compression ratio NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 177 of 1659

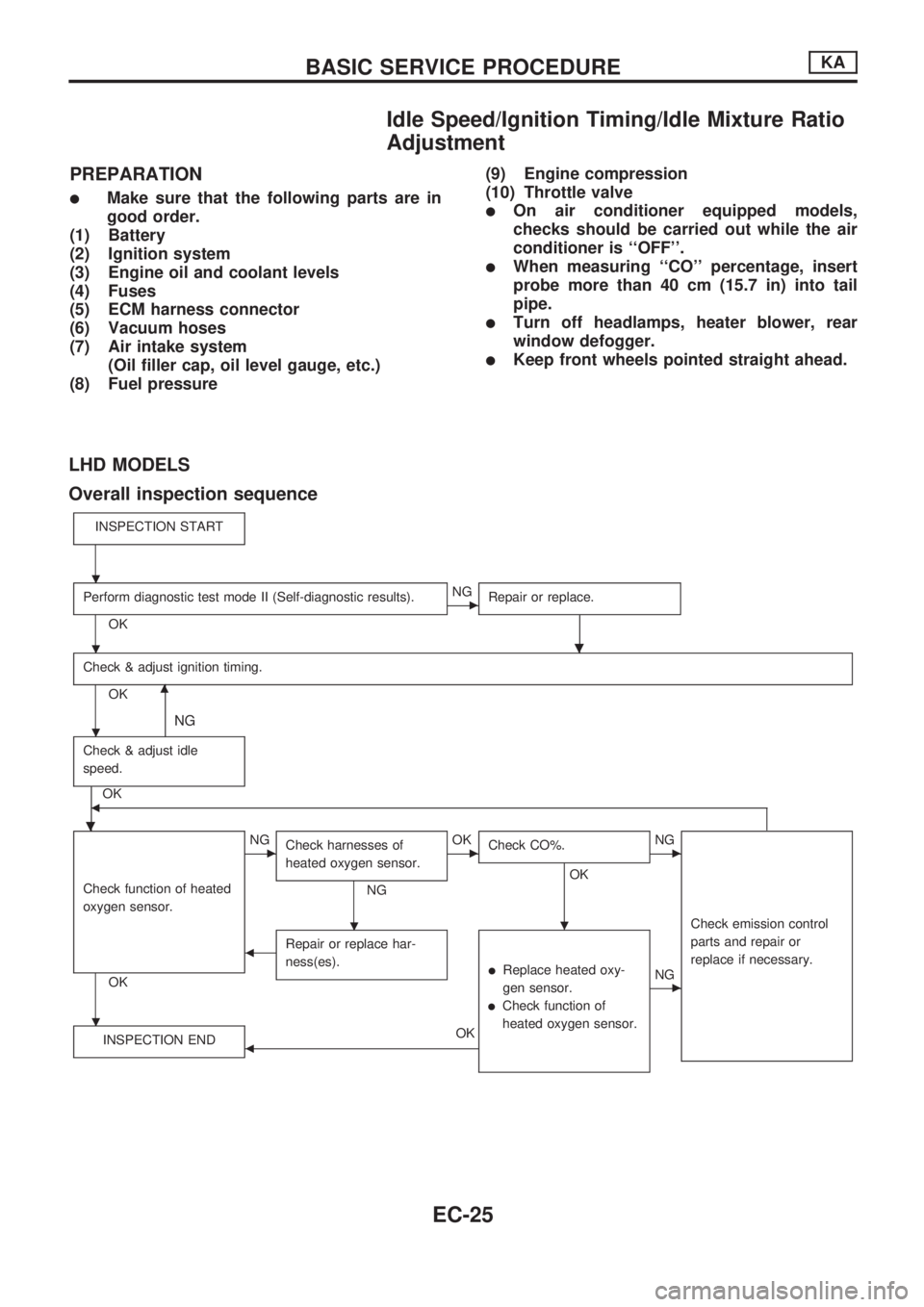

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment

PREPARATION

lMake sure that the following parts are in

good order.

(1) Battery

(2) Ignition system

(3) Engine oil and coolant levels

(4) Fuses

(5) ECM harness connector

(6) Vacuum hoses

(7) Air intake system

(Oil filler cap, oil level gauge, etc.)

(8) Fuel pressure(9) Engine compression

(10) Throttle valvelOn air conditioner equipped models,

checks should be carried out while the air

conditioner is ``OFF''.

lWhen measuring ``CO'' percentage, insert

probe more than 40 cm (15.7 in) into tail

pipe.

lTurn off headlamps, heater blower, rear

window defogger.

lKeep front wheels pointed straight ahead.

LHD MODELS

Overall inspection sequence

INSPECTION START

Perform diagnostic test mode II (Self-diagnostic results).

OK

cNG

Repair or replace.

.

Check & adjust ignition timing.

OKm

NG

Check & adjust idle

speed.

.

OKb

Check function of heated

oxygen sensor.

OK

cNG

Check harnesses of

heated oxygen sensor.

NG

cOK

Check CO%.

OK

.

cNG

Check emission control

parts and repair or

replace if necessary.

bRepair or replace har-

ness(es).

lReplace heated oxy-

gen sensor.

lCheck function of

heated oxygen sensor.

cNG

INSPECTION END

bOK

.

.

.

.

.

BASIC SERVICE PROCEDUREKA

EC-25

Page 202 of 1659

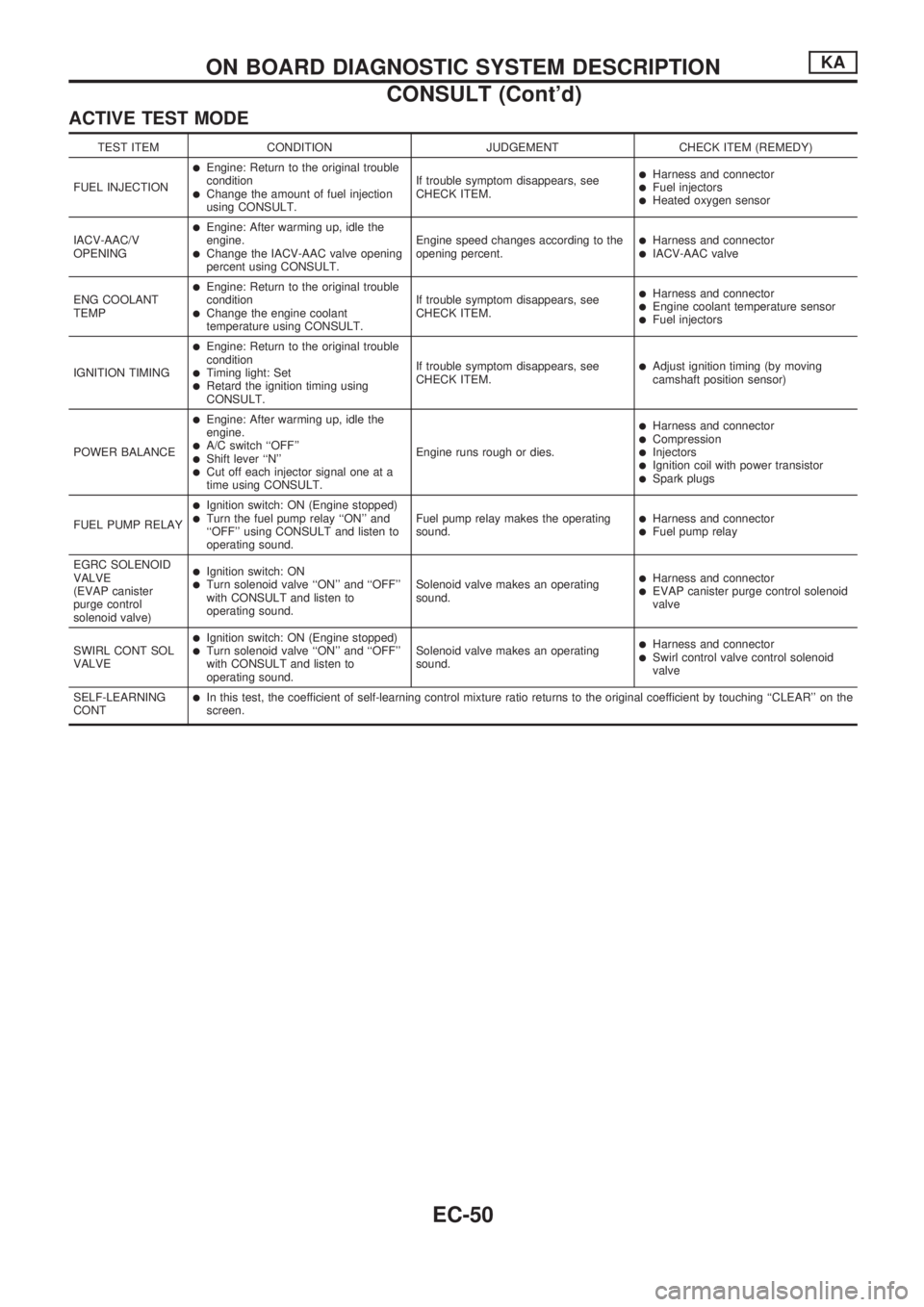

ACTIVE TEST MODE

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJECTION

lEngine: Return to the original trouble

condition

lChange the amount of fuel injection

using CONSULT.If trouble symptom disappears, see

CHECK ITEM.

lHarness and connectorlFuel injectorslHeated oxygen sensor

IACV-AAC/V

OPENING

lEngine: After warming up, idle the

engine.

lChange the IACV-AAC valve opening

percent using CONSULT.Engine speed changes according to the

opening percent.lHarness and connectorlIACV-AAC valve

ENG COOLANT

TEMP

lEngine: Return to the original trouble

condition

lChange the engine coolant

temperature using CONSULT.If trouble symptom disappears, see

CHECK ITEM.

lHarness and connectorlEngine coolant temperature sensorlFuel injectors

IGNITION TIMING

lEngine: Return to the original trouble

condition

lTiming light: SetlRetard the ignition timing using

CONSULT.If trouble symptom disappears, see

CHECK ITEM.

lAdjust ignition timing (by moving

camshaft position sensor)

POWER BALANCE

lEngine: After warming up, idle the

engine.

lA/C switch ``OFF''lShift lever ``N''lCut off each injector signal one at a

time using CONSULT.Engine runs rough or dies.

lHarness and connectorlCompressionlInjectorslIgnition coil with power transistorlSpark plugs

FUEL PUMP RELAY

lIgnition switch: ON (Engine stopped)lTurn the fuel pump relay ``ON'' and

``OFF'' using CONSULT and listen to

operating sound.Fuel pump relay makes the operating

sound.lHarness and connectorlFuel pump relay

EGRC SOLENOID

VALVE

(EVAP canister

purge control

solenoid valve)

lIgnition switch: ONlTurn solenoid valve ``ON'' and ``OFF''

with CONSULT and listen to

operating sound.Solenoid valve makes an operating

sound.lHarness and connectorlEVAP canister purge control solenoid

valve

SWIRL CONT SOL

VALVE

lIgnition switch: ON (Engine stopped)lTurn solenoid valve ``ON'' and ``OFF''

with CONSULT and listen to

operating sound.Solenoid valve makes an operating

sound.lHarness and connectorlSwirl control valve control solenoid

valve

SELF-LEARNING

CONT

lIn this test, the coefficient of self-learning control mixture ratio returns to the original coefficient by touching ``CLEAR'' on the

screen.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-50

Page 204 of 1659

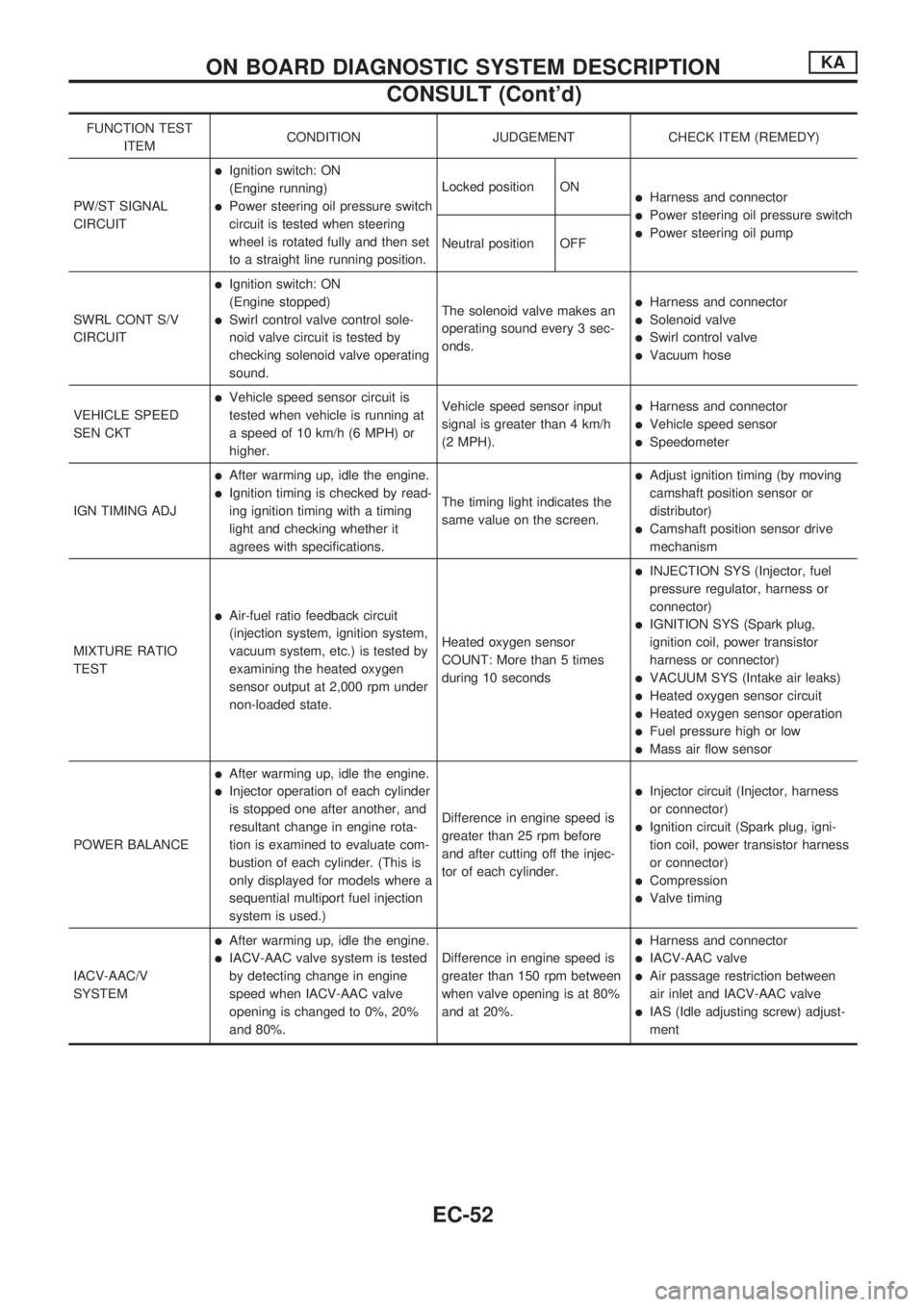

FUNCTION TEST

ITEMCONDITION JUDGEMENT CHECK ITEM (REMEDY)

PW/ST SIGNAL

CIRCUIT

lIgnition switch: ON

(Engine running)

lPower steering oil pressure switch

circuit is tested when steering

wheel is rotated fully and then set

to a straight line running position.Locked position ONlHarness and connector

lPower steering oil pressure switch

lPower steering oil pump

Neutral position OFF

SWRL CONT S/V

CIRCUIT

lIgnition switch: ON

(Engine stopped)

lSwirl control valve control sole-

noid valve circuit is tested by

checking solenoid valve operating

sound.The solenoid valve makes an

operating sound every 3 sec-

onds.

lHarness and connector

lSolenoid valve

lSwirl control valve

lVacuum hose

VEHICLE SPEED

SEN CKT

lVehicle speed sensor circuit is

tested when vehicle is running at

a speed of 10 km/h (6 MPH) or

higher.Vehicle speed sensor input

signal is greater than 4 km/h

(2 MPH).lHarness and connector

lVehicle speed sensor

lSpeedometer

IGN TIMING ADJ

lAfter warming up, idle the engine.

lIgnition timing is checked by read-

ing ignition timing with a timing

light and checking whether it

agrees with specifications.The timing light indicates the

same value on the screen.

lAdjust ignition timing (by moving

camshaft position sensor or

distributor)

lCamshaft position sensor drive

mechanism

MIXTURE RATIO

TEST

lAir-fuel ratio feedback circuit

(injection system, ignition system,

vacuum system, etc.) is tested by

examining the heated oxygen

sensor output at 2,000 rpm under

non-loaded state.Heated oxygen sensor

COUNT: More than 5 times

during 10 seconds

lINJECTION SYS (Injector, fuel

pressure regulator, harness or

connector)

lIGNITION SYS (Spark plug,

ignition coil, power transistor

harness or connector)

lVACUUM SYS (Intake air leaks)

lHeated oxygen sensor circuit

lHeated oxygen sensor operation

lFuel pressure high or low

lMass air flow sensor

POWER BALANCE

lAfter warming up, idle the engine.

lInjector operation of each cylinder

is stopped one after another, and

resultant change in engine rota-

tion is examined to evaluate com-

bustion of each cylinder. (This is

only displayed for models where a

sequential multiport fuel injection

system is used.)Difference in engine speed is

greater than 25 rpm before

and after cutting off the injec-

tor of each cylinder.lInjector circuit (Injector, harness

or connector)

lIgnition circuit (Spark plug, igni-

tion coil, power transistor harness

or connector)

lCompression

lValve timing

IACV-AAC/V

SYSTEM

lAfter warming up, idle the engine.

lIACV-AAC valve system is tested

by detecting change in engine

speed when IACV-AAC valve

opening is changed to 0%, 20%

and 80%.Difference in engine speed is

greater than 150 rpm between

when valve opening is at 80%

and at 20%.

lHarness and connector

lIACV-AAC valve

lAir passage restriction between

air inlet and IACV-AAC valve

lIAS (Idle adjusting screw) adjust-

ment

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-52

Page 644 of 1659

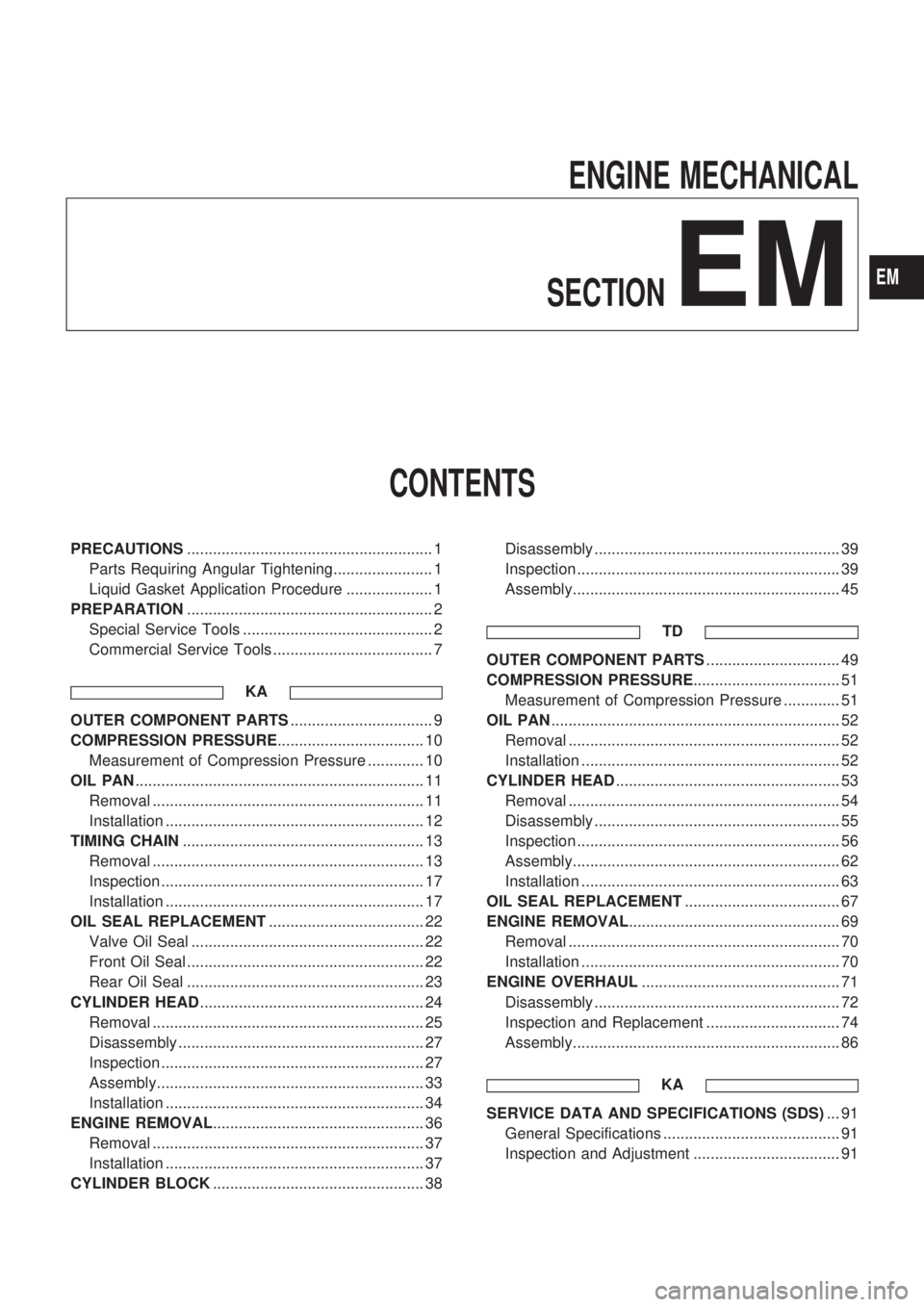

ENGINE MECHANICAL

SECTION

EM

CONTENTS

PRECAUTIONS......................................................... 1

Parts Requiring Angular Tightening....................... 1

Liquid Gasket Application Procedure .................... 1

PREPARATION......................................................... 2

Special Service Tools ............................................ 2

Commercial Service Tools ..................................... 7

KA

OUTER COMPONENT PARTS................................. 9

COMPRESSION PRESSURE.................................. 10

Measurement of Compression Pressure ............. 10

OIL PAN................................................................... 11

Removal ............................................................... 11

Installation ............................................................ 12

TIMING CHAIN........................................................ 13

Removal ............................................................... 13

Inspection ............................................................. 17

Installation ............................................................ 17

OIL SEAL REPLACEMENT.................................... 22

Valve Oil Seal ...................................................... 22

Front Oil Seal ....................................................... 22

Rear Oil Seal ....................................................... 23

CYLINDER HEAD.................................................... 24

Removal ............................................................... 25

Disassembly ......................................................... 27

Inspection ............................................................. 27

Assembly.............................................................. 33

Installation ............................................................ 34

ENGINE REMOVAL................................................. 36

Removal ............................................................... 37

Installation ............................................................ 37

CYLINDER BLOCK................................................. 38Disassembly ......................................................... 39

Inspection ............................................................. 39

Assembly.............................................................. 45

TD

OUTER COMPONENT PARTS............................... 49

COMPRESSION PRESSURE.................................. 51

Measurement of Compression Pressure ............. 51

OIL PAN................................................................... 52

Removal ............................................................... 52

Installation ............................................................ 52

CYLINDER HEAD.................................................... 53

Removal ............................................................... 54

Disassembly ......................................................... 55

Inspection ............................................................. 56

Assembly.............................................................. 62

Installation ............................................................ 63

OIL SEAL REPLACEMENT.................................... 67

ENGINE REMOVAL................................................. 69

Removal ............................................................... 70

Installation ............................................................ 70

ENGINE OVERHAUL.............................................. 71

Disassembly ......................................................... 72

Inspection and Replacement ............................... 74

Assembly.............................................................. 86

KA

SERVICE DATA AND SPECIFICATIONS (SDS)... 91

General Specifications ......................................... 91

Inspection and Adjustment .................................. 91

EM

Page 649 of 1659

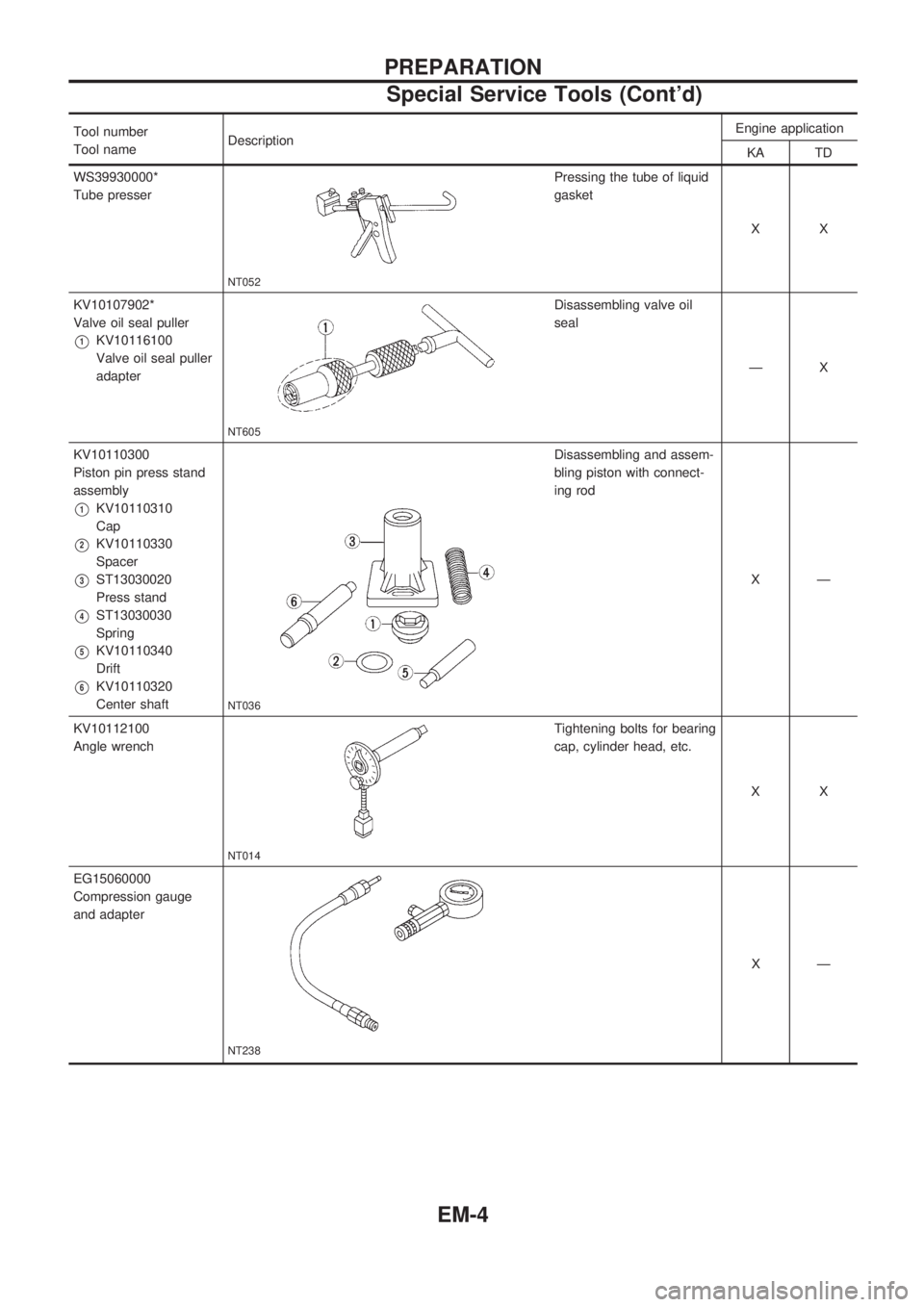

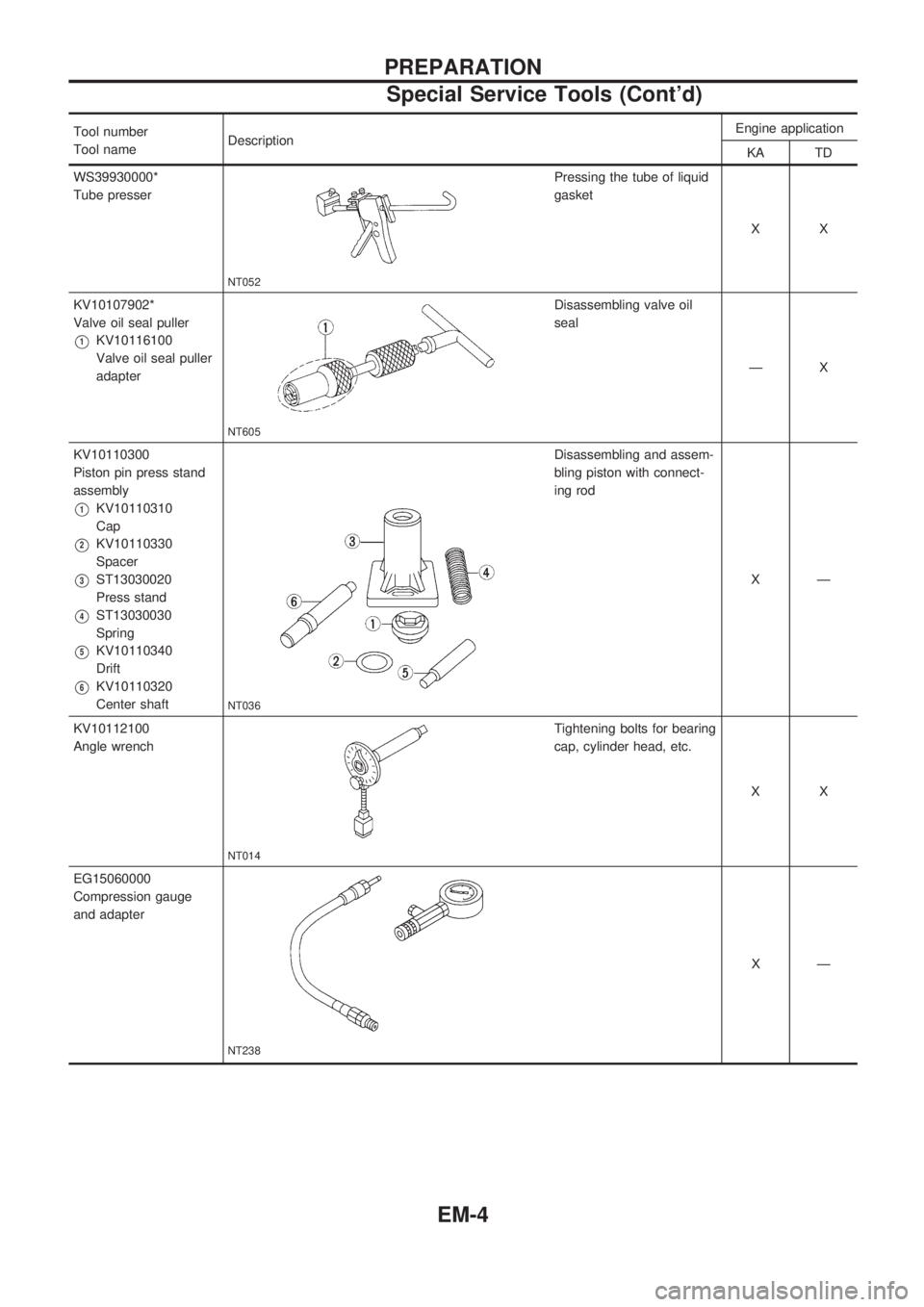

Tool number

Tool nameDescriptionEngine application

KA TD

WS39930000*

Tube presser

NT052

Pressing the tube of liquid

gasket

XX

KV10107902*

Valve oil seal puller

V1KV10116100

Valve oil seal puller

adapter

NT605

Disassembling valve oil

seal

ÐX

KV10110300

Piston pin press stand

assembly

V1KV10110310

Cap

V2KV10110330

Spacer

V3ST13030020

Press stand

V4ST13030030

Spring

V5KV10110340

Drift

V6KV10110320

Center shaft

NT036

Disassembling and assem-

bling piston with connect-

ing rod

XÐ

KV10112100

Angle wrench

NT014

Tightening bolts for bearing

cap, cylinder head, etc.

XX

EG15060000

Compression gauge

and adapter

NT238

XÐ

PREPARATION

Special Service Tools (Cont'd)

EM-4

Page 650 of 1659

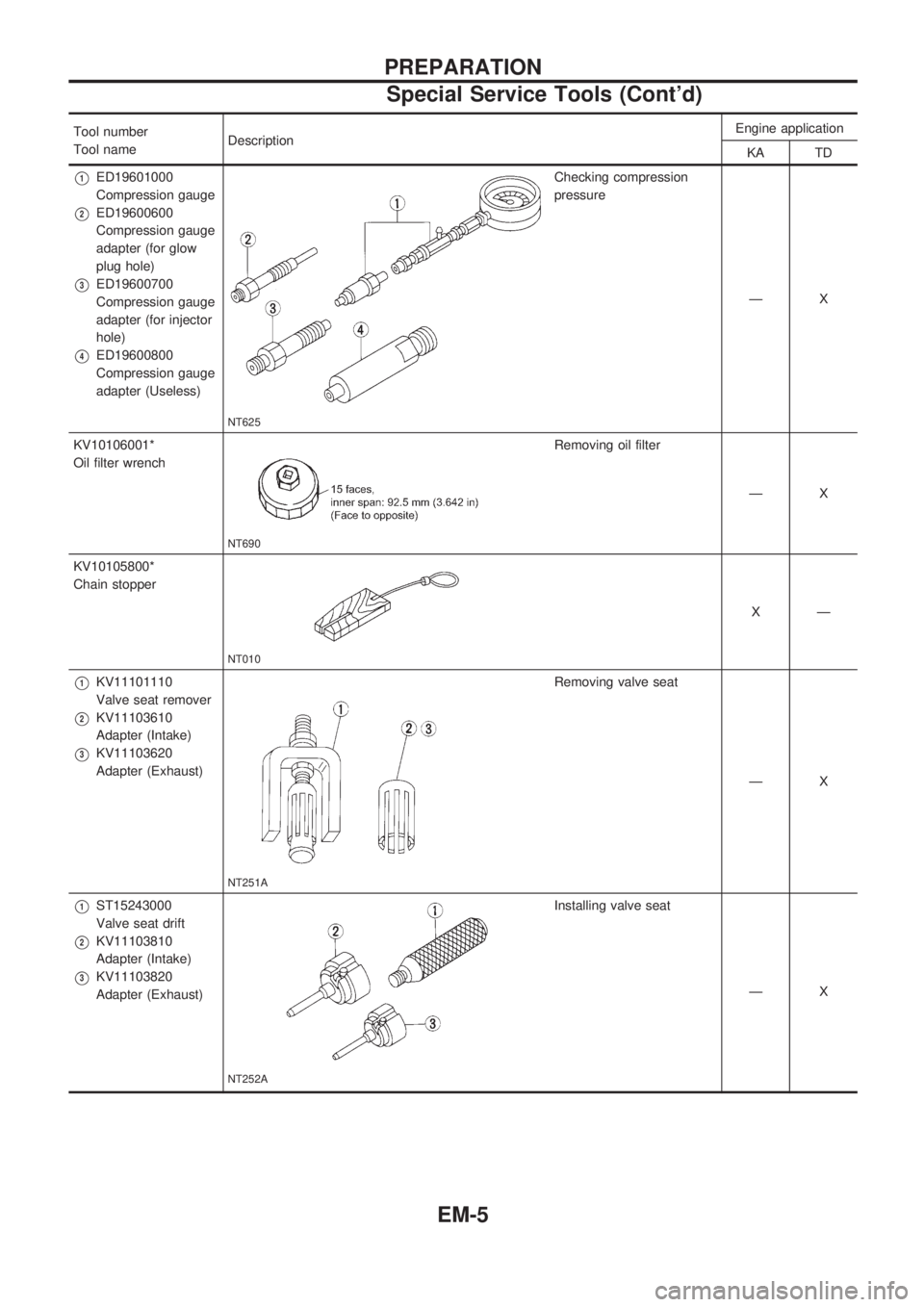

Tool number

Tool nameDescriptionEngine application

KA TD

V1ED19601000

Compression gauge

V2ED19600600

Compression gauge

adapter (for glow

plug hole)

V3ED19600700

Compression gauge

adapter (for injector

hole)

V4ED19600800

Compression gauge

adapter (Useless)

NT625

Checking compression

pressure

ÐX

KV10106001*

Oil filter wrench

NT690

Removing oil filter

ÐX

KV10105800*

Chain stopper

NT010

XÐ

V1KV11101110

Valve seat remover

V2KV11103610

Adapter (Intake)

V3KV11103620

Adapter (Exhaust)

NT251A

Removing valve seat

ÐX

V1ST15243000

Valve seat drift

V2KV11103810

Adapter (Intake)

V3KV11103820

Adapter (Exhaust)

NT252A

Installing valve seat

ÐX

PREPARATION

Special Service Tools (Cont'd)

EM-5

Page 736 of 1659

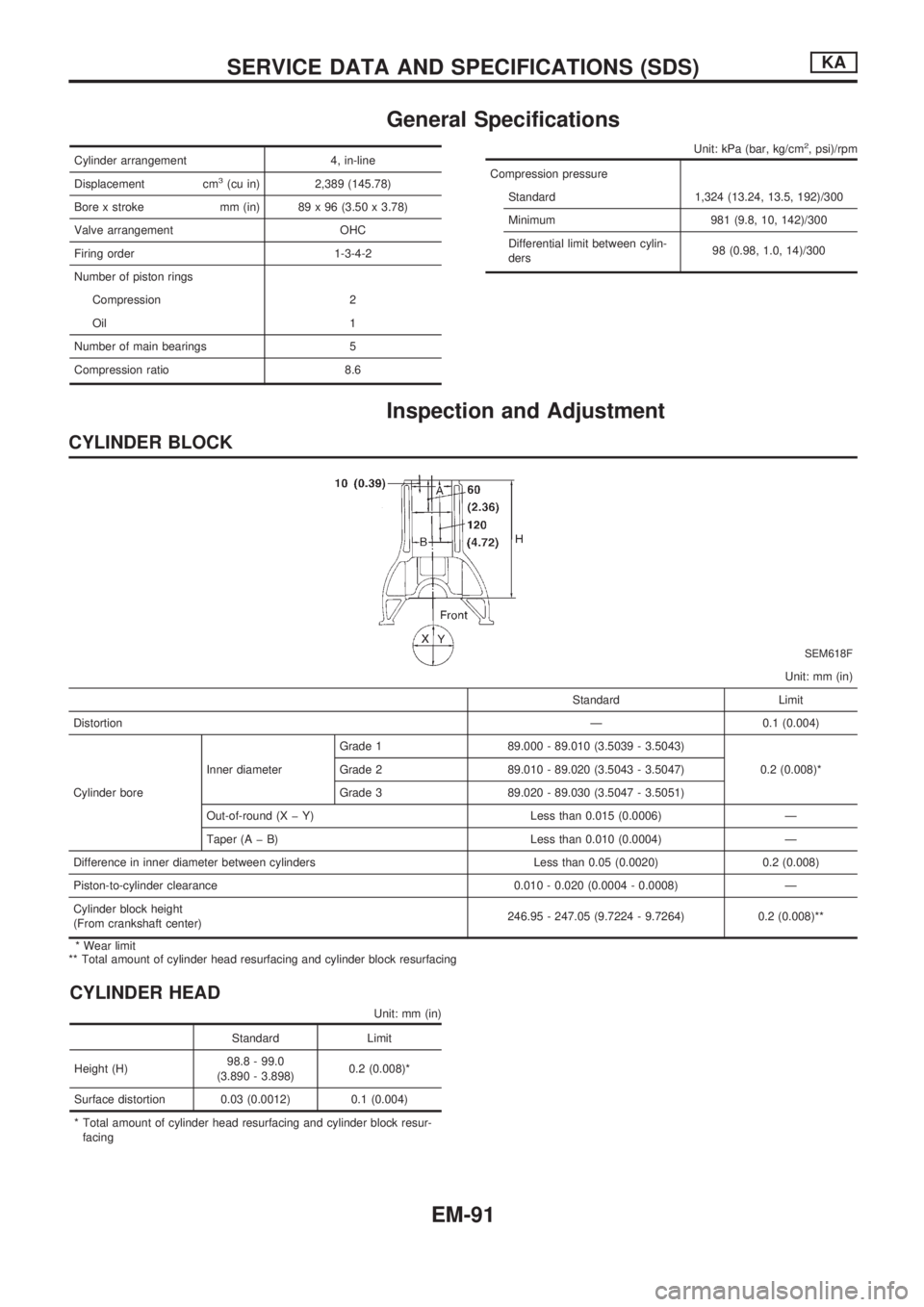

General Specifications

Cylinder arrangement 4, in-line

Displacement cm

3(cu in) 2,389 (145.78)

Bore x stroke mm (in) 89 x 96 (3.50 x 3.78)

Valve arrangement OHC

Firing order 1-3-4-2

Number of piston rings

Compression 2

Oil 1

Number of main bearings 5

Compression ratio 8.6

Unit: kPa (bar, kg/cm2, psi)/rpm

Compression pressure

Standard 1,324 (13.24, 13.5, 192)/300

Minimum 981 (9.8, 10, 142)/300

Differential limit between cylin-

ders98 (0.98, 1.0, 14)/300

Inspection and Adjustment

CYLINDER BLOCK

SEM618F

Unit: mm (in)

Standard Limit

DistortionÐ 0.1 (0.004)

Cylinder boreInner diameterGrade 1 89.000 - 89.010 (3.5039 - 3.5043)

0.2 (0.008)* Grade 2 89.010 - 89.020 (3.5043 - 3.5047)

Grade 3 89.020 - 89.030 (3.5047 - 3.5051)

Out-of-round (X þ Y) Less than 0.015 (0.0006) Ð

Taper (A þ B) Less than 0.010 (0.0004) Ð

Difference in inner diameter between cylinders Less than 0.05 (0.0020) 0.2 (0.008)

Piston-to-cylinder clearance 0.010 - 0.020 (0.0004 - 0.0008) Ð

Cylinder block height

(From crankshaft center)246.95 - 247.05 (9.7224 - 9.7264) 0.2 (0.008)**

* Wear limit

** Total amount of cylinder head resurfacing and cylinder block resurfacing

CYLINDER HEAD

Unit: mm (in)

Standard Limit

Height (H)98.8 - 99.0

(3.890 - 3.898)0.2 (0.008)*

Surface distortion 0.03 (0.0012) 0.1 (0.004)

* Total amount of cylinder head resurfacing and cylinder block resur-

facing

SERVICE DATA AND SPECIFICATIONS (SDS)KA

EM-91

Page 865 of 1659

Combination lamp, front, removal and

installation................................................... BT-5

Combination lamp, rear, removal and

installation................................................. BT-24

Combination meter removal and instal-

lation - See Instrument panel ................... BT-12

Combination switch ...................................... EL-42

Combustion chamber replacement ............. EM-59

Compression pressure (KA24 engine) ........ EM-10

Compression pressure (TD25 engine) ........ EM-51

Compressor clutch removal and

installation ................................................ HA-60

Compressor precaution ................................. HA-6

Compressor special service tool ................... HA-6

Connecting rod (KA24 engine).................... EM-40

Connecting rod (TD25 engine).................... EM-77

Connecting rod bearing clearance

(KA24 engine).......................................... EM-44

Connecting rod bearing clearance

(TD25 engine).......................................... EM-77

Connecting rod bushing clearance

(KA24 engine).......................................... EM-45

Connecting rod bushing clearance

(TD25 engine).......................................... EM-78

Connector inspection .................................... GI-18

Control lever (M/T) ...................................... MT-17

Control lever (Transfer) .................................. TF-7

Control units (terminal arrangement) ..........Foldout

Coolant mixture ratio ................................... MA-14

Coolant replacement (KA24 engine) ........... MA-16

Coolant replacement (TD25 engine) ........... MA-25

Cooling circuit (engine)

(KA24 engine) ............................................ LC-6

Cooling circuit (engine)

(TD25 engine) .......................................... LC-19

Cooling fan (KA24 engine)........................... LC-10

Cooling fan (TD25 engine) .................... LC-21, 26

Cooling fan control system .......................... LC-25

Counter gear (M/T) (FS5R30A)................... MT-36

Counter gear (M/T) (FS5W71C).................. MT-15

Counter gear (Transfer) ................................. TF-9

Coupling sleeve (M/T) (FS5R30A) .............. MT-36

Coupling sleeve (M/T) (FS5W71C) ............. MT-15

Crank angle sensor built into distribu-

tor - See Camshaft position sensor ......... EC-82

Crankcase emission control system -

See Positive crankcase ventilation .......... EC-21

Crankcase ventilation system - See

Positive crankcase ventilation.................. EC-21

Crankshaft (KA24 engine) ........................... EM-42

Crankshaft (TD25 engine) ........................... EM-79

Crankshaft position sensor (POS) ............... EC-82

Crankshaft position sensor (REF) ............... EC-82

Cylinder block (KA24 engine) ..................... EM-38

Cylinder block (TD25 engine) ..................... EM-74

Cylinder block boring................................... EM-41

Cylinder head (KA24 engine) ...................... EM-24

Cylinder head (TD25 engine) ...................... EM-53

Cylinder head bolt tightening ...................... EM-64

Cylinder head gasket selection ................... EM-63Cylinder liner ............................................... EM-74

D

D/LOCK - Wiring diagram ...........................EL-167

DEF - Wiring diagram ................................ EL-135

DTRL - Wiring diagram ................................ EL-54

Data link connector for Consult ................... EC-45

Daytime light system .................................... EL-51

Defroster door control rod adjustment......... HA-45

Diagnosis sensor unit .................................. RS-10

Diagnostic trouble code (DTC) for

ECCS OBD system.................................. EC-36

Differential carrier assembly (C200) ............ PD-51

Differential carrier assembly (H233B) ......... PD-72

Differential carrier assembly (R180A) ......... PD-27

Differential carrier disassembly

(C200) ...................................................... PD-34

Differential carrier disassembly

(H233B) .................................................... PD-57

Differential gear oil replacement ................. MA-34

Dim-dip lamp system.................................... EL-58

Dimensions ................................................... GI-44

Distributor ignition (DI) system .................... EC-17

Dome light - See Interior lamp ..................... EL-85

Door glass .................................................... BT-10

Door lock ...................................................... BT-10

Door mirror ................................................... BT-39

Door trim ...................................................... BT-18

Door, front .................................................... BT-10

Door, rear ..................................................... BT-11

Drive belt inspection (KA24 engine) ........... MA-15

Drive belt inspection (TD25 engine) ........... MA-23

Drive chain (Transfer) .................................... TF-9

Drive pinion diff. inspection (C200) ............. PD-38

Drive pinion diff. inspection (H233B) ........... PD-60

Drive pinion height (C200)........................... PD-47

Drive pinion height (H233B) ........................ PD-67

Drive pinion height (R180A) ........................ PD-24

Drive shaft (front) ......................................... FA-21

E

ECCS basic inspection .................................EC-58

ECCS circuit diagram .................................... EC-8

ECCS component parts location ................. EC-10

ECCS fail-safe chart .................................... EC-61

ECCS on board diagnostic system ............. EC-36

ECCS relay .................................................. EC-75

ECCS symptom matrix chart ....................... EC-62

ECCS system diagram .................................. EC-9

ECTS - Wiring diagram ............................... EC-96

EGR control (EGRC) - solenoid valve....... EC-218

EGR control valve...................................... EC-218

EGRC - Wiring diagram............................. EC-213

EVAP canister.............................................. EC-19

EVAP canister purge control solenoid

valve ....................................................... EC-140

ALPHABETICAL INDEX

IDX-3

Page 1552 of 1659

ENGINE MECHANICAL

SECTION

EM

CONTENTS

PRECAUTIONS......................................................... 1

Parts Requiring Angular Tightening....................... 1

Liquid Gasket Application Procedure .................... 1

PREPARATION......................................................... 2

Special Service Tools ............................................ 2

Commercial Service Tools ..................................... 7

KA

OUTER COMPONENT PARTS................................. 9

COMPRESSION PRESSURE.................................. 10

Measurement of Compression Pressure ............. 10

OIL PAN................................................................... 11

Removal ............................................................... 11

Installation ............................................................ 12

TIMING CHAIN........................................................ 13

Removal ............................................................... 13

Inspection ............................................................. 17

Installation ............................................................ 17

OIL SEAL REPLACEMENT.................................... 22

Valve Oil Seal ...................................................... 22

Front Oil Seal ....................................................... 22

Rear Oil Seal ....................................................... 23

CYLINDER HEAD.................................................... 24

Removal ............................................................... 25

Disassembly ......................................................... 27

Inspection ............................................................. 27

Assembly.............................................................. 33

Installation ............................................................ 34

ENGINE REMOVAL................................................. 36

Removal ............................................................... 37

Installation ............................................................ 37

CYLINDER BLOCK................................................. 38Disassembly ......................................................... 39

Inspection ............................................................. 39

Assembly.............................................................. 45

TD

OUTER COMPONENT PARTS............................... 49

COMPRESSION PRESSURE.................................. 51

Measurement of Compression Pressure ............. 51

OIL PAN................................................................... 52

Removal ............................................................... 52

Installation ............................................................ 52

CYLINDER HEAD.................................................... 53

Removal ............................................................... 54

Disassembly ......................................................... 55

Inspection ............................................................. 56

Assembly.............................................................. 62

Installation ............................................................ 63

OIL SEAL REPLACEMENT.................................... 67

ENGINE REMOVAL................................................. 69

Removal ............................................................... 70

Installation ............................................................ 70

ENGINE OVERHAUL.............................................. 71

Disassembly ......................................................... 72

Inspection and Replacement ............................... 74

Assembly.............................................................. 86

KA

SERVICE DATA AND SPECIFICATIONS (SDS)... 91

General Specifications ......................................... 91

Inspection and Adjustment .................................. 91

EM

Page 1557 of 1659

Tool number

Tool nameDescriptionEngine application

KA TD

WS39930000*

Tube presser

NT052

Pressing the tube of liquid

gasket

XX

KV10107902*

Valve oil seal puller

V1KV10116100

Valve oil seal puller

adapter

NT605

Disassembling valve oil

seal

ÐX

KV10110300

Piston pin press stand

assembly

V1KV10110310

Cap

V2KV10110330

Spacer

V3ST13030020

Press stand

V4ST13030030

Spring

V5KV10110340

Drift

V6KV10110320

Center shaft

NT036

Disassembling and assem-

bling piston with connect-

ing rod

XÐ

KV10112100

Angle wrench

NT014

Tightening bolts for bearing

cap, cylinder head, etc.

XX

EG15060000

Compression gauge

and adapter

NT238

XÐ

PREPARATION

Special Service Tools (Cont'd)

EM-4