accelerator NISSAN PICK-UP 1998 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 670 of 1659

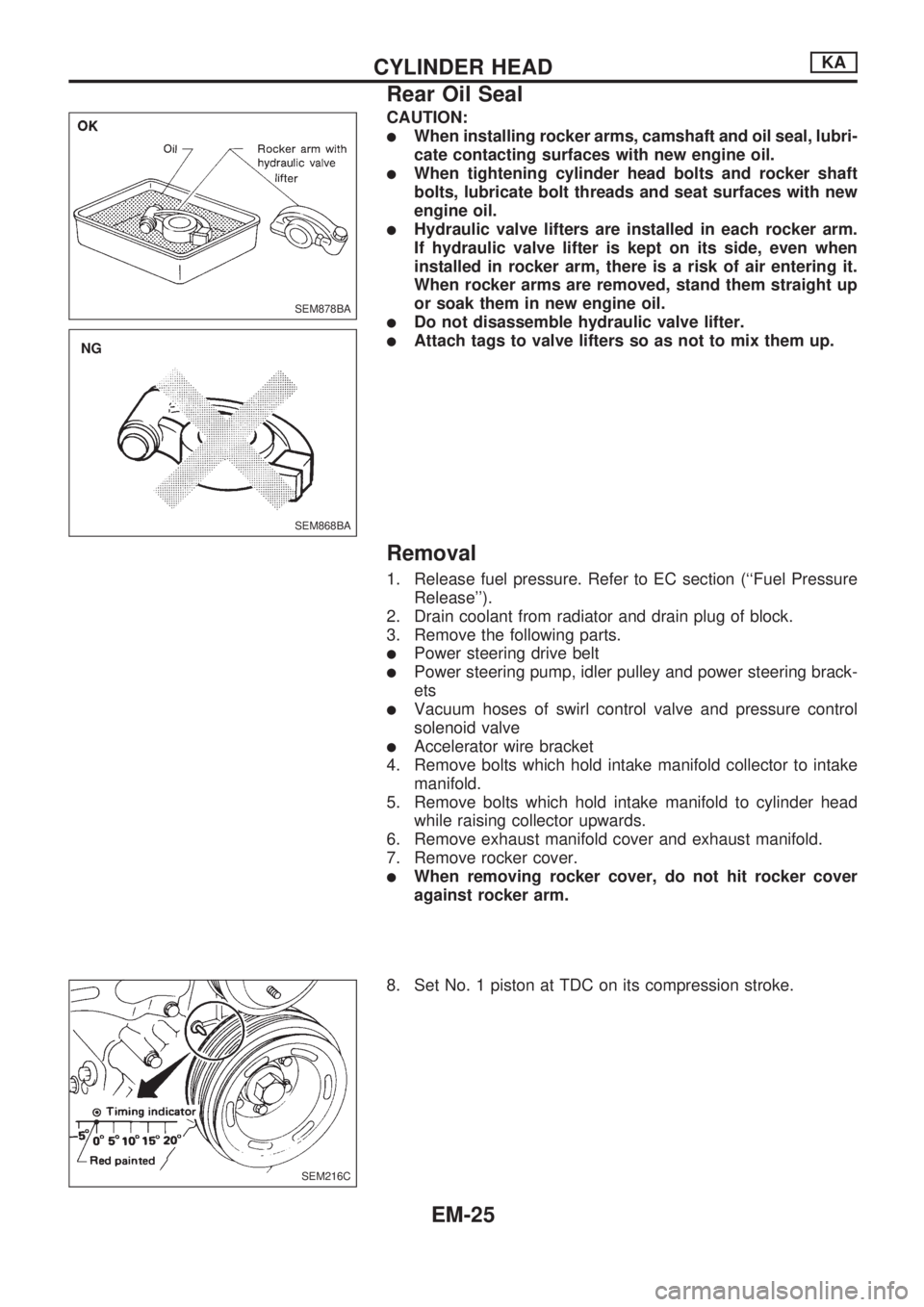

CAUTION:

lWhen installing rocker arms, camshaft and oil seal, lubri-

cate contacting surfaces with new engine oil.

lWhen tightening cylinder head bolts and rocker shaft

bolts, lubricate bolt threads and seat surfaces with new

engine oil.

lHydraulic valve lifters are installed in each rocker arm.

If hydraulic valve lifter is kept on its side, even when

installed in rocker arm, there is a risk of air entering it.

When rocker arms are removed, stand them straight up

or soak them in new engine oil.

lDo not disassemble hydraulic valve lifter.

lAttach tags to valve lifters so as not to mix them up.

Removal

1. Release fuel pressure. Refer to EC section (``Fuel Pressure

Release'').

2. Drain coolant from radiator and drain plug of block.

3. Remove the following parts.

lPower steering drive belt

lPower steering pump, idler pulley and power steering brack-

ets

lVacuum hoses of swirl control valve and pressure control

solenoid valve

lAccelerator wire bracket

4. Remove bolts which hold intake manifold collector to intake

manifold.

5. Remove bolts which hold intake manifold to cylinder head

while raising collector upwards.

6. Remove exhaust manifold cover and exhaust manifold.

7. Remove rocker cover.

lWhen removing rocker cover, do not hit rocker cover

against rocker arm.

8. Set No. 1 piston at TDC on its compression stroke.

SEM878BA

SEM868BA

.NG

SEM216C

CYLINDER HEADKA

Rear Oil Seal

EM-25

Page 681 of 1659

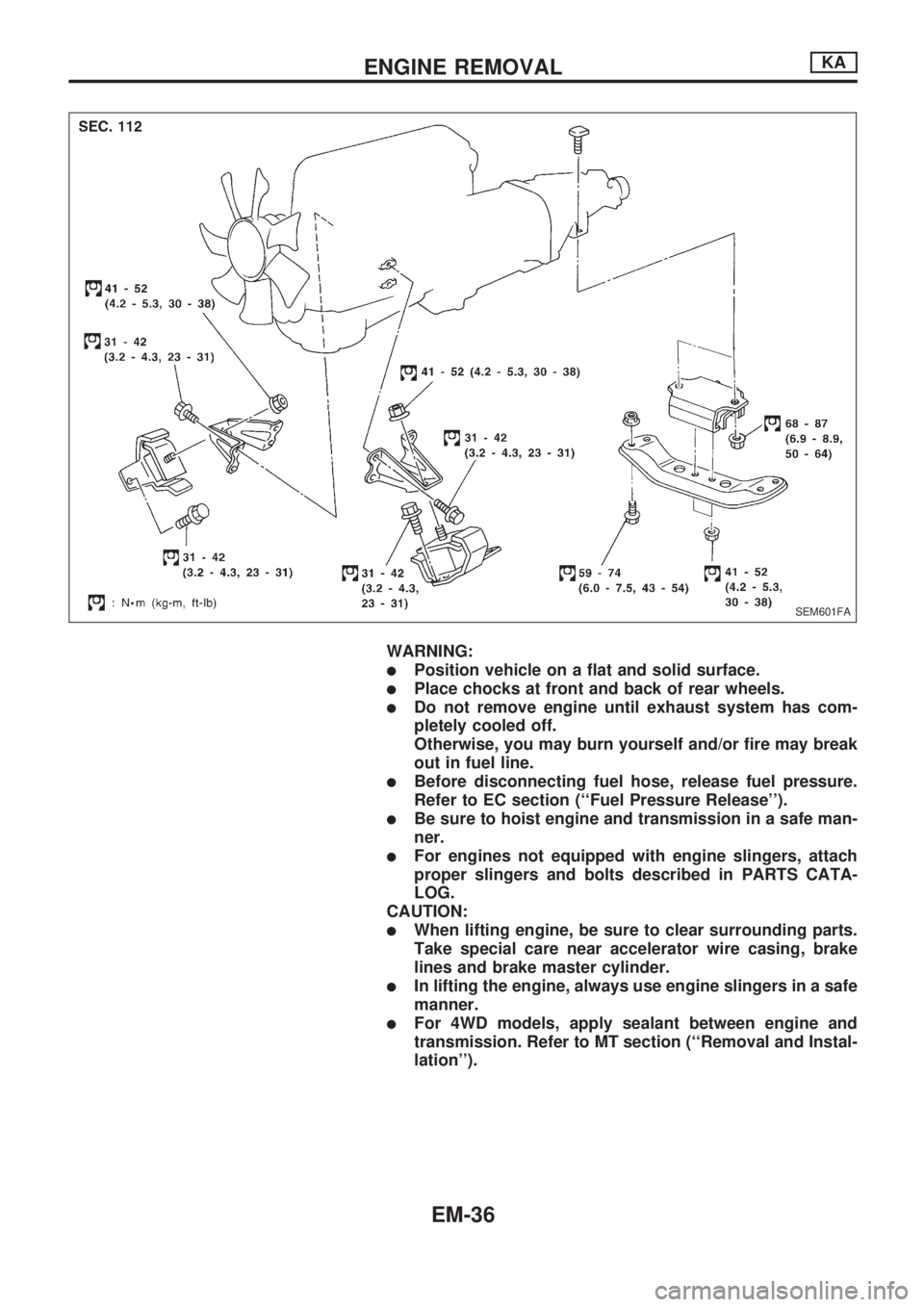

WARNING:

lPosition vehicle on a flat and solid surface.

lPlace chocks at front and back of rear wheels.

lDo not remove engine until exhaust system has com-

pletely cooled off.

Otherwise, you may burn yourself and/or fire may break

out in fuel line.

lBefore disconnecting fuel hose, release fuel pressure.

Refer to EC section (``Fuel Pressure Release'').

lBe sure to hoist engine and transmission in a safe man-

ner.

lFor engines not equipped with engine slingers, attach

proper slingers and bolts described in PARTS CATA-

LOG.

CAUTION:

lWhen lifting engine, be sure to clear surrounding parts.

Take special care near accelerator wire casing, brake

lines and brake master cylinder.

lIn lifting the engine, always use engine slingers in a safe

manner.

lFor 4WD models, apply sealant between engine and

transmission. Refer to MT section (``Removal and Instal-

lation'').

SEM601FA

ENGINE REMOVALKA

EM-36

Page 682 of 1659

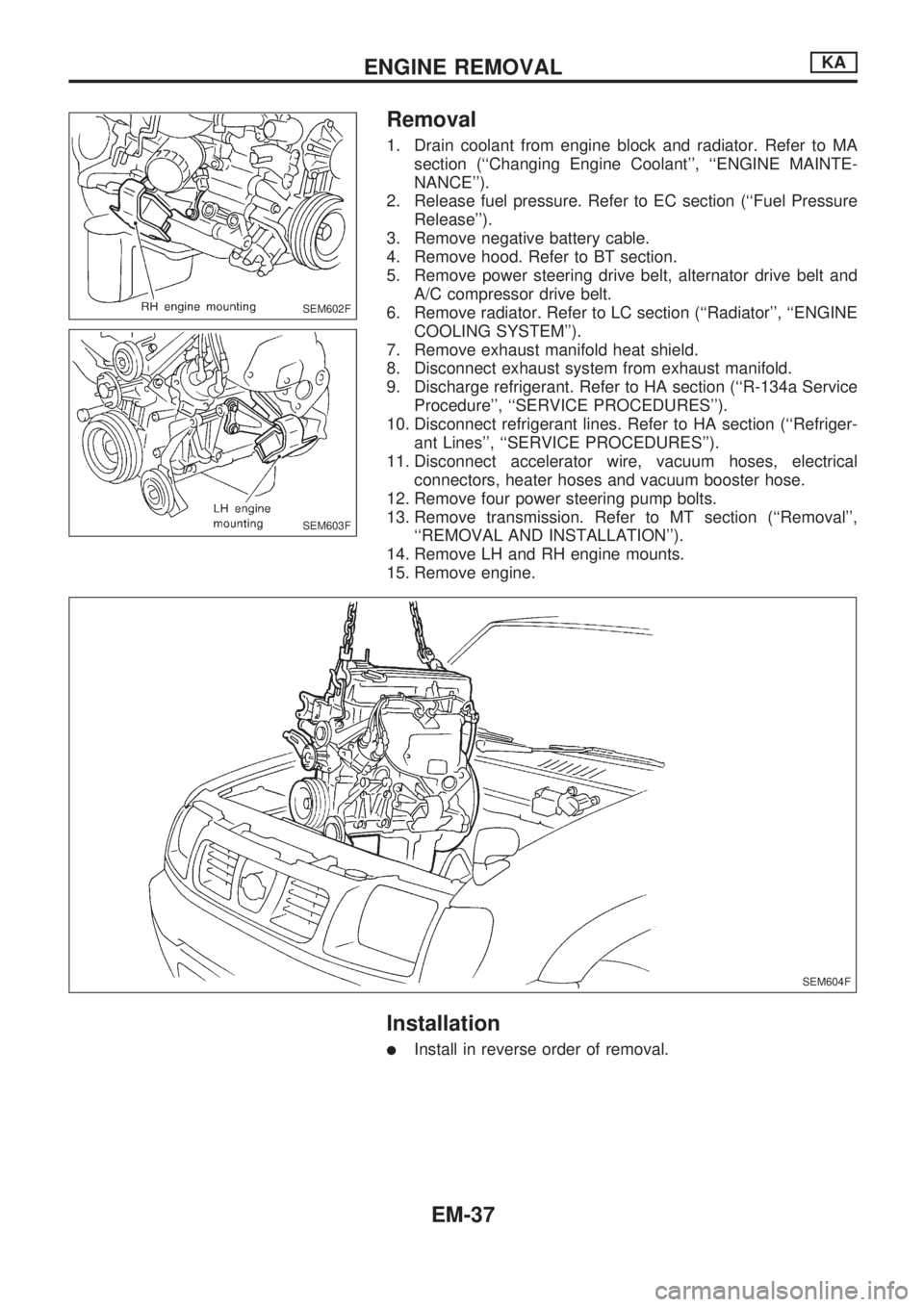

Removal

1. Drain coolant from engine block and radiator. Refer to MA

section (``Changing Engine Coolant'', ``ENGINE MAINTE-

NANCE'').

2. Release fuel pressure. Refer to EC section (``Fuel Pressure

Release'').

3. Remove negative battery cable.

4. Remove hood. Refer to BT section.

5. Remove power steering drive belt, alternator drive belt and

A/C compressor drive belt.

6. Remove radiator. Refer to LC section (``Radiator'', ``ENGINE

COOLING SYSTEM'').

7. Remove exhaust manifold heat shield.

8. Disconnect exhaust system from exhaust manifold.

9. Discharge refrigerant. Refer to HA section (``R-134a Service

Procedure'', ``SERVICE PROCEDURES'').

10. Disconnect refrigerant lines. Refer to HA section (``Refriger-

ant Lines'', ``SERVICE PROCEDURES'').

11. Disconnect accelerator wire, vacuum hoses, electrical

connectors, heater hoses and vacuum booster hose.

12. Remove four power steering pump bolts.

13. Remove transmission. Refer to MT section (``Removal'',

``REMOVAL AND INSTALLATION'').

14. Remove LH and RH engine mounts.

15. Remove engine.

Installation

lInstall in reverse order of removal.

SEM602F

SEM603F

SEM604F

ENGINE REMOVALKA

EM-37

Page 697 of 1659

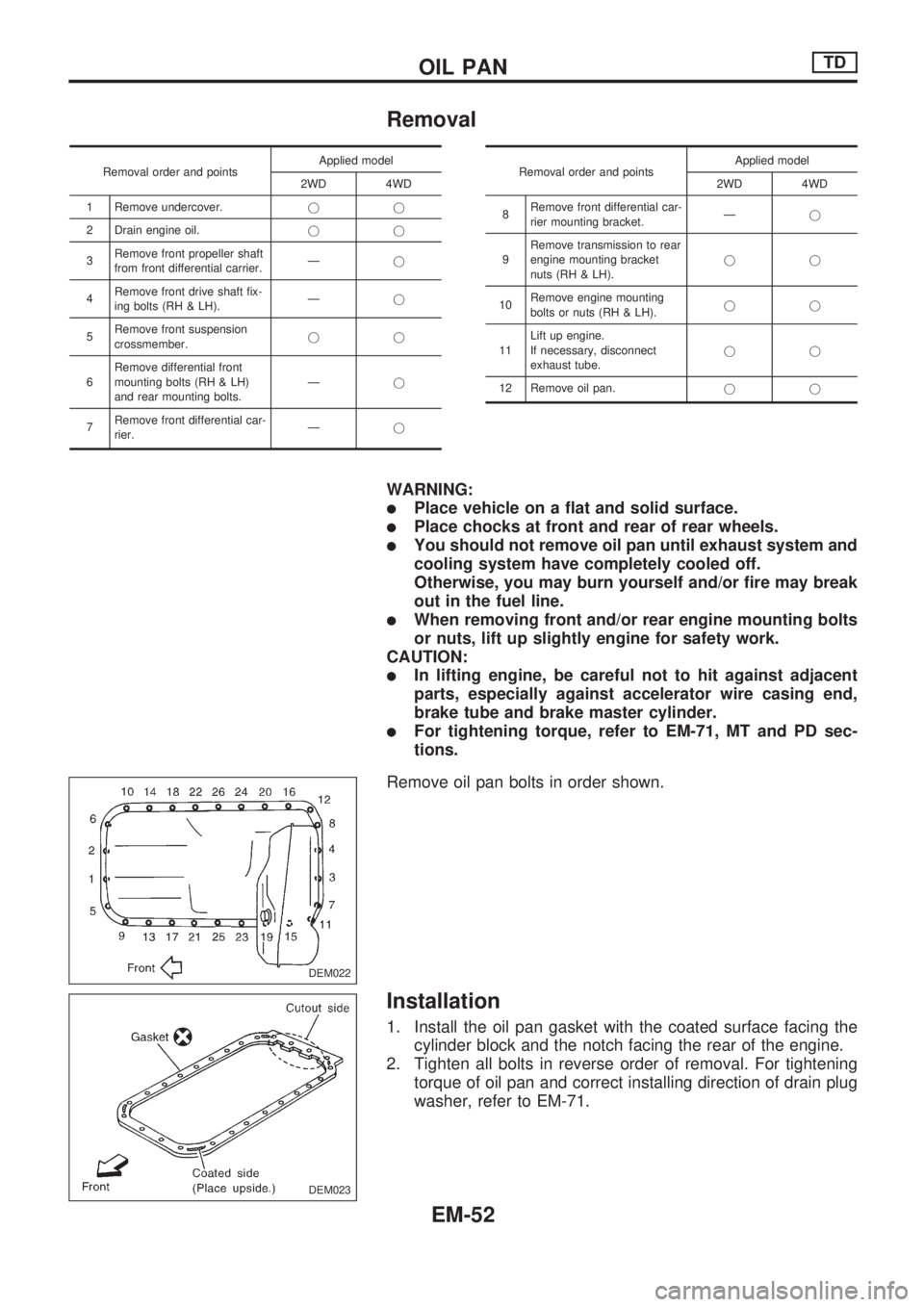

Removal

Removal order and pointsApplied model

2WD 4WD

1 Remove undercover.jj

2 Drain engine oil.jj

3Remove front propeller shaft

from front differential carrier.Ðj

4Remove front drive shaft fix-

ing bolts (RH & LH).Ðj

5Remove front suspension

crossmember.jj

6Remove differential front

mounting bolts (RH & LH)

and rear mounting bolts.Ðj

7Remove front differential car-

rier.ÐjRemoval order and pointsApplied model

2WD 4WD

8Remove front differential car-

rier mounting bracket.Ðj

9Remove transmission to rear

engine mounting bracket

nuts (RH & LH).jj

10Remove engine mounting

bolts or nuts (RH & LH).jj

11Lift up engine.

If necessary, disconnect

exhaust tube.jj

12 Remove oil pan.jj

WARNING:

lPlace vehicle on a flat and solid surface.

lPlace chocks at front and rear of rear wheels.

lYou should not remove oil pan until exhaust system and

cooling system have completely cooled off.

Otherwise, you may burn yourself and/or fire may break

out in the fuel line.

lWhen removing front and/or rear engine mounting bolts

or nuts, lift up slightly engine for safety work.

CAUTION:

lIn lifting engine, be careful not to hit against adjacent

parts, especially against accelerator wire casing end,

brake tube and brake master cylinder.

lFor tightening torque, refer to EM-71, MT and PD sec-

tions.

Remove oil pan bolts in order shown.

Installation

1. Install the oil pan gasket with the coated surface facing the

cylinder block and the notch facing the rear of the engine.

2. Tighten all bolts in reverse order of removal. For tightening

torque of oil pan and correct installing direction of drain plug

washer, refer to EM-71.

DEM022

DEM023

OIL PANTD

EM-52

Page 714 of 1659

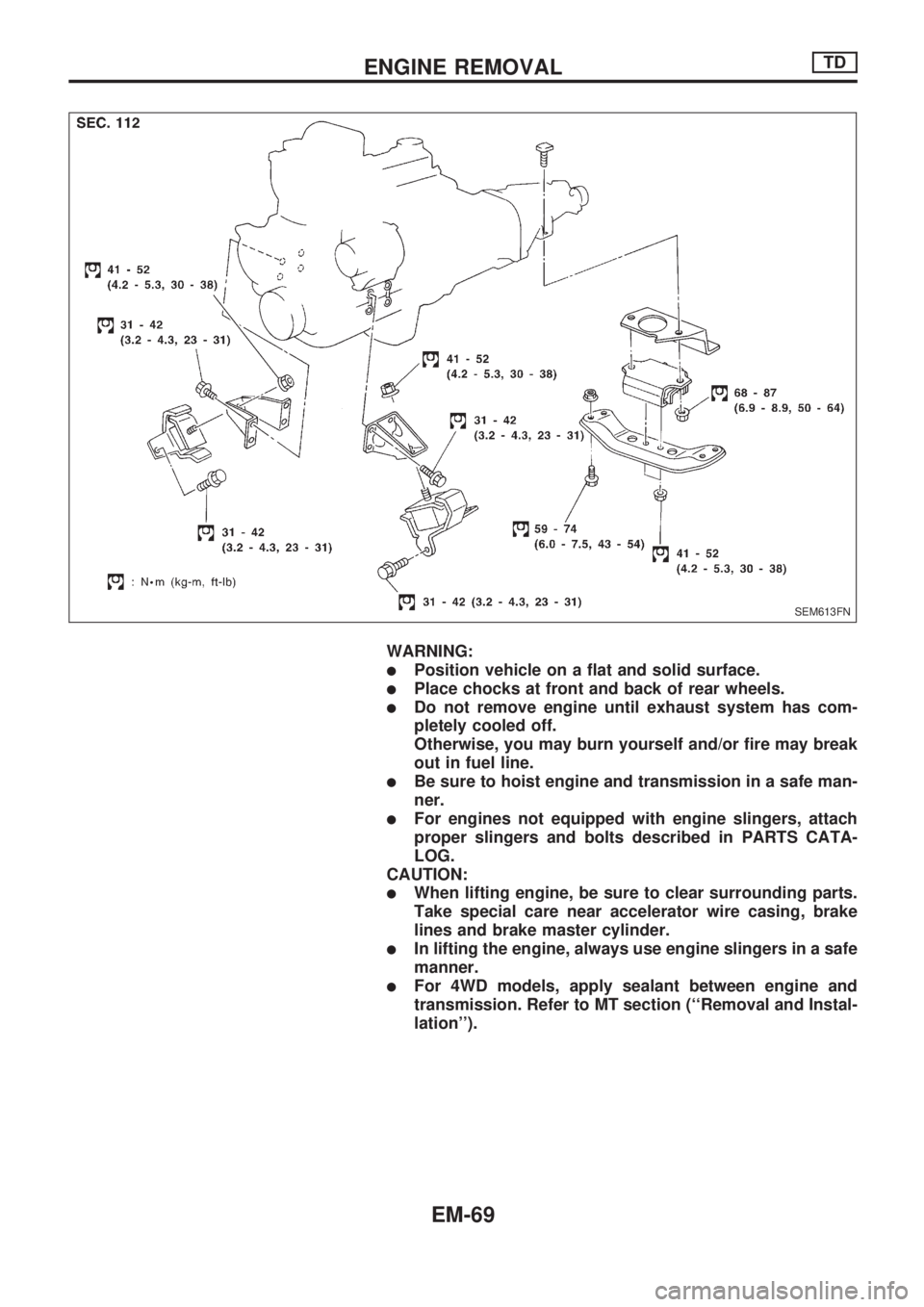

WARNING:

lPosition vehicle on a flat and solid surface.

lPlace chocks at front and back of rear wheels.

lDo not remove engine until exhaust system has com-

pletely cooled off.

Otherwise, you may burn yourself and/or fire may break

out in fuel line.

lBe sure to hoist engine and transmission in a safe man-

ner.

lFor engines not equipped with engine slingers, attach

proper slingers and bolts described in PARTS CATA-

LOG.

CAUTION:

lWhen lifting engine, be sure to clear surrounding parts.

Take special care near accelerator wire casing, brake

lines and brake master cylinder.

lIn lifting the engine, always use engine slingers in a safe

manner.

lFor 4WD models, apply sealant between engine and

transmission. Refer to MT section (``Removal and Instal-

lation'').

SEM613FN

ENGINE REMOVALTD

EM-69

Page 756 of 1659

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMS

SECTIONFE

CONTENTS

PREPARATION/ACCELERATOR CONTROL

SYSTEM..................................................................... 1

Special Service Tool .............................................. 1

Accelerator Control System ................................... 1Adjusting Accelerator Wire .................................... 2

FUEL SYSTEM.......................................................... 3

EXHAUST SYSTEM.................................................. 5

FE

Page 757 of 1659

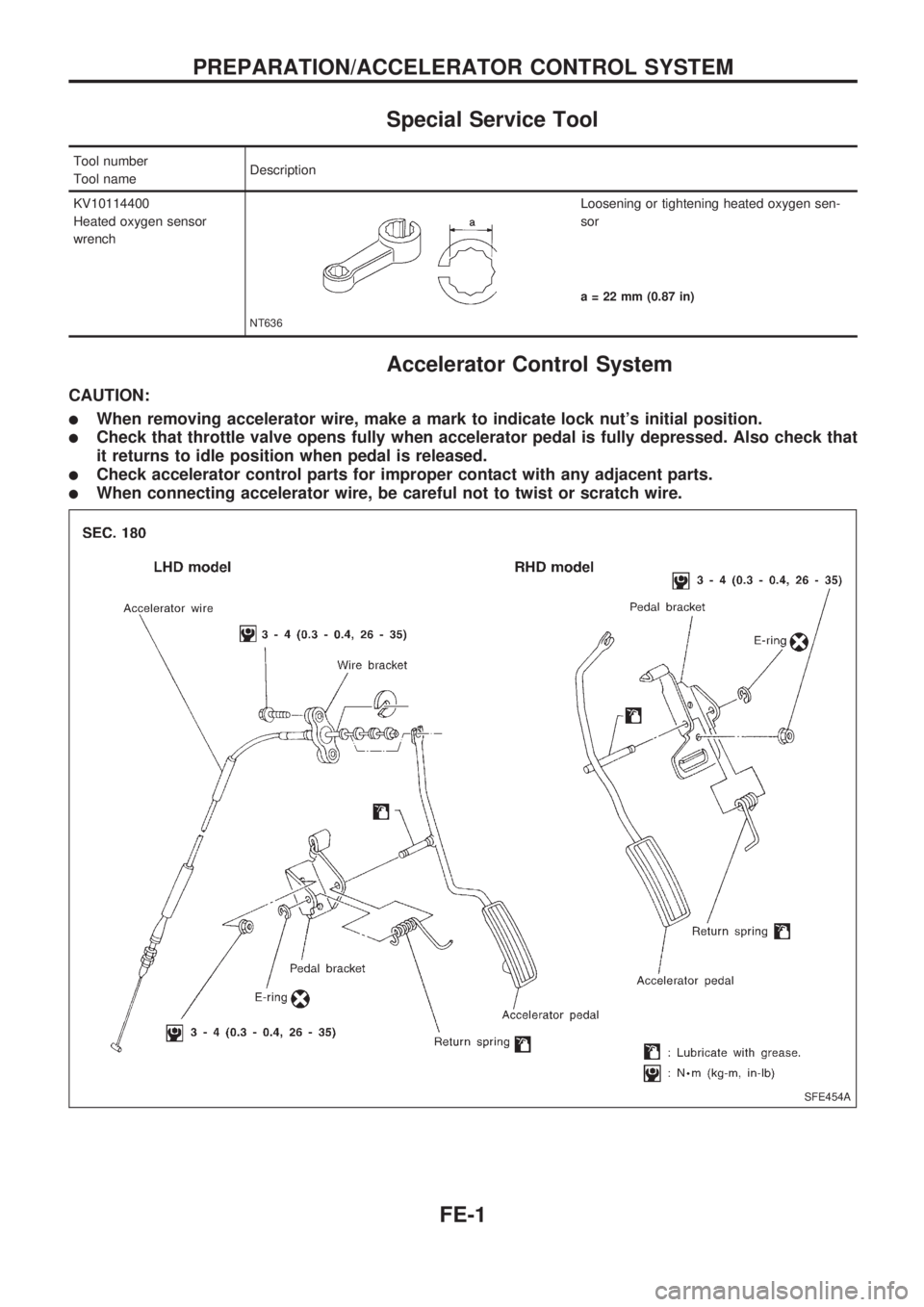

Special Service Tool

Tool number

Tool nameDescription

KV10114400

Heated oxygen sensor

wrench

NT636

Loosening or tightening heated oxygen sen-

sor

a = 22 mm (0.87 in)

Accelerator Control System

CAUTION:

lWhen removing accelerator wire, make a mark to indicate lock nut's initial position.

lCheck that throttle valve opens fully when accelerator pedal is fully depressed. Also check that

it returns to idle position when pedal is released.

lCheck accelerator control parts for improper contact with any adjacent parts.

lWhen connecting accelerator wire, be careful not to twist or scratch wire.

SFE454A

PREPARATION/ACCELERATOR CONTROL SYSTEM

FE-1

Page 758 of 1659

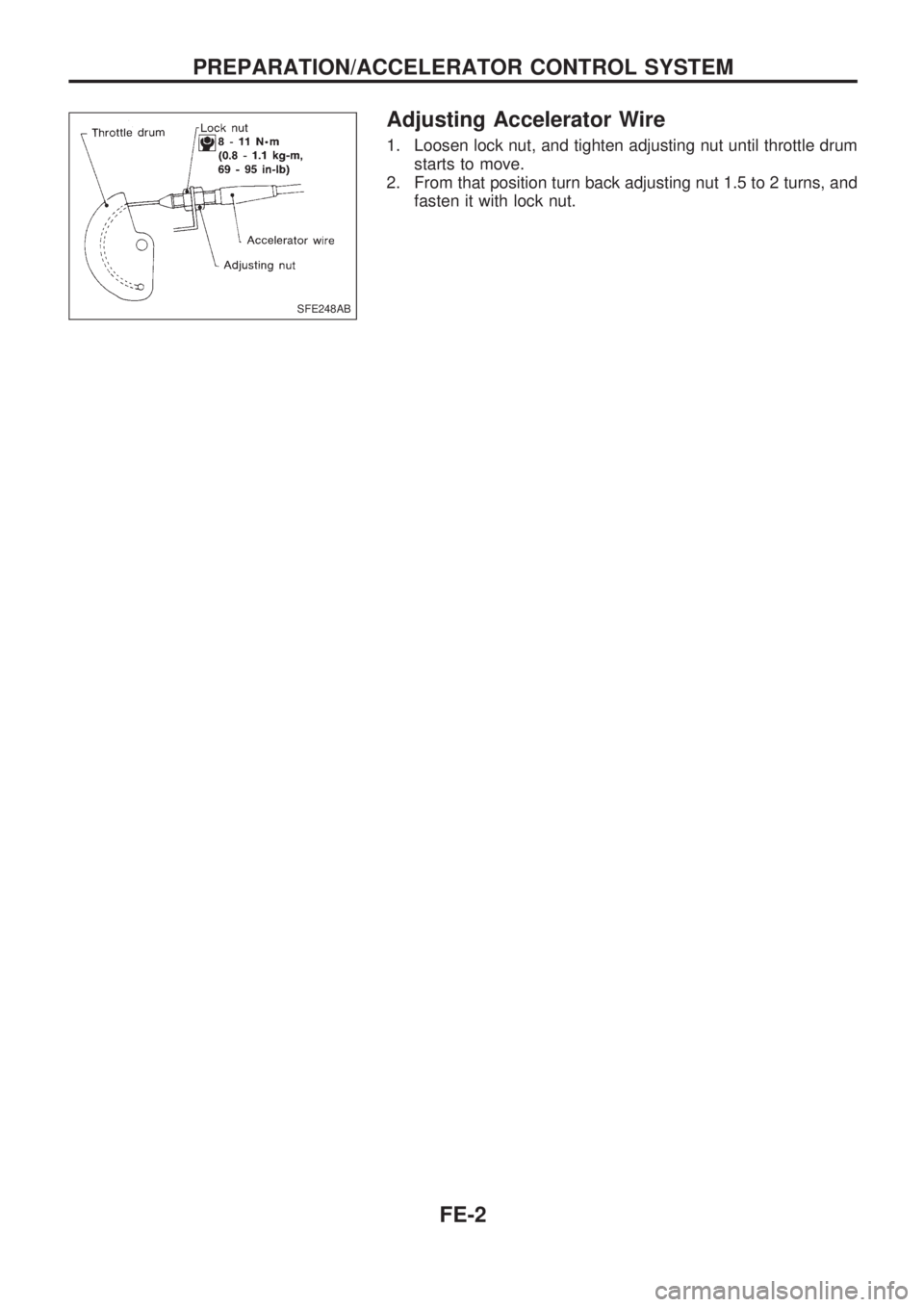

Adjusting Accelerator Wire

1. Loosen lock nut, and tighten adjusting nut until throttle drum

starts to move.

2. From that position turn back adjusting nut 1.5 to 2 turns, and

fasten it with lock nut.

SFE248AB

PREPARATION/ACCELERATOR CONTROL SYSTEM

FE-2

Page 837 of 1659

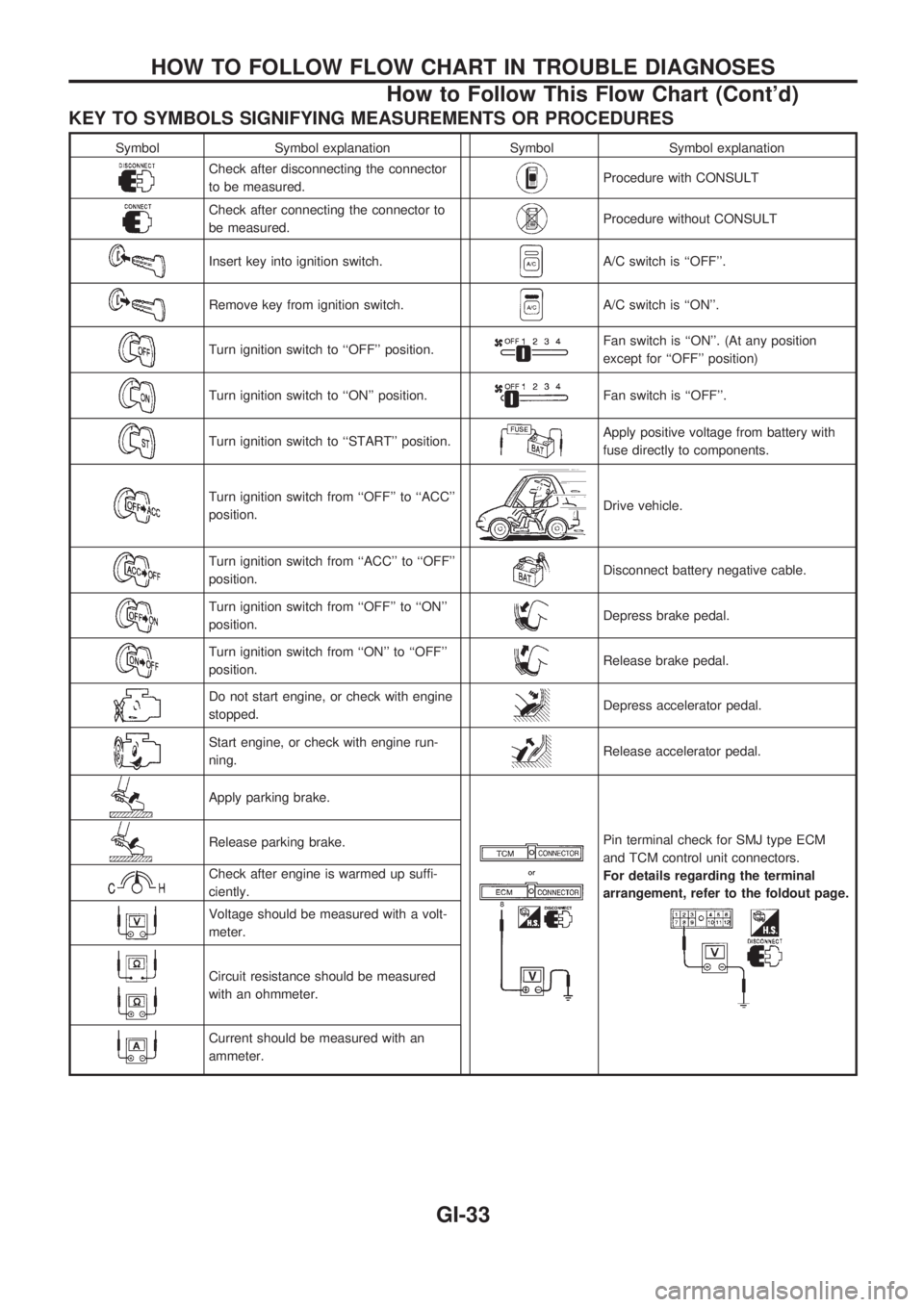

KEY TO SYMBOLS SIGNIFYING MEASUREMENTS OR PROCEDURES

Symbol Symbol explanation Symbol Symbol explanation

Check after disconnecting the connector

to be measured.Procedure with CONSULT

Check after connecting the connector to

be measured.Procedure without CONSULT

Insert key into ignition switch.A/C switch is ``OFF''.

Remove key from ignition switch.A/C switch is ``ON''.

Turn ignition switch to ``OFF'' position.Fan switch is ``ON''. (At any position

except for ``OFF'' position)

Turn ignition switch to ``ON'' position.Fan switch is ``OFF''.

Turn ignition switch to ``START'' position.Apply positive voltage from battery with

fuse directly to components.

Turn ignition switch from ``OFF'' to ``ACC''

position.Drive vehicle.

Turn ignition switch from ``ACC'' to ``OFF''

position.Disconnect battery negative cable.

Turn ignition switch from ``OFF'' to ``ON''

position.Depress brake pedal.

Turn ignition switch from ``ON'' to ``OFF''

position.Release brake pedal.

Do not start engine, or check with engine

stopped.Depress accelerator pedal.

Start engine, or check with engine run-

ning.Release accelerator pedal.

Apply parking brake.

Pin terminal check for SMJ type ECM

and TCM control unit connectors.

For details regarding the terminal

arrangement, refer to the foldout page.Release parking brake.

Check after engine is warmed up suffi-

ciently.

Voltage should be measured with a volt-

meter.

Circuit resistance should be measured

with an ohmmeter.

Current should be measured with an

ammeter.

HOW TO FOLLOW FLOW CHART IN TROUBLE DIAGNOSES

How to Follow This Flow Chart (Cont'd)

GI-33

Page 864 of 1659

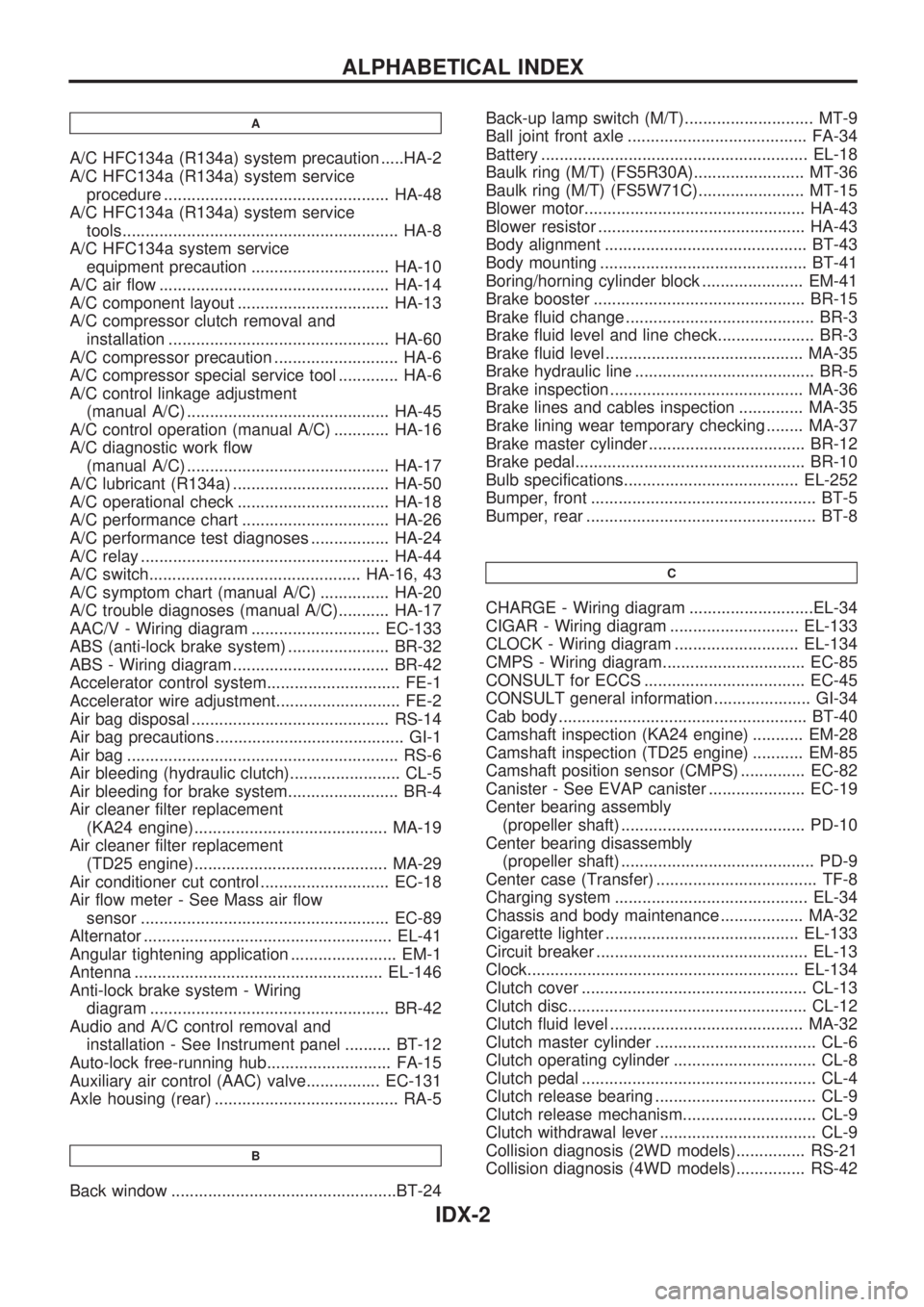

A

A/C HFC134a (R134a) system precaution .....HA-2

A/C HFC134a (R134a) system service

procedure ................................................. HA-48

A/C HFC134a (R134a) system service

tools............................................................ HA-8

A/C HFC134a system service

equipment precaution .............................. HA-10

A/C air flow .................................................. HA-14

A/C component layout ................................. HA-13

A/C compressor clutch removal and

installation ................................................ HA-60

A/C compressor precaution ........................... HA-6

A/C compressor special service tool ............. HA-6

A/C control linkage adjustment

(manual A/C) ............................................ HA-45

A/C control operation (manual A/C) ............ HA-16

A/C diagnostic work flow

(manual A/C) ............................................ HA-17

A/C lubricant (R134a) .................................. HA-50

A/C operational check ................................. HA-18

A/C performance chart ................................ HA-26

A/C performance test diagnoses ................. HA-24

A/C relay ...................................................... HA-44

A/C switch.............................................. HA-16, 43

A/C symptom chart (manual A/C) ............... HA-20

A/C trouble diagnoses (manual A/C)........... HA-17

AAC/V - Wiring diagram ............................ EC-133

ABS (anti-lock brake system) ...................... BR-32

ABS - Wiring diagram .................................. BR-42

Accelerator control system............................. FE-1

Accelerator wire adjustment........................... FE-2

Air bag disposal ........................................... RS-14

Air bag precautions ......................................... GI-1

Air bag ........................................................... RS-6

Air bleeding (hydraulic clutch)........................ CL-5

Air bleeding for brake system........................ BR-4

Air cleaner filter replacement

(KA24 engine).......................................... MA-19

Air cleaner filter replacement

(TD25 engine).......................................... MA-29

Air conditioner cut control ............................ EC-18

Air flow meter - See Mass air flow

sensor ...................................................... EC-89

Alternator ...................................................... EL-41

Angular tightening application ....................... EM-1

Antenna ...................................................... EL-146

Anti-lock brake system - Wiring

diagram .................................................... BR-42

Audio and A/C control removal and

installation - See Instrument panel .......... BT-12

Auto-lock free-running hub........................... FA-15

Auxiliary air control (AAC) valve................ EC-131

Axle housing (rear) ........................................ RA-5

B

Back window .................................................BT-24Back-up lamp switch (M/T)............................ MT-9

Ball joint front axle ....................................... FA-34

Battery .......................................................... EL-18

Baulk ring (M/T) (FS5R30A)........................ MT-36

Baulk ring (M/T) (FS5W71C)....................... MT-15

Blower motor................................................ HA-43

Blower resistor ............................................. HA-43

Body alignment ............................................ BT-43

Body mounting ............................................. BT-41

Boring/horning cylinder block ...................... EM-41

Brake booster .............................................. BR-15

Brake fluid change ......................................... BR-3

Brake fluid level and line check..................... BR-3

Brake fluid level ........................................... MA-35

Brake hydraulic line ....................................... BR-5

Brake inspection .......................................... MA-36

Brake lines and cables inspection .............. MA-35

Brake lining wear temporary checking ........ MA-37

Brake master cylinder .................................. BR-12

Brake pedal.................................................. BR-10

Bulb specifications...................................... EL-252

Bumper, front ................................................. BT-5

Bumper, rear .................................................. BT-8

C

CHARGE - Wiring diagram ...........................EL-34

CIGAR - Wiring diagram ............................ EL-133

CLOCK - Wiring diagram ........................... EL-134

CMPS - Wiring diagram............................... EC-85

CONSULT for ECCS ................................... EC-45

CONSULT general information ..................... GI-34

Cab body ...................................................... BT-40

Camshaft inspection (KA24 engine) ........... EM-28

Camshaft inspection (TD25 engine) ........... EM-85

Camshaft position sensor (CMPS) .............. EC-82

Canister - See EVAP canister ..................... EC-19

Center bearing assembly

(propeller shaft) ........................................ PD-10

Center bearing disassembly

(propeller shaft) .......................................... PD-9

Center case (Transfer) ................................... TF-8

Charging system .......................................... EL-34

Chassis and body maintenance .................. MA-32

Cigarette lighter .......................................... EL-133

Circuit breaker .............................................. EL-13

Clock........................................................... EL-134

Clutch cover ................................................. CL-13

Clutch disc.................................................... CL-12

Clutch fluid level .......................................... MA-32

Clutch master cylinder ................................... CL-6

Clutch operating cylinder ............................... CL-8

Clutch pedal ................................................... CL-4

Clutch release bearing ................................... CL-9

Clutch release mechanism............................. CL-9

Clutch withdrawal lever .................................. CL-9

Collision diagnosis (2WD models)............... RS-21

Collision diagnosis (4WD models)............... RS-42

ALPHABETICAL INDEX

IDX-2