run flat NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 725 of 1659

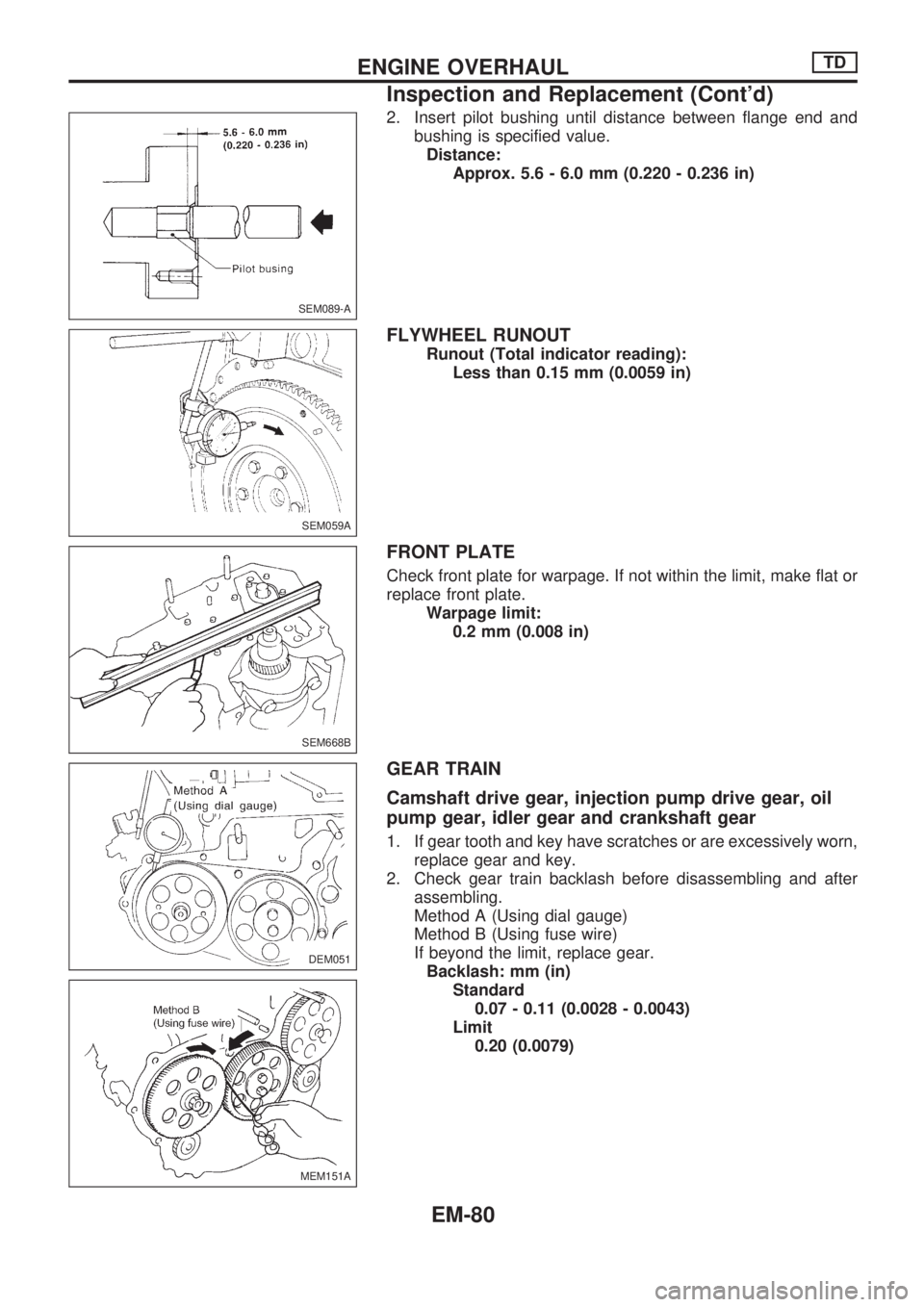

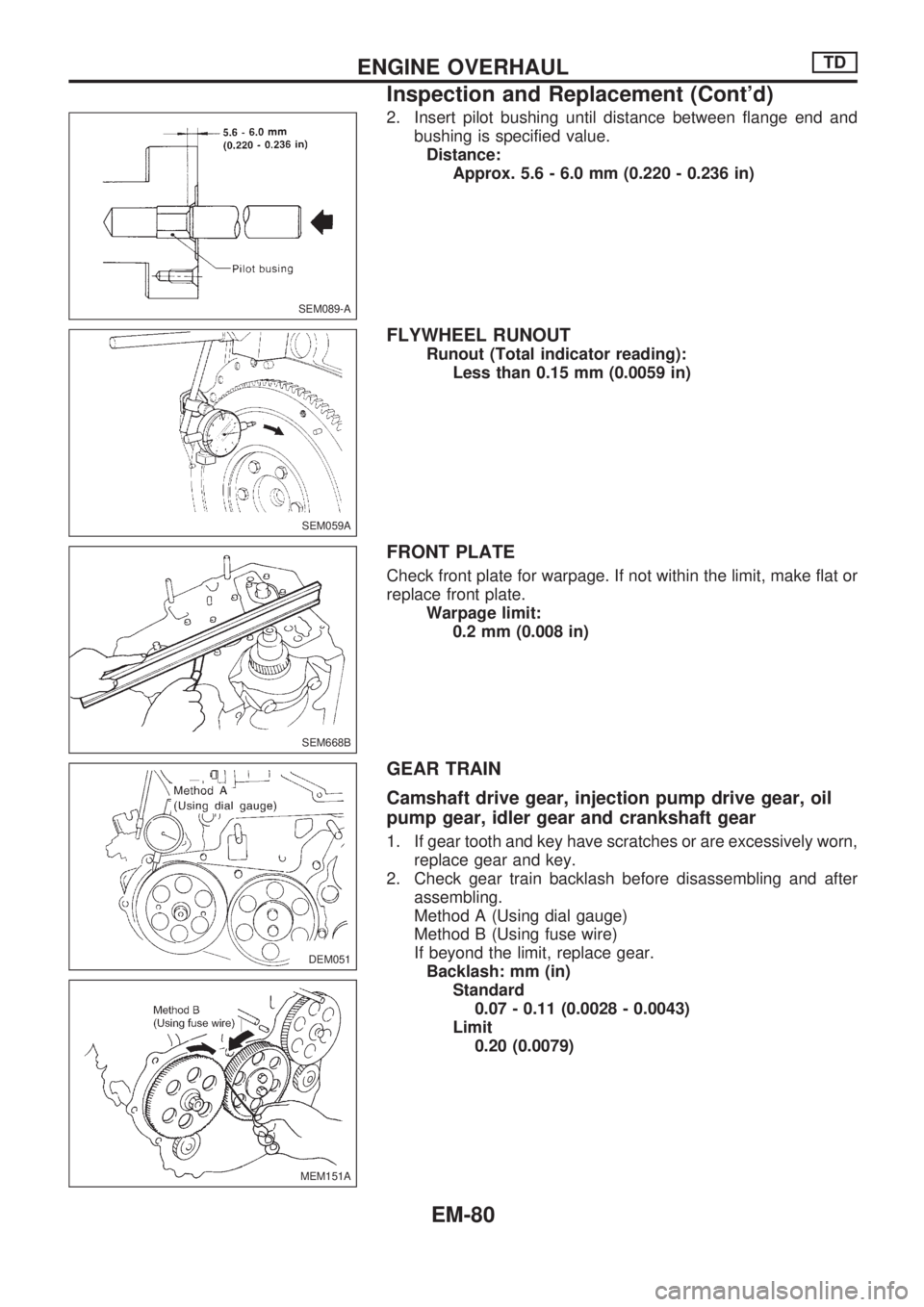

2. Insert pilot bushing until distance between flange end and

bushing is specified value.

Distance:

Approx. 5.6 - 6.0 mm (0.220 - 0.236 in)

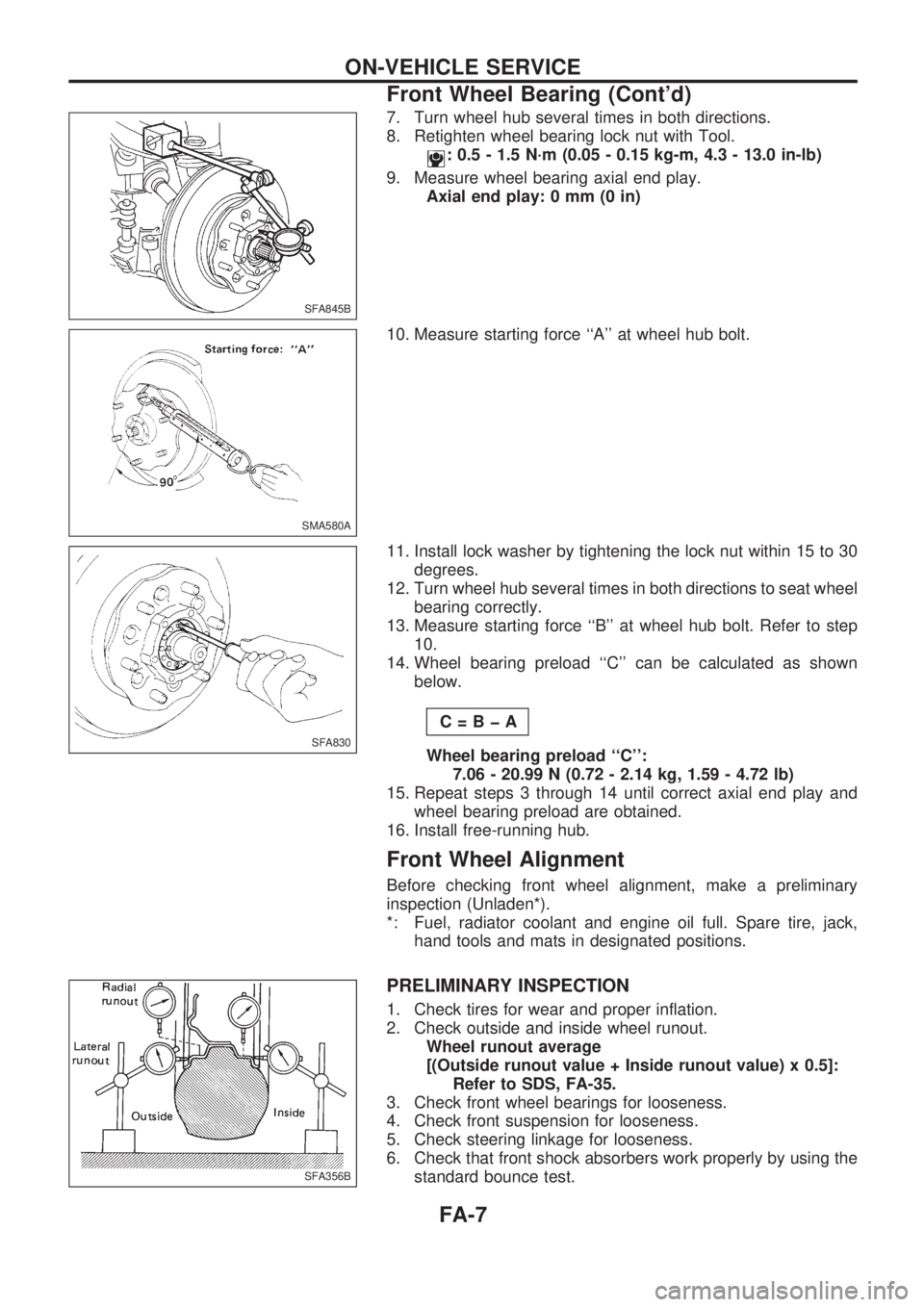

FLYWHEEL RUNOUT

Runout (Total indicator reading):

Less than 0.15 mm (0.0059 in)

FRONT PLATE

Check front plate for warpage. If not within the limit, make flat or

replace front plate.

Warpage limit:

0.2 mm (0.008 in)

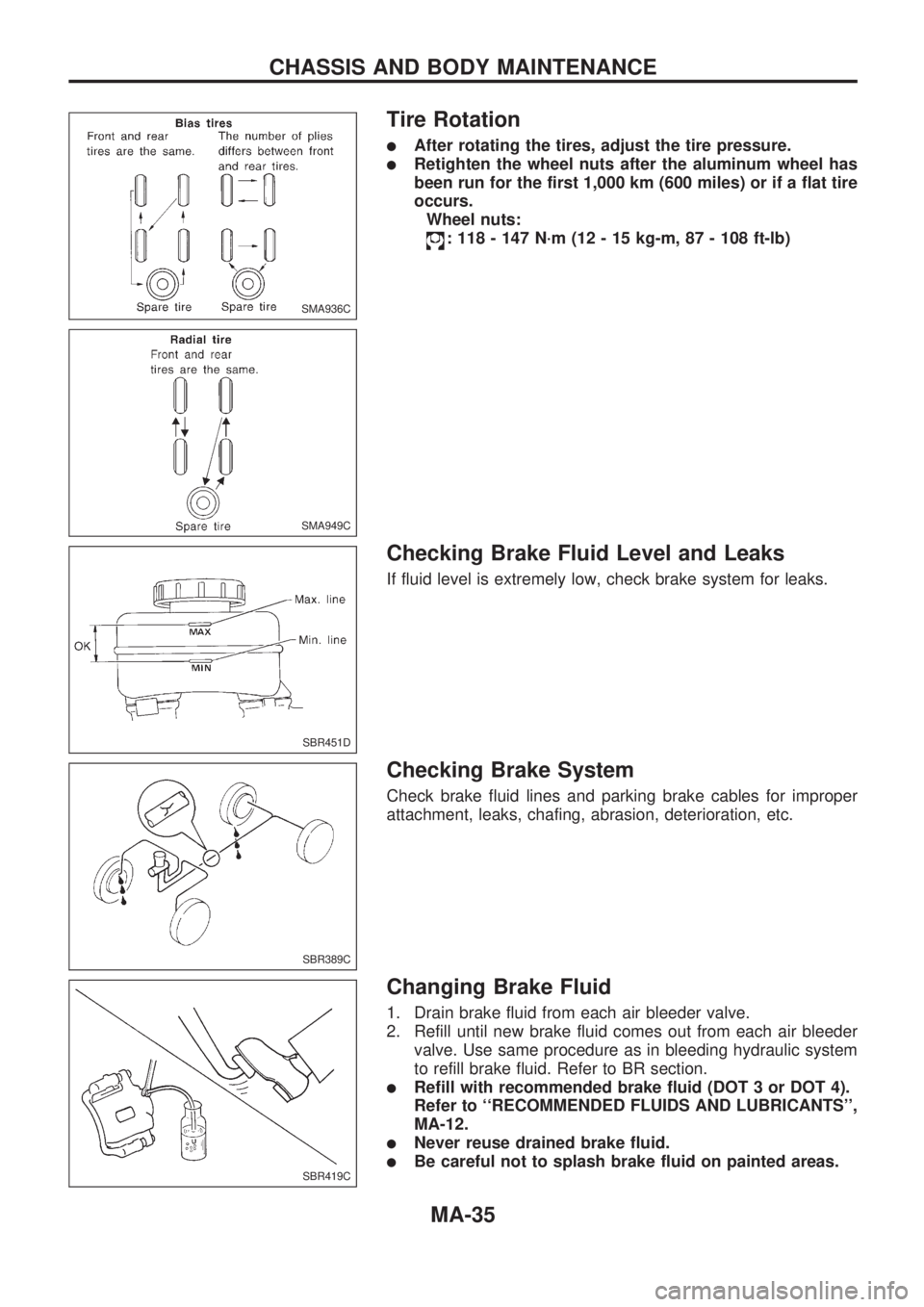

GEAR TRAIN

Camshaft drive gear, injection pump drive gear, oil

pump gear, idler gear and crankshaft gear

1. If gear tooth and key have scratches or are excessively worn,

replace gear and key.

2. Check gear train backlash before disassembling and after

assembling.

Method A (Using dial gauge)

Method B (Using fuse wire)

If beyond the limit, replace gear.

Backlash: mm (in)

Standard

0.07 - 0.11 (0.0028 - 0.0043)

Limit

0.20 (0.0079)

SEM089-A

SEM059A

SEM668B

DEM051

MEM151A

ENGINE OVERHAULTD

Inspection and Replacement (Cont'd)

EM-80

Page 772 of 1659

7. Turn wheel hub several times in both directions.

8. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N´m (0.05 - 0.15 kg-m, 4.3 - 13.0 in-lb)

9. Measure wheel bearing axial end play.

Axial end play: 0 mm (0 in)

10. Measure starting force ``A'' at wheel hub bolt.

11. Install lock washer by tightening the lock nut within 15 to 30

degrees.

12. Turn wheel hub several times in both directions to seat wheel

bearing correctly.

13. Measure starting force ``B'' at wheel hub bolt. Refer to step

10.

14. Wheel bearing preload ``C'' can be calculated as shown

below.

C=BþA

Wheel bearing preload ``C'':

7.06 - 20.99 N (0.72 - 2.14 kg, 1.59 - 4.72 lb)

15. Repeat steps 3 through 14 until correct axial end play and

wheel bearing preload are obtained.

16. Install free-running hub.

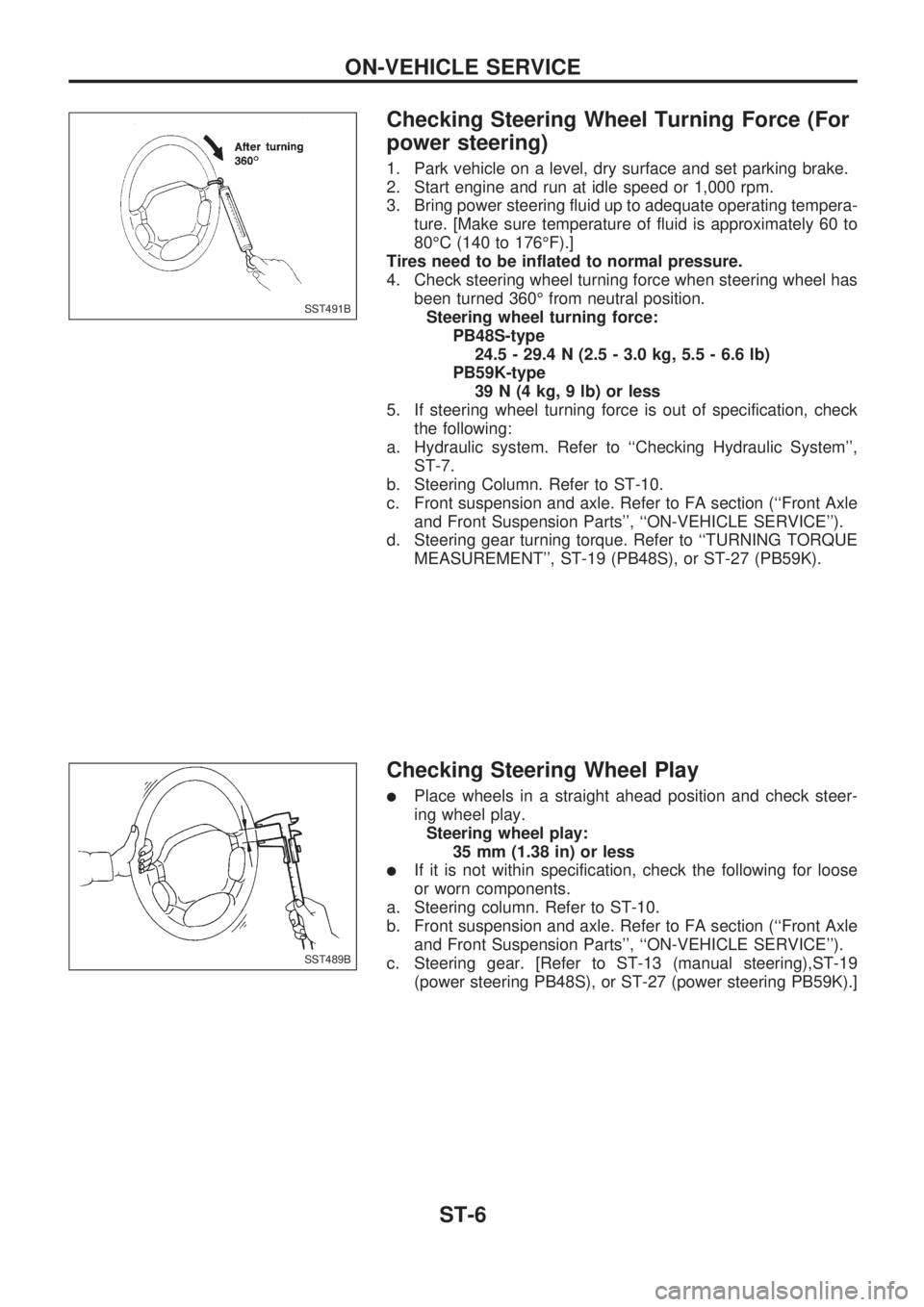

Front Wheel Alignment

Before checking front wheel alignment, make a preliminary

inspection (Unladen*).

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

PRELIMINARY INSPECTION

1. Check tires for wear and proper inflation.

2. Check outside and inside wheel runout.

Wheel runout average

[(Outside runout value + Inside runout value) x 0.5]:

Refer to SDS, FA-35.

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

5. Check steering linkage for looseness.

6. Check that front shock absorbers work properly by using the

standard bounce test.

SFA845B

SMA580A

SFA830

SFA356B

ON-VEHICLE SERVICE

Front Wheel Bearing (Cont'd)

FA-7

Page 1008 of 1659

Tire Rotation

lAfter rotating the tires, adjust the tire pressure.

lRetighten the wheel nuts after the aluminum wheel has

been run for the first 1,000 km (600 miles) or if a flat tire

occurs.

Wheel nuts:

: 118 - 147 N´m (12 - 15 kg-m, 87 - 108 ft-lb)

Checking Brake Fluid Level and Leaks

If fluid level is extremely low, check brake system for leaks.

Checking Brake System

Check brake fluid lines and parking brake cables for improper

attachment, leaks, chafing, abrasion, deterioration, etc.

Changing Brake Fluid

1. Drain brake fluid from each air bleeder valve.

2. Refill until new brake fluid comes out from each air bleeder

valve. Use same procedure as in bleeding hydraulic system

to refill brake fluid. Refer to BR section.

lRefill with recommended brake fluid (DOT 3 or DOT 4).

Refer to ``RECOMMENDED FLUIDS AND LUBRICANTS'',

MA-12.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.

SMA936C

SMA949C

SBR451D

SBR389C

SBR419C

CHASSIS AND BODY MAINTENANCE

MA-35

Page 1228 of 1659

Checking Steering Wheel Turning Force (For

power steering)

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine and run at idle speed or 1,000 rpm.

3. Bring power steering fluid up to adequate operating tempera-

ture. [Make sure temperature of fluid is approximately 60 to

80ÉC (140 to 176ÉF).]

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has

been turned 360É from neutral position.

Steering wheel turning force:

PB48S-type

24.5 - 29.4 N (2.5 - 3.0 kg, 5.5 - 6.6 lb)

PB59K-type

39 N (4 kg, 9 lb) or less

5. If steering wheel turning force is out of specification, check

the following:

a. Hydraulic system. Refer to ``Checking Hydraulic System'',

ST-7.

b. Steering Column. Refer to ST-10.

c. Front suspension and axle. Refer to FA section (``Front Axle

and Front Suspension Parts'', ``ON-VEHICLE SERVICE'').

d. Steering gear turning torque. Refer to ``TURNING TORQUE

MEASUREMENT'', ST-19 (PB48S), or ST-27 (PB59K).

Checking Steering Wheel Play

lPlace wheels in a straight ahead position and check steer-

ing wheel play.

Steering wheel play:

35 mm (1.38 in) or less

lIf it is not within specification, check the following for loose

or worn components.

a. Steering column. Refer to ST-10.

b. Front suspension and axle. Refer to FA section (``Front Axle

and Front Suspension Parts'', ``ON-VEHICLE SERVICE'').

c. Steering gear. [Refer to ST-13 (manual steering),ST-19

(power steering PB48S), or ST-27 (power steering PB59K).]

SST491B

SST489B

ON-VEHICLE SERVICE

ST-6

Page 1633 of 1659

2. Insert pilot bushing until distance between flange end and

bushing is specified value.

Distance:

Approx. 5.6 - 6.0 mm (0.220 - 0.236 in)

FLYWHEEL RUNOUT

Runout (Total indicator reading):

Less than 0.15 mm (0.0059 in)

FRONT PLATE

Check front plate for warpage. If not within the limit, make flat or

replace front plate.

Warpage limit:

0.2 mm (0.008 in)

GEAR TRAIN

Camshaft drive gear, injection pump drive gear, oil

pump gear, idler gear and crankshaft gear

1. If gear tooth and key have scratches or are excessively worn,

replace gear and key.

2. Check gear train backlash before disassembling and after

assembling.

Method A (Using dial gauge)

Method B (Using fuse wire)

If beyond the limit, replace gear.

Backlash: mm (in)

Standard

0.07 - 0.11 (0.0028 - 0.0043)

Limit

0.20 (0.0079)

SEM089-A

SEM059A

SEM668B

DEM051

MEM151A

ENGINE OVERHAULTD

Inspection and Replacement (Cont'd)

EM-80