check engine NISSAN PICK-UP 1998 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 79 of 1659

Note: ABS may operate and cause vibration under any of the

following conditions.

lApplying brake gradually when shifting or operating

clutch.

lLow friction (slippery) road.

lHigh speed cornering.

lDriving over bumps and pot holes.

lEngine speed is over 5,000 rpm with vehicle stopped.

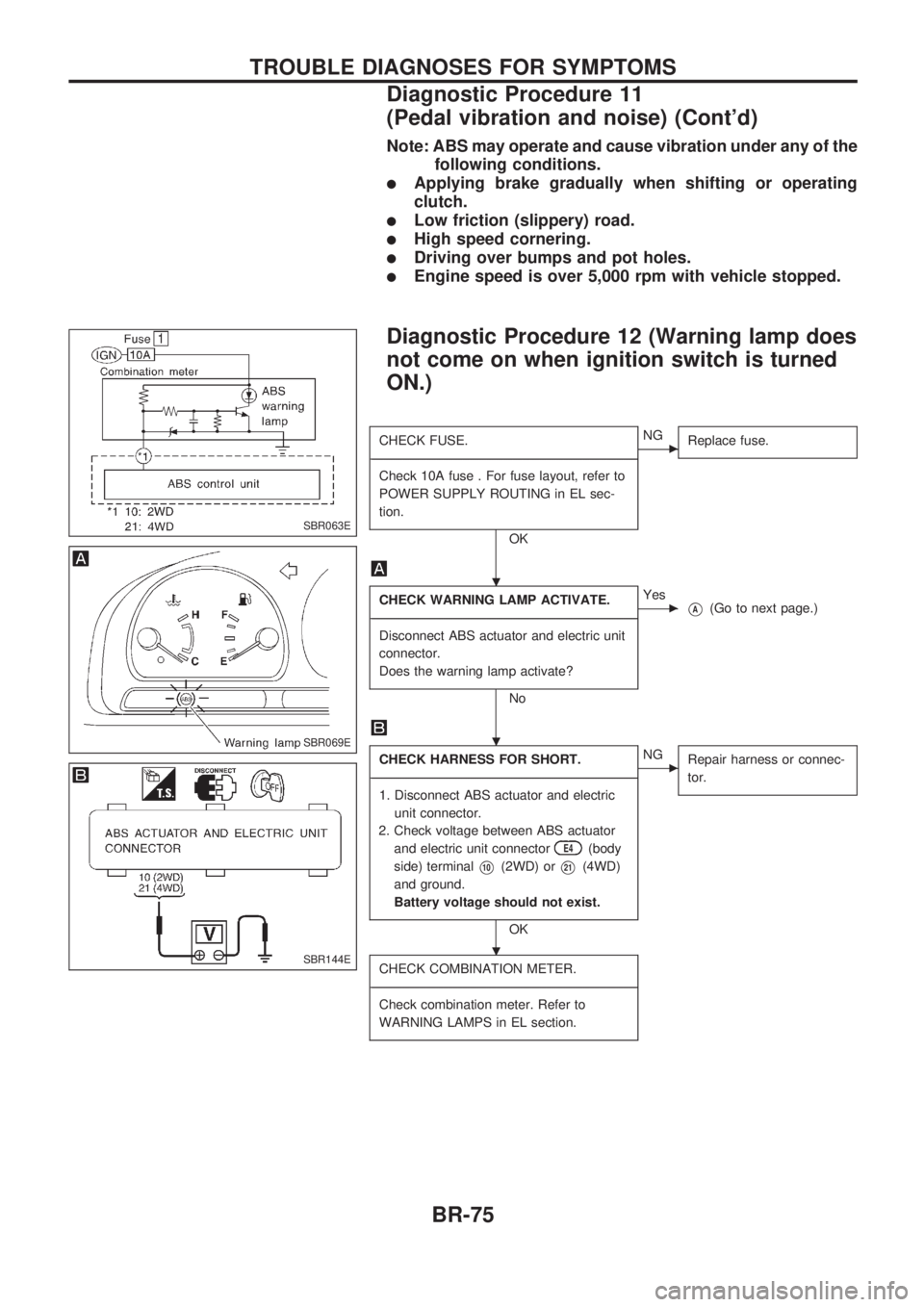

Diagnostic Procedure 12 (Warning lamp does

not come on when ignition switch is turned

ON.)

CHECK FUSE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check 10A fuse . For fuse layout, refer to

POWER SUPPLY ROUTING in EL sec-

tion.

OK

cNG

Replace fuse.

CHECK WARNING LAMP ACTIVATE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Disconnect ABS actuator and electric unit

connector.

Does the warning lamp activate?

No

cYes

VA(Go to next page.)

CHECK HARNESS FOR SHORT.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

E4(body

side) terminal

V10(2WD) orV21(4WD)

and ground.

Battery voltage should not exist.

OK

cNG

Repair harness or connec-

tor.

CHECK COMBINATION METER.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check combination meter. Refer to

WARNING LAMPS in EL section.

SBR063E

SBR069E

SBR144E

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

Diagnostic Procedure 11

(Pedal vibration and noise) (Cont'd)

BR-75

Page 93 of 1659

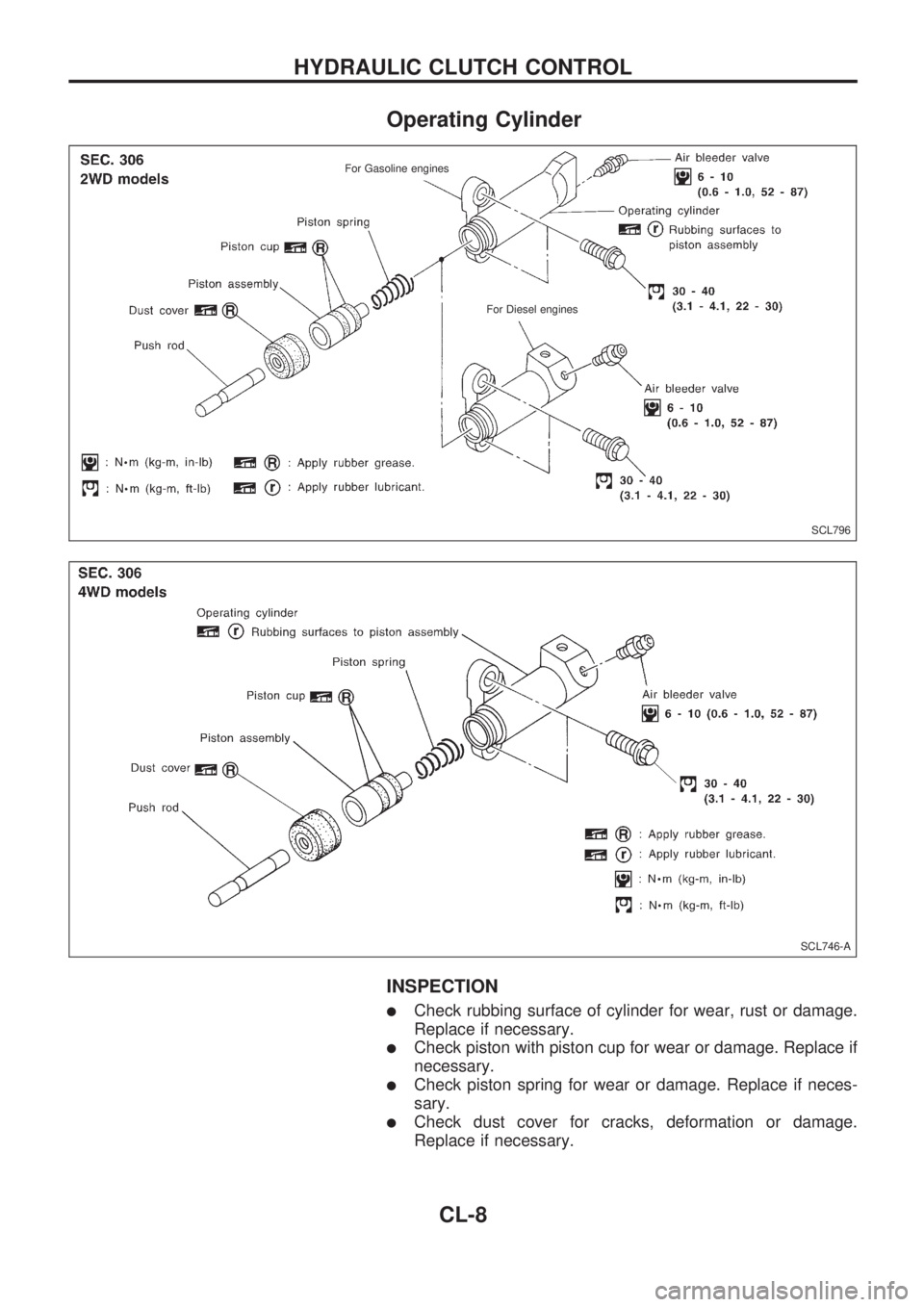

Operating Cylinder

INSPECTION

lCheck rubbing surface of cylinder for wear, rust or damage.

Replace if necessary.

lCheck piston with piston cup for wear or damage. Replace if

necessary.

lCheck piston spring for wear or damage. Replace if neces-

sary.

lCheck dust cover for cracks, deformation or damage.

Replace if necessary.

SCL796

.

For Gasoline engines

.

For Diesel engines

SCL746-A

.

HYDRAULIC CLUTCH CONTROL

CL-8

Page 97 of 1659

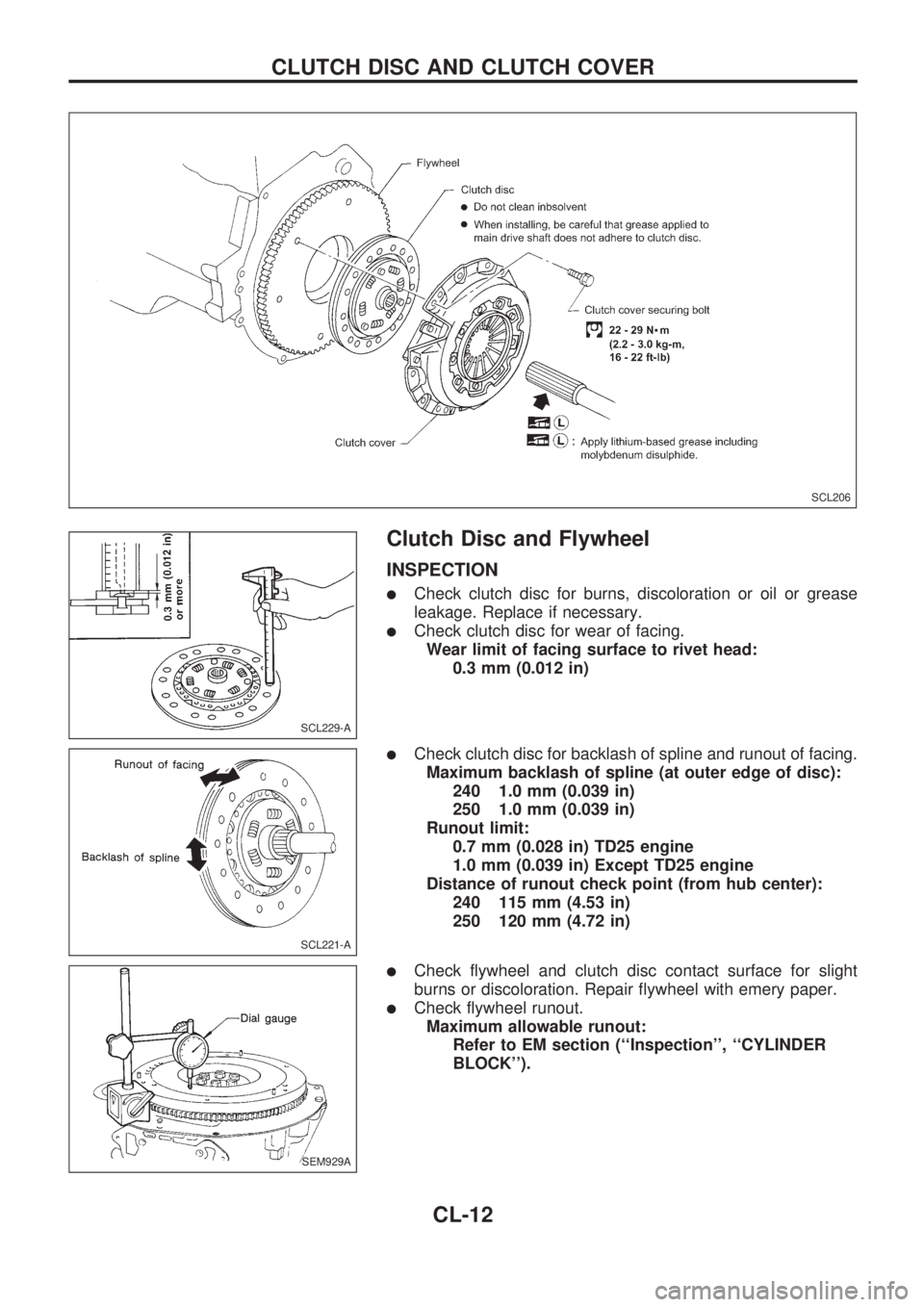

Clutch Disc and Flywheel

INSPECTION

lCheck clutch disc for burns, discoloration or oil or grease

leakage. Replace if necessary.

lCheck clutch disc for wear of facing.

Wear limit of facing surface to rivet head:

0.3 mm (0.012 in)

lCheck clutch disc for backlash of spline and runout of facing.

Maximum backlash of spline (at outer edge of disc):

240 1.0 mm (0.039 in)

250 1.0 mm (0.039 in)

Runout limit:

0.7 mm (0.028 in) TD25 engine

1.0 mm (0.039 in) Except TD25 engine

Distance of runout check point (from hub center):

240 115 mm (4.53 in)

250 120 mm (4.72 in)

lCheck flywheel and clutch disc contact surface for slight

burns or discoloration. Repair flywheel with emery paper.

lCheck flywheel runout.

Maximum allowable runout:

Refer to EM section (``Inspection'', ``CYLINDER

BLOCK'').

SCL206

SCL229-A

SCL221-A

SEM929A

CLUTCH DISC AND CLUTCH COVER

CL-12

Page 98 of 1659

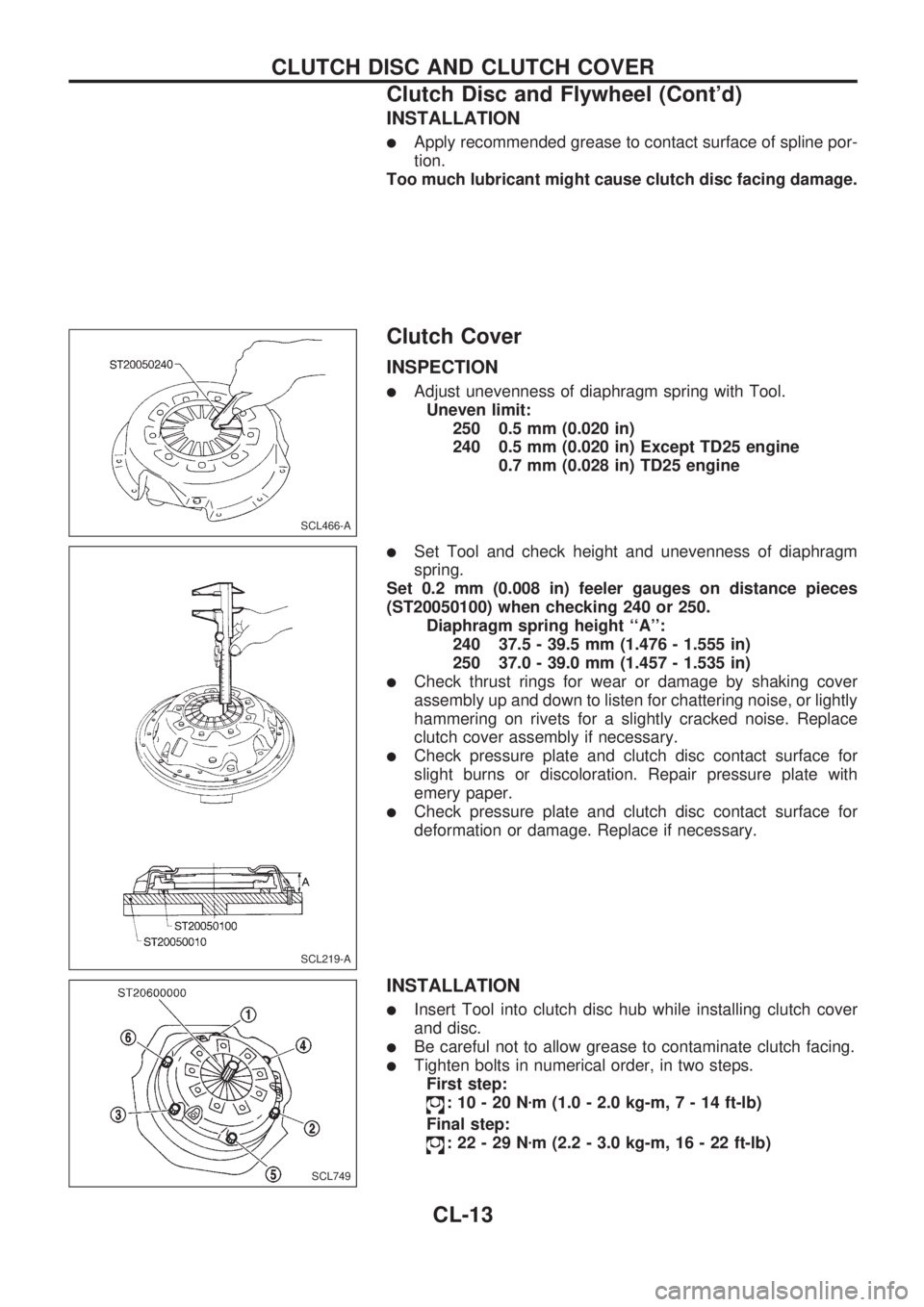

INSTALLATION

lApply recommended grease to contact surface of spline por-

tion.

Too much lubricant might cause clutch disc facing damage.

Clutch Cover

INSPECTION

lAdjust unevenness of diaphragm spring with Tool.

Uneven limit:

250 0.5 mm (0.020 in)

240 0.5 mm (0.020 in) Except TD25 engine

0.7 mm (0.028 in) TD25 engine

lSet Tool and check height and unevenness of diaphragm

spring.

Set 0.2 mm (0.008 in) feeler gauges on distance pieces

(ST20050100) when checking 240 or 250.

Diaphragm spring height ``A'':

240 37.5 - 39.5 mm (1.476 - 1.555 in)

250 37.0 - 39.0 mm (1.457 - 1.535 in)

lCheck thrust rings for wear or damage by shaking cover

assembly up and down to listen for chattering noise, or lightly

hammering on rivets for a slightly cracked noise. Replace

clutch cover assembly if necessary.

lCheck pressure plate and clutch disc contact surface for

slight burns or discoloration. Repair pressure plate with

emery paper.

lCheck pressure plate and clutch disc contact surface for

deformation or damage. Replace if necessary.

INSTALLATION

lInsert Tool into clutch disc hub while installing clutch cover

and disc.

lBe careful not to allow grease to contaminate clutch facing.

lTighten bolts in numerical order, in two steps.

First step:

:10-20Nzm (1.0 - 2.0 kg-m,7-14ft-lb)

Final step:

:22-29Nzm (2.2 - 3.0 kg-m, 16 - 22 ft-lb)

SCL466-A

SCL219-A

SCL749

CLUTCH DISC AND CLUTCH COVER

Clutch Disc and Flywheel (Cont'd)

CL-13

Page 99 of 1659

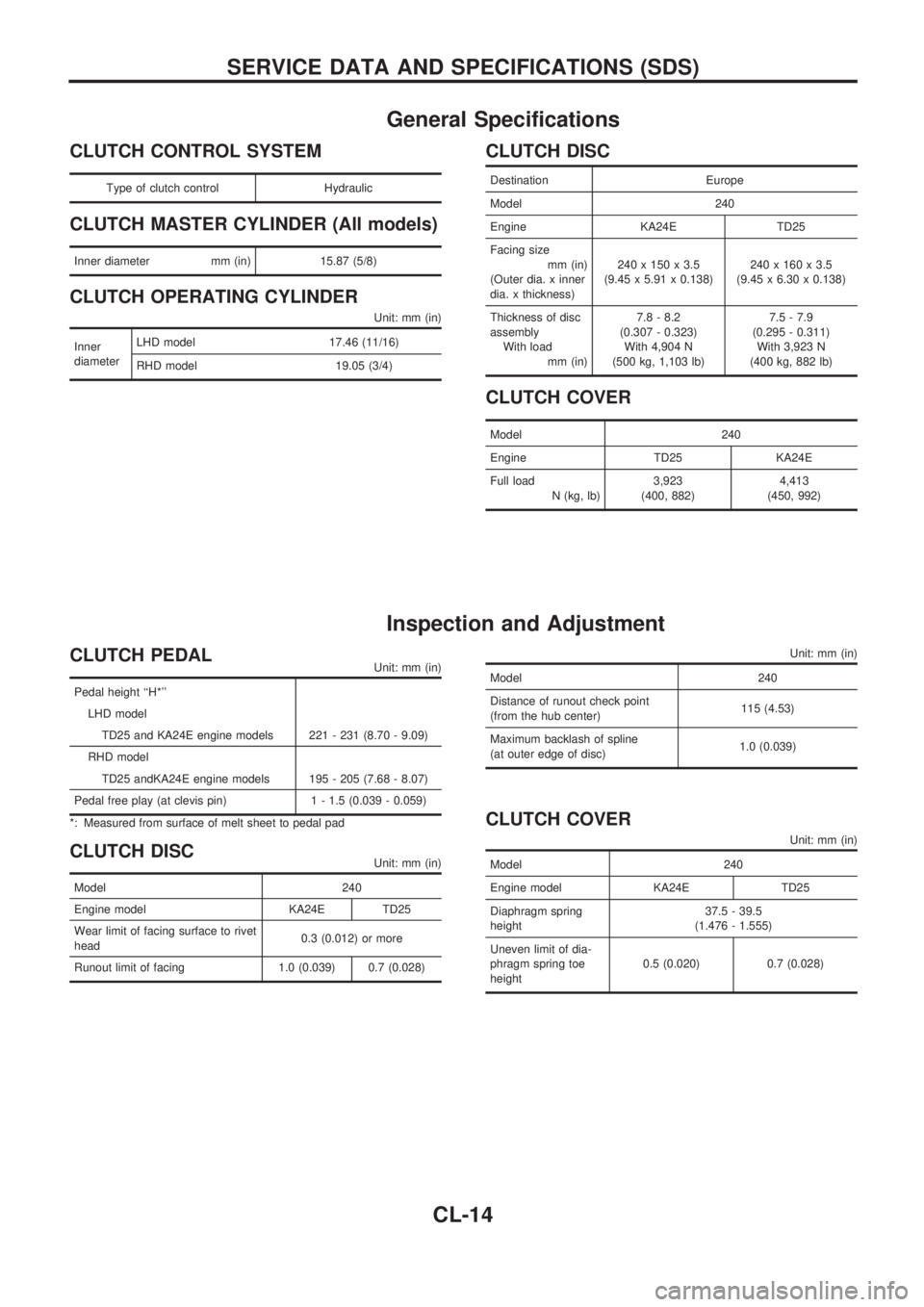

General Specifications

CLUTCH CONTROL SYSTEM

Type of clutch control Hydraulic

CLUTCH MASTER CYLINDER (All models)

Inner diameter mm (in) 15.87 (5/8)

CLUTCH OPERATING CYLINDER

Unit: mm (in)

Inner

diameterLHD model 17.46 (11/16)

RHD model 19.05 (3/4)

CLUTCH DISC

Destination Europe

Model 240

Engine KA24E TD25

Facing size

mm (in)

(Outer dia. x inner

dia. x thickness)240 x 150 x 3.5

(9.45 x 5.91 x 0.138)240 x 160 x 3.5

(9.45 x 6.30 x 0.138)

Thickness of disc

assembly

With load

mm (in)7.8 - 8.2

(0.307 - 0.323)

With 4,904 N

(500 kg, 1,103 lb)7.5 - 7.9

(0.295 - 0.311)

With 3,923 N

(400 kg, 882 lb)

CLUTCH COVER

Model 240

Engine TD25 KA24E

Full load

N (kg, lb)3,923

(400, 882)4,413

(450, 992)

Inspection and Adjustment

CLUTCH PEDALUnit: mm (in)

Pedal height ``H*''

LHD model

TD25 and KA24E engine models 221 - 231 (8.70 - 9.09)

RHD model

TD25 andKA24E engine models 195 - 205 (7.68 - 8.07)

Pedal free play (at clevis pin) 1 - 1.5 (0.039 - 0.059)

*: Measured from surface of melt sheet to pedal pad

CLUTCH DISCUnit: mm (in)

Model 240

Engine model KA24E TD25

Wear limit of facing surface to rivet

head0.3 (0.012) or more

Runout limit of facing 1.0 (0.039) 0.7 (0.028)

Unit: mm (in)

Model 240

Distance of runout check point

(from the hub center)115 (4.53)

Maximum backlash of spline

(at outer edge of disc)1.0 (0.039)

CLUTCH COVER

Unit: mm (in)

Model 240

Engine model KA24E TD25

Diaphragm spring

height37.5 - 39.5

(1.476 - 1.555)

Uneven limit of dia-

phragm spring toe

height0.5 (0.020) 0.7 (0.028)

SERVICE DATA AND SPECIFICATIONS (SDS)

CL-14

Page 150 of 1659

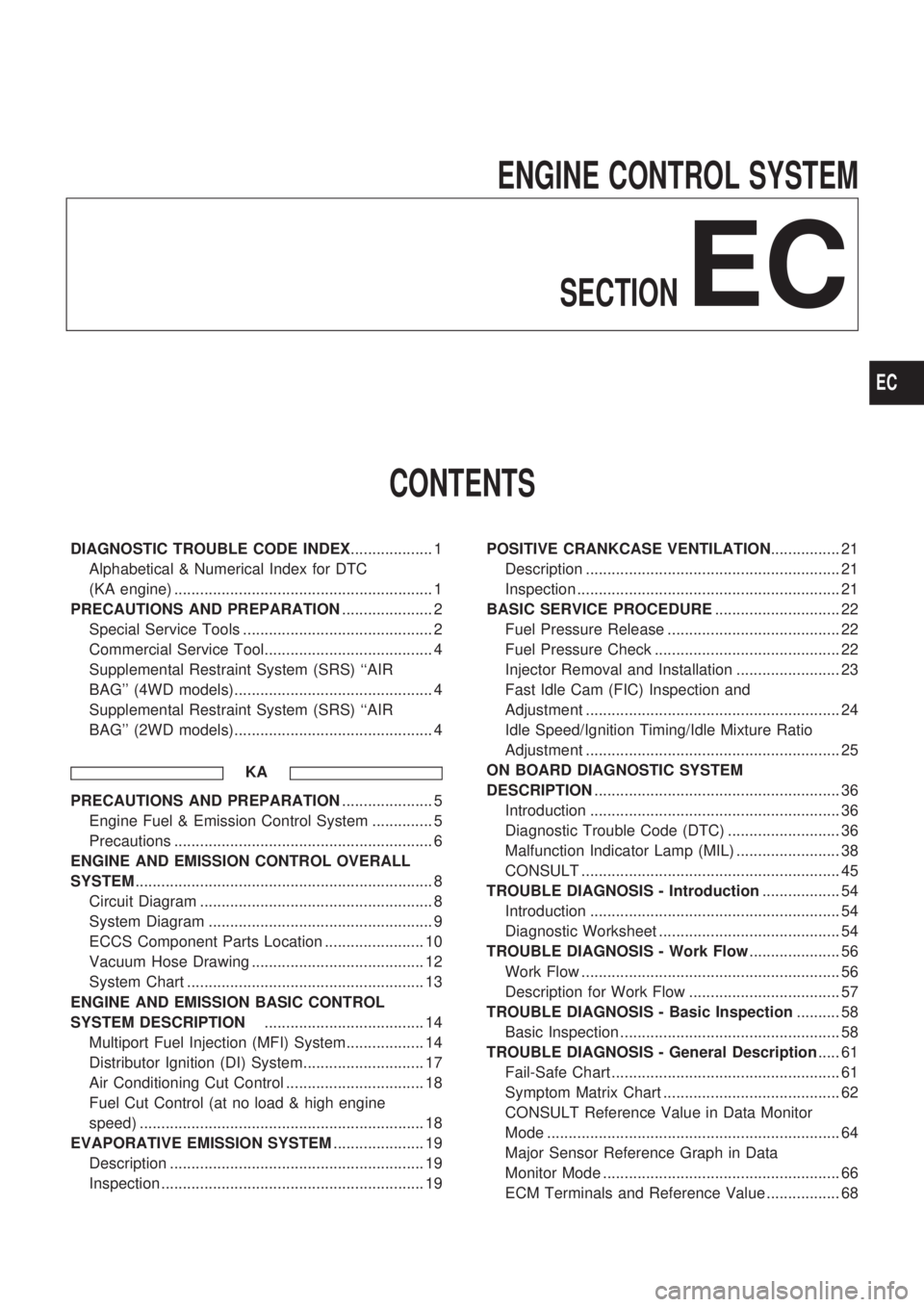

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

DIAGNOSTIC TROUBLE CODE INDEX................... 1

Alphabetical & Numerical Index for DTC

(KA engine) ............................................................ 1

PRECAUTIONS AND PREPARATION..................... 2

Special Service Tools ............................................ 2

Commercial Service Tool....................................... 4

Supplemental Restraint System (SRS) ``AIR

BAG'' (4WD models).............................................. 4

Supplemental Restraint System (SRS) ``AIR

BAG'' (2WD models).............................................. 4

KA

PRECAUTIONS AND PREPARATION..................... 5

Engine Fuel & Emission Control System .............. 5

Precautions ............................................................ 6

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM..................................................................... 8

Circuit Diagram ...................................................... 8

System Diagram .................................................... 9

ECCS Component Parts Location ....................... 10

Vacuum Hose Drawing ........................................ 12

System Chart ....................................................... 13

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION..................................... 14

Multiport Fuel Injection (MFI) System.................. 14

Distributor Ignition (DI) System............................ 17

Air Conditioning Cut Control ................................ 18

Fuel Cut Control (at no load & high engine

speed) .................................................................. 18

EVAPORATIVE EMISSION SYSTEM..................... 19

Description ........................................................... 19

Inspection ............................................................. 19POSITIVE CRANKCASE VENTILATION................ 21

Description ........................................................... 21

Inspection ............................................................. 21

BASIC SERVICE PROCEDURE............................. 22

Fuel Pressure Release ........................................ 22

Fuel Pressure Check ........................................... 22

Injector Removal and Installation ........................ 23

Fast Idle Cam (FIC) Inspection and

Adjustment ........................................................... 24

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment ........................................................... 25

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION......................................................... 36

Introduction .......................................................... 36

Diagnostic Trouble Code (DTC) .......................... 36

Malfunction Indicator Lamp (MIL) ........................ 38

CONSULT ............................................................ 45

TROUBLE DIAGNOSIS - Introduction.................. 54

Introduction .......................................................... 54

Diagnostic Worksheet .......................................... 54

TROUBLE DIAGNOSIS - Work Flow..................... 56

Work Flow ............................................................ 56

Description for Work Flow ................................... 57

TROUBLE DIAGNOSIS - Basic Inspection.......... 58

Basic Inspection ................................................... 58

TROUBLE DIAGNOSIS - General Description..... 61

Fail-Safe Chart ..................................................... 61

Symptom Matrix Chart ......................................... 62

CONSULT Reference Value in Data Monitor

Mode .................................................................... 64

Major Sensor Reference Graph in Data

Monitor Mode ....................................................... 66

ECM Terminals and Reference Value ................. 68

EC

Page 151 of 1659

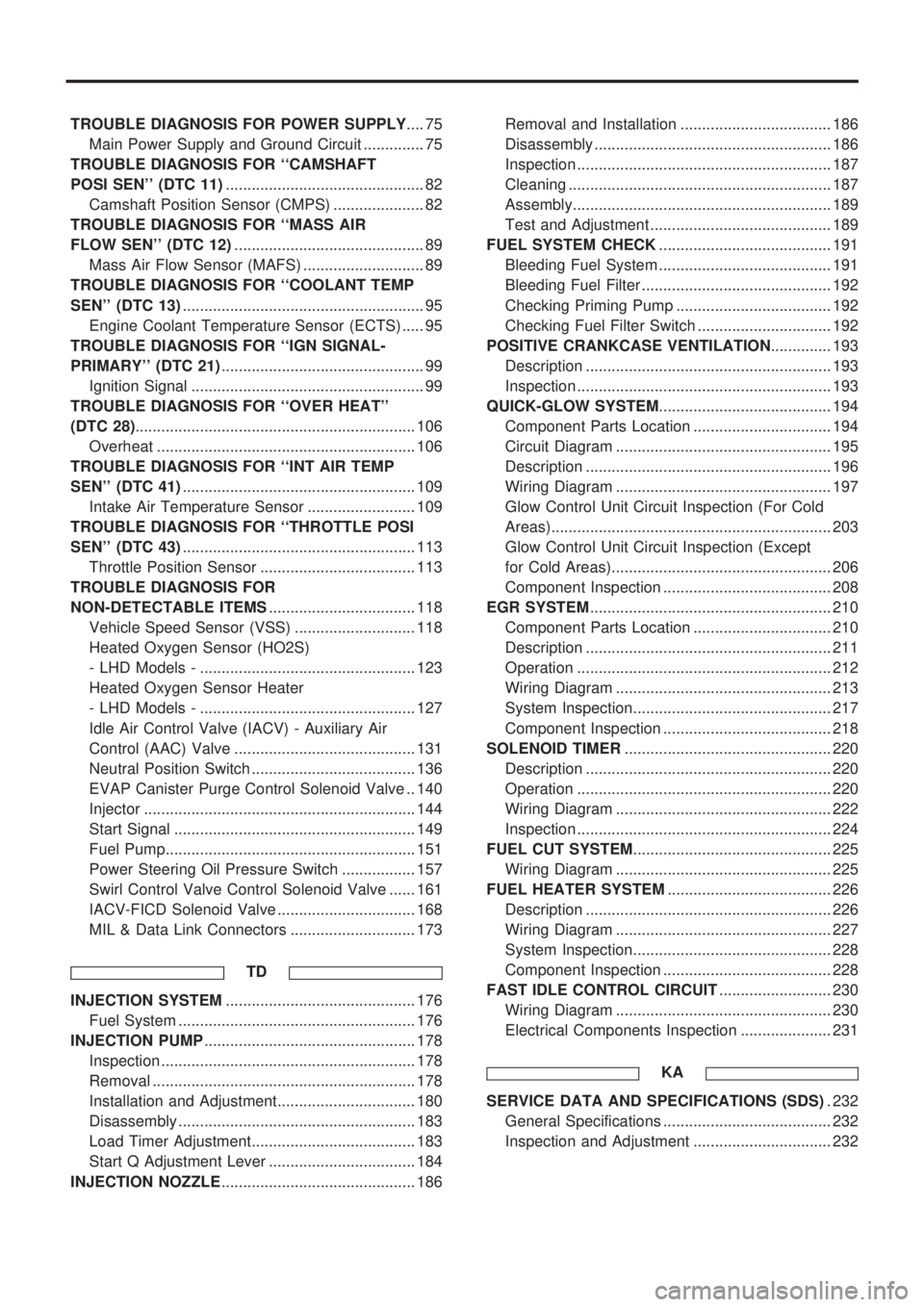

TROUBLE DIAGNOSIS FOR POWER SUPPLY.... 75

Main Power Supply and Ground Circuit .............. 75

TROUBLE DIAGNOSIS FOR ``CAMSHAFT

POSI SEN'' (DTC 11).............................................. 82

Camshaft Position Sensor (CMPS) ..................... 82

TROUBLE DIAGNOSIS FOR ``MASS AIR

FLOW SEN'' (DTC 12)............................................ 89

Mass Air Flow Sensor (MAFS) ............................ 89

TROUBLE DIAGNOSIS FOR ``COOLANT TEMP

SEN'' (DTC 13)........................................................ 95

Engine Coolant Temperature Sensor (ECTS) ..... 95

TROUBLE DIAGNOSIS FOR ``IGN SIGNAL-

PRIMARY'' (DTC 21)............................................... 99

Ignition Signal ...................................................... 99

TROUBLE DIAGNOSIS FOR ``OVER HEAT''

(DTC 28)................................................................. 106

Overheat ............................................................ 106

TROUBLE DIAGNOSIS FOR ``INT AIR TEMP

SEN'' (DTC 41)...................................................... 109

Intake Air Temperature Sensor ......................... 109

TROUBLE DIAGNOSIS FOR ``THROTTLE POSI

SEN'' (DTC 43)...................................................... 113

Throttle Position Sensor .................................... 113

TROUBLE DIAGNOSIS FOR

NON-DETECTABLE ITEMS.................................. 118

Vehicle Speed Sensor (VSS) ............................ 118

Heated Oxygen Sensor (HO2S)

- LHD Models - .................................................. 123

Heated Oxygen Sensor Heater

- LHD Models - .................................................. 127

Idle Air Control Valve (IACV) - Auxiliary Air

Control (AAC) Valve .......................................... 131

Neutral Position Switch ...................................... 136

EVAP Canister Purge Control Solenoid Valve .. 140

Injector ............................................................... 144

Start Signal ........................................................ 149

Fuel Pump.......................................................... 151

Power Steering Oil Pressure Switch ................. 157

Swirl Control Valve Control Solenoid Valve ...... 161

IACV-FICD Solenoid Valve ................................ 168

MIL & Data Link Connectors ............................. 173

TD

INJECTION SYSTEM............................................ 176

Fuel System ....................................................... 176

INJECTION PUMP................................................. 178

Inspection ........................................................... 178

Removal ............................................................. 178

Installation and Adjustment................................ 180

Disassembly ....................................................... 183

Load Timer Adjustment...................................... 183

Start Q Adjustment Lever .................................. 184

INJECTION NOZZLE............................................. 186Removal and Installation ................................... 186

Disassembly ....................................................... 186

Inspection ........................................................... 187

Cleaning ............................................................. 187

Assembly............................................................ 189

Test and Adjustment .......................................... 189

FUEL SYSTEM CHECK........................................ 191

Bleeding Fuel System ........................................ 191

Bleeding Fuel Filter ............................................ 192

Checking Priming Pump .................................... 192

Checking Fuel Filter Switch ............................... 192

POSITIVE CRANKCASE VENTILATION.............. 193

Description ......................................................... 193

Inspection ........................................................... 193

QUICK-GLOW SYSTEM........................................ 194

Component Parts Location ................................ 194

Circuit Diagram .................................................. 195

Description ......................................................... 196

Wiring Diagram .................................................. 197

Glow Control Unit Circuit Inspection (For Cold

Areas)................................................................. 203

Glow Control Unit Circuit Inspection (Except

for Cold Areas)................................................... 206

Component Inspection ....................................... 208

EGR SYSTEM........................................................ 210

Component Parts Location ................................ 210

Description ......................................................... 211

Operation ........................................................... 212

Wiring Diagram .................................................. 213

System Inspection.............................................. 217

Component Inspection ....................................... 218

SOLENOID TIMER................................................ 220

Description ......................................................... 220

Operation ........................................................... 220

Wiring Diagram .................................................. 222

Inspection ........................................................... 224

FUEL CUT SYSTEM.............................................. 225

Wiring Diagram .................................................. 225

FUEL HEATER SYSTEM...................................... 226

Description ......................................................... 226

Wiring Diagram .................................................. 227

System Inspection.............................................. 228

Component Inspection ....................................... 228

FAST IDLE CONTROL CIRCUIT.......................... 230

Wiring Diagram .................................................. 230

Electrical Components Inspection ..................... 231

KA

SERVICE DATA AND SPECIFICATIONS (SDS). 232

General Specifications ....................................... 232

Inspection and Adjustment ................................ 232

Page 156 of 1659

Commercial Service Tool

FOR KA ENGINE MODELS

Tool name Description

Fuel filler cap adapter

NT653

Checking fuel tank vacuum relief valve opening

pressure

Supplemental Restraint System (SRS) ``AIR

BAG'' (4WD models)

The Supplemental Restraint System ``AIR BAG'', used along with a seat belt, helps to reduce the risk or

severity of injury to the driver in a frontal collision. The Supplemental Restraint System consists of an air

bag module (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp, wiring har-

ness and spiral cable. Information necessary to service the system safely is included in theRS sectionof

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses are covered with yellow insulation either just before the

harness connectors or for the complete harness, for easy identification.

Supplemental Restraint System (SRS) ``AIR

BAG'' (2WD models)

The Supplemental Restraint System ``AIR BAG'', used along with a seat belt, helps to reduce the risk or

severity of injury to the driver in a frontal collision. The Supplemental Restraint System consists of an air

bag module (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp, wiring har-

ness and spiral cable. Information necessary to service the system safely is included in theRS sectionof

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit related to the SRS.

PRECAUTIONS AND PREPARATION

EC-4

Page 171 of 1659

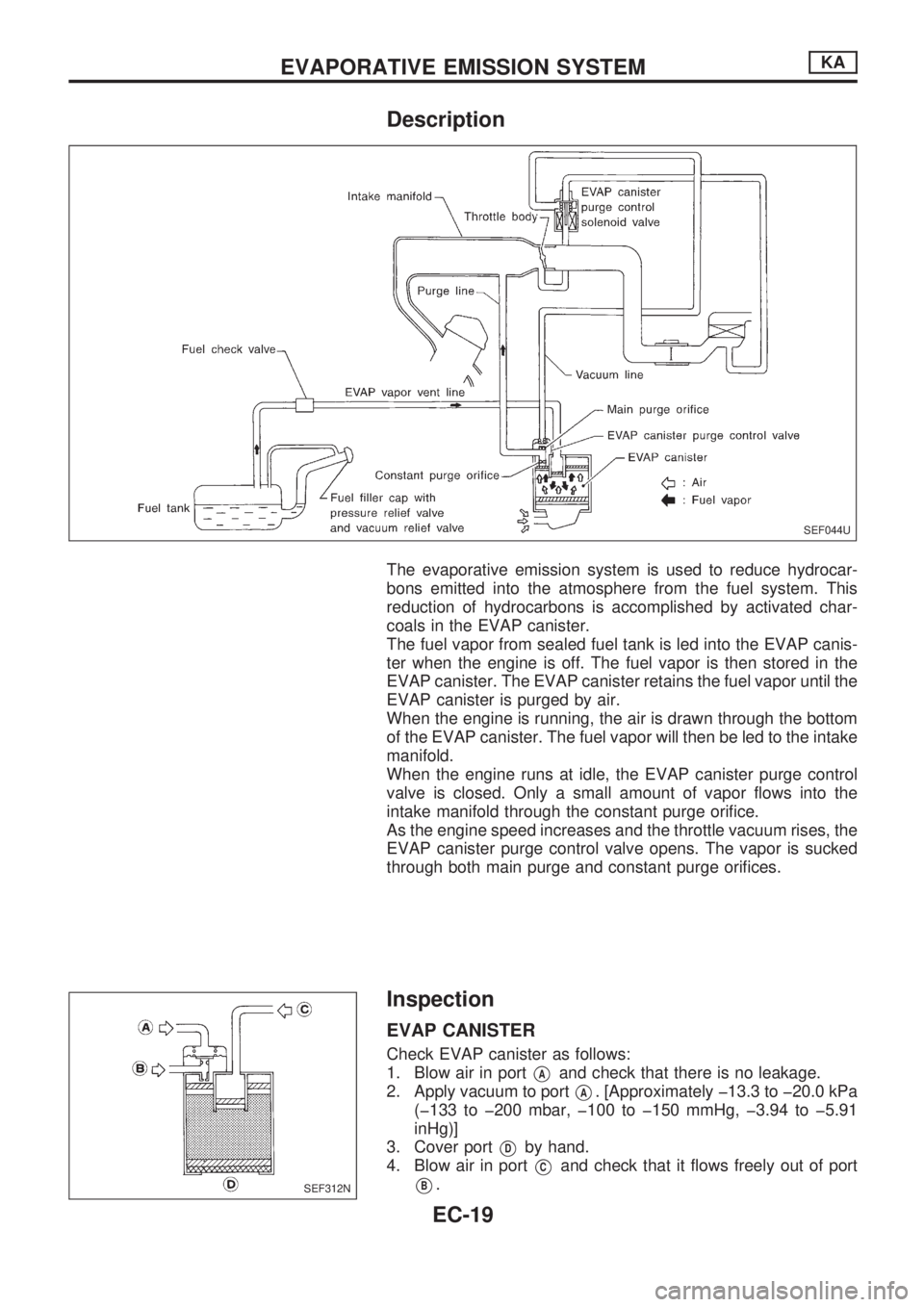

Description

The evaporative emission system is used to reduce hydrocar-

bons emitted into the atmosphere from the fuel system. This

reduction of hydrocarbons is accomplished by activated char-

coals in the EVAP canister.

The fuel vapor from sealed fuel tank is led into the EVAP canis-

ter when the engine is off. The fuel vapor is then stored in the

EVAP canister. The EVAP canister retains the fuel vapor until the

EVAP canister is purged by air.

When the engine is running, the air is drawn through the bottom

of the EVAP canister. The fuel vapor will then be led to the intake

manifold.

When the engine runs at idle, the EVAP canister purge control

valve is closed. Only a small amount of vapor flows into the

intake manifold through the constant purge orifice.

As the engine speed increases and the throttle vacuum rises, the

EVAP canister purge control valve opens. The vapor is sucked

through both main purge and constant purge orifices.

Inspection

EVAP CANISTER

Check EVAP canister as follows:

1. Blow air in port

VAand check that there is no leakage.

2. Apply vacuum to port

VA. [Approximately þ13.3 to þ20.0 kPa

(þ133 to þ200 mbar, þ100 to þ150 mmHg, þ3.94 to þ5.91

inHg)]

3. Cover port

VDby hand.

4. Blow air in port

VCand check that it flows freely out of port

VB.

SEF044U

SEF312N

EVAPORATIVE EMISSION SYSTEMKA

EC-19

Page 173 of 1659

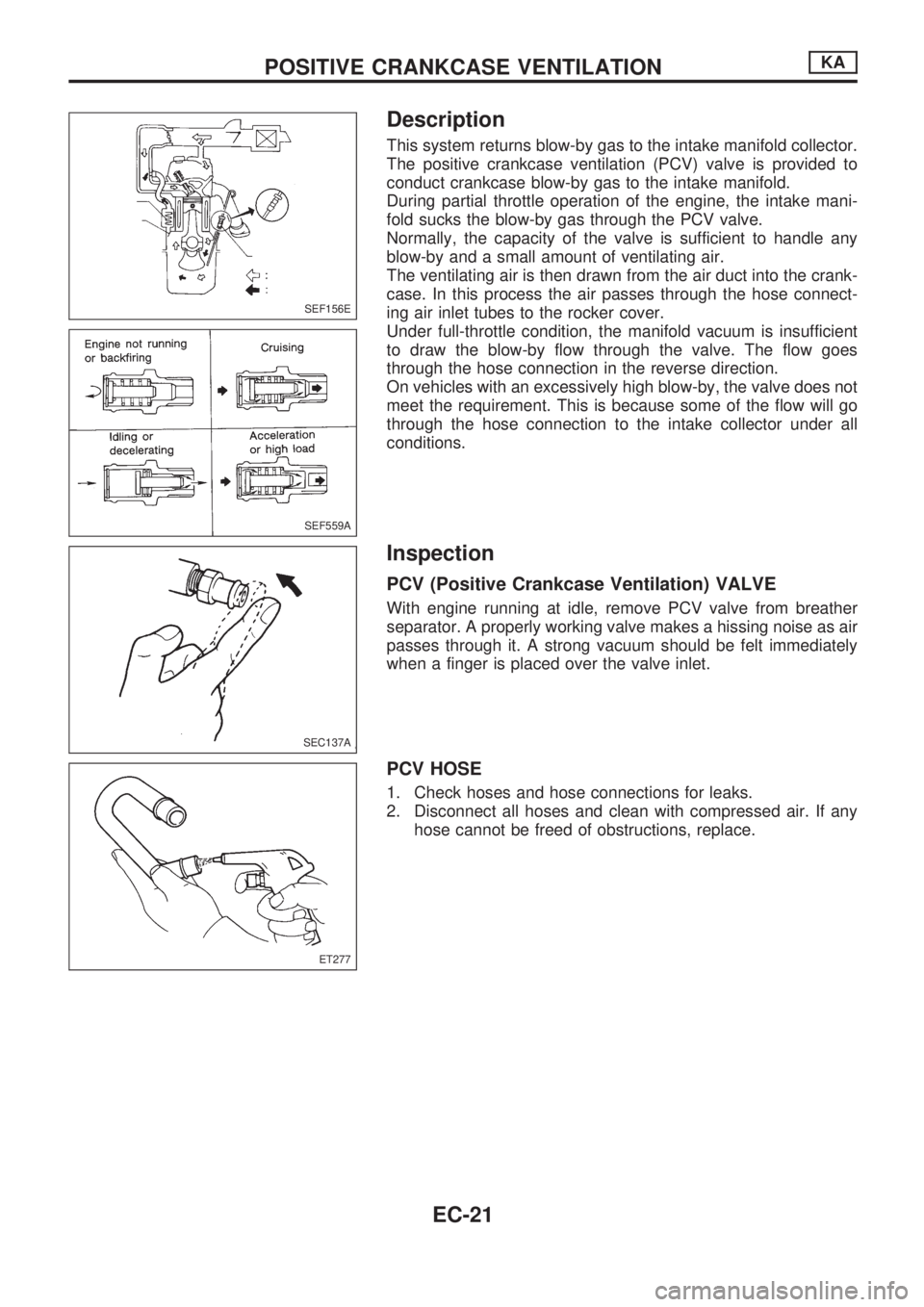

Description

This system returns blow-by gas to the intake manifold collector.

The positive crankcase ventilation (PCV) valve is provided to

conduct crankcase blow-by gas to the intake manifold.

During partial throttle operation of the engine, the intake mani-

fold sucks the blow-by gas through the PCV valve.

Normally, the capacity of the valve is sufficient to handle any

blow-by and a small amount of ventilating air.

The ventilating air is then drawn from the air duct into the crank-

case. In this process the air passes through the hose connect-

ing air inlet tubes to the rocker cover.

Under full-throttle condition, the manifold vacuum is insufficient

to draw the blow-by flow through the valve. The flow goes

through the hose connection in the reverse direction.

On vehicles with an excessively high blow-by, the valve does not

meet the requirement. This is because some of the flow will go

through the hose connection to the intake collector under all

conditions.

Inspection

PCV (Positive Crankcase Ventilation) VALVE

With engine running at idle, remove PCV valve from breather

separator. A properly working valve makes a hissing noise as air

passes through it. A strong vacuum should be felt immediately

when a finger is placed over the valve inlet.

PCV HOSE

1. Check hoses and hose connections for leaks.

2. Disconnect all hoses and clean with compressed air. If any

hose cannot be freed of obstructions, replace.

SEF156E

SEF559A

SEC137A

ET277

POSITIVE CRANKCASE VENTILATIONKA

EC-21