fuel NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 1 of 1659

GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMSFE

CLUTCHCL

MANUAL TRANSAXLEMT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

PICKUP

MODEL D22 SERIES

Edition: February 1998

Printing: May 1998 (01)

Publication No.: SM8E-0D22E0E

NISSAN EUROPE S.A.S.

1998 NISSAN EUROPE S.A.S. Printed in the Netherlands

Not to be reproduced in whole or in part without the prior written permission of Nissan Europe S.A.S., Paris, France.

QUICK REFERENCE INDEX

Page 13 of 1659

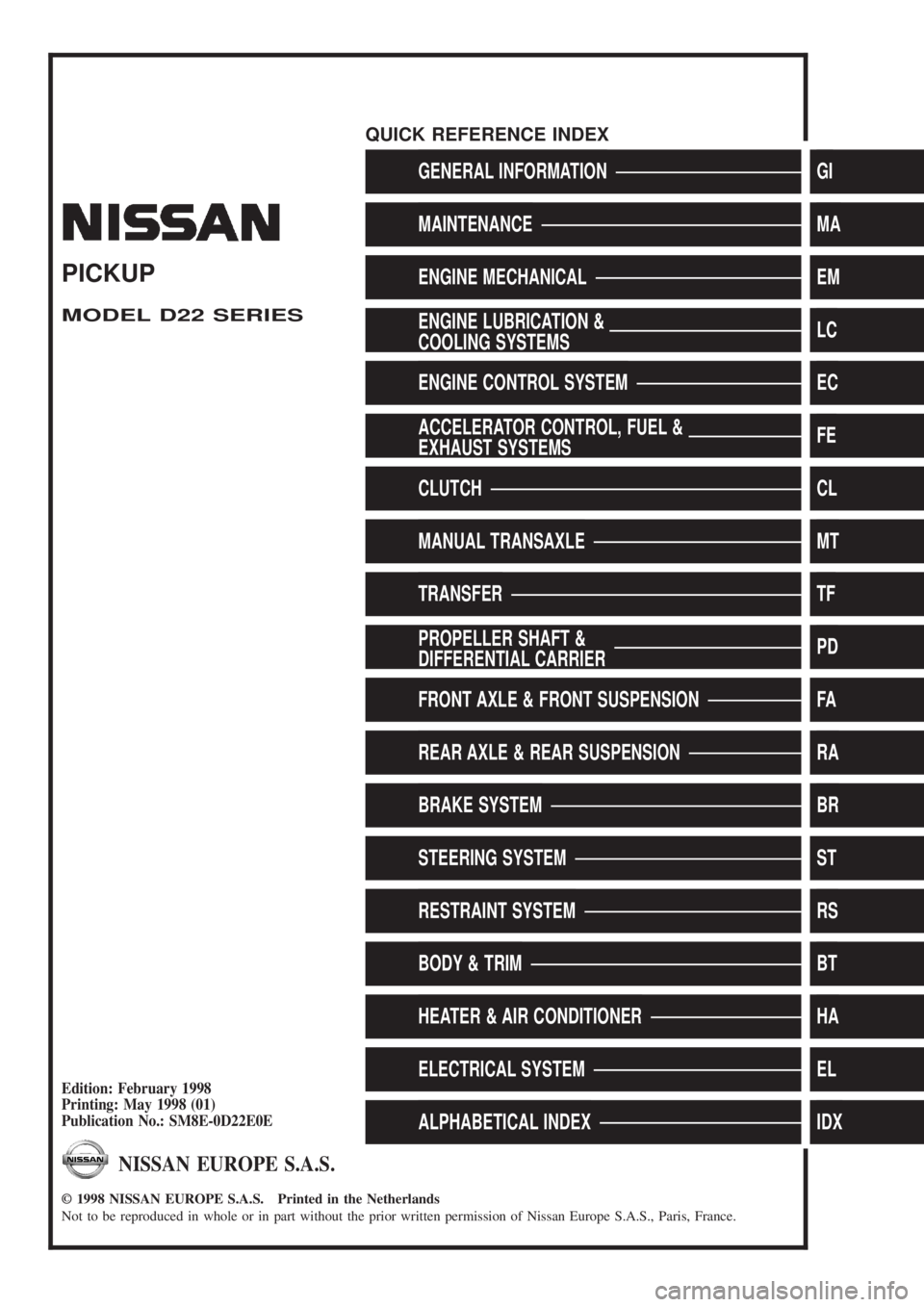

INSPECTION

1. Ensure vehicle is unladen condition*.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

2. Have a driver sit in the driver's seat and one person sit on

the rear of the vehicle. Then have the person on the rear of

the vehicle slowly get off. This is necessary to stabilize sus-

pension deflection.

3. Adjust length ``L'' as follows:

a. Loosen stopper bolt locknut (2WD JIDOSHA KIKI make).

b. Pull lever against stopper bolt and adjust by turning stopper

bolt.

c. Tighten stopper bolt locknut (2WD JIDOSHA KIKI make).

Length ``L'':

2WD models

Approx. 187.3 mm (7.37 in)

4WD models

Approx. 158.1 mm (6.22 in)

4. Install pressure gauge to front and rear brake air bleeder.

5. Bleed air from the Tool.

6. Raise front brake pressure to 4,904 kPa (49.0 bar, 50

kg/cm

2, 711 psi) and 9,807 kPa (98.1 bar, 100 kg/cm2, 1,422

psi) and check rear brake pressure.

Rear brake pressure:

Refer to table below.

7. Set down weight slowly over axle center so that sensor

spring length becomes the same as when in loaded condi-

tion (refer to table below). Check rear brake pressure in the

same way described in step 6.

Unit: kPa (bar, kg/cm2, psi)

Front brake

pressureRear brake pressure

2WD 4WD

Unladen

condition

L = 187.3 mm

(7.37 in)Loaded

condition

L = 204.0 mm

(8.03 in)Unladen

condition

L = 158.1 mm

(6.22 in)Loaded

condition

L = 184.0 mm

(7.24 in)

4,904

(49.0, 50, 711)1,667 - 2,648

(16.7 - 26.5, 17

- 27, 242 - 384)3,334 - 4,315

(33.3 - 43.2, 34

- 44, 483 - 626)1,863 - 2,844

(18.6 - 28.4, 19

- 29, 270 - 412)3,334 - 4,315

(33.3 - 43.2, 34

- 44, 483 - 626)

9,807

(98.1, 100,

1,422)2,844 - 3,825

(28.4 - 38.2, 29

- 39, 412 - 555)3,629 - 5,590

(36.3 - 55.9, 37

- 57, 526 - 811)2,059 - 4,021

(20.6 - 40.2, 21

- 41, 299 - 583)3,629 - 5,590

(36.3 - 55.9, 37

- 57, 526 - 811)

SBR967D

SBR968D

SBR013B

SBR014B

CONTROL VALVE

Load Sensing Valve (Cont'd)

BR-9

Page 140 of 1659

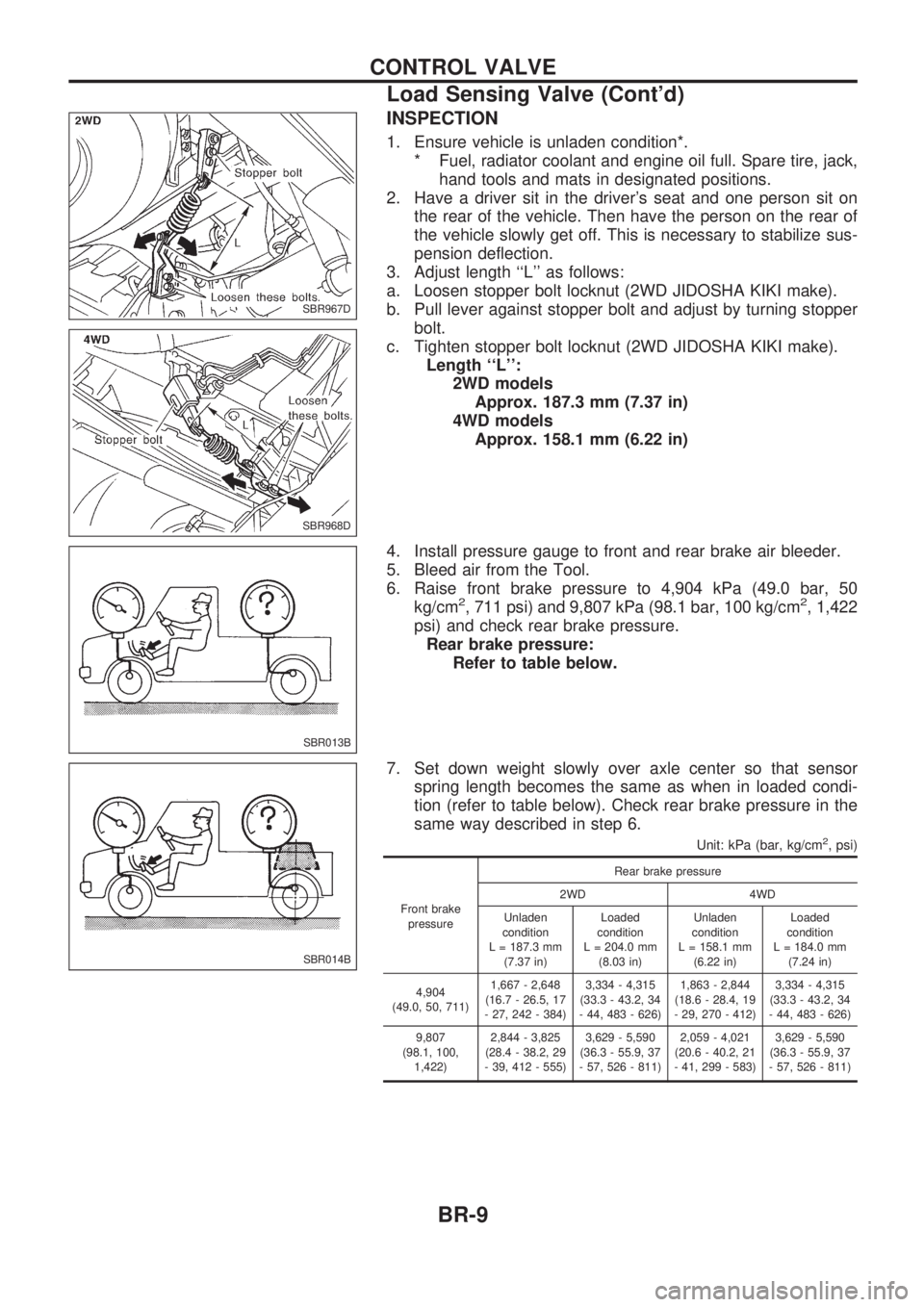

Removal

CAB BODY

lRemove the following parts in engine compartment at least.

(1) Main harness and other wiring harnesses

lDisconnect brake and clutch line in engine compartment.

lRemove the following parts from underbody at least.

(1) Transmission and transfer control levers

(2) Parking brake control lever and cables

(3) Main harness and other wiring harnesses

REAR BODY

lRemove the following parts at least.

(1) Rear combination lamp and license plate lamp harness

(2) Fuel filler tube fixing screws

SBF348C

ABT189

CAB AND REAR BODY

BT-40

Page 150 of 1659

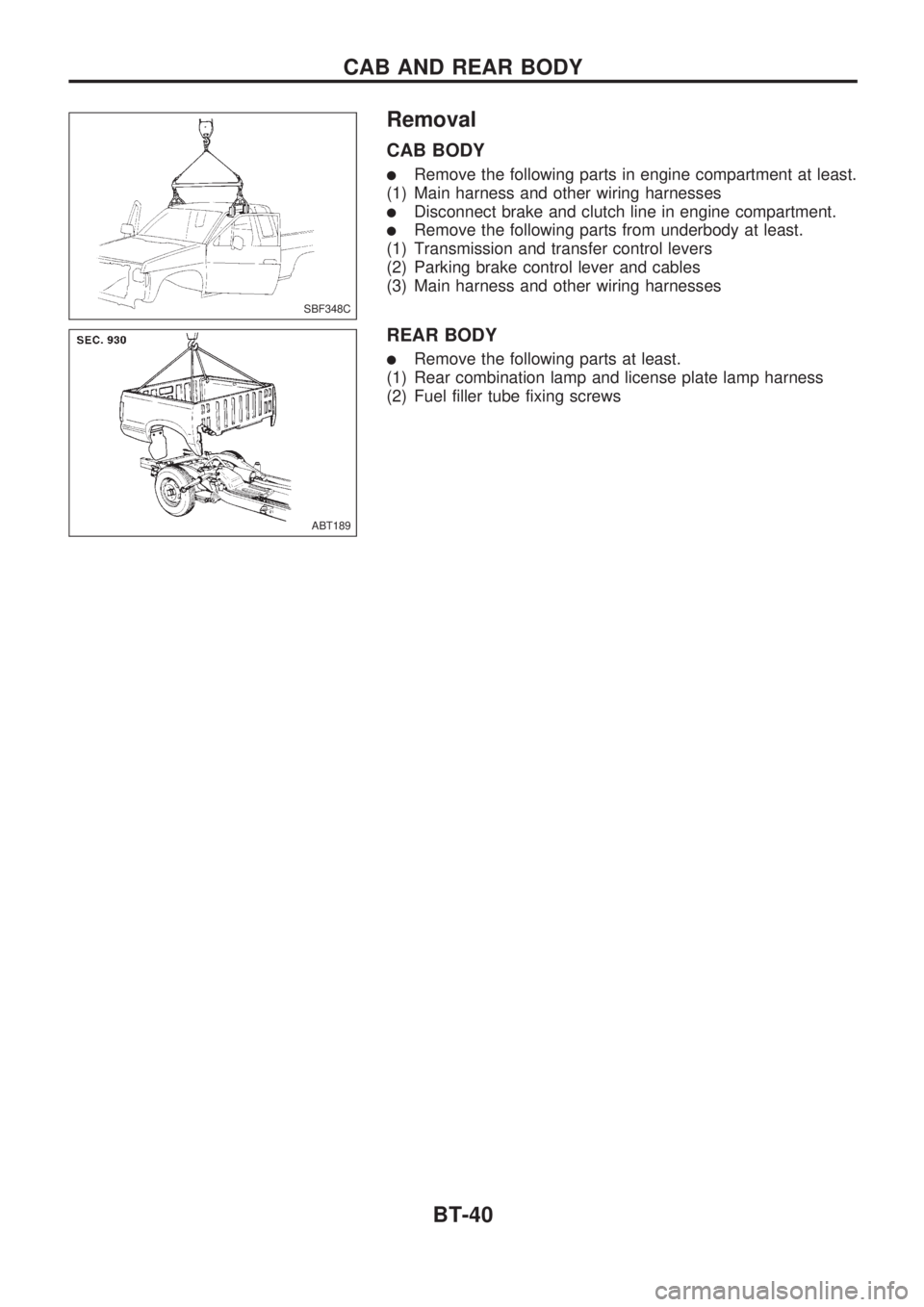

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

DIAGNOSTIC TROUBLE CODE INDEX................... 1

Alphabetical & Numerical Index for DTC

(KA engine) ............................................................ 1

PRECAUTIONS AND PREPARATION..................... 2

Special Service Tools ............................................ 2

Commercial Service Tool....................................... 4

Supplemental Restraint System (SRS) ``AIR

BAG'' (4WD models).............................................. 4

Supplemental Restraint System (SRS) ``AIR

BAG'' (2WD models).............................................. 4

KA

PRECAUTIONS AND PREPARATION..................... 5

Engine Fuel & Emission Control System .............. 5

Precautions ............................................................ 6

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM..................................................................... 8

Circuit Diagram ...................................................... 8

System Diagram .................................................... 9

ECCS Component Parts Location ....................... 10

Vacuum Hose Drawing ........................................ 12

System Chart ....................................................... 13

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION..................................... 14

Multiport Fuel Injection (MFI) System.................. 14

Distributor Ignition (DI) System............................ 17

Air Conditioning Cut Control ................................ 18

Fuel Cut Control (at no load & high engine

speed) .................................................................. 18

EVAPORATIVE EMISSION SYSTEM..................... 19

Description ........................................................... 19

Inspection ............................................................. 19POSITIVE CRANKCASE VENTILATION................ 21

Description ........................................................... 21

Inspection ............................................................. 21

BASIC SERVICE PROCEDURE............................. 22

Fuel Pressure Release ........................................ 22

Fuel Pressure Check ........................................... 22

Injector Removal and Installation ........................ 23

Fast Idle Cam (FIC) Inspection and

Adjustment ........................................................... 24

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment ........................................................... 25

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION......................................................... 36

Introduction .......................................................... 36

Diagnostic Trouble Code (DTC) .......................... 36

Malfunction Indicator Lamp (MIL) ........................ 38

CONSULT ............................................................ 45

TROUBLE DIAGNOSIS - Introduction.................. 54

Introduction .......................................................... 54

Diagnostic Worksheet .......................................... 54

TROUBLE DIAGNOSIS - Work Flow..................... 56

Work Flow ............................................................ 56

Description for Work Flow ................................... 57

TROUBLE DIAGNOSIS - Basic Inspection.......... 58

Basic Inspection ................................................... 58

TROUBLE DIAGNOSIS - General Description..... 61

Fail-Safe Chart ..................................................... 61

Symptom Matrix Chart ......................................... 62

CONSULT Reference Value in Data Monitor

Mode .................................................................... 64

Major Sensor Reference Graph in Data

Monitor Mode ....................................................... 66

ECM Terminals and Reference Value ................. 68

EC

Page 151 of 1659

TROUBLE DIAGNOSIS FOR POWER SUPPLY.... 75

Main Power Supply and Ground Circuit .............. 75

TROUBLE DIAGNOSIS FOR ``CAMSHAFT

POSI SEN'' (DTC 11).............................................. 82

Camshaft Position Sensor (CMPS) ..................... 82

TROUBLE DIAGNOSIS FOR ``MASS AIR

FLOW SEN'' (DTC 12)............................................ 89

Mass Air Flow Sensor (MAFS) ............................ 89

TROUBLE DIAGNOSIS FOR ``COOLANT TEMP

SEN'' (DTC 13)........................................................ 95

Engine Coolant Temperature Sensor (ECTS) ..... 95

TROUBLE DIAGNOSIS FOR ``IGN SIGNAL-

PRIMARY'' (DTC 21)............................................... 99

Ignition Signal ...................................................... 99

TROUBLE DIAGNOSIS FOR ``OVER HEAT''

(DTC 28)................................................................. 106

Overheat ............................................................ 106

TROUBLE DIAGNOSIS FOR ``INT AIR TEMP

SEN'' (DTC 41)...................................................... 109

Intake Air Temperature Sensor ......................... 109

TROUBLE DIAGNOSIS FOR ``THROTTLE POSI

SEN'' (DTC 43)...................................................... 113

Throttle Position Sensor .................................... 113

TROUBLE DIAGNOSIS FOR

NON-DETECTABLE ITEMS.................................. 118

Vehicle Speed Sensor (VSS) ............................ 118

Heated Oxygen Sensor (HO2S)

- LHD Models - .................................................. 123

Heated Oxygen Sensor Heater

- LHD Models - .................................................. 127

Idle Air Control Valve (IACV) - Auxiliary Air

Control (AAC) Valve .......................................... 131

Neutral Position Switch ...................................... 136

EVAP Canister Purge Control Solenoid Valve .. 140

Injector ............................................................... 144

Start Signal ........................................................ 149

Fuel Pump.......................................................... 151

Power Steering Oil Pressure Switch ................. 157

Swirl Control Valve Control Solenoid Valve ...... 161

IACV-FICD Solenoid Valve ................................ 168

MIL & Data Link Connectors ............................. 173

TD

INJECTION SYSTEM............................................ 176

Fuel System ....................................................... 176

INJECTION PUMP................................................. 178

Inspection ........................................................... 178

Removal ............................................................. 178

Installation and Adjustment................................ 180

Disassembly ....................................................... 183

Load Timer Adjustment...................................... 183

Start Q Adjustment Lever .................................. 184

INJECTION NOZZLE............................................. 186Removal and Installation ................................... 186

Disassembly ....................................................... 186

Inspection ........................................................... 187

Cleaning ............................................................. 187

Assembly............................................................ 189

Test and Adjustment .......................................... 189

FUEL SYSTEM CHECK........................................ 191

Bleeding Fuel System ........................................ 191

Bleeding Fuel Filter ............................................ 192

Checking Priming Pump .................................... 192

Checking Fuel Filter Switch ............................... 192

POSITIVE CRANKCASE VENTILATION.............. 193

Description ......................................................... 193

Inspection ........................................................... 193

QUICK-GLOW SYSTEM........................................ 194

Component Parts Location ................................ 194

Circuit Diagram .................................................. 195

Description ......................................................... 196

Wiring Diagram .................................................. 197

Glow Control Unit Circuit Inspection (For Cold

Areas)................................................................. 203

Glow Control Unit Circuit Inspection (Except

for Cold Areas)................................................... 206

Component Inspection ....................................... 208

EGR SYSTEM........................................................ 210

Component Parts Location ................................ 210

Description ......................................................... 211

Operation ........................................................... 212

Wiring Diagram .................................................. 213

System Inspection.............................................. 217

Component Inspection ....................................... 218

SOLENOID TIMER................................................ 220

Description ......................................................... 220

Operation ........................................................... 220

Wiring Diagram .................................................. 222

Inspection ........................................................... 224

FUEL CUT SYSTEM.............................................. 225

Wiring Diagram .................................................. 225

FUEL HEATER SYSTEM...................................... 226

Description ......................................................... 226

Wiring Diagram .................................................. 227

System Inspection.............................................. 228

Component Inspection ....................................... 228

FAST IDLE CONTROL CIRCUIT.......................... 230

Wiring Diagram .................................................. 230

Electrical Components Inspection ..................... 231

KA

SERVICE DATA AND SPECIFICATIONS (SDS). 232

General Specifications ....................................... 232

Inspection and Adjustment ................................ 232

Page 156 of 1659

Commercial Service Tool

FOR KA ENGINE MODELS

Tool name Description

Fuel filler cap adapter

NT653

Checking fuel tank vacuum relief valve opening

pressure

Supplemental Restraint System (SRS) ``AIR

BAG'' (4WD models)

The Supplemental Restraint System ``AIR BAG'', used along with a seat belt, helps to reduce the risk or

severity of injury to the driver in a frontal collision. The Supplemental Restraint System consists of an air

bag module (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp, wiring har-

ness and spiral cable. Information necessary to service the system safely is included in theRS sectionof

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses are covered with yellow insulation either just before the

harness connectors or for the complete harness, for easy identification.

Supplemental Restraint System (SRS) ``AIR

BAG'' (2WD models)

The Supplemental Restraint System ``AIR BAG'', used along with a seat belt, helps to reduce the risk or

severity of injury to the driver in a frontal collision. The Supplemental Restraint System consists of an air

bag module (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp, wiring har-

ness and spiral cable. Information necessary to service the system safely is included in theRS sectionof

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit related to the SRS.

PRECAUTIONS AND PREPARATION

EC-4

Page 157 of 1659

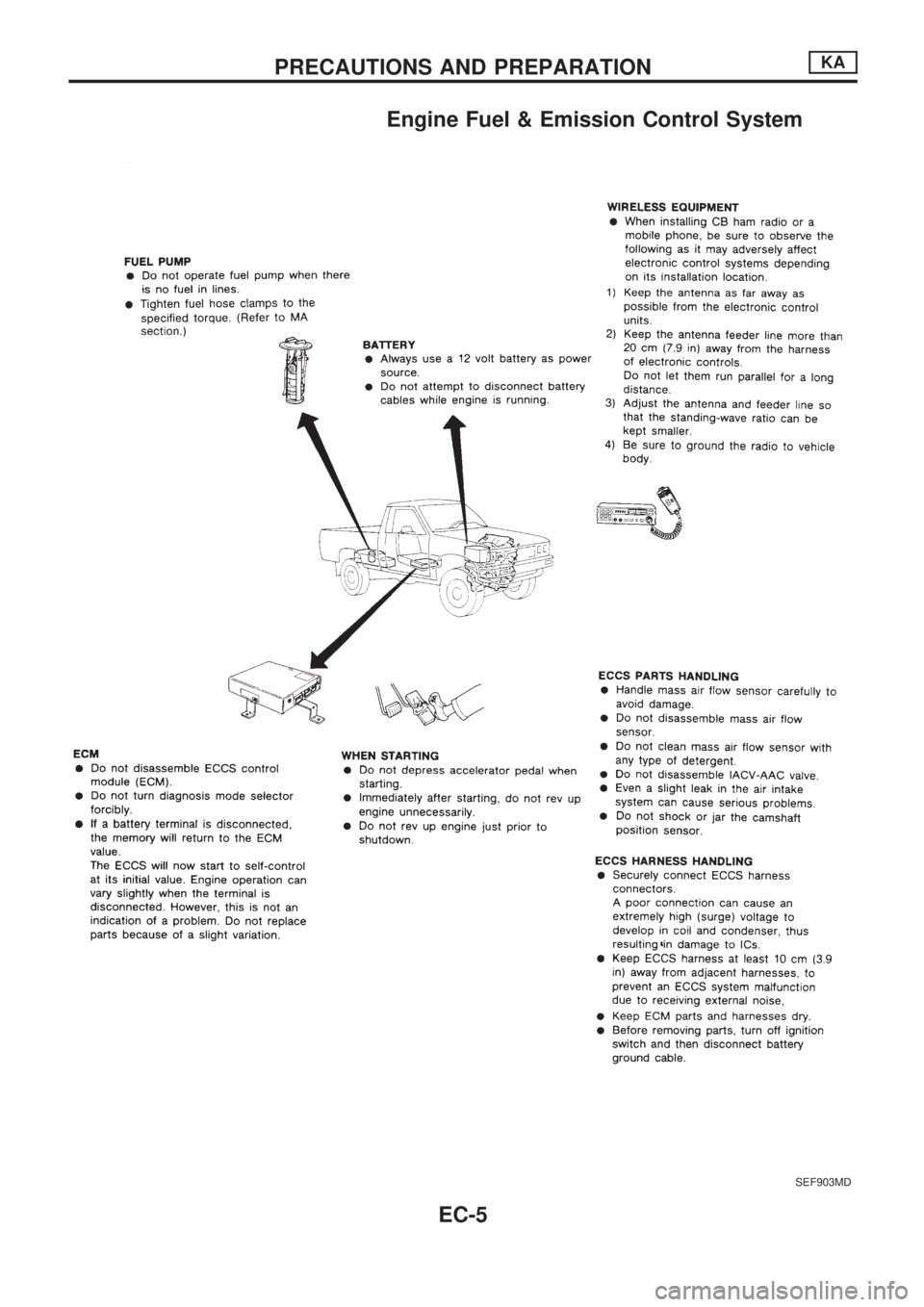

Engine Fuel & Emission Control System

SEF903MD

PRECAUTIONS AND PREPARATIONKA

EC-5

Page 164 of 1659

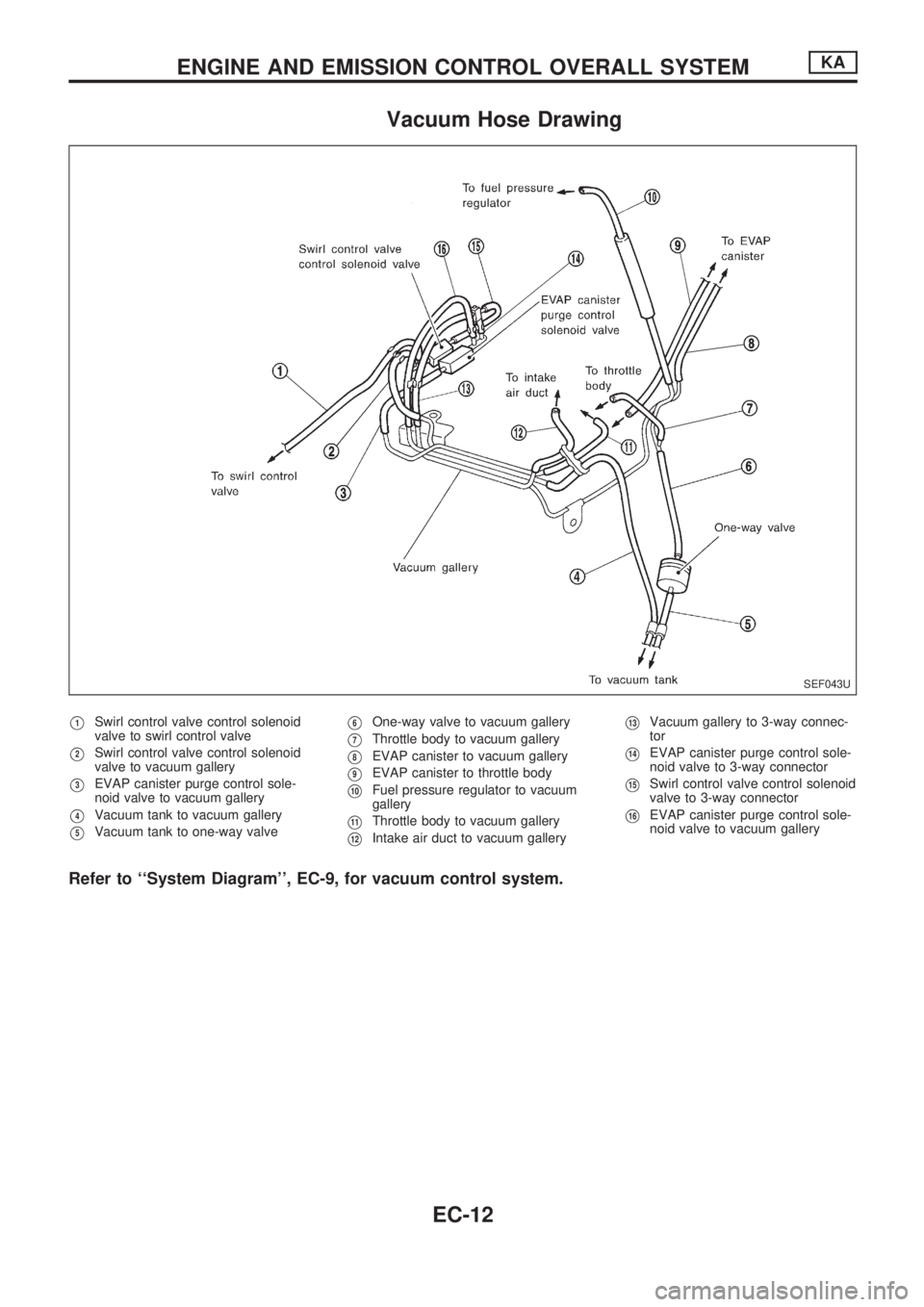

Vacuum Hose Drawing

V1Swirl control valve control solenoid

valve to swirl control valve

V2Swirl control valve control solenoid

valve to vacuum gallery

V3EVAP canister purge control sole-

noid valve to vacuum gallery

V4Vacuum tank to vacuum gallery

V5Vacuum tank to one-way valve

V6One-way valve to vacuum gallery

V7Throttle body to vacuum gallery

V8EVAP canister to vacuum gallery

V9EVAP canister to throttle body

V10Fuel pressure regulator to vacuum

gallery

V11Throttle body to vacuum gallery

V12Intake air duct to vacuum gallery

V13Vacuum gallery to 3-way connec-

tor

V14EVAP canister purge control sole-

noid valve to 3-way connector

V15Swirl control valve control solenoid

valve to 3-way connector

V16EVAP canister purge control sole-

noid valve to vacuum gallery

Refer to ``System Diagram'', EC-9, for vacuum control system.

SEF043U

ENGINE AND EMISSION CONTROL OVERALL SYSTEMKA

EC-12

Page 165 of 1659

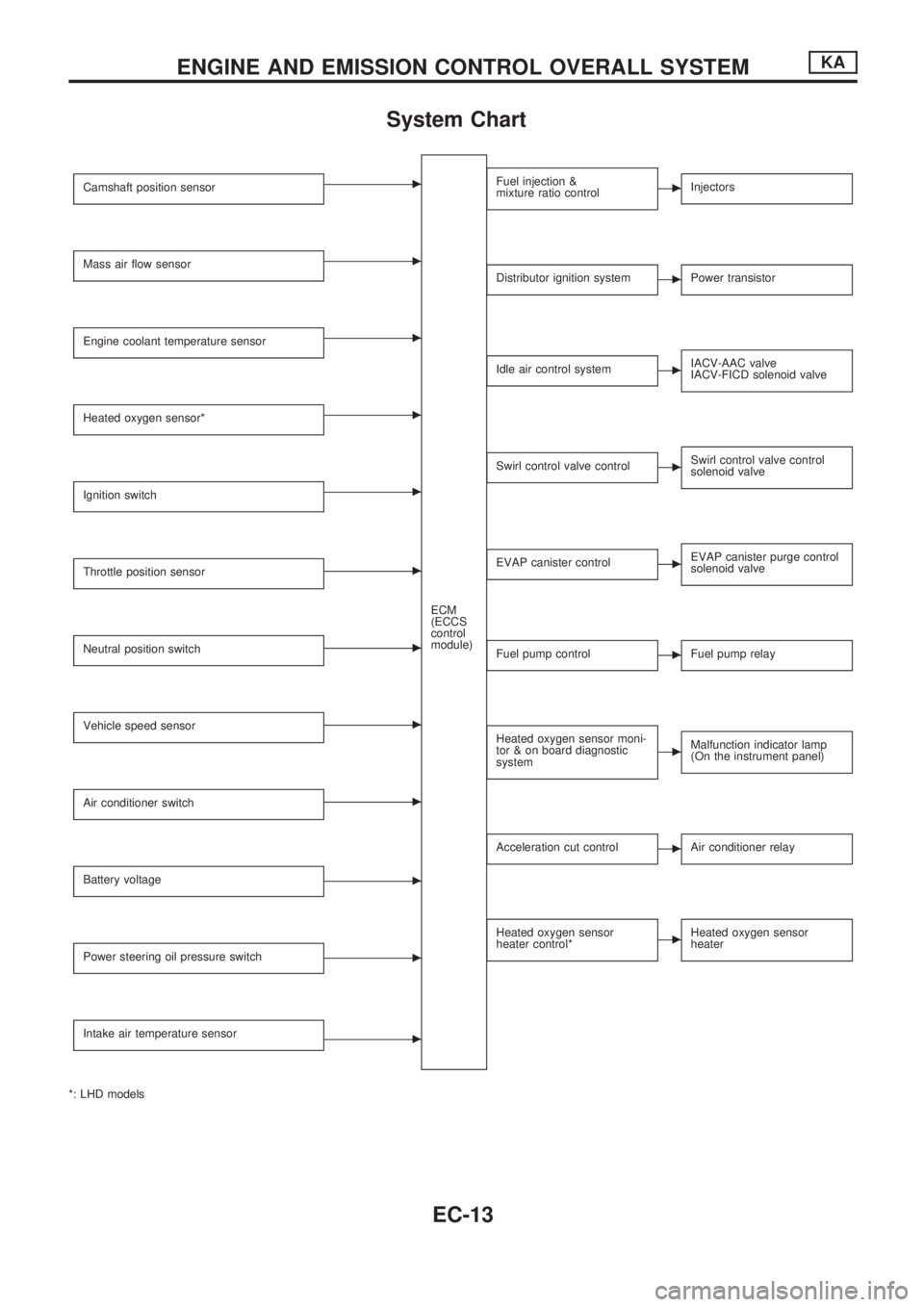

System Chart

Camshaft position sensorc

ECM

(ECCS

control

module)

Mass air flow sensorc

Engine coolant temperature sensorc

Heated oxygen sensor*c

Ignition switchc

Throttle position sensorc

Neutral position switchc

Vehicle speed sensorc

Air conditioner switchc

Battery voltagec

Power steering oil pressure switchc

Intake air temperature sensorc

*: LHD models

Fuel injection &

mixture ratio controlcInjectors

Distributor ignition systemcPower transistor

Idle air control systemcIACV-AAC valve

IACV-FICD solenoid valve

Swirl control valve controlcSwirl control valve control

solenoid valve

EVAP canister controlcEVAP canister purge control

solenoid valve

Fuel pump controlcFuel pump relay

Heated oxygen sensor moni-

tor & on board diagnostic

systemcMalfunction indicator lamp

(On the instrument panel)

Acceleration cut controlcAir conditioner relay

Heated oxygen sensor

heater control*cHeated oxygen sensor

heater

ENGINE AND EMISSION CONTROL OVERALL SYSTEMKA

EC-13

Page 166 of 1659

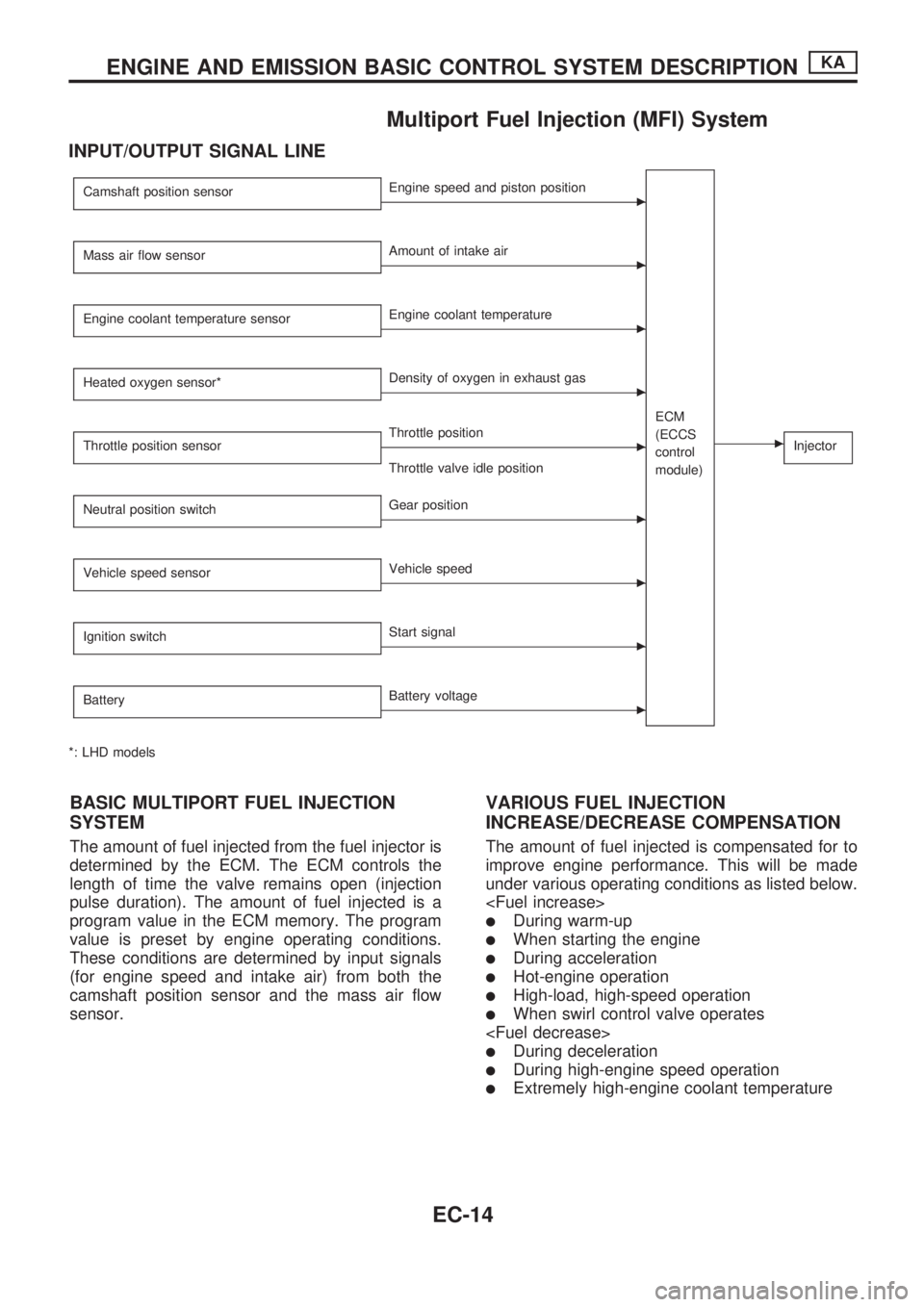

Multiport Fuel Injection (MFI) System

INPUT/OUTPUT SIGNAL LINE

Camshaft position sensorcEngine speed and piston position

ECM

(ECCS

control

module)

cInjector

Mass air flow sensorcAmount of intake air

Engine coolant temperature sensor

cEngine coolant temperature

Heated oxygen sensor*

cDensity of oxygen in exhaust gas

Throttle position sensor

cThrottle position

Throttle valve idle position

Neutral position switch

cGear position

Vehicle speed sensor

cVehicle speed

Ignition switch

cStart signal

Battery

cBattery voltage

*: LHD models

BASIC MULTIPORT FUEL INJECTION

SYSTEM

The amount of fuel injected from the fuel injector is

determined by the ECM. The ECM controls the

length of time the valve remains open (injection

pulse duration). The amount of fuel injected is a

program value in the ECM memory. The program

value is preset by engine operating conditions.

These conditions are determined by input signals

(for engine speed and intake air) from both the

camshaft position sensor and the mass air flow

sensor.

VARIOUS FUEL INJECTION

INCREASE/DECREASE COMPENSATION

The amount of fuel injected is compensated for to

improve engine performance. This will be made

under various operating conditions as listed below.

lDuring warm-up

lWhen starting the engine

lDuring acceleration

lHot-engine operation

lHigh-load, high-speed operation

lWhen swirl control valve operates

lDuring deceleration

lDuring high-engine speed operation

lExtremely high-engine coolant temperature

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONKA

EC-14