NISSAN PATROL 2006 Service Manual

Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 311 of 1226

jA

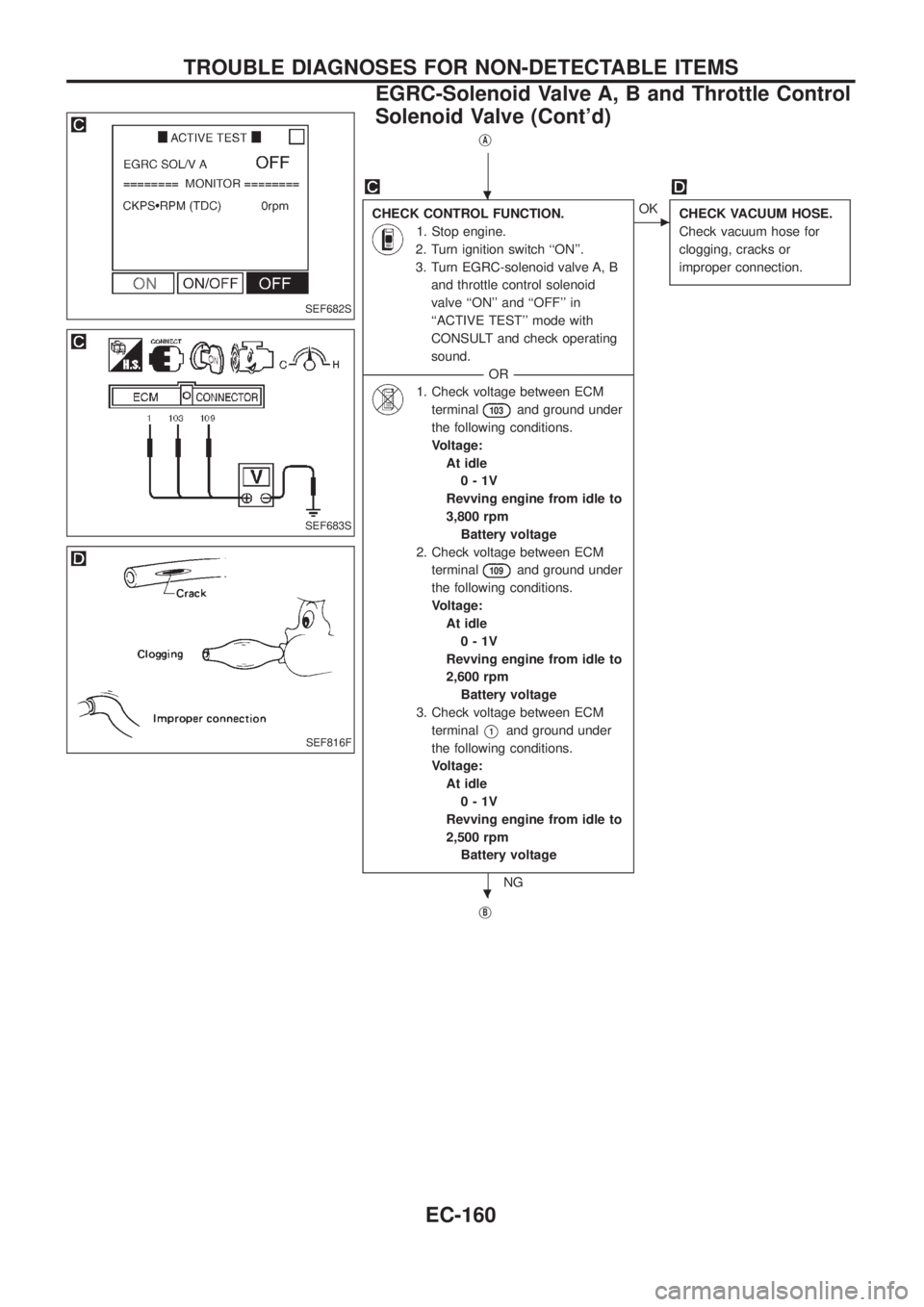

CHECK CONTROL FUNCTION.

1. Stop engine.

2. Turn ignition switch ``ON''.

3. Turn EGRC-solenoid valve A, B

and throttle control solenoid

valve ``ON'' and ``OFF'' in

``ACTIVE TEST'' mode with

CONSULT and check operating

sound.

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

1. Check voltage between ECM

terminal

103and ground under

the following conditions.

Voltage:

At idle

0-1V

Revving engine from idle to

3,800 rpm

Battery voltage

2. Check voltage between ECM

terminal

109and ground under

the following conditions.

Voltage:

At idle

0-1V

Revving engine from idle to

2,600 rpm

Battery voltage

3. Check voltage between ECM

terminal

V1and ground under

the following conditions.

Voltage:

At idle

0-1V

Revving engine from idle to

2,500 rpm

Battery voltage

NG

cOK

CHECK VACUUM HOSE.

Check vacuum hose for

clogging, cracks or

improper connection.

jB

SEF682S

SEF683S

SEF816F

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EGRC-Solenoid Valve A, B and Throttle Control

Solenoid Valve (Cont'd)

EC-160

Page 312 of 1226

jB

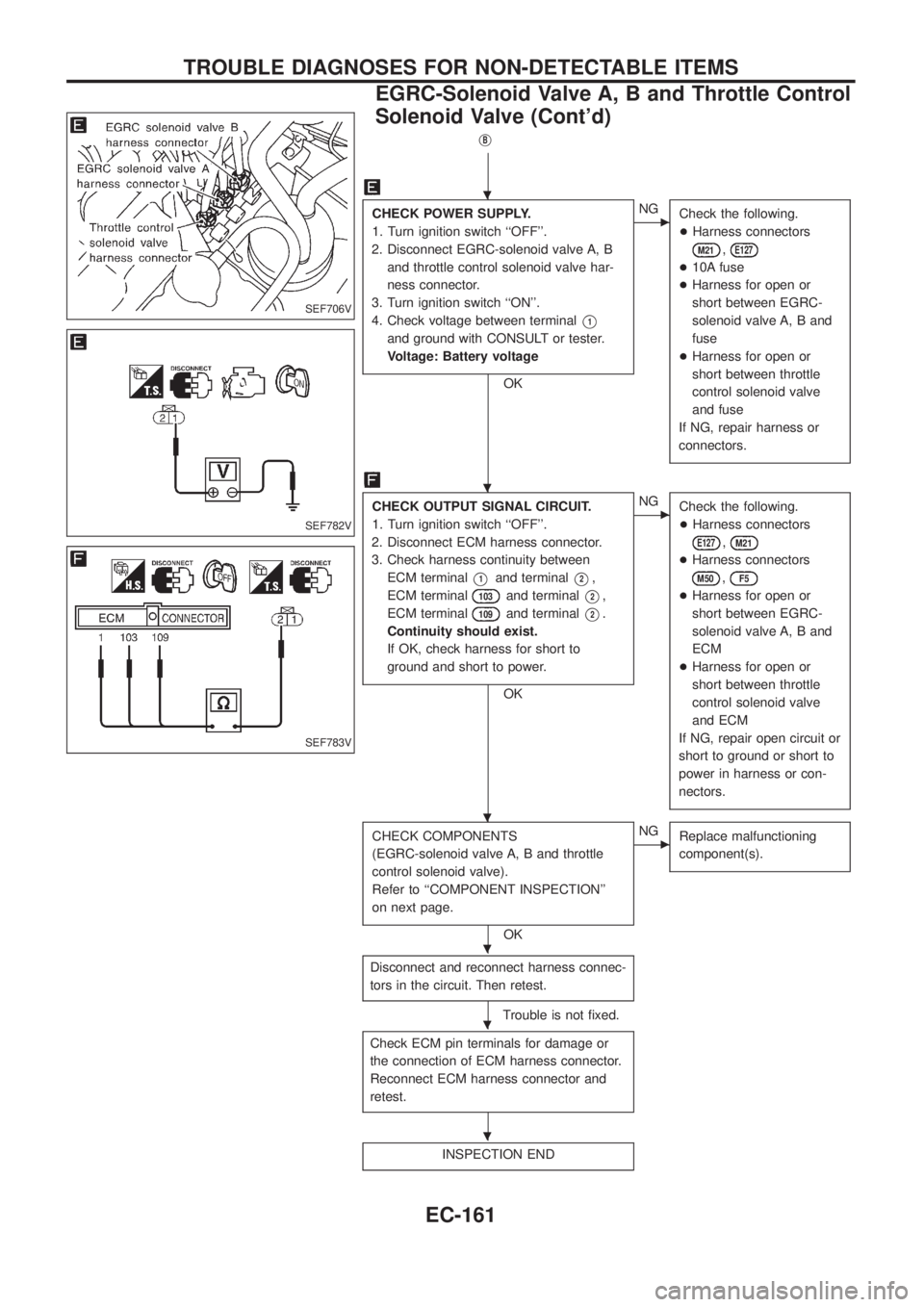

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect EGRC-solenoid valve A, B

and throttle control solenoid valve har-

ness connector.

3. Turn ignition switch ``ON''.

4. Check voltage between terminal

V1

and ground with CONSULT or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+Harness connectors

M21,E127

+10A fuse

+Harness for open or

short between EGRC-

solenoid valve A, B and

fuse

+Harness for open or

short between throttle

control solenoid valve

and fuse

If NG, repair harness or

connectors.

CHECK OUTPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM terminal

V1and terminalV2,

ECM terminal

103and terminalV2,

ECM terminal

109and terminalV2.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

E127,M21

+Harness connectors

M50,F5

+Harness for open or

short between EGRC-

solenoid valve A, B and

ECM

+Harness for open or

short between throttle

control solenoid valve

and ECM

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENTS

(EGRC-solenoid valve A, B and throttle

control solenoid valve).

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace malfunctioning

component(s).

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage or

the connection of ECM harness connector.

Reconnect ECM harness connector and

retest.

INSPECTION END

SEF706V

SEF782V

SEF783V

.

.

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EGRC-Solenoid Valve A, B and Throttle Control

Solenoid Valve (Cont'd)

EC-161

Page 313 of 1226

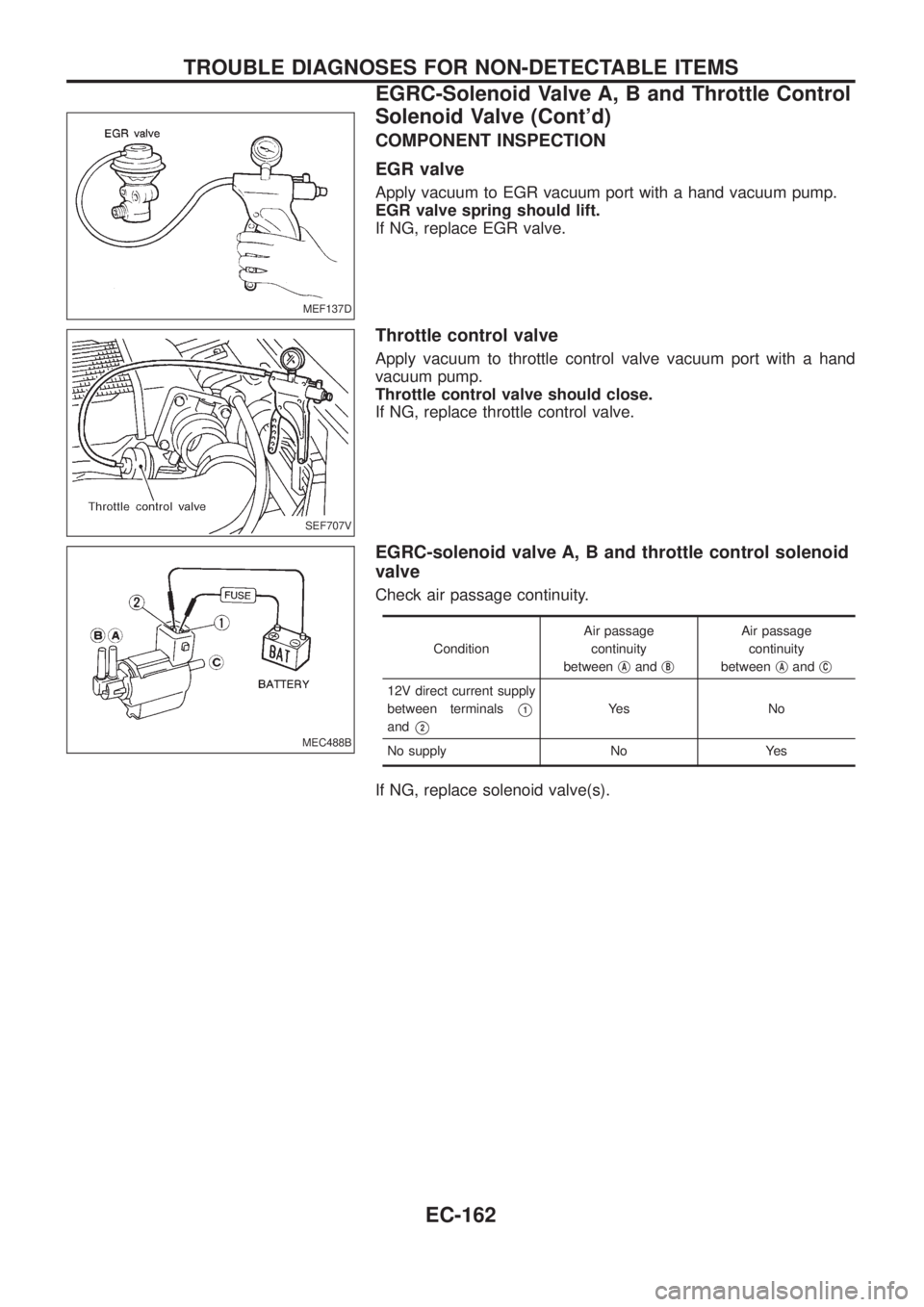

COMPONENT INSPECTION

EGR valve

Apply vacuum to EGR vacuum port with a hand vacuum pump.

EGR valve spring should lift.

If NG, replace EGR valve.

Throttle control valve

Apply vacuum to throttle control valve vacuum port with a hand

vacuum pump.

Throttle control valve should close.

If NG, replace throttle control valve.

EGRC-solenoid valve A, B and throttle control solenoid

valve

Check air passage continuity.

ConditionAir passage

continuity

betweenj

AandjB

Air passage

continuity

betweenj

AandjC

12V direct current supply

between terminals

V1

andV2

Ye s N o

No supply No Yes

If NG, replace solenoid valve(s).

MEF137D

SEF707V

MEC488B

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EGRC-Solenoid Valve A, B and Throttle Control

Solenoid Valve (Cont'd)

EC-162

Page 314 of 1226

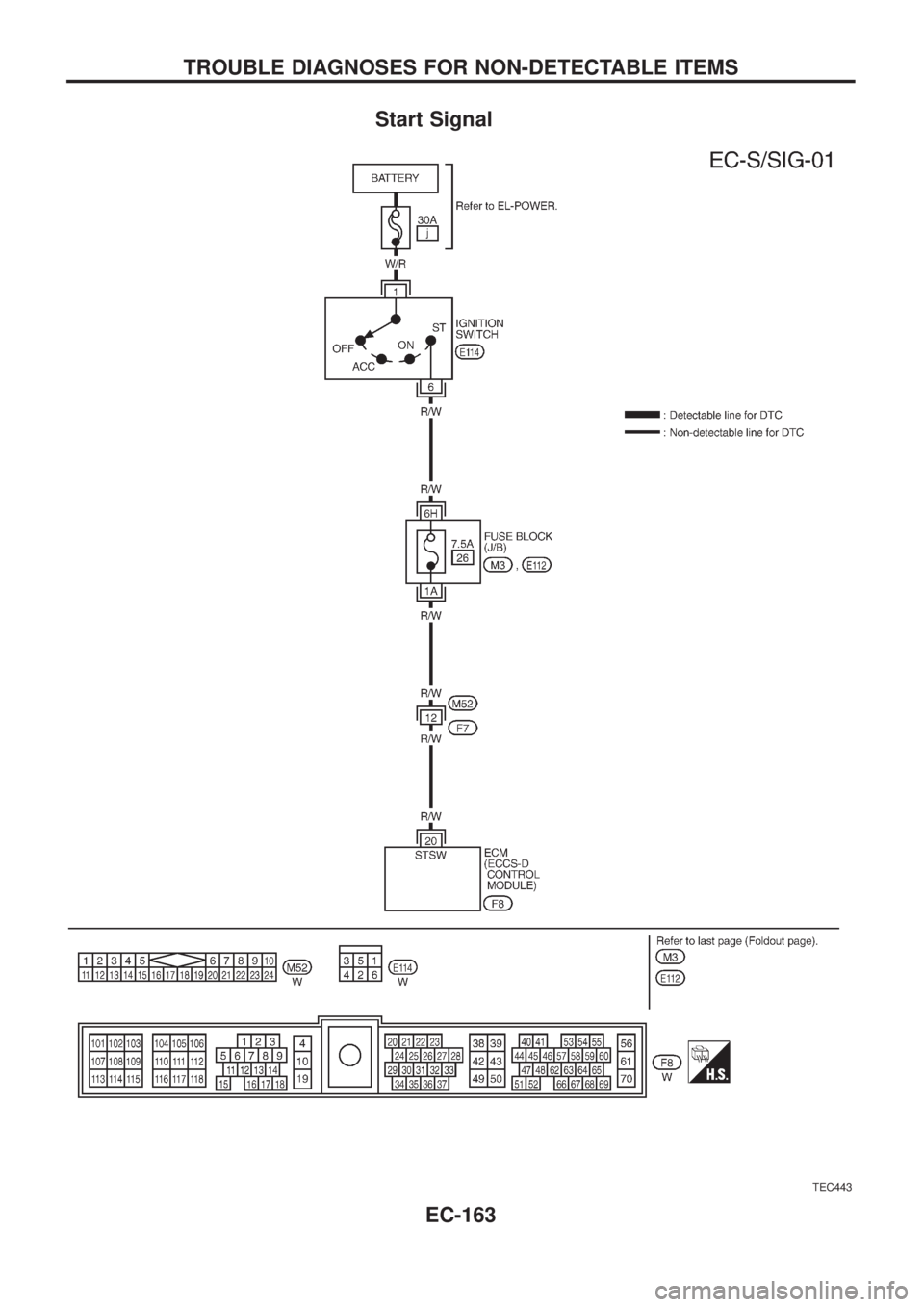

Start Signal

TEC443

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EC-163

Page 315 of 1226

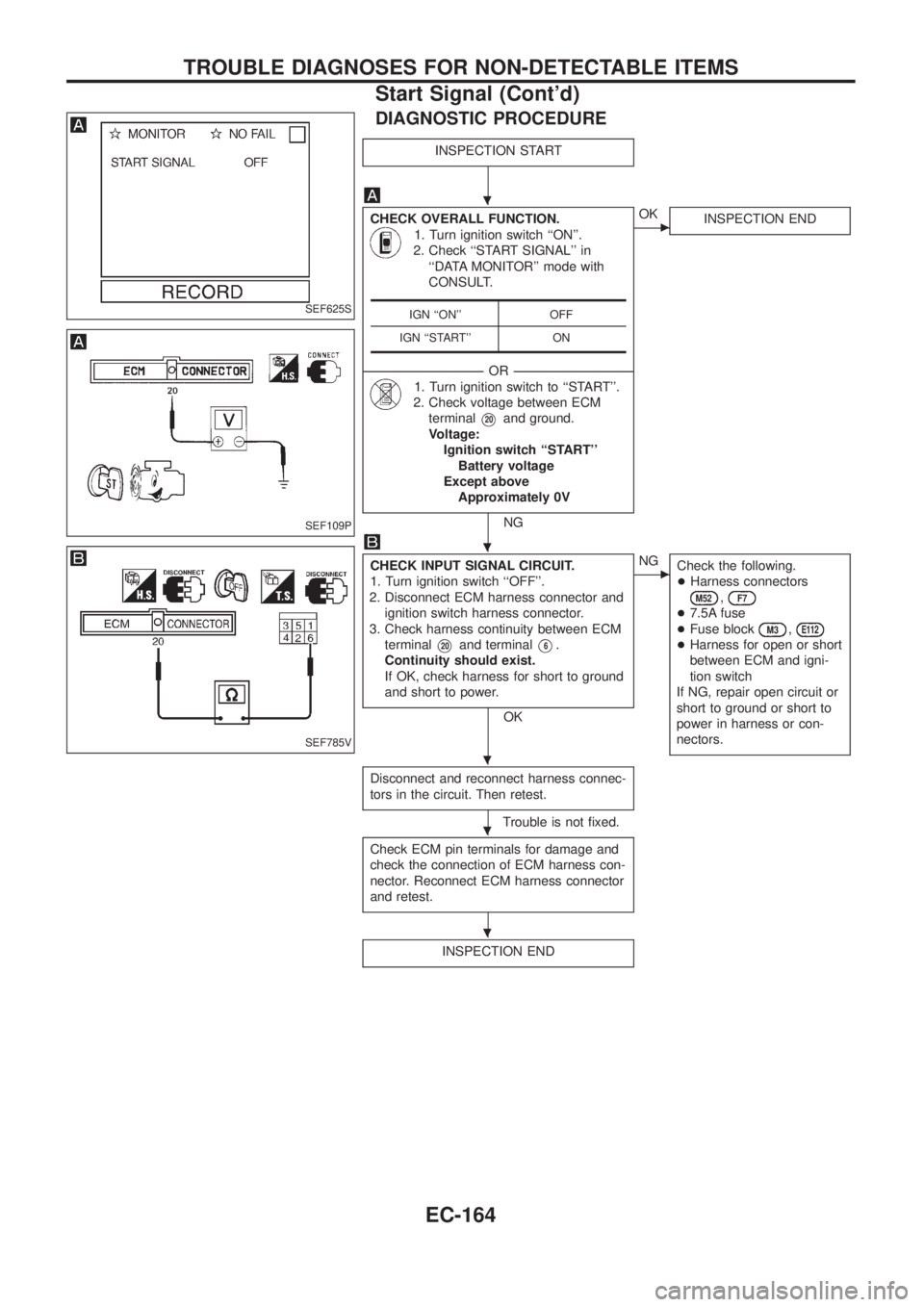

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``ON''.

2. Check ``START SIGNAL'' in

``DATA MONITOR'' mode with

CONSULT.

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ``START''.

2. Check voltage between ECM

terminal

V20and ground.

Voltage:

Ignition switch ``START''

Battery voltage

Except above

Approximately 0V

NG

cOK

INSPECTION END

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector and

ignition switch harness connector.

3. Check harness continuity between ECM

terminal

V20and terminalV6.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Check the following.

+Harness connectors

M52,F7

+7.5A fuse

+Fuse block

M3,E112

+Harness for open or short

between ECM and igni-

tion switch

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

IGN ``ON'' OFF

IGN ``START'' ONSEF625S

SEF109P

SEF785V

.

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Start Signal (Cont'd)

EC-164

Page 316 of 1226

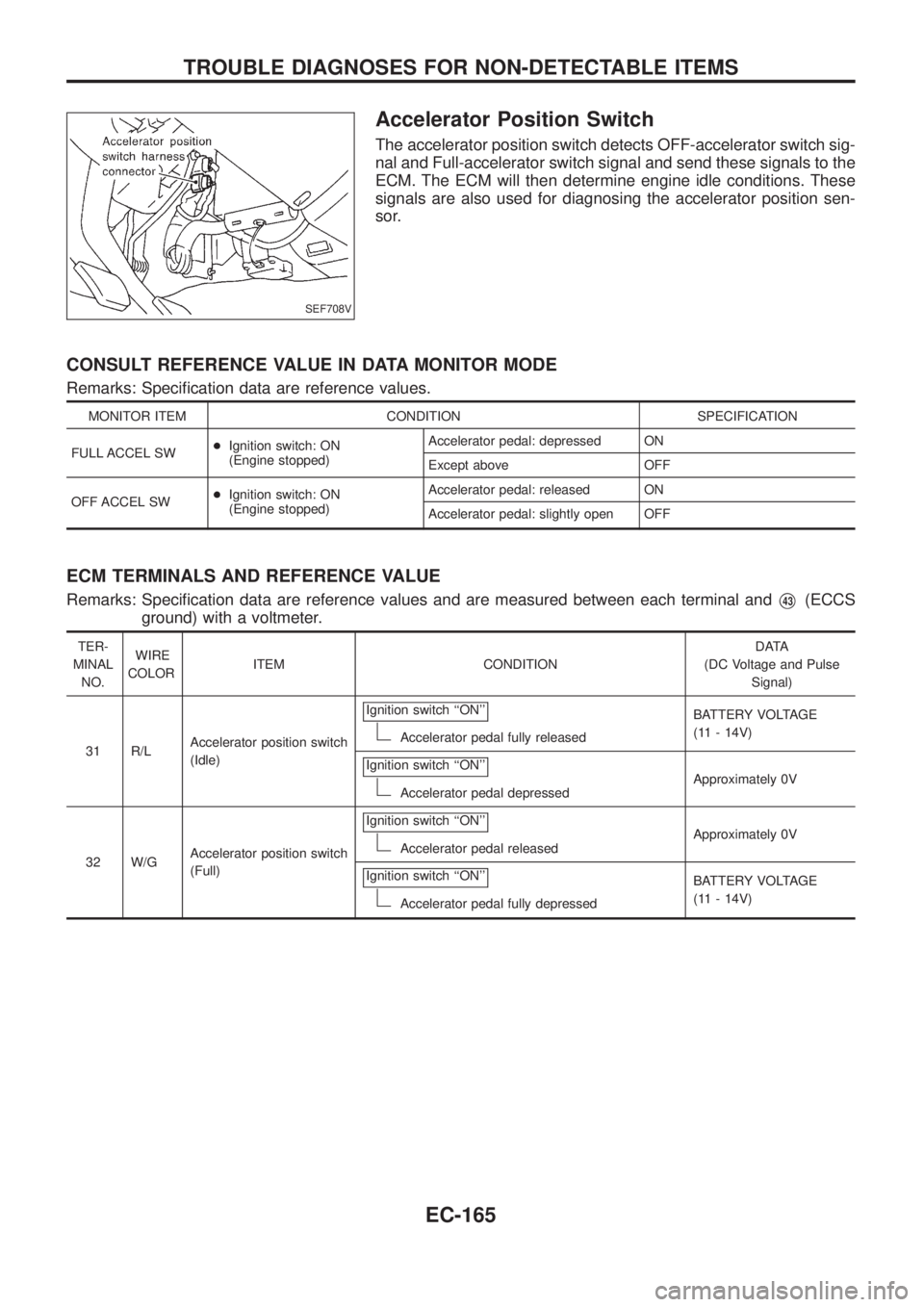

Accelerator Position Switch

The accelerator position switch detects OFF-accelerator switch sig-

nal and Full-accelerator switch signal and send these signals to the

ECM. The ECM will then determine engine idle conditions. These

signals are also used for diagnosing the accelerator position sen-

sor.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

FULL ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: depressed ON

Except above OFF

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: released ON

Accelerator pedal: slightly open OFF

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

31 R/LAccelerator position switch

(Idle)Ignition switch ``ON''

Accelerator pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

Ignition switch ``ON''

Accelerator pedal depressedApproximately 0V

32 W/GAccelerator position switch

(Full)Ignition switch ``ON''

Accelerator pedal releasedApproximately 0V

Ignition switch ``ON''

Accelerator pedal fully depressedBATTERY VOLTAGE

(11 - 14V)

SEF708V

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EC-165

Page 317 of 1226

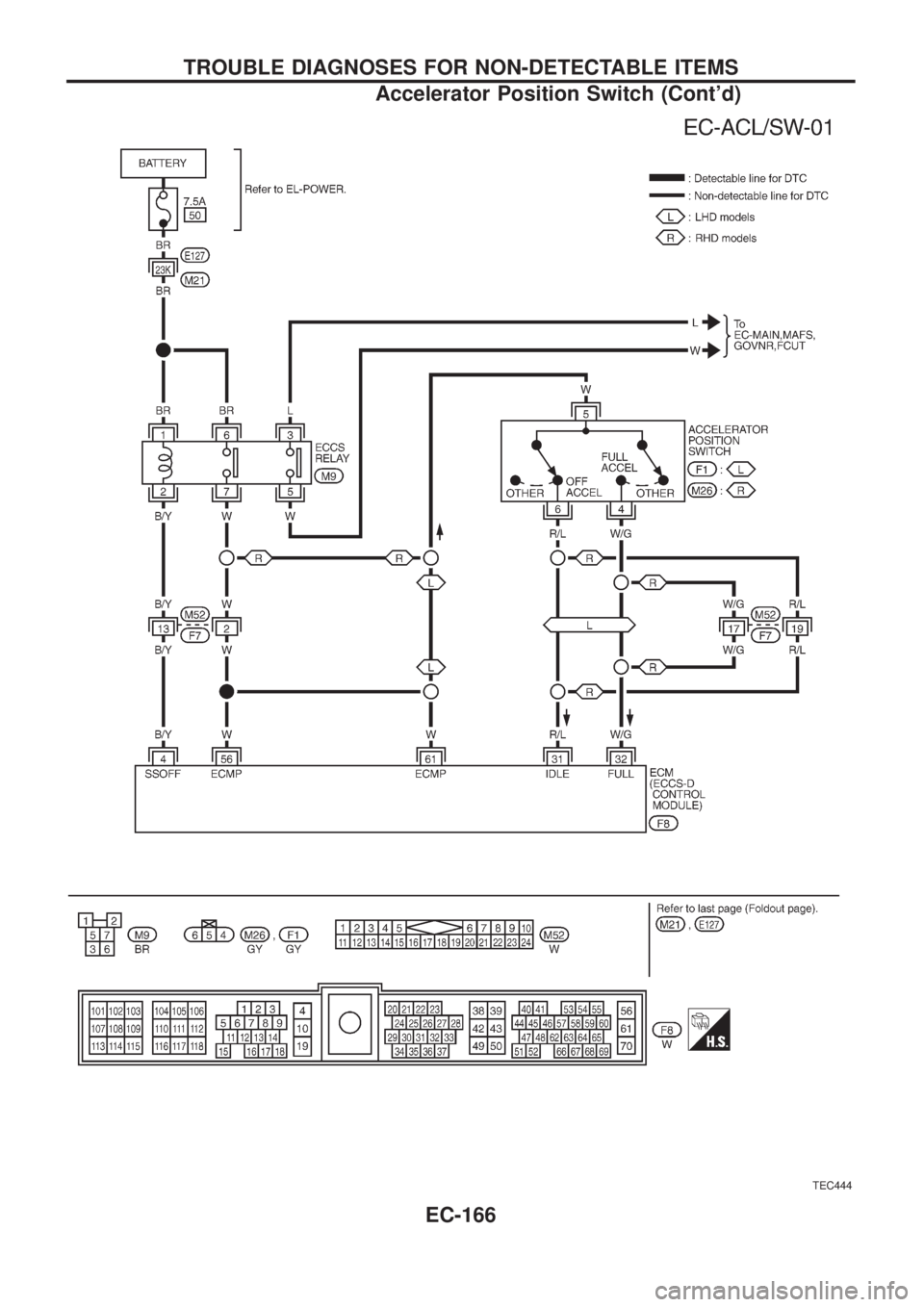

TEC444

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Accelerator Position Switch (Cont'd)

EC-166

Page 318 of 1226

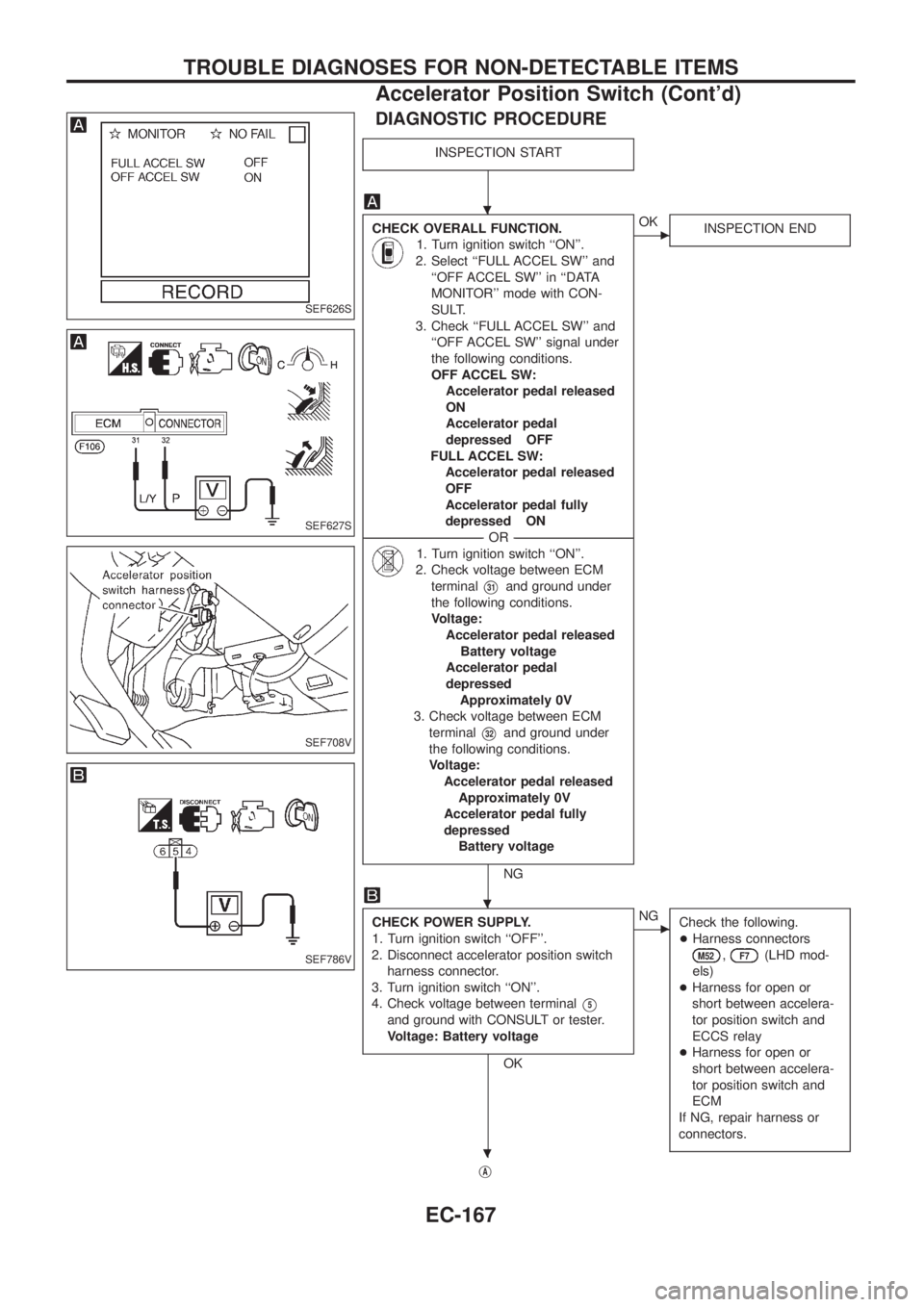

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``ON''.

2. Select ``FULL ACCEL SW'' and

``OFF ACCEL SW'' in ``DATA

MONITOR'' mode with CON-

SULT.

3. Check ``FULL ACCEL SW'' and

``OFF ACCEL SW'' signal under

the following conditions.

OFF ACCEL SW:

Accelerator pedal released

ON

Accelerator pedal

depressed OFF

FULL ACCEL SW:

Accelerator pedal released

OFF

Accelerator pedal fully

depressed ON

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch ``ON''.

2. Check voltage between ECM

terminal

V31and ground under

the following conditions.

Voltage:

Accelerator pedal released

Battery voltage

Accelerator pedal

depressed

Approximately 0V

3. Check voltage between ECM

terminal

V32and ground under

the following conditions.

Voltage:

Accelerator pedal released

Approximately 0V

Accelerator pedal fully

depressed

Battery voltage

NG

cOK

INSPECTION END

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect accelerator position switch

harness connector.

3. Turn ignition switch ``ON''.

4. Check voltage between terminal

V5

and ground with CONSULT or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+Harness connectors

M52,F7(LHD mod-

els)

+Harness for open or

short between accelera-

tor position switch and

ECCS relay

+Harness for open or

short between accelera-

tor position switch and

ECM

If NG, repair harness or

connectors.

jA

SEF626S

SEF627S

SEF708V

SEF786V

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Accelerator Position Switch (Cont'd)

EC-167

Page 319 of 1226

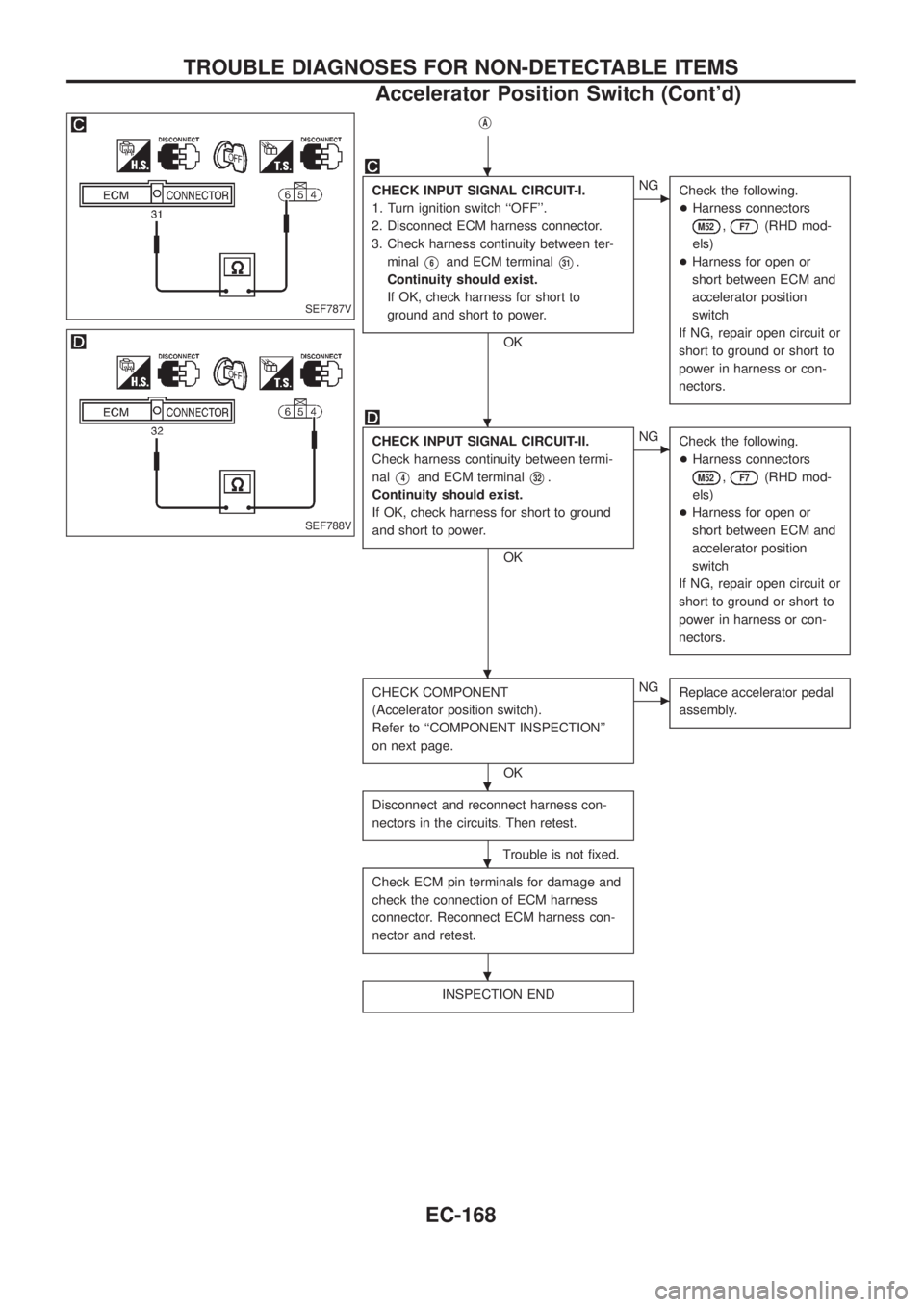

jA

CHECK INPUT SIGNAL CIRCUIT-I.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector.

3. Check harness continuity between ter-

minal

V6and ECM terminalV31.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

M52,F7(RHD mod-

els)

+Harness for open or

short between ECM and

accelerator position

switch

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK INPUT SIGNAL CIRCUIT-II.

Check harness continuity between termi-

nal

V4and ECM terminalV32.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Check the following.

+Harness connectors

M52,F7(RHD mod-

els)

+Harness for open or

short between ECM and

accelerator position

switch

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Accelerator position switch).

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace accelerator pedal

assembly.

Disconnect and reconnect harness con-

nectors in the circuits. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

SEF787V

SEF788V

.

.

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Accelerator Position Switch (Cont'd)

EC-168

Page 320 of 1226

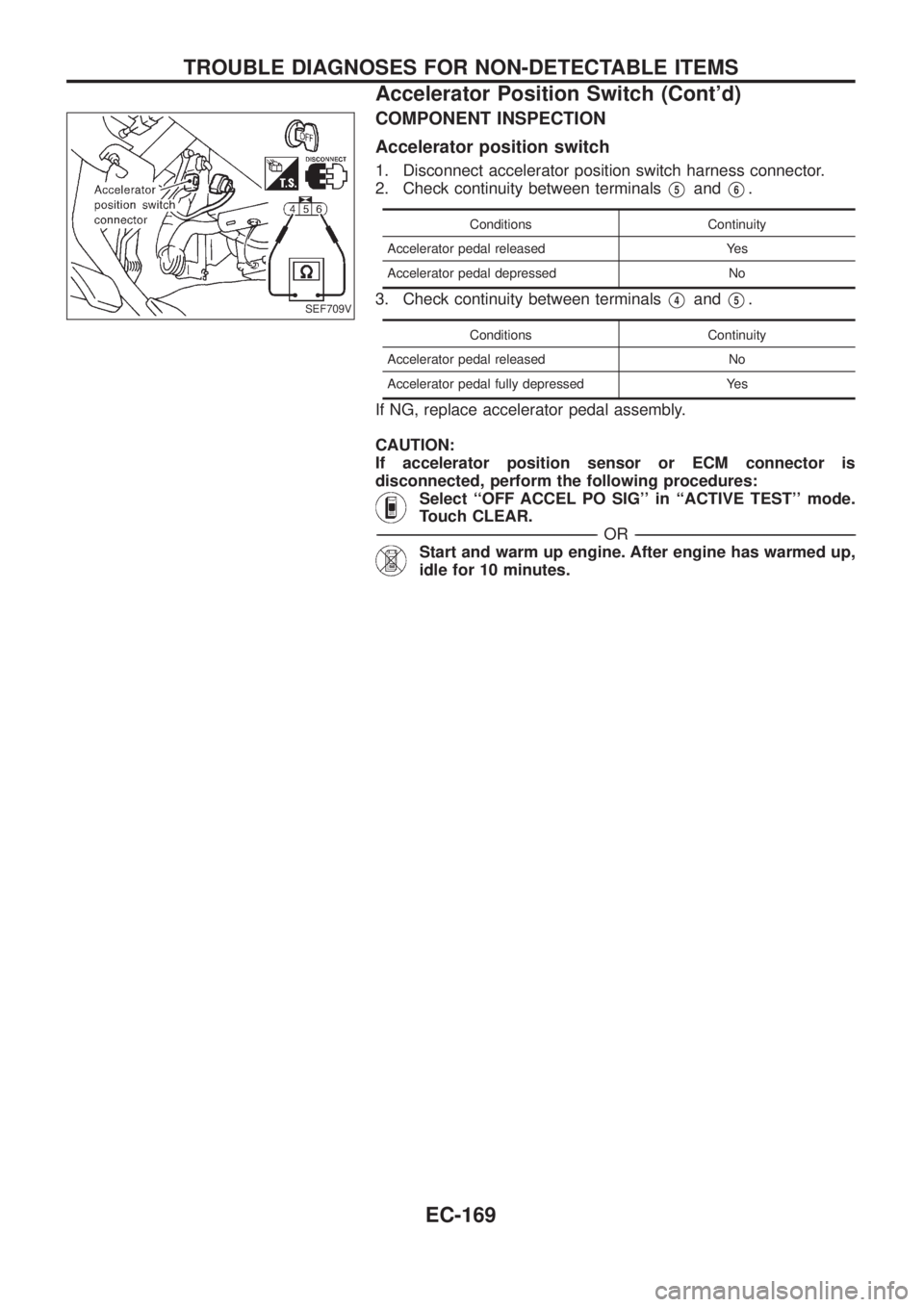

COMPONENT INSPECTION

Accelerator position switch

1. Disconnect accelerator position switch harness connector.

2. Check continuity between terminals

V5andV6.

Conditions Continuity

Accelerator pedal released Yes

Accelerator pedal depressed No

3. Check continuity between terminalsV4andV5.

Conditions Continuity

Accelerator pedal released No

Accelerator pedal fully depressed Yes

If NG, replace accelerator pedal assembly.

CAUTION:

If accelerator position sensor or ECM connector is

disconnected, perform the following procedures:

Select ``OFF ACCEL PO SIG'' in ``ACTIVE TEST'' mode.

Touch CLEAR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Start and warm up engine. After engine has warmed up,

idle for 10 minutes.

SEF709V

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Accelerator Position Switch (Cont'd)

EC-169