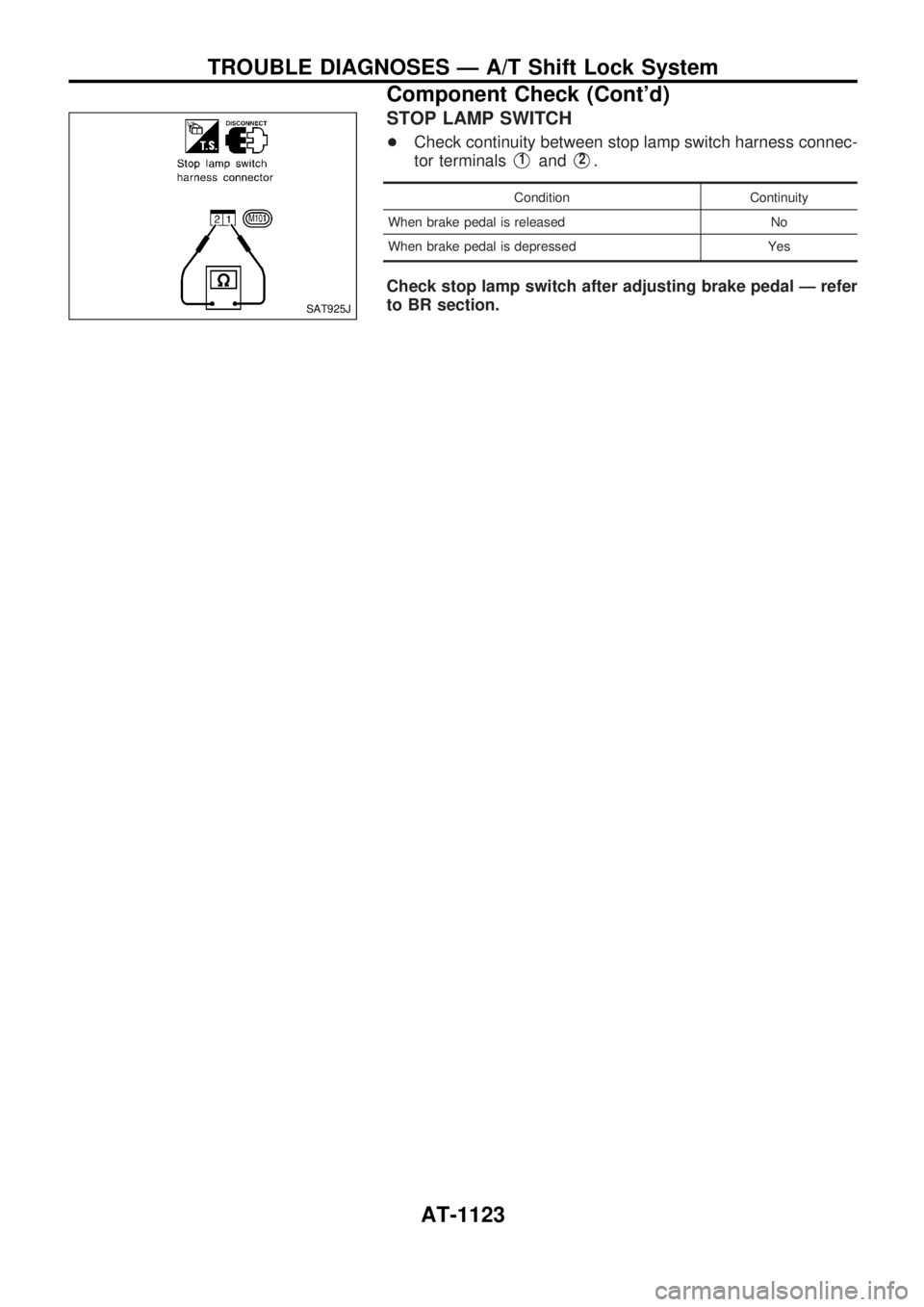

STOP LAMP SWITCH

+Check continuity between stop lamp switch harness connec-

tor terminals

V1andV2.

Condition Continuity

When brake pedal is released No

When brake pedal is depressed Yes

Check stop lamp switch after adjusting brake pedal Ð refer

to BR section.

SAT925J

TROUBLE DIAGNOSES Ð A/T Shift Lock System

Component Check (Cont'd)

AT-1123

Page 129 of 1033

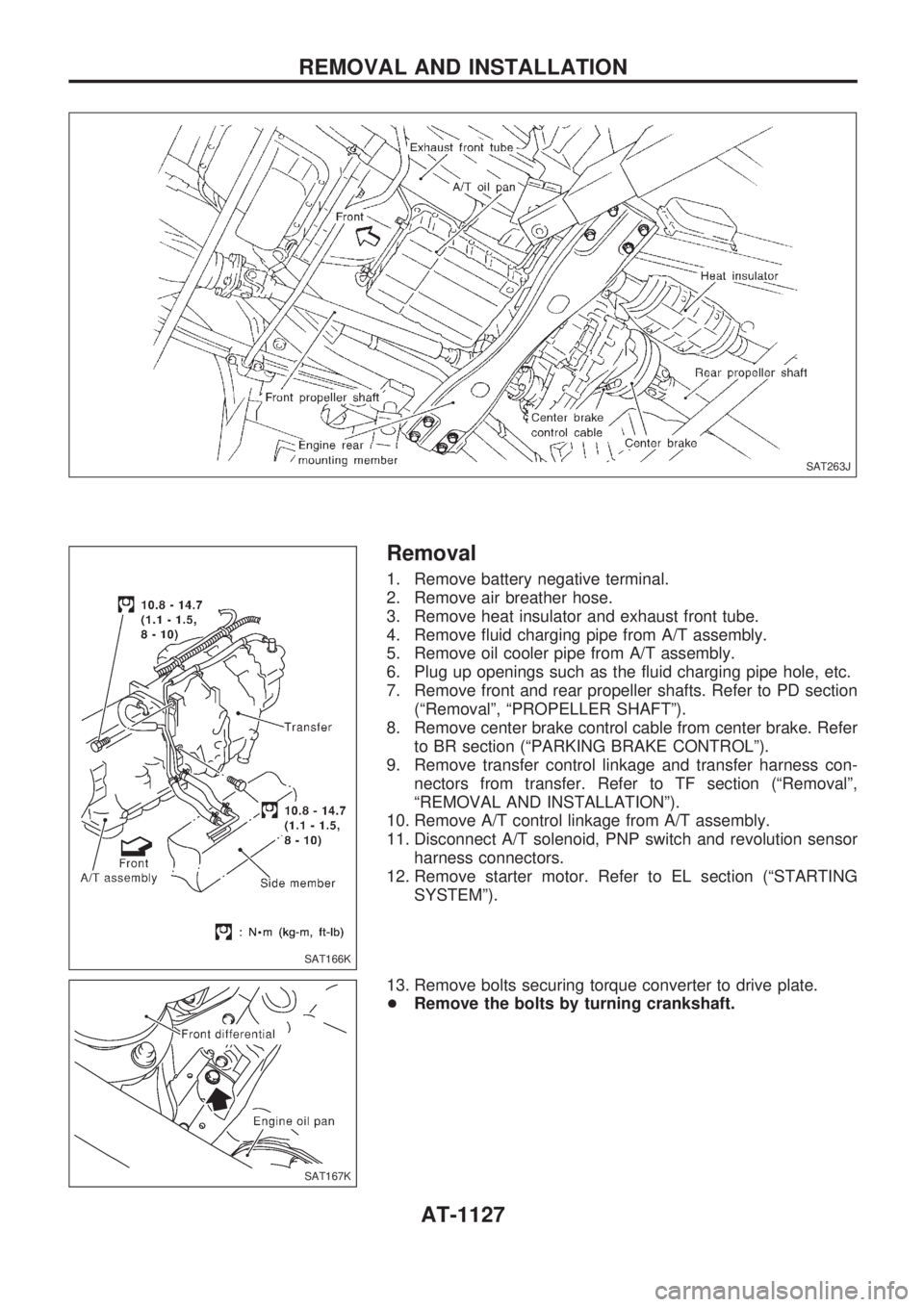

Removal

1. Remove battery negative terminal.

2. Remove air breather hose.

3. Remove heat insulator and exhaust front tube.

4. Remove fluid charging pipe from A/T assembly.

5. Remove oil cooler pipe from A/T assembly.

6. Plug up openings such as the fluid charging pipe hole, etc.

7. Remove front and rear propeller shafts. Refer to PD section

(ªRemovalº, ªPROPELLER SHAFTº).

8. Remove center brake control cable from center brake. Refer

to BR section (ªPARKING BRAKE CONTROLº).

9. Remove transfer control linkage and transfer harness con-

nectors from transfer. Refer to TF section (ªRemovalº,

ªREMOVAL AND INSTALLATIONº).

10. Remove A/T control linkage from A/T assembly.

11. Disconnect A/T solenoid, PNP switch and revolution sensor

harness connectors.

12. Remove starter motor. Refer to EL section (ªSTARTING

SYSTEMº).

13. Remove bolts securing torque converter to drive plate.

+Remove the bolts by turning crankshaft.

SAT263J

SAT166K

SAT167K

REMOVAL AND INSTALLATION

AT-1127