NISSAN PATROL 2000 Electronic Owner's Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 21 of 1033

TAT022M

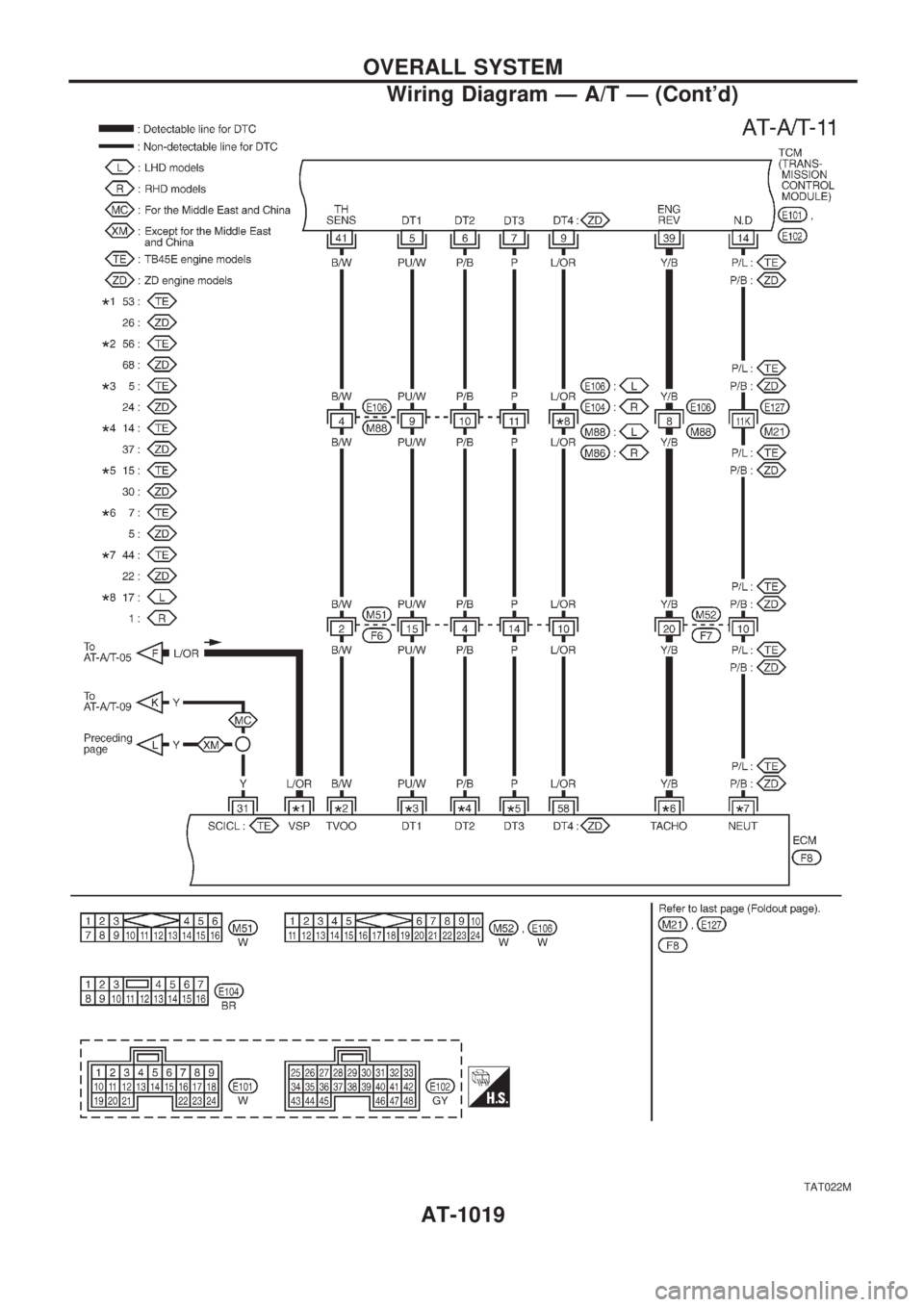

OVERALL SYSTEM

Wiring Diagram Ð A/T Ð (Cont'd)

AT-1019

Page 22 of 1033

TAT023M

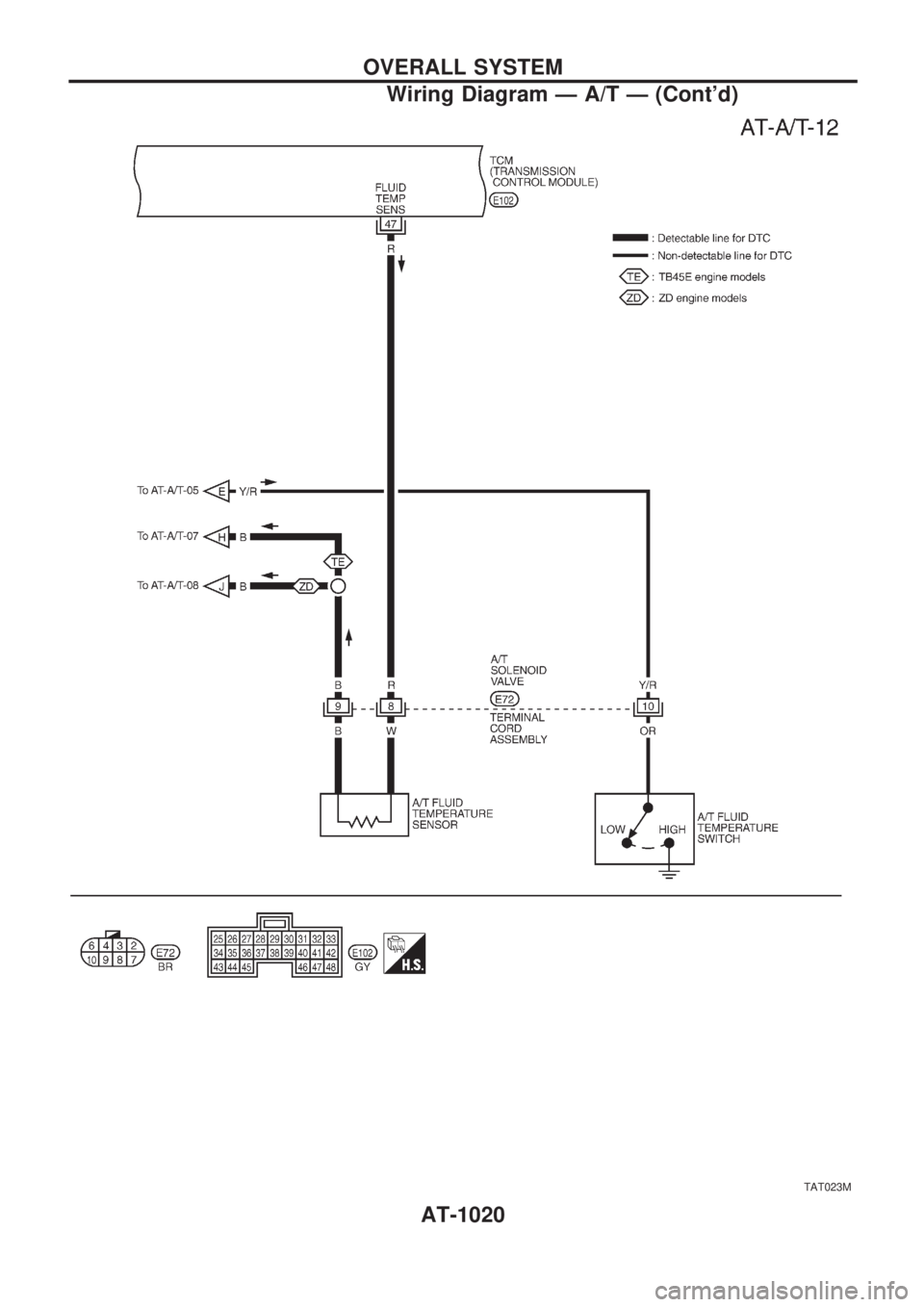

OVERALL SYSTEM

Wiring Diagram Ð A/T Ð (Cont'd)

AT-1020

Page 23 of 1033

TAT024M

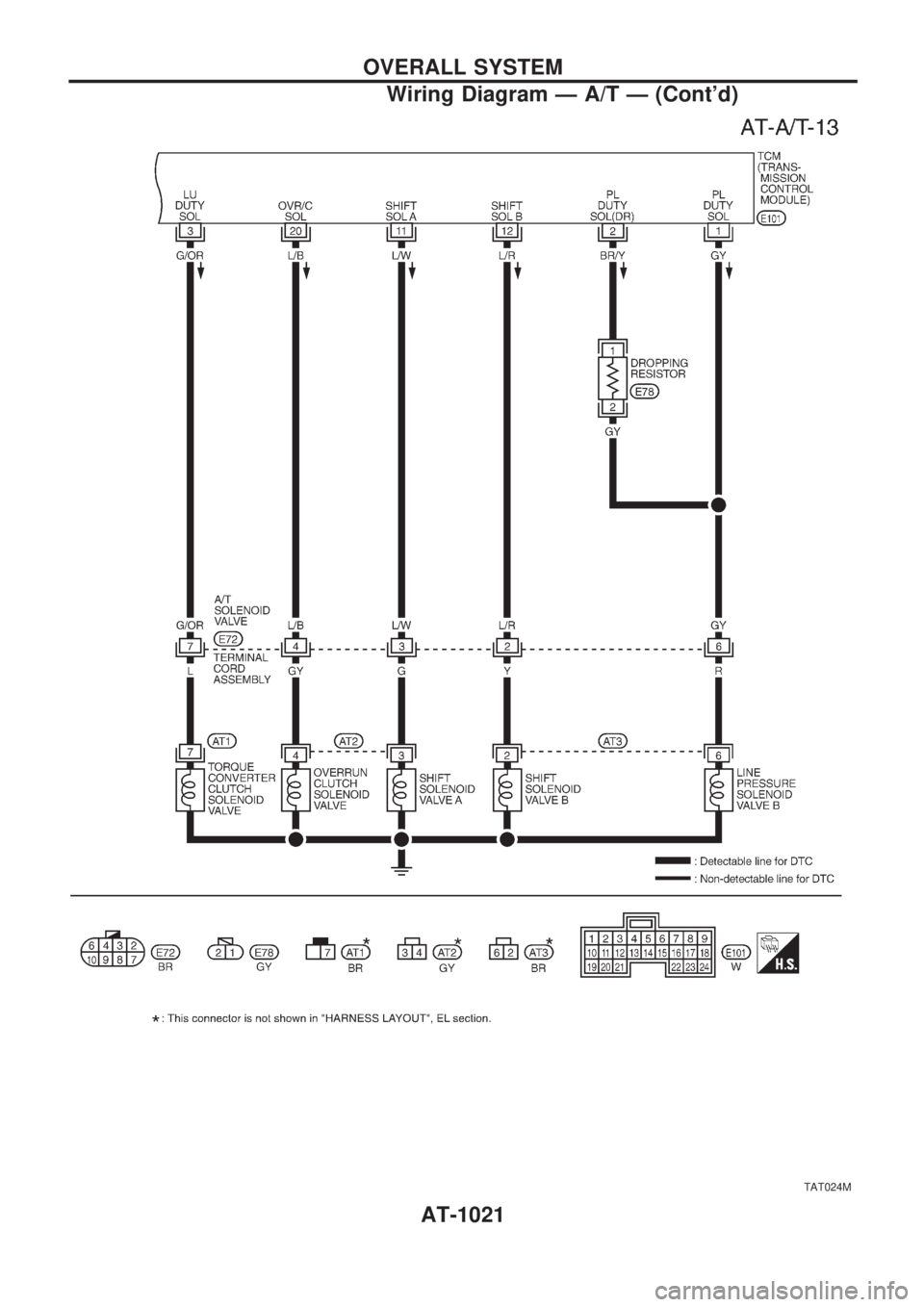

OVERALL SYSTEM

Wiring Diagram Ð A/T Ð (Cont'd)

AT-1021

Page 24 of 1033

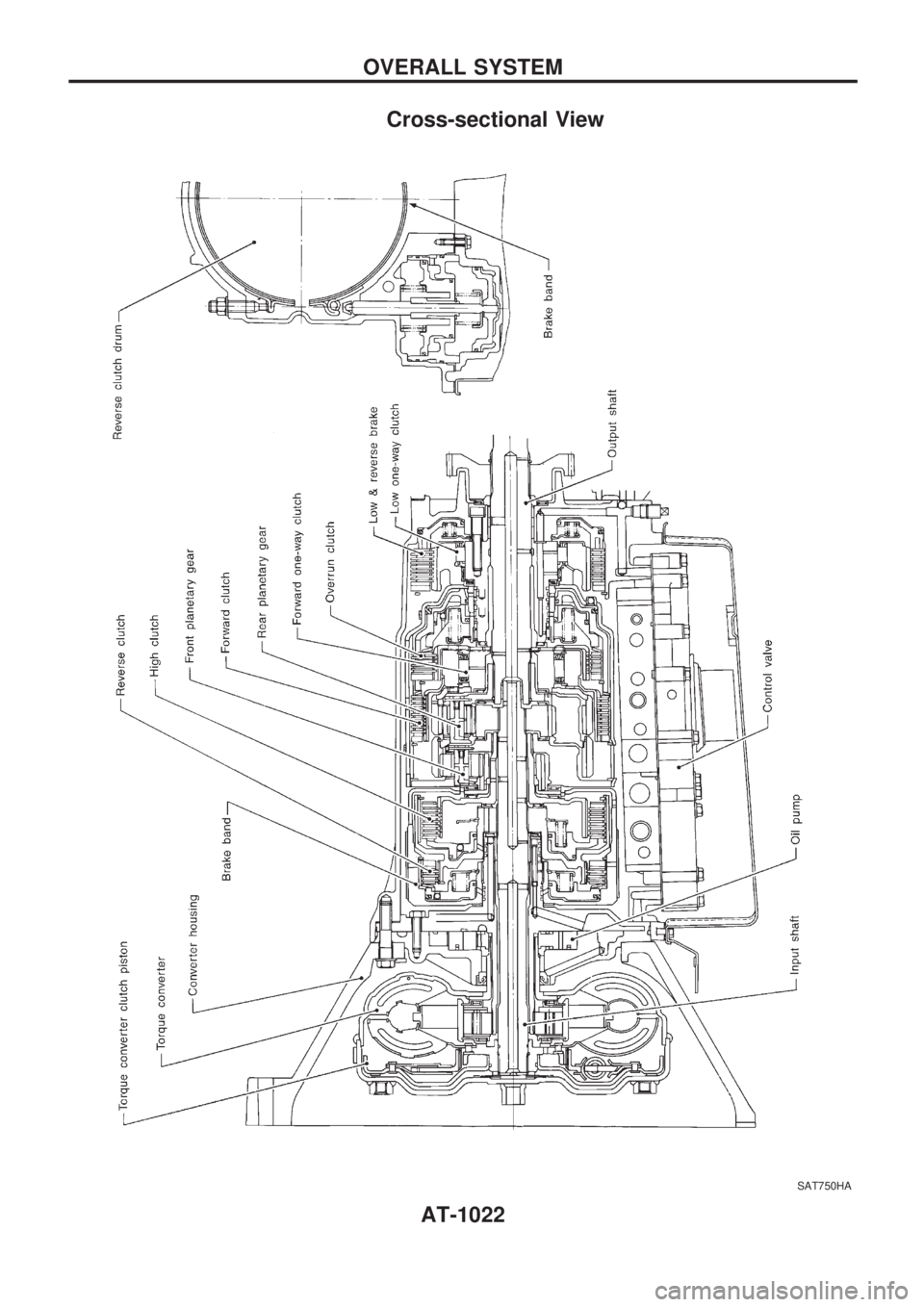

Cross-sectional View

SAT750HA

OVERALL SYSTEM

AT-1022

Page 25 of 1033

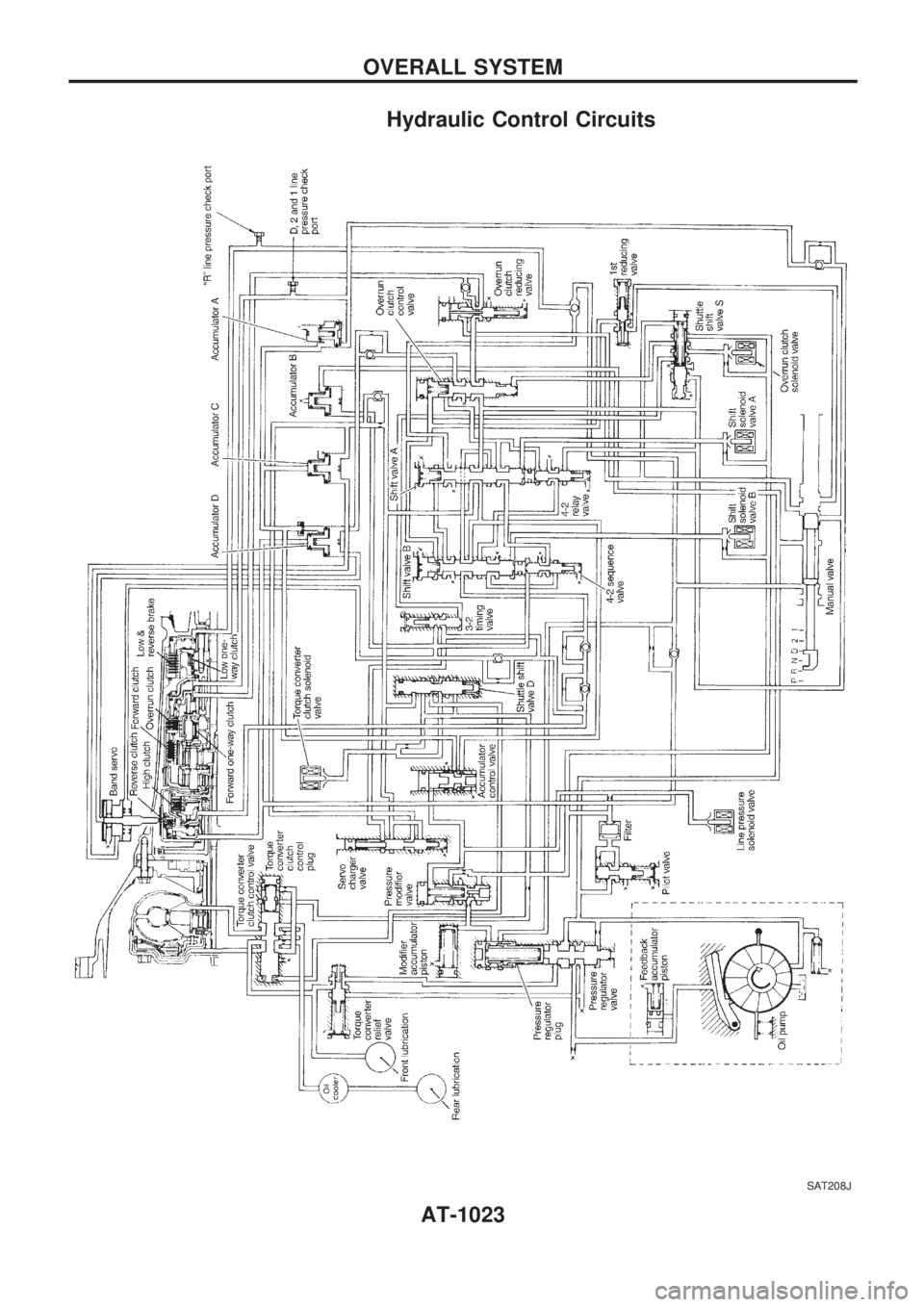

Hydraulic Control Circuits

SAT208J

OVERALL SYSTEM

AT-1023

Page 26 of 1033

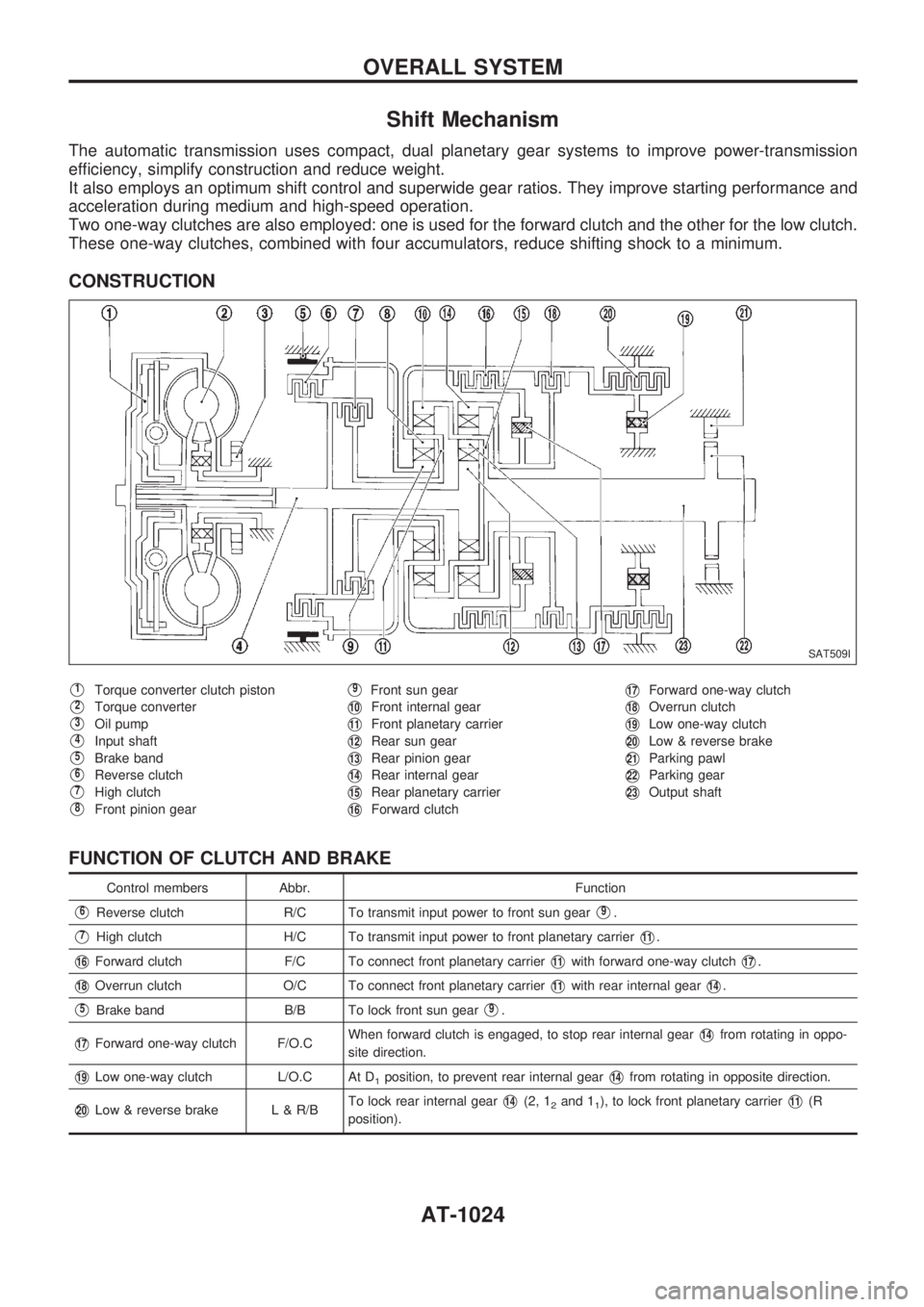

Shift Mechanism

The automatic transmission uses compact, dual planetary gear systems to improve power-transmission

efficiency, simplify construction and reduce weight.

It also employs an optimum shift control and superwide gear ratios. They improve starting performance and

acceleration during medium and high-speed operation.

Two one-way clutches are also employed: one is used for the forward clutch and the other for the low clutch.

These one-way clutches, combined with four accumulators, reduce shifting shock to a minimum.

CONSTRUCTION

V1Torque converter clutch piston

V2Torque converter

V3Oil pump

V4Input shaft

V5Brake band

V6Reverse clutch

V7High clutch

V8Front pinion gear

V9Front sun gear

V10Front internal gear

V11Front planetary carrier

V12Rear sun gear

V13Rear pinion gear

V14Rear internal gear

V15Rear planetary carrier

V16Forward clutch

V17Forward one-way clutch

V18Overrun clutch

V19Low one-way clutch

V20Low & reverse brake

V21Parking pawl

V22Parking gear

V23Output shaft

FUNCTION OF CLUTCH AND BRAKE

Control members Abbr. Function

V6Reverse clutch R/C To transmit input power to front sun gearV9.

V7High clutch H/C To transmit input power to front planetary carrierV11.

V16Forward clutch F/C To connect front planetary carrierV11with forward one-way clutchV17.

V18Overrun clutch O/C To connect front planetary carrierV11with rear internal gearV14.

V5Brake band B/B To lock front sun gearV9.

V17Forward one-way clutch F/O.CWhen forward clutch is engaged, to stop rear internal gearV14from rotating in oppo-

site direction.

V19Low one-way clutch L/O.C At D1position, to prevent rear internal gearV14from rotating in opposite direction.

V20Low & reverse brake L & R/BTo lock rear internal gearV14(2, 12and 11), to lock front planetary carrierV11(R

position).

SAT509I

OVERALL SYSTEM

AT-1024

Page 27 of 1033

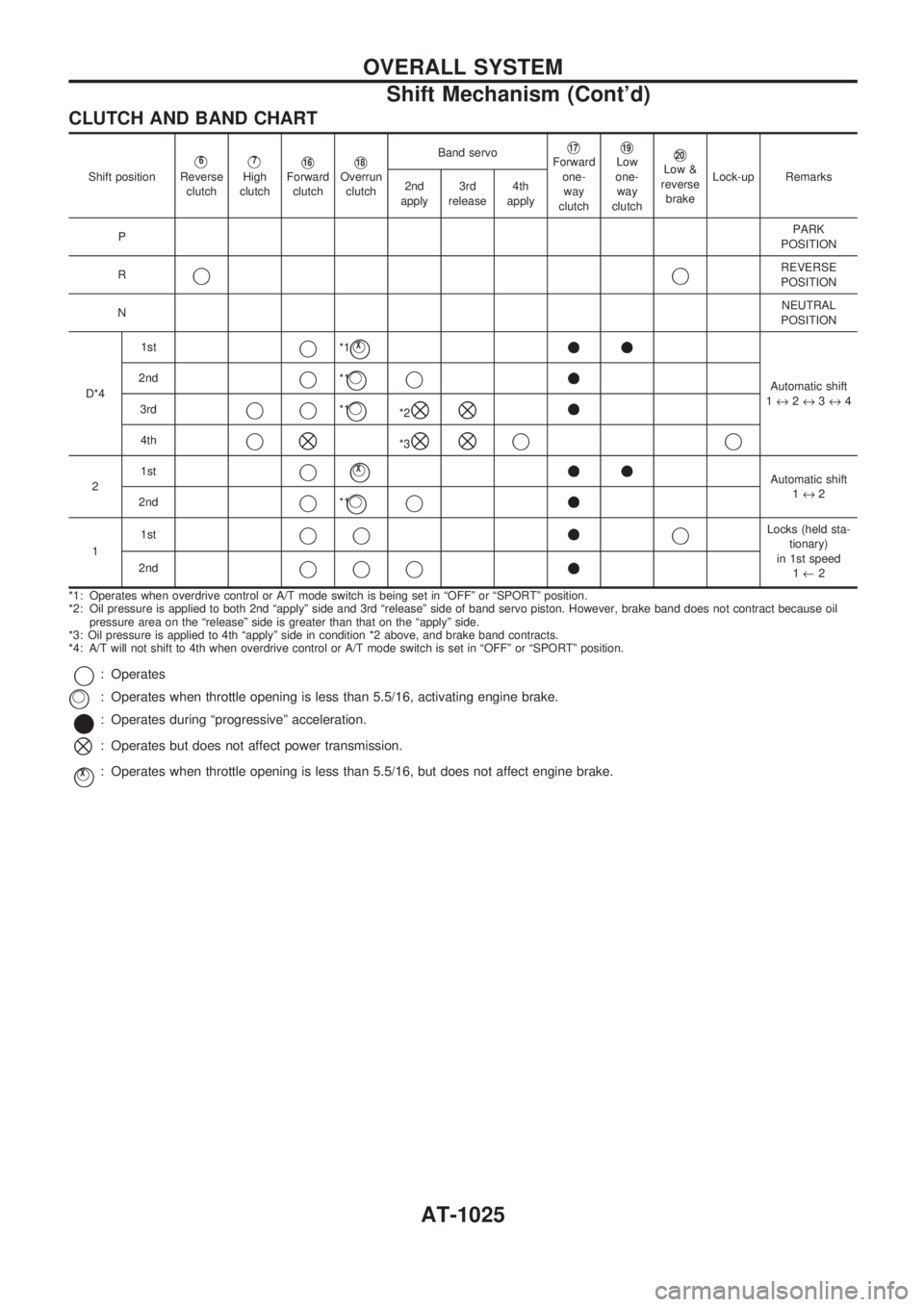

CLUTCH AND BAND CHART

Shift positionV6

Reverse

clutchV7

High

clutchV16Forward

clutchV18Overrun

clutchBand servo

V17Forward

one-

way

clutchV19Low

one-

way

clutchV20Low &

reverse

brakeLock-up Remarks

2nd

apply3rd

release4th

apply

PPARK

POSITION

R

jjREVERSE

POSITION

NNEUTRAL

POSITION

D*41st

j*1jVX++

Automatic shift

1«2«3«4 2ndj*1jVj+

3rdjj*1jV*2^^+

4thj^*3^^jj

21stjjVX++Automatic shift

1«2

2nd

j*1jVj+

11stjj+jLocks (held sta-

tionary)

in 1st speed

1¬2 2nd

jjj+

*1: Operates when overdrive control or A/T mode switch is being set in ªOFFº or ªSPORTº position.

*2: Oil pressure is applied to both 2nd ªapplyº side and 3rd ªreleaseº side of band servo piston. However, brake band does not contract because oil

pressure area on the ªreleaseº side is greater than that on the ªapplyº side.

*3: Oil pressure is applied to 4th ªapplyº side in condition *2 above, and brake band contracts.

*4: A/T will not shift to 4th when overdrive control or A/T mode switch is set in ªOFFº or ªSPORTº position.

j: Operates

: Operates when throttle opening is less than 5.5/16, activating engine brake.

*: Operates during ªprogressiveº acceleration.

^: Operates but does not affect power transmission.

jVX: Operates when throttle opening is less than 5.5/16, but does not affect engine brake.

jV

OVERALL SYSTEM

Shift Mechanism (Cont'd)

AT-1025

Page 28 of 1033

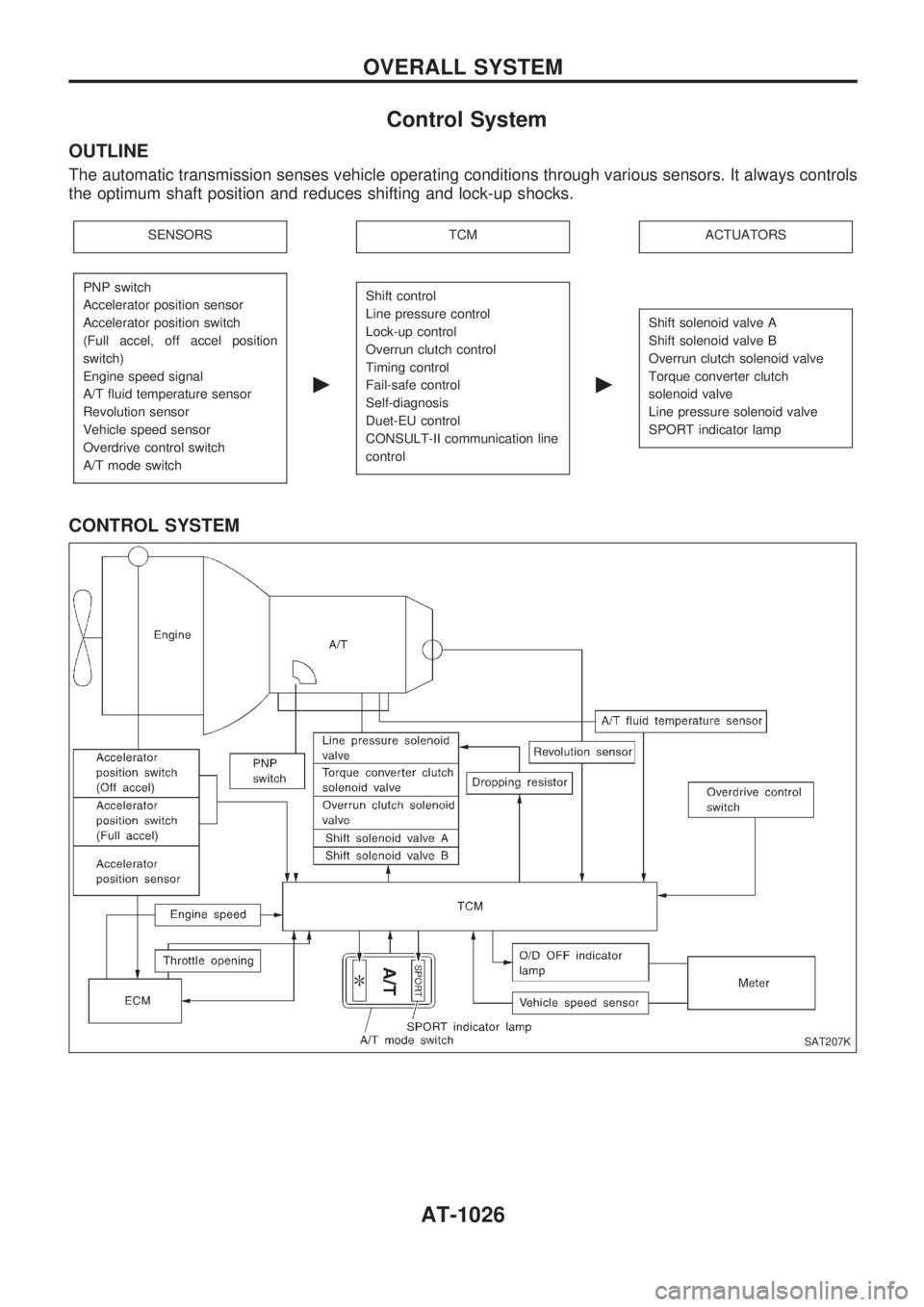

Control System

OUTLINE

The automatic transmission senses vehicle operating conditions through various sensors. It always controls

the optimum shaft position and reduces shifting and lock-up shocks.

SENSORSTCMACTUATORS

PNP switch

Accelerator position sensor

Accelerator position switch

(Full accel, off accel position

switch)

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed sensor

Overdrive control switch

A/T mode switch

c

Shift control

Line pressure control

Lock-up control

Overrun clutch control

Timing control

Fail-safe control

Self-diagnosis

Duet-EU control

CONSULT-II communication line

control

c

Shift solenoid valve A

Shift solenoid valve B

Overrun clutch solenoid valve

Torque converter clutch

solenoid valve

Line pressure solenoid valve

SPORT indicator lamp

CONTROL SYSTEM

SAT207K

OVERALL SYSTEM

AT-1026

Page 29 of 1033

TCM FUNCTION

The function of the TCM is to:

+Receive input signals sent from various switches and sensors.

+Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

+Send required output signals to the respective solenoids.

INPUT/OUTPUT SIGNAL OF TCM

Sensors and solenoid valves Function

InputPNP switch Detects select lever position and sends a signal to TCM.

Accelerator position sensor Detects throttle valve position and sends a signal to TCM.

Accelerator position switch

(Off accel)Detects throttle valve's fully-closed position and sends a signal to TCM.

Accelerator position switch

(Full accel)Detects a throttle valve position of greater than 1/2 of full throttle and sends a

signal to TCM.

Engine speed signal From ECM.

A/T fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

Revolution sensor Detects output shaft rpm and sends a signal to TCM.

Vehicle speed sensorUsed as an auxiliary vehicle speed sensor. Sends a signal when revolution sen-

sor (installed on transmission) malfunctions.

Overdrive control switch

A/T mode switchSends a signal, which prohibits a shift to ªD

4º (overdrive) position, to the TCM.

OutputShift solenoid valve A/BSelects shifting point suited to driving conditions in relation to a signal sent from

TCM.

Line pressure solenoid valveRegulates (or decreases) line pressure suited to driving conditions in relation to

a signal sent from TCM.

Torque converter clutch solenoid valveRegulates (or decreases) lock-up pressure suited to driving conditions in relation

to a signal sent from TCM.

Overrun clutch solenoid valveControls an ªengine brakeº effect suited to driving conditions in relation to a sig-

nal sent from TCM.

O/D OFF indicator lamp

SPORT indicator lampShows TCM faults, when A/T control components malfunction.

OVERALL SYSTEM

Control System (Cont'd)

AT-1027

Page 30 of 1033

Self-diagnosis

After performing this procedure, place check marks for results on

the ªDIAGNOSTIC WORKSHEETº, AT-1038. Reference pages

are provided following the items.

SELF-DIAGNOSTIC PROCEDURE (With

CONSULT-II)

1. Turn on CONSULT-II and touch ªA/Tº.

If A/T is not displayed, check TCM power supply and ground

circuit. Refer to AT-1060. If result is NG, refer to EL section

(ªPOWER SUPPLY ROUTINGº).

2. Touch ªSELF-DIAG RESULTSº.

Display shows malfunction experienced since the last eras-

ing operation.

CONSULT-II performs REAL-TIME SELF-DIAGNOSIS.

Also, any malfunction detected while in this mode will be

displayed at real time.

Item Display Description Remarks

No failure

****NO FAILURE

****+No failure has been detected.

Initial start

*INITIAL START

*+This is NOT a malfunction message.

Whenever shutting off a power supply to the

TCM, this message appears on the screen.

[]

Vehicle speed sensorzA/T

(Revolution sensor)VHCL SPEED SENzA/T+No signal input from vehicle speed sensorzA/T

(revolution sensor) during traveling due to

disconnection, or input of abnormal signal.

Vehicle speed sensorzMTR

(Meter)VHCL SPEED SENzMTR+No signal input from vehicle speed sensorzMTR

during traveling due to disconnection, or input of

abnormal signal.

Accelerator position sensor THROTTLE POSI SEN+Accelerator position sensor signal voltage is abnor-

mally high.

+Throttle (accelerator) position sensor signal voltage

is abnormally low with closed throttle position

switch ªOFFº or wide open throttle position switch

ªONº.

Shift solenoid valve A SHIFT SOLENOID/V A+Specified voltage is not applied to solenoid valve

due to disconnection or shortcircuit.

Shift solenoid valve B SHIFT SOLENOID/V B+Specified voltage is not applied to solenoid valve

due to disconnection or shortcircuit.

Overrun clutch solenoid

valveOVERRUN CLUTCH S/V+Specified voltage is not applied to solenoid valve

due to disconnection or shortcircuit.

T/C clutch solenoid valve T/C CLUTCH SOL/V+Specified voltage is not applied to solenoid valve

due to disconnection or shortcircuit.

A/T fluid temperature

sensor/TCM power sourceBATT/FLUID TEMP SEN+Supply voltage to TCM is abnormally low during

traveling.

+Fluid temperature signal voltage is abnormally high

(fluid temperature is low) during traveling.To be dis-

played in case

of abnormality

and no record-

ing is made

Engine speed signal ENGINE SPEED SIG+Engine RPM is abnormally low during traveling.

Line pressure solenoid

valveLINE PRESSURE S/V+Specified voltage is not applied to solenoid valve

due to disconnection or shortcircuit.

TCM (ROM) CONTROL UNIT (ROM)+TCM memory (ROM) is malfunctioning.

TCM (RAM) CONTROL UNIT (RAM)+TCM memory (RAM) is malfunctioning.

TCM (EEP ROM) CONTROL UNIT (EEP ROM)+TCM memory (EEP ROM) is malfunctioning.

SAT014K

SAT987J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-1028