NISSAN PICK-UP 2001 Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 1101 of 1306

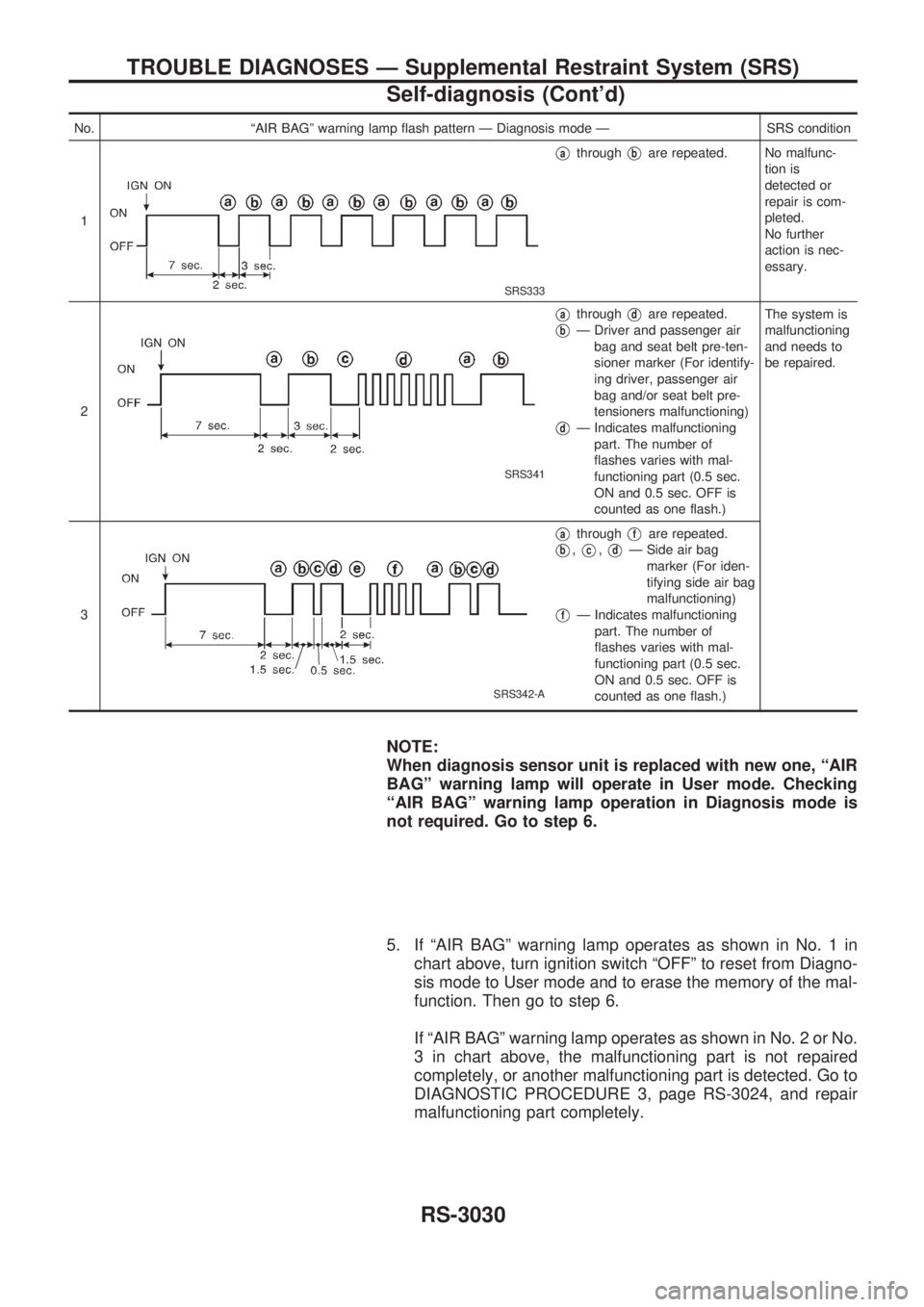

No. ªAIR BAGº warning lamp flash pattern Ð Diagnosis mode Ð SRS condition

1

SRS333

VathroughVbare repeated. No malfunc-

tion is

detected or

repair is com-

pleted.

No further

action is nec-

essary.

2

SRS341

VathroughVdare repeated.

VbÐ Driver and passenger air

bag and seat belt pre-ten-

sioner marker (For identify-

ing driver, passenger air

bag and/or seat belt pre-

tensioners malfunctioning)

VdÐ Indicates malfunctioning

part. The number of

flashes varies with mal-

functioning part (0.5 sec.

ON and 0.5 sec. OFF is

counted as one flash.)The system is

malfunctioning

and needs to

be repaired.

3

SRS342-A

VathroughVfare repeated.

Vb,Vc,VdÐ Side air bag

marker (For iden-

tifying side air bag

malfunctioning)

VfÐ Indicates malfunctioning

part. The number of

flashes varies with mal-

functioning part (0.5 sec.

ON and 0.5 sec. OFF is

counted as one flash.)

NOTE:

When diagnosis sensor unit is replaced with new one, ªAIR

BAGº warning lamp will operate in User mode. Checking

ªAIR BAGº warning lamp operation in Diagnosis mode is

not required. Go to step 6.

5. If ªAIR BAGº warning lamp operates as shown in No. 1 in

chart above, turn ignition switch ªOFFº to reset from Diagno-

sis mode to User mode and to erase the memory of the mal-

function. Then go to step 6.

If ªAIR BAGº warning lamp operates as shown in No. 2 or No.

3 in chart above, the malfunctioning part is not repaired

completely, or another malfunctioning part is detected. Go to

DIAGNOSTIC PROCEDURE 3, page RS-3024, and repair

malfunctioning part completely.

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

Self-diagnosis (Cont'd)

RS-3030

Page 1102 of 1306

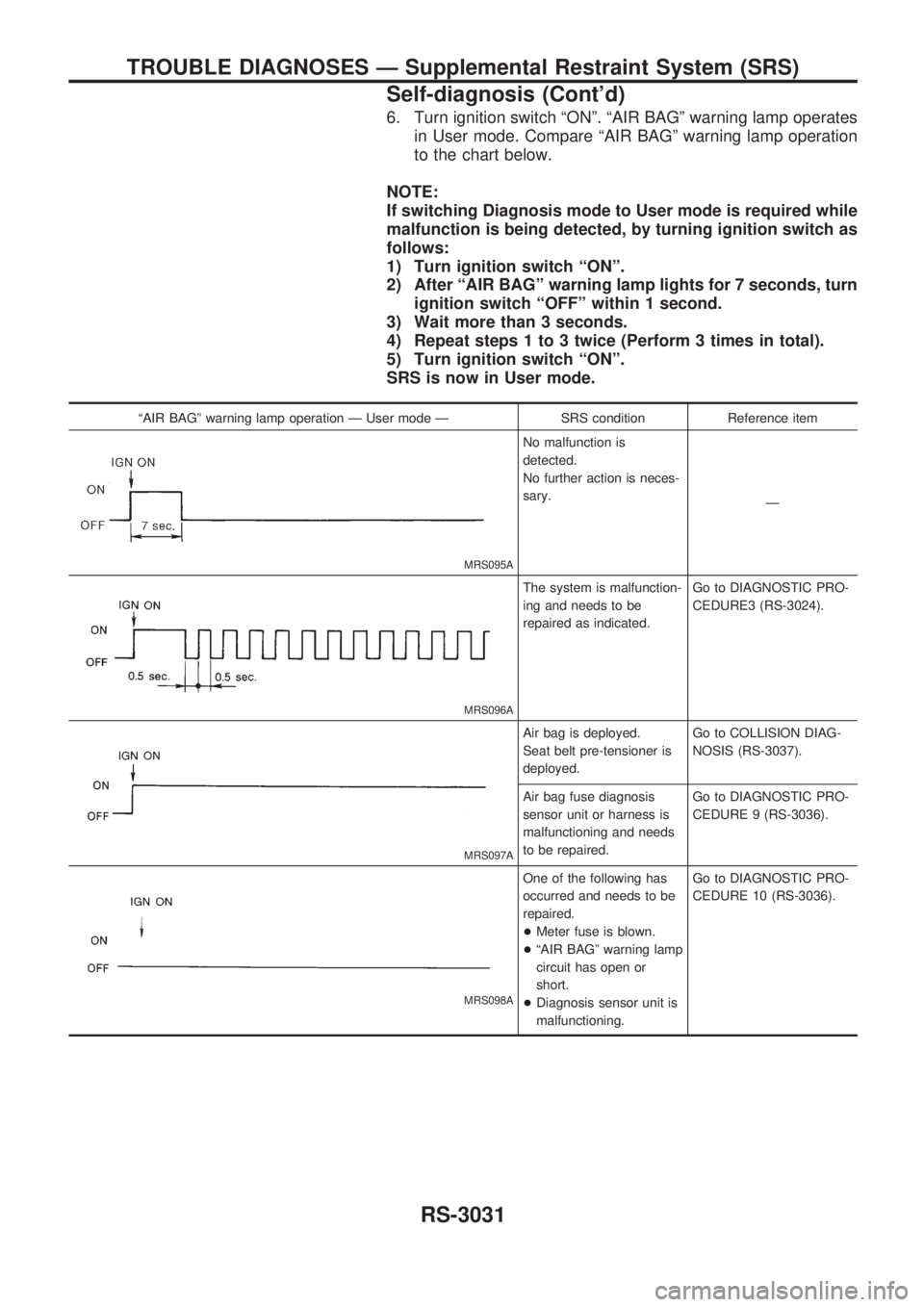

6. Turn ignition switch ªONº. ªAIR BAGº warning lamp operates

in User mode. Compare ªAIR BAGº warning lamp operation

to the chart below.

NOTE:

If switching Diagnosis mode to User mode is required while

malfunction is being detected, by turning ignition switch as

follows:

1) Turn ignition switch ªONº.

2) After ªAIR BAGº warning lamp lights for 7 seconds, turn

ignition switch ªOFFº within 1 second.

3) Wait more than 3 seconds.

4) Repeat steps 1 to 3 twice (Perform 3 times in total).

5) Turn ignition switch ªONº.

SRS is now in User mode.

ªAIR BAGº warning lamp operation Ð User mode Ð SRS condition Reference item

MRS095A

No malfunction is

detected.

No further action is neces-

sary.

Ð

MRS096A

The system is malfunction-

ing and needs to be

repaired as indicated.Go to DIAGNOSTIC PRO-

CEDURE3 (RS-3024).

MRS097A

Air bag is deployed.

Seat belt pre-tensioner is

deployed.Go to COLLISION DIAG-

NOSIS (RS-3037).

Air bag fuse diagnosis

sensor unit or harness is

malfunctioning and needs

to be repaired.Go to DIAGNOSTIC PRO-

CEDURE 9 (RS-3036).

MRS098A

One of the following has

occurred and needs to be

repaired.

+Meter fuse is blown.

+ªAIR BAGº warning lamp

circuit has open or

short.

+Diagnosis sensor unit is

malfunctioning.Go to DIAGNOSTIC PRO-

CEDURE 10 (RS-3036).

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

Self-diagnosis (Cont'd)

RS-3031

Page 1103 of 1306

![NISSAN PICK-UP 2001 Repair Manual DIAGNOSTIC PROCEDURE 6 (Continued from

DIAGNOSTIC PROCEDURE 2)

Inspecting SRS malfunctioning record

Is it the first time for maintenance of

SRS?

Yes

cNo

ªSELF-DIAG [PAST]º

(which was previously

ente NISSAN PICK-UP 2001 Repair Manual DIAGNOSTIC PROCEDURE 6 (Continued from

DIAGNOSTIC PROCEDURE 2)

Inspecting SRS malfunctioning record

Is it the first time for maintenance of

SRS?

Yes

cNo

ªSELF-DIAG [PAST]º

(which was previously

ente](/img/5/57372/w960_57372-1102.png)

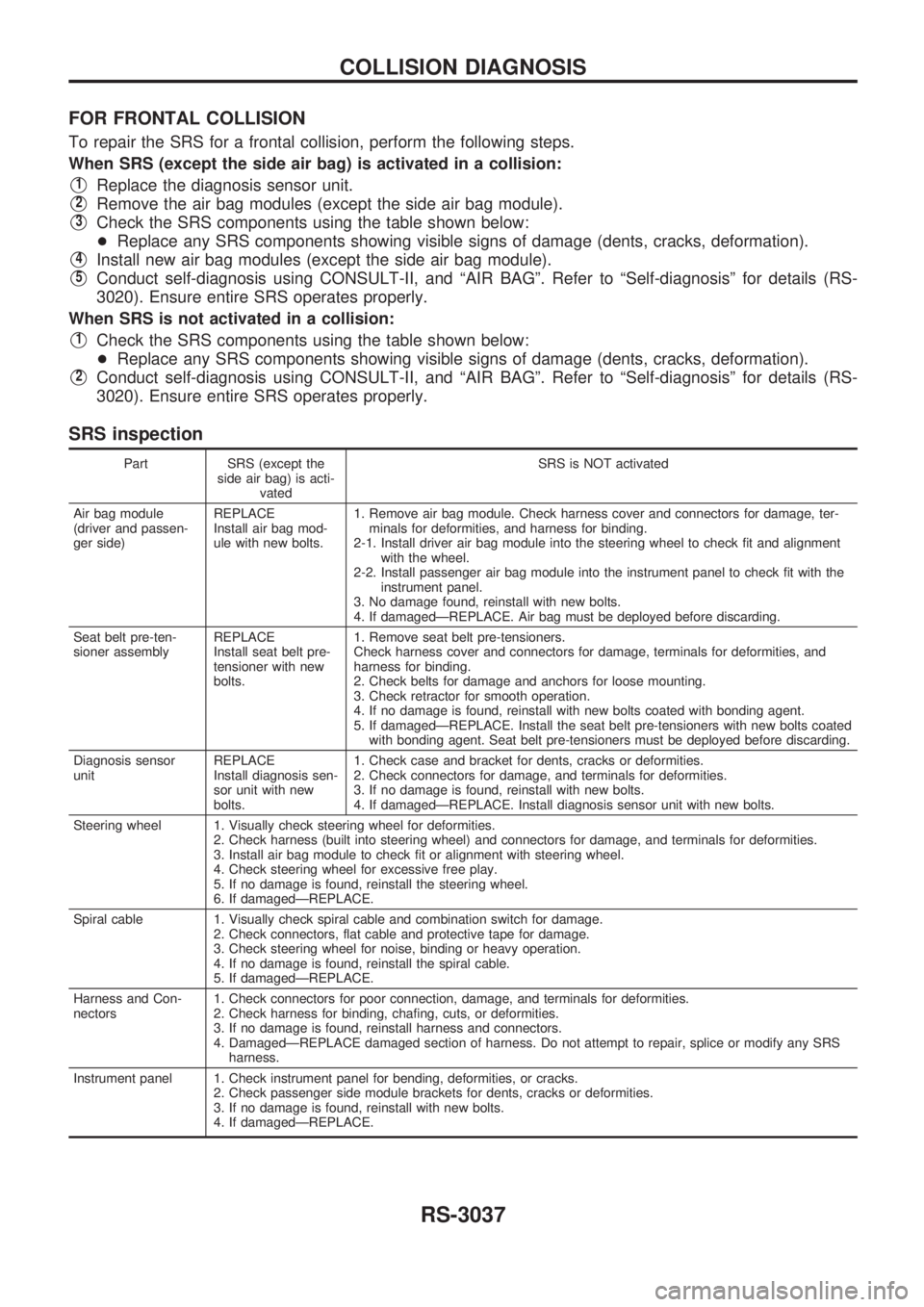

DIAGNOSTIC PROCEDURE 6 (Continued from

DIAGNOSTIC PROCEDURE 2)

Inspecting SRS malfunctioning record

Is it the first time for maintenance of

SRS?

Yes

cNo

ªSELF-DIAG [PAST]º

(which was previously

entered) is still retained in

memory.

Go to DIAGNOSTIC PRO-

CEDURE 4 (RS-3028).

Go to DIAGNOSTIC PROCEDURE 8

(RS-3032).

DIAGNOSTIC PROCEDURE 7 (Continued from

DIAGNOSTIC PROCEDURE 3) (

without

CONSULT-II)

Inspecting SRS malfunctioning record

Is it the first time for maintenance of

SRS?

Yes

cNo

Diagnosis results (previ-

ously stored in the

memory) might not be

erased after repair.

Go to DIAGNOSTIC PRO-

CEDURE 5, step 5 (RS-

3029).

GO TO DIAGNOSTIC PROCEDURE 8

(RS-3032).Further inspection cannot be

performed without CONSULT-II.

DIAGNOSTIC PROCEDURE 8 (with CONSULT-II)

Inspecting SRS intermittent malfunction by using CON-

SULT-II Ð Diagnosis mode

1. Turn ignition switch ªOFFº.

2. Connect CONSULT-II to data link connector.

3. Turn ignition switch ªONº.

4. Touch ªSTARTº.

SHIA0203E

SRS695

.

.

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

Self-diagnosis (Cont'd)

RS-3032

Page 1104 of 1306

![NISSAN PICK-UP 2001 Repair Manual 5. Touch ªAIR BAGº.

6. Touch ªSELF-DIAG [PAST]º.

7. If diagnostic codes are displayed on ªSELF-DIAG [PAST]º,

go to step 10.

If no malfunction is detected on ªSELF-DIAG [PAST]º, touch

ªBACKº NISSAN PICK-UP 2001 Repair Manual 5. Touch ªAIR BAGº.

6. Touch ªSELF-DIAG [PAST]º.

7. If diagnostic codes are displayed on ªSELF-DIAG [PAST]º,

go to step 10.

If no malfunction is detected on ªSELF-DIAG [PAST]º, touch

ªBACKº](/img/5/57372/w960_57372-1103.png)

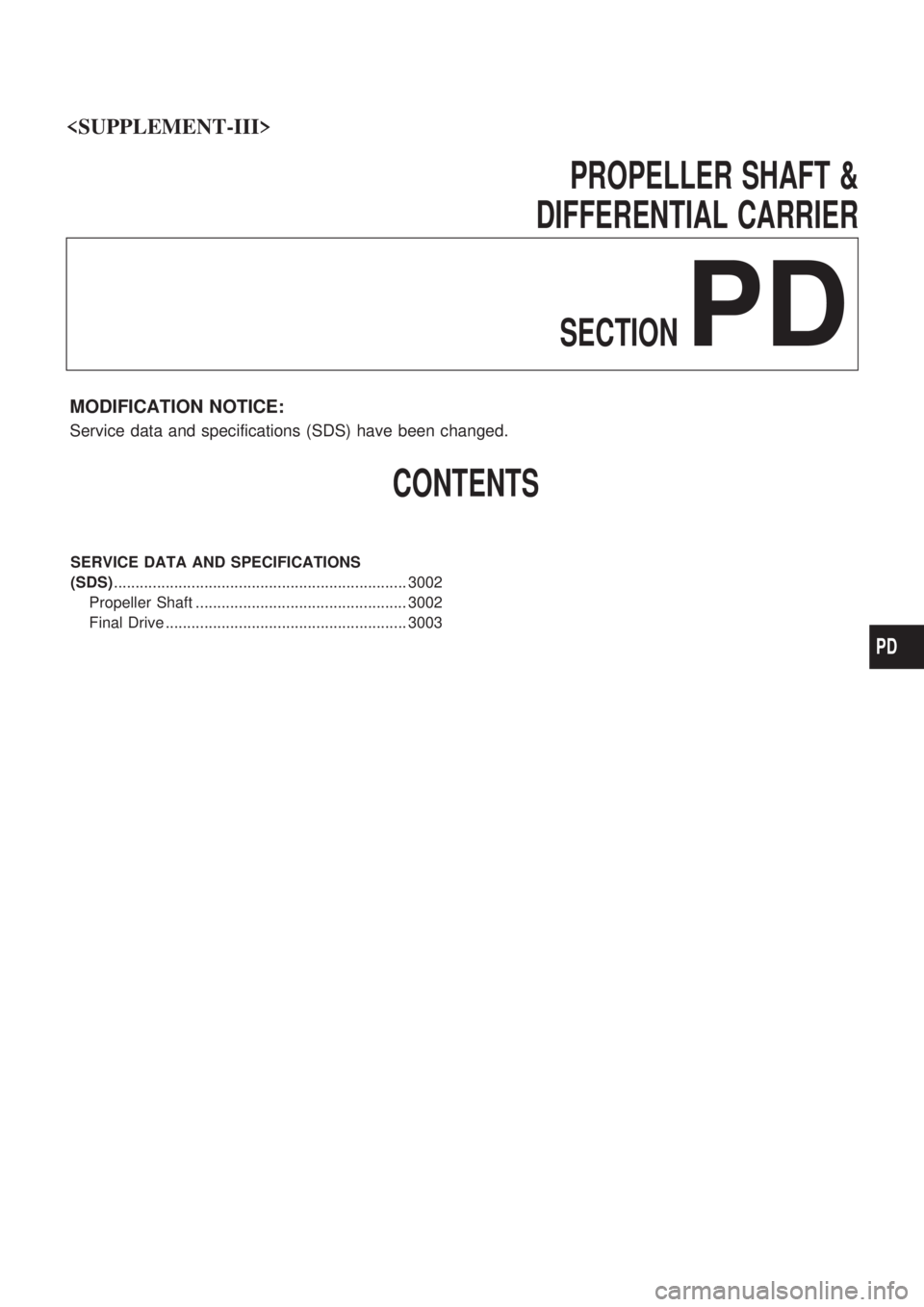

5. Touch ªAIR BAGº.

6. Touch ªSELF-DIAG [PAST]º.

7. If diagnostic codes are displayed on ªSELF-DIAG [PAST]º,

go to step 10.

If no malfunction is detected on ªSELF-DIAG [PAST]º, touch

ªBACKº and go back to ªSELECT DIAG MODEº.

8. Touch ªTROUBLE DIAG RECORDº.

NOTE:

With ªTROUBLE DIAG RECORDº, diagnosis results previ-

ously erased by a reset operation can be displayed.

SRS771

SRS697

SHIA0181E

SRS702

SRS697

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

Self-diagnosis (Cont'd)

RS-3033

Page 1105 of 1306

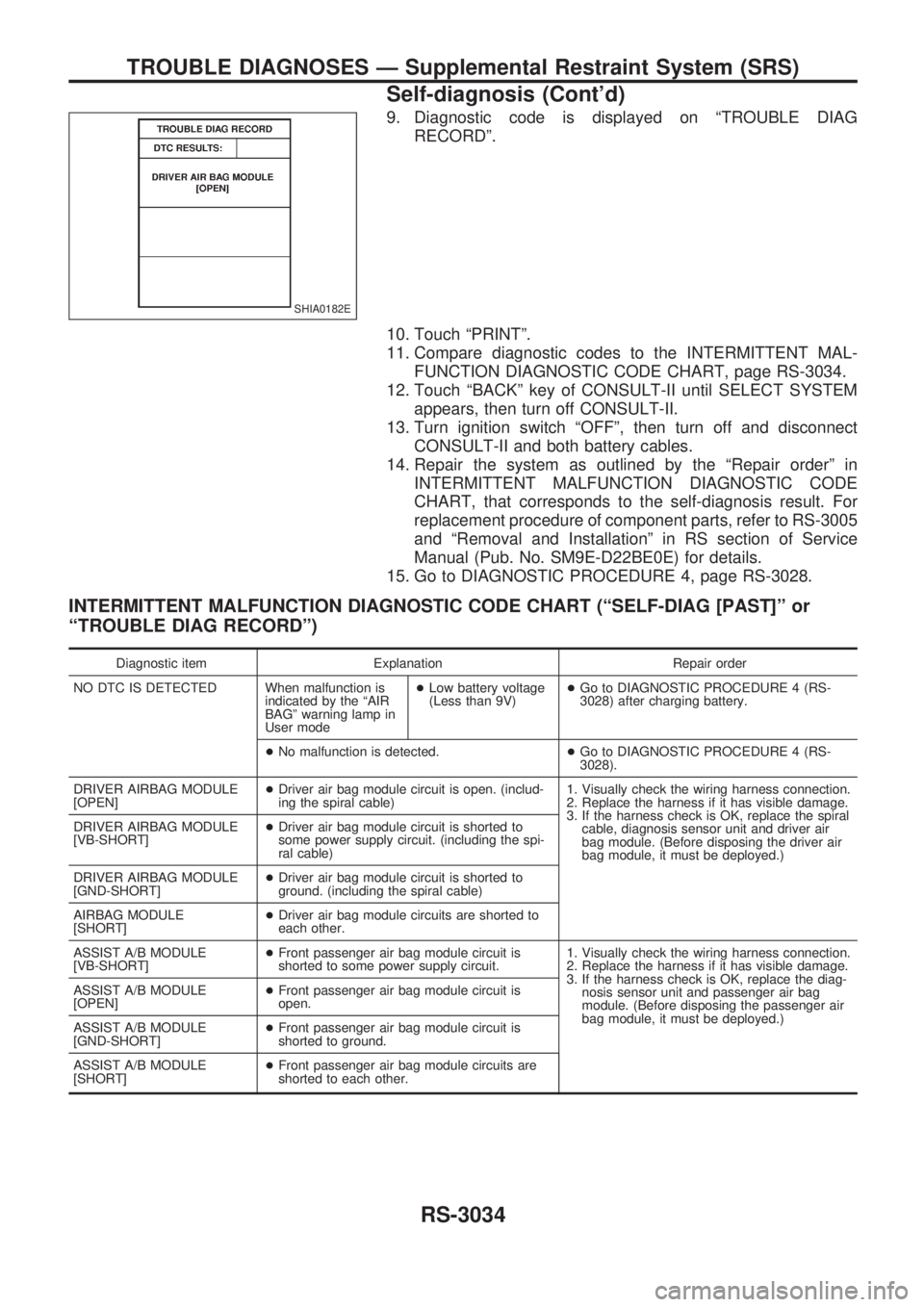

9. Diagnostic code is displayed on ªTROUBLE DIAG

RECORDº.

10. Touch ªPRINTº.

11. Compare diagnostic codes to the INTERMITTENT MAL-

FUNCTION DIAGNOSTIC CODE CHART, page RS-3034.

12. Touch ªBACKº key of CONSULT-II until SELECT SYSTEM

appears, then turn off CONSULT-II.

13. Turn ignition switch ªOFFº, then turn off and disconnect

CONSULT-II and both battery cables.

14. Repair the system as outlined by the ªRepair orderº in

INTERMITTENT MALFUNCTION DIAGNOSTIC CODE

CHART, that corresponds to the self-diagnosis result. For

replacement procedure of component parts, refer to RS-3005

and ªRemoval and Installationº in RS section of Service

Manual (Pub. No. SM9E-D22BE0E) for details.

15. Go to DIAGNOSTIC PROCEDURE 4, page RS-3028.

INTERMITTENT MALFUNCTION DIAGNOSTIC CODE CHART (ªSELF-DIAG [PAST]º or

ªTROUBLE DIAG RECORDº)

Diagnostic item Explanation Repair order

NO DTC IS DETECTED When malfunction is

indicated by the ªAIR

BAGº warning lamp in

User mode+Low battery voltage

(Less than 9V)+Go to DIAGNOSTIC PROCEDURE 4 (RS-

3028) after charging battery.

+No malfunction is detected.+Go to DIAGNOSTIC PROCEDURE 4 (RS-

3028).

DRIVER AIRBAG MODULE

[OPEN]+Driver air bag module circuit is open. (includ-

ing the spiral cable)1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. If the harness check is OK, replace the spiral

cable, diagnosis sensor unit and driver air

bag module. (Before disposing the driver air

bag module, it must be deployed.) DRIVER AIRBAG MODULE

[VB-SHORT]+Driver air bag module circuit is shorted to

some power supply circuit. (including the spi-

ral cable)

DRIVER AIRBAG MODULE

[GND-SHORT]+Driver air bag module circuit is shorted to

ground. (including the spiral cable)

AIRBAG MODULE

[SHORT]+Driver air bag module circuits are shorted to

each other.

ASSIST A/B MODULE

[VB-SHORT]+Front passenger air bag module circuit is

shorted to some power supply circuit.1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. If the harness check is OK, replace the diag-

nosis sensor unit and passenger air bag

module. (Before disposing the passenger air

bag module, it must be deployed.) ASSIST A/B MODULE

[OPEN]+Front passenger air bag module circuit is

open.

ASSIST A/B MODULE

[GND-SHORT]+Front passenger air bag module circuit is

shorted to ground.

ASSIST A/B MODULE

[SHORT]+Front passenger air bag module circuits are

shorted to each other.

SHIA0182E

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

Self-diagnosis (Cont'd)

RS-3034

Page 1106 of 1306

![NISSAN PICK-UP 2001 Repair Manual Diagnostic item Explanation Repair order

PRE-TEN FRONT LH

[OPEN]+The circuit for seat belt pre-tensioner (LH) is

open or shorted to a power supply circuit.1. Visually check the wiring harness connec-

NISSAN PICK-UP 2001 Repair Manual Diagnostic item Explanation Repair order

PRE-TEN FRONT LH

[OPEN]+The circuit for seat belt pre-tensioner (LH) is

open or shorted to a power supply circuit.1. Visually check the wiring harness connec-](/img/5/57372/w960_57372-1105.png)

Diagnostic item Explanation Repair order

PRE-TEN FRONT LH

[OPEN]+The circuit for seat belt pre-tensioner (LH) is

open or shorted to a power supply circuit.1. Visually check the wiring harness connec-

tions.

2. Replace the harness if it has visible damage.

3. If the harness check is OK, replace the diag-

nosis sensor unit and seat belt (LH).

(Before disposing the seat belt (LH) pre-

tensioner, it must be deployed.) PRE-TEN FRONT LH

[VB-SHORT]+The circuit for seat belt pre-tensioner (LH) is

shorted to a power supply circuit.

PRE-TEN FRONT LH

[GND-SHORT]+The circuit for seat belt pre-tensioner (LH) is

shorted to ground.

PRE-TEN FRONT RH

[OPEN/VB-SHORT]+The circuit for seat belt pre-tensioner (RH) is

open or shorted to a power supply circuit.1. Visually check the wiring harness connec-

tions.

2. Replace the harness if it has visible damage.

3. If the harness check is OK, replace the diag-

nosis sensor unit and seat belt (RH).

(Before disposing the seat belt (RH) pre-

tensioner, it must be deployed.) PRE-TEN FRONT RH

[VB-SHORT]+The circuit for seat belt pre-tensioner (RH) is

shorted to a power supply circuit.

PRE-TEN FRONT RH

[GND-SHORT]+The circuit for seat belt pre-tensioner (RH) is

shorted to ground.

CONTROL UNIT+Diagnosis sensor unit is malfunctioning. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. If the harness check is OK, replace the diag-

nosis sensor unit.

* Follow the procedures in numerical order when repairing malfunctioning parts, then make the final system check.

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

Self-diagnosis (Cont'd)

RS-3035

Page 1107 of 1306

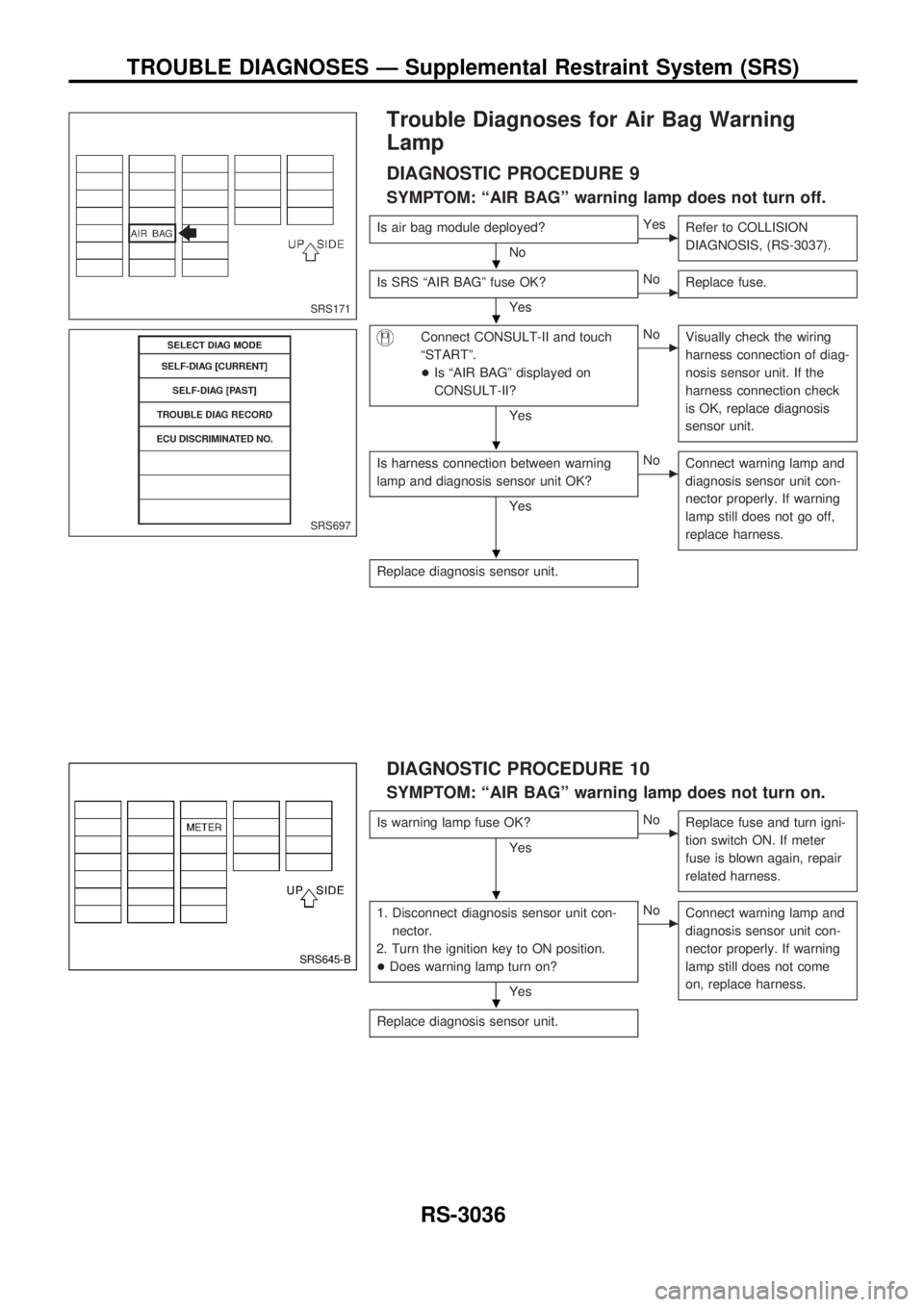

Trouble Diagnoses for Air Bag Warning

Lamp

DIAGNOSTIC PROCEDURE 9

SYMPTOM: ªAIR BAGº warning lamp does not turn off.

Is air bag module deployed?

NocYes

Refer to COLLISION

DIAGNOSIS, (RS-3037).

Is SRS ªAIR BAGº fuse OK?

YescNo

Replace fuse.

Connect CONSULT-II and touch

ªSTARTº.

+Is ªAIR BAGº displayed on

CONSULT-II?

Yes

cNo

Visually check the wiring

harness connection of diag-

nosis sensor unit. If the

harness connection check

is OK, replace diagnosis

sensor unit.

Is harness connection between warning

lamp and diagnosis sensor unit OK?

Yes

cNo

Connect warning lamp and

diagnosis sensor unit con-

nector properly. If warning

lamp still does not go off,

replace harness.

Replace diagnosis sensor unit.

DIAGNOSTIC PROCEDURE 10

SYMPTOM: ªAIR BAGº warning lamp does not turn on.

Is warning lamp fuse OK?

YescNo

Replace fuse and turn igni-

tion switch ON. If meter

fuse is blown again, repair

related harness.

1. Disconnect diagnosis sensor unit con-

nector.

2. Turn the ignition key to ON position.

+Does warning lamp turn on?

Yes

cNo

Connect warning lamp and

diagnosis sensor unit con-

nector properly. If warning

lamp still does not come

on, replace harness.

Replace diagnosis sensor unit.

SRS171

SRS697

SRS645-B

.

.

.

.

.

.

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

RS-3036

Page 1108 of 1306

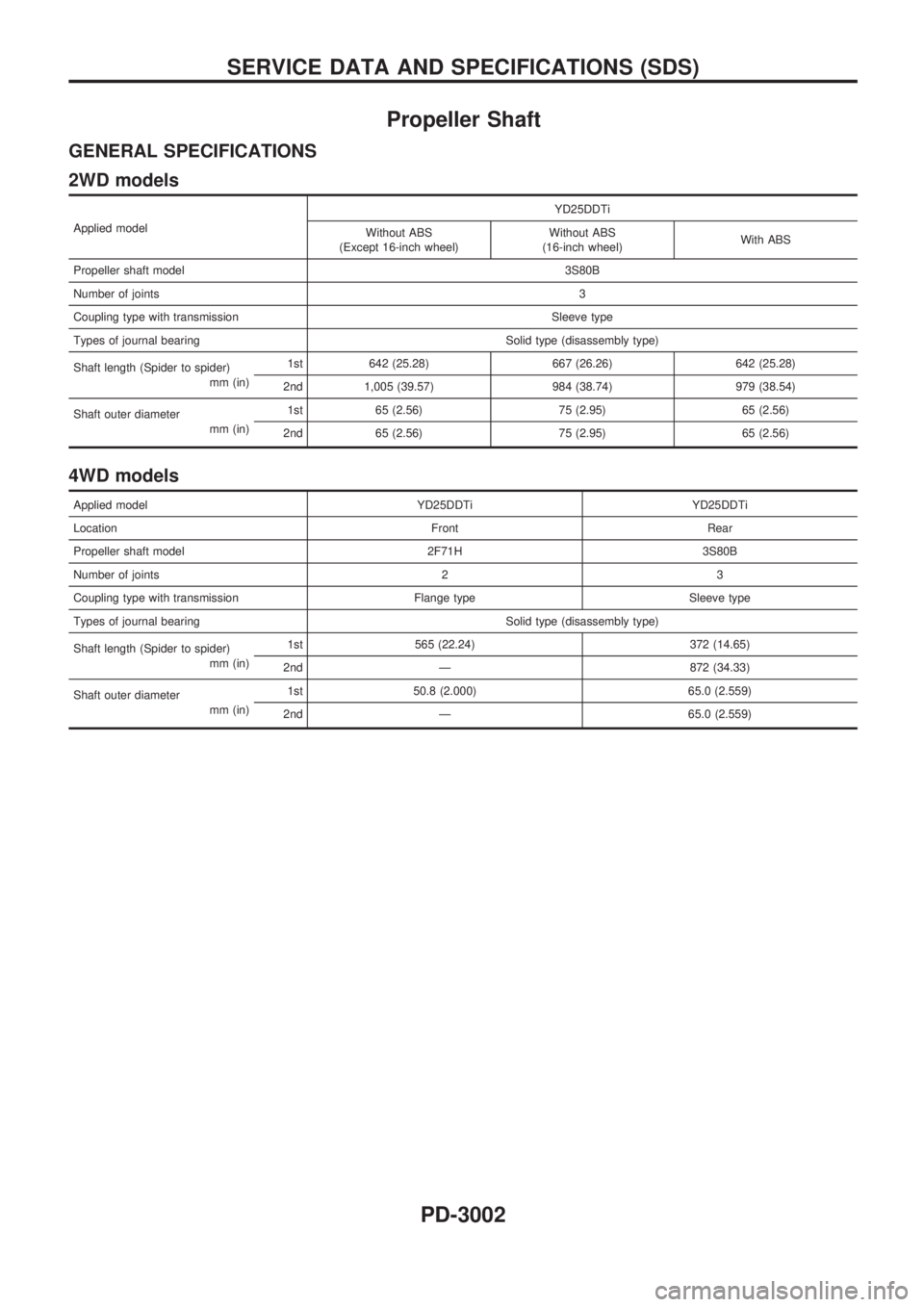

FOR FRONTAL COLLISION

To repair the SRS for a frontal collision, perform the following steps.

When SRS (except the side air bag) is activated in a collision:

V1Replace the diagnosis sensor unit.

V2Remove the air bag modules (except the side air bag module).

V3Check the SRS components using the table shown below:

+Replace any SRS components showing visible signs of damage (dents, cracks, deformation).

V4Install new air bag modules (except the side air bag module).

V5Conduct self-diagnosis using CONSULT-II, and ªAIR BAGº. Refer to ªSelf-diagnosisº for details (RS-

3020). Ensure entire SRS operates properly.

When SRS is not activated in a collision:

V1Check the SRS components using the table shown below:

+Replace any SRS components showing visible signs of damage (dents, cracks, deformation).

V2Conduct self-diagnosis using CONSULT-II, and ªAIR BAGº. Refer to ªSelf-diagnosisº for details (RS-

3020). Ensure entire SRS operates properly.

SRS inspection

Part SRS (except the

side air bag) is acti-

vatedSRS is NOT activated

Air bag module

(driver and passen-

ger side)REPLACE

Install air bag mod-

ule with new bolts.1. Remove air bag module. Check harness cover and connectors for damage, ter-

minals for deformities, and harness for binding.

2-1. Install driver air bag module into the steering wheel to check fit and alignment

with the wheel.

2-2. Install passenger air bag module into the instrument panel to check fit with the

instrument panel.

3. No damage found, reinstall with new bolts.

4. If damagedÐREPLACE. Air bag must be deployed before discarding.

Seat belt pre-ten-

sioner assemblyREPLACE

Install seat belt pre-

tensioner with new

bolts.1. Remove seat belt pre-tensioners.

Check harness cover and connectors for damage, terminals for deformities, and

harness for binding.

2. Check belts for damage and anchors for loose mounting.

3. Check retractor for smooth operation.

4. If no damage is found, reinstall with new bolts coated with bonding agent.

5. If damagedÐREPLACE. Install the seat belt pre-tensioners with new bolts coated

with bonding agent. Seat belt pre-tensioners must be deployed before discarding.

Diagnosis sensor

unitREPLACE

Install diagnosis sen-

sor unit with new

bolts.1. Check case and bracket for dents, cracks or deformities.

2. Check connectors for damage, and terminals for deformities.

3. If no damage is found, reinstall with new bolts.

4. If damagedÐREPLACE. Install diagnosis sensor unit with new bolts.

Steering wheel 1. Visually check steering wheel for deformities.

2. Check harness (built into steering wheel) and connectors for damage, and terminals for deformities.

3. Install air bag module to check fit or alignment with steering wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall the steering wheel.

6. If damagedÐREPLACE.

Spiral cable 1. Visually check spiral cable and combination switch for damage.

2. Check connectors, flat cable and protective tape for damage.

3. Check steering wheel for noise, binding or heavy operation.

4. If no damage is found, reinstall the spiral cable.

5. If damagedÐREPLACE.

Harness and Con-

nectors1. Check connectors for poor connection, damage, and terminals for deformities.

2. Check harness for binding, chafing, cuts, or deformities.

3. If no damage is found, reinstall harness and connectors.

4. DamagedÐREPLACE damaged section of harness. Do not attempt to repair, splice or modify any SRS

harness.

Instrument panel 1. Check instrument panel for bending, deformities, or cracks.

2. Check passenger side module brackets for dents, cracks or deformities.

3. If no damage is found, reinstall with new bolts.

4. If damagedÐREPLACE.

COLLISION DIAGNOSIS

RS-3037

Page 1109 of 1306

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

MODIFICATION NOTICE:

Service data and specifications (SDS) have been changed.

CONTENTS

SERVICE DATA AND SPECIFICATIONS

(SDS).................................................................... 3002

Propeller Shaft ................................................. 3002

Final Drive ........................................................ 3003

PD

Page 1110 of 1306

Propeller Shaft

GENERAL SPECIFICATIONS

2WD models

Applied modelYD25DDTi

Without ABS

(Except 16-inch wheel)Without ABS

(16-inch wheel)With ABS

Propeller shaft model3S80B

Number of joints3

Coupling type with transmission Sleeve type

Types of journal bearing Solid type (disassembly type)

Shaft length (Spider to spider)

mm (in)1st 642 (25.28) 667 (26.26) 642 (25.28)

2nd 1,005 (39.57) 984 (38.74) 979 (38.54)

Shaft outer diameter

mm (in)1st 65 (2.56) 75 (2.95) 65 (2.56)

2nd 65 (2.56) 75 (2.95) 65 (2.56)

4WD models

Applied model YD25DDTi YD25DDTi

Location Front Rear

Propeller shaft model 2F71H 3S80B

Number of joints 2 3

Coupling type with transmission Flange type Sleeve type

Types of journal bearing Solid type (disassembly type)

Shaft length (Spider to spider)

mm (in)1st 565 (22.24) 372 (14.65)

2nd Ð 872 (34.33)

Shaft outer diameter

mm (in)1st 50.8 (2.000) 65.0 (2.559)

2nd Ð 65.0 (2.559)

SERVICE DATA AND SPECIFICATIONS (SDS)

PD-3002