check engine NISSAN PICK-UP 1998 Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 258 of 1659

Overheat

ON BOARD DIAGNOSIS LOGIC

If the cooling fan or another component in the cooling system malfunctions, the engine coolant temperature

will rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Diagnostic trouble

code No.Malfunction is detected when ...Check Items

(Possible Cause)

28

lEngine coolant temperature reaches an abnormally

high temperature.lCooling fan

lRadiator hose

lRadiator

lRadiator cap

lWater pump

lThermostat

For more information, refer to ``MAIN 12

CAUSES OF OVERHEATING'', EC-108.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in MA sec-

tion (``Changing Engine Coolant'', ``ENGINE MAINTENANCE''). Also, replace the engine oil.

lFill radiator with coolant up to specified level with a filling speed of 2 liters per minute like pour-

ing coolant by kettle. Be sure to use coolant with the proper mixture ratio. Refer to MA section

(``Anti-freeze Coolant Mixture Ratio'', ``RECOMMENDED FLUIDS AND LUBRICANTS'').

lAfter refilling coolant, run engine to ensure that no water-flow noise is emitted.

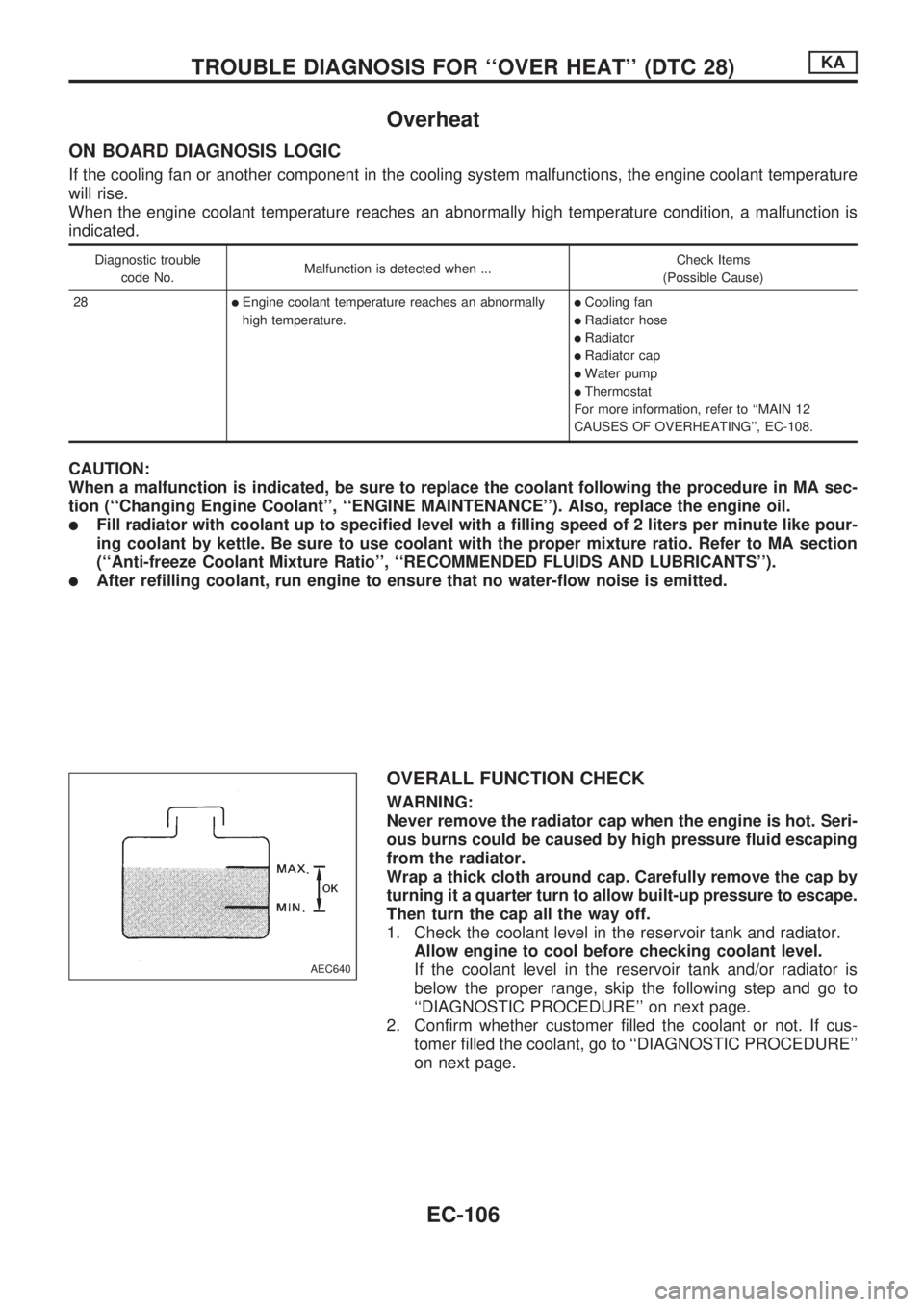

OVERALL FUNCTION CHECK

WARNING:

Never remove the radiator cap when the engine is hot. Seri-

ous burns could be caused by high pressure fluid escaping

from the radiator.

Wrap a thick cloth around cap. Carefully remove the cap by

turning it a quarter turn to allow built-up pressure to escape.

Then turn the cap all the way off.

1. Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is

below the proper range, skip the following step and go to

``DIAGNOSTIC PROCEDURE'' on next page.

2. Confirm whether customer filled the coolant or not. If cus-

tomer filled the coolant, go to ``DIAGNOSTIC PROCEDURE''

on next page.

AEC640

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)KA

EC-106

Page 259 of 1659

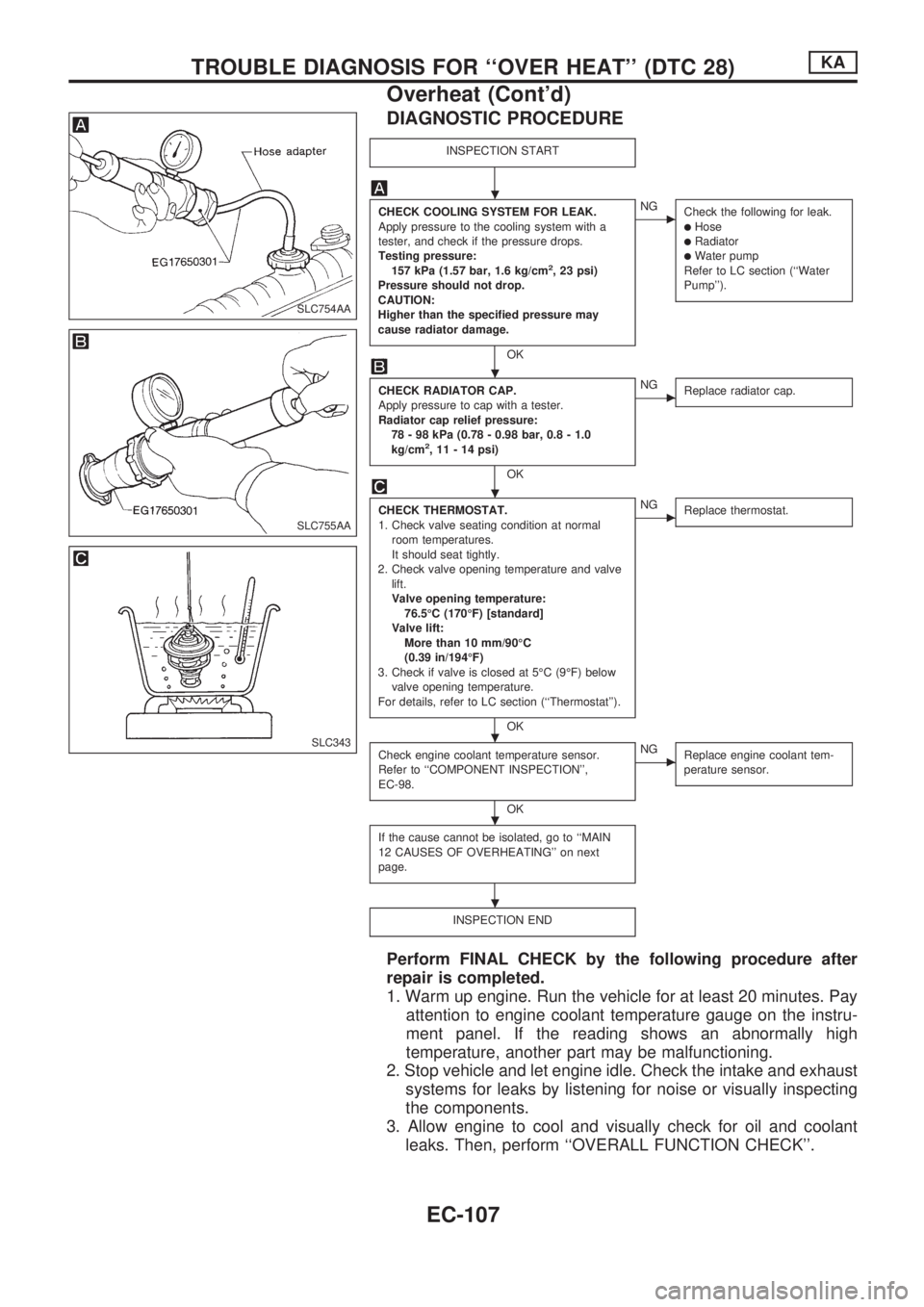

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK COOLING SYSTEM FOR LEAK.

Apply pressure to the cooling system with a

tester, and check if the pressure drops.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

Pressure should not drop.

CAUTION:

Higher than the specified pressure may

cause radiator damage.

OK

cNG

Check the following for leak.

lHoselRadiatorlWater pump

Refer to LC section (``Water

Pump'').

CHECK RADIATOR CAP.

Apply pressure to cap with a tester.

Radiator cap relief pressure:

78 - 98 kPa (0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

OK

cNG

Replace radiator cap.

CHECK THERMOSTAT.

1. Check valve seating condition at normal

room temperatures.

It should seat tightly.

2. Check valve opening temperature and valve

lift.

Valve opening temperature:

76.5ÉC (170ÉF) [standard]

Valve lift:

More than 10 mm/90ÉC

(0.39 in/194ÉF)

3. Check if valve is closed at 5ÉC (9ÉF) below

valve opening temperature.

For details, refer to LC section (``Thermostat'').

OK

cNG

Replace thermostat.

Check engine coolant temperature sensor.

Refer to ``COMPONENT INSPECTION'',

EC-98.

OK

cNG

Replace engine coolant tem-

perature sensor.

If the cause cannot be isolated, go to ``MAIN

12 CAUSES OF OVERHEATING'' on next

page.

INSPECTION END

Perform FINAL CHECK by the following procedure after

repair is completed.

1. Warm up engine. Run the vehicle for at least 20 minutes. Pay

attention to engine coolant temperature gauge on the instru-

ment panel. If the reading shows an abnormally high

temperature, another part may be malfunctioning.

2. Stop vehicle and let engine idle. Check the intake and exhaust

systems for leaks by listening for noise or visually inspecting

the components.

3. Allow engine to cool and visually check for oil and coolant

leaks. Then, perform ``OVERALL FUNCTION CHECK''.

SLC754AA

SLC755AA

SLC343

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)KA

Overheat (Cont'd)

EC-107

Page 260 of 1659

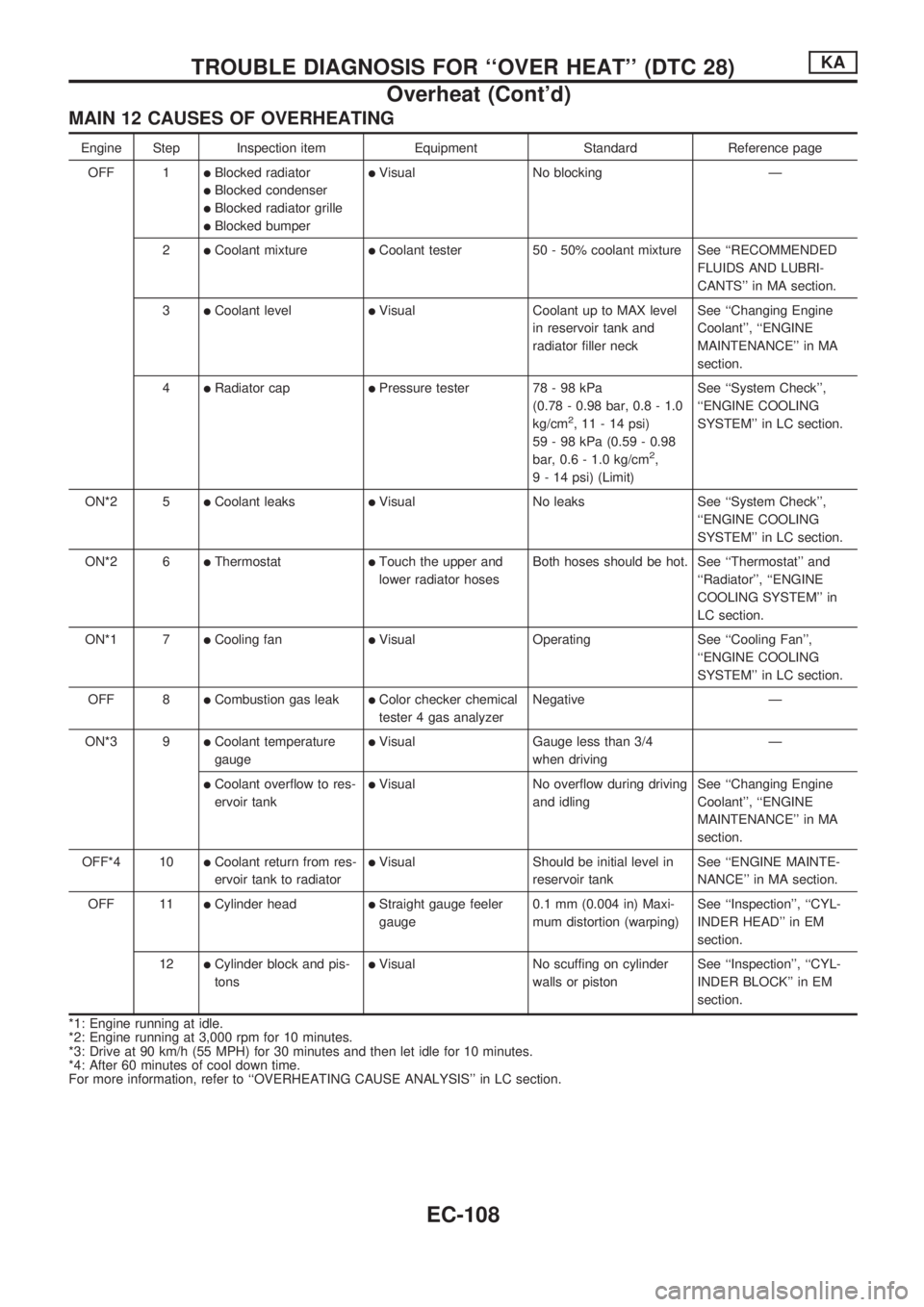

MAIN 12 CAUSES OF OVERHEATING

Engine Step Inspection item Equipment Standard Reference page

OFF 1

lBlocked radiator

lBlocked condenser

lBlocked radiator grille

lBlocked bumper

lVisual No blocking Ð

2

lCoolant mixturelCoolant tester 50 - 50% coolant mixture See ``RECOMMENDED

FLUIDS AND LUBRI-

CANTS'' in MA section.

3

lCoolant levellVisual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee ``Changing Engine

Coolant'', ``ENGINE

MAINTENANCE'' in MA

section.

4

lRadiator caplPressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit)See ``System Check'',

``ENGINE COOLING

SYSTEM'' in LC section.

ON*2 5

lCoolant leakslVisual No leaks See ``System Check'',

``ENGINE COOLING

SYSTEM'' in LC section.

ON*2 6

lThermostatlTouch the upper and

lower radiator hosesBoth hoses should be hot. See ``Thermostat'' and

``Radiator'', ``ENGINE

COOLING SYSTEM'' in

LC section.

ON*1 7

lCooling fanlVisual Operating See ``Cooling Fan'',

``ENGINE COOLING

SYSTEM'' in LC section.

OFF 8

lCombustion gas leaklColor checker chemical

tester 4 gas analyzerNegative Ð

ON*3 9

lCoolant temperature

gaugelVisual Gauge less than 3/4

when drivingÐ

lCoolant overflow to res-

ervoir tanklVisual No overflow during driving

and idlingSee ``Changing Engine

Coolant'', ``ENGINE

MAINTENANCE'' in MA

section.

OFF*4 10

lCoolant return from res-

ervoir tank to radiatorlVisual Should be initial level in

reservoir tankSee ``ENGINE MAINTE-

NANCE'' in MA section.

OFF 11

lCylinder headlStraight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ``Inspection'', ``CYL-

INDER HEAD'' in EM

section.

12

lCylinder block and pis-

tonslVisual No scuffing on cylinder

walls or pistonSee ``Inspection'', ``CYL-

INDER BLOCK'' in EM

section.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ``OVERHEATING CAUSE ANALYSIS'' in LC section.

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)KA

Overheat (Cont'd)

EC-108

Page 261 of 1659

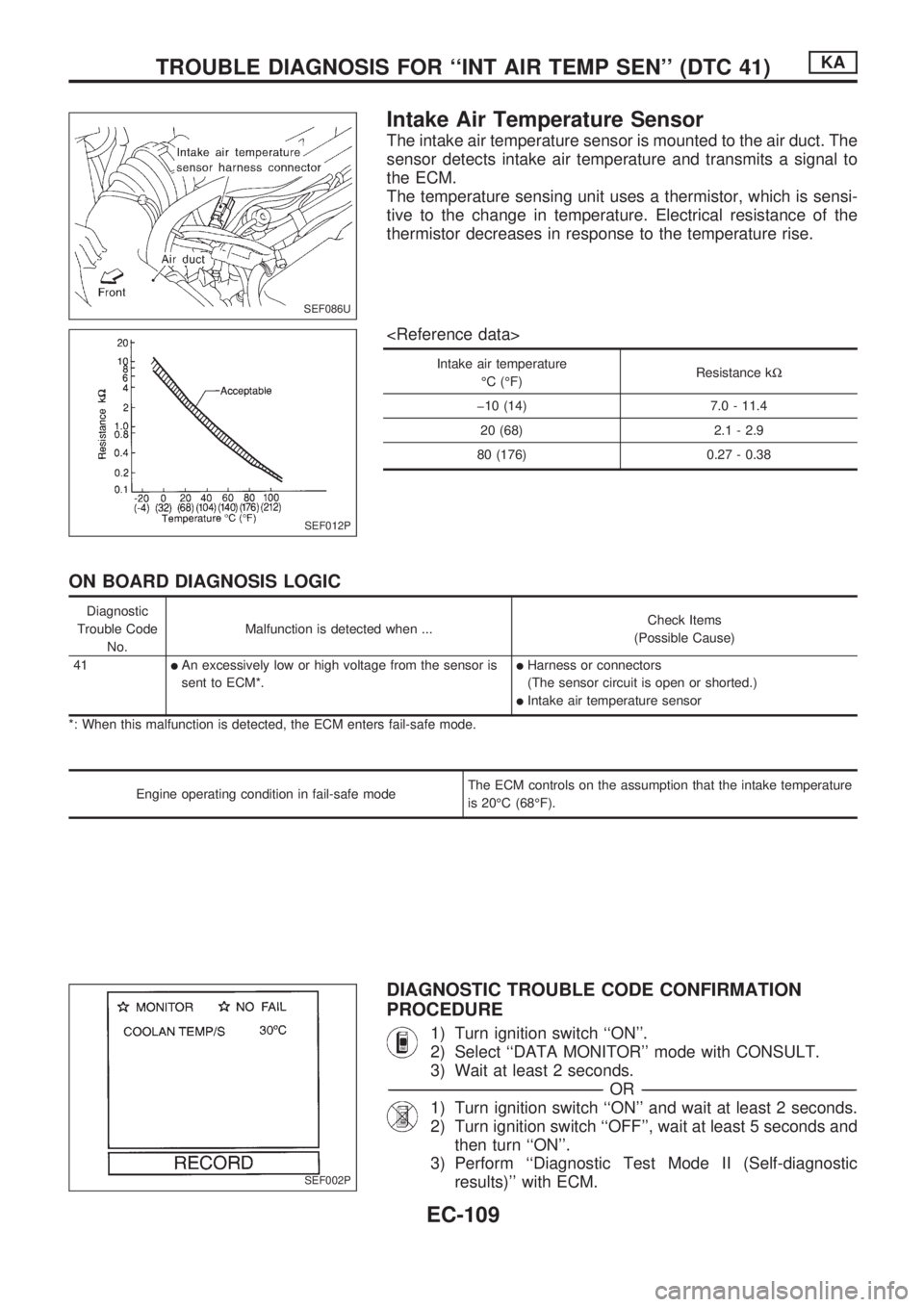

Intake Air Temperature Sensor

The intake air temperature sensor is mounted to the air duct. The

sensor detects intake air temperature and transmits a signal to

the ECM.

The temperature sensing unit uses a thermistor, which is sensi-

tive to the change in temperature. Electrical resistance of the

thermistor decreases in response to the temperature rise.

Intake air temperature

ÉC (ÉF)Resistance kW

þ10 (14) 7.0 - 11.4

20 (68) 2.1 - 2.9

80 (176) 0.27 - 0.38

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ...Check Items

(Possible Cause)

41

lAn excessively low or high voltage from the sensor is

sent to ECM*.lHarness or connectors

(The sensor circuit is open or shorted.)

lIntake air temperature sensor

*: When this malfunction is detected, the ECM enters fail-safe mode.

Engine operating condition in fail-safe modeThe ECM controls on the assumption that the intake temperature

is 20ÉC (68ÉF).

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON''.

2) Select ``DATA MONITOR'' mode with CONSULT.

3) Wait at least 2 seconds.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Turn ignition switch ``ON'' and wait at least 2 seconds.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

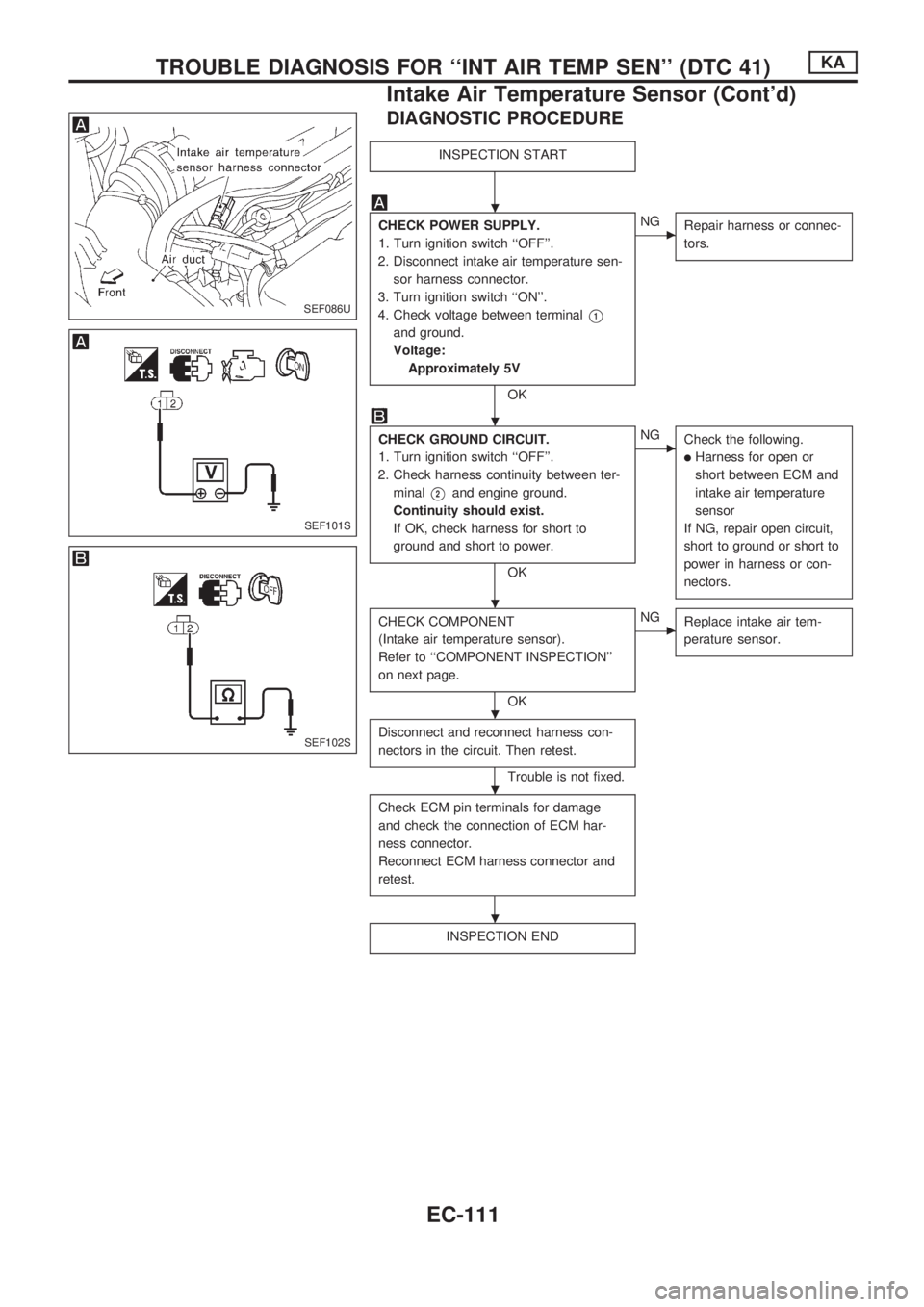

SEF086U

SEF012P

SEF002P

TROUBLE DIAGNOSIS FOR ``INT AIR TEMP SEN'' (DTC 41)KA

EC-109

Page 263 of 1659

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect intake air temperature sen-

sor harness connector.

3. Turn ignition switch ``ON''.

4. Check voltage between terminal

V1

and ground.

Voltage:

Approximately 5V

OK

cNG

Repair harness or connec-

tors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Check harness continuity between ter-

minal

V2and engine ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

lHarness for open or

short between ECM and

intake air temperature

sensor

If NG, repair open circuit,

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Intake air temperature sensor).

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace intake air tem-

perature sensor.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage

and check the connection of ECM har-

ness connector.

Reconnect ECM harness connector and

retest.

INSPECTION END

SEF086U

SEF101S

SEF102S

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``INT AIR TEMP SEN'' (DTC 41)KA

Intake Air Temperature Sensor (Cont'd)

EC-111

Page 266 of 1659

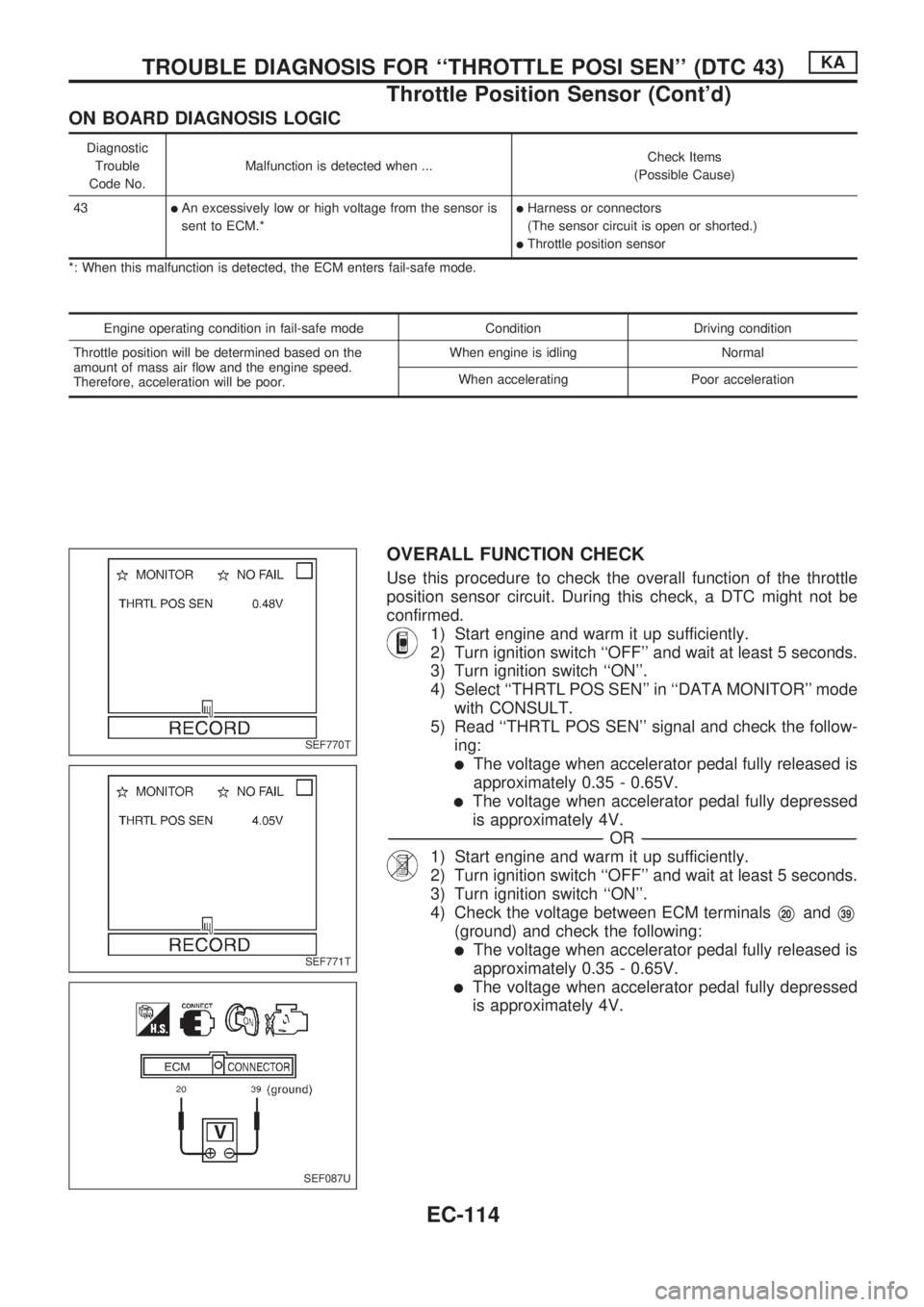

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble

Code No.Malfunction is detected when ...Check Items

(Possible Cause)

43

lAn excessively low or high voltage from the sensor is

sent to ECM.*lHarness or connectors

(The sensor circuit is open or shorted.)

lThrottle position sensor

*: When this malfunction is detected, the ECM enters fail-safe mode.

Engine operating condition in fail-safe mode Condition Driving condition

Throttle position will be determined based on the

amount of mass air flow and the engine speed.

Therefore, acceleration will be poor.When engine is idling Normal

When accelerating Poor acceleration

OVERALL FUNCTION CHECK

Use this procedure to check the overall function of the throttle

position sensor circuit. During this check, a DTC might not be

confirmed.

1) Start engine and warm it up sufficiently.

2) Turn ignition switch ``OFF'' and wait at least 5 seconds.

3) Turn ignition switch ``ON''.

4) Select ``THRTL POS SEN'' in ``DATA MONITOR'' mode

with CONSULT.

5) Read ``THRTL POS SEN'' signal and check the follow-

ing:

lThe voltage when accelerator pedal fully released is

approximately 0.35 - 0.65V.

lThe voltage when accelerator pedal fully depressed

is approximately 4V.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine and warm it up sufficiently.

2) Turn ignition switch ``OFF'' and wait at least 5 seconds.

3) Turn ignition switch ``ON''.

4) Check the voltage between ECM terminals

V20andV39

(ground) and check the following:

lThe voltage when accelerator pedal fully released is

approximately 0.35 - 0.65V.

lThe voltage when accelerator pedal fully depressed

is approximately 4V.

SEF770T

SEF771T

SEF087U

TROUBLE DIAGNOSIS FOR ``THROTTLE POSI SEN'' (DTC 43)KA

Throttle Position Sensor (Cont'd)

EC-114

Page 268 of 1659

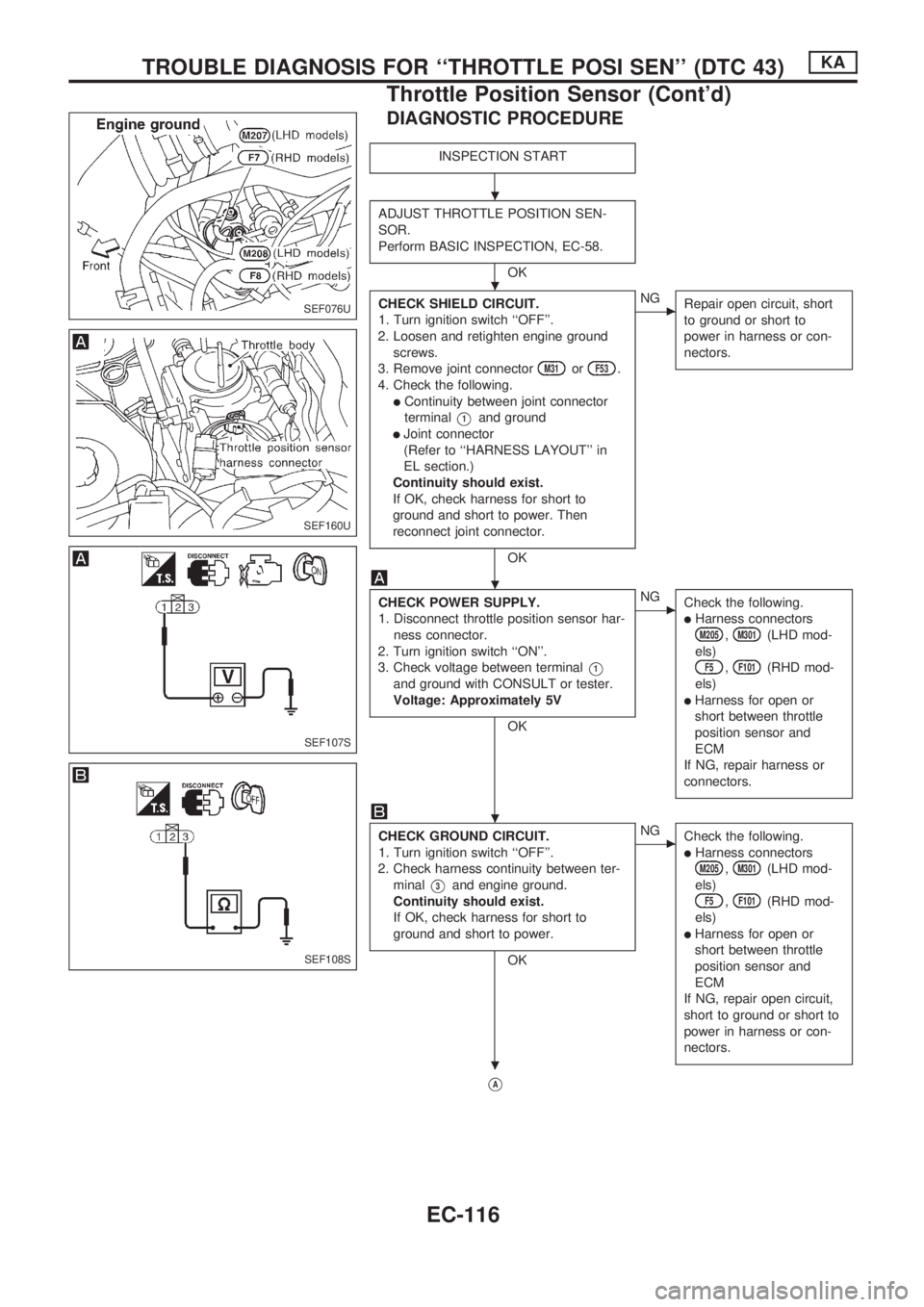

DIAGNOSTIC PROCEDURE

INSPECTION START

ADJUST THROTTLE POSITION SEN-

SOR.

Perform BASIC INSPECTION, EC-58.

OK

CHECK SHIELD CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Loosen and retighten engine ground

screws.

3. Remove joint connector

M31orF53.

4. Check the following.

lContinuity between joint connector

terminal

V1and ground

lJoint connector

(Refer to ``HARNESS LAYOUT'' in

EL section.)

Continuity should exist.

If OK, check harness for short to

ground and short to power. Then

reconnect joint connector.

OK

cNG

Repair open circuit, short

to ground or short to

power in harness or con-

nectors.

CHECK POWER SUPPLY.

1. Disconnect throttle position sensor har-

ness connector.

2. Turn ignition switch ``ON''.

3. Check voltage between terminal

V1

and ground with CONSULT or tester.

Voltage: Approximately 5V

OK

cNG

Check the following.

lHarness connectorsM205,M301(LHD mod-

els)

F5,F101(RHD mod-

els)

lHarness for open or

short between throttle

position sensor and

ECM

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Check harness continuity between ter-

minal

V3and engine ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

lHarness connectorsM205,M301(LHD mod-

els)

F5,F101(RHD mod-

els)

lHarness for open or

short between throttle

position sensor and

ECM

If NG, repair open circuit,

short to ground or short to

power in harness or con-

nectors.

VA

SEF076U

SEF160U

SEF107S

SEF108S

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``THROTTLE POSI SEN'' (DTC 43)KA

Throttle Position Sensor (Cont'd)

EC-116

Page 269 of 1659

VA

CHECK INPUT SIGNAL CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between

ECM terminal

V20and terminalV2.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

lHarness connectorsM205,M301(LHD models)

F5,F101(RHD models)

lHarness for open or short

between throttle position

sensor and ECM

If NG, repair open circuit,

short to ground or short to

power in harness or connec-

tors.

CHECK COMPONENT

(Throttle position sensor).

Refer to ``COMPONENT INSPECTION''

below.

OK

cNG

Replace throttle position

sensor. To adjust it, perform

BASIC INSPECTION,

EC-58.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage

and check the connection of ECM har-

ness connector.

Reconnect ECM harness connector and

retest.

INSPECTION END

COMPONENT INSPECTION

Throttle position sensor

1. Start engine and warm it up sufficiently.

2. Turn ignition switch ``OFF''.

3. Disconnect throttle position sensor harness connector.

4. Make sure that resistance between terminals

V2andV3

changes when opening throttle valve manually.

Throttle valve conditions Resistance at 25ÉC (77ÉF)

Completely closed Approximately 0.6 kW

Partially open 0.6 - 4.0 kW

Completely open Approximately 4 kW

If NG, replace throttle position sensor.

To adjust throttle position sensor, perform ``BASIC

INSPECTION'', EC-58.

SEF088U

SEF161U

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``THROTTLE POSI SEN'' (DTC 43)KA

Throttle Position Sensor (Cont'd)

EC-117

Page 273 of 1659

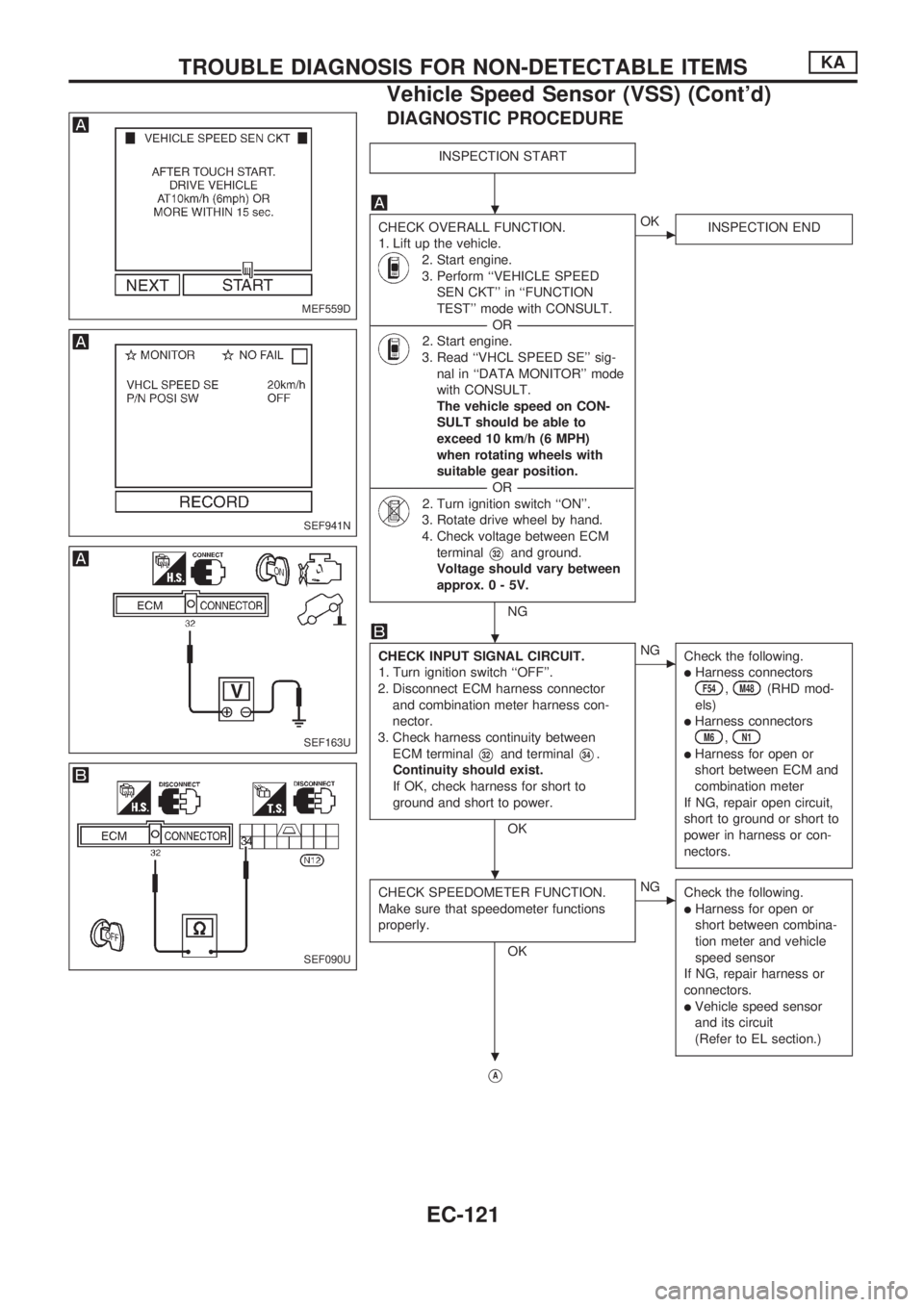

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Lift up the vehicle.

2. Start engine.

3. Perform ``VEHICLE SPEED

SEN CKT'' in ``FUNCTION

TEST'' mode with CONSULT.

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

2. Start engine.

3. Read ``VHCL SPEED SE'' sig-

nal in ``DATA MONITOR'' mode

with CONSULT.

The vehicle speed on CON-

SULT should be able to

exceed 10 km/h (6 MPH)

when rotating wheels with

suitable gear position.

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

2. Turn ignition switch ``ON''.

3. Rotate drive wheel by hand.

4. Check voltage between ECM

terminal

V32and ground.

Voltage should vary between

approx.0-5V.

NG

cOK

INSPECTION END

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector

and combination meter harness con-

nector.

3. Check harness continuity between

ECM terminal

V32and terminalV34.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

lHarness connectorsF54,M48(RHD mod-

els)

lHarness connectorsM6,N1

lHarness for open or

short between ECM and

combination meter

If NG, repair open circuit,

short to ground or short to

power in harness or con-

nectors.

CHECK SPEEDOMETER FUNCTION.

Make sure that speedometer functions

properly.

OK

cNG

Check the following.

lHarness for open or

short between combina-

tion meter and vehicle

speed sensor

If NG, repair harness or

connectors.

lVehicle speed sensor

and its circuit

(Refer to EL section.)

VA

MEF559D

SEF941N

SEF163U

SEF090U

.

.

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Vehicle Speed Sensor (VSS) (Cont'd)

EC-121

Page 277 of 1659

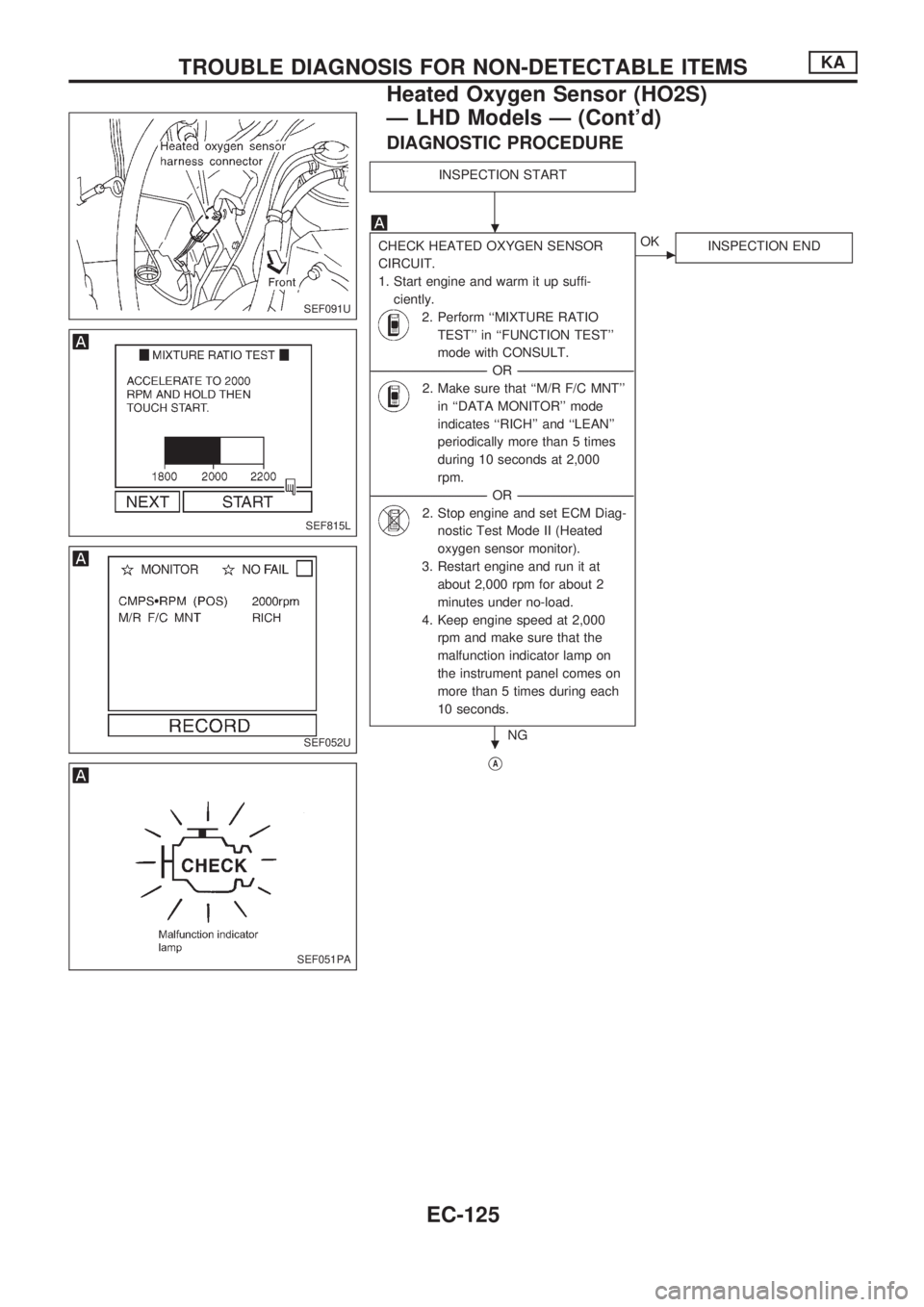

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK HEATED OXYGEN SENSOR

CIRCUIT.

1. Start engine and warm it up suffi-

ciently.

2. Perform ``MIXTURE RATIO

TEST'' in ``FUNCTION TEST''

mode with CONSULT.

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

2. Make sure that ``M/R F/C MNT''

in ``DATA MONITOR'' mode

indicates ``RICH'' and ``LEAN''

periodically more than 5 times

during 10 seconds at 2,000

rpm.

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

2. Stop engine and set ECM Diag-

nostic Test Mode II (Heated

oxygen sensor monitor).

3. Restart engine and run it at

about 2,000 rpm for about 2

minutes under no-load.

4. Keep engine speed at 2,000

rpm and make sure that the

malfunction indicator lamp on

the instrument panel comes on

more than 5 times during each

10 seconds.

NG

cOK

INSPECTION END

VA

SEF091U

SEF815L

SEF052U

SEF051PA

.

.

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

Heated Oxygen Sensor (HO2S)

Ð LHD Models Ð (Cont'd)

EC-125