heating NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 132 of 1659

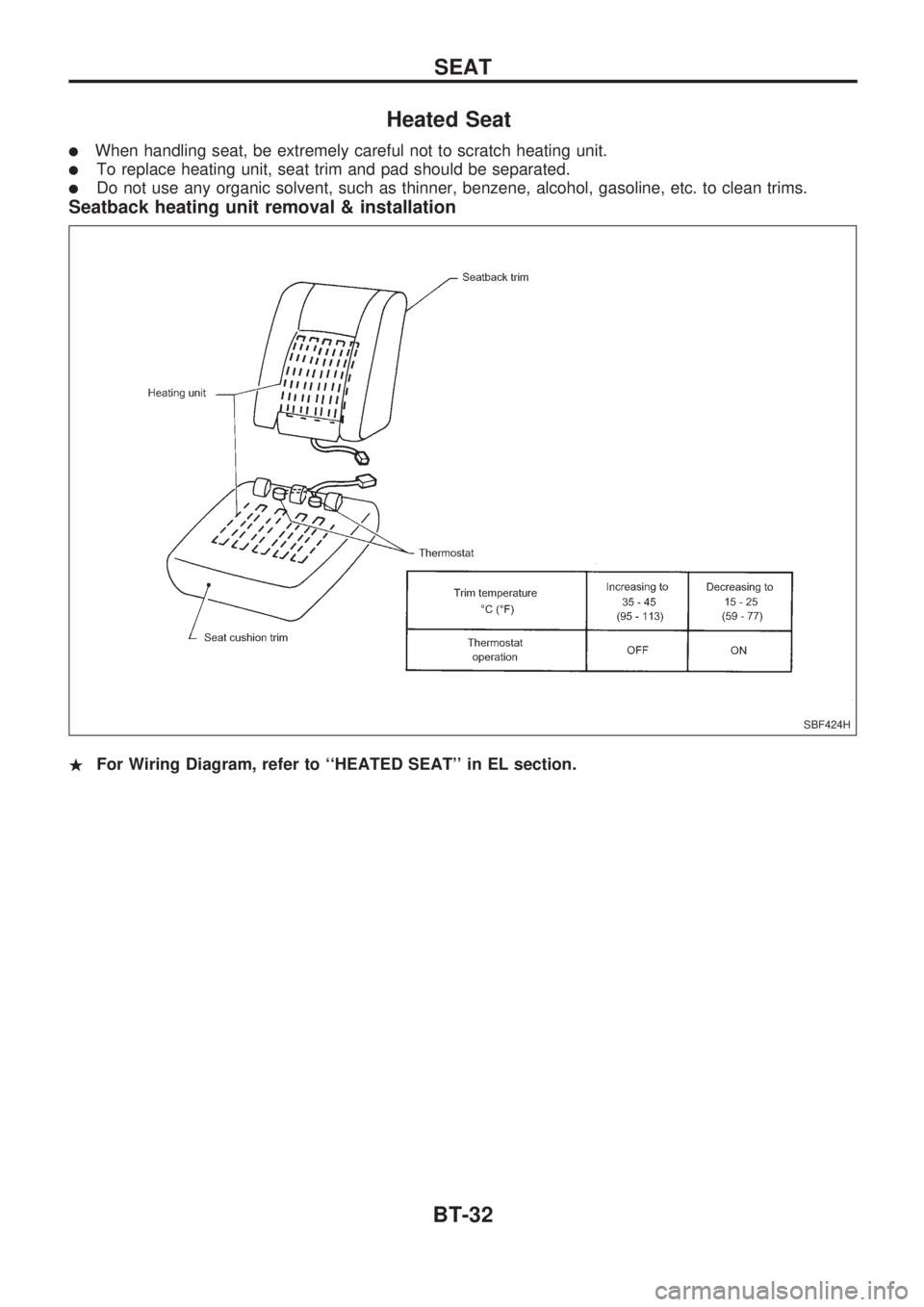

Heated Seat

lWhen handling seat, be extremely careful not to scratch heating unit.

lTo replace heating unit, seat trim and pad should be separated.

lDo not use any organic solvent, such as thinner, benzene, alcohol, gasoline, etc. to clean trims.

Seatback heating unit removal & installation

.For Wiring Diagram, refer to ``HEATED SEAT'' in EL section.

SBF424H

SEAT

BT-32

Page 258 of 1659

Overheat

ON BOARD DIAGNOSIS LOGIC

If the cooling fan or another component in the cooling system malfunctions, the engine coolant temperature

will rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Diagnostic trouble

code No.Malfunction is detected when ...Check Items

(Possible Cause)

28

lEngine coolant temperature reaches an abnormally

high temperature.lCooling fan

lRadiator hose

lRadiator

lRadiator cap

lWater pump

lThermostat

For more information, refer to ``MAIN 12

CAUSES OF OVERHEATING'', EC-108.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in MA sec-

tion (``Changing Engine Coolant'', ``ENGINE MAINTENANCE''). Also, replace the engine oil.

lFill radiator with coolant up to specified level with a filling speed of 2 liters per minute like pour-

ing coolant by kettle. Be sure to use coolant with the proper mixture ratio. Refer to MA section

(``Anti-freeze Coolant Mixture Ratio'', ``RECOMMENDED FLUIDS AND LUBRICANTS'').

lAfter refilling coolant, run engine to ensure that no water-flow noise is emitted.

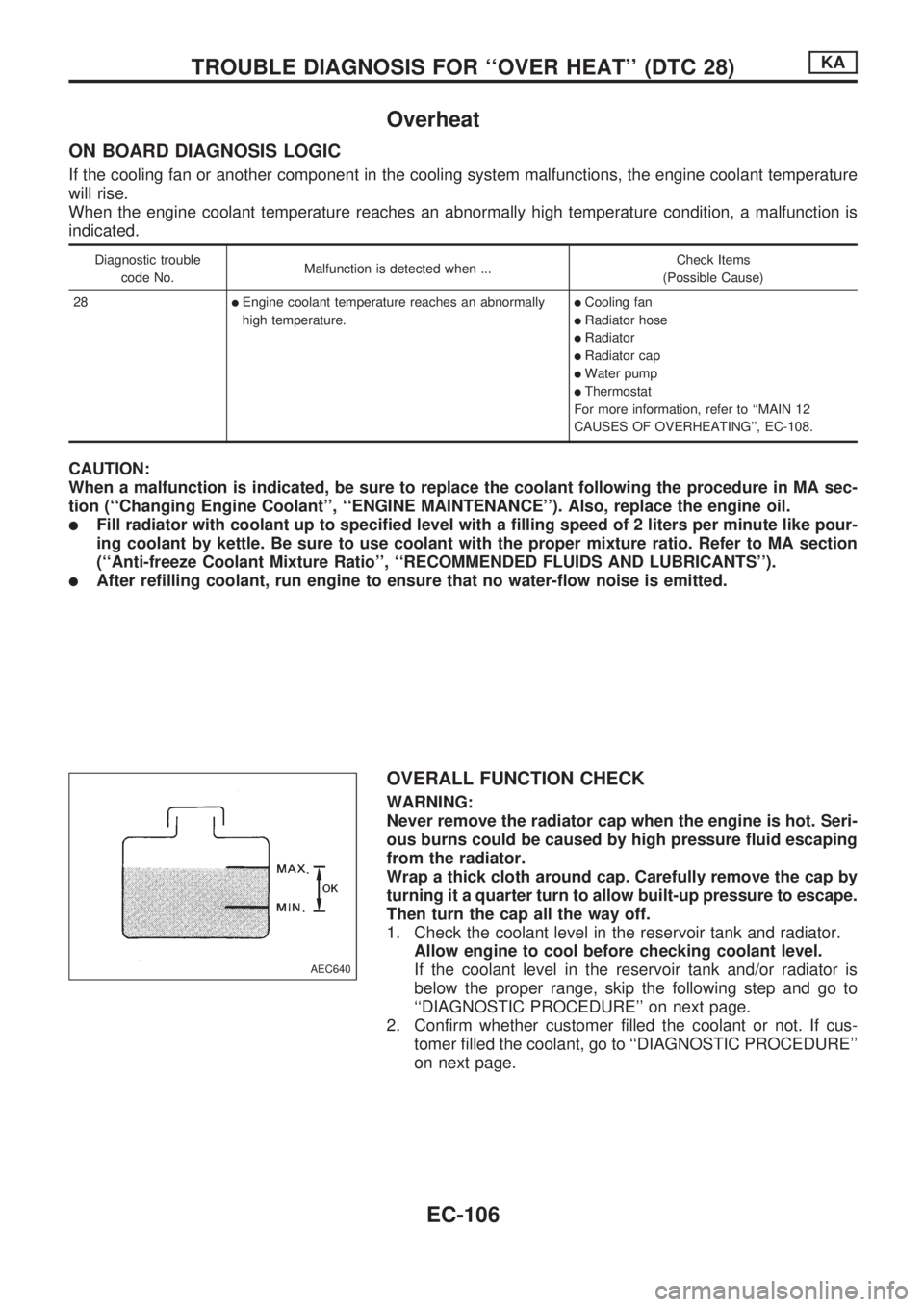

OVERALL FUNCTION CHECK

WARNING:

Never remove the radiator cap when the engine is hot. Seri-

ous burns could be caused by high pressure fluid escaping

from the radiator.

Wrap a thick cloth around cap. Carefully remove the cap by

turning it a quarter turn to allow built-up pressure to escape.

Then turn the cap all the way off.

1. Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is

below the proper range, skip the following step and go to

``DIAGNOSTIC PROCEDURE'' on next page.

2. Confirm whether customer filled the coolant or not. If cus-

tomer filled the coolant, go to ``DIAGNOSTIC PROCEDURE''

on next page.

AEC640

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)KA

EC-106

Page 259 of 1659

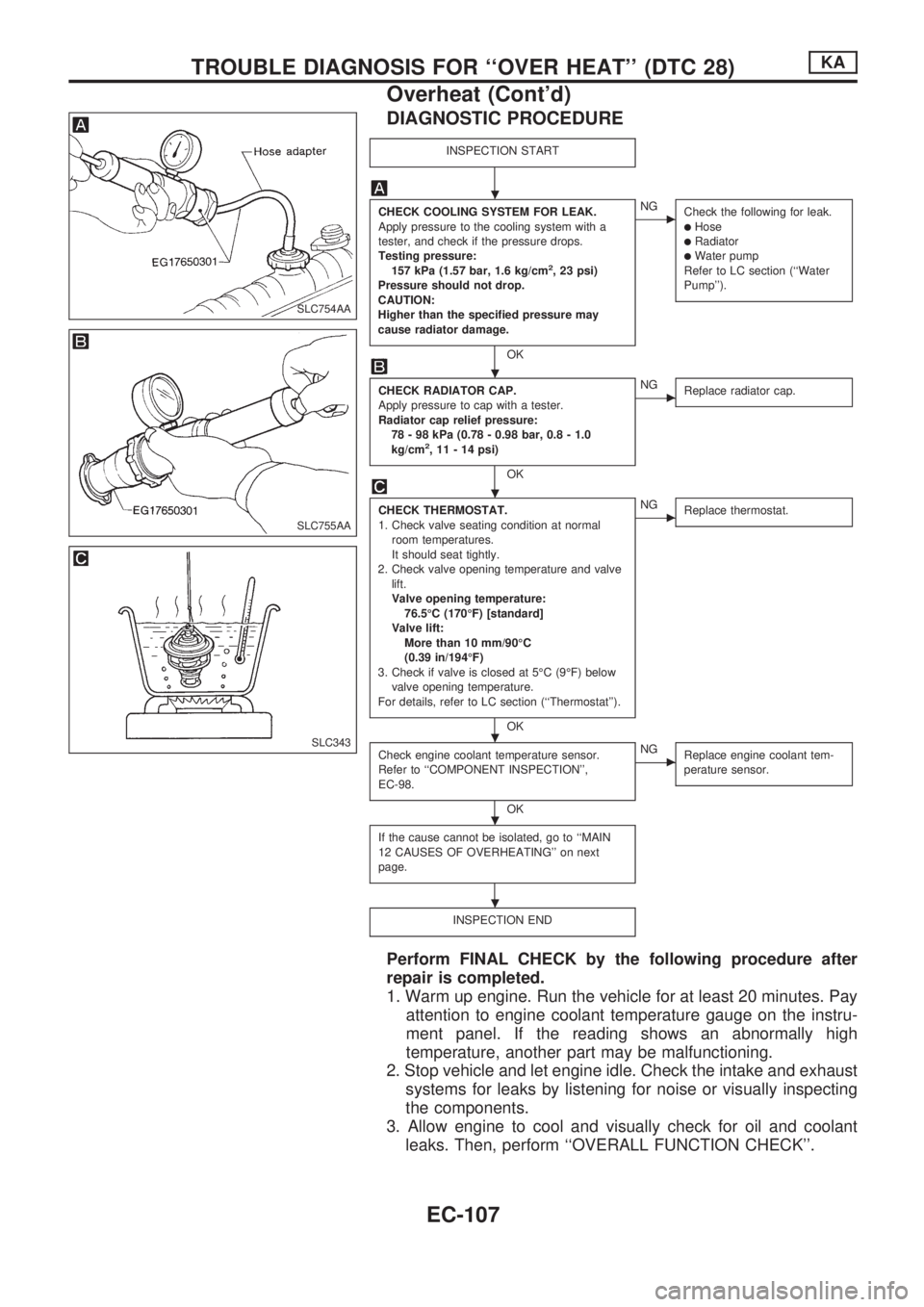

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK COOLING SYSTEM FOR LEAK.

Apply pressure to the cooling system with a

tester, and check if the pressure drops.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

Pressure should not drop.

CAUTION:

Higher than the specified pressure may

cause radiator damage.

OK

cNG

Check the following for leak.

lHoselRadiatorlWater pump

Refer to LC section (``Water

Pump'').

CHECK RADIATOR CAP.

Apply pressure to cap with a tester.

Radiator cap relief pressure:

78 - 98 kPa (0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

OK

cNG

Replace radiator cap.

CHECK THERMOSTAT.

1. Check valve seating condition at normal

room temperatures.

It should seat tightly.

2. Check valve opening temperature and valve

lift.

Valve opening temperature:

76.5ÉC (170ÉF) [standard]

Valve lift:

More than 10 mm/90ÉC

(0.39 in/194ÉF)

3. Check if valve is closed at 5ÉC (9ÉF) below

valve opening temperature.

For details, refer to LC section (``Thermostat'').

OK

cNG

Replace thermostat.

Check engine coolant temperature sensor.

Refer to ``COMPONENT INSPECTION'',

EC-98.

OK

cNG

Replace engine coolant tem-

perature sensor.

If the cause cannot be isolated, go to ``MAIN

12 CAUSES OF OVERHEATING'' on next

page.

INSPECTION END

Perform FINAL CHECK by the following procedure after

repair is completed.

1. Warm up engine. Run the vehicle for at least 20 minutes. Pay

attention to engine coolant temperature gauge on the instru-

ment panel. If the reading shows an abnormally high

temperature, another part may be malfunctioning.

2. Stop vehicle and let engine idle. Check the intake and exhaust

systems for leaks by listening for noise or visually inspecting

the components.

3. Allow engine to cool and visually check for oil and coolant

leaks. Then, perform ``OVERALL FUNCTION CHECK''.

SLC754AA

SLC755AA

SLC343

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)KA

Overheat (Cont'd)

EC-107

Page 260 of 1659

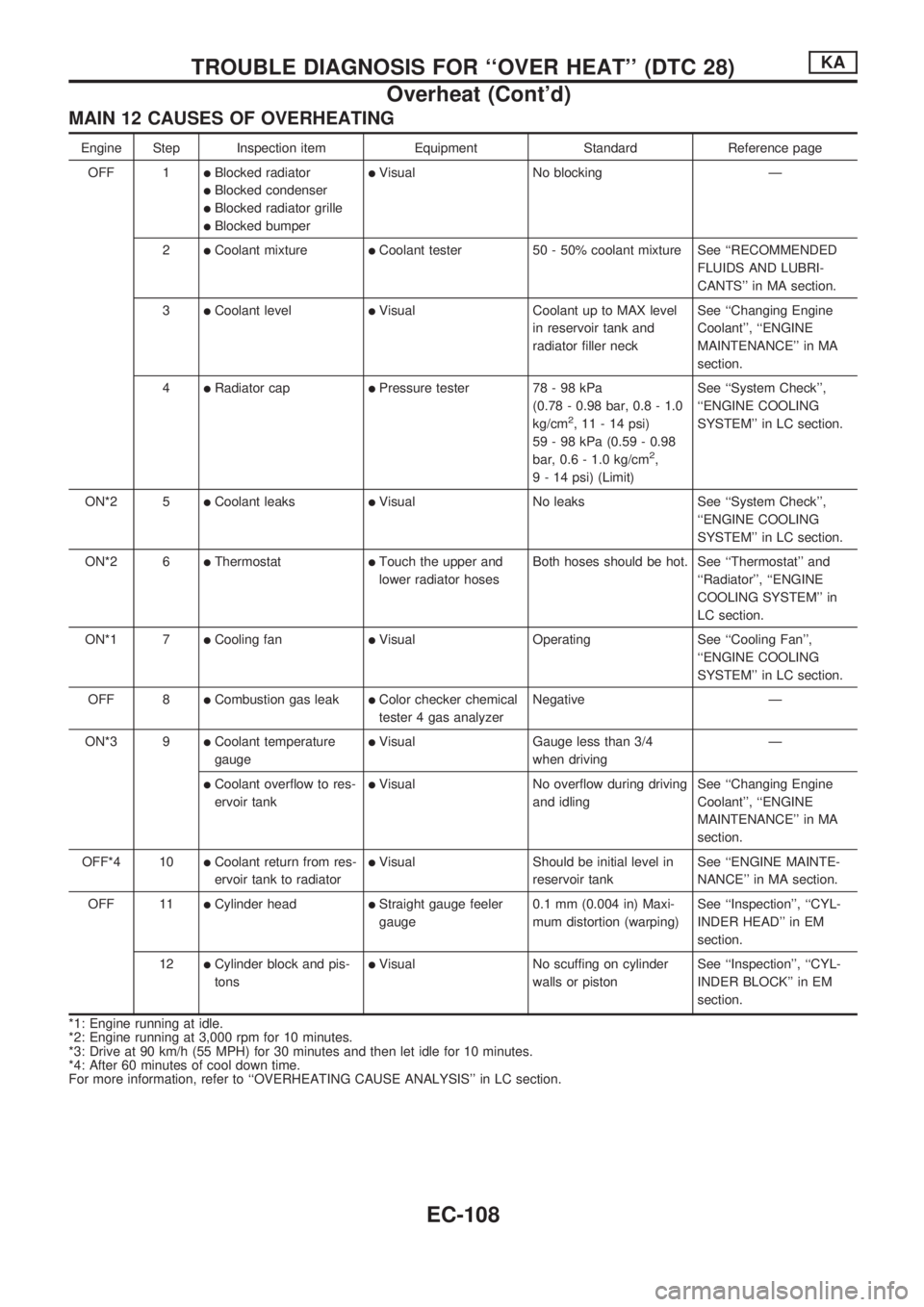

MAIN 12 CAUSES OF OVERHEATING

Engine Step Inspection item Equipment Standard Reference page

OFF 1

lBlocked radiator

lBlocked condenser

lBlocked radiator grille

lBlocked bumper

lVisual No blocking Ð

2

lCoolant mixturelCoolant tester 50 - 50% coolant mixture See ``RECOMMENDED

FLUIDS AND LUBRI-

CANTS'' in MA section.

3

lCoolant levellVisual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee ``Changing Engine

Coolant'', ``ENGINE

MAINTENANCE'' in MA

section.

4

lRadiator caplPressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit)See ``System Check'',

``ENGINE COOLING

SYSTEM'' in LC section.

ON*2 5

lCoolant leakslVisual No leaks See ``System Check'',

``ENGINE COOLING

SYSTEM'' in LC section.

ON*2 6

lThermostatlTouch the upper and

lower radiator hosesBoth hoses should be hot. See ``Thermostat'' and

``Radiator'', ``ENGINE

COOLING SYSTEM'' in

LC section.

ON*1 7

lCooling fanlVisual Operating See ``Cooling Fan'',

``ENGINE COOLING

SYSTEM'' in LC section.

OFF 8

lCombustion gas leaklColor checker chemical

tester 4 gas analyzerNegative Ð

ON*3 9

lCoolant temperature

gaugelVisual Gauge less than 3/4

when drivingÐ

lCoolant overflow to res-

ervoir tanklVisual No overflow during driving

and idlingSee ``Changing Engine

Coolant'', ``ENGINE

MAINTENANCE'' in MA

section.

OFF*4 10

lCoolant return from res-

ervoir tank to radiatorlVisual Should be initial level in

reservoir tankSee ``ENGINE MAINTE-

NANCE'' in MA section.

OFF 11

lCylinder headlStraight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ``Inspection'', ``CYL-

INDER HEAD'' in EM

section.

12

lCylinder block and pis-

tonslVisual No scuffing on cylinder

walls or pistonSee ``Inspection'', ``CYL-

INDER BLOCK'' in EM

section.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ``OVERHEATING CAUSE ANALYSIS'' in LC section.

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)KA

Overheat (Cont'd)

EC-108

Page 809 of 1659

If skin contact is made, wash thoroughly with soap or hand

cleaner as soon as possible.

HEALTH PROTECTION PRECAUTIONS

lAvoid prolonged and repeated contact with oils, particularly

used engine oils.

lWear protective clothing, including impervious gloves where

practicable.

lDo not put oily rags in pockets.

lAvoid contaminating clothes, particularly underpants, with oil.

lHeavily soiled clothing and oil-impregnated footwear should

not be worn. Overalls must be cleaned regularly.

lFirst Aid treatment should be obtained immediately for open

cuts and wounds.

lUse barrier creams, applying them before each work period,

to help the removal of oil from the skin.

lWash with soap and water to ensure all oil is removed (skin

cleansers and nail brushes will help). Preparations contain-

ing lanolin replace the natural skin oils which have been

removed.

lDo not use gasoline, kerosine, diesel fuel, gas oil, thinners

or solvents for cleaning skin.

lIf skin disorders develop, obtain medical advice without

delay.

lWhere practicable, degrease components prior to handling.

lWhere there is a risk of eye contact, eye protection should

be worn, for example, chemical goggles or face shields; in

addition an eye wash facility should be provided.

ENVIRONMENTAL PROTECTION PRECAUTIONS

Burning used engine oil in small space heaters or boilers can be

recommended only for units of approved design. The heating

system must meet the requirements of HM Inspectorate of Pol-

lution for small burners of less than 0.4 MW. If in doubt check

with the appropriate local authority and/or manufacturer of the

approved appliance.

Dispose of used oil and used oil filters through authorized waste

disposal contractors to licensed waste disposal sites, or to the

waste oil reclamation trade. If in doubt, contact the local author-

ity for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down sewers or

drains, or into water courses.

The regulations concerning the pollution of the environment

will vary from country to country.

Precautions for Fuel

GASOLINE ENGINE:

Three way catalyst equipped models ... unleaded gasoline of at

least 91 octane (RON)

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will dam-

age the three way catalyst.

Except for the above models ... unleaded or leaded gasoline of

above 88 octane (RON)

Use unleaded fuel if instructed on the fuel filler lid.

PRECAUTIONS

Precautions for Engine Oils (Cont'd)

GI-5

Page 810 of 1659

DIESEL ENGINE*:

For Europe: diesel fuel of above 50 cetane

* If two types of diesel fuel are available, use summer or win-

ter fuel properly according to the following temperature con-

ditions.

lAbove þ7ÉC (20ÉF) ... Summer type diesel fuel.

lBelow þ7ÉC (20ÉF) ... Winter type diesel fuel.

CAUTION:

lDo not use home heating oil, gasoline, or other alternate

fuels in your diesel engine. The use of those can cause

engine damage.

lDo not use summer fuel at temperature below þ7ÉC

(20ÉF). The cold temperature will cause wax to form in

the fuel. As a result, it may prevent the engine from run-

ning smoothly.

lDo not add gasoline or other alternate fuels to diesel

fuel.

Precautions for Air Conditioning

Use an approved refrigerant recovery unit any time the air con-

ditioning system must be discharged. Refer to HA section

(``HFC-134a (R-134a) Service Procedure'', ``SERVICE PRO-

CEDURES'') for specific instructions.

PRECAUTIONS

Precautions for Fuel (Cont'd)

GI-6

Page 827 of 1659

Engine compartment

There are several reasons a vehicle or engine vibration could

cause an electrical complaint. Some of the things to check for

are:

lConnectors not fully seated.

lWiring harness not long enough and is being stressed due

to engine vibrations or rocking.

lWires laying across brackets or moving components.

lLoose, dirty or corroded ground wires.

lWires routed too close to hot components.

To inspect components under the hood, start by verifying the

integrity of ground connections. (Refer to GROUND INSPEC-

TION described later.) First check that the system is properly

grounded. Then check for loose connection bygently shaking

the wiring or components as previously explained. Using the

wiring diagrams inspect the wiring for continuity.

Behind the instrument panel

An improperly routed or improperly clamped harness can

become pinched during accessory installation. Vehicle vibration

can aggravate a harness which is routed along a bracket or near

a screw.

Under seating areas

An unclamped or loose harness can cause wiring to be pinched

by seat components (such as slide guides) during vehicle vibra-

tion. If the wiring runs under seating areas, inspect wire routing

for possible damage or pinching.

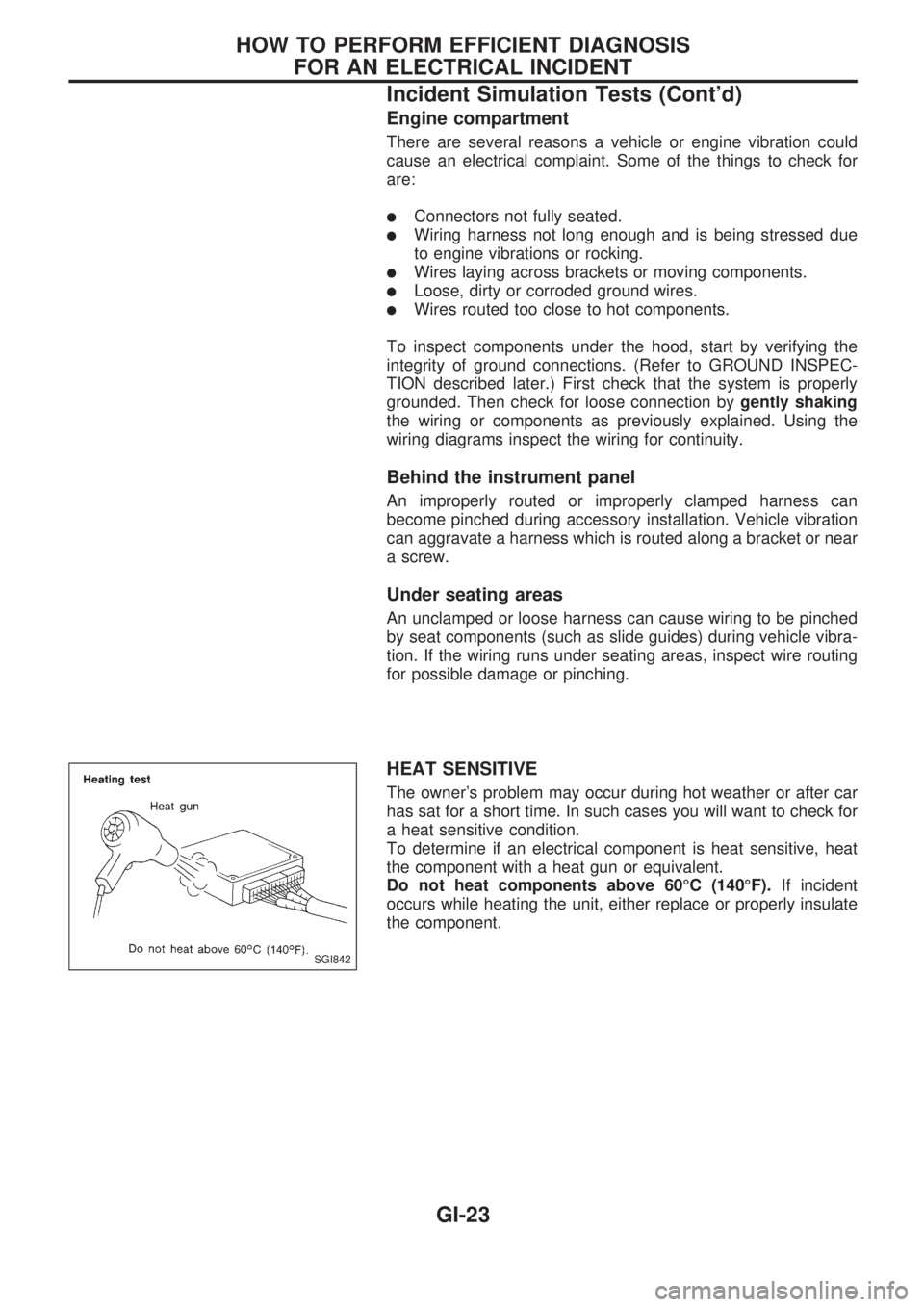

HEAT SENSITIVE

The owner's problem may occur during hot weather or after car

has sat for a short time. In such cases you will want to check for

a heat sensitive condition.

To determine if an electrical component is heat sensitive, heat

the component with a heat gun or equivalent.

Do not heat components above 60ÉC (140ÉF).If incident

occurs while heating the unit, either replace or properly insulate

the component.

SGI842

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-23

Page 891 of 1659

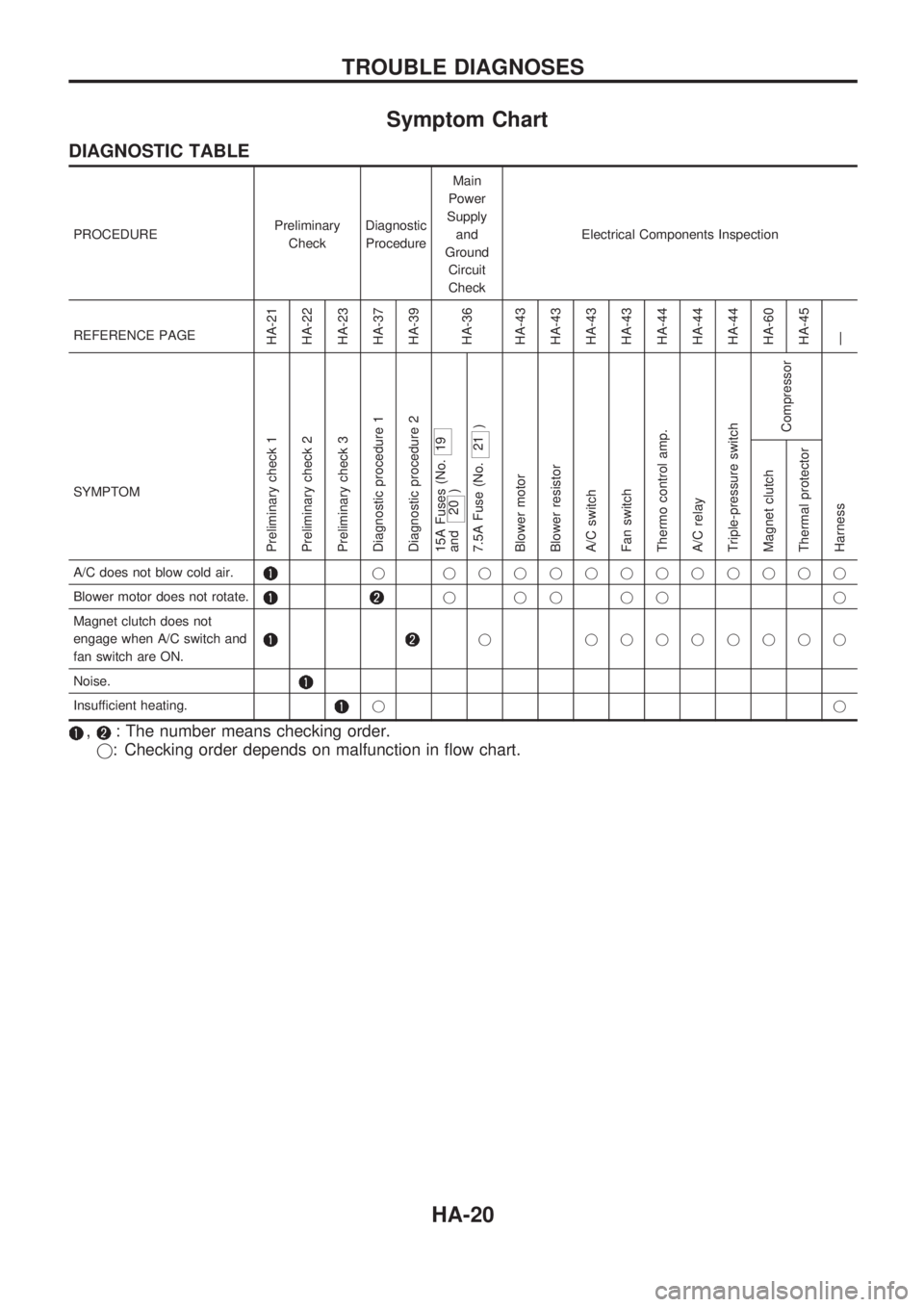

Symptom Chart

DIAGNOSTIC TABLE

PROCEDUREPreliminary

CheckDiagnostic

ProcedureMain

Power

Supply

and

Ground

Circuit

CheckElectrical Components Inspection

REFERENCE PAGE

HA-21

HA-22

HA-23

HA-37

HA-39

HA-36

HA-43

HA-43

HA-43

HA-43

HA-44

HA-44

HA-44

HA-60

HA-45

Ð

SYMPTOM

Preliminary check 1

Preliminary check 2

Preliminary check 3

Diagnostic procedure 1

Diagnostic procedure 2

15A Fuses (No.

19

and

20 )

7.5A Fuse (No.

21 )

Blower motor

Blower resistor

A/C switch

Fan switch

Thermo control amp.

A/C relay

Triple-pressure switch

Compressor

Harness Magnet clutch

Thermal protector

A/C does not blow cold air.j jjjjjjjjjjjj

Blower motor does not rotate.

jjjjj j

Magnet clutch does not

engage when A/C switch and

fan switch are ON.

j jjjjjjjj

Noise.

Insufficient heating.jj

,: The number means checking order.

j: Checking order depends on malfunction in flow chart.

TROUBLE DIAGNOSES

HA-20

Page 894 of 1659

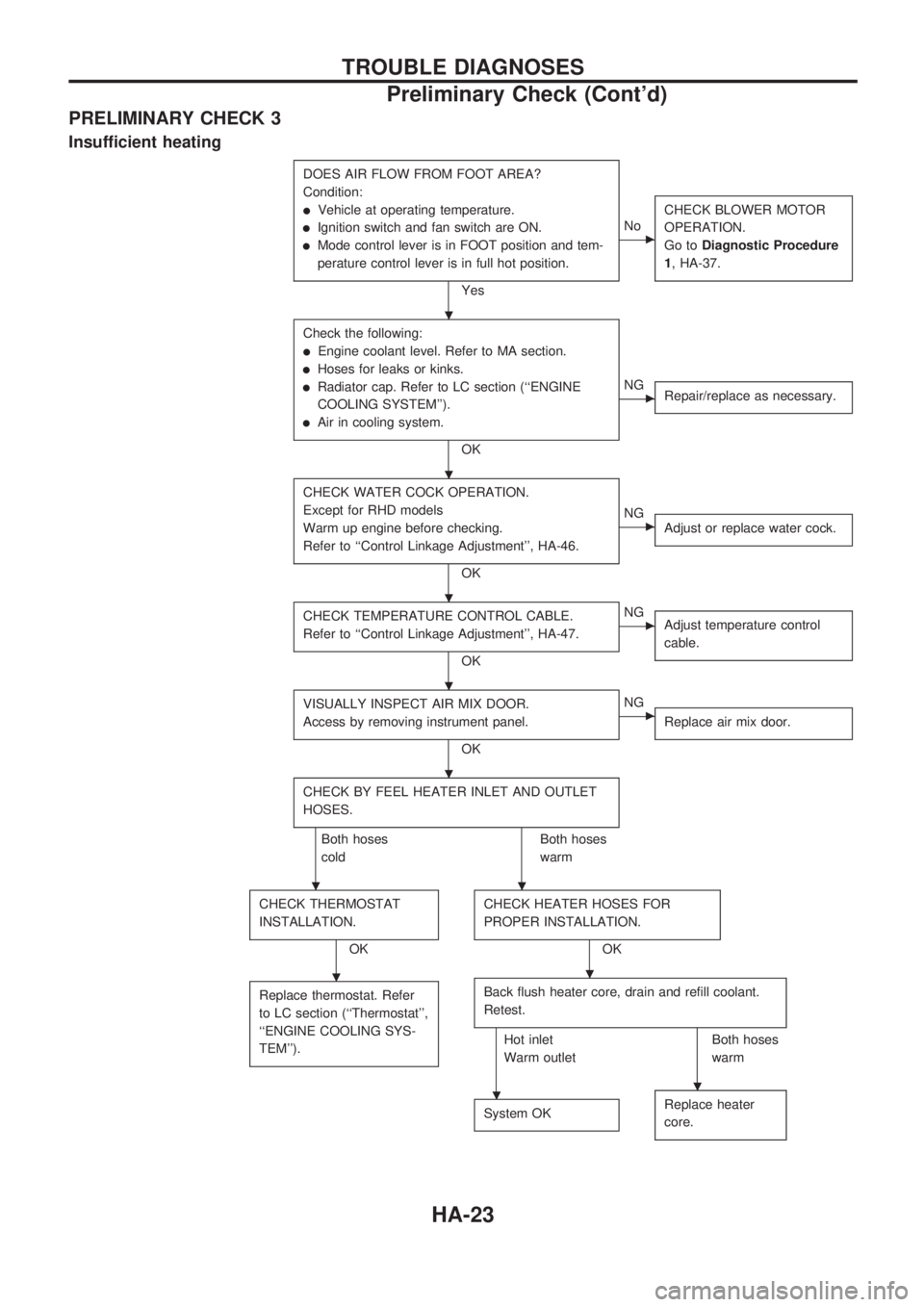

PRELIMINARY CHECK 3

Insufficient heating

DOES AIR FLOW FROM FOOT AREA?

Condition:

lVehicle at operating temperature.

lIgnition switch and fan switch are ON.

lMode control lever is in FOOT position and tem-

perature control lever is in full hot position.

Yes

cNoCHECK BLOWER MOTOR

OPERATION.

Go toDiagnostic Procedure

1, HA-37.

Check the following:

lEngine coolant level. Refer to MA section.

lHoses for leaks or kinks.

lRadiator cap. Refer to LC section (``ENGINE

COOLING SYSTEM'').

lAir in cooling system.

OK

cNG

Repair/replace as necessary.

CHECK WATER COCK OPERATION.

Except for RHD models

Warm up engine before checking.

Refer to ``Control Linkage Adjustment'', HA-46.

OK

cNG

Adjust or replace water cock.

CHECK TEMPERATURE CONTROL CABLE.

Refer to ``Control Linkage Adjustment'', HA-47.

OK

cNG

Adjust temperature control

cable.

VISUALLY INSPECT AIR MIX DOOR.

Access by removing instrument panel.

OK

cNG

Replace air mix door.

CHECK BY FEEL HEATER INLET AND OUTLET

HOSES.

Both hoses

coldBoth hoses

warm

CHECK THERMOSTAT

INSTALLATION.

OKCHECK HEATER HOSES FOR

PROPER INSTALLATION.OK

Replace thermostat. Refer

to LC section (``Thermostat'',

``ENGINE COOLING SYS-

TEM'').

Back flush heater core, drain and refill coolant.

Retest.

Hot inlet

Warm outletBoth hoses

warm

System OK

Replace heater

core.

.

.

.

.

.

..

..

..

TROUBLE DIAGNOSES

Preliminary Check (Cont'd)

HA-23

Page 939 of 1659

ENGINE LUBRICATION &

COOLING SYSTEMS

SECTION

LC

CONTENTS

PRECAUTIONS AND PREPARATION..................... 1

Liquid Gasket Application Procedure .................... 1

Special Service Tools ............................................ 2

KA

ENGINE LUBRICATION SYSTEM............................ 3

Lubrication Circuit .................................................. 3

Oil Pressure Check ................................................ 4

Oil Pump ................................................................ 4

ENGINE COOLING SYSTEM.................................... 6

Cooling Circuit........................................................ 6

System Check ........................................................ 6

Water Pump ........................................................... 7

Thermostat ............................................................. 8

Radiator.................................................................. 9

Cooling Fan (Crankshaft driven).......................... 10

TD

ENGINE LUBRICATION SYSTEM.......................... 12

Lubrication Circuit ................................................ 12

Oil Pressure Check (On-vehicle service) ............ 13

Oil Pump .............................................................. 14

Oil Filter Bracket .................................................. 16

Oil Cooler ............................................................. 17Oil Jet ................................................................... 18

ENGINE COOLING SYSTEM.................................. 19

Cooling Circuit...................................................... 19

Cooling System Inspection .................................. 20

Water Pump and Cooling Fan (Camshaft

driven) .................................................................. 21

Thermostat ........................................................... 23

Radiator................................................................ 24

Refilling Engine Coolant ...................................... 24

ENGINE ROOM FAN MOTOR ELECTRICAL

CIRCUIT................................................................... 25

Wiring Diagram .................................................... 25

Cooling Fan (Motor driven) .................................. 26

Electrical Components Inspection ....................... 26

ENGINE COOLING SYSTEM.................................. 28

Radiator (Aluminum type) .................................... 28

Overheating Cause Analysis ............................... 31

SERVICE DATA AND SPECIFICATIONS (SDS)... 32

Engine Lubrication System (KA).......................... 32

Engine Cooling System (KA) ............................... 32

Engine Lubrication System (TD).......................... 32

Engine Cooling System (TD) ............................... 32

LC