NISSAN PATROL 2004 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2004, Model line: PATROL, Model: NISSAN PATROL 2004Pages: 579, PDF Size: 26.61 MB

Page 451 of 579

Removal

1. Remove the following parts.

+Undercover

+Engine oil (Drain)

+Engine coolant (Drain)

+Engine cover

+Intercooler

+Air inlet pipe

+Air cleaner case

+Throttle body

+Swirl and intake air control valve control solenoid valve and

bracket

+Vacuum tank

+Glow plate

+Rocker cover

+Spill tube

+Radiator shrouds (Rear and Lower)

+Cooling fan

+Radiator hose (Upper and Lower)

+Auxiliary belt and auto tensioner.

2. Remove the alternator.

3. Remove the A/C compressor and bracket with piping con-

nected. Move and support it at the LH side of engine bay with

a rope to avoid putting load on piping.

Refer to HA section in NISSAN Service Manual (Publication No.

SM9E-Y61CG2 or SM9E-Y61CG3).

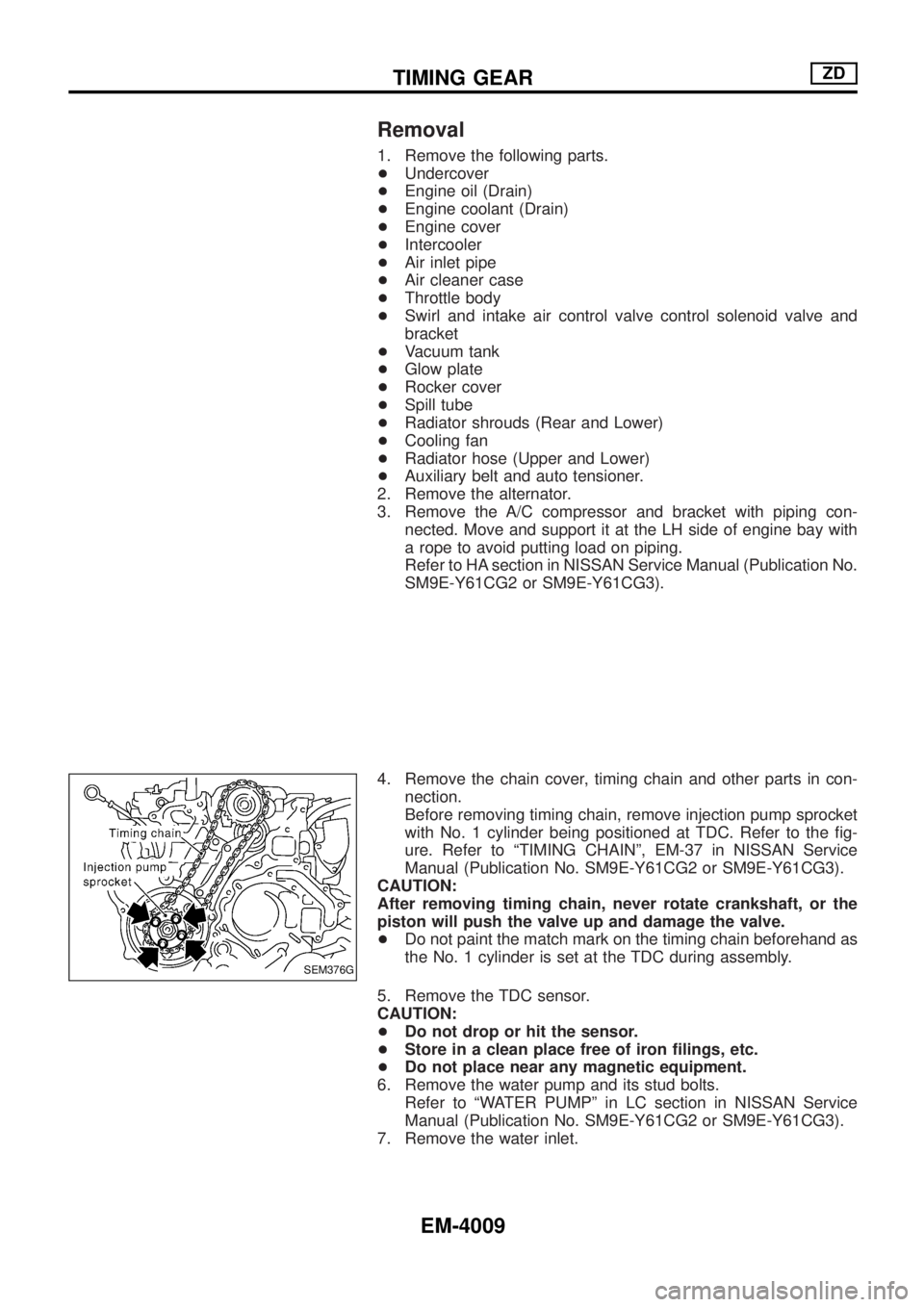

4. Remove the chain cover, timing chain and other parts in con-

nection.

Before removing timing chain, remove injection pump sprocket

with No. 1 cylinder being positioned at TDC. Refer to the ®g-

ure. Refer to ªTIMING CHAINº, EM-37 in NISSAN Service

Manual (Publication No. SM9E-Y61CG2 or SM9E-Y61CG3).

CAUTION:

After removing timing chain, never rotate crankshaft, or the

piston will push the valve up and damage the valve.

+Do not paint the match mark on the timing chain beforehand as

the No. 1 cylinder is set at the TDC during assembly.

5. Remove the TDC sensor.

CAUTION:

+Do not drop or hit the sensor.

+Store in a clean place free of iron ®lings, etc.

+Do not place near any magnetic equipment.

6. Remove the water pump and its stud bolts.

Refer to ªWATER PUMPº in LC section in NISSAN Service

Manual (Publication No. SM9E-Y61CG2 or SM9E-Y61CG3).

7. Remove the water inlet.

SEM376G

TIMING GEARZD

EM-4009

Page 452 of 579

8. Remove the crankshaft pulley.

+To ®x the crankshaft, remove the starter motor, and set ring

gear stopper (SST).

CAUTION:

+Do not damage or magnetize the signal detection protru-

sions of the crankshaft pulley.

+After removing timing chain, never rotate crankshaft, or

the piston will push the valve up and damage the valve.

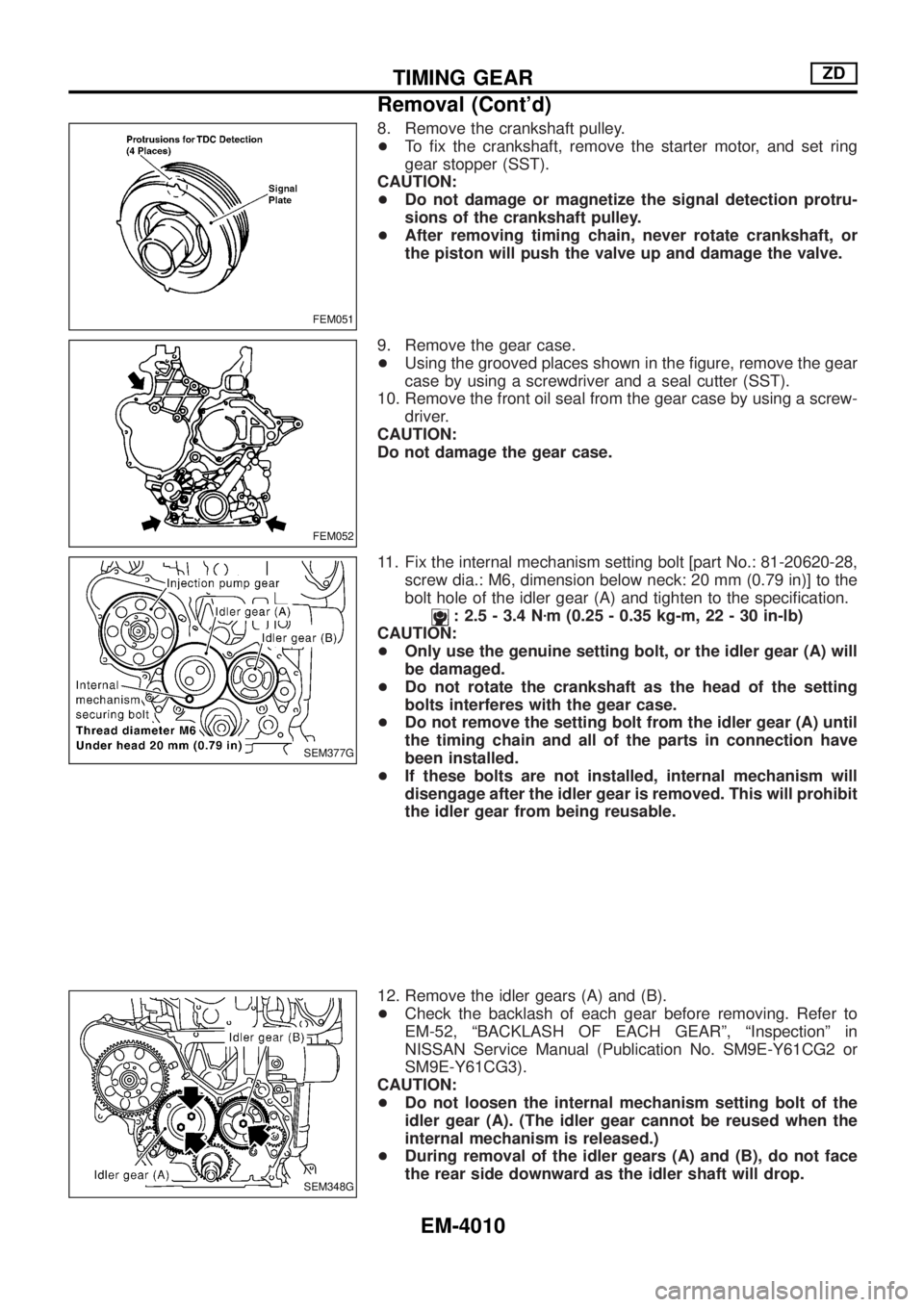

9. Remove the gear case.

+Using the grooved places shown in the ®gure, remove the gear

case by using a screwdriver and a seal cutter (SST).

10. Remove the front oil seal from the gear case by using a screw-

driver.

CAUTION:

Do not damage the gear case.

11. Fix the internal mechanism setting bolt [part No.: 81-20620-28,

screw dia.: M6, dimension below neck: 20 mm (0.79 in)] to the

bolt hole of the idler gear (A) and tighten to the speci®cation.

: 2.5 - 3.4 Nzm (0.25 - 0.35 kg-m, 22 - 30 in-lb)

CAUTION:

+Only use the genuine setting bolt, or the idler gear (A) will

be damaged.

+Do not rotate the crankshaft as the head of the setting

bolts interferes with the gear case.

+Do not remove the setting bolt from the idler gear (A) until

the timing chain and all of the parts in connection have

been installed.

+If these bolts are not installed, internal mechanism will

disengage after the idler gear is removed. This will prohibit

the idler gear from being reusable.

12. Remove the idler gears (A) and (B).

+Check the backlash of each gear before removing. Refer to

EM-52, ªBACKLASH OF EACH GEARº, ªInspectionº in

NISSAN Service Manual (Publication No. SM9E-Y61CG2 or

SM9E-Y61CG3).

CAUTION:

+Do not loosen the internal mechanism setting bolt of the

idler gear (A). (The idler gear cannot be reused when the

internal mechanism is released.)

+During removal of the idler gears (A) and (B), do not face

the rear side downward as the idler shaft will drop.

FEM051

FEM052

SEM377G

SEM348G

TIMING GEARZD

Removal (Cont'd)

EM-4010

Page 453 of 579

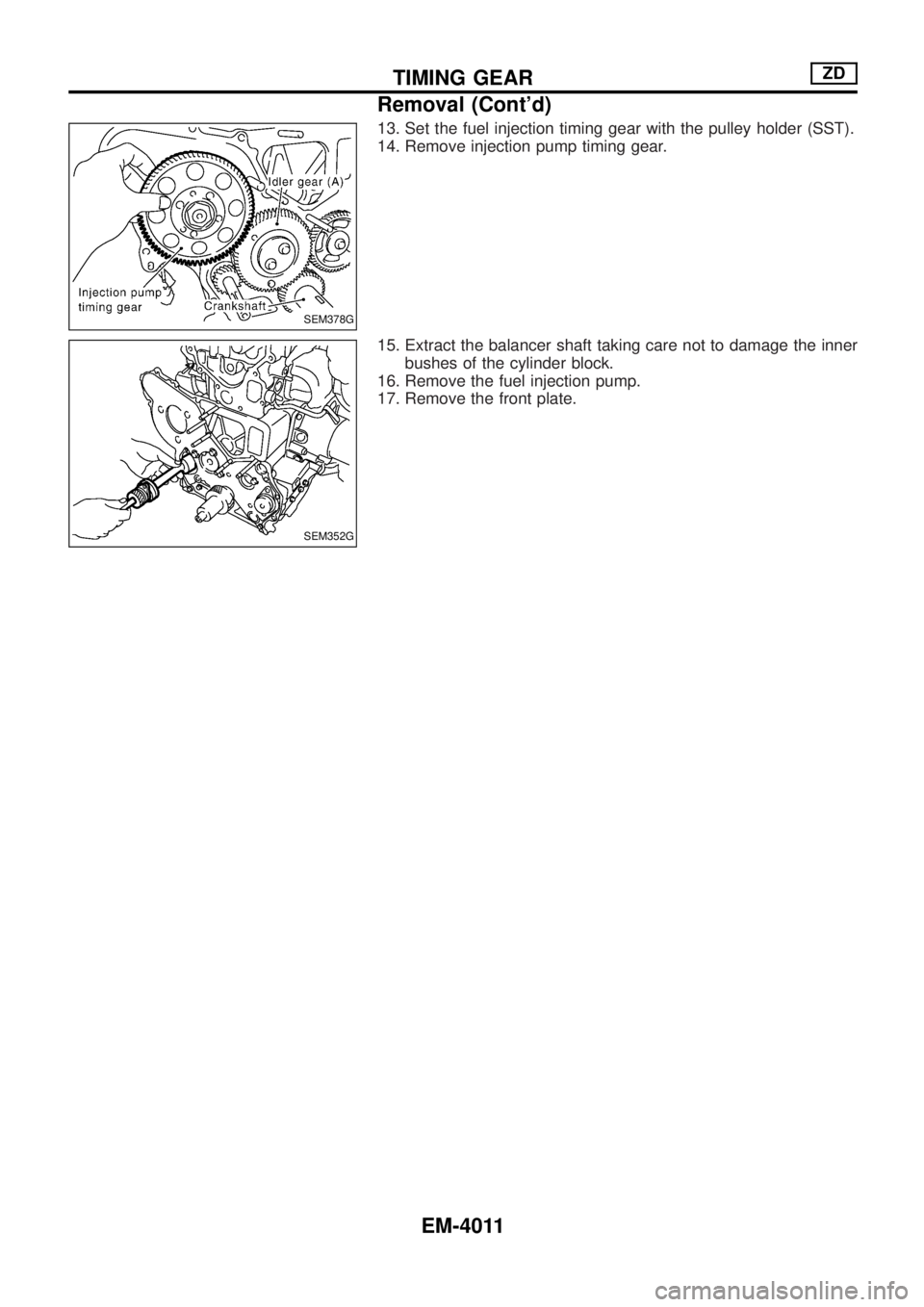

13. Set the fuel injection timing gear with the pulley holder (SST).

14. Remove injection pump timing gear.

15. Extract the balancer shaft taking care not to damage the inner

bushes of the cylinder block.

16. Remove the fuel injection pump.

17. Remove the front plate.

SEM378G

SEM352G

TIMING GEARZD

Removal (Cont'd)

EM-4011

Page 454 of 579

Installation

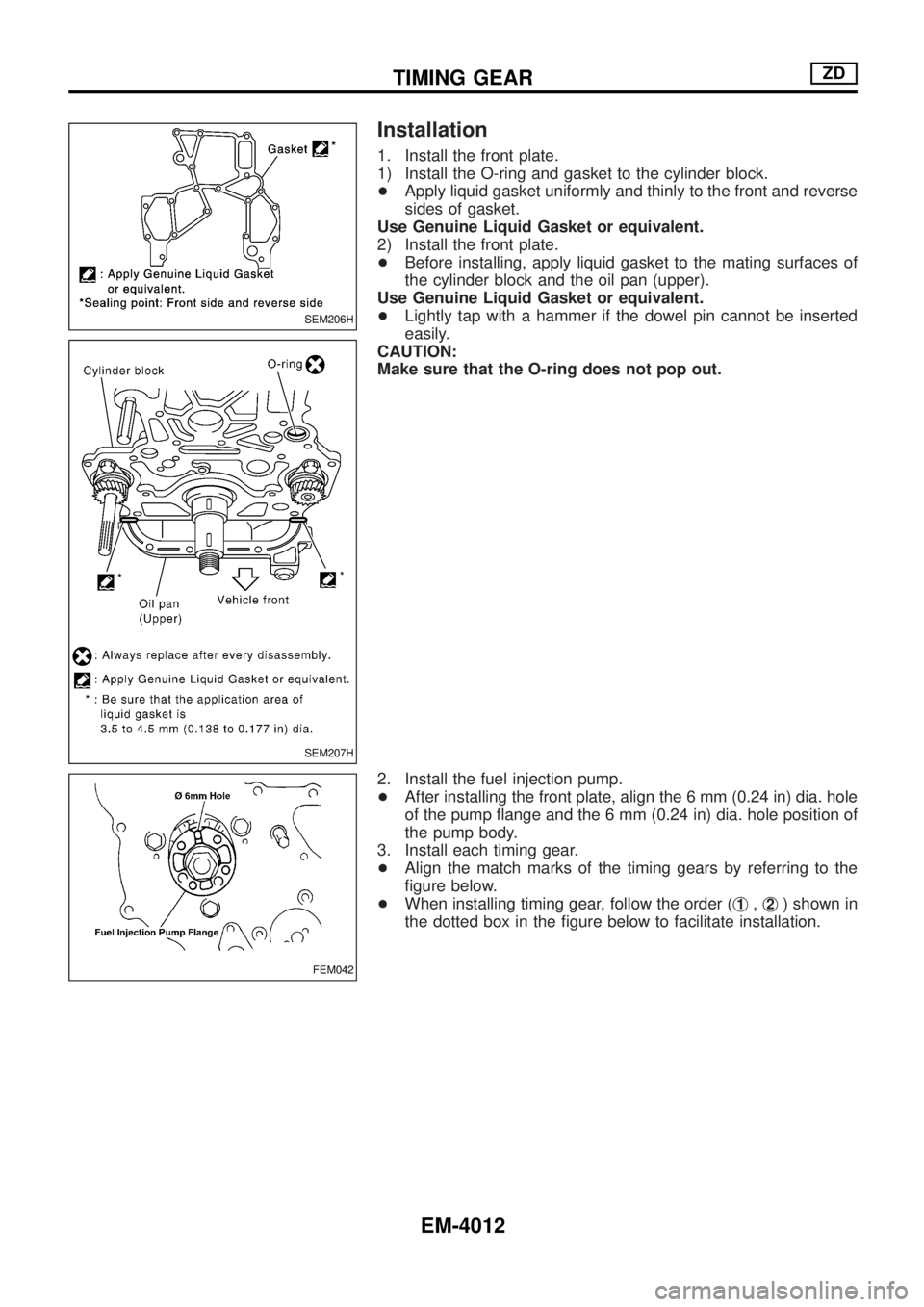

1. Install the front plate.

1) Install the O-ring and gasket to the cylinder block.

+Apply liquid gasket uniformly and thinly to the front and reverse

sides of gasket.

Use Genuine Liquid Gasket or equivalent.

2) Install the front plate.

+Before installing, apply liquid gasket to the mating surfaces of

the cylinder block and the oil pan (upper).

Use Genuine Liquid Gasket or equivalent.

+Lightly tap with a hammer if the dowel pin cannot be inserted

easily.

CAUTION:

Make sure that the O-ring does not pop out.

2. Install the fuel injection pump.

+After installing the front plate, align the 6 mm (0.24 in) dia. hole

of the pump ¯ange and the 6 mm (0.24 in) dia. hole position of

the pump body.

3. Install each timing gear.

+Align the match marks of the timing gears by referring to the

®gure below.

+When installing timing gear, follow the order (j

1,j2) shown in

the dotted box in the ®gure below to facilitate installation.

SEM206H

SEM207H

FEM042

TIMING GEARZD

EM-4012

Page 455 of 579

![NISSAN PATROL 2004 Electronic Repair Manual 4. Install the front oil seal to the gear case.

+Apply engine oil to the ®tting side.

+Evenly insert the front oil seal using a drift [outer dia.: approx.

64 mm (2.52 in)] completely.

CAUTION:

Make s NISSAN PATROL 2004 Electronic Repair Manual 4. Install the front oil seal to the gear case.

+Apply engine oil to the ®tting side.

+Evenly insert the front oil seal using a drift [outer dia.: approx.

64 mm (2.52 in)] completely.

CAUTION:

Make s](/img/5/57364/w960_57364-454.png)

4. Install the front oil seal to the gear case.

+Apply engine oil to the ®tting side.

+Evenly insert the front oil seal using a drift [outer dia.: approx.

64 mm (2.52 in)] completely.

CAUTION:

Make sure the oil seal does not spill off the end side of the gear

case.

5. Install the gear case.

1) Before installing gear case, remove all traces of liquid gasket

from mating surface using a scraper.

2) Align gasket with dowel and install.

FEM043

FEM044

SEM353G

TIMING GEARZD

Installation (Cont'd)

EM-4013

Page 456 of 579

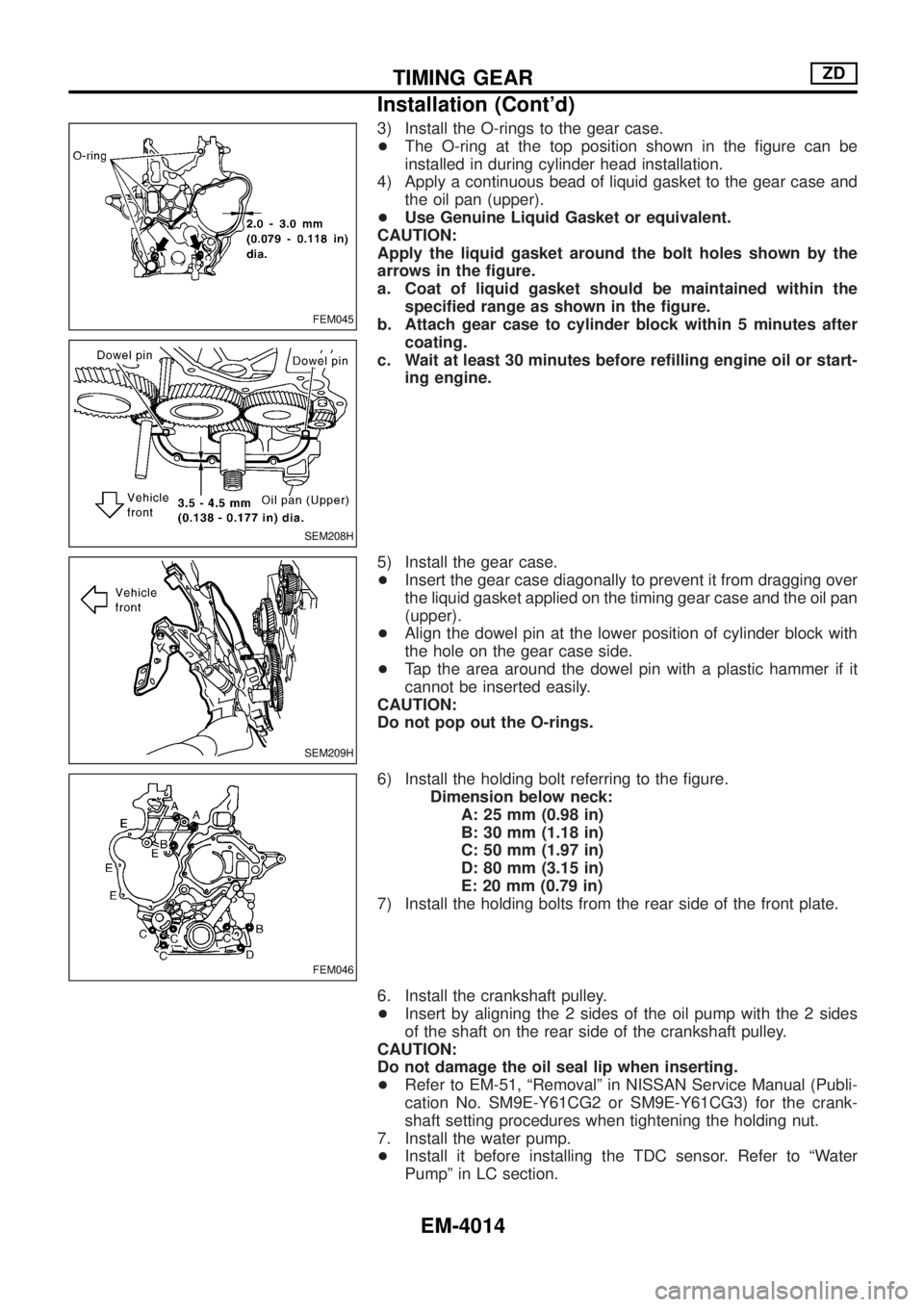

3) Install the O-rings to the gear case.

+The O-ring at the top position shown in the ®gure can be

installed in during cylinder head installation.

4) Apply a continuous bead of liquid gasket to the gear case and

the oil pan (upper).

+Use Genuine Liquid Gasket or equivalent.

CAUTION:

Apply the liquid gasket around the bolt holes shown by the

arrows in the ®gure.

a. Coat of liquid gasket should be maintained within the

speci®ed range as shown in the ®gure.

b. Attach gear case to cylinder block within 5 minutes after

coating.

c. Wait at least 30 minutes before re®lling engine oil or start-

ing engine.

5) Install the gear case.

+Insert the gear case diagonally to prevent it from dragging over

the liquid gasket applied on the timing gear case and the oil pan

(upper).

+Align the dowel pin at the lower position of cylinder block with

the hole on the gear case side.

+Tap the area around the dowel pin with a plastic hammer if it

cannot be inserted easily.

CAUTION:

Do not pop out the O-rings.

6) Install the holding bolt referring to the ®gure.

Dimension below neck:

A: 25 mm (0.98 in)

B: 30 mm (1.18 in)

C: 50 mm (1.97 in)

D: 80 mm (3.15 in)

E: 20 mm (0.79 in)

7) Install the holding bolts from the rear side of the front plate.

6. Install the crankshaft pulley.

+Insert by aligning the 2 sides of the oil pump with the 2 sides

of the shaft on the rear side of the crankshaft pulley.

CAUTION:

Do not damage the oil seal lip when inserting.

+Refer to EM-51, ªRemovalº in NISSAN Service Manual (Publi-

cation No. SM9E-Y61CG2 or SM9E-Y61CG3) for the crank-

shaft setting procedures when tightening the holding nut.

7. Install the water pump.

+Install it before installing the TDC sensor. Refer to ªWater

Pumpº in LC section.

FEM045

SEM208H

SEM209H

FEM046

TIMING GEARZD

Installation (Cont'd)

EM-4014

Page 457 of 579

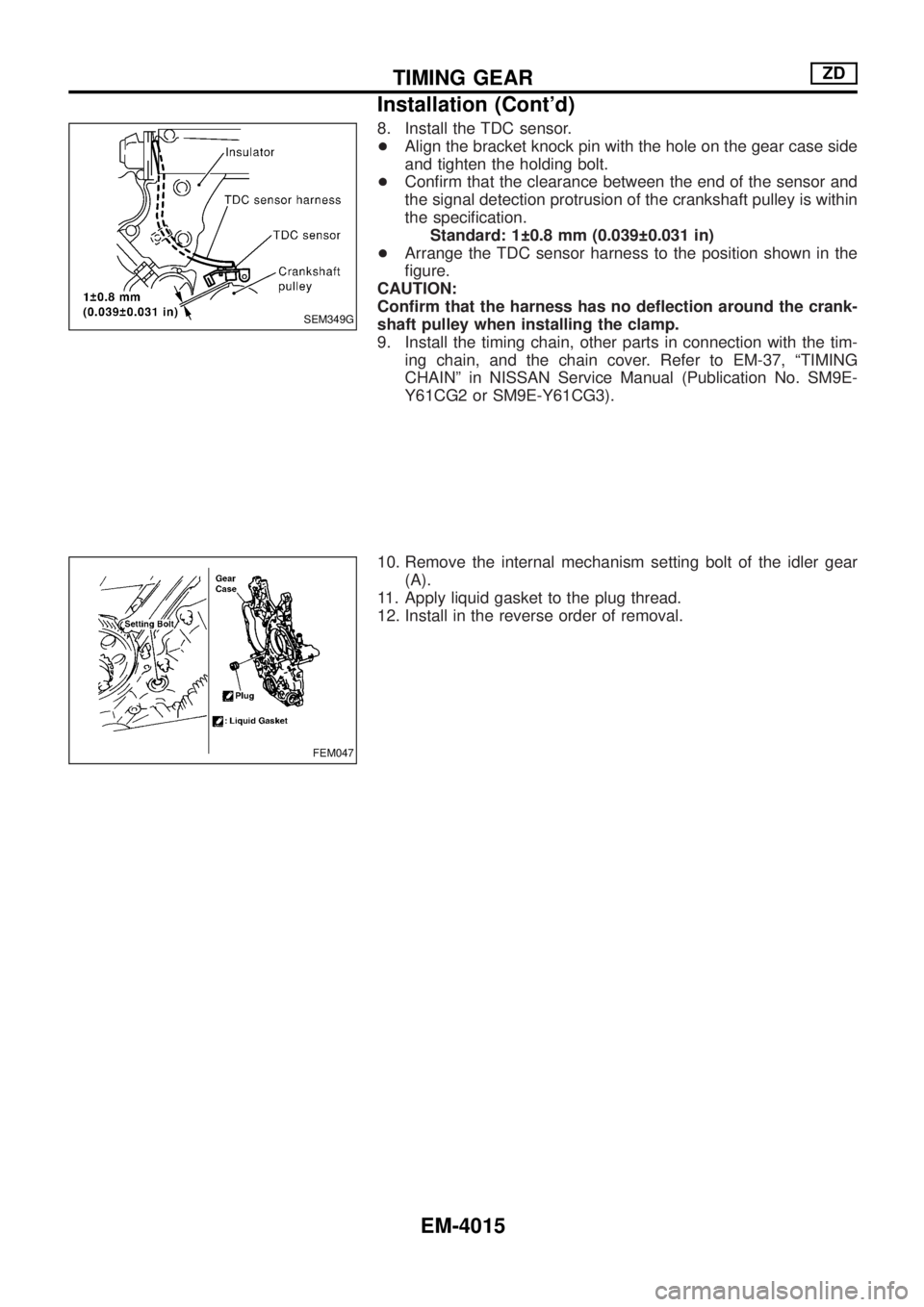

8. Install the TDC sensor.

+Align the bracket knock pin with the hole on the gear case side

and tighten the holding bolt.

+Con®rm that the clearance between the end of the sensor and

the signal detection protrusion of the crankshaft pulley is within

the speci®cation.

Standard: 1 0.8 mm (0.039 0.031 in)

+Arrange the TDC sensor harness to the position shown in the

®gure.

CAUTION:

Con®rm that the harness has no de¯ection around the crank-

shaft pulley when installing the clamp.

9. Install the timing chain, other parts in connection with the tim-

ing chain, and the chain cover. Refer to EM-37, ªTIMING

CHAINº in NISSAN Service Manual (Publication No. SM9E-

Y61CG2 or SM9E-Y61CG3).

10. Remove the internal mechanism setting bolt of the idler gear

(A).

11. Apply liquid gasket to the plug thread.

12. Install in the reverse order of removal.

SEM349G

FEM047

TIMING GEARZD

Installation (Cont'd)

EM-4015

Page 458 of 579

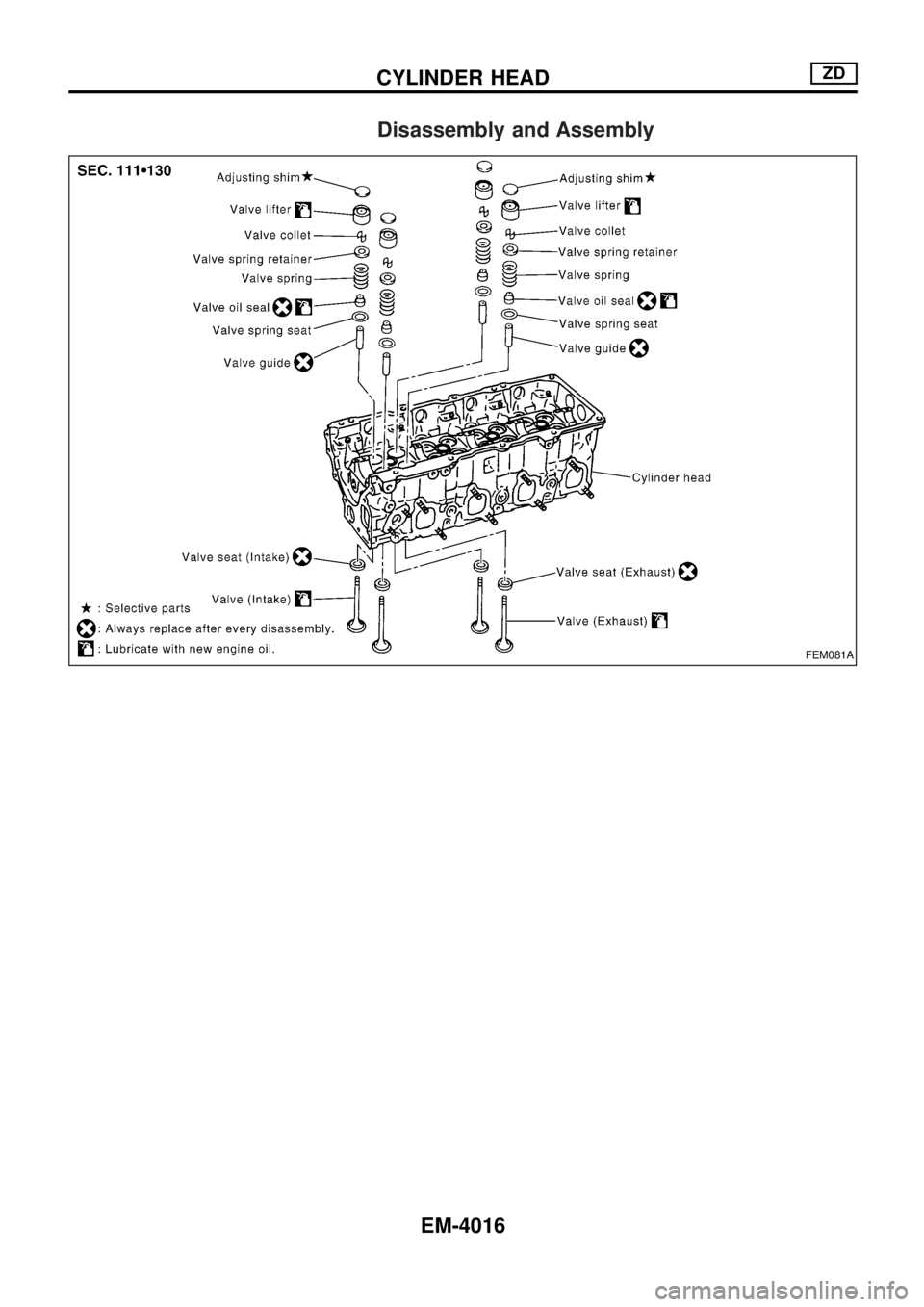

Disassembly and Assembly

FEM081A

CYLINDER HEADZD

EM-4016

Page 459 of 579

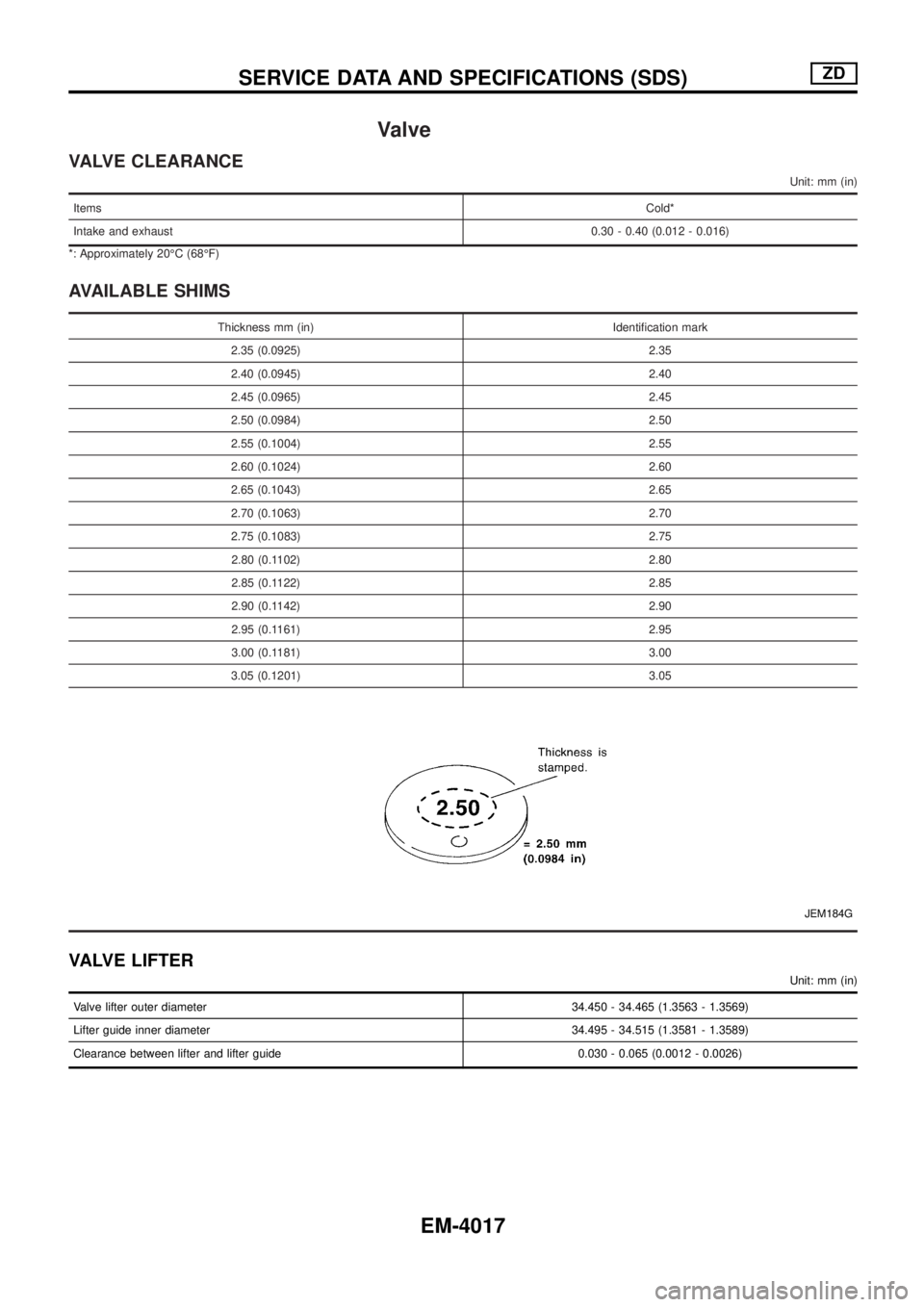

Valve

VALVE CLEARANCE

Unit: mm (in)

ItemsCold*

Intake and exhaust0.30 - 0.40 (0.012 - 0.016)

*: Approximately 20ÉC (68ÉF)

AVAILABLE SHIMS

Thickness mm (in) Identi®cation mark

2.35 (0.0925) 2.35

2.40 (0.0945) 2.40

2.45 (0.0965) 2.45

2.50 (0.0984) 2.50

2.55 (0.1004) 2.55

2.60 (0.1024) 2.60

2.65 (0.1043) 2.65

2.70 (0.1063) 2.70

2.75 (0.1083) 2.75

2.80 (0.1102) 2.80

2.85 (0.1122) 2.85

2.90 (0.1142) 2.90

2.95 (0.1161) 2.95

3.00 (0.1181) 3.00

3.05 (0.1201) 3.05

JEM184G

VALVE LIFTER

Unit: mm (in)

Valve lifter outer diameter 34.450 - 34.465 (1.3563 - 1.3569)

Lifter guide inner diameter 34.495 - 34.515 (1.3581 - 1.3589)

Clearance between lifter and lifter guide 0.030 - 0.065 (0.0012 - 0.0026)

SERVICE DATA AND SPECIFICATIONS (SDS)ZD

EM-4017

Page 460 of 579

EXHAUST SYSTEMS

SECTION

FE

MODIFICATION NOTICE:

+ Wiring diagram of sub fuel tank control system has been modi®ed.

CONTENTS

TROUBLE DIAGNOSES ...........................................4002

Self-diagnosis for Sub Fuel Tank Control Module.4002

Circuit Diagram Ð S/TANK Ð ..............................4003 Wiring Diagram Ð S/TANK Ð ..............................4004

EXHAUST SYSTEM ..................................................4008

FE-4001