NISSAN PATROL 2004 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2004, Model line: PATROL, Model: NISSAN PATROL 2004Pages: 579, PDF Size: 26.61 MB

Page 441 of 579

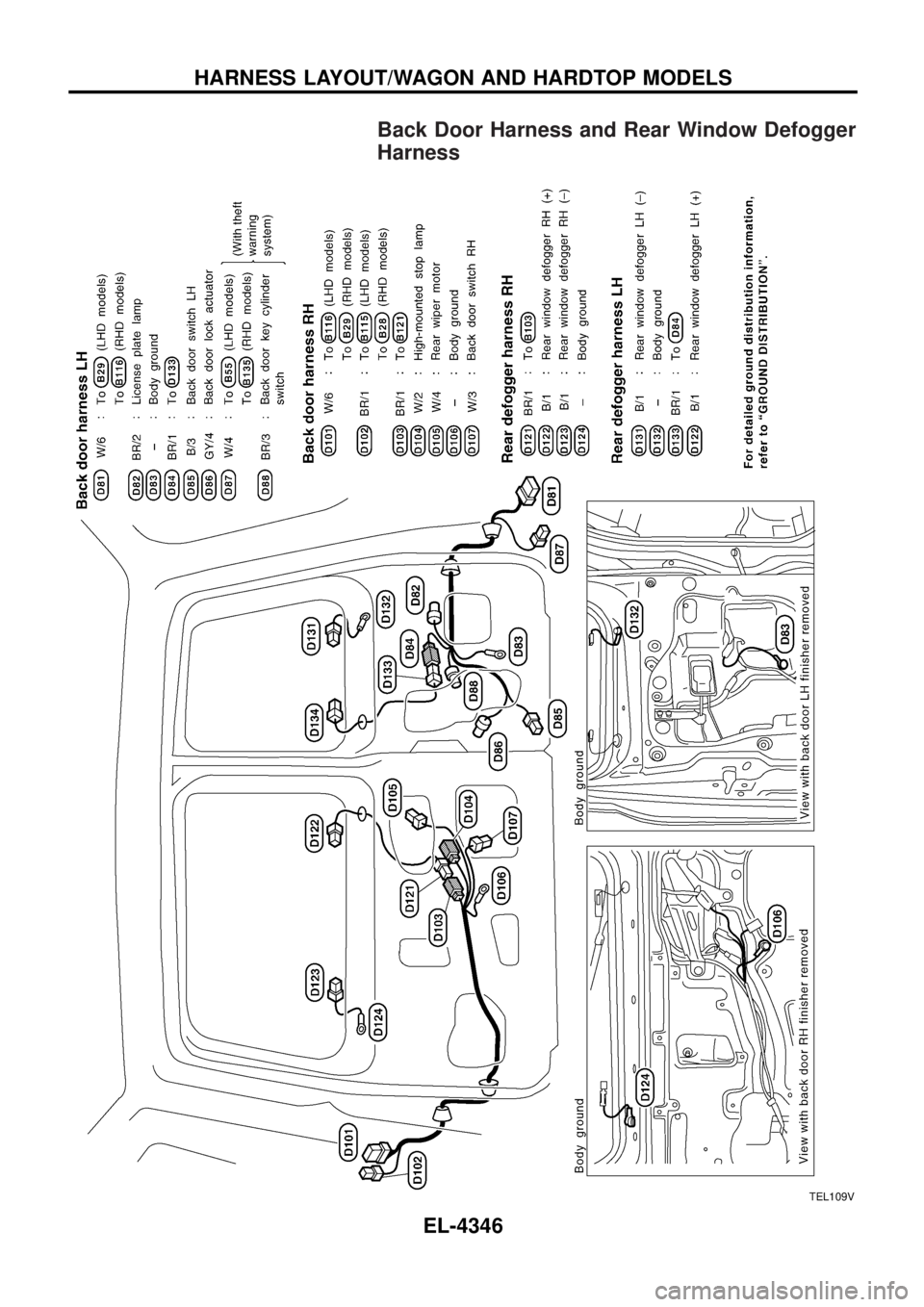

Back Door Harness and Rear Window Defogger

Harness

TEL109V

HARNESS LAYOUT/WAGON AND HARDTOP MODELS

EL-4346

Page 442 of 579

Wiring Diagram Codes (Cell Codes)

Use the chart below to ®nd out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to ®nd

the location (Page number) of each wiring diagram.

Code Section Wiring Diagram Name

A/C, A HA Auto Air Conditioner

A/C, M HA Manual Air Conditioner

A/CCUT EC Air Conditioner Control

A/T AT A/T

ASCD EL Automatic Speed Control Device

AUDIO EL Audio

BACK/L EL Back-up Lamp

CD/CHG EL CD Auto Changer

CHIME EL Warning Chime

COMPAS EL Compass and Thermometer

COOL/B HA Cool Box

D/LOCK EL Power Door Lock

DEF EL Rear Window Defogger

DEICER EL Wiper Deicer

DTRL EL Headlamp Ð Daytime Light System

F/FOG EL Front Fog Lamp

FICD EC IACV-FICD Solenoid Valve

GLOW EC Quick Glow System

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

HEATUP EC Heat Up Switch

HLC EL Headlamp Washer

HORN EL Horn

HSEAT EL Heated Seat

ILL EL Illumination

LOAD EC Electrical Load Signal

MAFS EC Mass Air Flow Sensor

METER EL Meter and Gauges

MIRROR EL Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-Theft System

NAVI EL Navigation System

NONDTC AT Non-detective Items

P/ANT EL Power Antenna

PHONE EL Telephone

POWER EL Power Supply Routing

R/COOL HA Rear Cooler System

R/FOG EL Rear Fog LampCode Section Wiring Diagram Name

R/HEAT HA Rear Heater System

REMOTE EL Audio (Remote Control Switch)

ROOM/L EL Interior Room Lamp

S/LOCK EL Power Door Lock Ð Super Lock

S/TANK FE Sub Fuel Tank Control System

SRS RS Supplemental Restraint System

STAB RA Stabilizer Release Device

STOP/L EL Stop Lamp

TAIL/L EL Parking, License and Tail Lamps

THEFT EL Theft Warning System

TRQ/SG EC Engine Torque Control Signal

TURN EL Turn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

WARN EL Warning Lamps

WINDOW EL Power Window

WIP/R EL Rear Wiper and Washer

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-4347

Page 443 of 579

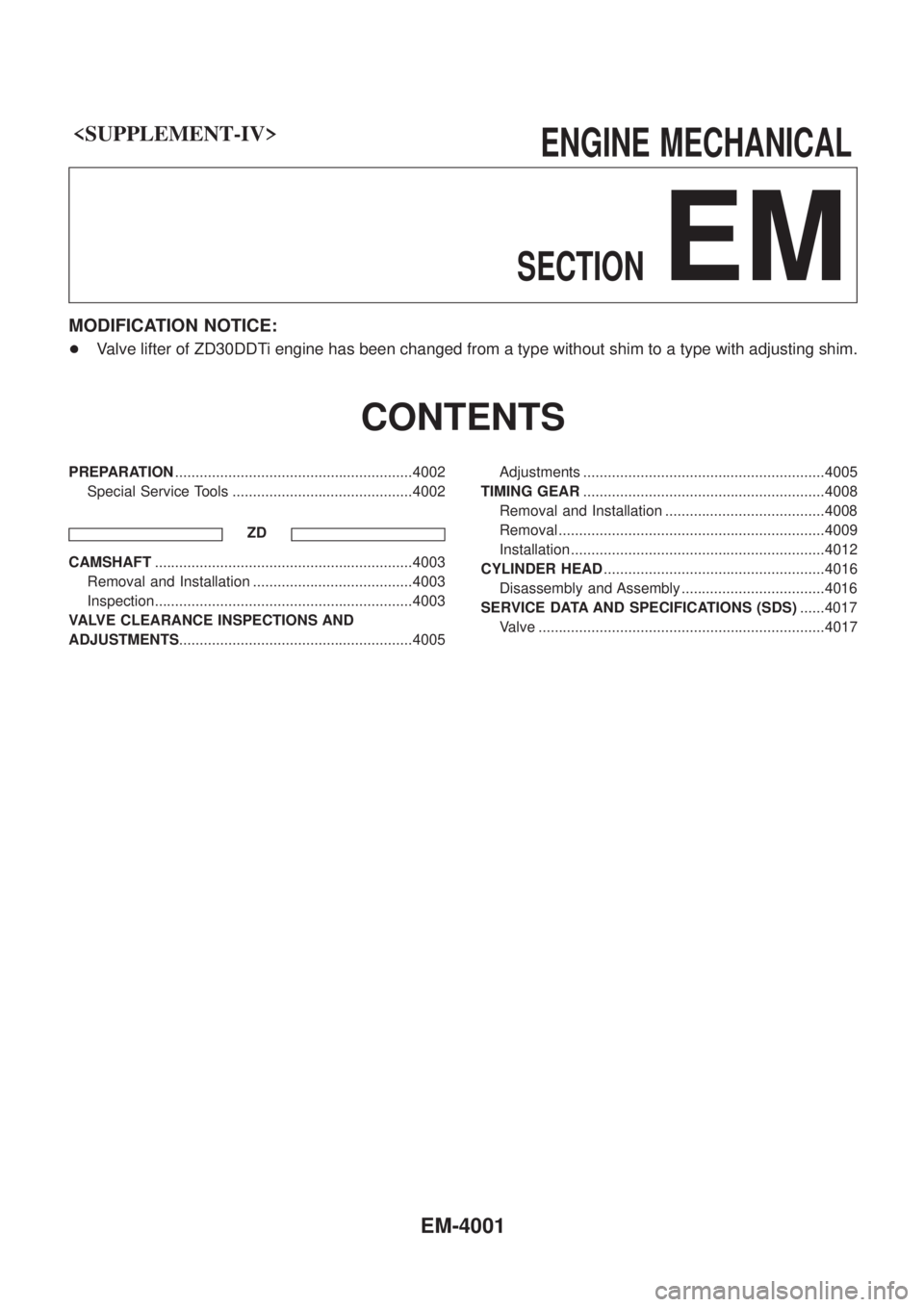

SECTION

EM

MODIFICATION NOTICE:

+ Valve lifter of ZD30DDTi engine has been changed from a type without shim to a type with adjusting shim.

CONTENTS

PREPARATION ..........................................................4002

Special Service Tools ............................................4002

ZD

CAMSHAFT...............................................................4003

Removal and Installation .......................................4003

Inspection...............................................................4003

VALVE CLEARANCE INSPECTIONS AND

ADJUSTMENTS .........................................................4005 Adjustments ...........................................................4005

TIMING GEAR ...........................................................4008

Removal and Installation .......................................4008

Removal .................................................................4009

Installation ..............................................................4012

CYLINDER HEAD ......................................................4016

Disassembly and Assembly ...................................4016

SERVICE DATA AND SPECIFICATIONS (SDS) ......4017

Valve ......................................................................4017

EM-4001

Page 444 of 579

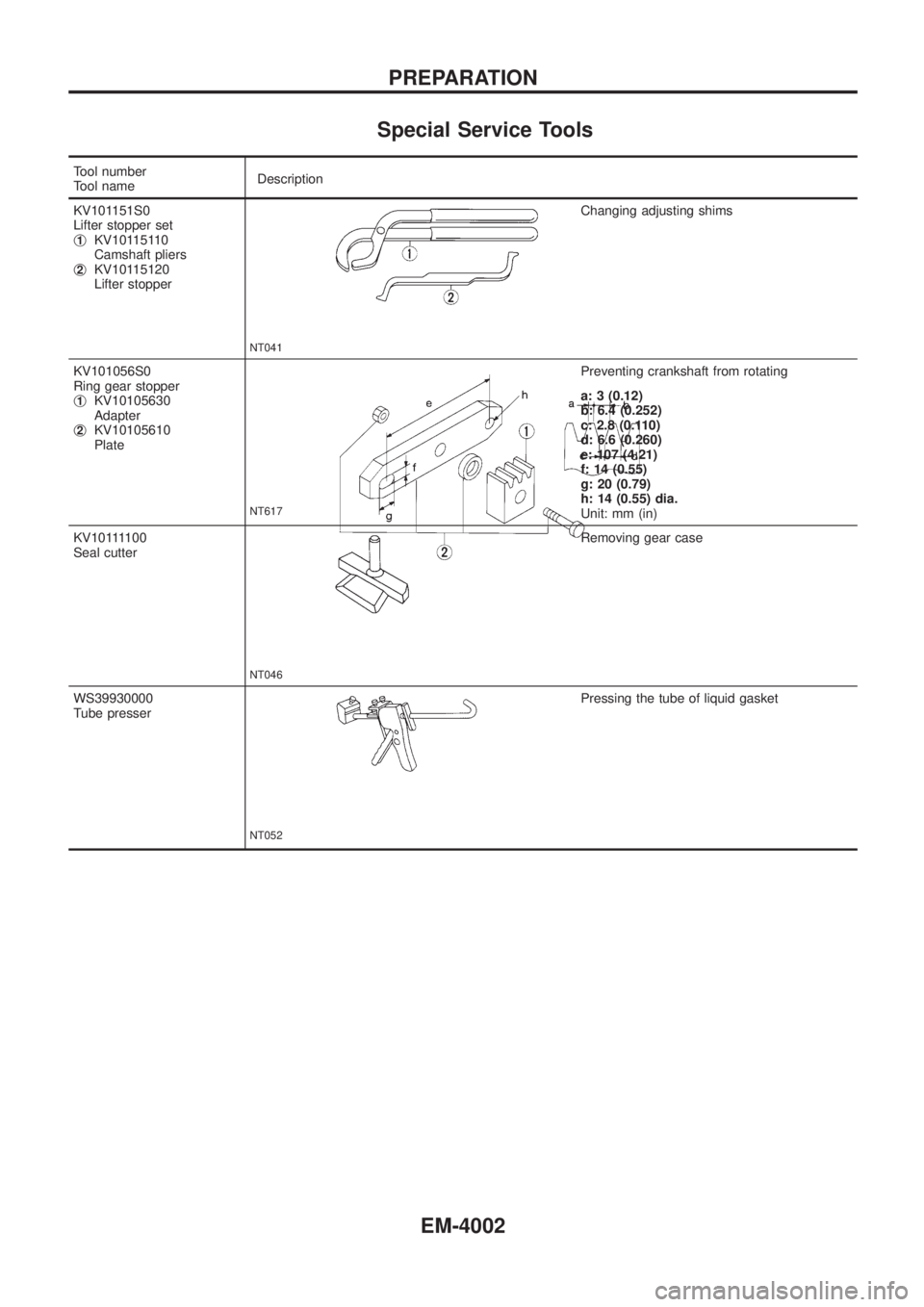

Special Service Tools

Tool number

Tool nameDescription

KV101151S0

Lifter stopper set

j

1KV10115110

Camshaft pliers

j

2KV10115120

Lifter stopper

NT041

Changing adjusting shims

KV101056S0

Ring gear stopper

j

1KV10105630

Adapter

j

2KV10105610

Plate

NT617

Preventing crankshaft from rotating

a: 3 (0.12)

b: 6.4 (0.252)

c: 2.8 (0.110)

d: 6.6 (0.260)

e: 107 (4.21)

f: 14 (0.55)

g: 20 (0.79)

h: 14 (0.55) dia.

Unit: mm (in)

KV101111 0 0

Seal cutter

NT046

Removing gear case

WS39930000

Tube presser

NT052

Pressing the tube of liquid gasket

PREPARATION

EM-4002

Page 445 of 579

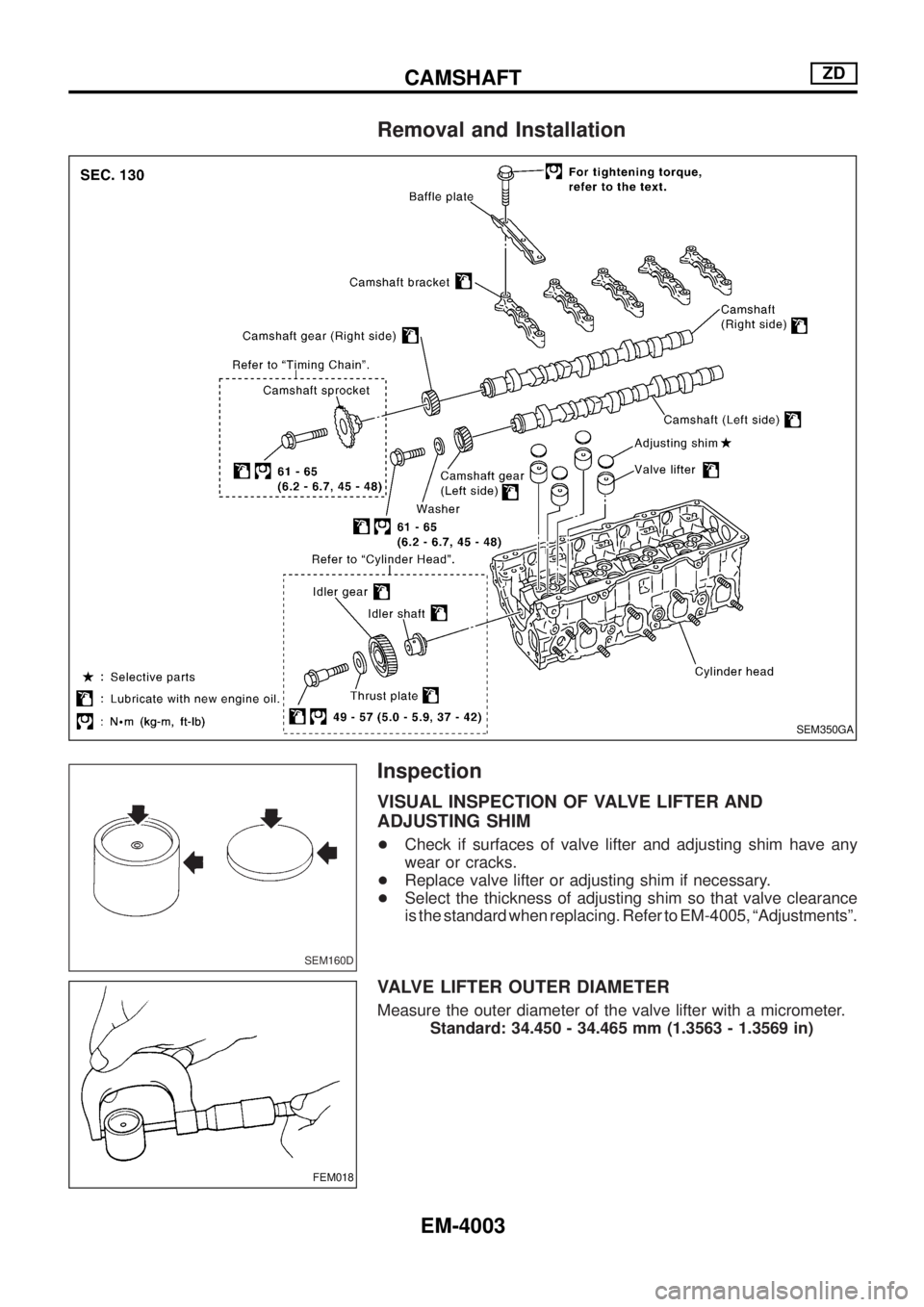

Removal and Installation

Inspection

VISUAL INSPECTION OF VALVE LIFTER AND

ADJUSTING SHIM

+Check if surfaces of valve lifter and adjusting shim have any

wear or cracks.

+Replace valve lifter or adjusting shim if necessary.

+Select the thickness of adjusting shim so that valve clearance

is the standard when replacing. Refer to EM-4005, ªAdjustmentsº.

VALVE LIFTER OUTER DIAMETER

Measure the outer diameter of the valve lifter with a micrometer.

Standard: 34.450 - 34.465 mm (1.3563 - 1.3569 in)

SEM350GA

SEM160D

FEM018

CAMSHAFTZD

EM-4003

Page 446 of 579

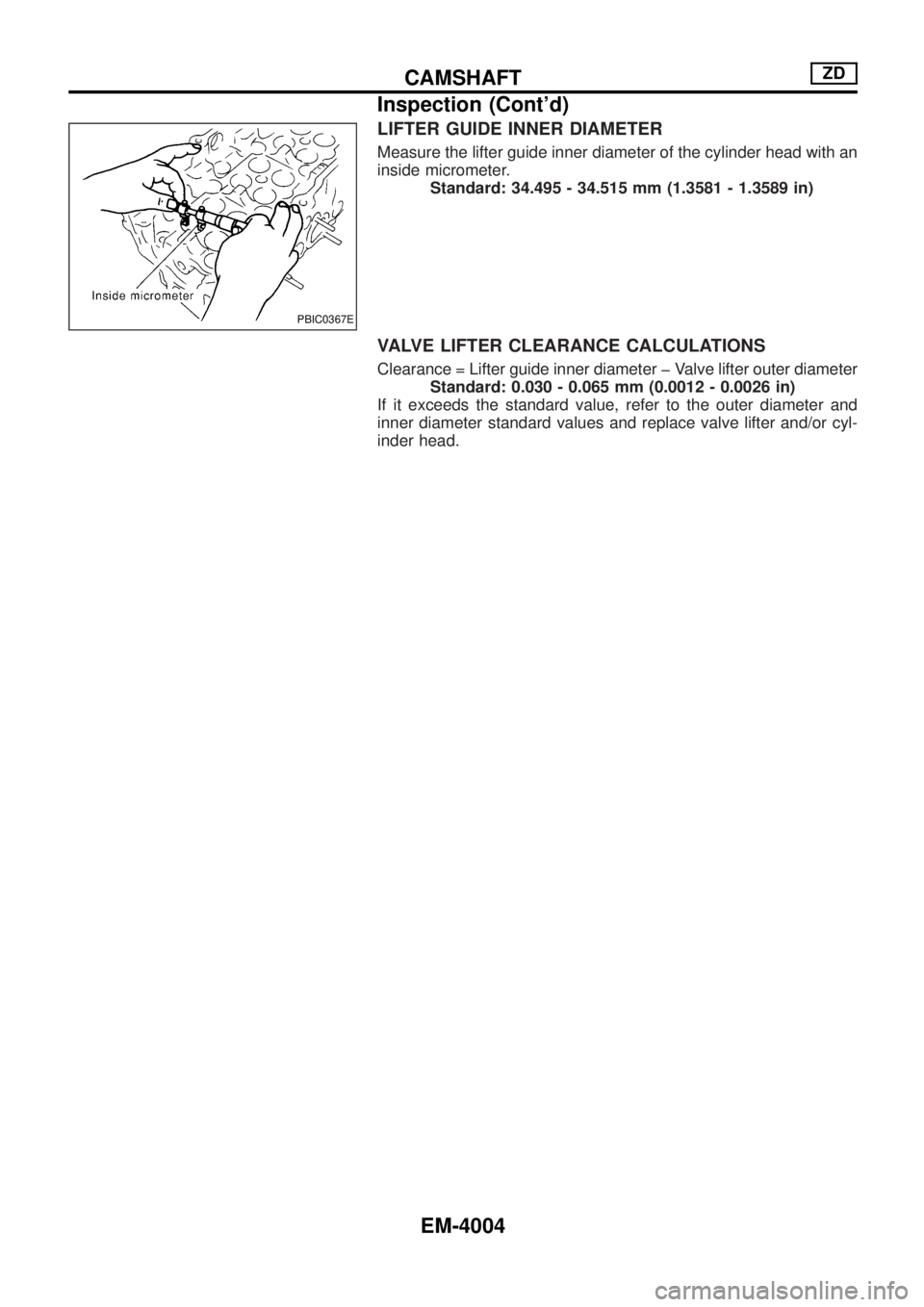

LIFTER GUIDE INNER DIAMETER

Measure the lifter guide inner diameter of the cylinder head with an

inside micrometer.

Standard: 34.495 - 34.515 mm (1.3581 - 1.3589 in)

VALVE LIFTER CLEARANCE CALCULATIONS

Clearance = Lifter guide inner diameter þ Valve lifter outer diameter

Standard: 0.030 - 0.065 mm (0.0012 - 0.0026 in)

If it exceeds the standard value, refer to the outer diameter and

inner diameter standard values and replace valve lifter and/or cyl-

inder head.

PBIC0367E

CAMSHAFTZD

Inspection (Cont'd)

EM-4004

Page 447 of 579

Adjustments

NOTE:

Adjust valve clearance while engine is cold.

+Remove the adjusting shim for parts which are outside the

speci®ed valve clearance.

1. Remove the spill tube. Refer to ªBASIC SERVICE PROCE-

DUREº in EC section.

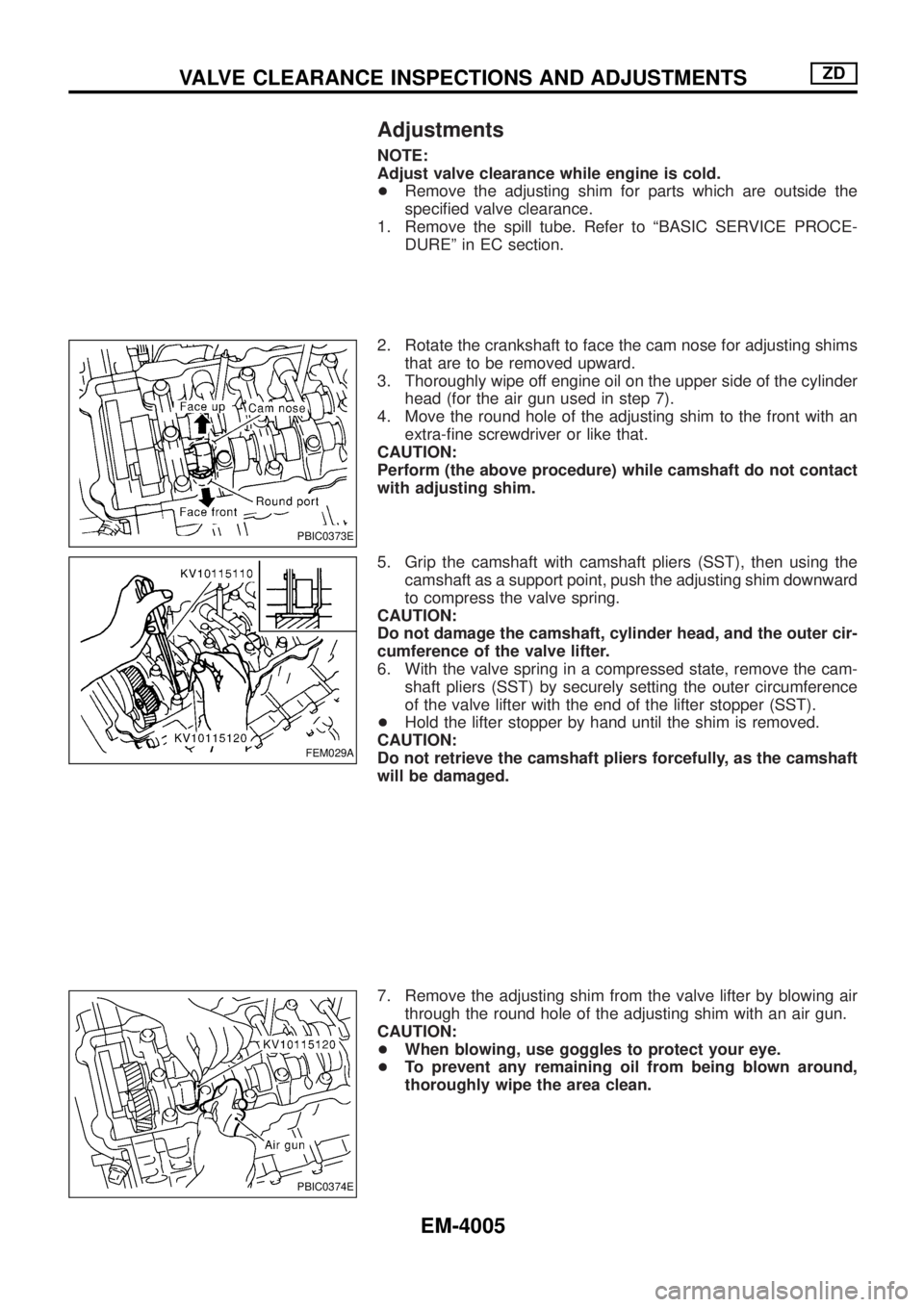

2. Rotate the crankshaft to face the cam nose for adjusting shims

that are to be removed upward.

3. Thoroughly wipe off engine oil on the upper side of the cylinder

head (for the air gun used in step 7).

4. Move the round hole of the adjusting shim to the front with an

extra-®ne screwdriver or like that.

CAUTION:

Perform (the above procedure) while camshaft do not contact

with adjusting shim.

5. Grip the camshaft with camshaft pliers (SST), then using the

camshaft as a support point, push the adjusting shim downward

to compress the valve spring.

CAUTION:

Do not damage the camshaft, cylinder head, and the outer cir-

cumference of the valve lifter.

6. With the valve spring in a compressed state, remove the cam-

shaft pliers (SST) by securely setting the outer circumference

of the valve lifter with the end of the lifter stopper (SST).

+Hold the lifter stopper by hand until the shim is removed.

CAUTION:

Do not retrieve the camshaft pliers forcefully, as the camshaft

will be damaged.

7. Remove the adjusting shim from the valve lifter by blowing air

through the round hole of the adjusting shim with an air gun.

CAUTION:

+When blowing, use goggles to protect your eye.

+To prevent any remaining oil from being blown around,

thoroughly wipe the area clean.

PBIC0373E

FEM029A

PBIC0374E

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

EM-4005

Page 448 of 579

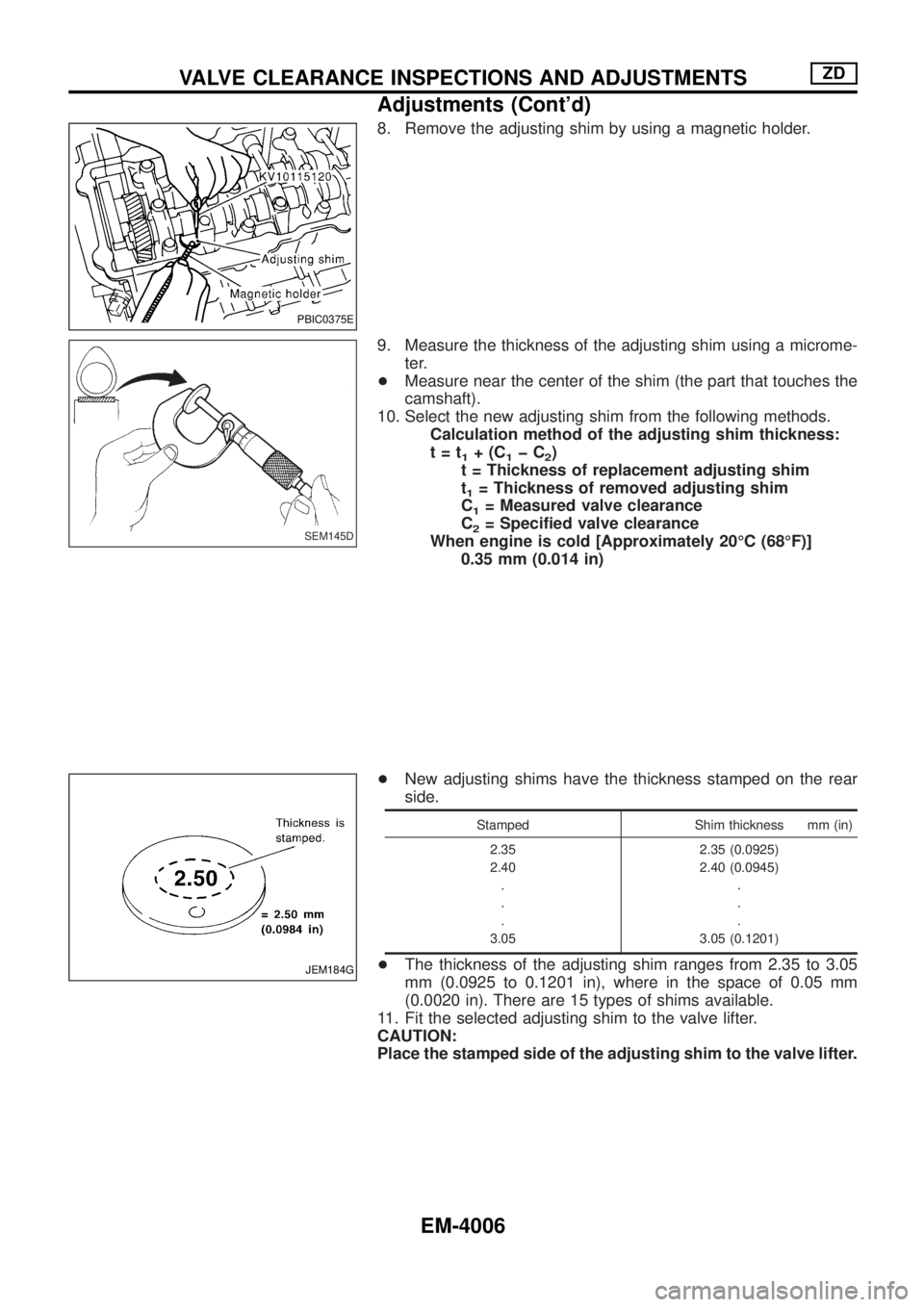

8. Remove the adjusting shim by using a magnetic holder.

9. Measure the thickness of the adjusting shim using a microme-

ter.

+Measure near the center of the shim (the part that touches the

camshaft).

10. Select the new adjusting shim from the following methods.

Calculation method of the adjusting shim thickness:

t=t

1+(C1þC2)

t = Thickness of replacement adjusting shim

t

1= Thickness of removed adjusting shim

C

1= Measured valve clearance

C

2= Speci®ed valve clearance

When engine is cold [Approximately 20ÉC (68ÉF)]

0.35 mm (0.014 in)

+New adjusting shims have the thickness stamped on the rear

side.

Stamped Shim thickness mm (in)

2.35

2.40

.

.

.

3.052.35 (0.0925)

2.40 (0.0945)

.

.

.

3.05 (0.1201)

+The thickness of the adjusting shim ranges from 2.35 to 3.05

mm (0.0925 to 0.1201 in), where in the space of 0.05 mm

(0.0020 in). There are 15 types of shims available.

11. Fit the selected adjusting shim to the valve lifter.

CAUTION:

Place the stamped side of the adjusting shim to the valve lifter.

PBIC0375E

SEM145D

JEM184G

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

Adjustments (Cont'd)

EM-4006

Page 449 of 579

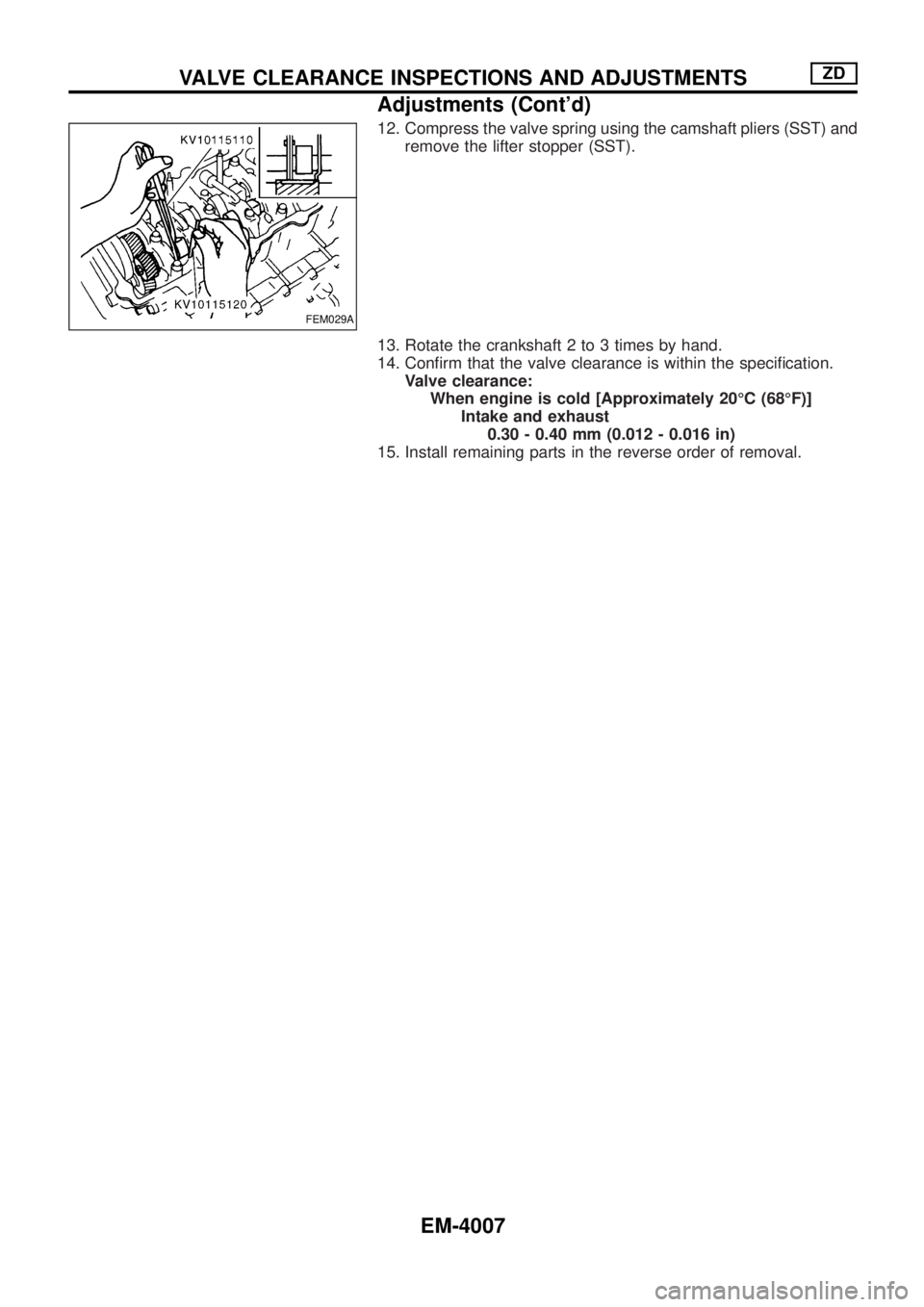

12. Compress the valve spring using the camshaft pliers (SST) and

remove the lifter stopper (SST).

13. Rotate the crankshaft 2 to 3 times by hand.

14. Con®rm that the valve clearance is within the speci®cation.

Valve clearance:

When engine is cold [Approximately 20ÉC (68ÉF)]

Intake and exhaust

0.30 - 0.40 mm (0.012 - 0.016 in)

15. Install remaining parts in the reverse order of removal.

FEM029A

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

Adjustments (Cont'd)

EM-4007

Page 450 of 579

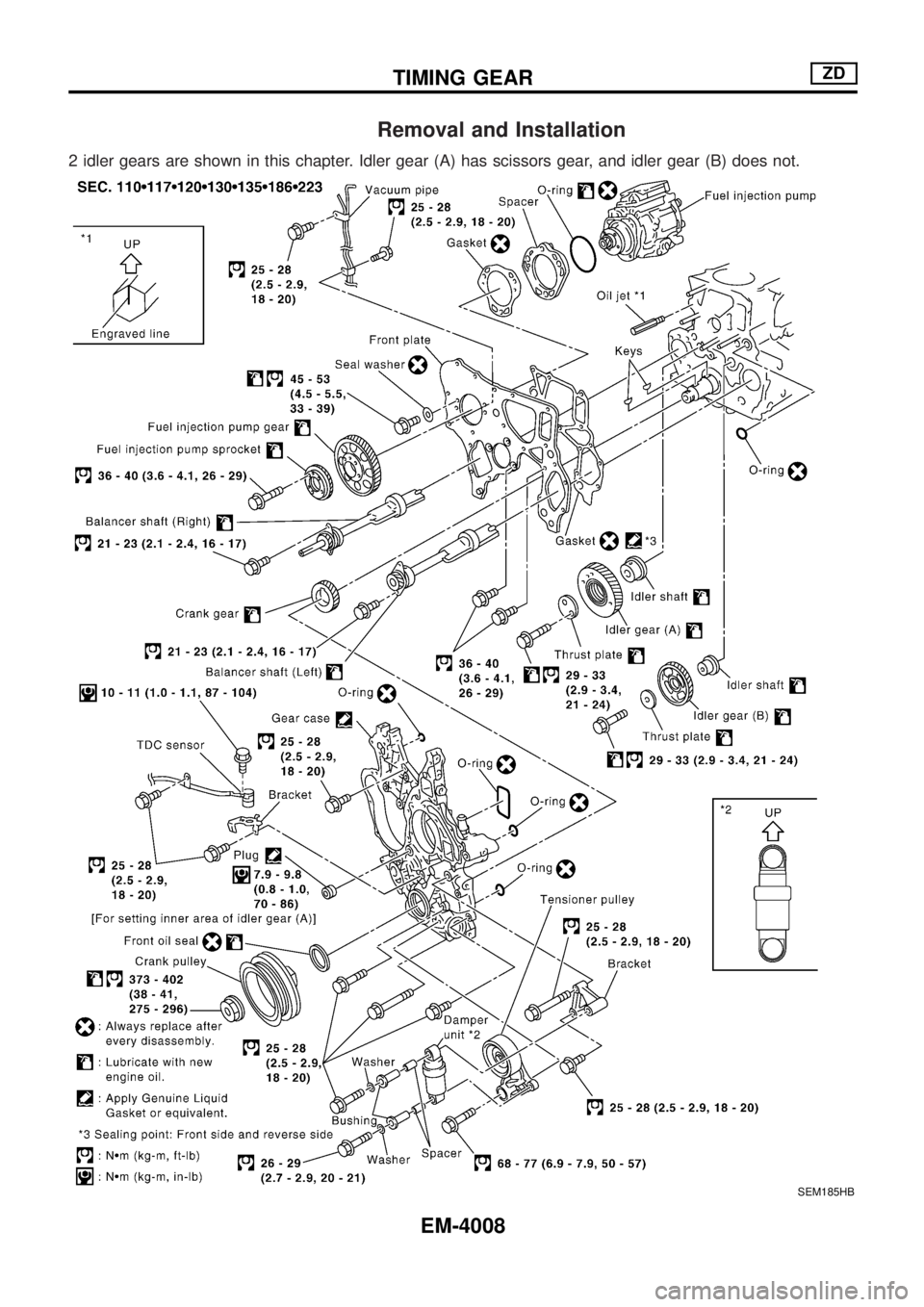

Removal and Installation

2 idler gears are shown in this chapter. Idler gear (A) has scissors gear, and idler gear (B) does not.

SEM185HB

TIMING GEARZD

EM-4008