ignition NISSAN PATROL 2000 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 64 of 1033

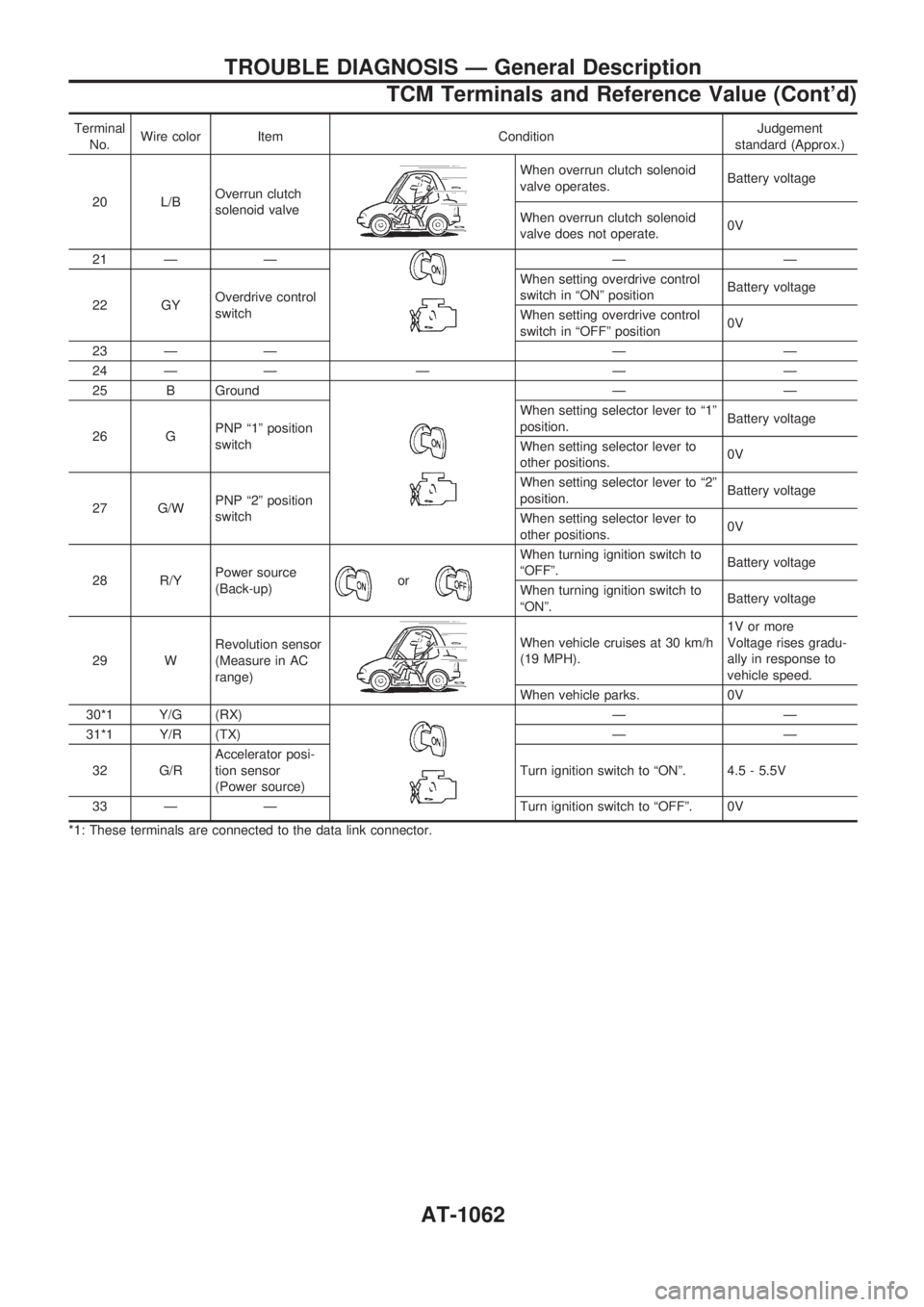

Terminal

No.Wire color Item ConditionJudgement

standard (Approx.)

20 L/BOverrun clutch

solenoid valve

When overrun clutch solenoid

valve operates.Battery voltage

When overrun clutch solenoid

valve does not operate.0V

21 Ð Ð

ÐÐ

22 GYOverdrive control

switchWhen setting overdrive control

switch in ªONº positionBattery voltage

When setting overdrive control

switch in ªOFFº position0V

23 Ð Ð Ð Ð

24 Ð Ð Ð Ð Ð

25 B Ground

ÐÐ

26 GPNP ª1º position

switchWhen setting selector lever to ª1º

position.Battery voltage

When setting selector lever to

other positions.0V

27 G/WPNP ª2º position

switchWhen setting selector lever to ª2º

position.Battery voltage

When setting selector lever to

other positions.0V

28 R/YPower source

(Back-up)

or

When turning ignition switch to

ªOFFº.Battery voltage

When turning ignition switch to

ªONº.Battery voltage

29 WRevolution sensor

(Measure in AC

range)

When vehicle cruises at 30 km/h

(19 MPH).1V or more

Voltage rises gradu-

ally in response to

vehicle speed.

When vehicle parks. 0V

30*1 Y/G (RX)

ÐÐ

31*1 Y/R (TX) Ð Ð

32 G/RAccelerator posi-

tion sensor

(Power source)Turn ignition switch to ªONº. 4.5 - 5.5V

33 Ð Ð Turn ignition switch to ªOFFº. 0V

*1: These terminals are connected to the data link connector.

TROUBLE DIAGNOSIS Ð General Description

TCM Terminals and Reference Value (Cont'd)

AT-1062

Page 71 of 1033

![NISSAN PATROL 2000 Electronic User Guide DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Refer to EC section [ªMalfunction Indica-

tor (MI)º, ªON BOARD DIAGNOSTIC

SYSTEM DESCRIPTIONº].

NISSAN PATROL 2000 Electronic User Guide DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Refer to EC section [ªMalfunction Indica-

tor (MI)º, ªON BOARD DIAGNOSTIC

SYSTEM DESCRIPTIONº].](/img/5/57367/w960_57367-70.png)

DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Refer to EC section [ªMalfunction Indica-

tor (MI)º, ªON BOARD DIAGNOSTIC

SYSTEM DESCRIPTIONº].

OK

cNG

Check accelerator position

sensor circuit for engine

control. Refer to EC sec-

tion [ªTROUBLE DIAGNO-

SIS FOR ªTHRTL

(ACCEL) POSI SENº

(DTC 43)].

CHECK INPUT SIGNAL.

1. Turn ignition switch to ªONº

position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªTHRTL

POS SENº.

Voltage:

Fully-closed throttle:

Approximately 0.5V

Fully-open throttle:

Approximately 4V

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº

position. (Do not start engine.)

2. Check voltage between TCM

terminals

V41andV42while

accelerator pedal is depressed

slowly.

Voltage:

Fully-closed throttle valve:

Approximately 0.5 - 0.7V

Fully-open throttle valve:

Approximately 4V

(Voltage rises gradually in

response to throttle position)

OK

cNG

Check harness for short or

open between ECM and

TCM regarding accelerator

position sensor circuit.

(Main harness)

CHECK ACCELERATOR POSITION

SWITCH.

Refer to ªCHECK ACCELERATOR POSI-

TION SWITCHº, AT-1091.

OK

cNG

Repair or replace dam-

aged parts.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1068.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT738J

SAT239J

.

.

.

.

TROUBLE DIAGNOSIS FOR THROTTLE POSI SEN

Accelerator Position Sensor (Cont'd)

AT-1069

Page 73 of 1033

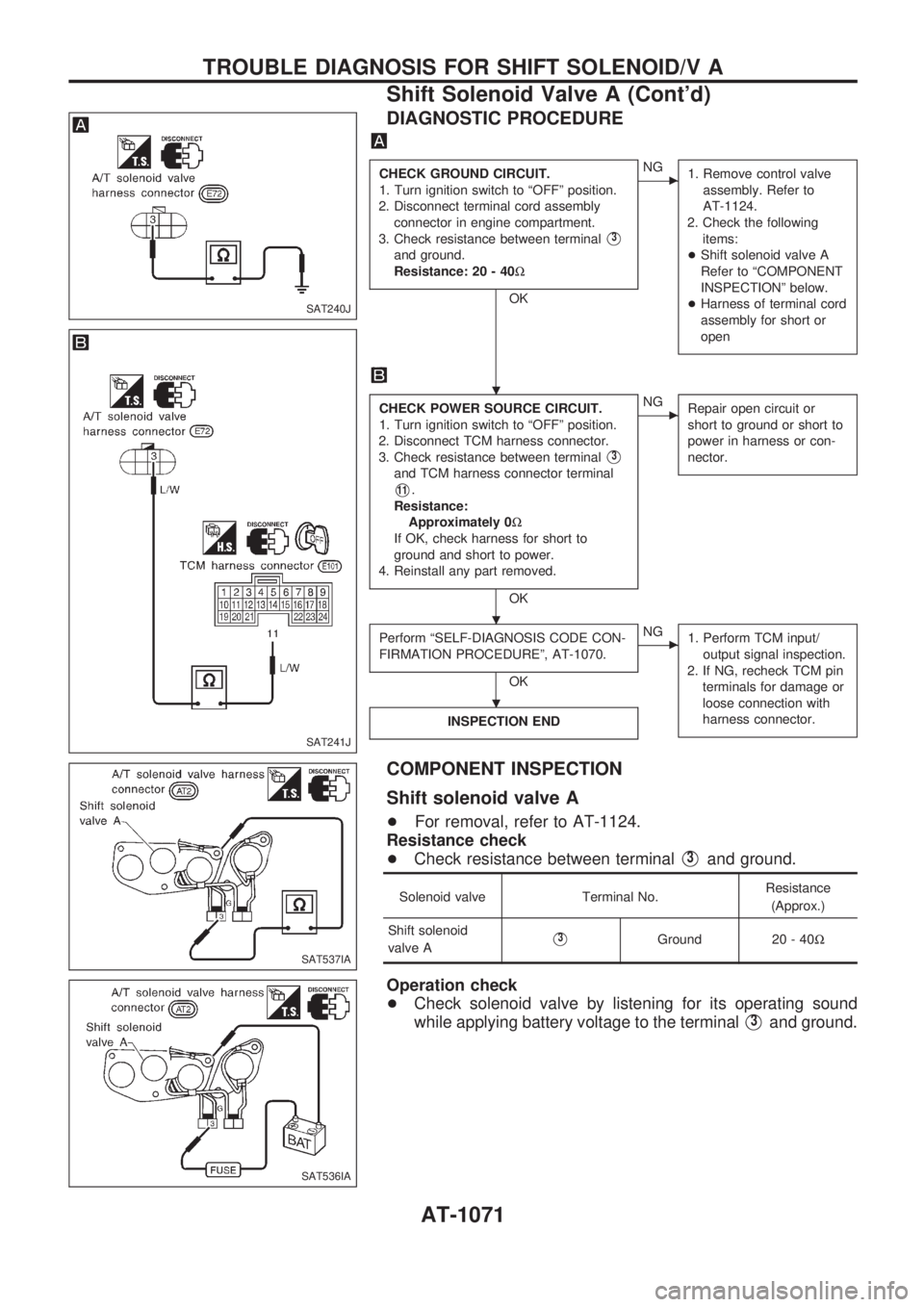

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminal

V3

and ground.

Resistance: 20 - 40W

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Shift solenoid valve A

Refer to ªCOMPONENT

INSPECTIONº below.

+Harness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal

V3

and TCM harness connector terminal

V11.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

cNG

Repair open circuit or

short to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1070.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

Shift solenoid valve A

+For removal, refer to AT-1124.

Resistance check

+Check resistance between terminal

V3and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Shift solenoid

valve A

V3Ground 20 - 40W

Operation check

+Check solenoid valve by listening for its operating sound

while applying battery voltage to the terminal

V3and ground.

SAT240J

SAT241J

SAT537IA

SAT536IA

.

.

.

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V A

Shift Solenoid Valve A (Cont'd)

AT-1071

Page 75 of 1033

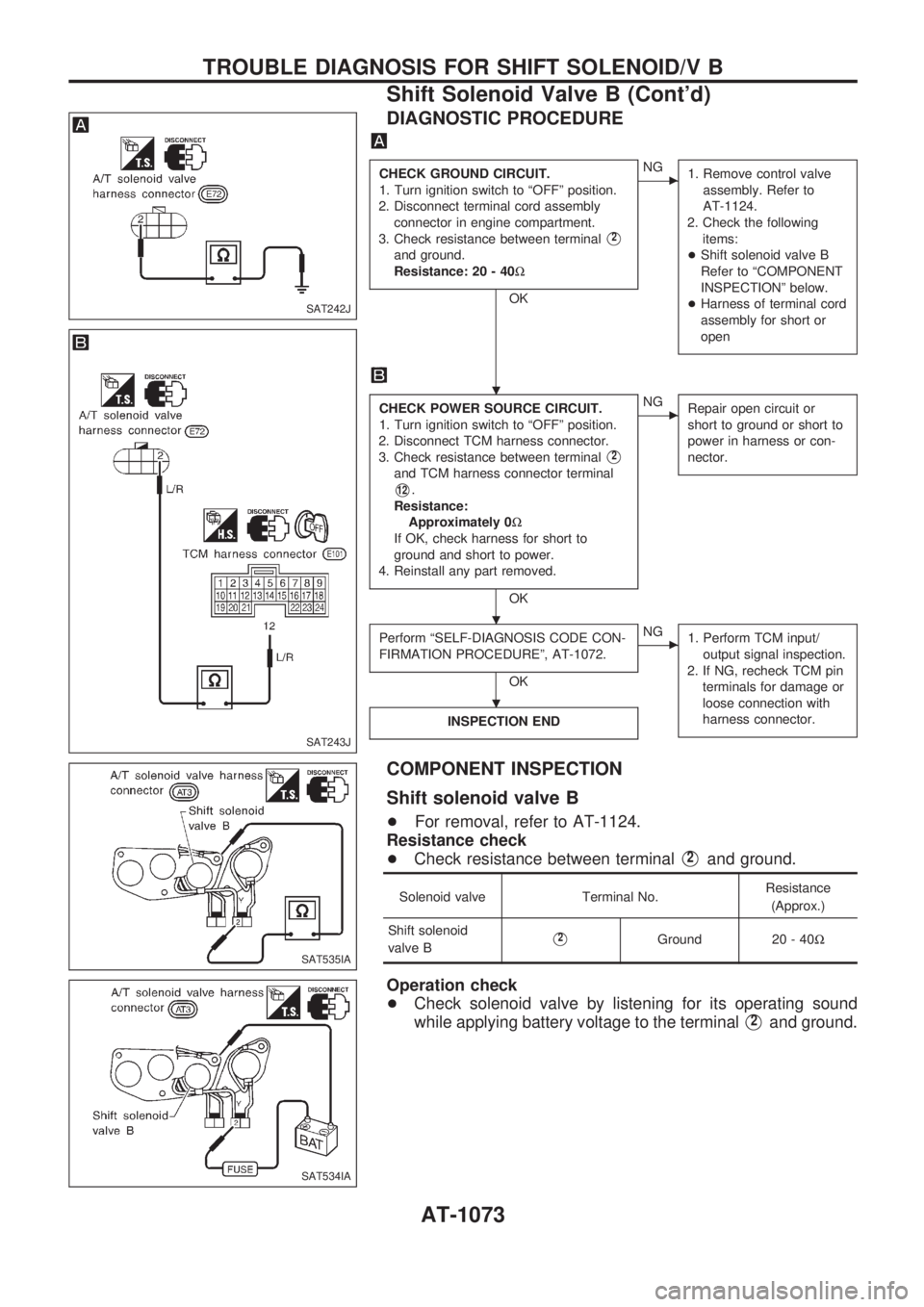

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminal

V2

and ground.

Resistance: 20 - 40W

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Shift solenoid valve B

Refer to ªCOMPONENT

INSPECTIONº below.

+Harness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal

V2

and TCM harness connector terminal

V12.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

cNG

Repair open circuit or

short to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1072.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

Shift solenoid valve B

+For removal, refer to AT-1124.

Resistance check

+Check resistance between terminal

V2and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Shift solenoid

valve B

V2Ground 20 - 40W

Operation check

+Check solenoid valve by listening for its operating sound

while applying battery voltage to the terminal

V2and ground.

SAT242J

SAT243J

SAT535IA

SAT534IA

.

.

.

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V B

Shift Solenoid Valve B (Cont'd)

AT-1073

Page 77 of 1033

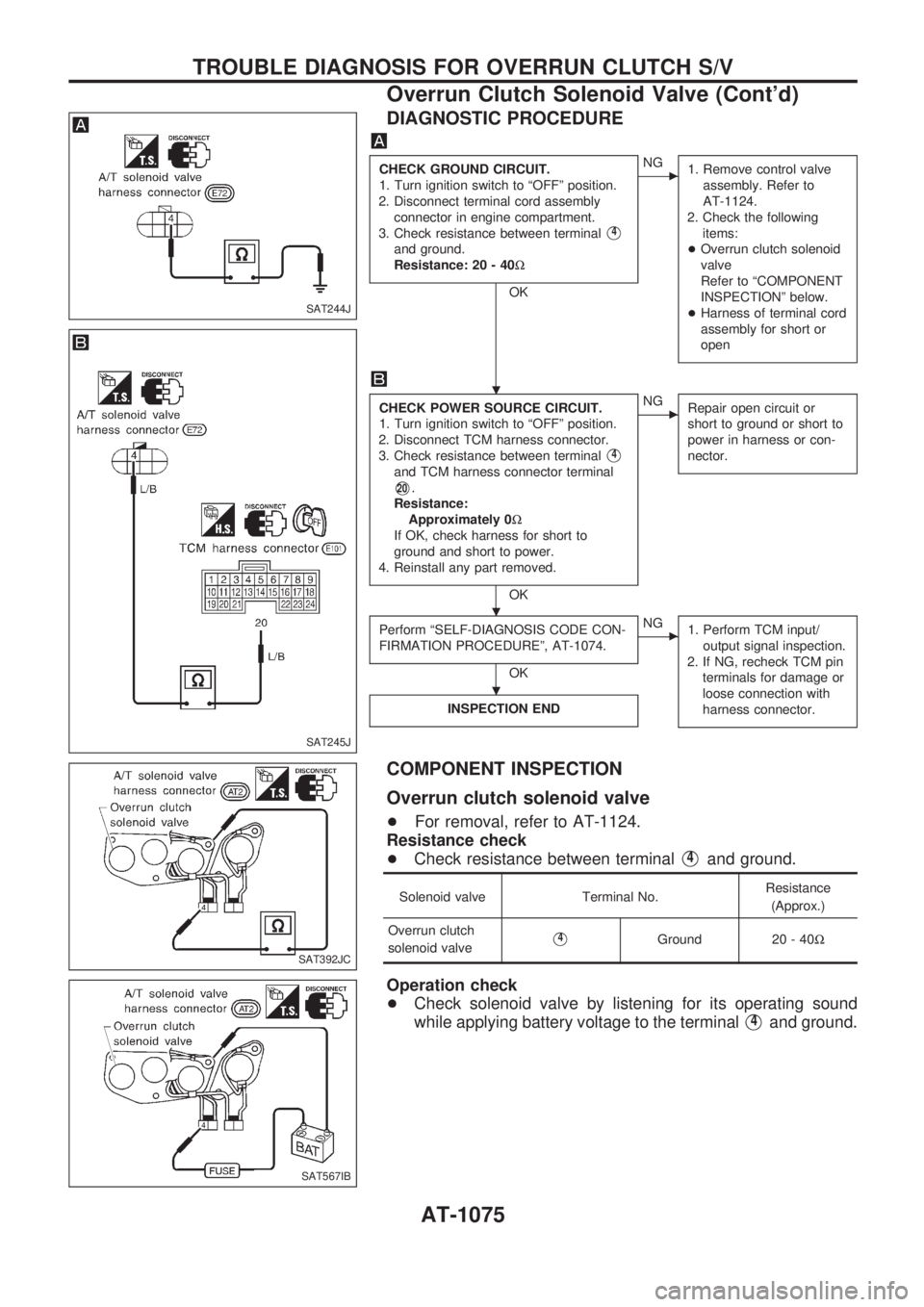

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminal

V4

and ground.

Resistance: 20 - 40W

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Overrun clutch solenoid

valve

Refer to ªCOMPONENT

INSPECTIONº below.

+Harness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal

V4

and TCM harness connector terminal

V20.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

cNG

Repair open circuit or

short to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1074.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

Overrun clutch solenoid valve

+For removal, refer to AT-1124.

Resistance check

+Check resistance between terminal

V4and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Overrun clutch

solenoid valve

V4Ground 20 - 40W

Operation check

+Check solenoid valve by listening for its operating sound

while applying battery voltage to the terminal

V4and ground.

SAT244J

SAT245J

SAT392JC

SAT567IB

.

.

.

TROUBLE DIAGNOSIS FOR OVERRUN CLUTCH S/V

Overrun Clutch Solenoid Valve (Cont'd)

AT-1075

Page 79 of 1033

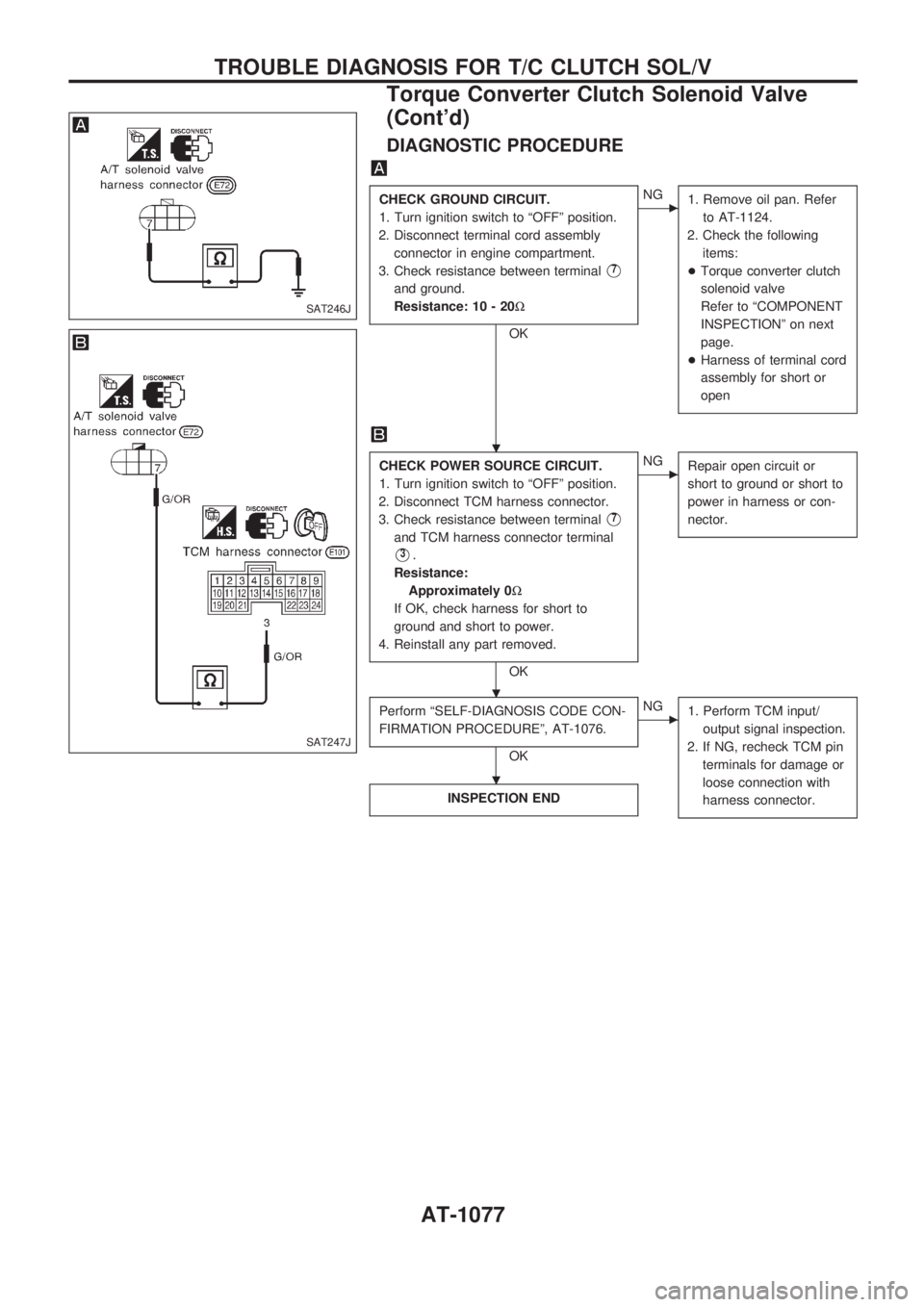

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminal

V7

and ground.

Resistance: 10 - 20W

OK

cNG

1. Remove oil pan. Refer

to AT-1124.

2. Check the following

items:

+Torque converter clutch

solenoid valve

Refer to ªCOMPONENT

INSPECTIONº on next

page.

+Harness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal

V7

and TCM harness connector terminal

V3.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

cNG

Repair open circuit or

short to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1076.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT246J

SAT247J

.

.

.

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V

Torque Converter Clutch Solenoid Valve

(Cont'd)

AT-1077

Page 82 of 1033

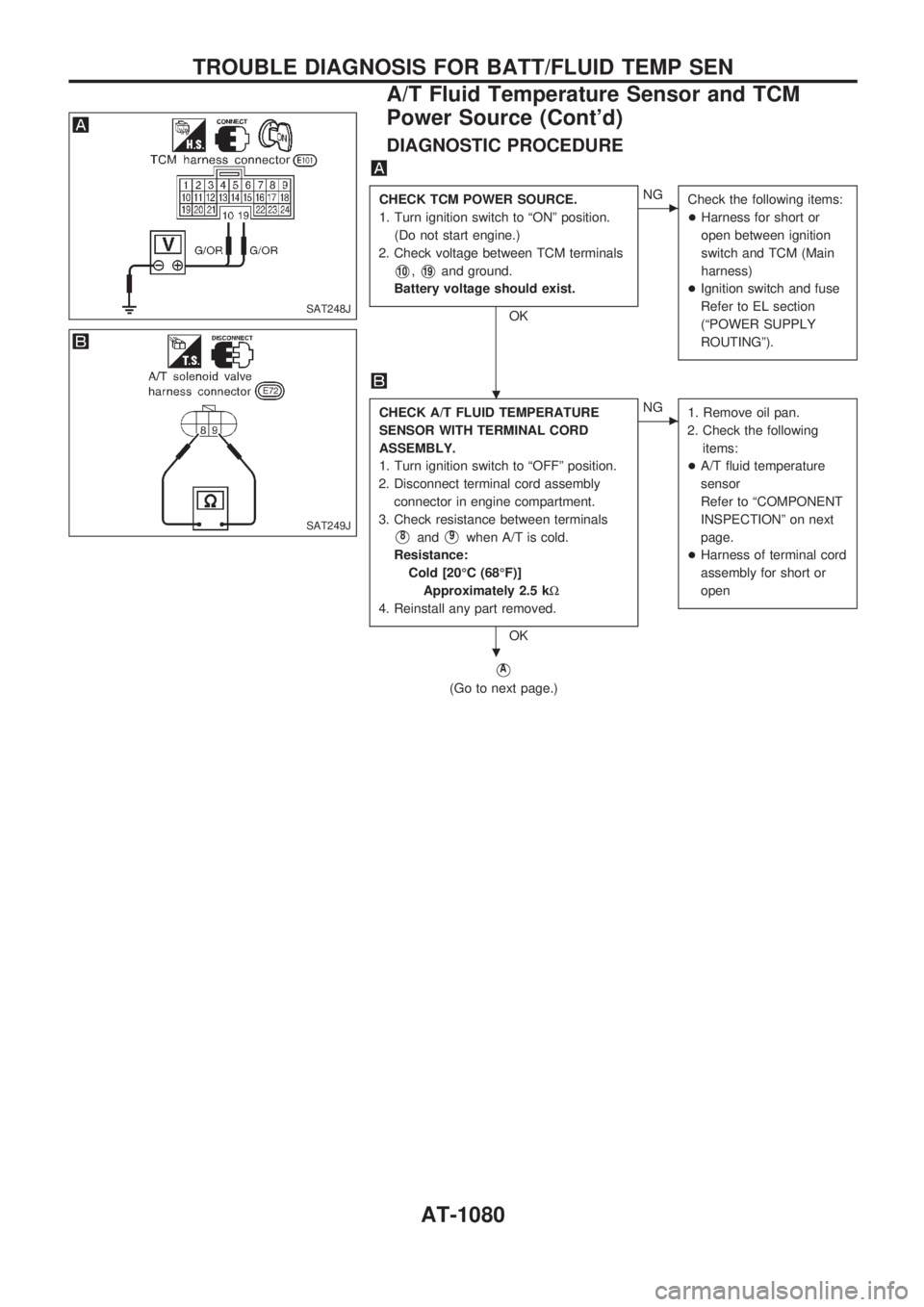

DIAGNOSTIC PROCEDURE

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals

V10,V19and ground.

Battery voltage should exist.

OK

cNG

Check the following items:

+Harness for short or

open between ignition

switch and TCM (Main

harness)

+Ignition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK A/T FLUID TEMPERATURE

SENSOR WITH TERMINAL CORD

ASSEMBLY.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminals

V8andV9when A/T is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

4. Reinstall any part removed.

OK

cNG

1. Remove oil pan.

2. Check the following

items:

+A/T fluid temperature

sensor

Refer to ªCOMPONENT

INSPECTIONº on next

page.

+Harness of terminal cord

assembly for short or

open

VA

(Go to next page.)

SAT248J

SAT249J

.

.

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

A/T Fluid Temperature Sensor and TCM

Power Source (Cont'd)

AT-1080

Page 85 of 1033

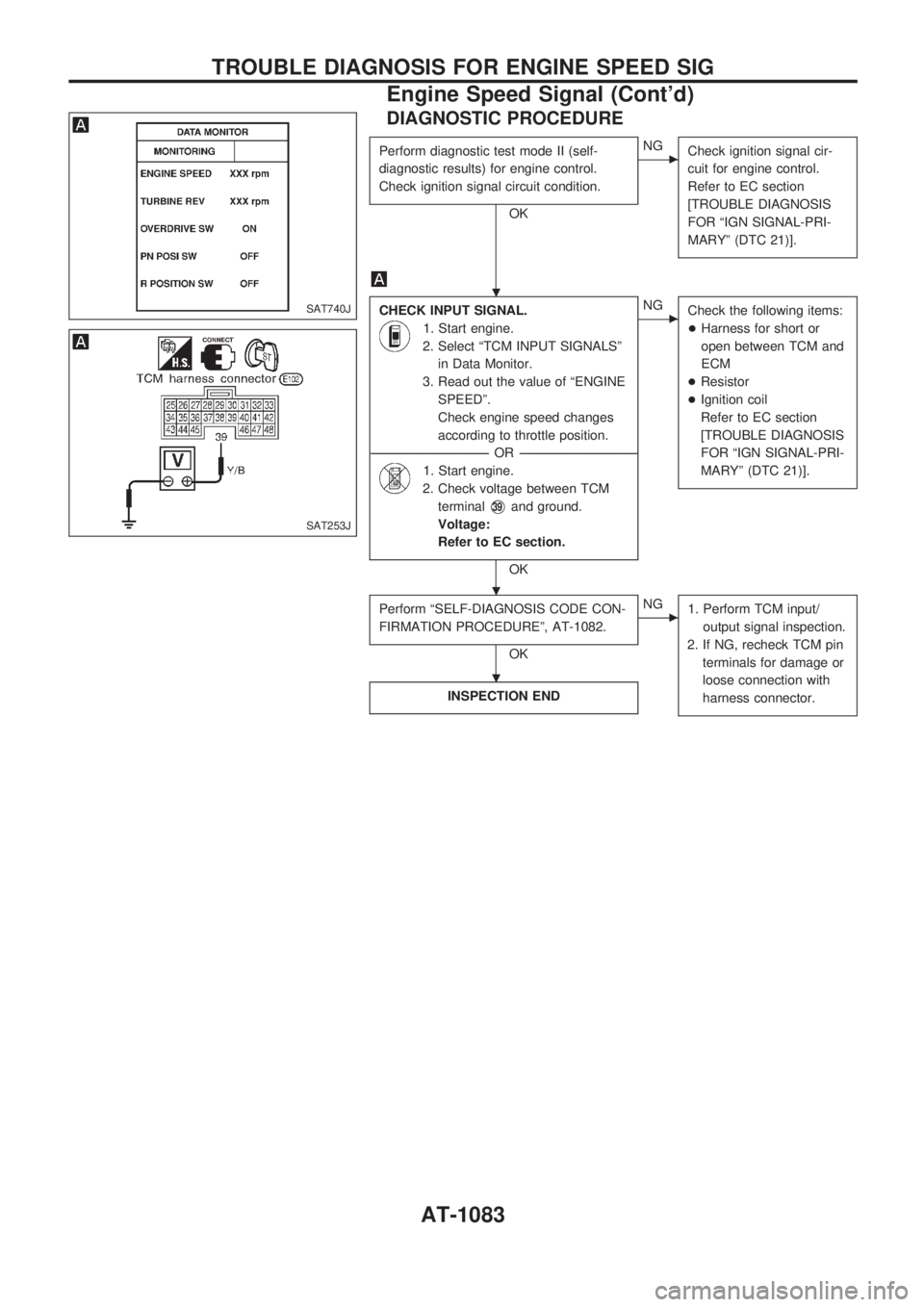

DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Check ignition signal circuit condition.

OK

cNG

Check ignition signal cir-

cuit for engine control.

Refer to EC section

[TROUBLE DIAGNOSIS

FOR ªIGN SIGNAL-PRI-

MARYº (DTC 21)].

CHECK INPUT SIGNAL.

1. Start engine.

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªENGINE

SPEEDº.

Check engine speed changes

according to throttle position.

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM

terminal

V39and ground.

Voltage:

Refer to EC section.

OK

cNG

Check the following items:

+Harness for short or

open between TCM and

ECM

+Resistor

+Ignition coil

Refer to EC section

[TROUBLE DIAGNOSIS

FOR ªIGN SIGNAL-PRI-

MARYº (DTC 21)].

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1082.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT740J

SAT253J

.

.

.

TROUBLE DIAGNOSIS FOR ENGINE SPEED SIG

Engine Speed Signal (Cont'd)

AT-1083

Page 87 of 1033

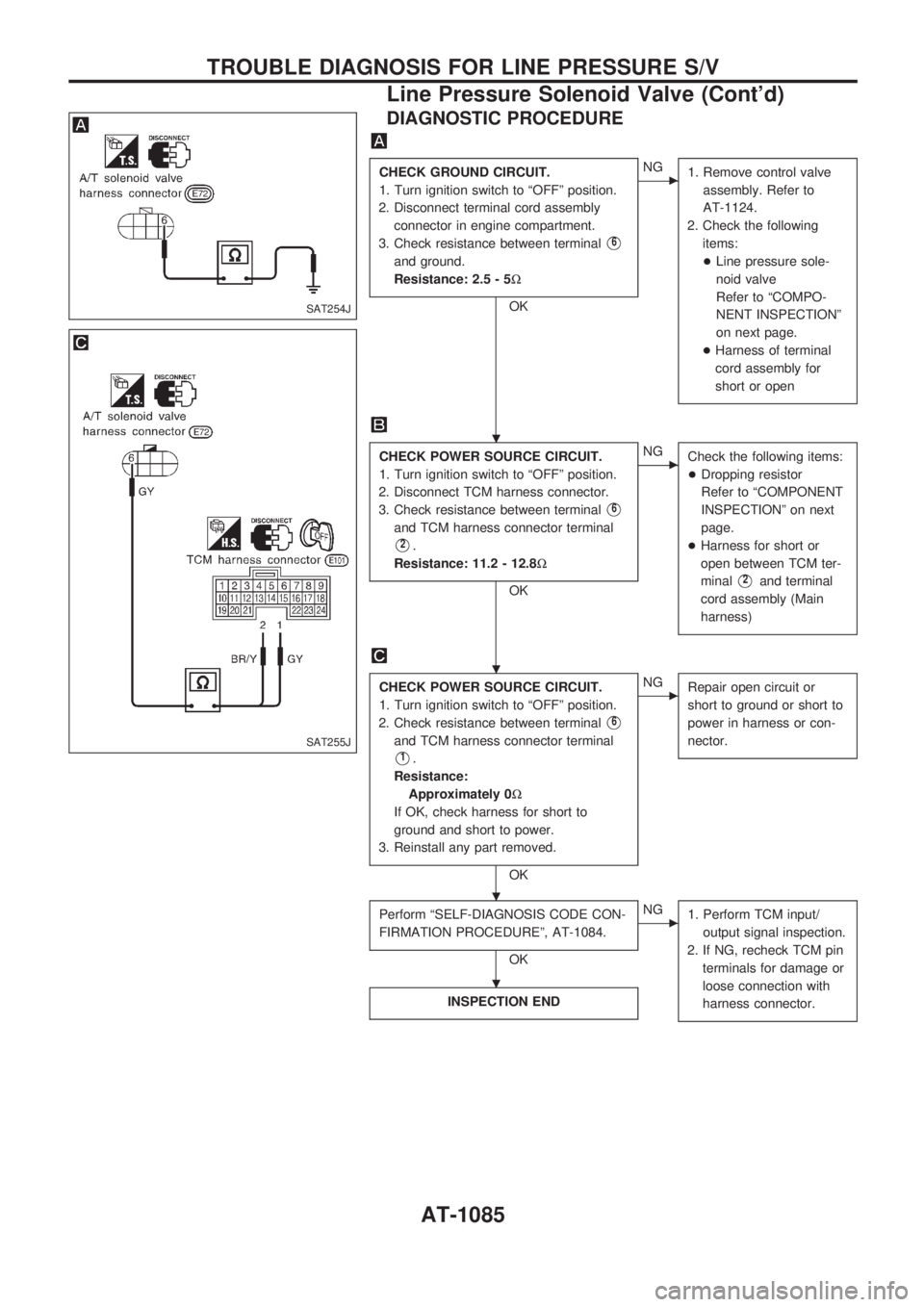

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminal

V6

and ground.

Resistance: 2.5 - 5W

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Line pressure sole-

noid valve

Refer to ªCOMPO-

NENT INSPECTIONº

on next page.

+Harness of terminal

cord assembly for

short or open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal

V6

and TCM harness connector terminal

V2.

Resistance: 11.2 - 12.8W

OK

cNG

Check the following items:

+Dropping resistor

Refer to ªCOMPONENT

INSPECTIONº on next

page.

+Harness for short or

open between TCM ter-

minal

V2and terminal

cord assembly (Main

harness)

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Check resistance between terminal

V6

and TCM harness connector terminal

V1.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

3. Reinstall any part removed.

OK

cNG

Repair open circuit or

short to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1084.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT254J

SAT255J

.

.

.

.

TROUBLE DIAGNOSIS FOR LINE PRESSURE S/V

Line Pressure Solenoid Valve (Cont'd)

AT-1085

Page 89 of 1033

Description

The TCM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the A/T.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check item

(Possible cause)

:

CONTROL UNIT (RAM)

TCM memory (RAM) or (ROM) is mal-

functioning.TCM

:CONTROL UNIT (ROM)

SELF-DIAGNOSIS CODE CONFIRMATION

PROCEDURE

NOTE:

If ªSELF-DIAGNOSIS CODE CONFIRMATION PROCEDUREº

has been previously conducted, always turn ignition switch

ªOFFº and wait at least 5 seconds before conducting the

next test.

WITH CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº

mode for A/T with CONSULT-II.

2) Start engine.

3) Run engine for at least 2 seconds at idle speed.

SAT574J

SAT014K

SAT971J

TROUBLE DIAGNOSIS FOR CONTROL UNIT (RAM), CONTROL UNIT (ROM)

AT-1087