NISSAN PATROL 2004 Electronic Repair Manual

PATROL 2004

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57364/w960_57364-0.png

NISSAN PATROL 2004 Electronic Repair Manual

Trending: fuses, diagram, battery location, engine oil, audio, General information, service

Page 511 of 579

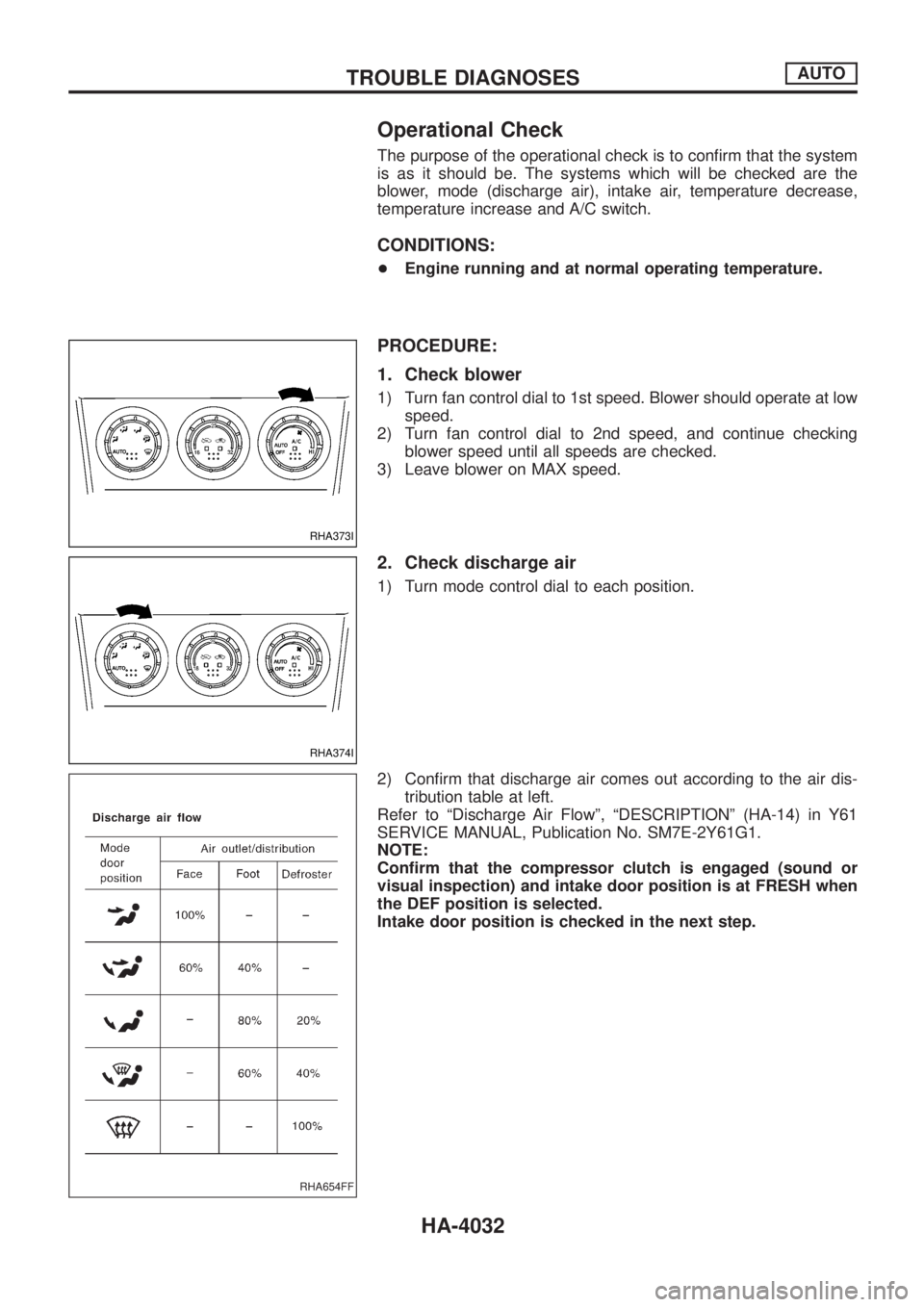

Operational Check

The purpose of the operational check is to con®rm that the system

is as it should be. The systems which will be checked are the

blower, mode (discharge air), intake air, temperature decrease,

temperature increase and A/C switch.

CONDITIONS:

+Engine running and at normal operating temperature.

PROCEDURE:

1. Check blower

1) Turn fan control dial to 1st speed. Blower should operate at low

speed.

2) Turn fan control dial to 2nd speed, and continue checking

blower speed until all speeds are checked.

3) Leave blower on MAX speed.

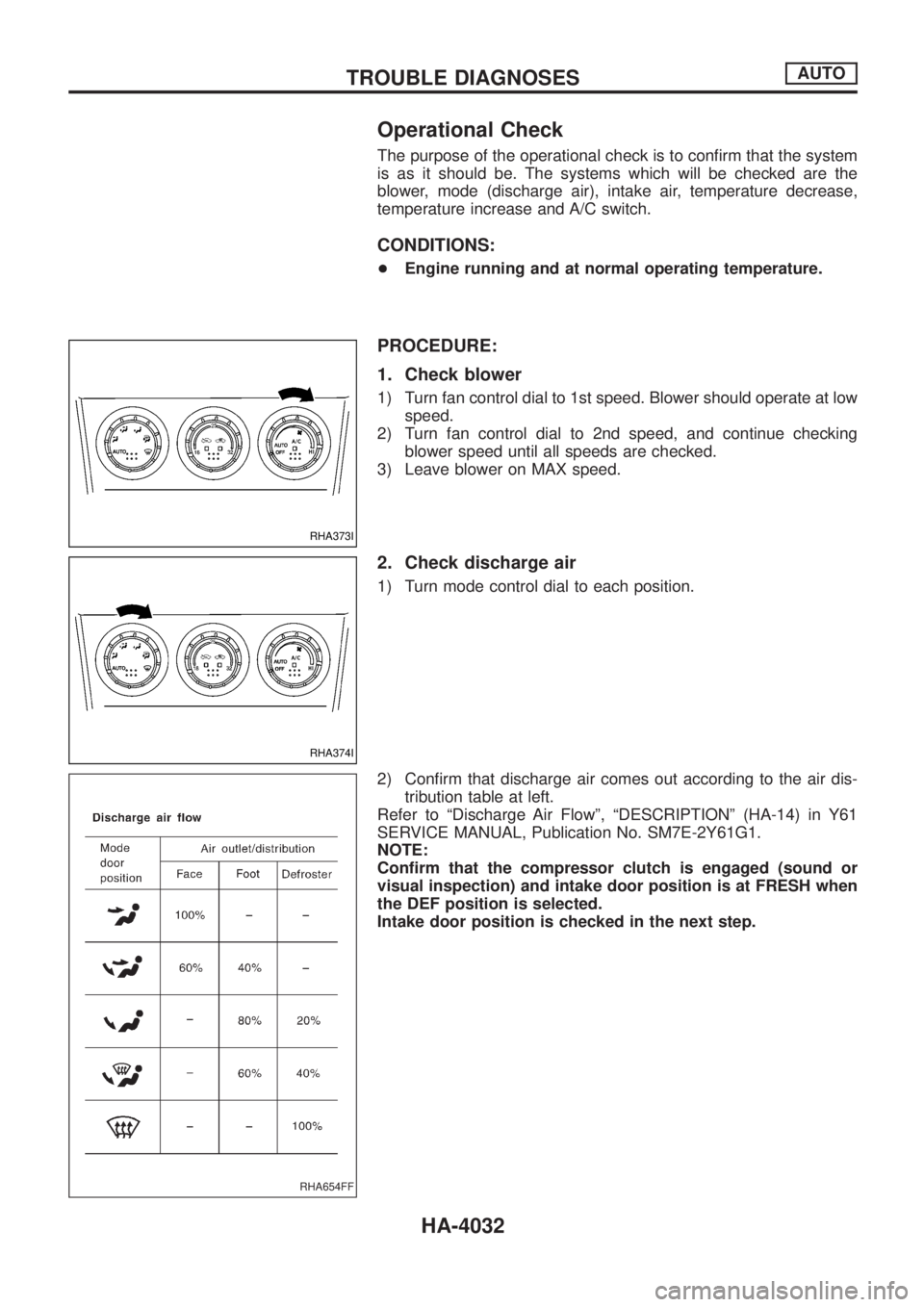

2. Check discharge air

1) Turn mode control dial to each position.

2) Con®rm that discharge air comes out according to the air dis-

tribution table at left.

Refer to ªDischarge Air Flowº, ªDESCRIPTIONº (HA-14) in Y61

SERVICE MANUAL, Publication No. SM7E-2Y61G1.

NOTE:

Con®rm that the compressor clutch is engaged (sound or

visual inspection) and intake door position is at FRESH when

the DEF position is selected.

Intake door position is checked in the next step.

RHA373I

RHA374I

RHA654FF

TROUBLE DIAGNOSESAUTO

HA-4032

Page 512 of 579

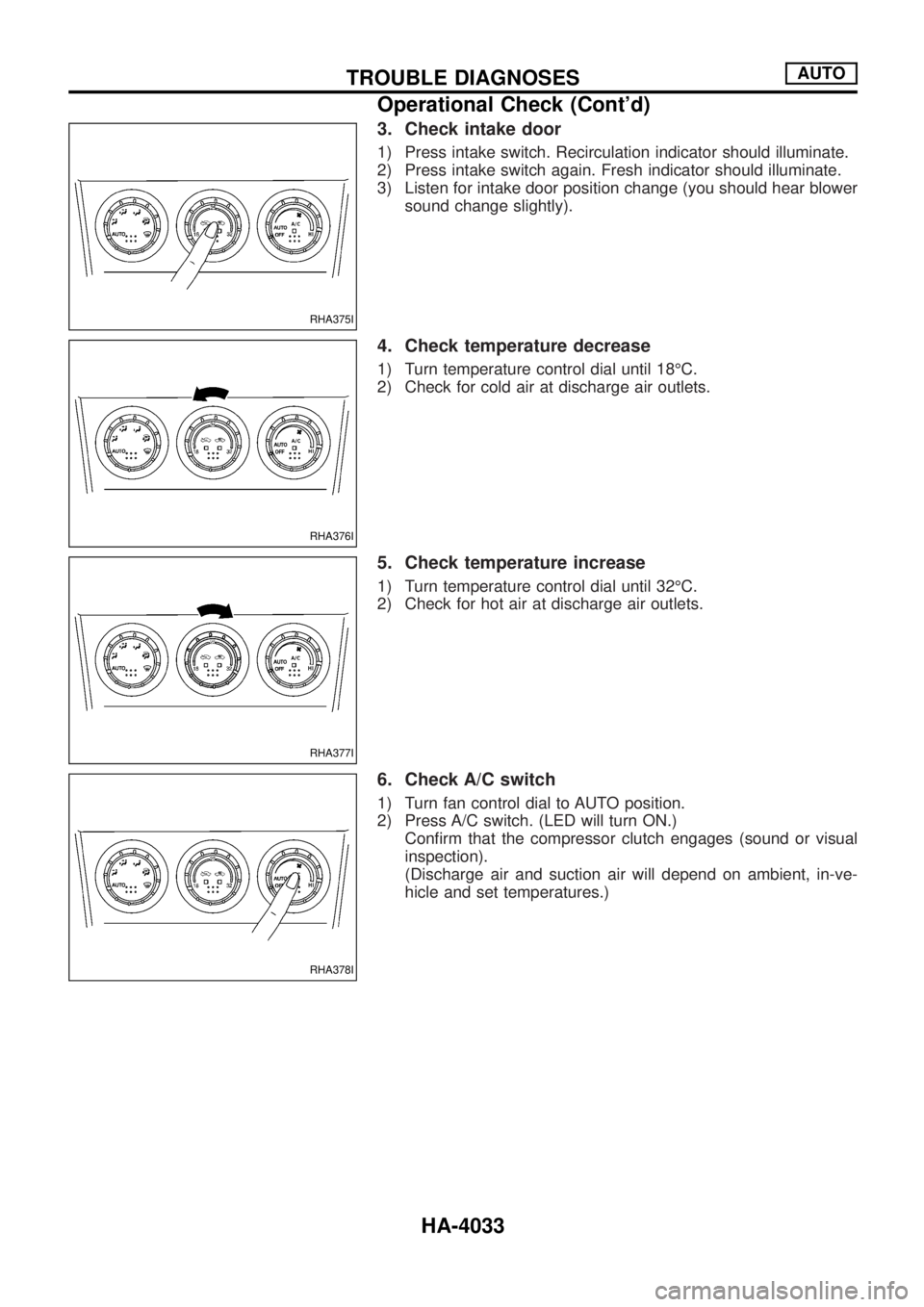

3. Check intake door

1) Press intake switch. Recirculation indicator should illuminate.

2) Press intake switch again. Fresh indicator should illuminate.

3) Listen for intake door position change (you should hear blower

sound change slightly).

4. Check temperature decrease

1) Turn temperature control dial until 18ÉC.

2) Check for cold air at discharge air outlets.

5. Check temperature increase

1) Turn temperature control dial until 32ÉC.

2) Check for hot air at discharge air outlets.

6. Check A/C switch

1) Turn fan control dial to AUTO position.

2) Press A/C switch. (LED will turn ON.)

Con®rm that the compressor clutch engages (sound or visual

inspection).

(Discharge air and suction air will depend on ambient, in-ve-

hicle and set temperatures.)

RHA375I

RHA376I

RHA377I

RHA378I

TROUBLE DIAGNOSESAUTO

Operational Check (Cont'd)

HA-4033

Page 513 of 579

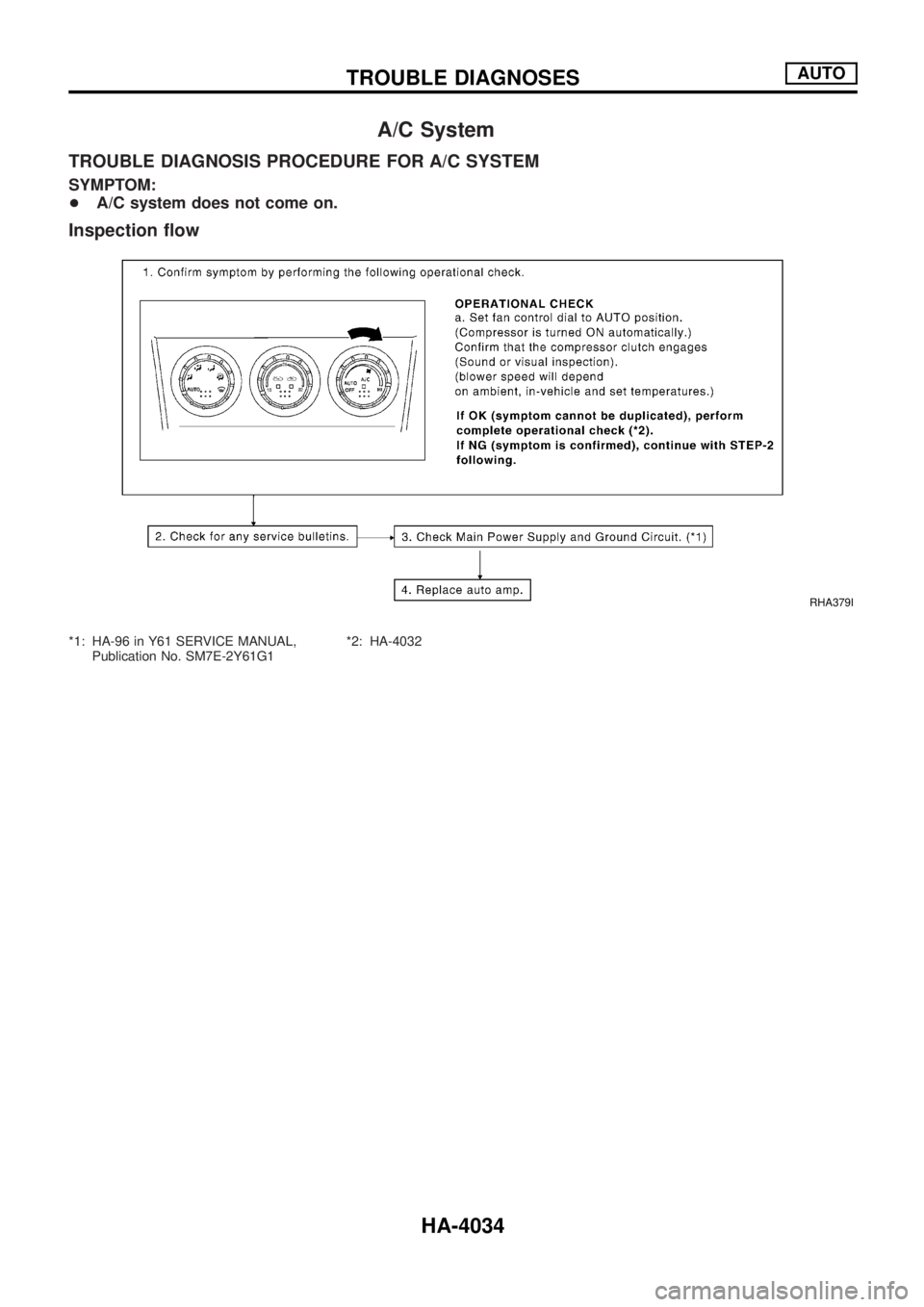

A/C System

TROUBLE DIAGNOSIS PROCEDURE FOR A/C SYSTEM

SYMPTOM:

+A/C system does not come on.

Inspection ¯ow

*1: HA-96 in Y61 SERVICE MANUAL,

Publication No. SM7E-2Y61G1*2: HA-4032

RHA379I

TROUBLE DIAGNOSESAUTO

HA-4034

Page 514 of 579

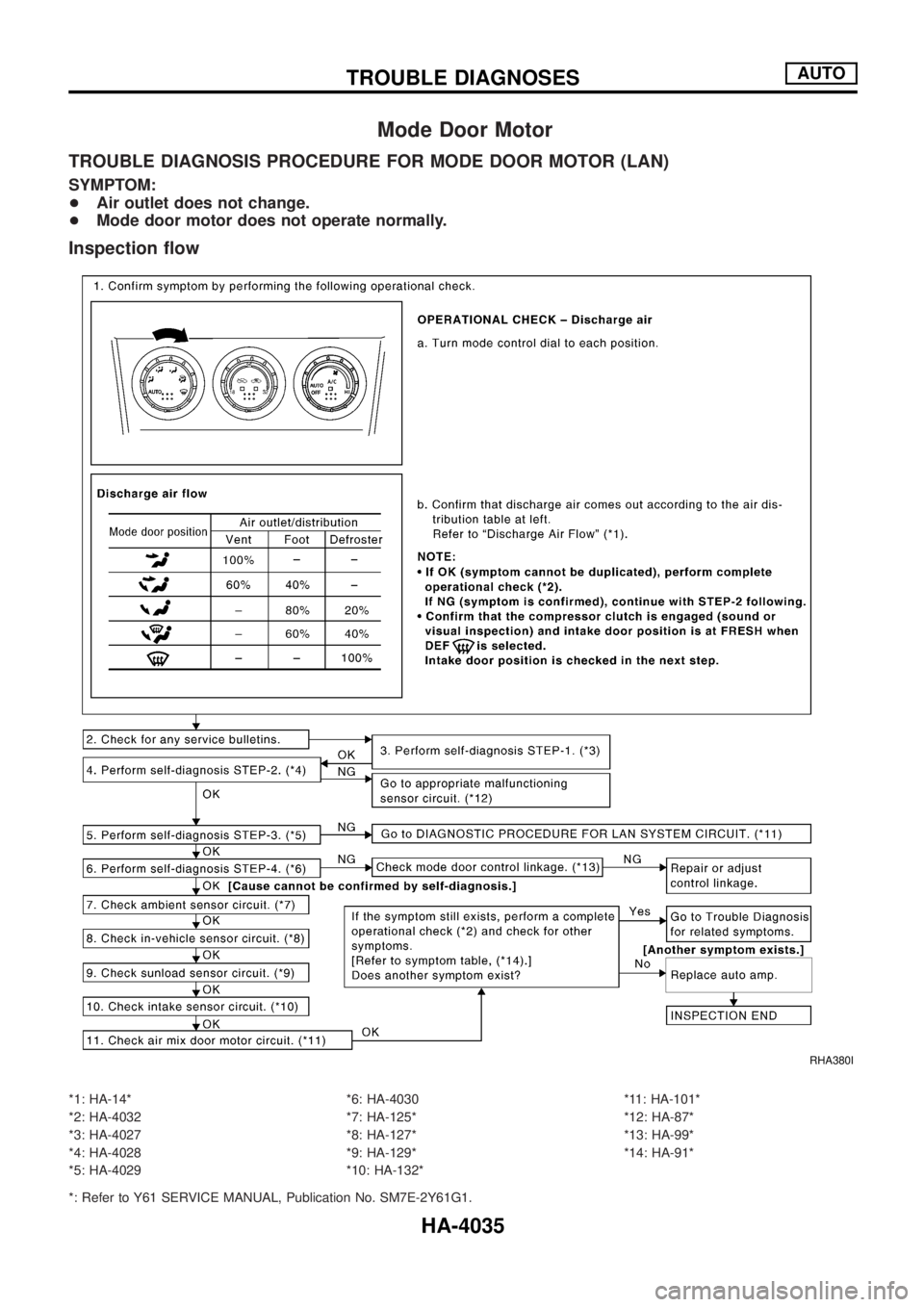

Mode Door Motor

TROUBLE DIAGNOSIS PROCEDURE FOR MODE DOOR MOTOR (LAN)

SYMPTOM:

+Air outlet does not change.

+Mode door motor does not operate normally.

Inspection ¯ow

*1: HA-14*

*2: HA-4032

*3: HA-4027

*4: HA-4028

*5: HA-4029*6: HA-4030

*7: HA-125*

*8: HA-127*

*9: HA-129*

*10: HA-132**11: HA-101*

*12: HA-87*

*13: HA-99*

*14: HA-91*

*: Refer to Y61 SERVICE MANUAL, Publication No. SM7E-2Y61G1.

RHA380I

TROUBLE DIAGNOSESAUTO

HA-4035

Page 515 of 579

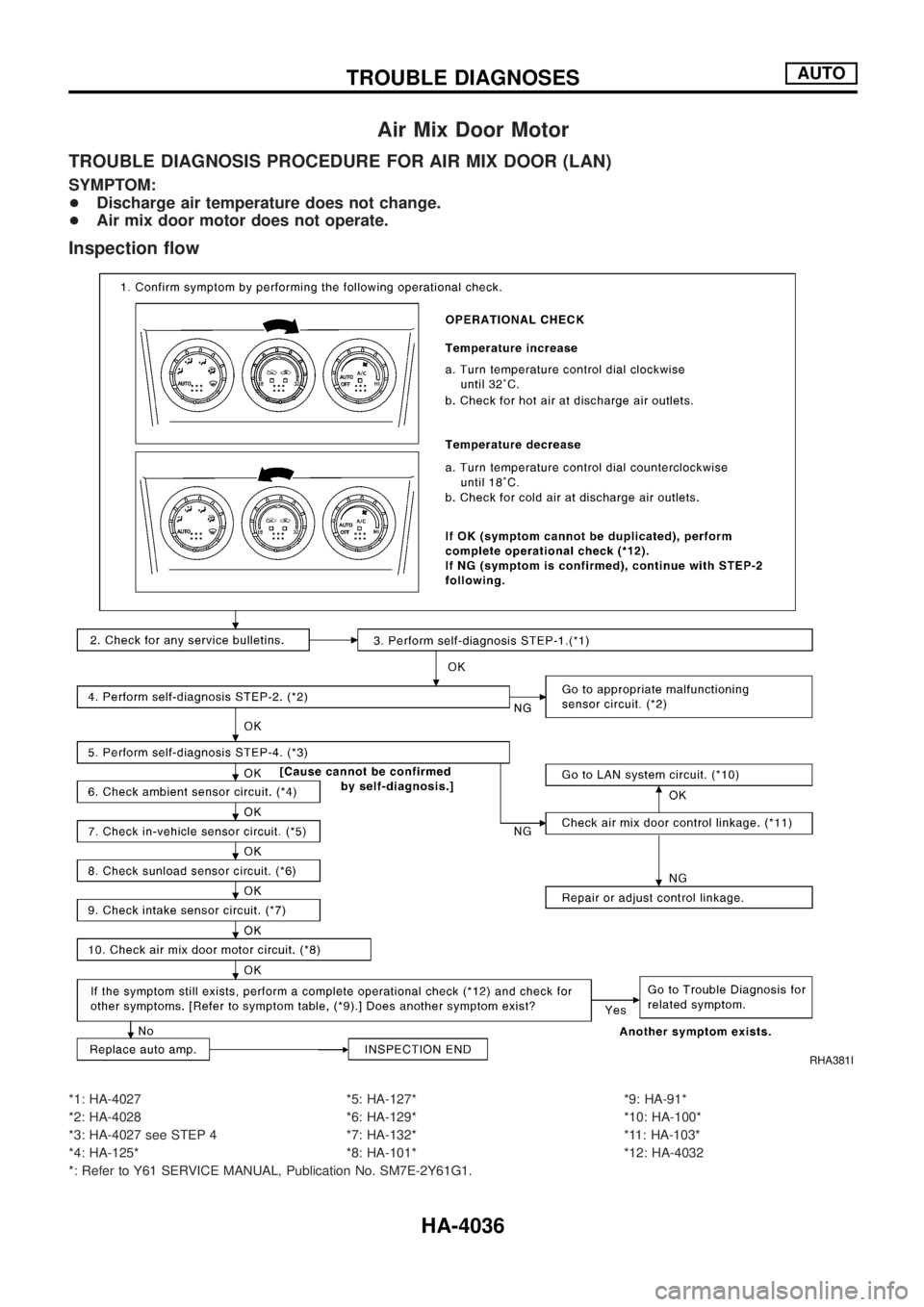

Air Mix Door Motor

TROUBLE DIAGNOSIS PROCEDURE FOR AIR MIX DOOR (LAN)

SYMPTOM:

+Discharge air temperature does not change.

+Air mix door motor does not operate.

Inspection ¯ow

*1: HA-4027

*2: HA-4028

*3: HA-4027 see STEP 4

*4: HA-125**5: HA-127*

*6: HA-129*

*7: HA-132*

*8: HA-101**9: HA-91*

*10: HA-100*

*11: HA-103*

*12: HA-4032

*: Refer to Y61 SERVICE MANUAL, Publication No. SM7E-2Y61G1.

RHA381I

TROUBLE DIAGNOSESAUTO

HA-4036

Page 516 of 579

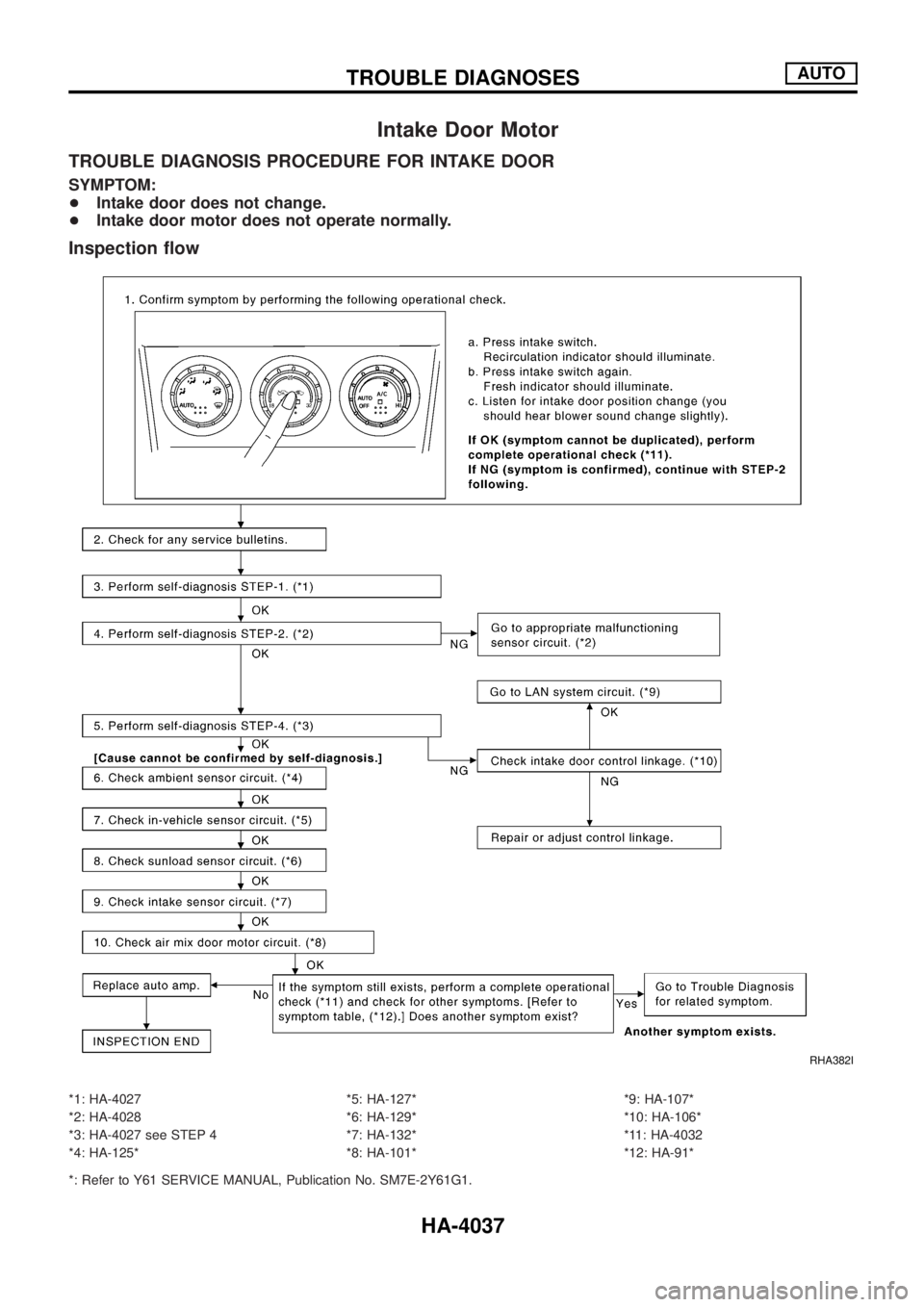

Intake Door Motor

TROUBLE DIAGNOSIS PROCEDURE FOR INTAKE DOOR

SYMPTOM:

+Intake door does not change.

+Intake door motor does not operate normally.

Inspection ¯ow

*1: HA-4027

*2: HA-4028

*3: HA-4027 see STEP 4

*4: HA-125**5: HA-127*

*6: HA-129*

*7: HA-132*

*8: HA-101**9: HA-107*

*10: HA-106*

*11: HA-4032

*12: HA-91*

*: Refer to Y61 SERVICE MANUAL, Publication No. SM7E-2Y61G1.

RHA382I

TROUBLE DIAGNOSESAUTO

HA-4037

Page 517 of 579

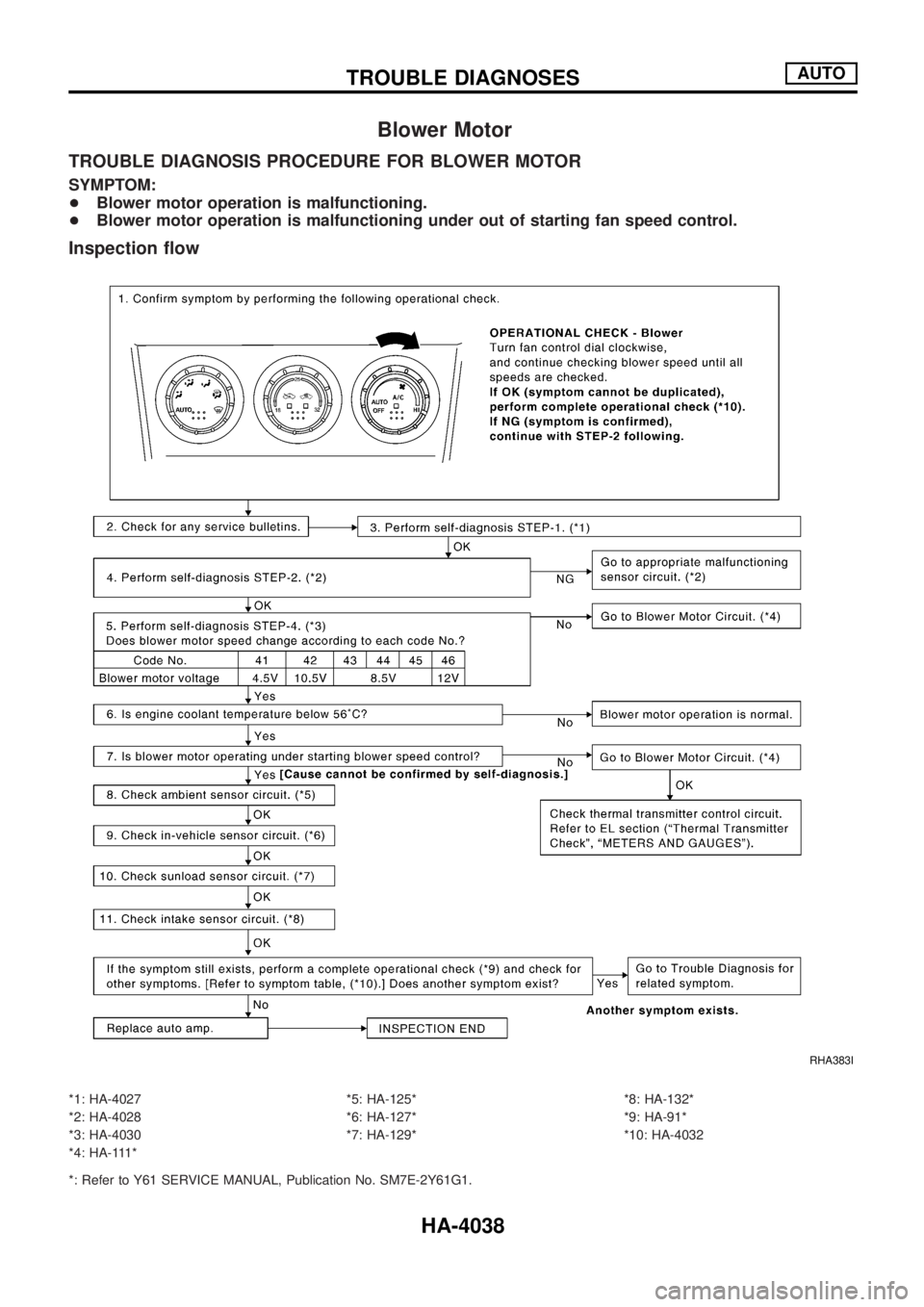

Blower Motor

TROUBLE DIAGNOSIS PROCEDURE FOR BLOWER MOTOR

SYMPTOM:

+Blower motor operation is malfunctioning.

+Blower motor operation is malfunctioning under out of starting fan speed control.

Inspection ¯ow

*1: HA-4027

*2: HA-4028

*3: HA-4030

*4: HA-111**5: HA-125*

*6: HA-127*

*7: HA-129**8: HA-132*

*9: HA-91*

*10: HA-4032

*: Refer to Y61 SERVICE MANUAL, Publication No. SM7E-2Y61G1.

RHA383I

TROUBLE DIAGNOSESAUTO

HA-4038

Page 518 of 579

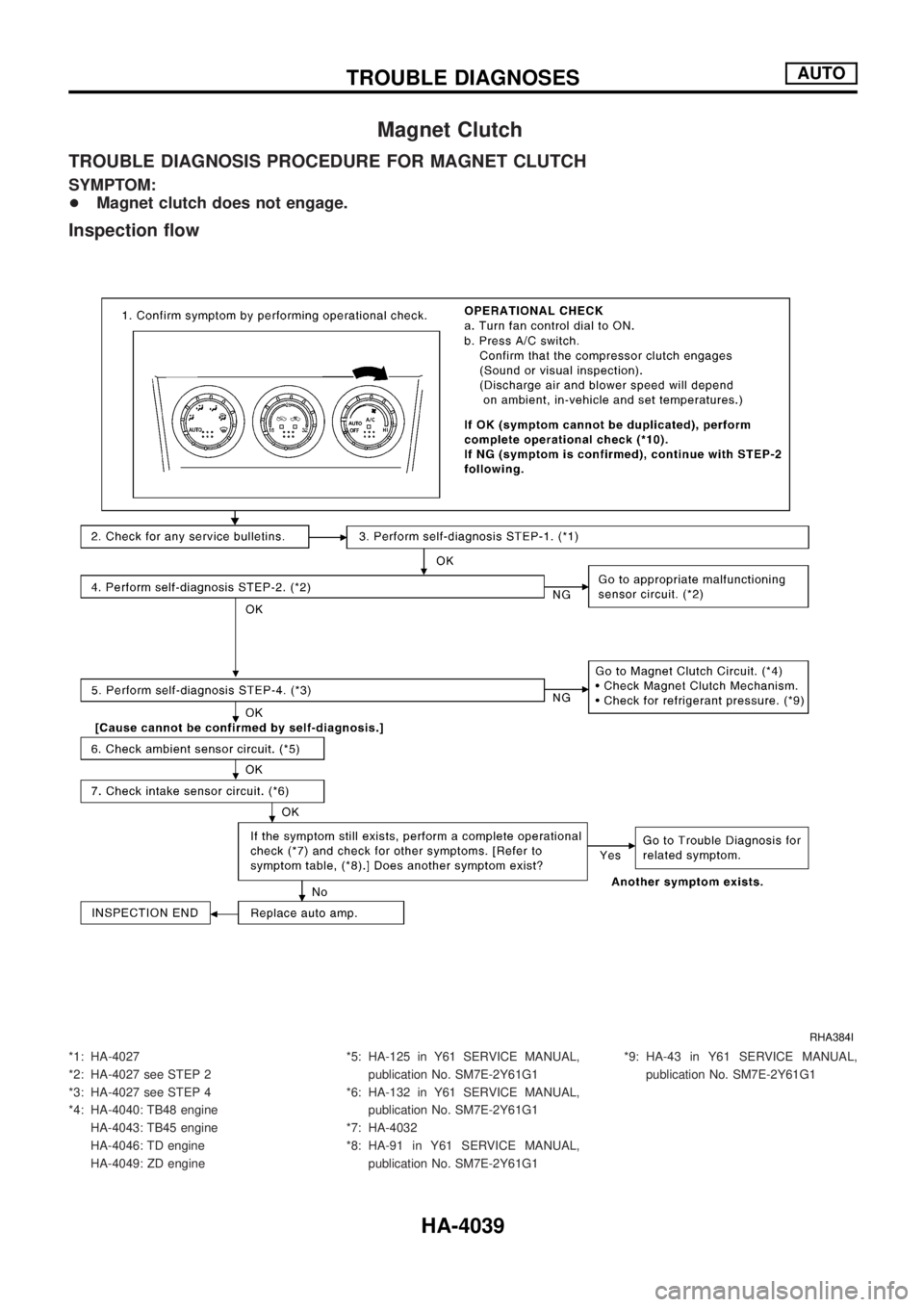

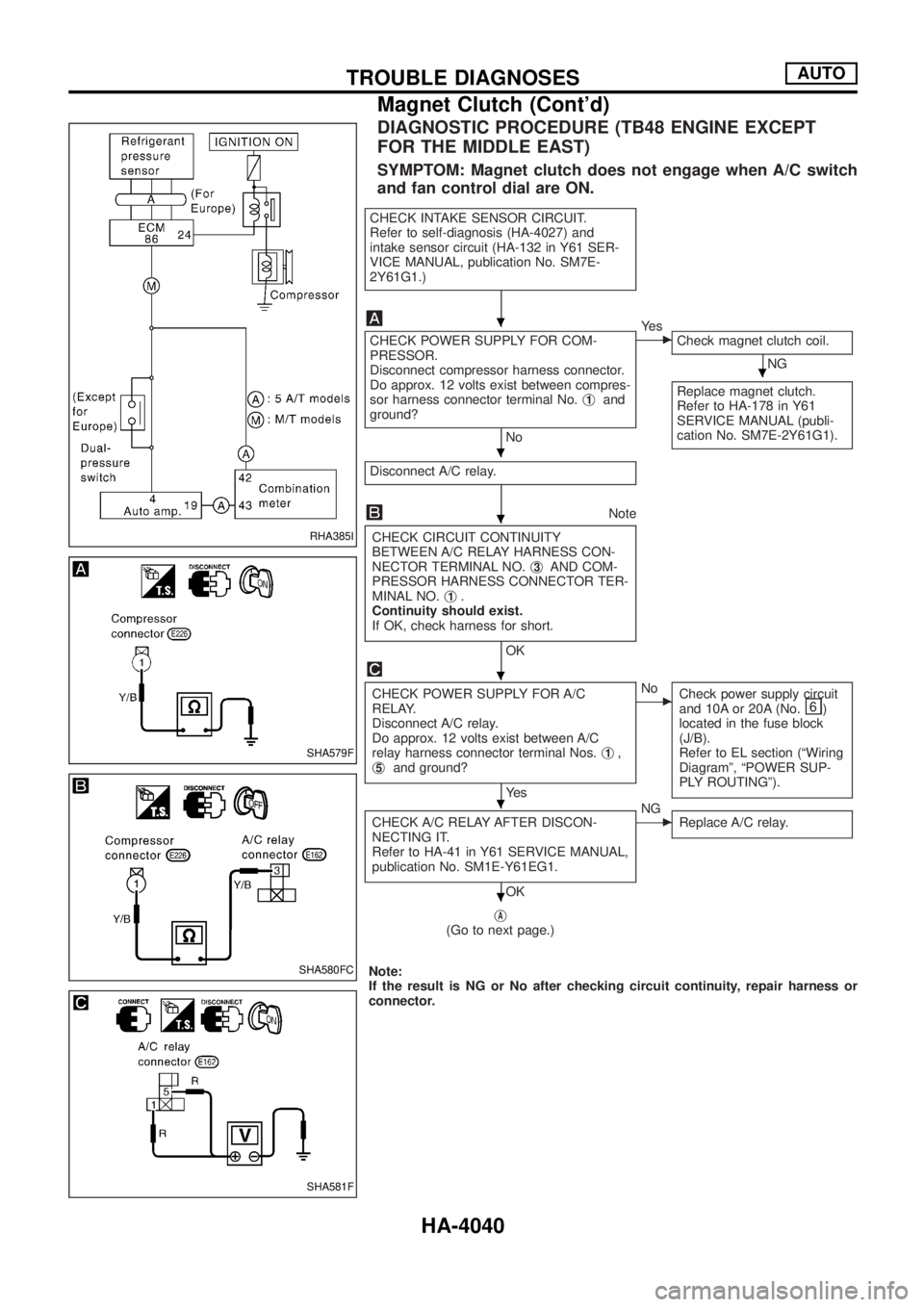

Magnet Clutch

TROUBLE DIAGNOSIS PROCEDURE FOR MAGNET CLUTCH

SYMPTOM:

+Magnet clutch does not engage.

Inspection ¯ow

*1: HA-4027

*2: HA-4027 see STEP 2

*3: HA-4027 see STEP 4

*4: HA-4040: TB48 engine

HA-4043: TB45 engine

HA-4046: TD engine

HA-4049: ZD engine*5: HA-125 in Y61 SERVICE MANUAL,

publication No. SM7E-2Y61G1

*6: HA-132 in Y61 SERVICE MANUAL,

publication No. SM7E-2Y61G1

*7: HA-4032

*8: HA-91 in Y61 SERVICE MANUAL,

publication No. SM7E-2Y61G1*9: HA-43 in Y61 SERVICE MANUAL,

publication No. SM7E-2Y61G1

RHA384I

TROUBLE DIAGNOSESAUTO

HA-4039

Page 519 of 579

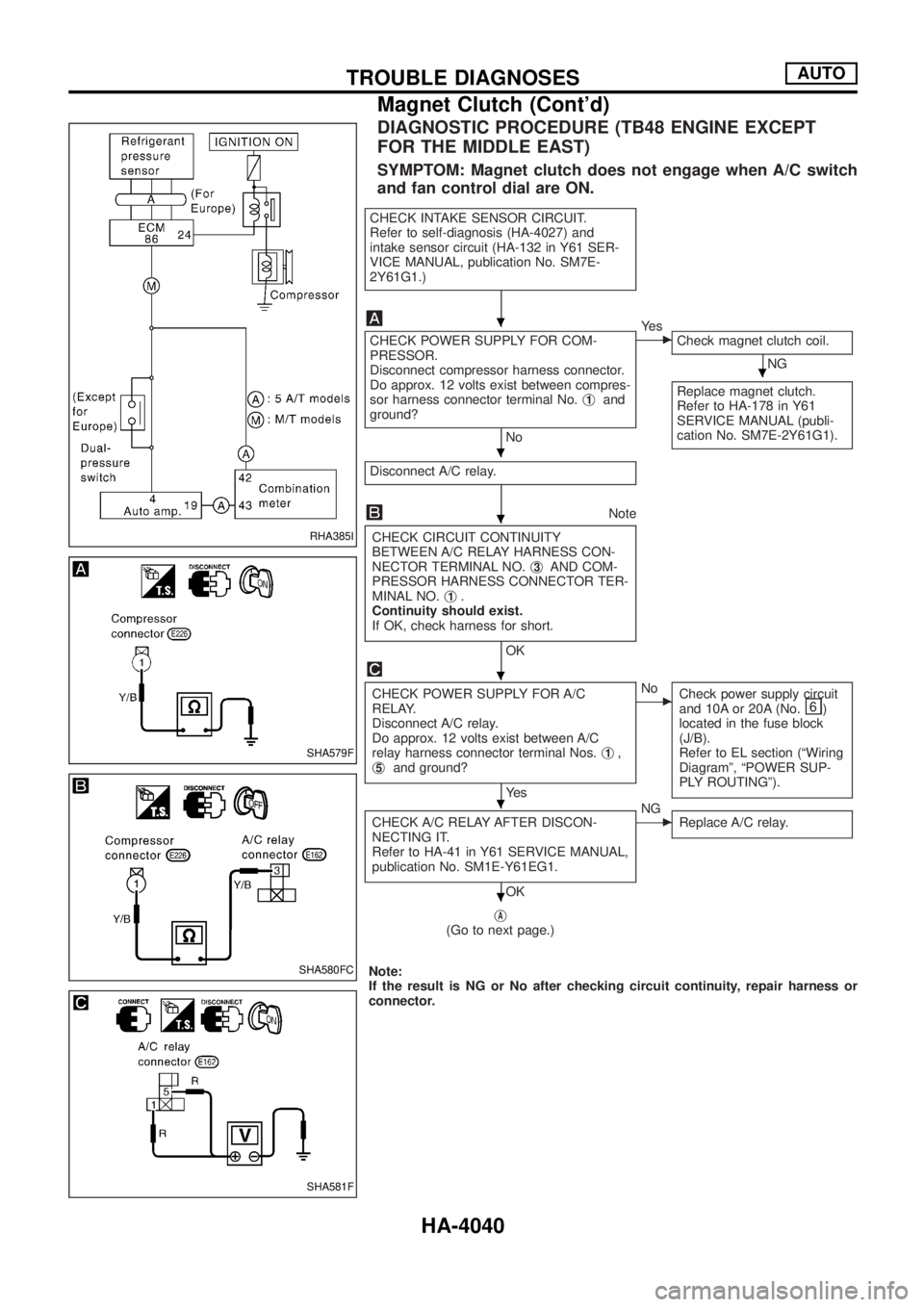

DIAGNOSTIC PROCEDURE (TB48 ENGINE EXCEPT

FOR THE MIDDLE EAST)

SYMPTOM: Magnet clutch does not engage when A/C switch

and fan control dial are ON.

CHECK INTAKE SENSOR CIRCUIT.

Refer to self-diagnosis (HA-4027) and

intake sensor circuit (HA-132 in Y61 SER-

VICE MANUAL, publication No. SM7E-

2Y61G1.)

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connector.

Do approx. 12 volts exist between compres-

sor harness connector terminal No.j

1and

ground?

No

cYe s

Check magnet clutch coil.

NG

Replace magnet clutch.

Refer to HA-178 in Y61

SERVICE MANUAL (publi-

cation No. SM7E-2Y61G1).

Disconnect A/C relay.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C RELAY HARNESS CON-

NECTOR TERMINAL NO.j

3AND COM-

PRESSOR HARNESS CONNECTOR TER-

MINAL NO.j

1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK POWER SUPPLY FOR A/C

RELAY.

Disconnect A/C relay.

Do approx. 12 volts exist between A/C

relay harness connector terminal Nos.j

1,

j5and ground?

Ye s

cNo

Check power supply circuit

and 10A or 20A (No.

)

located in the fuse block

(J/B).

Refer to EL section (ªWiring

Diagramº, ªPOWER SUP-

PLY ROUTINGº).

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

Refer to HA-41 in Y61 SERVICE MANUAL,

publication No. SM1E-Y61EG1.

OK

cNG

Replace A/C relay.

jA(Go to next page.)

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA385I

SHA579F

SHA580FC

SHA581F

.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-4040

Page 520 of 579

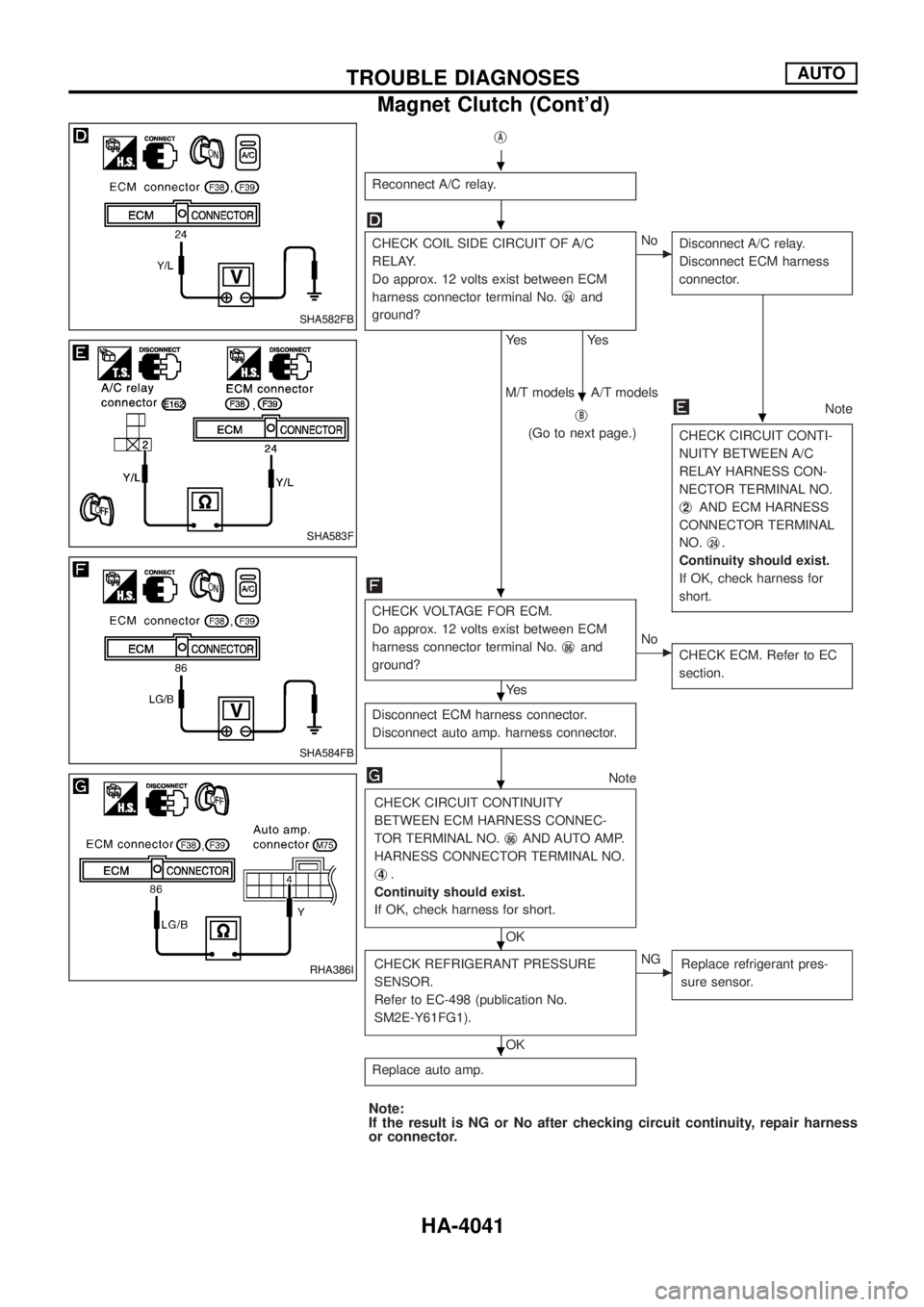

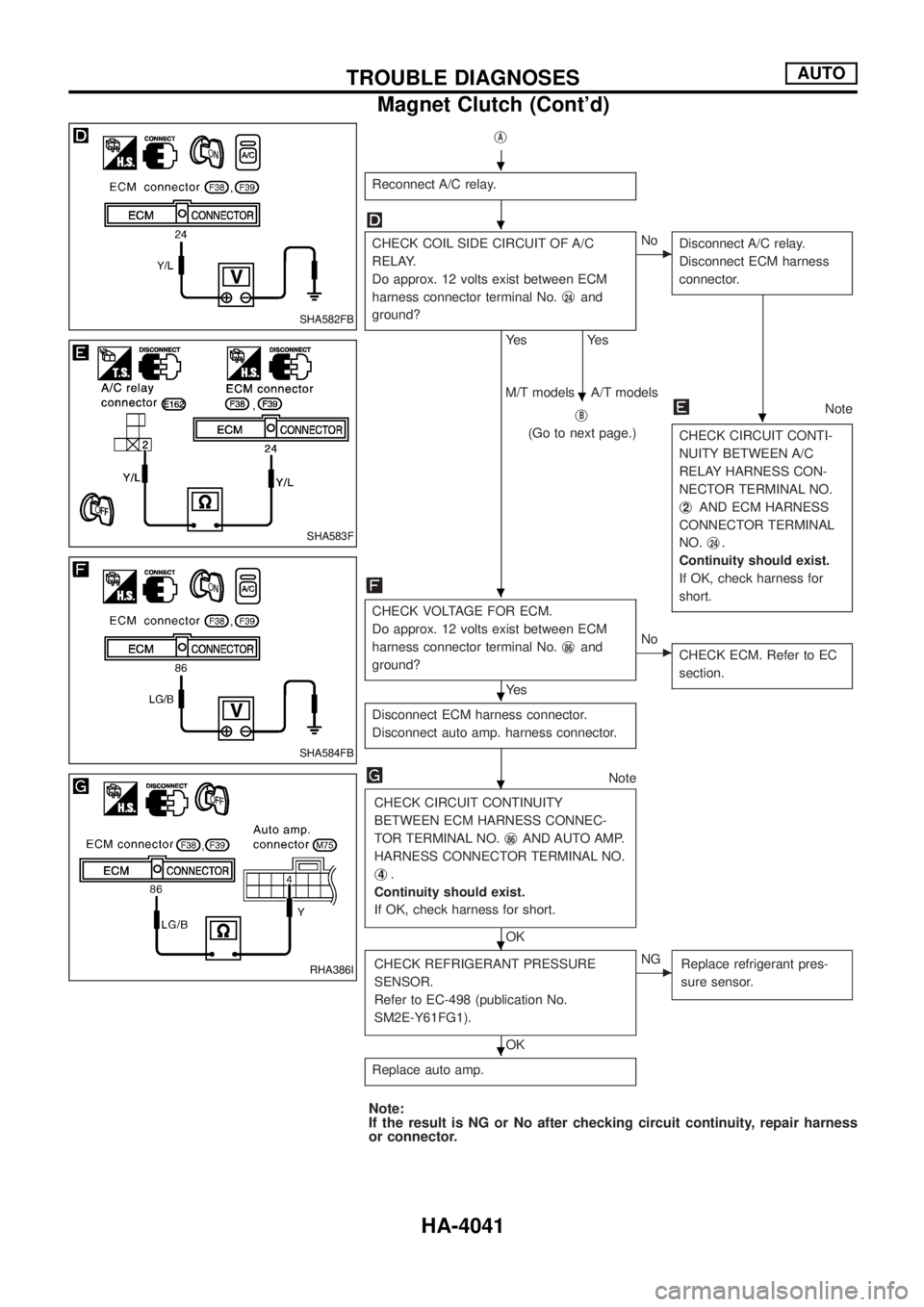

jA

Reconnect A/C relay.

CHECK COIL SIDE CIRCUIT OF A/C

RELAY.

Do approx. 12 volts exist between ECM

harness connector terminal No.j

24and

ground?

Ye s

Ye s

cNo

Disconnect A/C relay.

Disconnect ECM harness

connector.

jB

(Go to next page.)

Note

CHECK CIRCUIT CONTI-

NUITY BETWEEN A/C

RELAY HARNESS CON-

NECTOR TERMINAL NO.

j

2AND ECM HARNESS

CONNECTOR TERMINAL

NO.j

24.

Continuity should exist.

If OK, check harness for

short.

M/T models A/T models

CHECK VOLTAGE FOR ECM.

Do approx. 12 volts exist between ECM

harness connector terminal No.j

86and

ground?

Ye s

cNo

CHECK ECM. Refer to EC

section.

Disconnect ECM harness connector.

Disconnect auto amp. harness connector.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN ECM HARNESS CONNEC-

TOR TERMINAL NO.j

86AND AUTO AMP.

HARNESS CONNECTOR TERMINAL NO.

j

4.

Continuity should exist.

If OK, check harness for short.

OK

CHECK REFRIGERANT PRESSURE

SENSOR.

Refer to EC-498 (publication No.

SM2E-Y61FG1).

OK

cNG

Replace refrigerant pres-

sure sensor.

Replace auto amp.

Note:

If the result is NG or No after checking circuit continuity, repair harness

or connector.

SHA582FB

SHA583F

SHA584FB

RHA386I

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-4041

Trending: engine control, remote control, Wir conditioner, key, spare tire, radiator, ECM DIAGRAM