lock NISSAN PATROL 2006 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 887 of 1226

jB

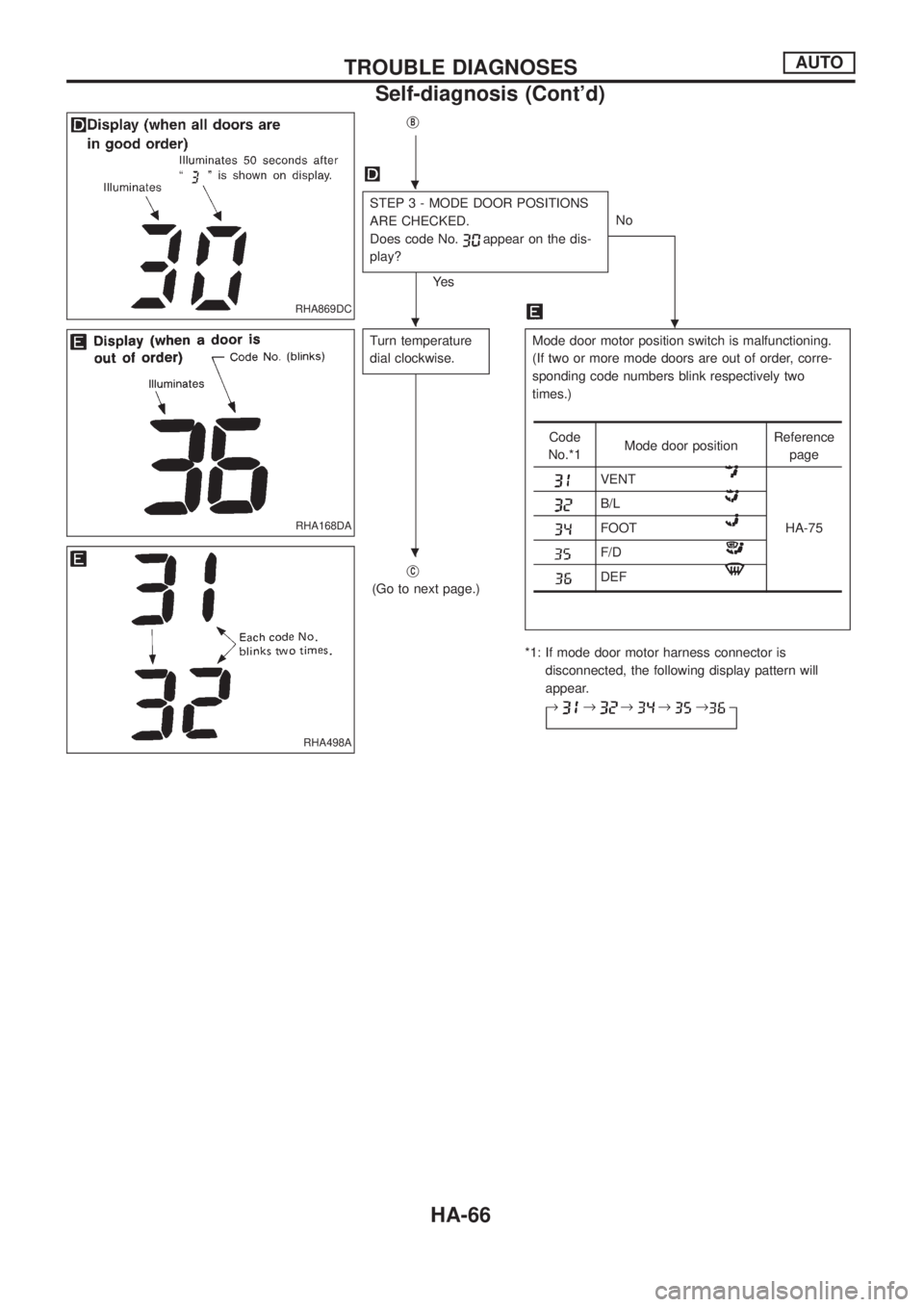

STEP 3 - MODE DOOR POSITIONS

ARE CHECKED.

Does code No.

appear on the dis-

play?

Ye sNo

.

Turn temperature

dial clockwise.Mode door motor position switch is malfunctioning.

(If two or more mode doors are out of order, corre-

sponding code numbers blink respectively two

times.)

*1: If mode door motor harness connector is

disconnected, the following display pattern will

appear.

®

®®®®þ

jC

(Go to next page.)

Code

No.*1Mode door positionReference

page

VENT

HA-75

B/L

FOOT

F/D

DEF

RHA869DC

RHA168DA

RHA498A

.

.

.

TROUBLE DIAGNOSESAUTO

Self-diagnosis (Cont'd)

HA-66

Page 889 of 1226

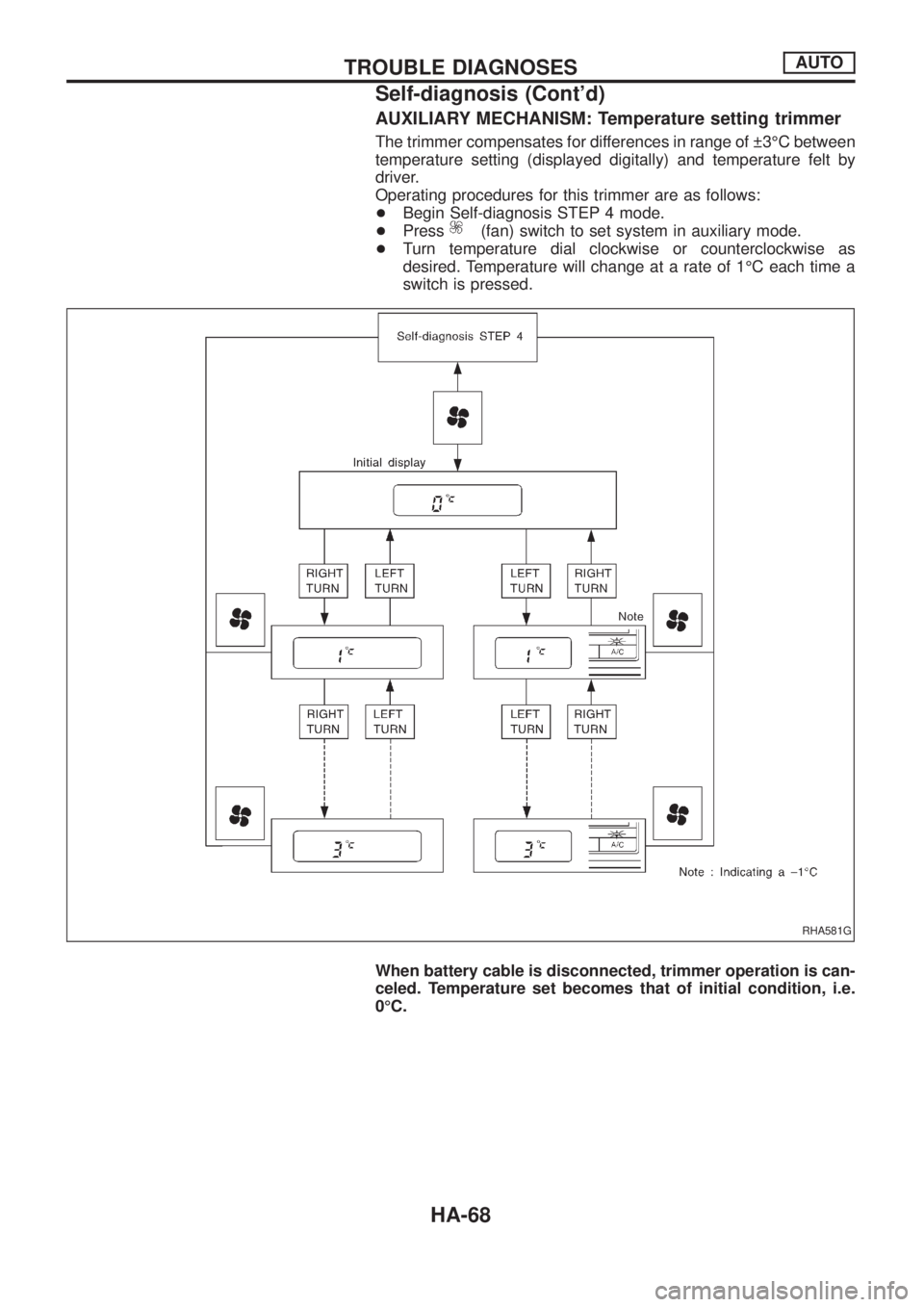

AUXILIARY MECHANISM: Temperature setting trimmer

The trimmer compensates for differences in range of 3ÉC between

temperature setting (displayed digitally) and temperature felt by

driver.

Operating procedures for this trimmer are as follows:

+Begin Self-diagnosis STEP 4 mode.

+Press

(fan) switch to set system in auxiliary mode.

+Turn temperature dial clockwise or counterclockwise as

desired. Temperature will change at a rate of 1ÉC each time a

switch is pressed.

When battery cable is disconnected, trimmer operation is can-

celed. Temperature set becomes that of initial condition, i.e.

0ÉC.

RHA581G

TROUBLE DIAGNOSESAUTO

Self-diagnosis (Cont'd)

HA-68

Page 892 of 1226

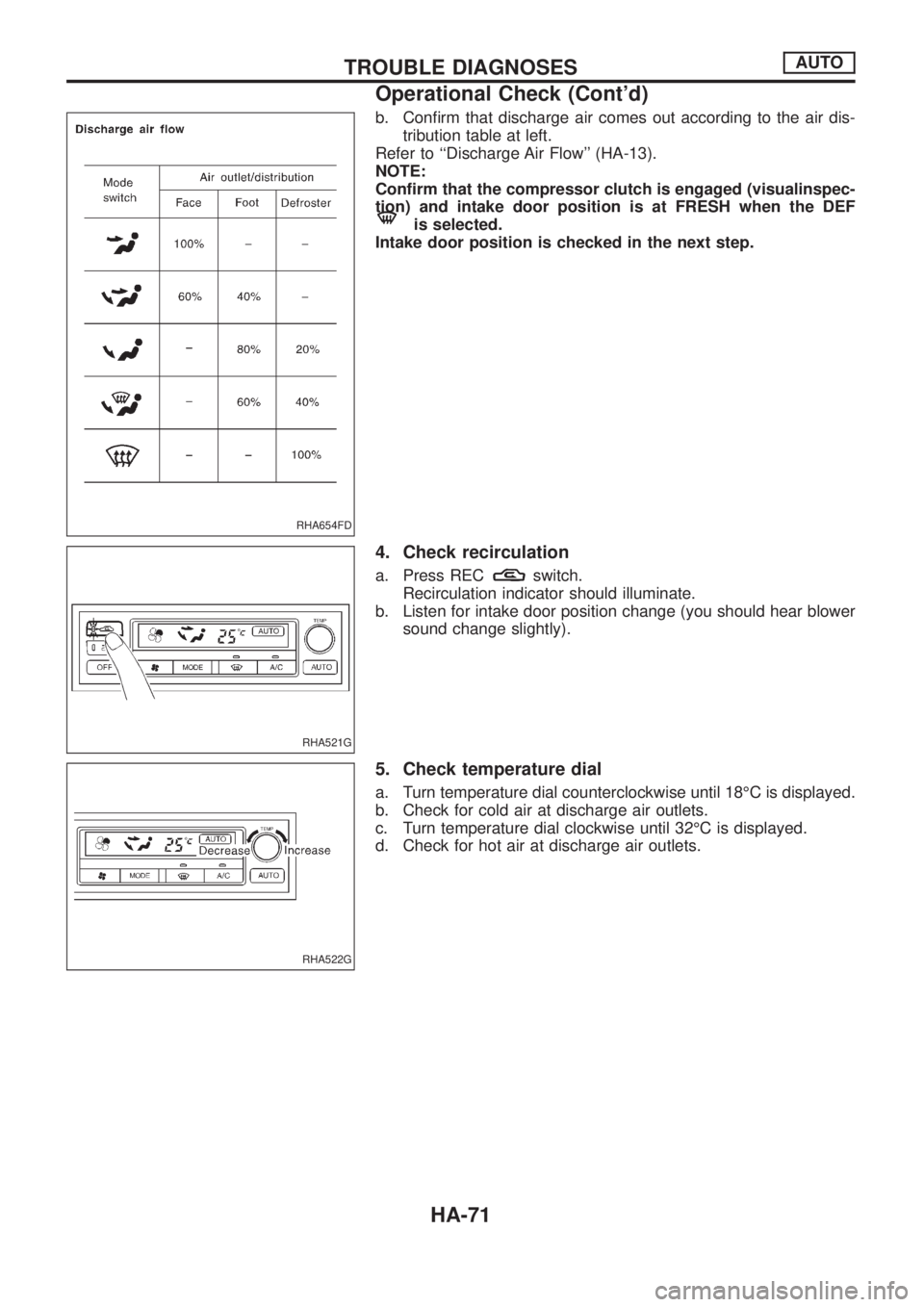

b. Con®rm that discharge air comes out according to the air dis-

tribution table at left.

Refer to ``Discharge Air Flow'' (HA-13).

NOTE:

Con®rm that the compressor clutch is engaged (visualinspec-

tion) and intake door position is at FRESH when the DEF

is selected.

Intake door position is checked in the next step.

4. Check recirculation

a. Press RECswitch.

Recirculation indicator should illuminate.

b. Listen for intake door position change (you should hear blower

sound change slightly).

5. Check temperature dial

a. Turn temperature dial counterclockwise until 18ÉC is displayed.

b. Check for cold air at discharge air outlets.

c. Turn temperature dial clockwise until 32ÉC is displayed.

d. Check for hot air at discharge air outlets.

RHA654FD

RHA521G

RHA522G

TROUBLE DIAGNOSESAUTO

Operational Check (Cont'd)

HA-71

Page 902 of 1226

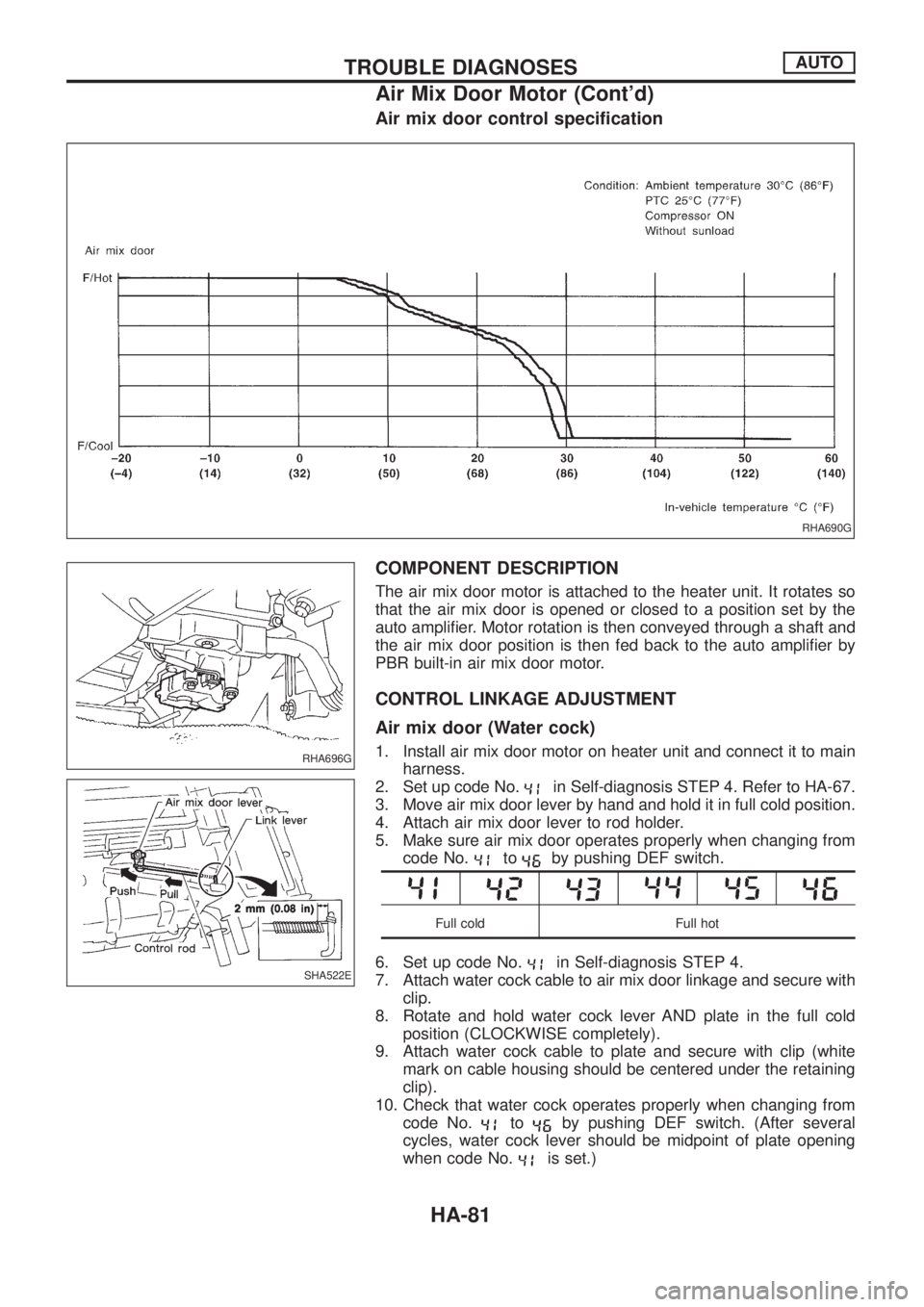

Air mix door control speci®cation

COMPONENT DESCRIPTION

The air mix door motor is attached to the heater unit. It rotates so

that the air mix door is opened or closed to a position set by the

auto ampli®er. Motor rotation is then conveyed through a shaft and

the air mix door position is then fed back to the auto ampli®er by

PBR built-in air mix door motor.

CONTROL LINKAGE ADJUSTMENT

Air mix door (Water cock)

1. Install air mix door motor on heater unit and connect it to main

harness.

2. Set up code No.

in Self-diagnosis STEP 4. Refer to HA-67.

3. Move air mix door lever by hand and hold it in full cold position.

4. Attach air mix door lever to rod holder.

5. Make sure air mix door operates properly when changing from

code No.

toby pushing DEF switch.

Full cold Full hot

6. Set up code No.in Self-diagnosis STEP 4.

7. Attach water cock cable to air mix door linkage and secure with

clip.

8. Rotate and hold water cock lever AND plate in the full cold

position (CLOCKWISE completely).

9. Attach water cock cable to plate and secure with clip (white

mark on cable housing should be centered under the retaining

clip).

10. Check that water cock operates properly when changing from

code No.

toby pushing DEF switch. (After several

cycles, water cock lever should be midpoint of plate opening

when code No.

is set.)

RHA690G

RHA696G

SHA522E

TROUBLE DIAGNOSESAUTO

Air Mix Door Motor (Cont'd)

HA-81

Page 906 of 1226

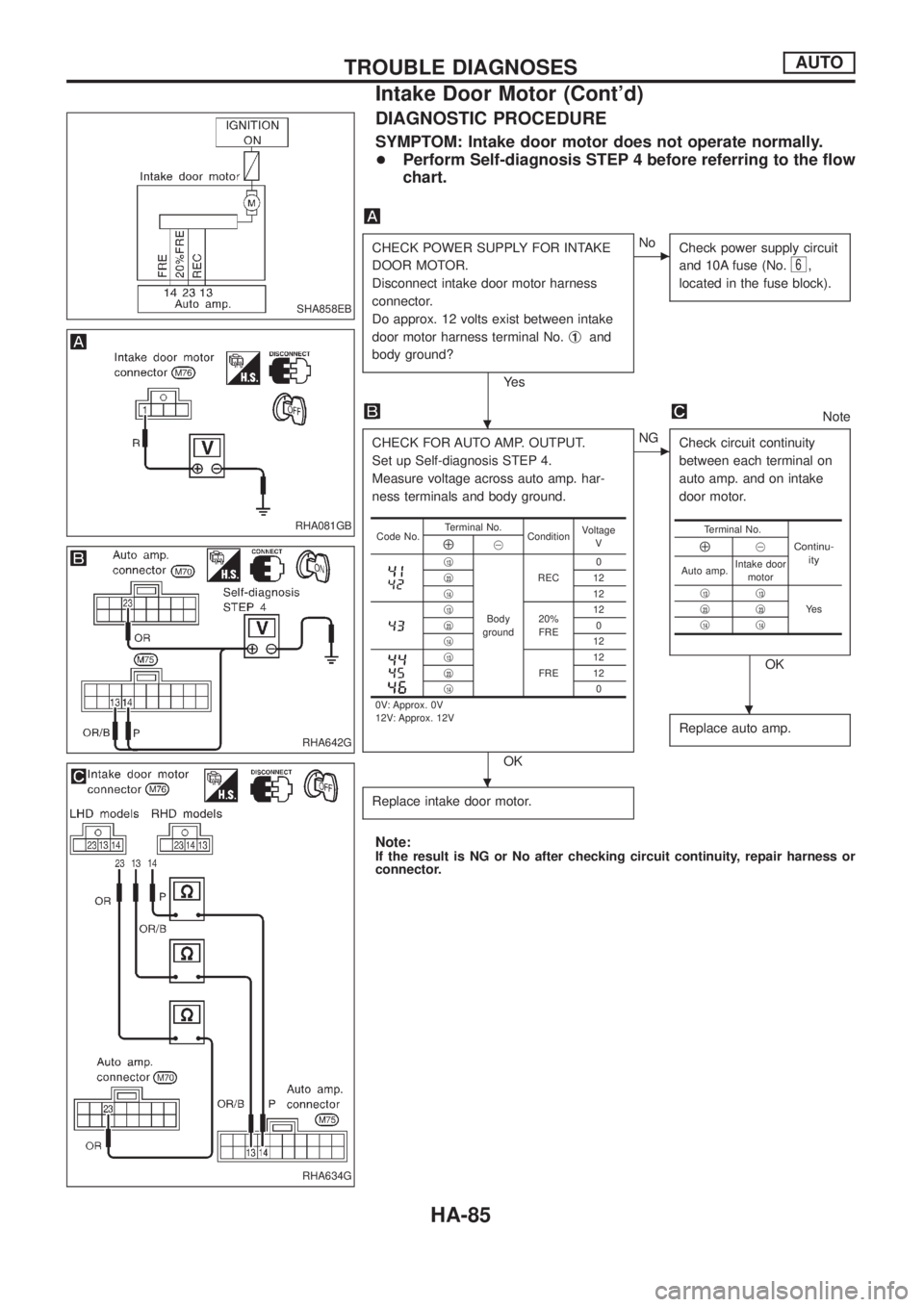

DIAGNOSTIC PROCEDURE

SYMPTOM: Intake door motor does not operate normally.

+Perform Self-diagnosis STEP 4 before referring to the ¯ow

chart.

CHECK POWER SUPPLY FOR INTAKE

DOOR MOTOR.

Disconnect intake door motor harness

connector.

Do approx. 12 volts exist between intake

door motor harness terminal No.j

1and

body ground?

Ye s

cNo

Check power supply circuit

and 10A fuse (No.

6,

located in the fuse block).

Note

CHECK FOR AUTO AMP. OUTPUT.

Set up Self-diagnosis STEP 4.

Measure voltage across auto amp. har-

ness terminals and body ground.

OK

cNG

Check circuit continuity

between each terminal on

auto amp. and on intake

door motor.

OK

Replace auto amp.

Replace intake door motor.

Note:If the result is NG or No after checking circuit continuity, repair harness or

connector.

Code No.Terminal No.

ConditionVoltage

VÅ@

j13

Body

groundREC0

j

2312

j

1412j1320%

FRE12

j230

j

1412j13

FRE12

j2312

j

140

0V: Approx. 0V

12V: Approx. 12V

Terminal No.

Continu-

ityÅ@

Auto amp.Intake door

motor

j

13j13

Ye s j23j23j14j14

SHA858EB

RHA081GB

RHA642G

RHA634G

.

.

.

TROUBLE DIAGNOSESAUTO

Intake Door Motor (Cont'd)

HA-85

Page 910 of 1226

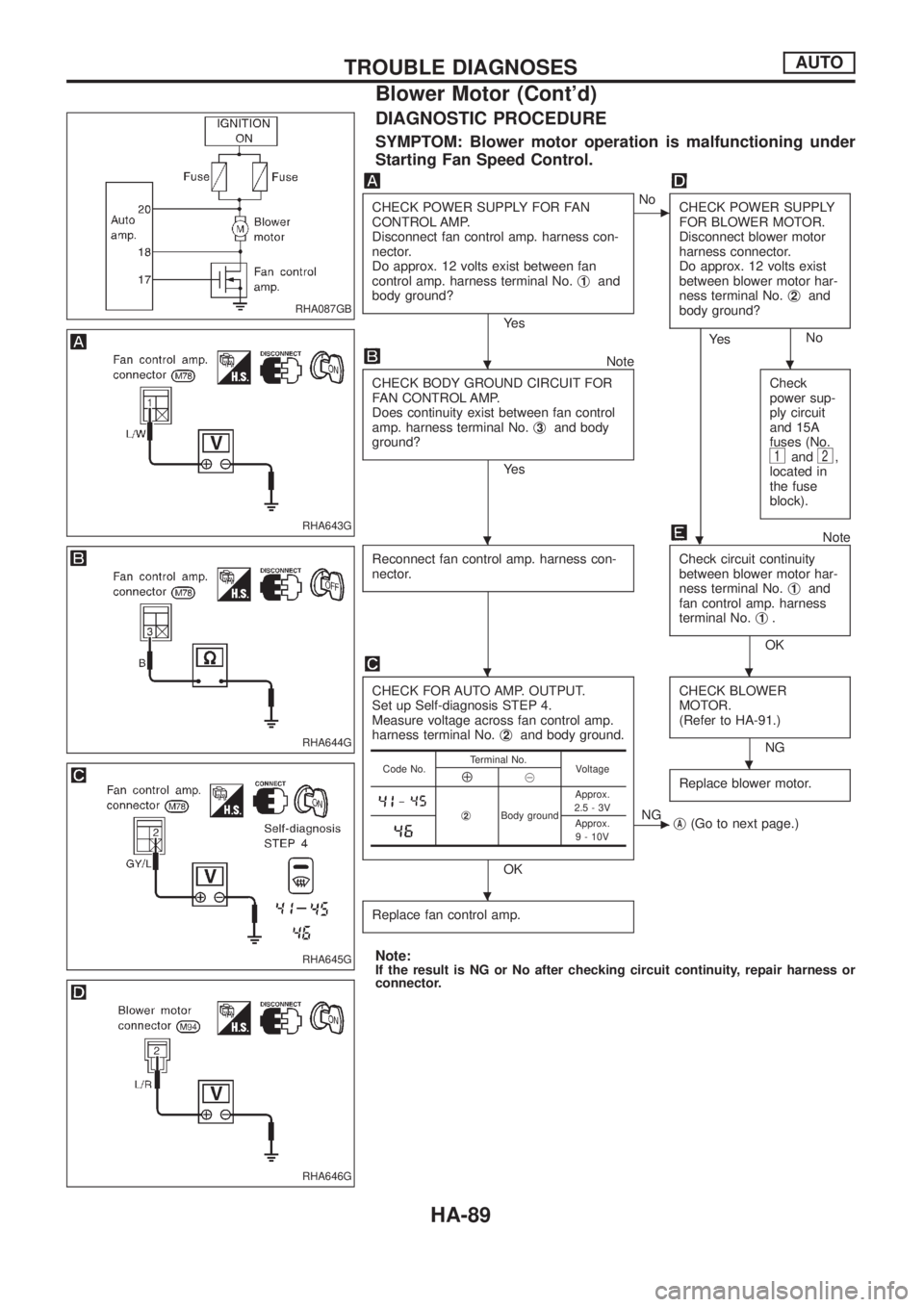

DIAGNOSTIC PROCEDURE

SYMPTOM: Blower motor operation is malfunctioning under

Starting Fan Speed Control.

CHECK POWER SUPPLY FOR FAN

CONTROL AMP.

Disconnect fan control amp. harness con-

nector.

Do approx. 12 volts exist between fan

control amp. harness terminal No.j

1and

body ground?

Ye s

cNo

CHECK POWER SUPPLY

FOR BLOWER MOTOR.

Disconnect blower motor

harness connector.

Do approx. 12 volts exist

between blower motor har-

ness terminal No.j

2and

body ground?

No

.

Ye s

Note

CHECK BODY GROUND CIRCUIT FOR

FAN CONTROL AMP.

Does continuity exist between fan control

amp. harness terminal No.j

3and body

ground?

Ye sCheck

power sup-

ply circuit

and 15A

fuses (No.1and2,

located in

the fuse

block).

Note

Reconnect fan control amp. harness con-

nector.

Check circuit continuity

between blower motor har-

ness terminal No.j

1and

fan control amp. harness

terminal No.j

1.

OK

CHECK FOR AUTO AMP. OUTPUT.

Set up Self-diagnosis STEP 4.

Measure voltage across fan control amp.

harness terminal No.j

2and body ground.

OKCHECK BLOWER

MOTOR.

(Refer to HA-91.)

NG

Replace blower motor.

cNG

jA(Go to next page.)

Replace fan control amp.

Note:If the result is NG or No after checking circuit continuity, repair harness or

connector.

Code No.Terminal No.

VoltageÅ@

þj2Body groundApprox.

2.5-3VApprox.

9 - 10V

RHA087GB

RHA643G

RHA644G

RHA645G

RHA646G

..

.

..

.

.

TROUBLE DIAGNOSESAUTO

Blower Motor (Cont'd)

HA-89

Page 911 of 1226

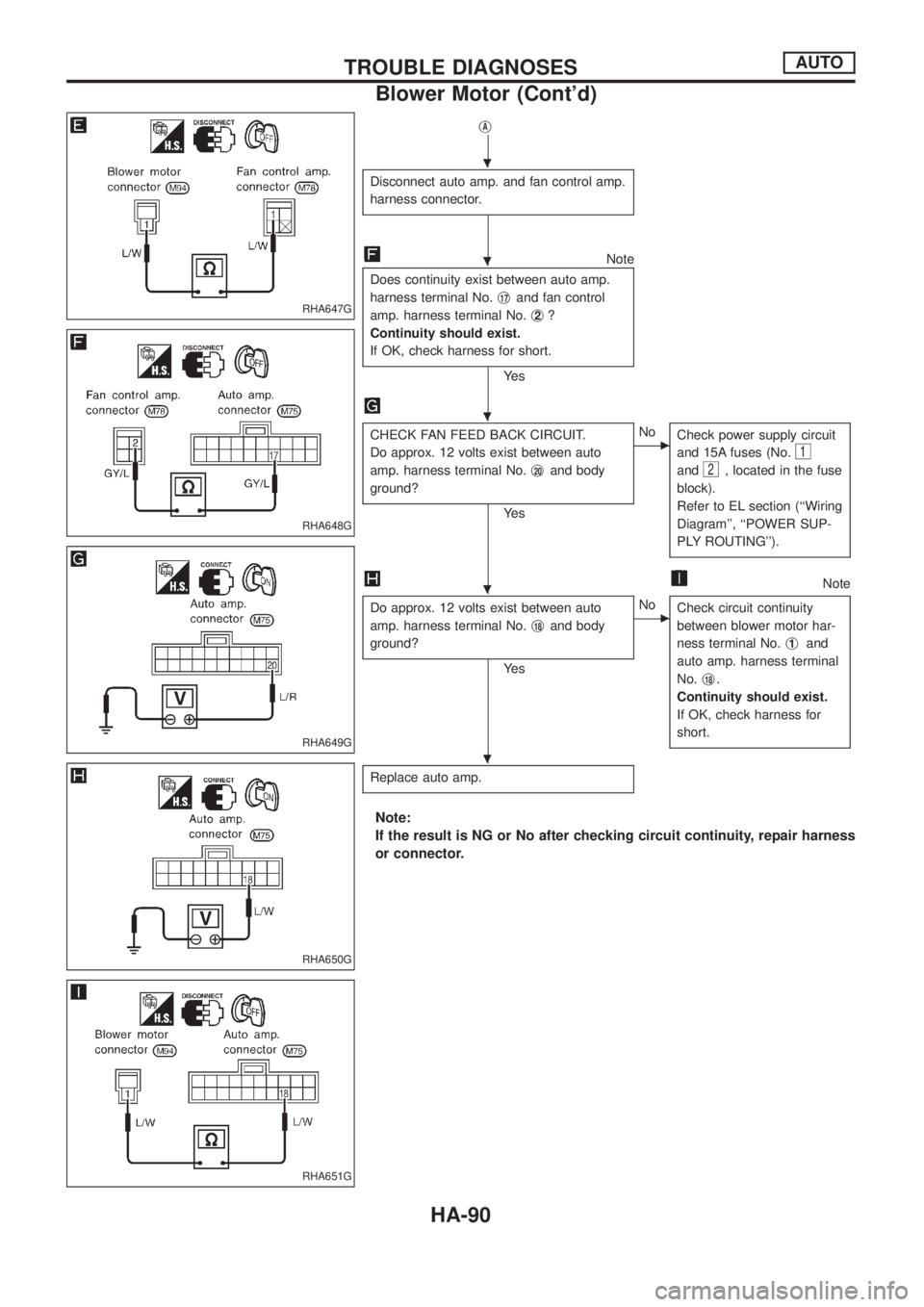

jA

Disconnect auto amp. and fan control amp.

harness connector.

Note

Does continuity exist between auto amp.

harness terminal No.j

17and fan control

amp. harness terminal No.j

2?

Continuity should exist.

If OK, check harness for short.

Ye s

CHECK FAN FEED BACK CIRCUIT.

Do approx. 12 volts exist between auto

amp. harness terminal No.j

20and body

ground?

Ye s

cNo

Check power supply circuit

and 15A fuses (No.

1

and2, located in the fuse

block).

Refer to EL section (``Wiring

Diagram'', ``POWER SUP-

PLY ROUTING'').

Note

Do approx. 12 volts exist between auto

amp. harness terminal No.j

18and body

ground?

Ye s

cNo

Check circuit continuity

between blower motor har-

ness terminal No.j

1and

auto amp. harness terminal

No.j

18.

Continuity should exist.

If OK, check harness for

short.

Replace auto amp.

Note:

If the result is NG or No after checking circuit continuity, repair harness

or connector.

RHA647G

RHA648G

RHA649G

RHA650G

RHA651G

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Blower Motor (Cont'd)

HA-90

Page 915 of 1226

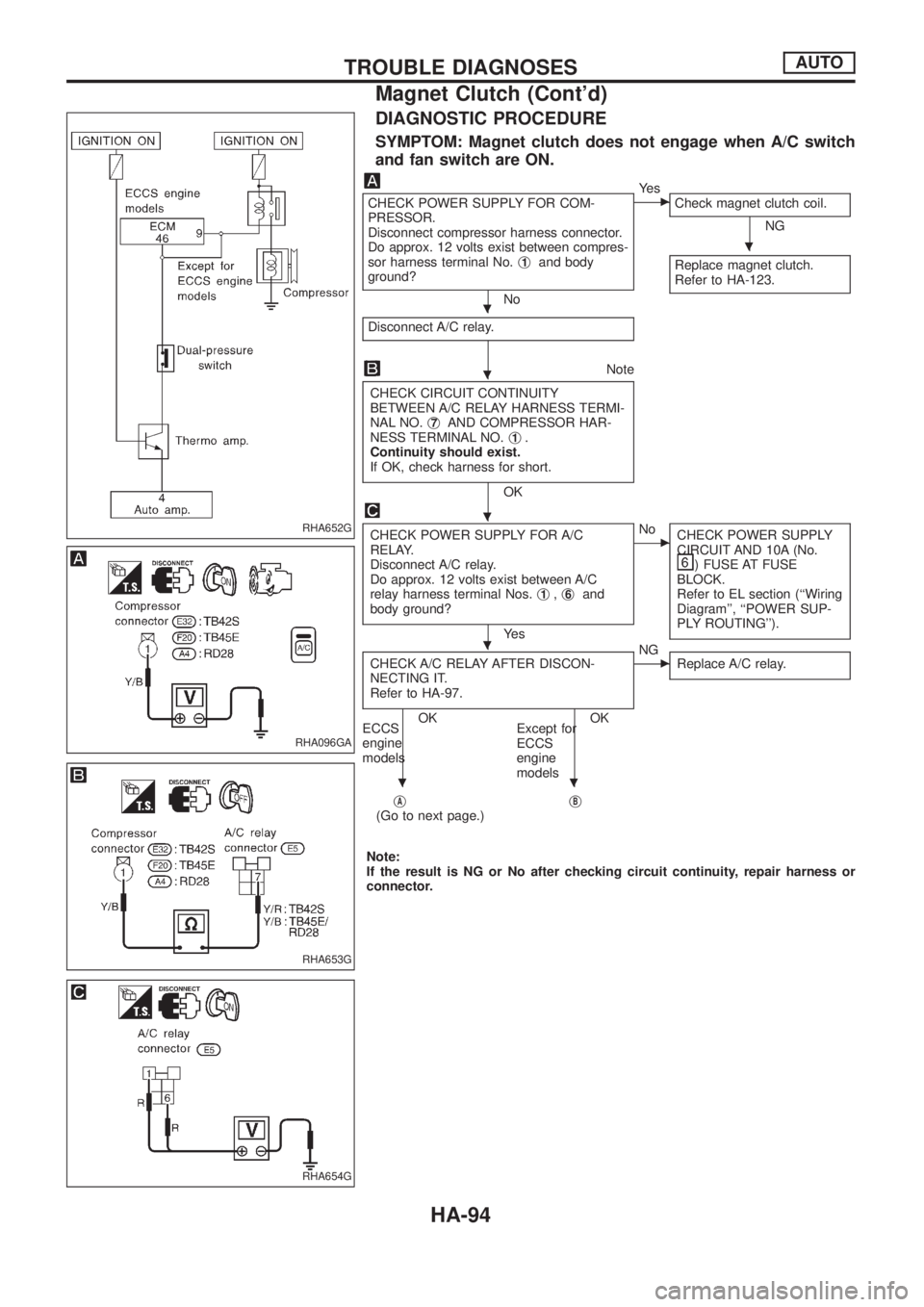

DIAGNOSTIC PROCEDURE

SYMPTOM: Magnet clutch does not engage when A/C switch

and fan switch are ON.

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connector.

Do approx. 12 volts exist between compres-

sor harness terminal No.j

1and body

ground?

No

cYe s

Check magnet clutch coil.

NG

Replace magnet clutch.

Refer to HA-123.

Disconnect A/C relay.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C RELAY HARNESS TERMI-

NAL NO.j

7AND COMPRESSOR HAR-

NESS TERMINAL NO.j1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK POWER SUPPLY FOR A/C

RELAY.

Disconnect A/C relay.

Do approx. 12 volts exist between A/C

relay harness terminal Nos.j

1,j6and

body ground?

Ye s

cNo

CHECK POWER SUPPLY

CIRCUIT AND 10A (No.

) FUSE AT FUSE

BLOCK.

Refer to EL section (``Wiring

Diagram'', ``POWER SUP-

PLY ROUTING'').

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

Refer to HA-97.

OK OK

ECCS

engine

modelsExcept for

ECCS

engine

models

cNG

Replace A/C relay.

jA(Go to next page.)jB

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA652G

RHA096GA

RHA653G

RHA654G

.

.

.

.

.

..

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-94

Page 917 of 1226

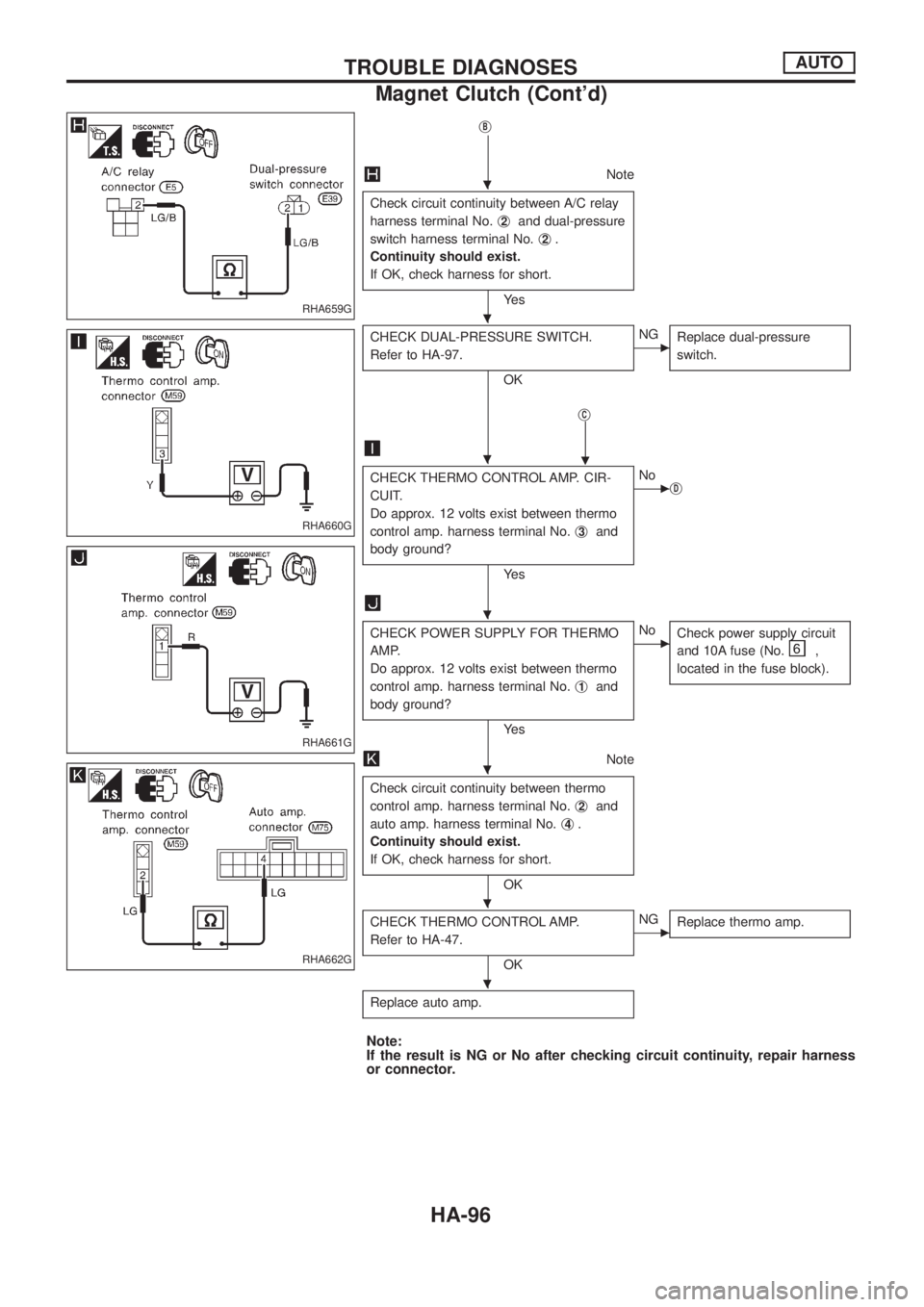

jB

Note

Check circuit continuity between A/C relay

harness terminal No.j

2and dual-pressure

switch harness terminal No.j

2.

Continuity should exist.

If OK, check harness for short.

Ye s

CHECK DUAL-PRESSURE SWITCH.

Refer to HA-97.

OK

cNG

Replace dual-pressure

switch.

jC

.

CHECK THERMO CONTROL AMP. CIR-

CUIT.

Do approx. 12 volts exist between thermo

control amp. harness terminal No.j

3and

body ground?

Ye s

cNo

jD

CHECK POWER SUPPLY FOR THERMO

AMP.

Do approx. 12 volts exist between thermo

control amp. harness terminal No.j

1and

body ground?

Ye s

cNo

Check power supply circuit

and 10A fuse (No.

,

located in the fuse block).

Note

Check circuit continuity between thermo

control amp. harness terminal No.j

2and

auto amp. harness terminal No.j

4.

Continuity should exist.

If OK, check harness for short.

OK

CHECK THERMO CONTROL AMP.

Refer to HA-47.

OK

cNG

Replace thermo amp.

Replace auto amp.

Note:

If the result is NG or No after checking circuit continuity, repair harness

or connector.

RHA659G

RHA660G

RHA661G

RHA662G

.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-96

Page 944 of 1226

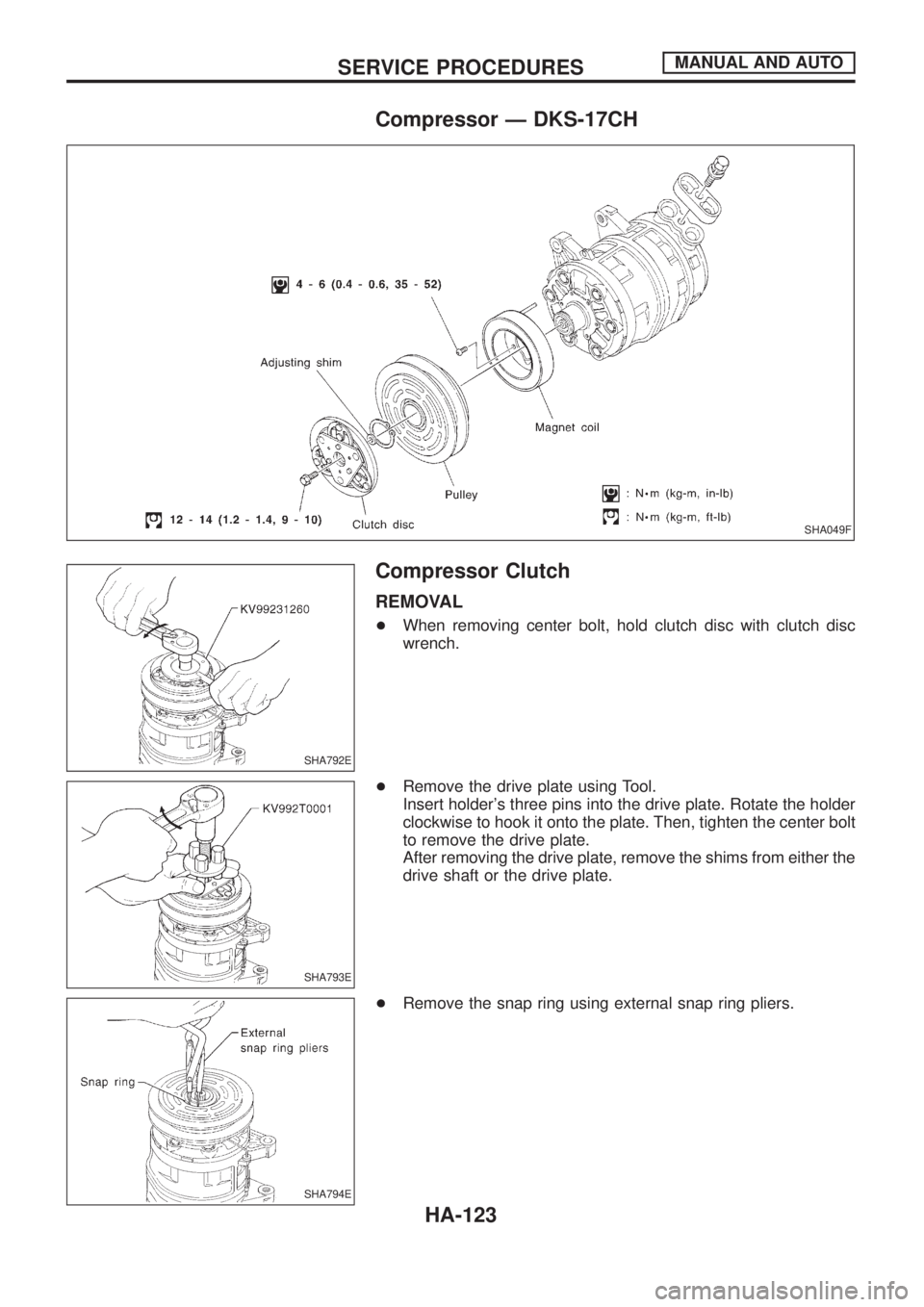

Compressor Ð DKS-17CH

Compressor Clutch

REMOVAL

+When removing center bolt, hold clutch disc with clutch disc

wrench.

+Remove the drive plate using Tool.

Insert holder's three pins into the drive plate. Rotate the holder

clockwise to hook it onto the plate. Then, tighten the center bolt

to remove the drive plate.

After removing the drive plate, remove the shims from either the

drive shaft or the drive plate.

+Remove the snap ring using external snap ring pliers.

SHA049F

SHA792E

SHA793E

SHA794E

SERVICE PROCEDURESMANUAL AND AUTO

HA-123