NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 481 of 1033

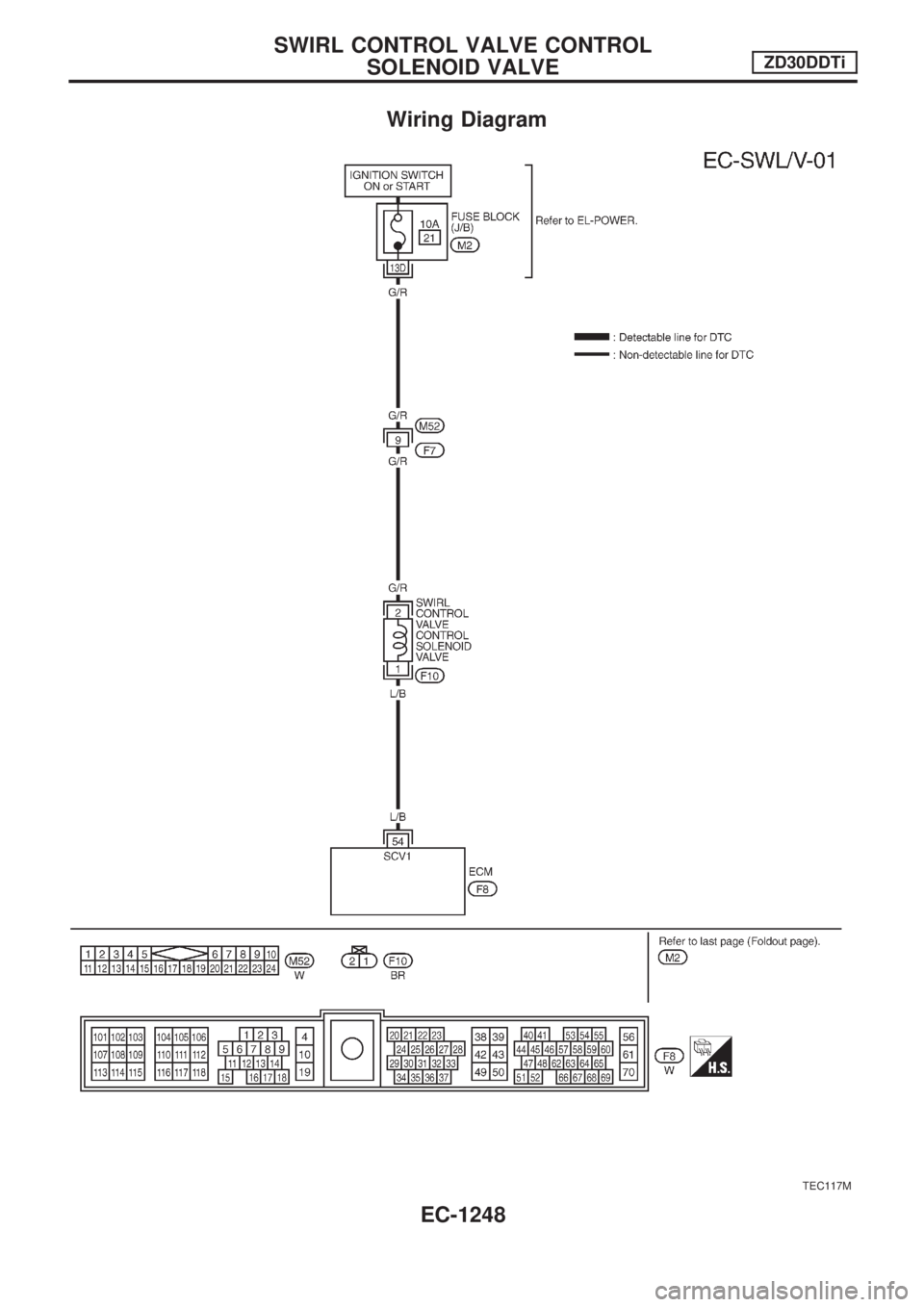

Wiring Diagram

TEC117M

SWIRL CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

EC-1248

Page 482 of 1033

Diagnostic Procedure

1 INSPECTION START

Do you have CONSULT-II?

Yes or No

YescGO TO 2.

NocGO TO 3.

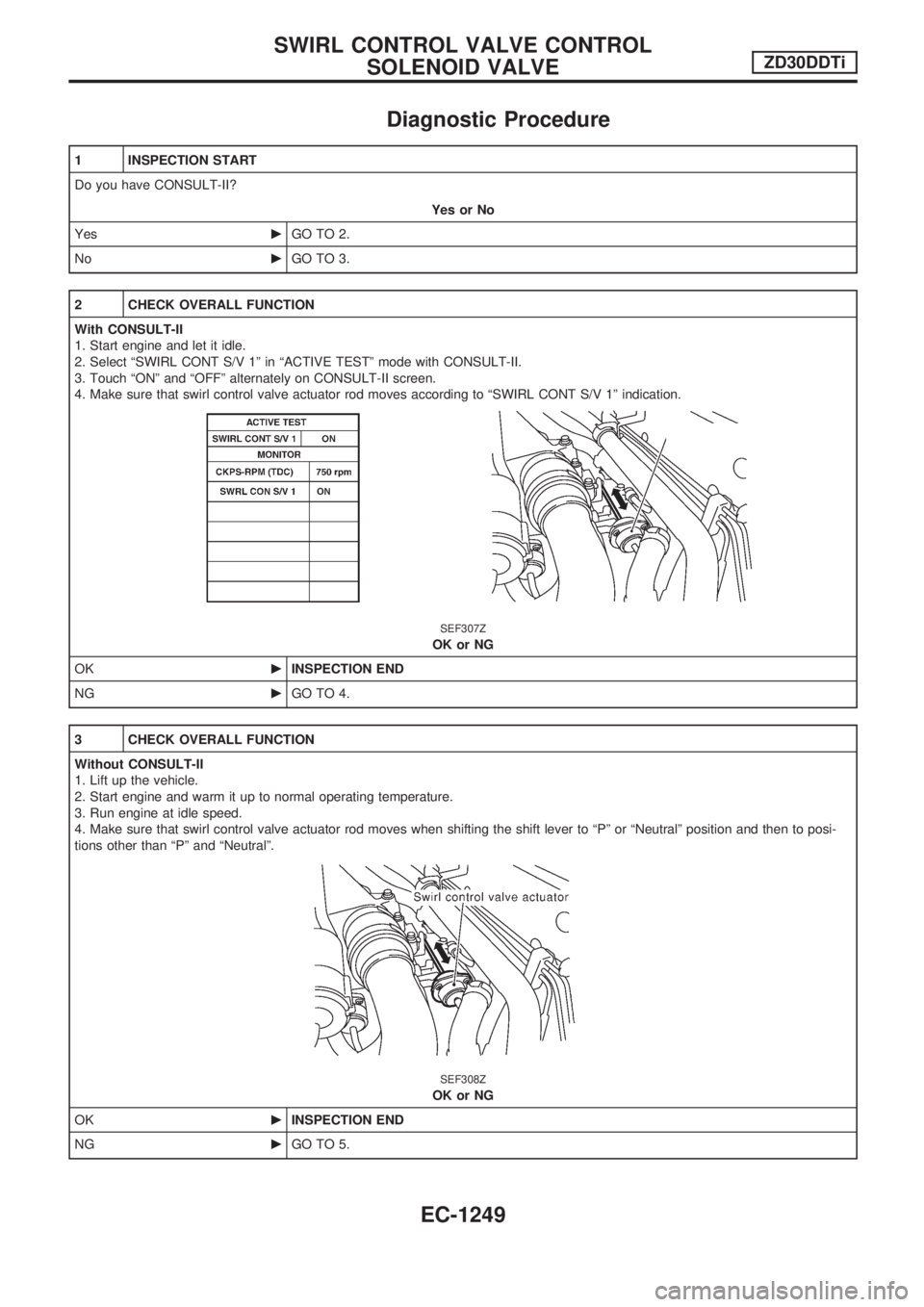

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine and let it idle.

2. Select ªSWIRL CONT S/V 1º in ªACTIVE TESTº mode with CONSULT-II.

3. Touch ªONº and ªOFFº alternately on CONSULT-II screen.

4. Make sure that swirl control valve actuator rod moves according to ªSWIRL CONT S/V 1º indication.

SEF307Z

OK or NG

OKcINSPECTION END

NGcGO TO 4.

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Lift up the vehicle.

2. Start engine and warm it up to normal operating temperature.

3. Run engine at idle speed.

4. Make sure that swirl control valve actuator rod moves when shifting the shift lever to ªPº or ªNeutralº position and then to posi-

tions other than ªPº and ªNeutralº.

SEF308Z

OK or NG

OKcINSPECTION END

NGcGO TO 5.

SWIRL CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

EC-1249

Page 483 of 1033

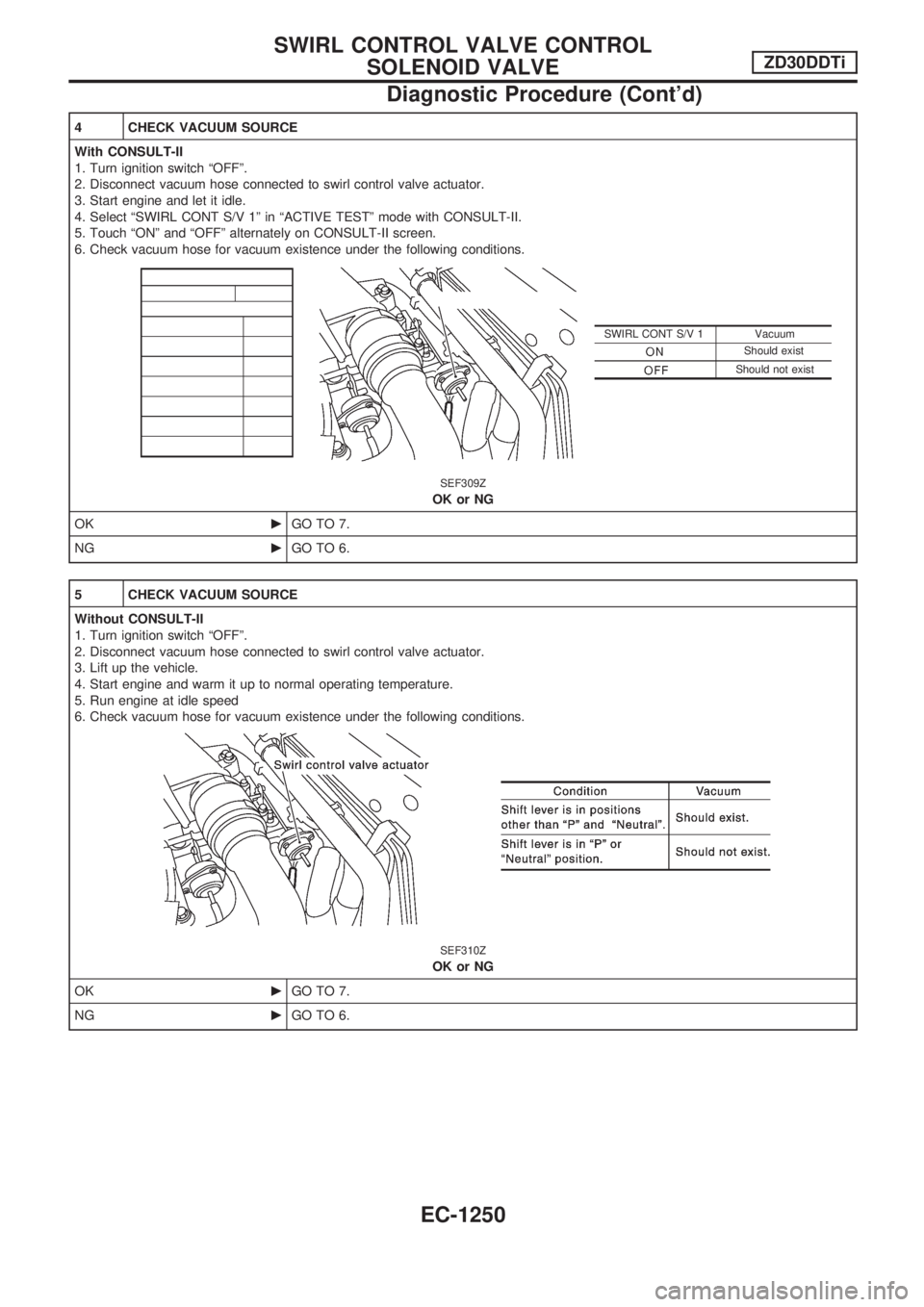

4 CHECK VACUUM SOURCE

With CONSULT-II

1. Turn ignition switch ªOFFº.

2. Disconnect vacuum hose connected to swirl control valve actuator.

3. Start engine and let it idle.

4. Select ªSWIRL CONT S/V 1º in ªACTIVE TESTº mode with CONSULT-II.

5. Touch ªONº and ªOFFº alternately on CONSULT-II screen.

6. Check vacuum hose for vacuum existence under the following conditions.

SEF309Z

OK or NG

OKcGO TO 7.

NGcGO TO 6.

5 CHECK VACUUM SOURCE

Without CONSULT-II

1. Turn ignition switch ªOFFº.

2. Disconnect vacuum hose connected to swirl control valve actuator.

3. Lift up the vehicle.

4. Start engine and warm it up to normal operating temperature.

5. Run engine at idle speed

6. Check vacuum hose for vacuum existence under the following conditions.

SEF310Z

OK or NG

OKcGO TO 7.

NGcGO TO 6.

SWIRL CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1250

SWIRL CONT S/V 1 Vacuum

Should exist

Should not exist

Page 484 of 1033

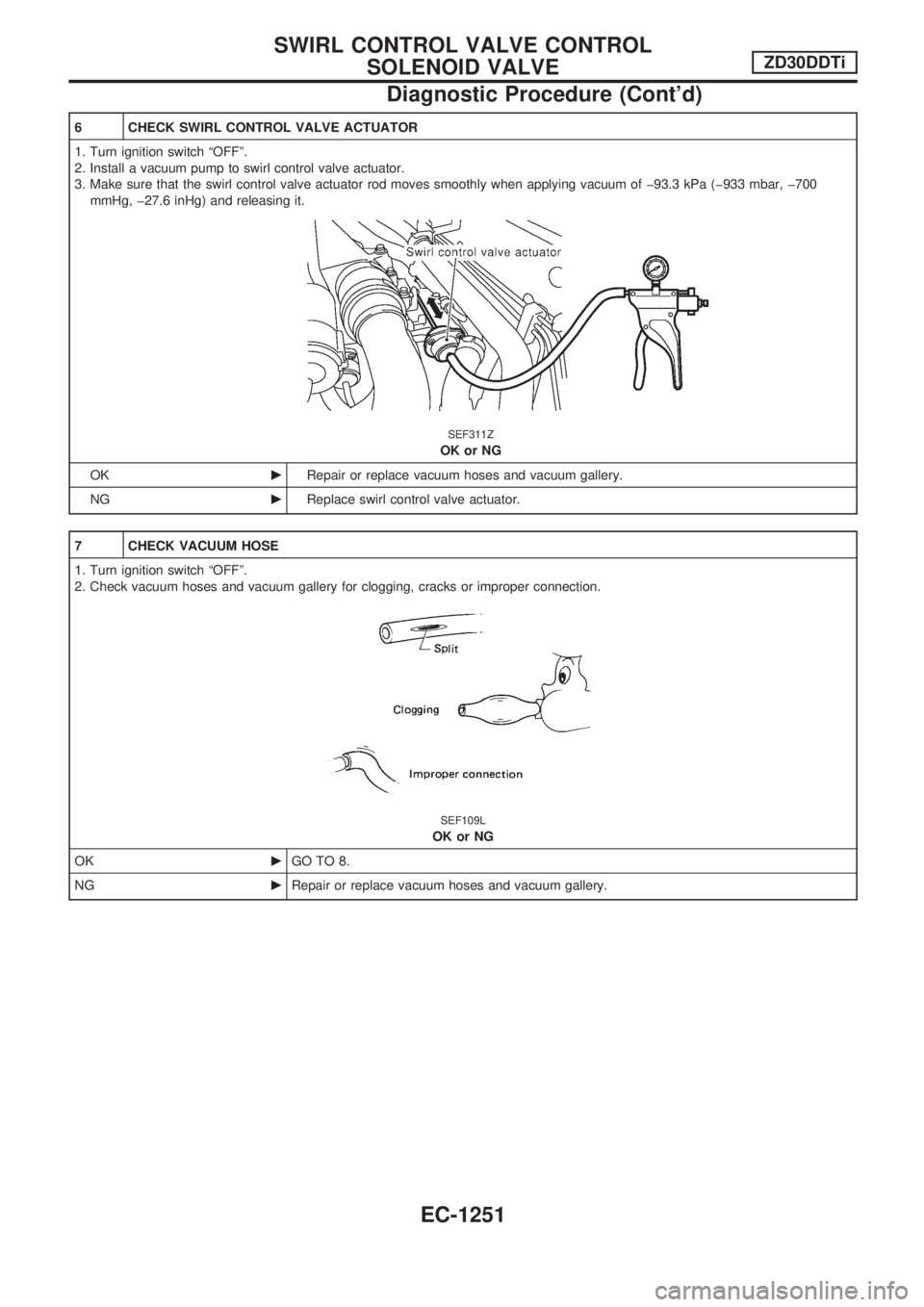

6 CHECK SWIRL CONTROL VALVE ACTUATOR

1. Turn ignition switch ªOFFº.

2. Install a vacuum pump to swirl control valve actuator.

3. Make sure that the swirl control valve actuator rod moves smoothly when applying vacuum of þ93.3 kPa (þ933 mbar, þ700

mmHg, þ27.6 inHg) and releasing it.

SEF311Z

OK or NG

OKcRepair or replace vacuum hoses and vacuum gallery.

NGcReplace swirl control valve actuator.

7 CHECK VACUUM HOSE

1. Turn ignition switch ªOFFº.

2. Check vacuum hoses and vacuum gallery for clogging, cracks or improper connection.

SEF109L

OK or NG

OKcGO TO 8.

NGcRepair or replace vacuum hoses and vacuum gallery.

SWIRL CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1251

Page 485 of 1033

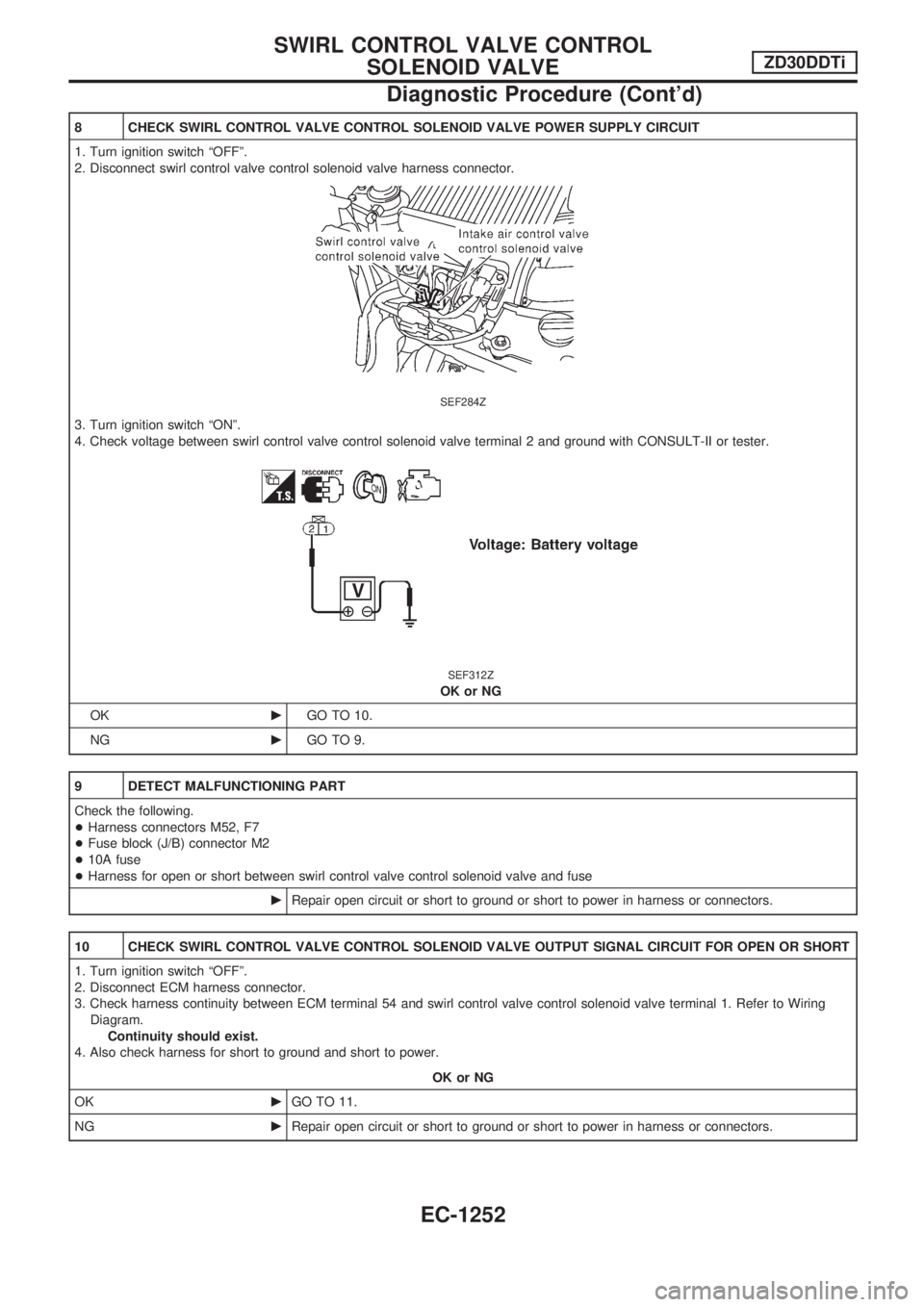

8 CHECK SWIRL CONTROL VALVE CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect swirl control valve control solenoid valve harness connector.

SEF284Z

3. Turn ignition switch ªONº.

4. Check voltage between swirl control valve control solenoid valve terminal 2 and ground with CONSULT-II or tester.

SEF312Z

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M52, F7

+Fuse block (J/B) connector M2

+10A fuse

+Harness for open or short between swirl control valve control solenoid valve and fuse

cRepair open circuit or short to ground or short to power in harness or connectors.

10 CHECK SWIRL CONTROL VALVE CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN OR SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 54 and swirl control valve control solenoid valve terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 11.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

SWIRL CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1252

Page 486 of 1033

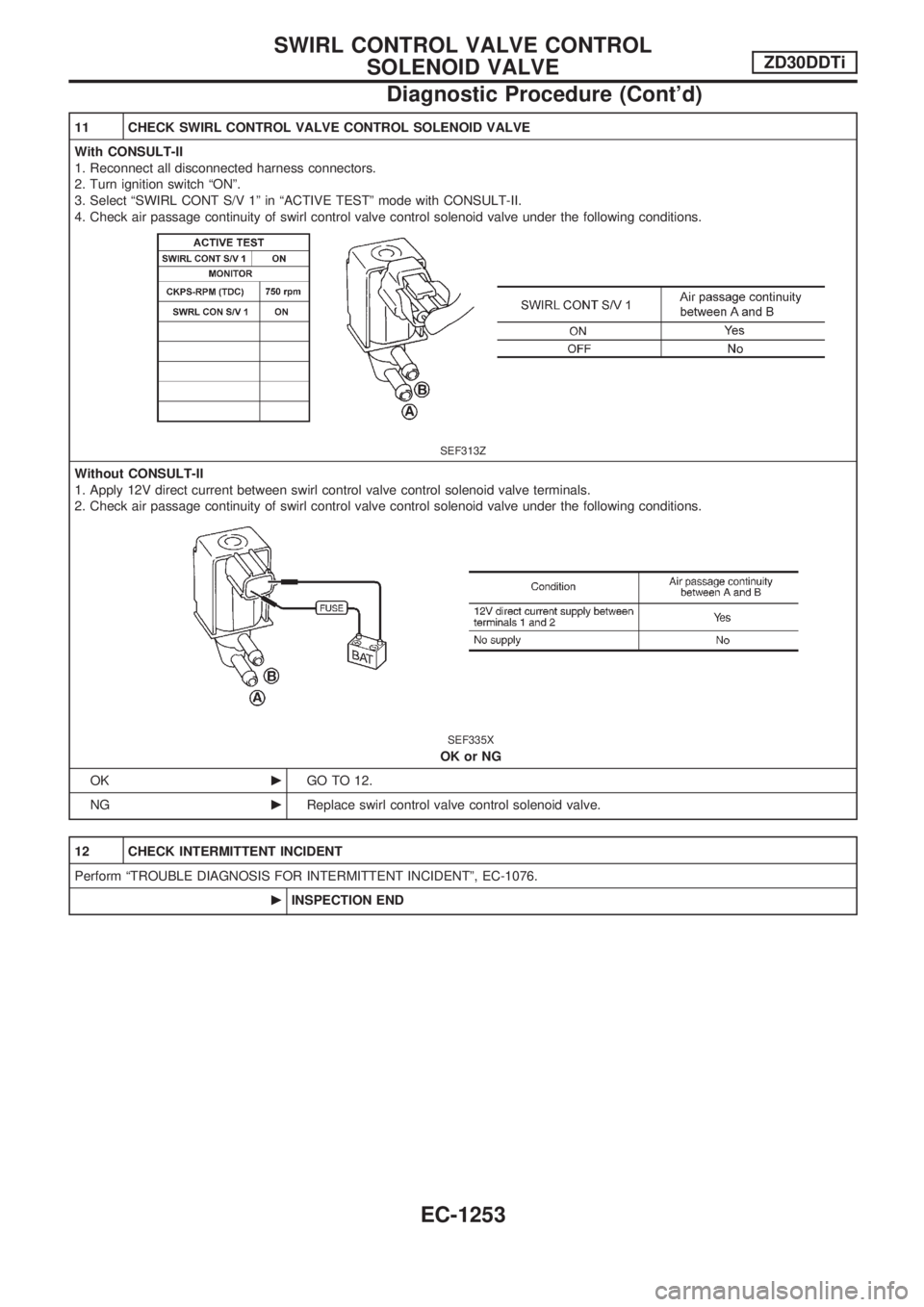

11 CHECK SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

With CONSULT-II

1. Reconnect all disconnected harness connectors.

2. Turn ignition switch ªONº.

3. Select ªSWIRL CONT S/V 1º in ªACTIVE TESTº mode with CONSULT-II.

4. Check air passage continuity of swirl control valve control solenoid valve under the following conditions.

SEF313Z

Without CONSULT-II

1. Apply 12V direct current between swirl control valve control solenoid valve terminals.

2. Check air passage continuity of swirl control valve control solenoid valve under the following conditions.

SEF335X

OK or NG

OKcGO TO 12.

NGcReplace swirl control valve control solenoid valve.

12 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

SWIRL CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1253

Page 487 of 1033

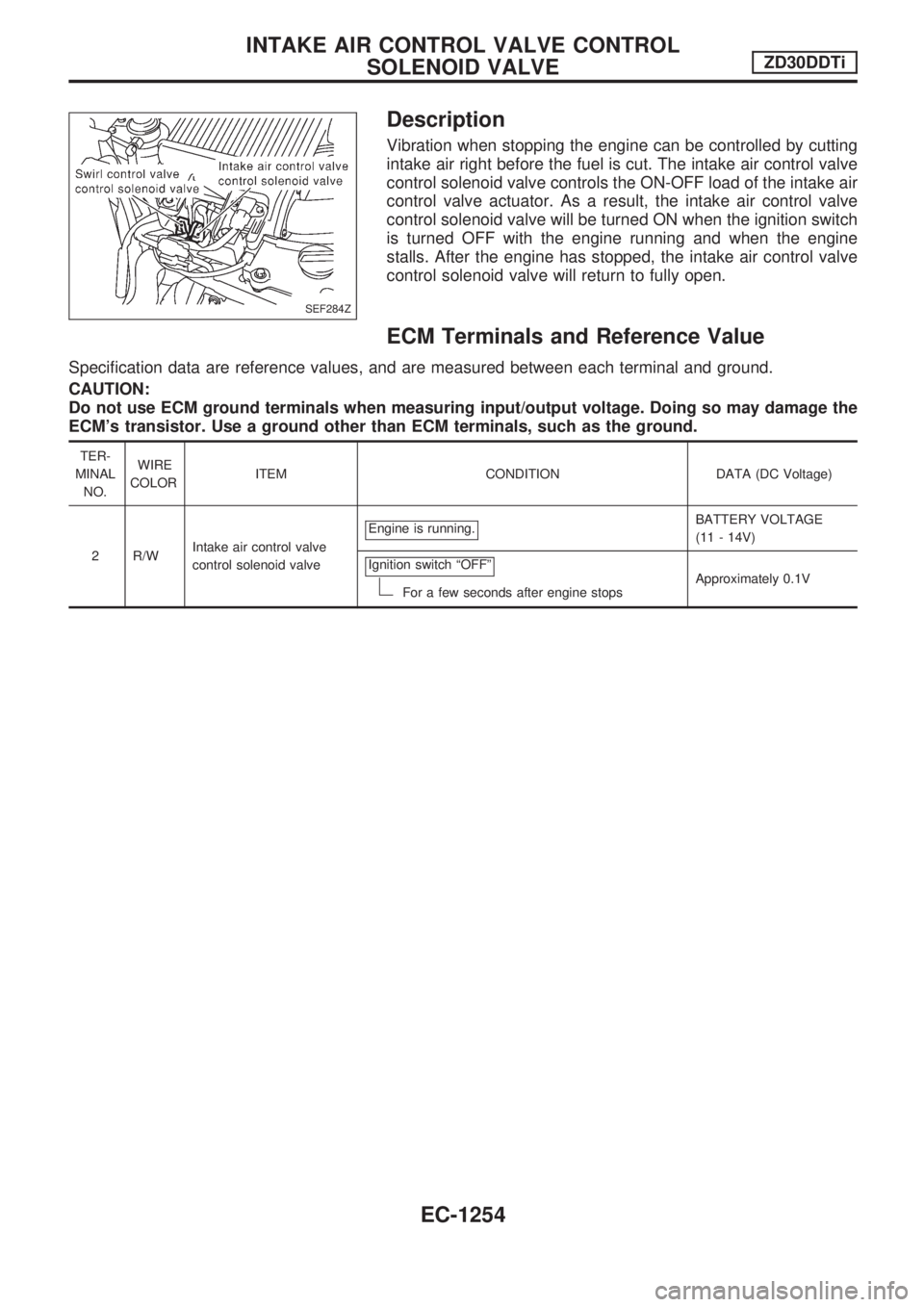

Description

Vibration when stopping the engine can be controlled by cutting

intake air right before the fuel is cut. The intake air control valve

control solenoid valve controls the ON-OFF load of the intake air

control valve actuator. As a result, the intake air control valve

control solenoid valve will be turned ON when the ignition switch

is turned OFF with the engine running and when the engine

stalls. After the engine has stopped, the intake air control valve

control solenoid valve will return to fully open.

ECM Terminals and Reference Value

Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

2 R/WIntake air control valve

control solenoid valveEngine is running.

BATTERY VOLTAGE

(11 - 14V)

Ignition switch ªOFFº

For a few seconds after engine stopsApproximately 0.1V

SEF284Z

INTAKE AIR CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

EC-1254

Page 488 of 1033

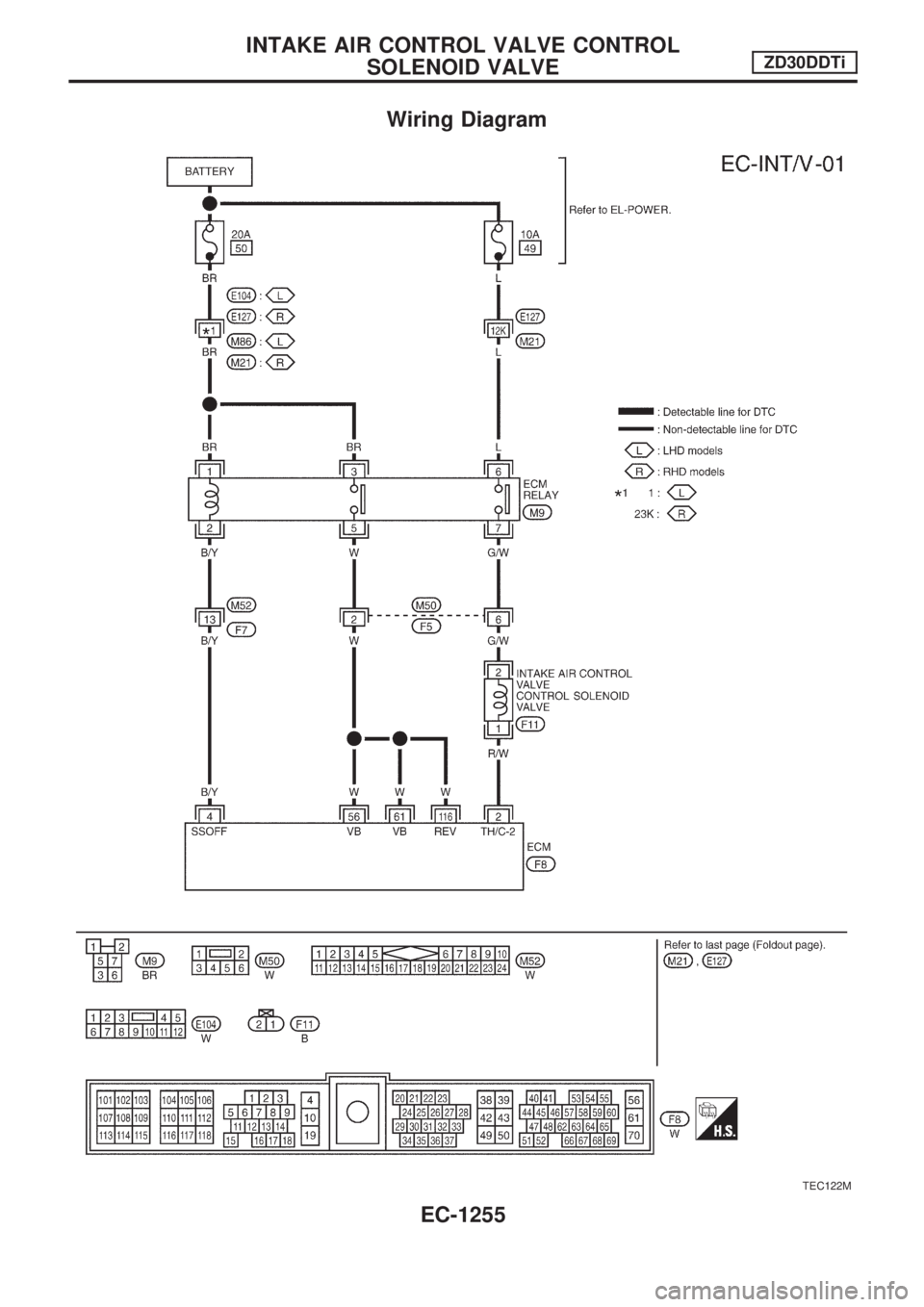

Wiring Diagram

TEC122M

INTAKE AIR CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

EC-1255

Page 489 of 1033

Diagnostic Procedure

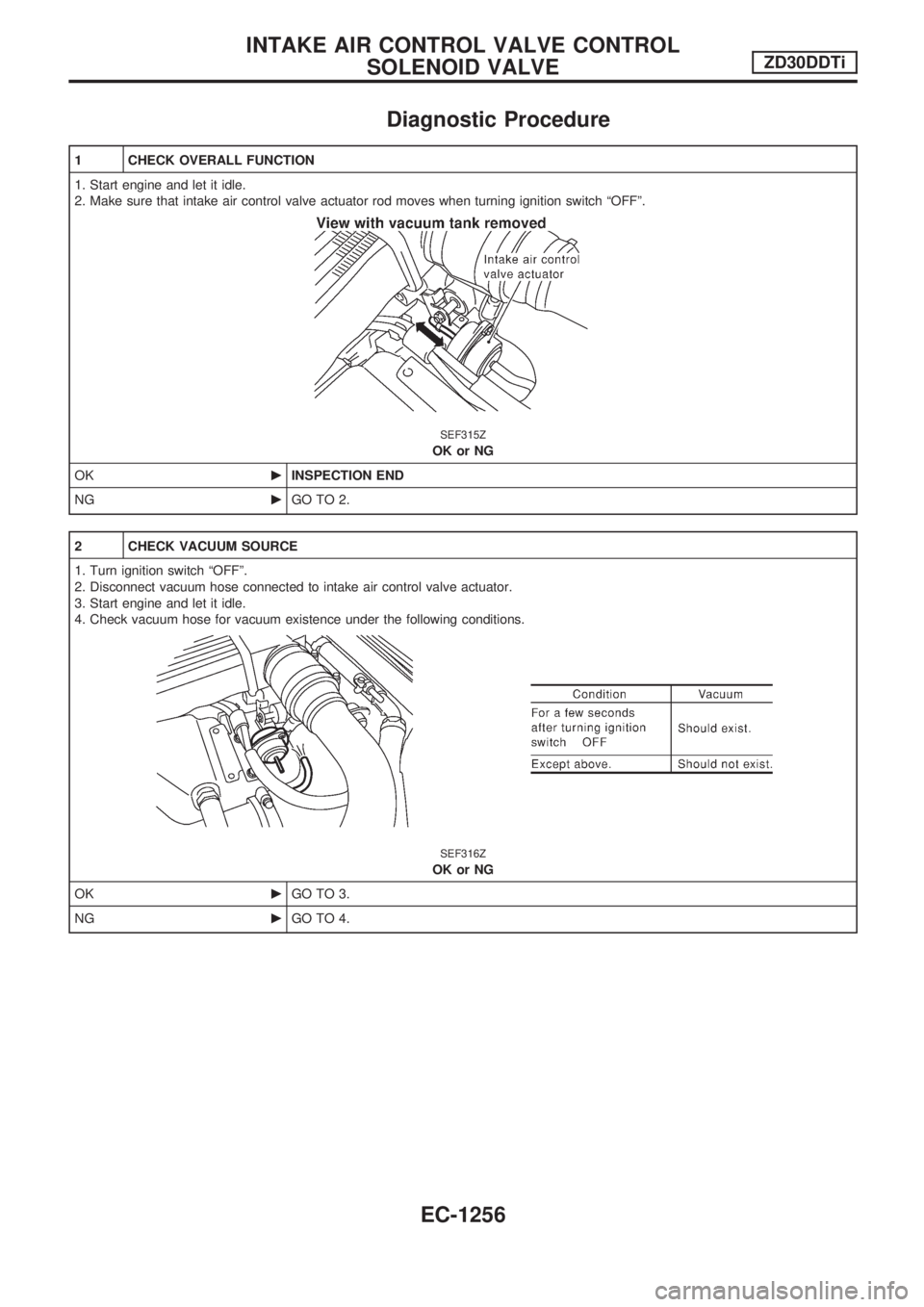

1 CHECK OVERALL FUNCTION

1. Start engine and let it idle.

2. Make sure that intake air control valve actuator rod moves when turning ignition switch ªOFFº.

SEF315Z

OK or NG

OKcINSPECTION END

NGcGO TO 2.

2 CHECK VACUUM SOURCE

1. Turn ignition switch ªOFFº.

2. Disconnect vacuum hose connected to intake air control valve actuator.

3. Start engine and let it idle.

4. Check vacuum hose for vacuum existence under the following conditions.

SEF316Z

OK or NG

OKcGO TO 3.

NGcGO TO 4.

INTAKE AIR CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

EC-1256

Page 490 of 1033

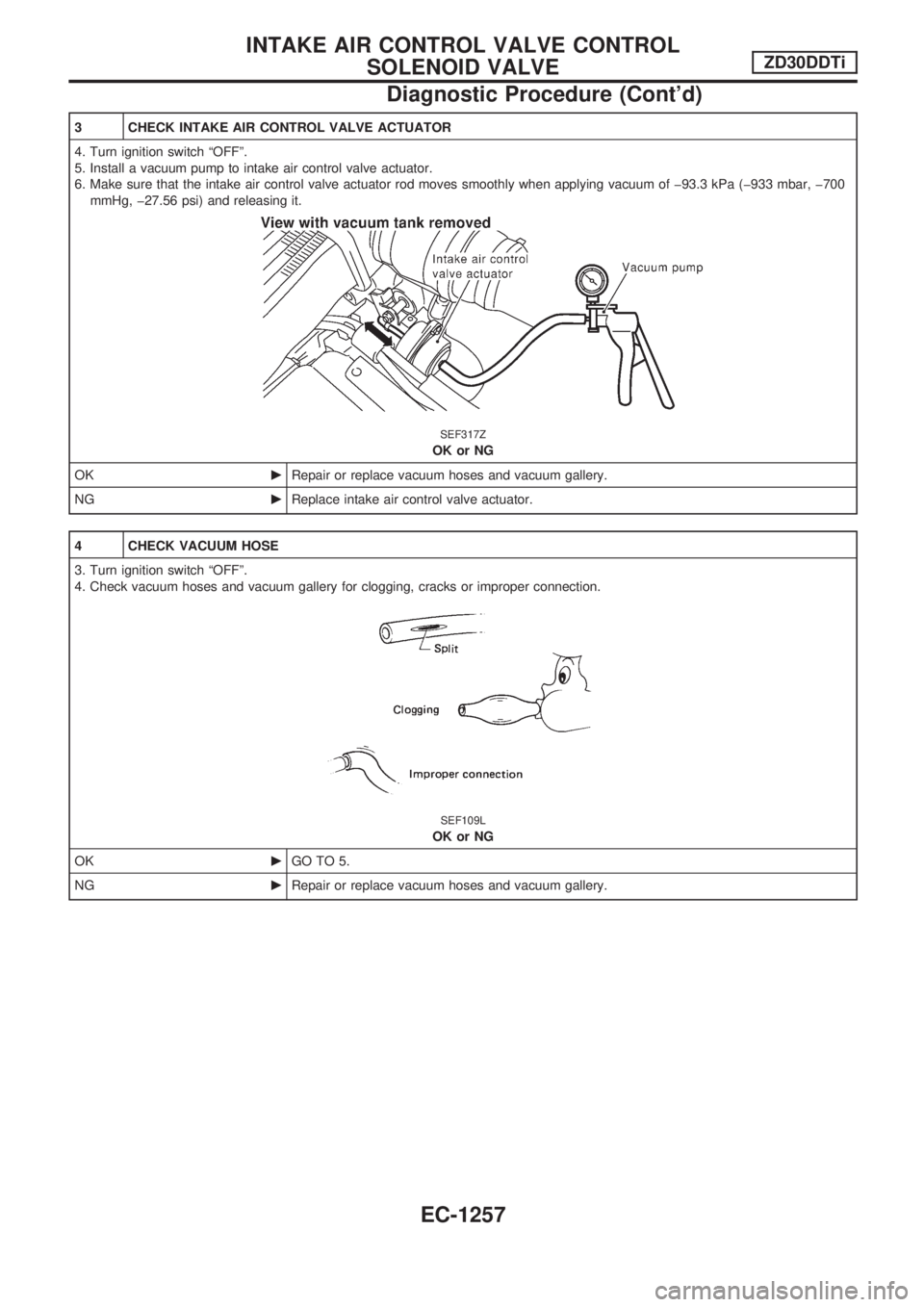

3 CHECK INTAKE AIR CONTROL VALVE ACTUATOR

4. Turn ignition switch ªOFFº.

5. Install a vacuum pump to intake air control valve actuator.

6. Make sure that the intake air control valve actuator rod moves smoothly when applying vacuum of þ93.3 kPa (þ933 mbar, þ700

mmHg, þ27.56 psi) and releasing it.

SEF317Z

OK or NG

OKcRepair or replace vacuum hoses and vacuum gallery.

NGcReplace intake air control valve actuator.

4 CHECK VACUUM HOSE

3. Turn ignition switch ªOFFº.

4. Check vacuum hoses and vacuum gallery for clogging, cracks or improper connection.

SEF109L

OK or NG

OKcGO TO 5.

NGcRepair or replace vacuum hoses and vacuum gallery.

INTAKE AIR CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1257