NISSAN PICK-UP 2001 Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 121 of 1306

16 CHECK CLOSED THROTTLE POSITION SWITCH IDLE POSITION (CHECK THROTTLE POSITION SEN-

SOR IDLE POSITION)

Without CONSULT-II

NOTE:

Always check ignition timing and base idle speed before performing the following.

1. Warm up engine to normal operating temperature.

2. Check FI cam. Refer to procedure 5.

3. Stop engine.

4. Disconnect closed throttle position switch harness connector .

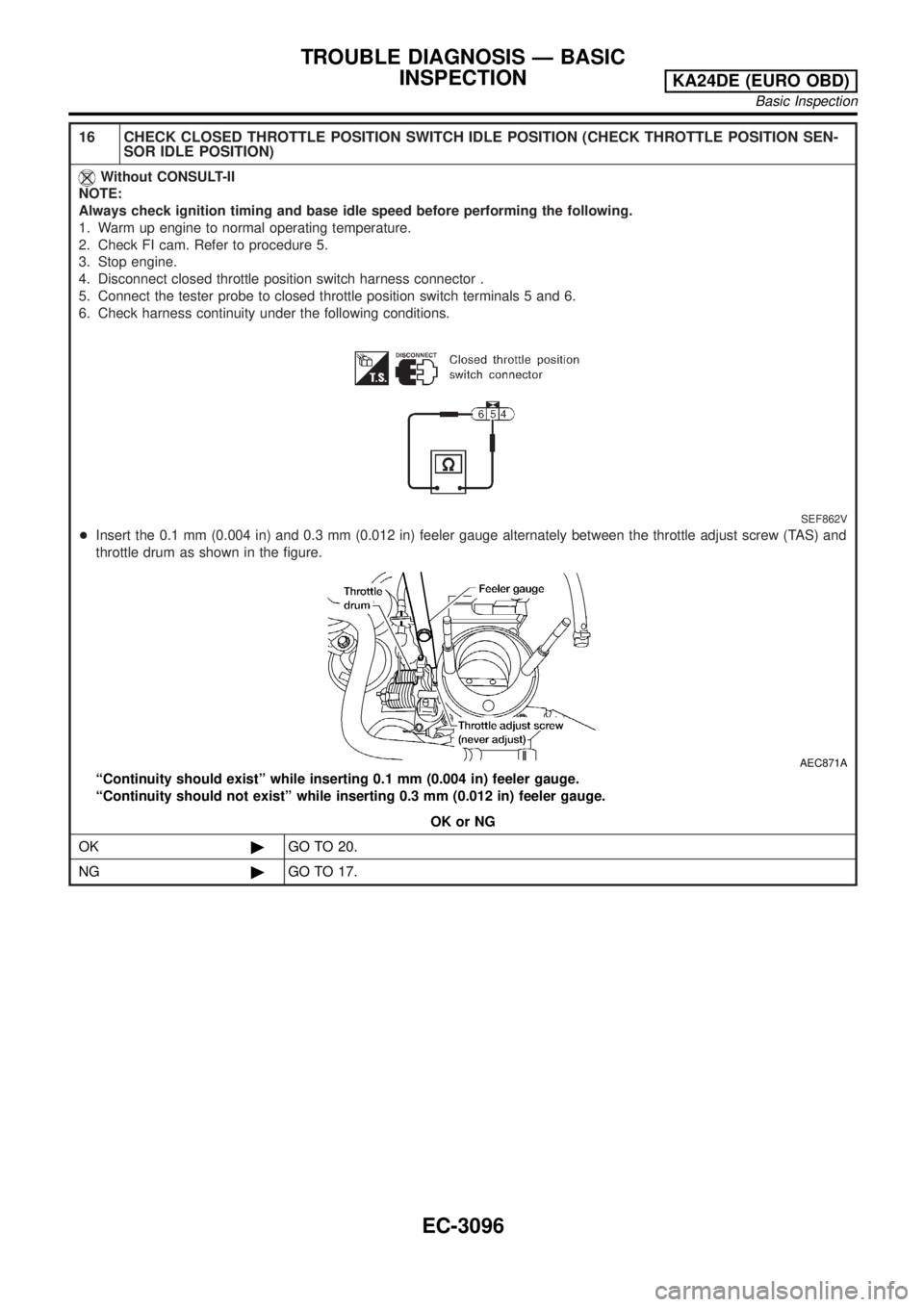

5. Connect the tester probe to closed throttle position switch terminals 5 and 6.

6. Check harness continuity under the following conditions.

SEF862V

+Insert the 0.1 mm (0.004 in) and 0.3 mm (0.012 in) feeler gauge alternately between the throttle adjust screw (TAS) and

throttle drum as shown in the figure.

AEC871A

ªContinuity should existº while inserting 0.1 mm (0.004 in) feeler gauge.

ªContinuity should not existº while inserting 0.3 mm (0.012 in) feeler gauge.

OK or NG

OK©GO TO 20.

NG©GO TO 17.

TROUBLE DIAGNOSIS Ð BASIC

INSPECTION

KA24DE (EURO OBD)

Basic Inspection

EC-3096

Page 122 of 1306

17 ADJUSTMENT THROTTLE POSITION SENSOR IDLE POSITION-1

Without CONSULT-II

NOTE:

+Never adjust throttle adjust screw (TAS).

+Do not touch throttle drum when checking ªcontinuityº.

Doing so may cause an incorrect adjustment.

1. Warm engine up to normal operating temperature.

2. Check FI cam. Refer to procedure 5.

3. Stop engine.

4. Loosen throttle position sensor fixing bolts.

5. Disconnect closed throttle position sensor harness connector.

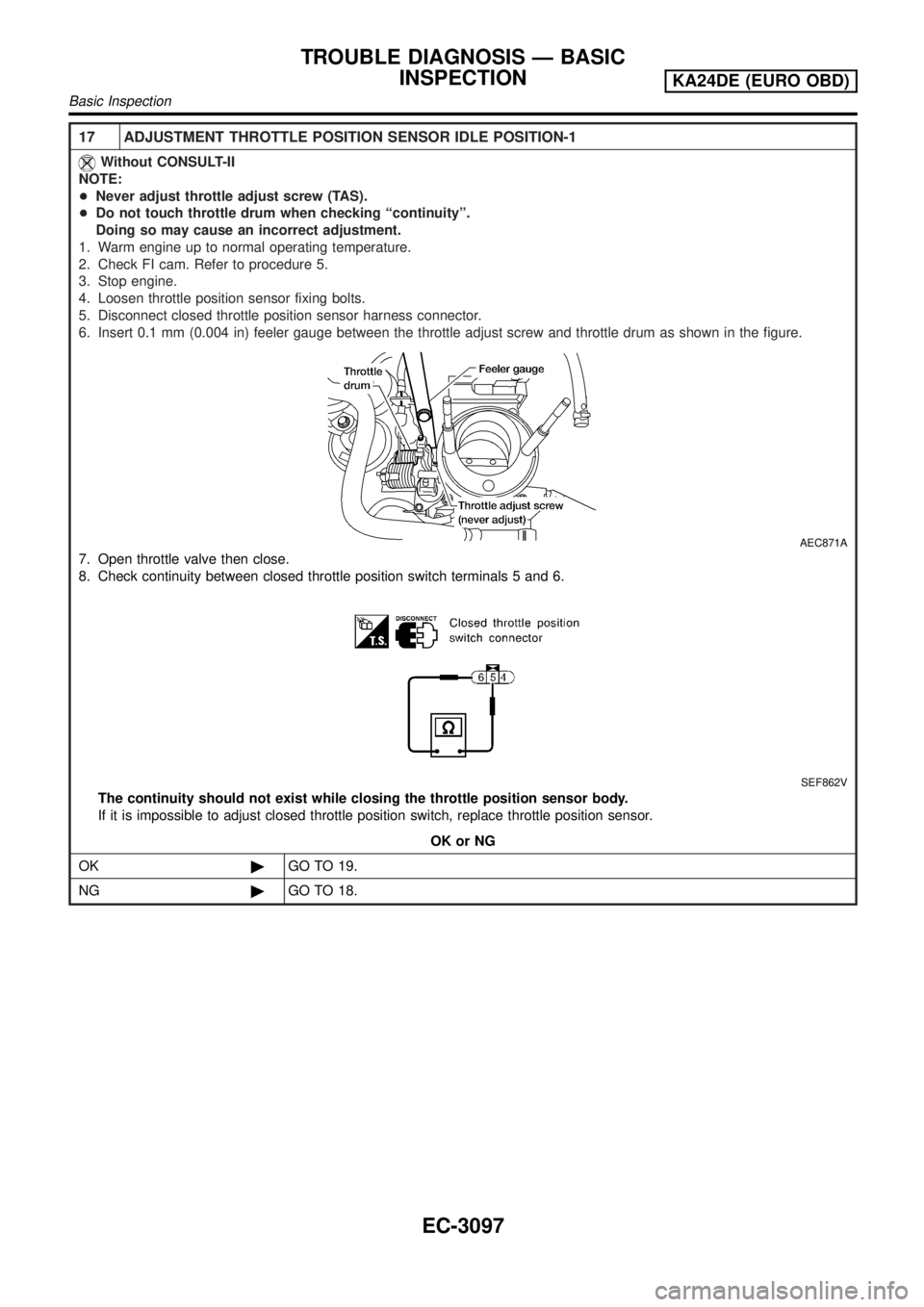

6. Insert 0.1 mm (0.004 in) feeler gauge between the throttle adjust screw and throttle drum as shown in the figure.

AEC871A

7. Open throttle valve then close.

8. Check continuity between closed throttle position switch terminals 5 and 6.

SEF862V

The continuity should not exist while closing the throttle position sensor body.

If it is impossible to adjust closed throttle position switch, replace throttle position sensor.

OK or NG

OK©GO TO 19.

NG©GO TO 18.

TROUBLE DIAGNOSIS Ð BASIC

INSPECTION

KA24DE (EURO OBD)

Basic Inspection

EC-3097

Page 123 of 1306

18 ADJUSTMENT THROTTLE POSITION SENSOR IDLE POSITION-2

Without CONSULT-II

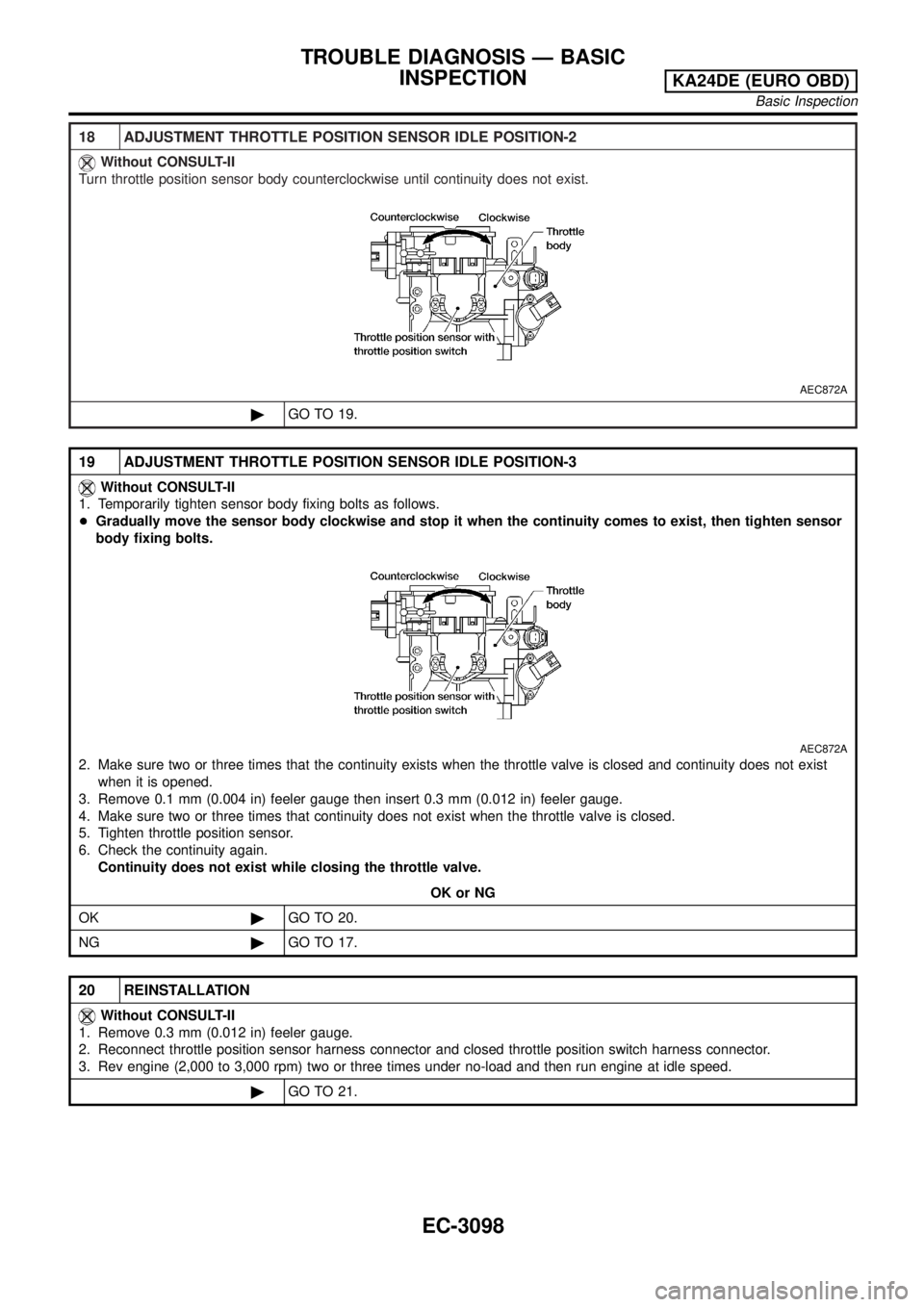

Turn throttle position sensor body counterclockwise until continuity does not exist.

AEC872A

©GO TO 19.

19 ADJUSTMENT THROTTLE POSITION SENSOR IDLE POSITION-3

Without CONSULT-II

1. Temporarily tighten sensor body fixing bolts as follows.

+Gradually move the sensor body clockwise and stop it when the continuity comes to exist, then tighten sensor

body fixing bolts.

AEC872A

2. Make sure two or three times that the continuity exists when the throttle valve is closed and continuity does not exist

when it is opened.

3. Remove 0.1 mm (0.004 in) feeler gauge then insert 0.3 mm (0.012 in) feeler gauge.

4. Make sure two or three times that continuity does not exist when the throttle valve is closed.

5. Tighten throttle position sensor.

6. Check the continuity again.

Continuity does not exist while closing the throttle valve.

OK or NG

OK©GO TO 20.

NG©GO TO 17.

20 REINSTALLATION

Without CONSULT-II

1. Remove 0.3 mm (0.012 in) feeler gauge.

2. Reconnect throttle position sensor harness connector and closed throttle position switch harness connector.

3. Rev engine (2,000 to 3,000 rpm) two or three times under no-load and then run engine at idle speed.

©GO TO 21.

TROUBLE DIAGNOSIS Ð BASIC

INSPECTION

KA24DE (EURO OBD)

Basic Inspection

EC-3098

Page 124 of 1306

21 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

NOTE:

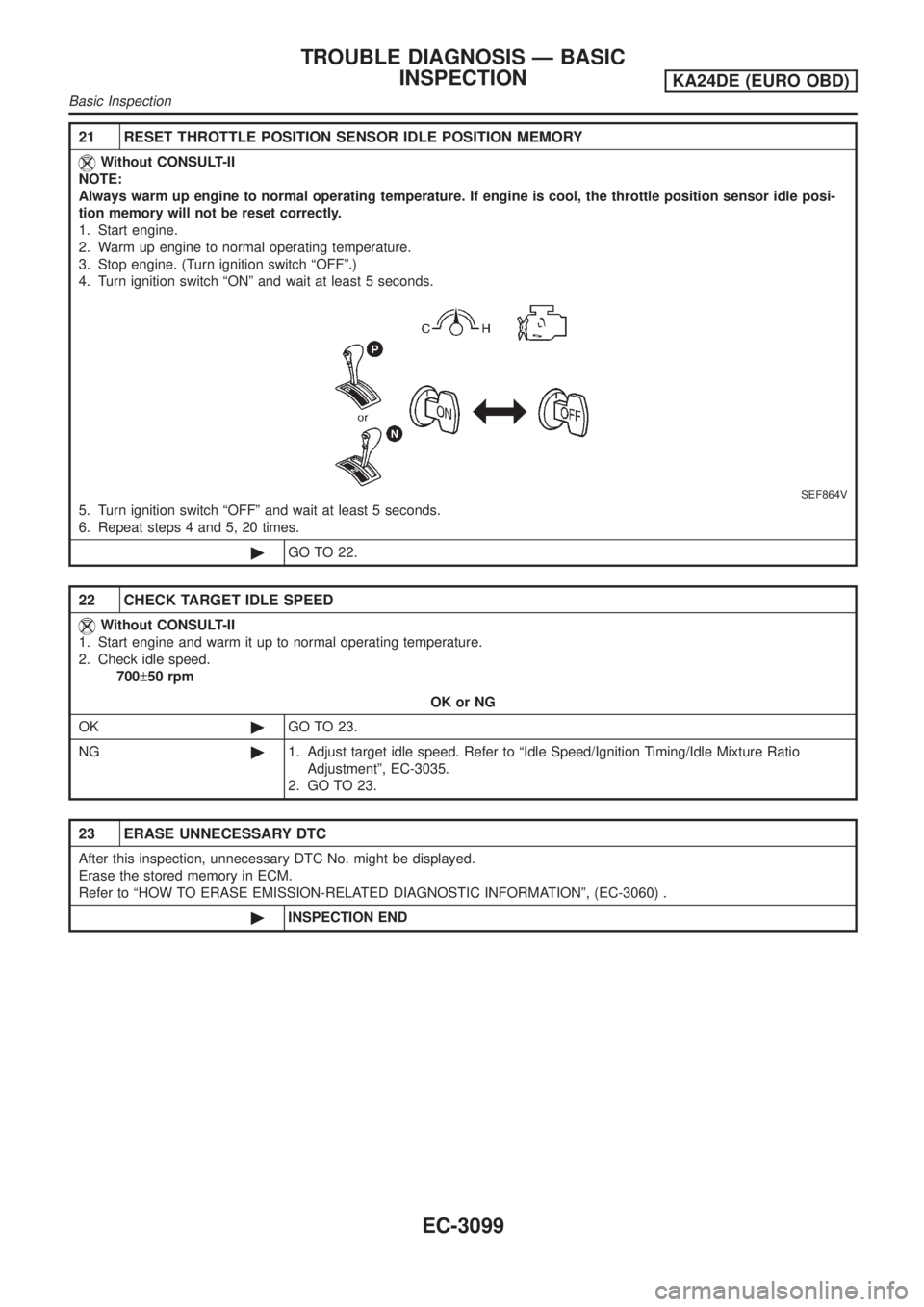

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Start engine.

2. Warm up engine to normal operating temperature.

3. Stop engine. (Turn ignition switch ªOFFº.)

4. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

5. Turn ignition switch ªOFFº and wait at least 5 seconds.

6. Repeat steps 4 and 5, 20 times.

©GO TO 22.

22 CHECK TARGET IDLE SPEED

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

700±50 rpm

OK or NG

OK©GO TO 23.

NG©1. Adjust target idle speed. Refer to ªIdle Speed/Ignition Timing/Idle Mixture Ratio

Adjustmentº, EC-3035.

2. GO TO 23.

23 ERASE UNNECESSARY DTC

After this inspection, unnecessary DTC No. might be displayed.

Erase the stored memory in ECM.

Refer to ªHOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATIONº, (EC-3060) .

©INSPECTION END

TROUBLE DIAGNOSIS Ð BASIC

INSPECTION

KA24DE (EURO OBD)

Basic Inspection

EC-3099

Page 125 of 1306

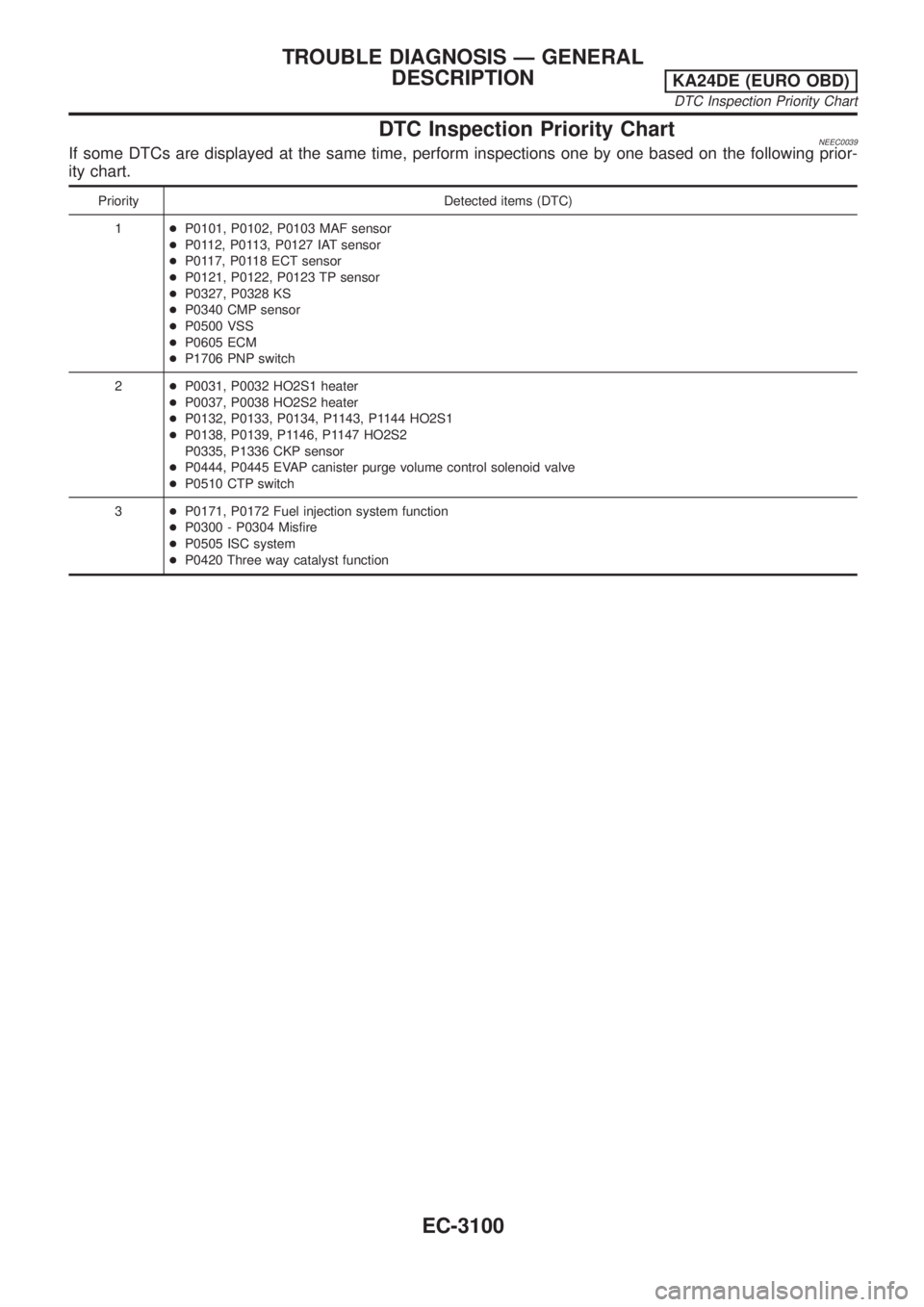

DTC Inspection Priority ChartNEEC0039If some DTCs are displayed at the same time, perform inspections one by one based on the following prior-

ity chart.

Priority Detected items (DTC)

1+P0101, P0102, P0103 MAF sensor

+P0112, P0113, P0127 IAT sensor

+P0117, P0118 ECT sensor

+P0121, P0122, P0123 TP sensor

+P0327, P0328 KS

+P0340 CMP sensor

+P0500 VSS

+P0605 ECM

+P1706 PNP switch

2+P0031, P0032 HO2S1 heater

+P0037, P0038 HO2S2 heater

+P0132, P0133, P0134, P1143, P1144 HO2S1

+P0138, P0139, P1146, P1147 HO2S2

P0335, P1336 CKP sensor

+P0444, P0445 EVAP canister purge volume control solenoid valve

+P0510 CTP switch

3+P0171, P0172 Fuel injection system function

+P0300 - P0304 Misfire

+P0505 ISC system

+P0420 Three way catalyst function

TROUBLE DIAGNOSIS Ð GENERAL

DESCRIPTION

KA24DE (EURO OBD)

DTC Inspection Priority Chart

EC-3100

Page 126 of 1306

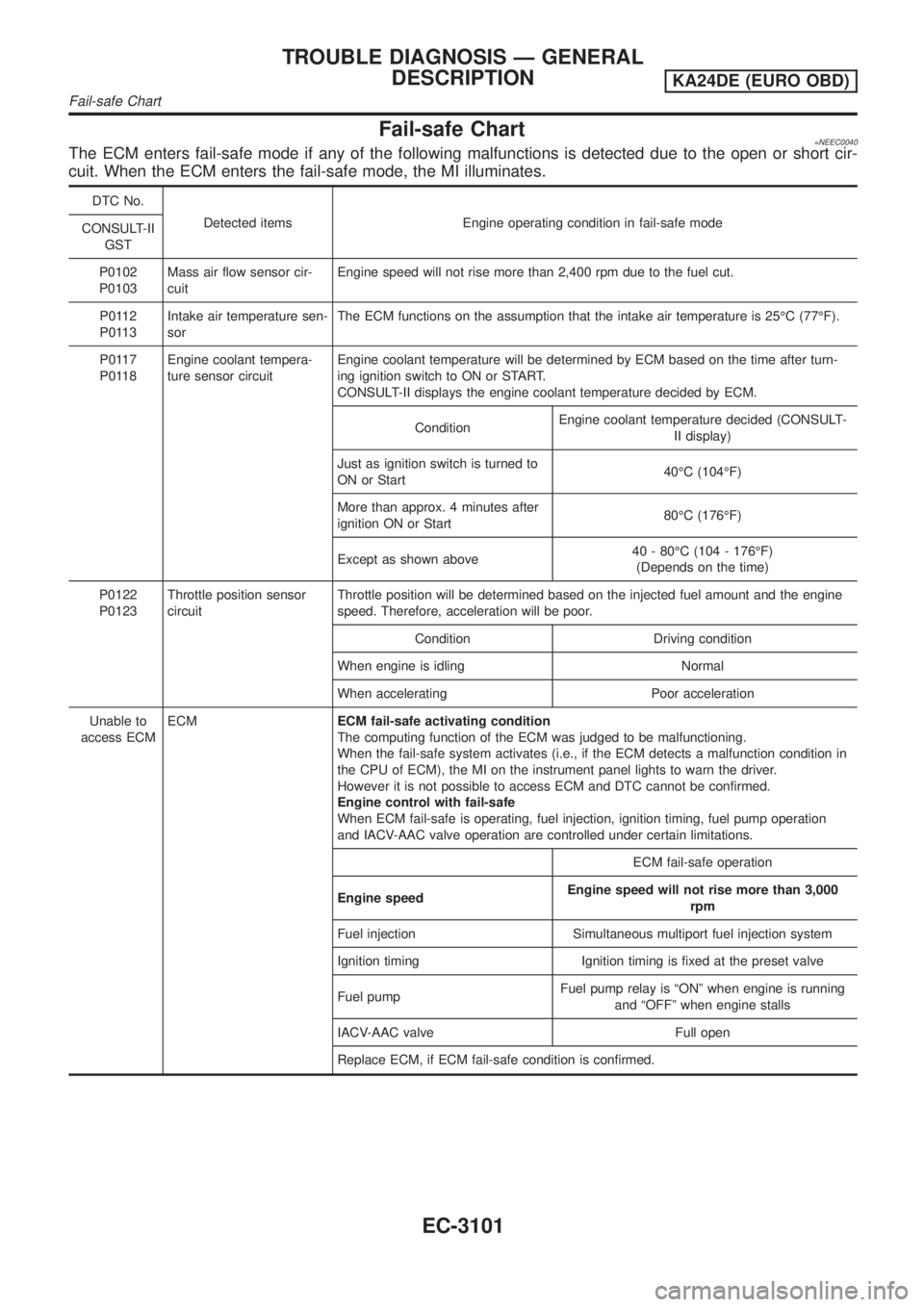

Fail-safe Chart=NEEC0040The ECM enters fail-safe mode if any of the following malfunctions is detected due to the open or short cir-

cuit. When the ECM enters the fail-safe mode, the MI illuminates.

DTC No.

Detected items Engine operating condition in fail-safe mode

CONSULT-II

GST

P0102

P0103Mass air flow sensor cir-

cuitEngine speed will not rise more than 2,400 rpm due to the fuel cut.

P0112

P0113Intake air temperature sen-

sorThe ECM functions on the assumption that the intake air temperature is 25ÉC (77ÉF).

P0117

P0118Engine coolant tempera-

ture sensor circuitEngine coolant temperature will be determined by ECM based on the time after turn-

ing ignition switch to ON or START.

CONSULT-II displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided (CONSULT-

II display)

Just as ignition switch is turned to

ON or Start40ÉC (104ÉF)

More than approx. 4 minutes after

ignition ON or Start80ÉC (176ÉF)

Except as shown above40 - 80ÉC (104 - 176ÉF)

(Depends on the time)

P0122

P0123Throttle position sensor

circuitThrottle position will be determined based on the injected fuel amount and the engine

speed. Therefore, acceleration will be poor.

Condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

Unable to

access ECMECMECM fail-safe activating condition

The computing function of the ECM was judged to be malfunctioning.

When the fail-safe system activates (i.e., if the ECM detects a malfunction condition in

the CPU of ECM), the MI on the instrument panel lights to warn the driver.

However it is not possible to access ECM and DTC cannot be confirmed.

Engine control with fail-safe

When ECM fail-safe is operating, fuel injection, ignition timing, fuel pump operation

and IACV-AAC valve operation are controlled under certain limitations.

ECM fail-safe operation

Engine speedEngine speed will not rise more than 3,000

rpm

Fuel injection Simultaneous multiport fuel injection system

Ignition timing Ignition timing is fixed at the preset valve

Fuel pumpFuel pump relay is ªONº when engine is running

and ªOFFº when engine stalls

IACV-AAC valve Full open

Replace ECM, if ECM fail-safe condition is confirmed.

TROUBLE DIAGNOSIS Ð GENERAL

DESCRIPTION

KA24DE (EURO OBD)

Fail-safe Chart

EC-3101

Page 127 of 1306

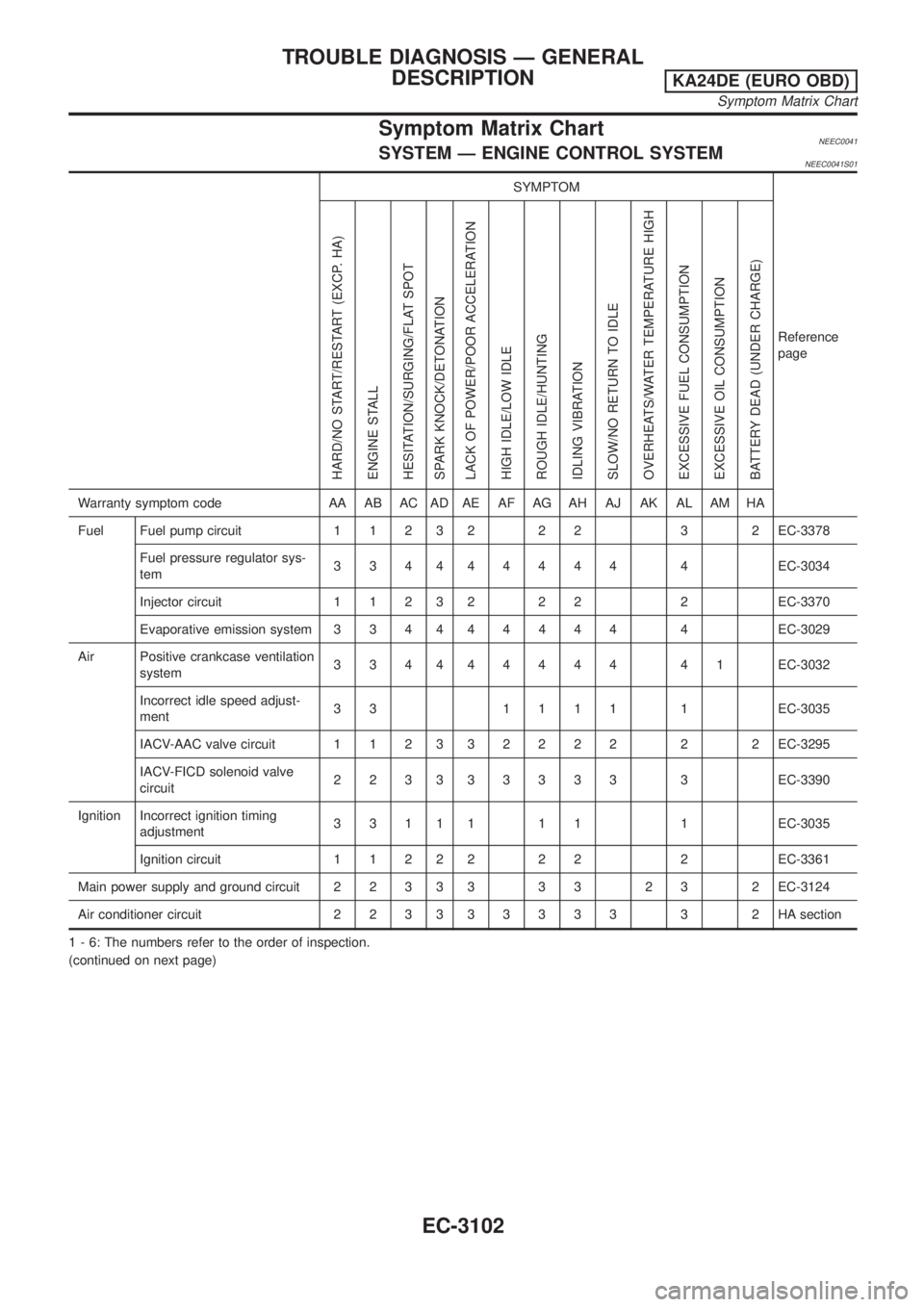

Symptom Matrix ChartNEEC0041SYSTEM Ð ENGINE CONTROL SYSTEMNEEC0041S01

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit 1 1 2 3 2 2 2 3 2 EC-3378

Fuel pressure regulator sys-

tem334444444 4EC-3034

Injector circuit 1 1 2 3 2 2 2 2 EC-3370

Evaporative emission system 3 3 4 444444 4EC-3029

Air Positive crankcase ventilation

system334444444 41EC-3032

Incorrect idle speed adjust-

ment33 1111 1EC-3035

IACV-AAC valve circuit 1 1 2 332222 2 2EC-3295

IACV-FICD solenoid valve

circuit223333333 3EC-3390

Ignition Incorrect ignition timing

adjustment3 3 1 1 1 1 1 1 EC-3035

Ignition circuit 1 1 2 2 2 2 2 2 EC-3361

Main power supply and ground circuit 2 2 3 3 3 3 3 2 3 2 EC-3124

Air conditioner circuit 2 2 3 333333 3 2HAsection

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL

DESCRIPTION

KA24DE (EURO OBD)

Symptom Matrix Chart

EC-3102

Page 128 of 1306

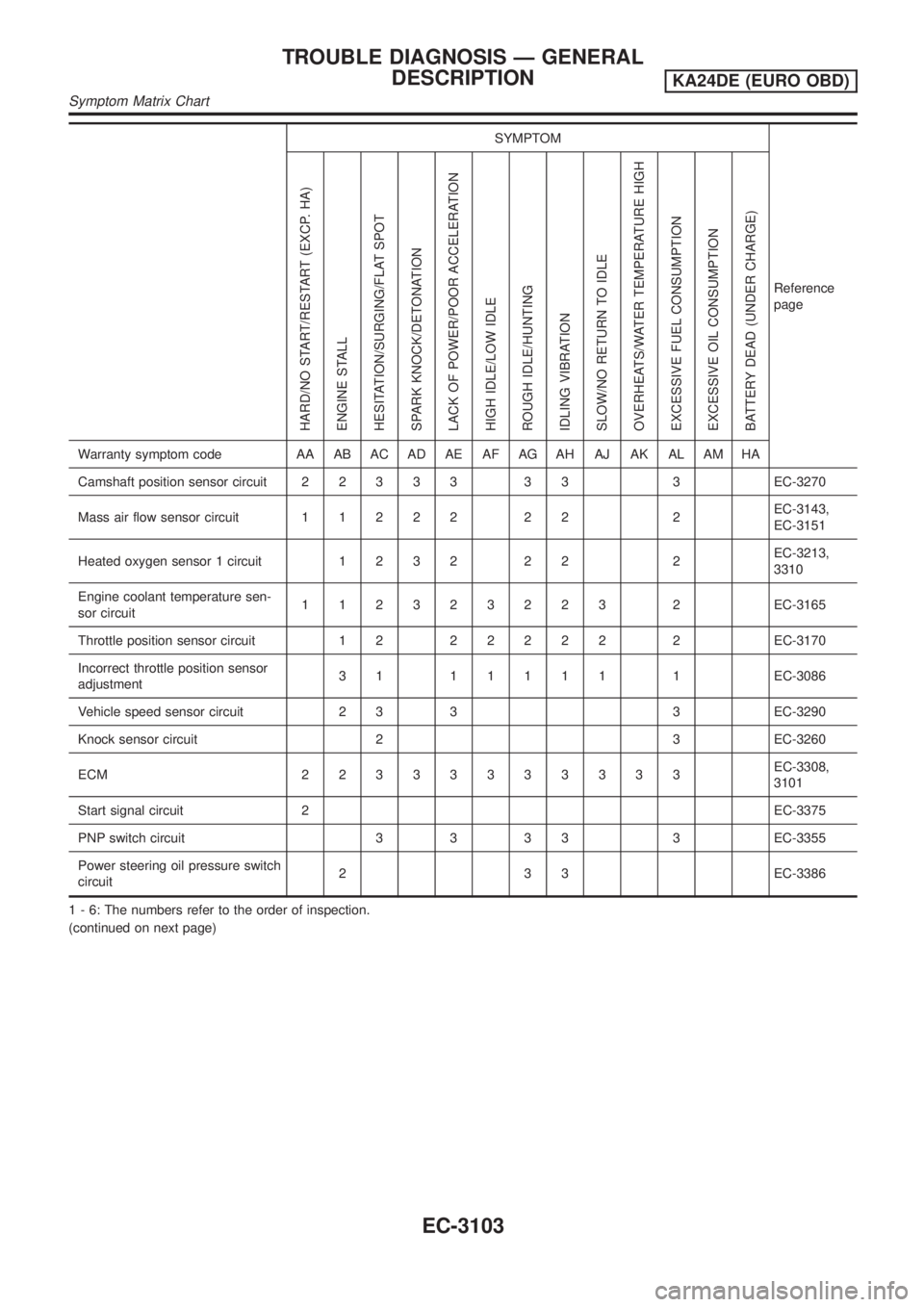

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Camshaft position sensor circuit22333 33 3EC-3270

Mass air flow sensor circuit11222 22 2EC-3143,

EC-3151

Heated oxygen sensor 1 circuit1232 22 2EC-3213,

3310

Engine coolant temperature sen-

sor circuit112323223 2EC-3165

Throttle position sensor circuit 1 222222 2EC-3170

Incorrect throttle position sensor

adjustment31 11111 1EC-3086

Vehicle speed sensor circuit 2 3 3 3 EC-3290

Knock sensor circuit 2 3 EC-3260

ECM 22333333333EC-3308,

3101

Start signal circuit 2EC-3375

PNP switch circuit 3 3 3 3 3 EC-3355

Power steering oil pressure switch

circuit2 3 3 EC-3386

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL

DESCRIPTION

KA24DE (EURO OBD)

Symptom Matrix Chart

EC-3103

Page 129 of 1306

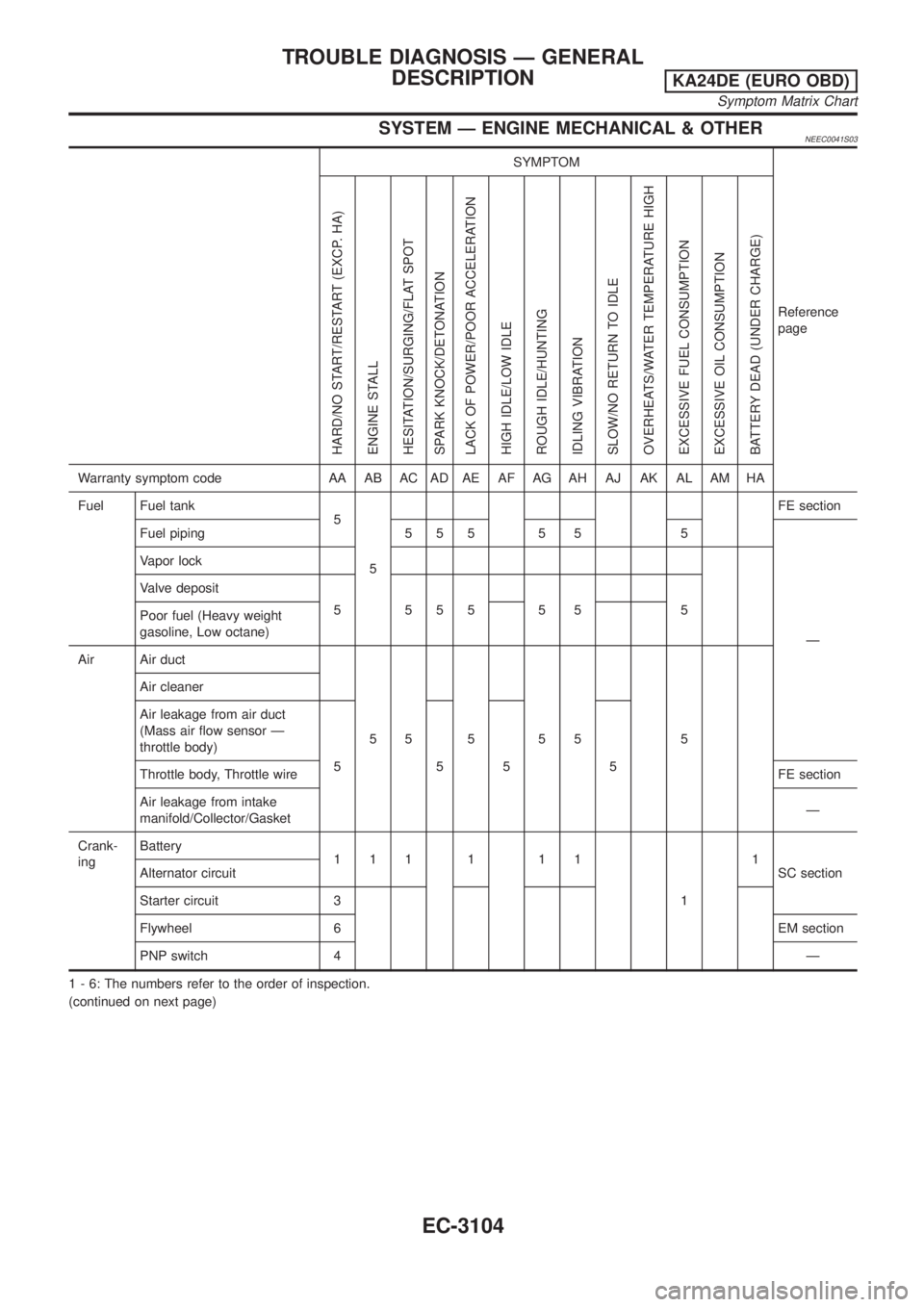

SYSTEM Ð ENGINE MECHANICAL & OTHERNEEC0041S03

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FE section

Fuel piping 5 5 5 5 5 5

Ð Vapor lock

Valve deposit

555555 5

Poor fuel (Heavy weight

gasoline, Low octane)

Air Air duct

55 5 55 5 Air cleaner

Air leakage from air duct

(Mass air flow sensor Ð

throttle body)

555 5

Throttle body, Throttle wireFE section

Air leakage from intake

manifold/Collector/GasketÐ

Crank-

ingBattery

111 1 11

11

SC section Alternator circuit

Starter circuit 3

Flywheel 6EM section

PNP switch 4Ð

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL

DESCRIPTION

KA24DE (EURO OBD)

Symptom Matrix Chart

EC-3104

Page 130 of 1306

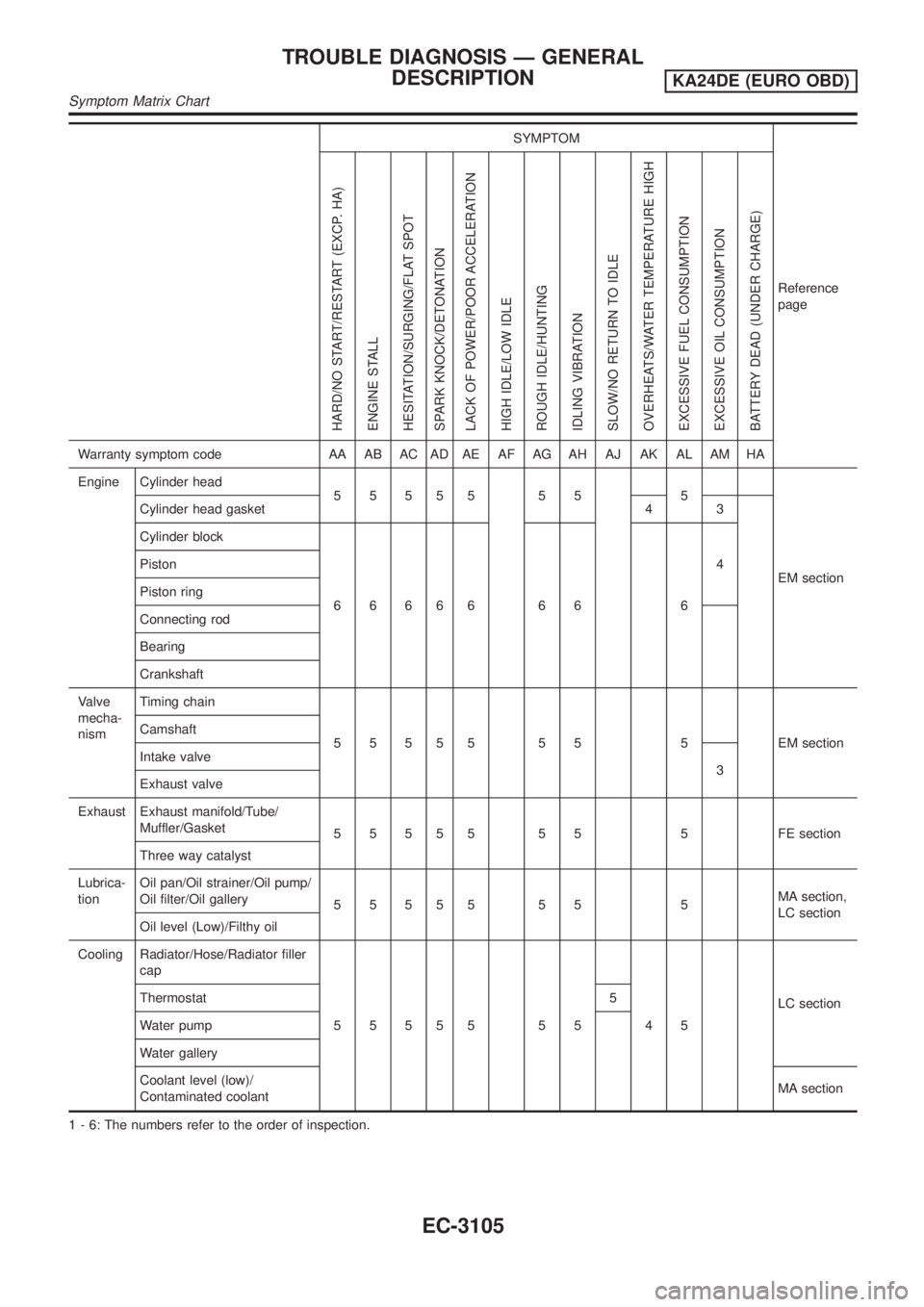

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine Cylinder head

55555 55 5

EM section Cylinder head gasket 4 3

Cylinder block

66666 66 64 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Valve

mecha-

nismTiming chain

5 5 5 5 5 5 5 5 EM section Camshaft

Intake valve

3

Exhaust valve

Exhaust Exhaust manifold/Tube/

Muffler/Gasket

5 5 5 5 5 5 5 5 FE section

Three way catalyst

Lubrica-

tionOil pan/Oil strainer/Oil pump/

Oil filter/Oil gallery

55555 55 5MA section,

LC section

Oil level (Low)/Filthy oil

Cooling Radiator/Hose/Radiator filler

cap

55555 55 45LC section Thermostat 5

Water pump

Water gallery

Coolant level (low)/

Contaminated coolantMA section

1 - 6: The numbers refer to the order of inspection.

TROUBLE DIAGNOSIS Ð GENERAL

DESCRIPTION

KA24DE (EURO OBD)

Symptom Matrix Chart

EC-3105