NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 461 of 1033

14 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E127, M21

+Harness connectors M51, F6

+Harness for open or short between glow relay and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

15 CHECK HARNESS CONTINUITY BETWEEN GLOW RELAY AND GLOW PLUG FOR OPEN AND SHORT

1. Disconnect glow plug harness connector.

2. Check harness continuity between glow relay terminal 5 and glow plug harness connector. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 16.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

16 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E67, E223

+Harness connectors E225, E241

+Harness for open or short between glow relay and glow plug

cRepair open circuit or short to ground or short to power in harness or connectors.

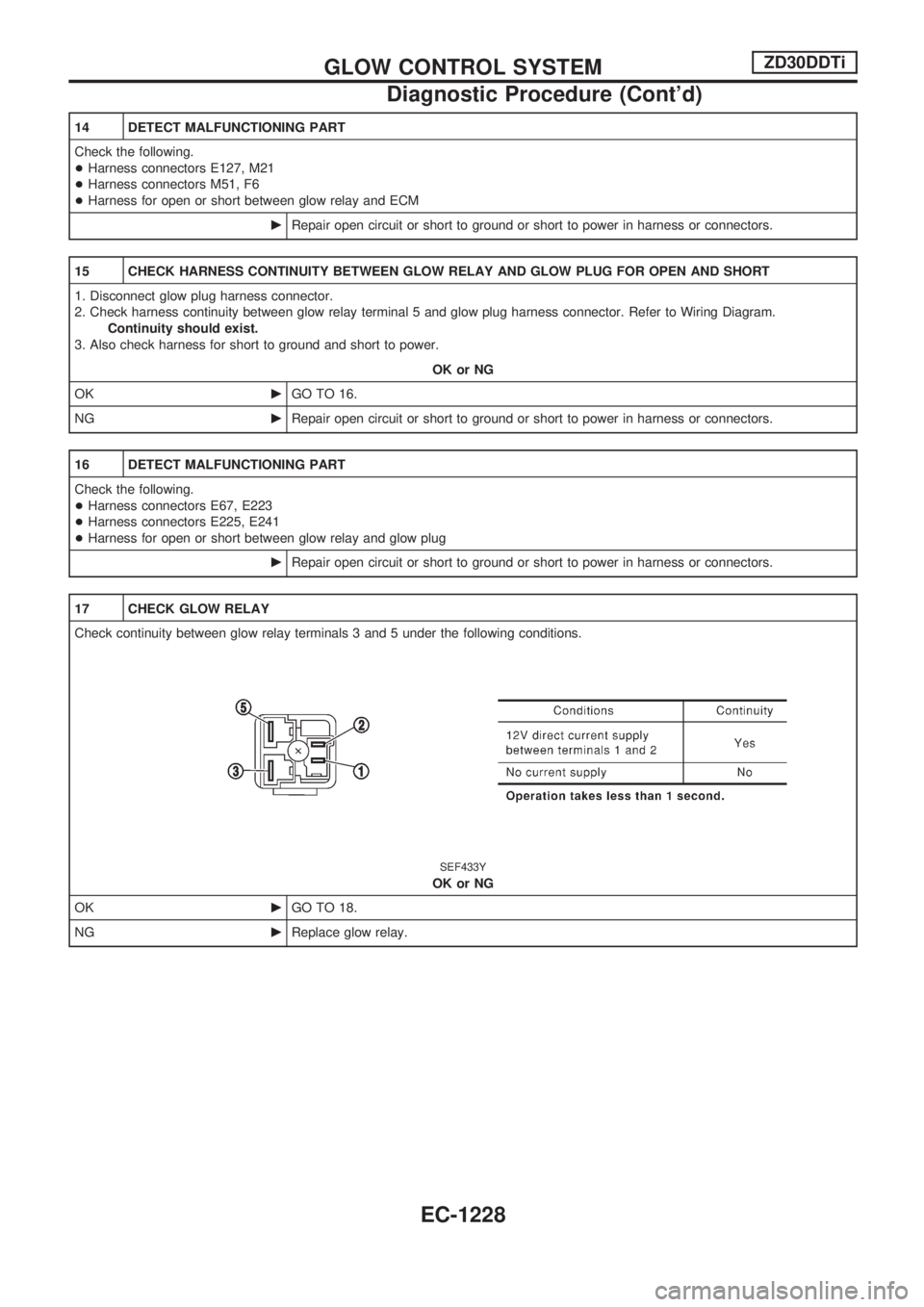

17 CHECK GLOW RELAY

Check continuity between glow relay terminals 3 and 5 under the following conditions.

SEF433Y

OK or NG

OKcGO TO 18.

NGcReplace glow relay.

GLOW CONTROL SYSTEMZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1228

Page 462 of 1033

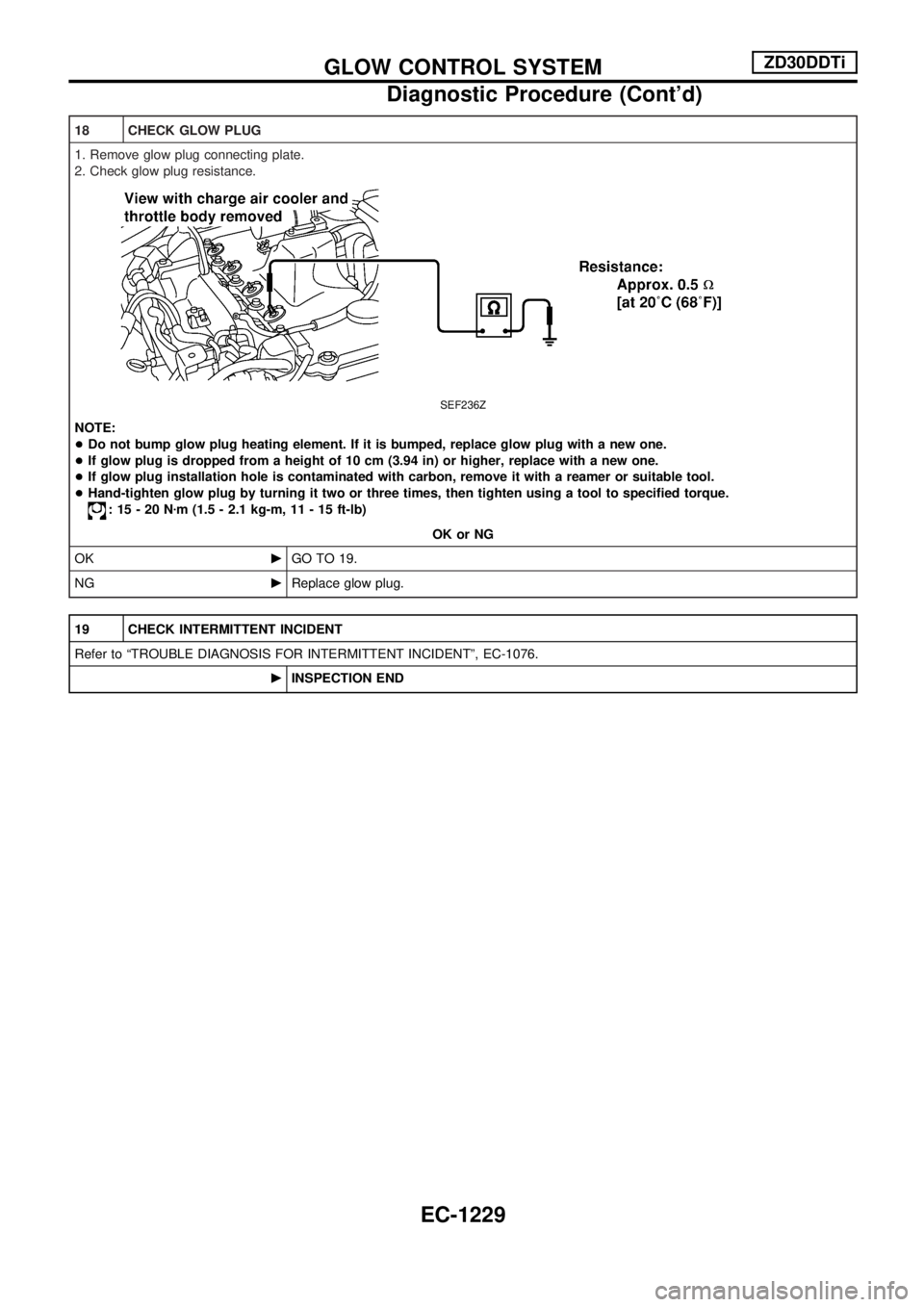

18 CHECK GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

SEF236Z

NOTE:

+Do not bump glow plug heating element. If it is bumped, replace glow plug with a new one.

+If glow plug is dropped from a height of 10 cm (3.94 in) or higher, replace with a new one.

+If glow plug installation hole is contaminated with carbon, remove it with a reamer or suitable tool.

+Hand-tighten glow plug by turning it two or three times, then tighten using a tool to specified torque.

:15-20Nzm (1.5 - 2.1 kg-m, 11 - 15 ft-lb)

OK or NG

OKcGO TO 19.

NGcReplace glow plug.

19 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

GLOW CONTROL SYSTEMZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1229

Page 463 of 1033

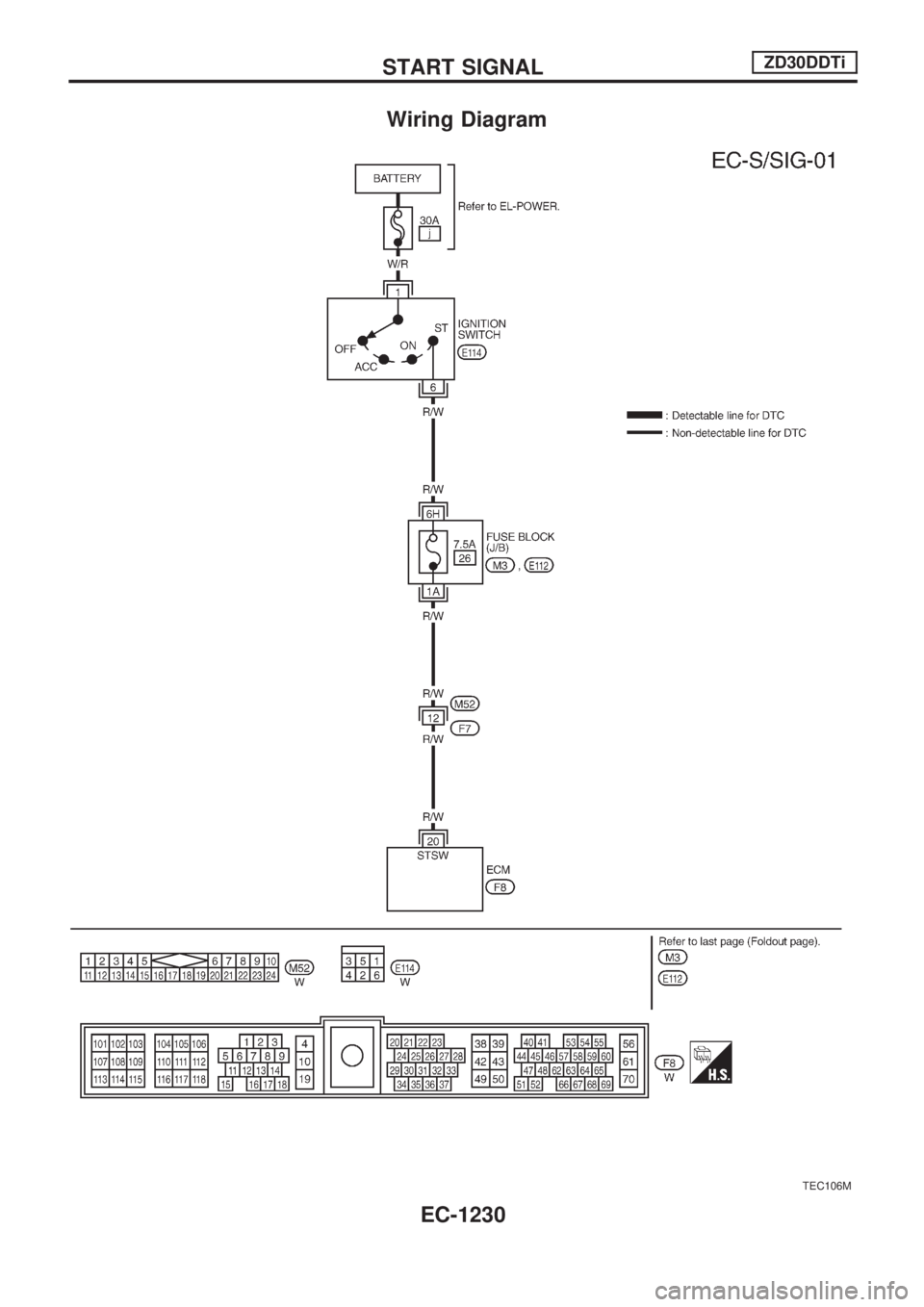

Wiring Diagram

TEC106M

START SIGNALZD30DDTi

EC-1230

Page 464 of 1033

Diagnostic Procedure

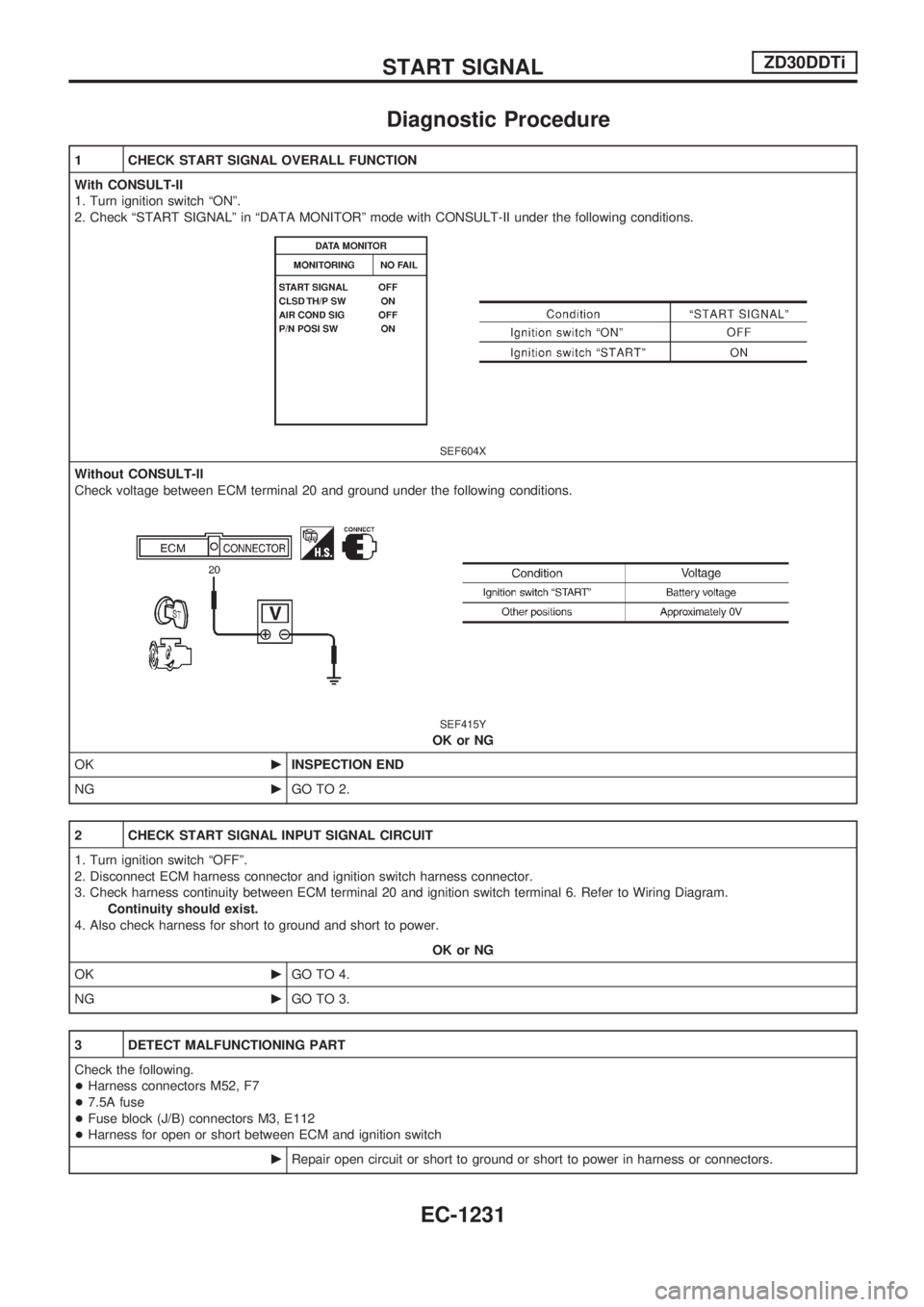

1 CHECK START SIGNAL OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Check ªSTART SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

SEF604X

Without CONSULT-II

Check voltage between ECM terminal 20 and ground under the following conditions.

SEF415Y

OK or NG

OKcINSPECTION END

NGcGO TO 2.

2 CHECK START SIGNAL INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and ignition switch harness connector.

3. Check harness continuity between ECM terminal 20 and ignition switch terminal 6. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 4.

NGcGO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M52, F7

+7.5A fuse

+Fuse block (J/B) connectors M3, E112

+Harness for open or short between ECM and ignition switch

cRepair open circuit or short to ground or short to power in harness or connectors.

START SIGNALZD30DDTi

EC-1231

Page 465 of 1033

4 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

START SIGNALZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1232

Page 466 of 1033

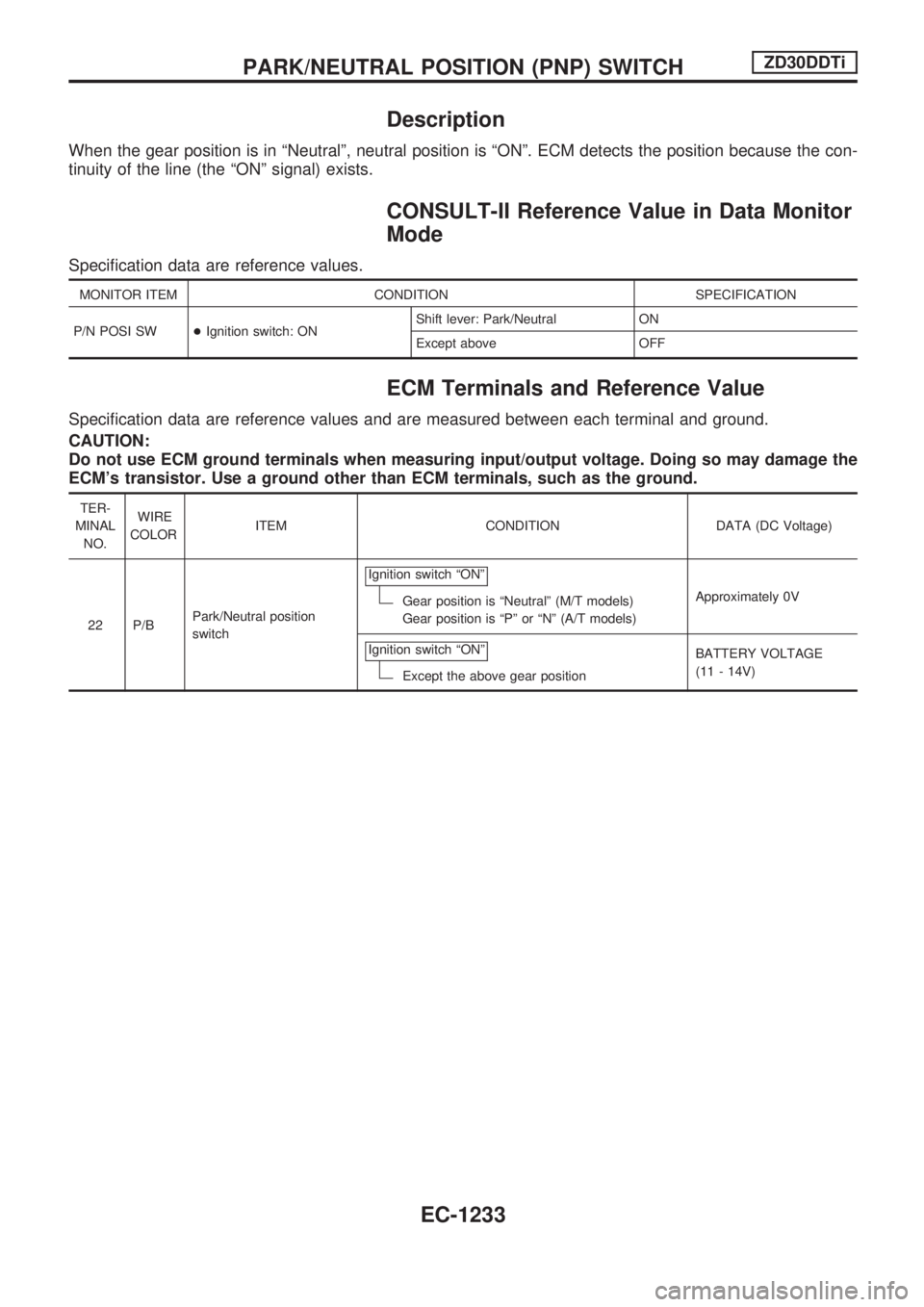

Description

When the gear position is in ªNeutralº, neutral position is ªONº. ECM detects the position because the con-

tinuity of the line (the ªONº signal) exists.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SW+Ignition switch: ONShift lever: Park/Neutral ON

Except above OFF

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

22 P/BPark/Neutral position

switchIgnition switch ªONº

Gear position is ªNeutralº (M/T models)

Gear position is ªPº or ªNº (A/T models)Approximately 0V

Ignition switch ªONº

Except the above gear positionBATTERY VOLTAGE

(11 - 14V)

PARK/NEUTRAL POSITION (PNP) SWITCHZD30DDTi

EC-1233

Page 467 of 1033

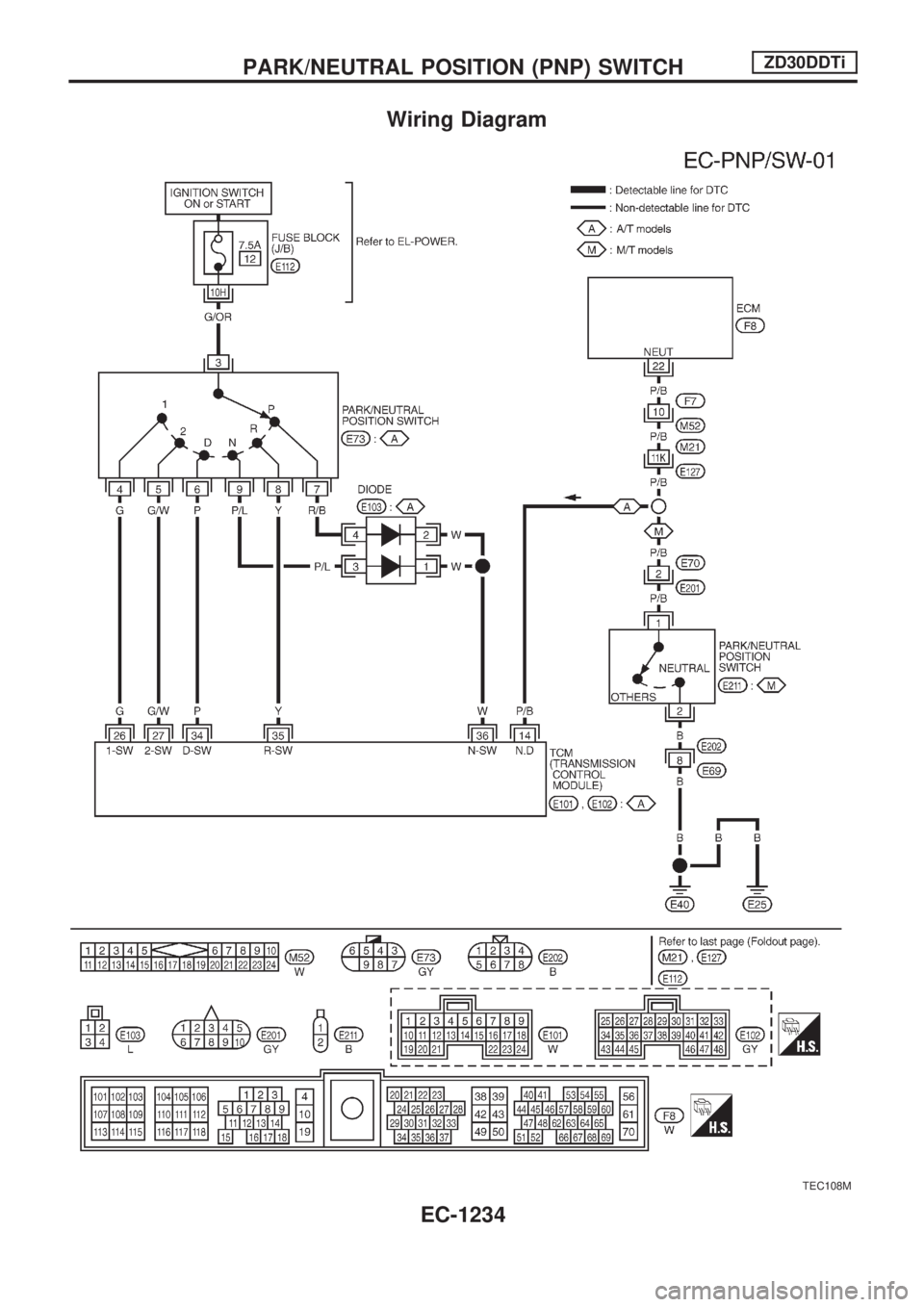

Wiring Diagram

TEC108M

PARK/NEUTRAL POSITION (PNP) SWITCHZD30DDTi

EC-1234

Page 468 of 1033

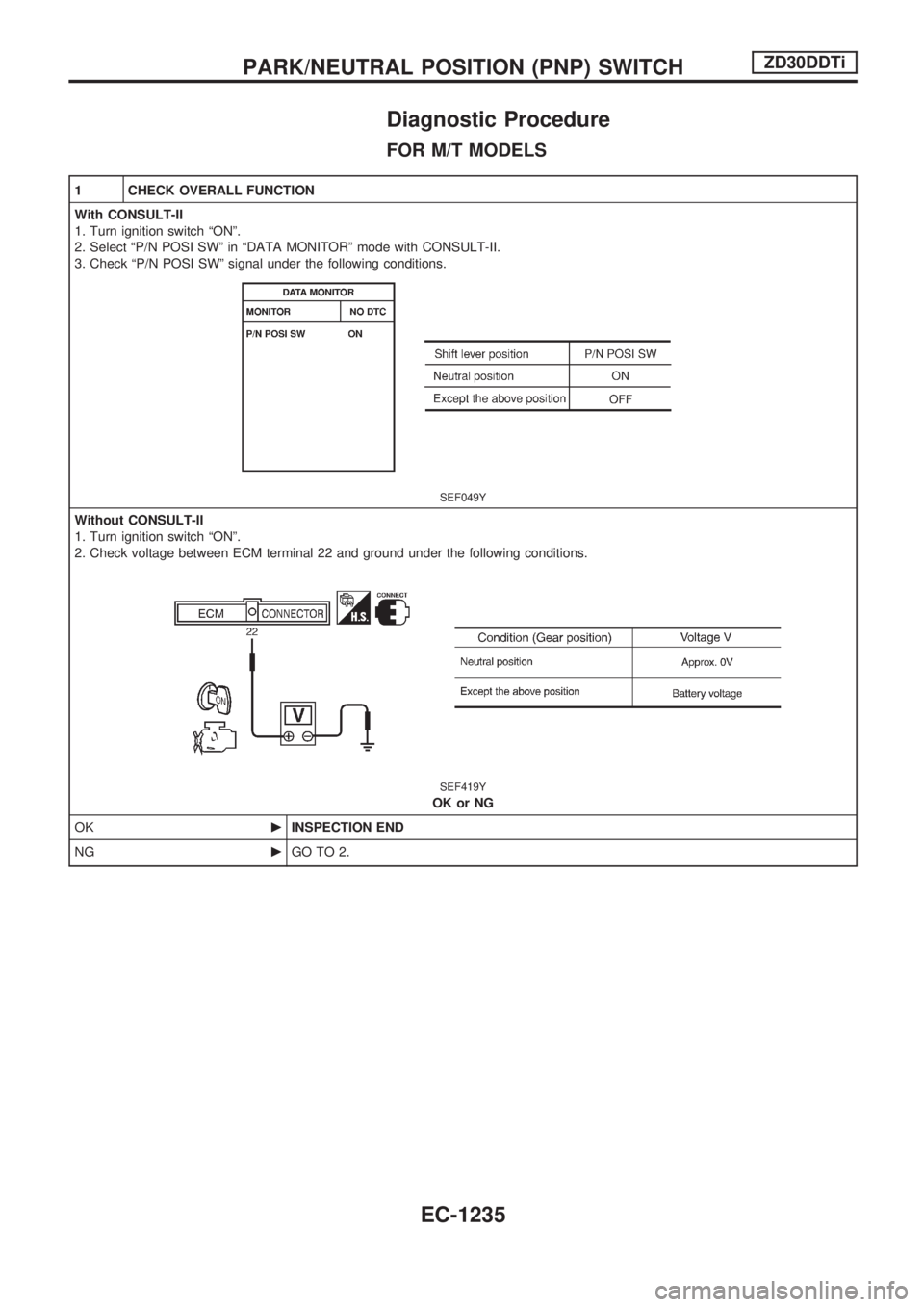

Diagnostic Procedure

FOR M/T MODELS

1 CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªP/N POSI SWº in ªDATA MONITORº mode with CONSULT-II.

3. Check ªP/N POSI SWº signal under the following conditions.

SEF049Y

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 22 and ground under the following conditions.

SEF419Y

OK or NG

OKcINSPECTION END

NGcGO TO 2.

PARK/NEUTRAL POSITION (PNP) SWITCHZD30DDTi

EC-1235

Page 469 of 1033

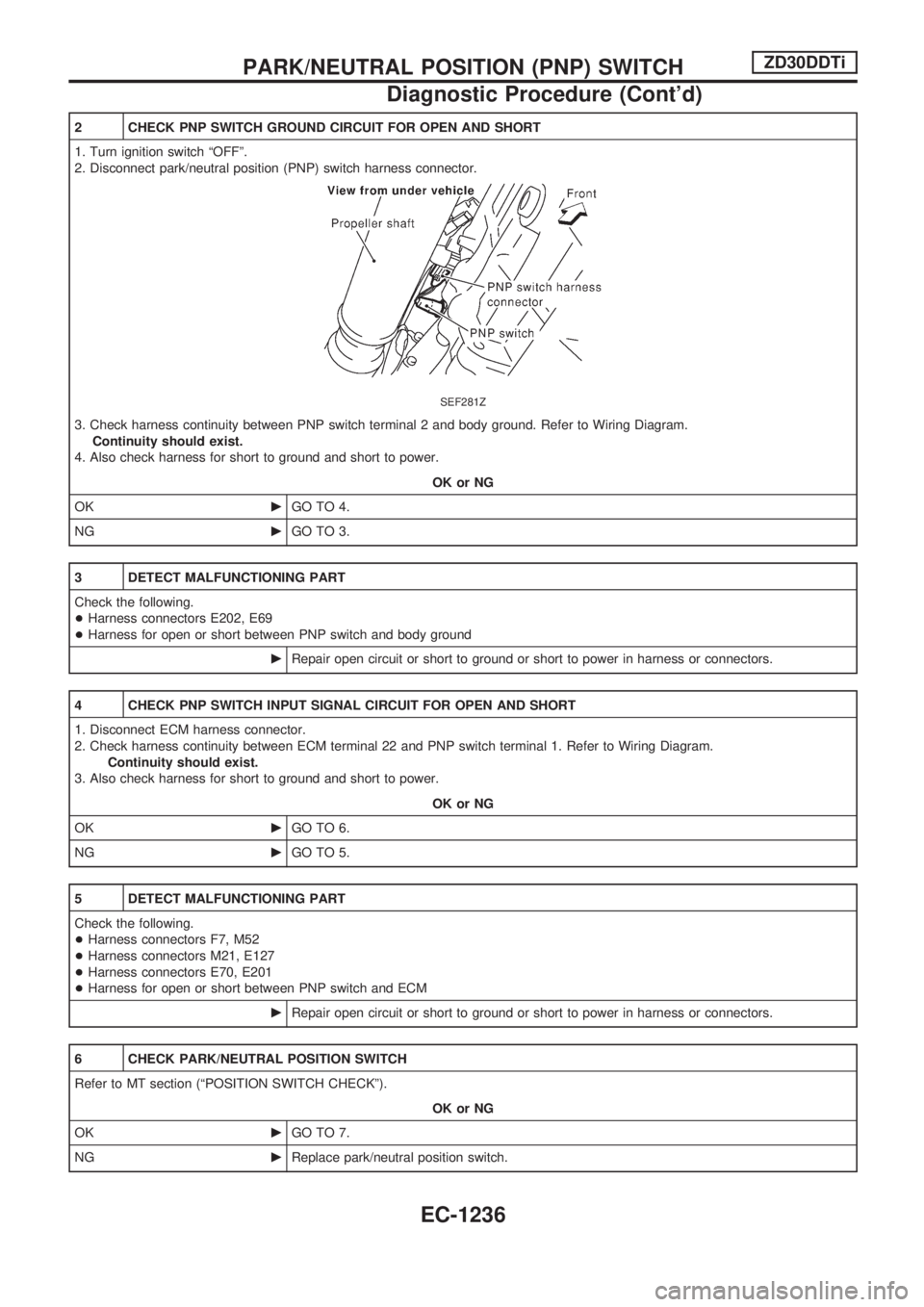

2 CHECK PNP SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect park/neutral position (PNP) switch harness connector.

SEF281Z

3. Check harness continuity between PNP switch terminal 2 and body ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 4.

NGcGO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E202, E69

+Harness for open or short between PNP switch and body ground

cRepair open circuit or short to ground or short to power in harness or connectors.

4 CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 22 and PNP switch terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 6.

NGcGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F7, M52

+Harness connectors M21, E127

+Harness connectors E70, E201

+Harness for open or short between PNP switch and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

6 CHECK PARK/NEUTRAL POSITION SWITCH

Refer to MT section (ªPOSITION SWITCH CHECKº).

OK or NG

OKcGO TO 7.

NGcReplace park/neutral position switch.

PARK/NEUTRAL POSITION (PNP) SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1236

Page 470 of 1033

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

FOR A/T MODELS

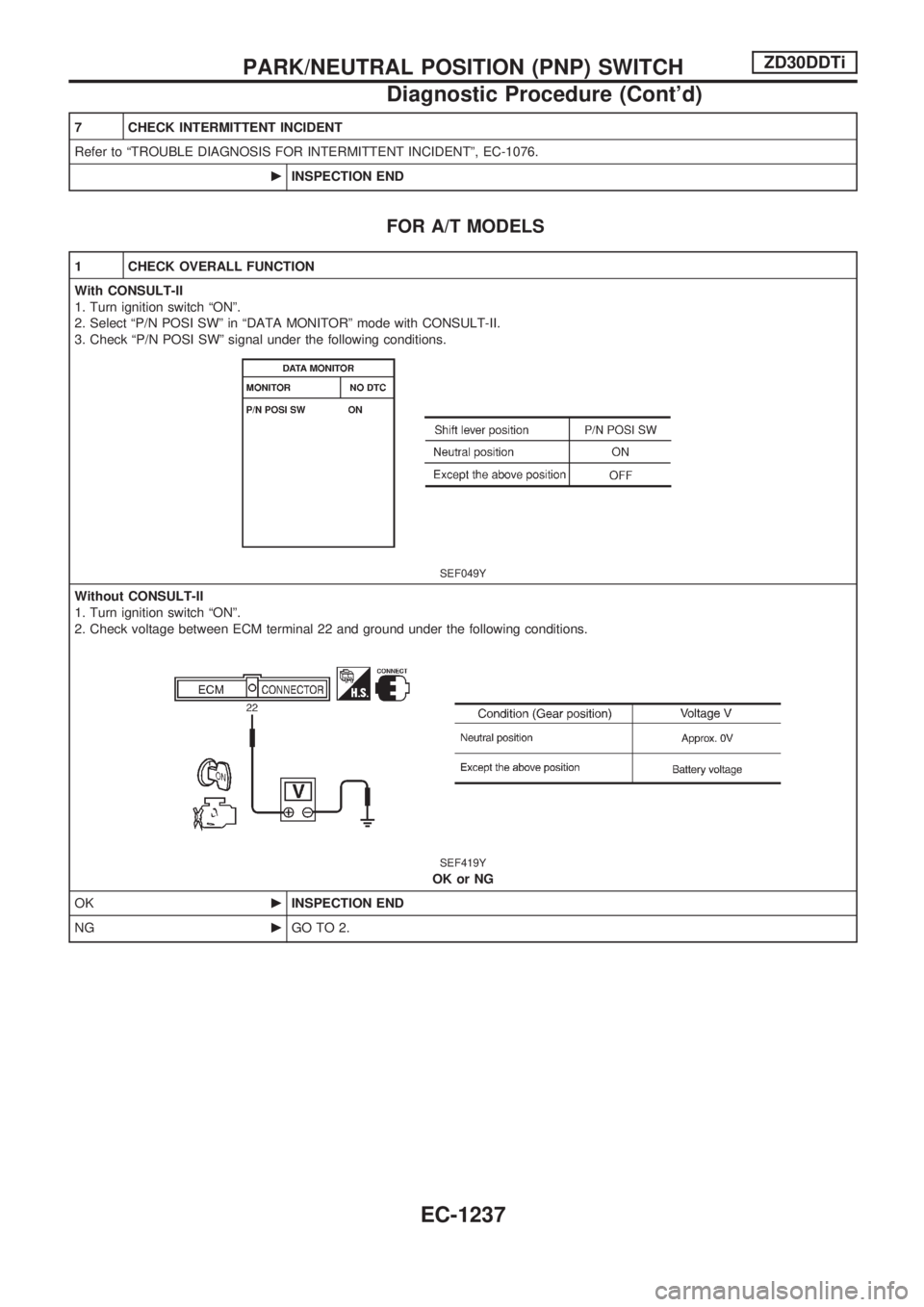

1 CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªP/N POSI SWº in ªDATA MONITORº mode with CONSULT-II.

3. Check ªP/N POSI SWº signal under the following conditions.

SEF049Y

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 22 and ground under the following conditions.

SEF419Y

OK or NG

OKcINSPECTION END

NGcGO TO 2.

PARK/NEUTRAL POSITION (PNP) SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1237