lock NISSAN PICK-UP 2001 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 373 of 1306

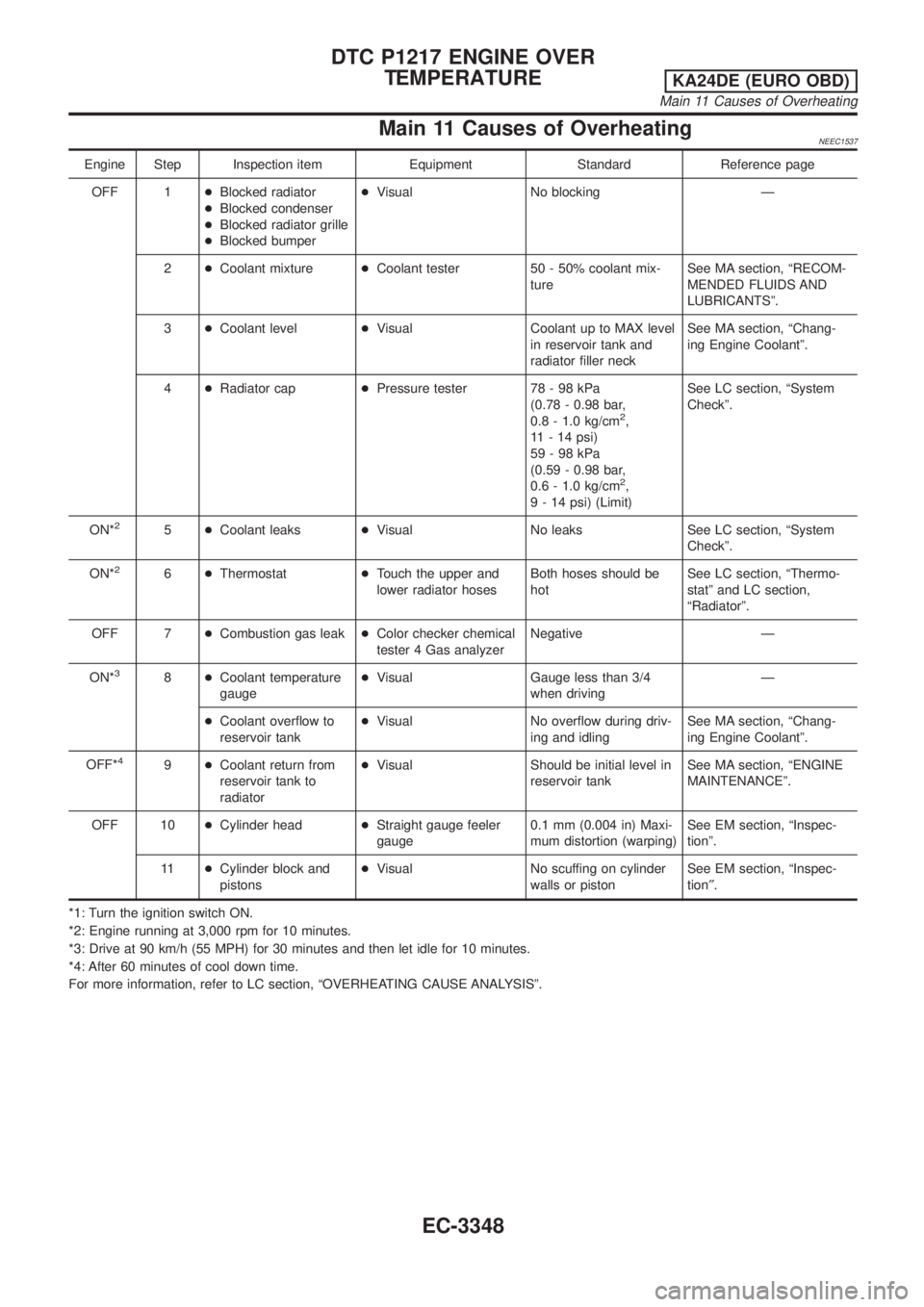

Main 11 Causes of OverheatingNEEC1537

Engine Step Inspection item Equipment Standard Reference page

OFF 1+Blocked radiator

+Blocked condenser

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 50 - 50% coolant mix-

tureSee MA section, ªRECOM-

MENDED FLUIDS AND

LUBRICANTSº.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee MA section, ªChang-

ing Engine Coolantº.

4+Radiator cap+Pressure tester 78 - 98 kPa

(0.78 - 0.98 bar,

0.8 - 1.0 kg/cm

2,

11 - 14 psi)

59-98kPa

(0.59 - 0.98 bar,

0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit)See LC section, ªSystem

Checkº.

ON*

25+Coolant leaks+Visual No leaks See LC section, ªSystem

Checkº.

ON*

26+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be

hotSee LC section, ªThermo-

statº and LC section,

ªRadiatorº.

OFF 7+Combustion gas leak+Color checker chemical

tester 4 Gas analyzerNegative Ð

ON*

38+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to

reservoir tank+Visual No overflow during driv-

ing and idlingSee MA section, ªChang-

ing Engine Coolantº.

OFF*

49+Coolant return from

reservoir tank to

radiator+Visual Should be initial level in

reservoir tankSee MA section, ªENGINE

MAINTENANCEº.

OFF 10+Cylinder head+Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See EM section, ªInspec-

tionº.

11+Cylinder block and

pistons+Visual No scuffing on cylinder

walls or pistonSee EM section, ªInspec-

tion².

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to LC section, ªOVERHEATING CAUSE ANALYSISº.

DTC P1217 ENGINE OVER

TEMPERATURE

KA24DE (EURO OBD)

Main 11 Causes of Overheating

EC-3348

Page 402 of 1306

4 DETECT MALFUNCTIONING PART

Check the following.

+40A fuse

+Harness connectors E101, M5

+Harness for open or short between ignition switch and 40A fuse

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector and ignition switch.

3. Check harness continuity between ECM terminal 20 and ignition switch terminal 6. Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Fuse block connectors M10, M12

+Harness for open or short between ECM and ignition switch

OK or NG

OK©GO TO 7.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3123.

©INSPECTION END

START SIGNALKA24DE (EURO OBD)

Diagnostic Procedure

EC-3377

Page 442 of 1306

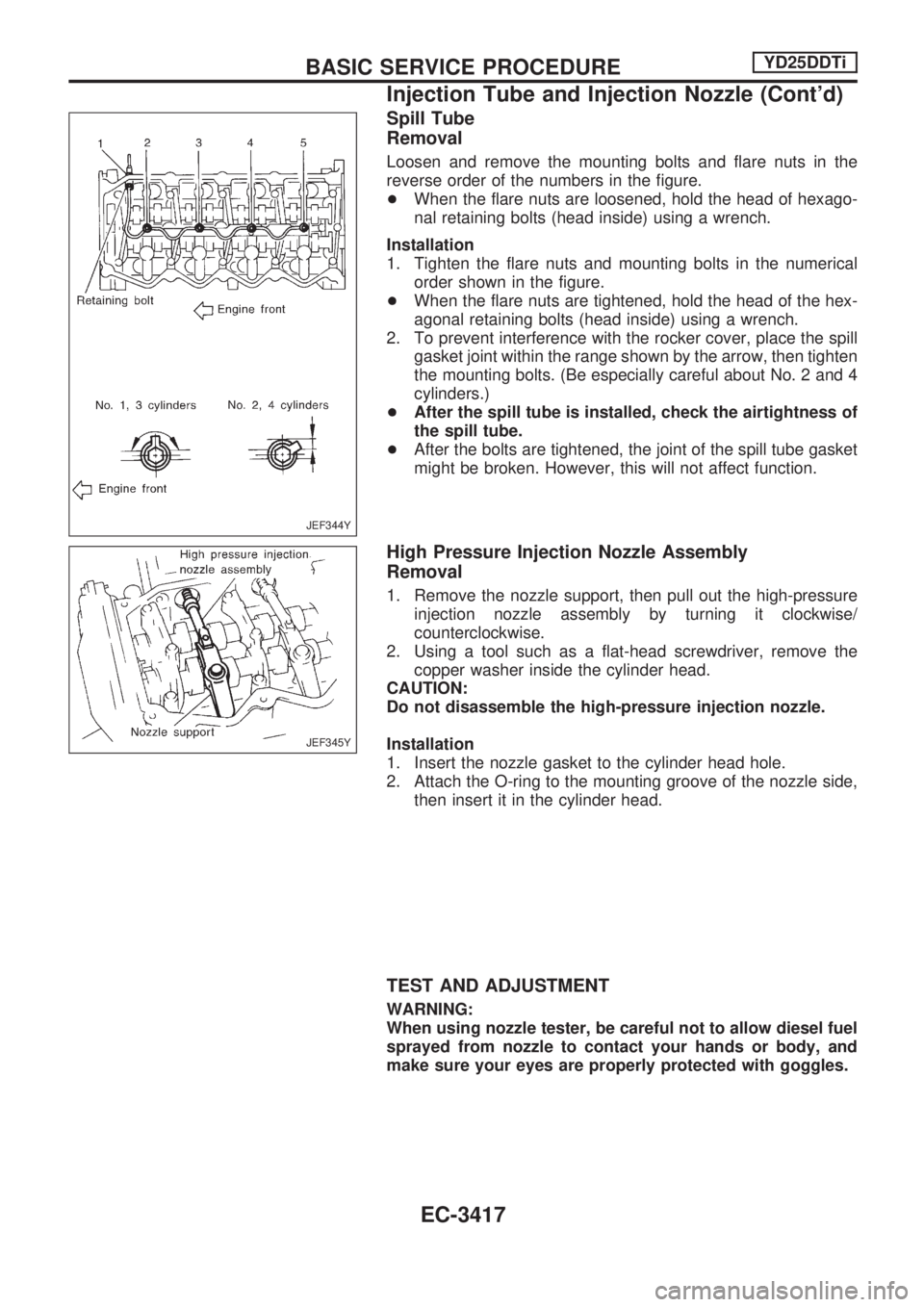

Spill Tube

Removal

Loosen and remove the mounting bolts and flare nuts in the

reverse order of the numbers in the figure.

+When the flare nuts are loosened, hold the head of hexago-

nal retaining bolts (head inside) using a wrench.

Installation

1. Tighten the flare nuts and mounting bolts in the numerical

order shown in the figure.

+When the flare nuts are tightened, hold the head of the hex-

agonal retaining bolts (head inside) using a wrench.

2. To prevent interference with the rocker cover, place the spill

gasket joint within the range shown by the arrow, then tighten

the mounting bolts. (Be especially careful about No. 2 and 4

cylinders.)

+After the spill tube is installed, check the airtightness of

the spill tube.

+After the bolts are tightened, the joint of the spill tube gasket

might be broken. However, this will not affect function.

High Pressure Injection Nozzle Assembly

Removal

1. Remove the nozzle support, then pull out the high-pressure

injection nozzle assembly by turning it clockwise/

counterclockwise.

2. Using a tool such as a flat-head screwdriver, remove the

copper washer inside the cylinder head.

CAUTION:

Do not disassemble the high-pressure injection nozzle.

Installation

1. Insert the nozzle gasket to the cylinder head hole.

2. Attach the O-ring to the mounting groove of the nozzle side,

then insert it in the cylinder head.

TEST AND ADJUSTMENT

WARNING:

When using nozzle tester, be careful not to allow diesel fuel

sprayed from nozzle to contact your hands or body, and

make sure your eyes are properly protected with goggles.

JEF344Y

JEF345Y

BASIC SERVICE PROCEDUREYD25DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-3417

Page 445 of 1306

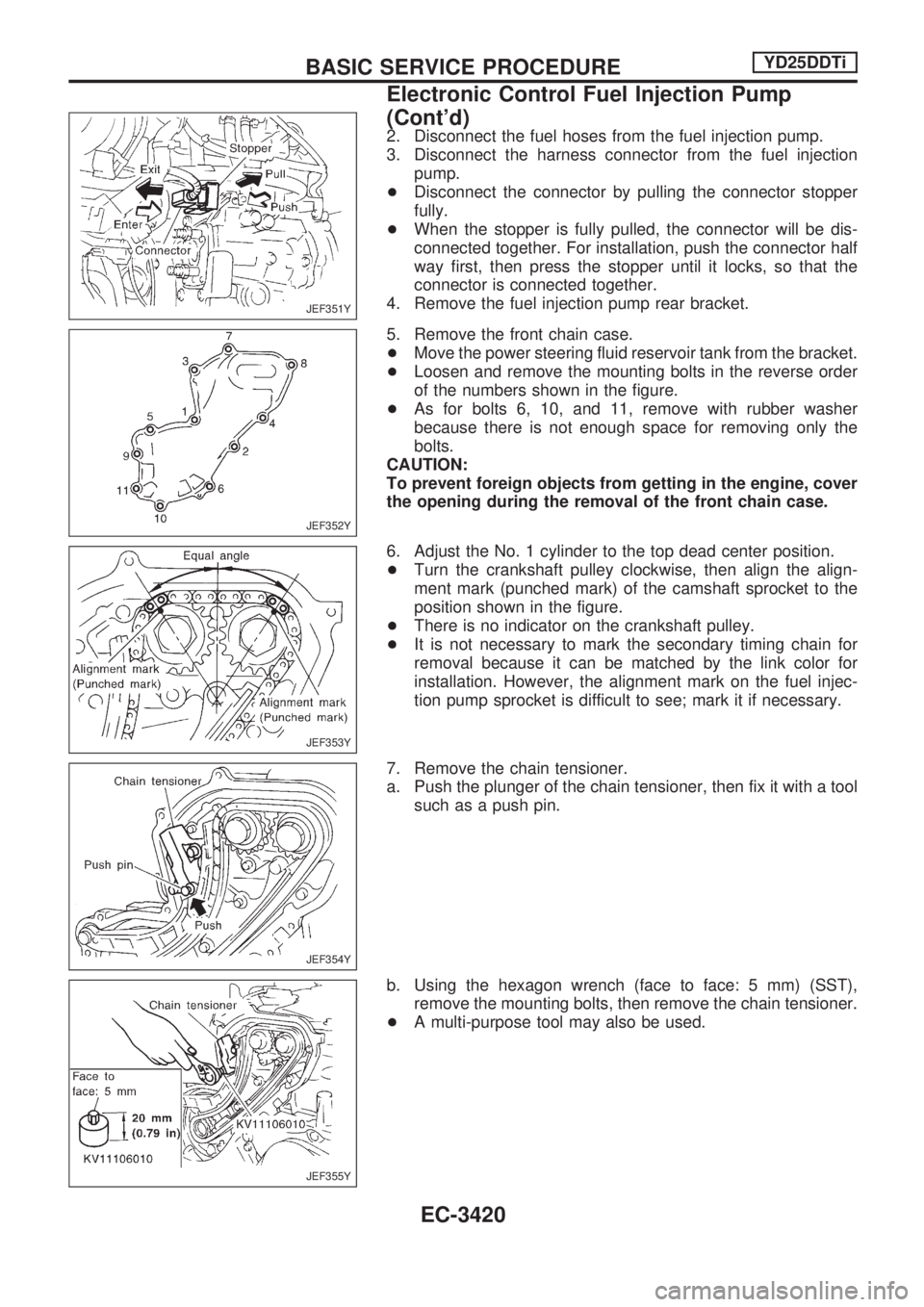

2. Disconnect the fuel hoses from the fuel injection pump.

3. Disconnect the harness connector from the fuel injection

pump.

+Disconnect the connector by pulling the connector stopper

fully.

+When the stopper is fully pulled, the connector will be dis-

connected together. For installation, push the connector half

way first, then press the stopper until it locks, so that the

connector is connected together.

4. Remove the fuel injection pump rear bracket.

5. Remove the front chain case.

+Move the power steering fluid reservoir tank from the bracket.

+Loosen and remove the mounting bolts in the reverse order

of the numbers shown in the figure.

+As for bolts 6, 10, and 11, remove with rubber washer

because there is not enough space for removing only the

bolts.

CAUTION:

To prevent foreign objects from getting in the engine, cover

the opening during the removal of the front chain case.

6. Adjust the No. 1 cylinder to the top dead center position.

+Turn the crankshaft pulley clockwise, then align the align-

ment mark (punched mark) of the camshaft sprocket to the

position shown in the figure.

+There is no indicator on the crankshaft pulley.

+It is not necessary to mark the secondary timing chain for

removal because it can be matched by the link color for

installation. However, the alignment mark on the fuel injec-

tion pump sprocket is difficult to see; mark it if necessary.

7. Remove the chain tensioner.

a. Push the plunger of the chain tensioner, then fix it with a tool

such as a push pin.

b. Using the hexagon wrench (face to face: 5 mm) (SST),

remove the mounting bolts, then remove the chain tensioner.

+A multi-purpose tool may also be used.

JEF351Y

JEF352Y

JEF353Y

JEF354Y

JEF355Y

BASIC SERVICE PROCEDUREYD25DDTi

Electronic Control Fuel Injection Pump

(Cont'd)

EC-3420

Page 450 of 1306

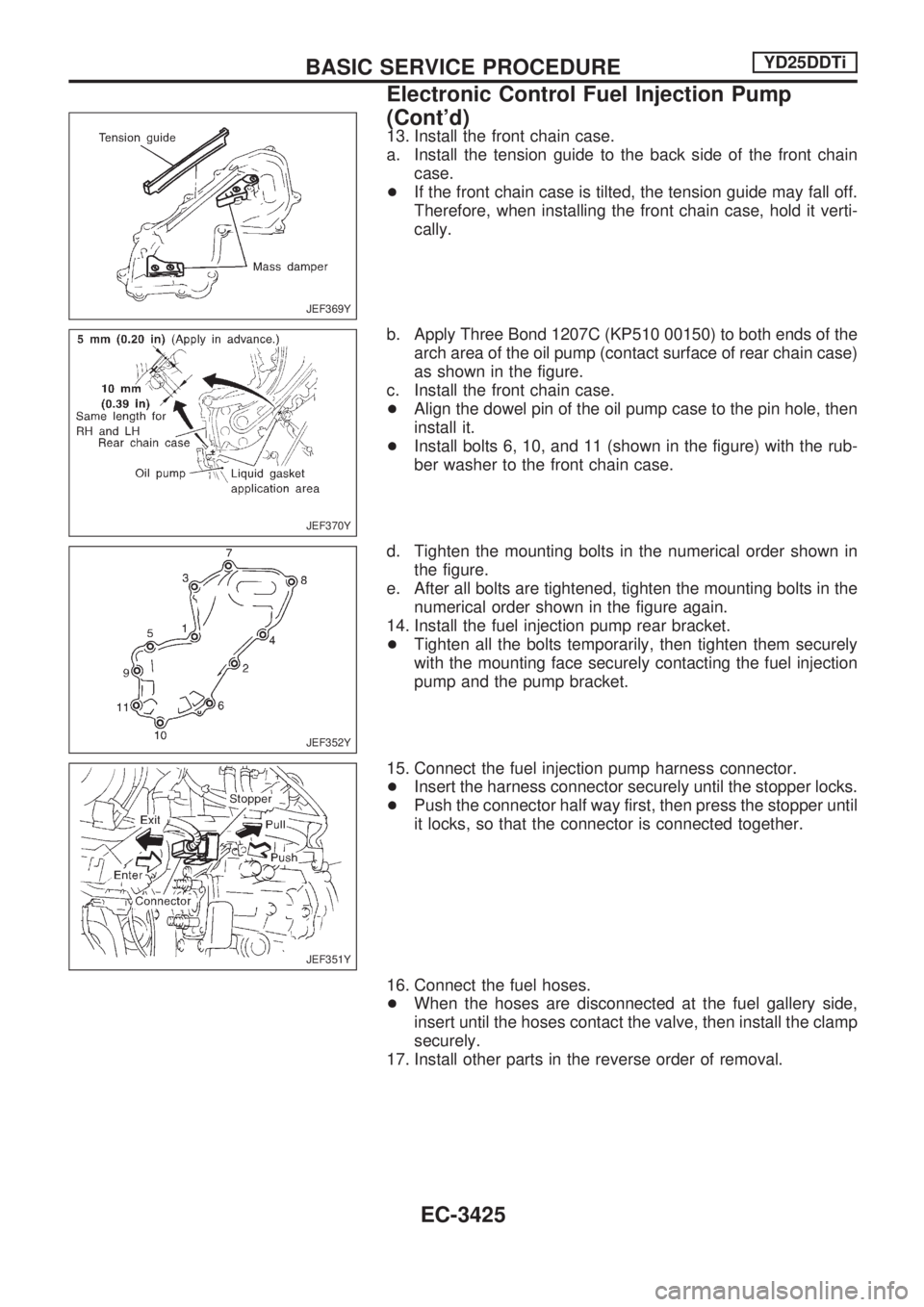

13. Install the front chain case.

a. Install the tension guide to the back side of the front chain

case.

+If the front chain case is tilted, the tension guide may fall off.

Therefore, when installing the front chain case, hold it verti-

cally.

b. Apply Three Bond 1207C (KP510 00150) to both ends of the

arch area of the oil pump (contact surface of rear chain case)

as shown in the figure.

c. Install the front chain case.

+Align the dowel pin of the oil pump case to the pin hole, then

install it.

+Install bolts 6, 10, and 11 (shown in the figure) with the rub-

ber washer to the front chain case.

d. Tighten the mounting bolts in the numerical order shown in

the figure.

e. After all bolts are tightened, tighten the mounting bolts in the

numerical order shown in the figure again.

14. Install the fuel injection pump rear bracket.

+Tighten all the bolts temporarily, then tighten them securely

with the mounting face securely contacting the fuel injection

pump and the pump bracket.

15. Connect the fuel injection pump harness connector.

+Insert the harness connector securely until the stopper locks.

+Push the connector half way first, then press the stopper until

it locks, so that the connector is connected together.

16. Connect the fuel hoses.

+When the hoses are disconnected at the fuel gallery side,

insert until the hoses contact the valve, then install the clamp

securely.

17. Install other parts in the reverse order of removal.

JEF369Y

JEF370Y

JEF352Y

JEF351Y

BASIC SERVICE PROCEDUREYD25DDTi

Electronic Control Fuel Injection Pump

(Cont'd)

EC-3425

Page 500 of 1306

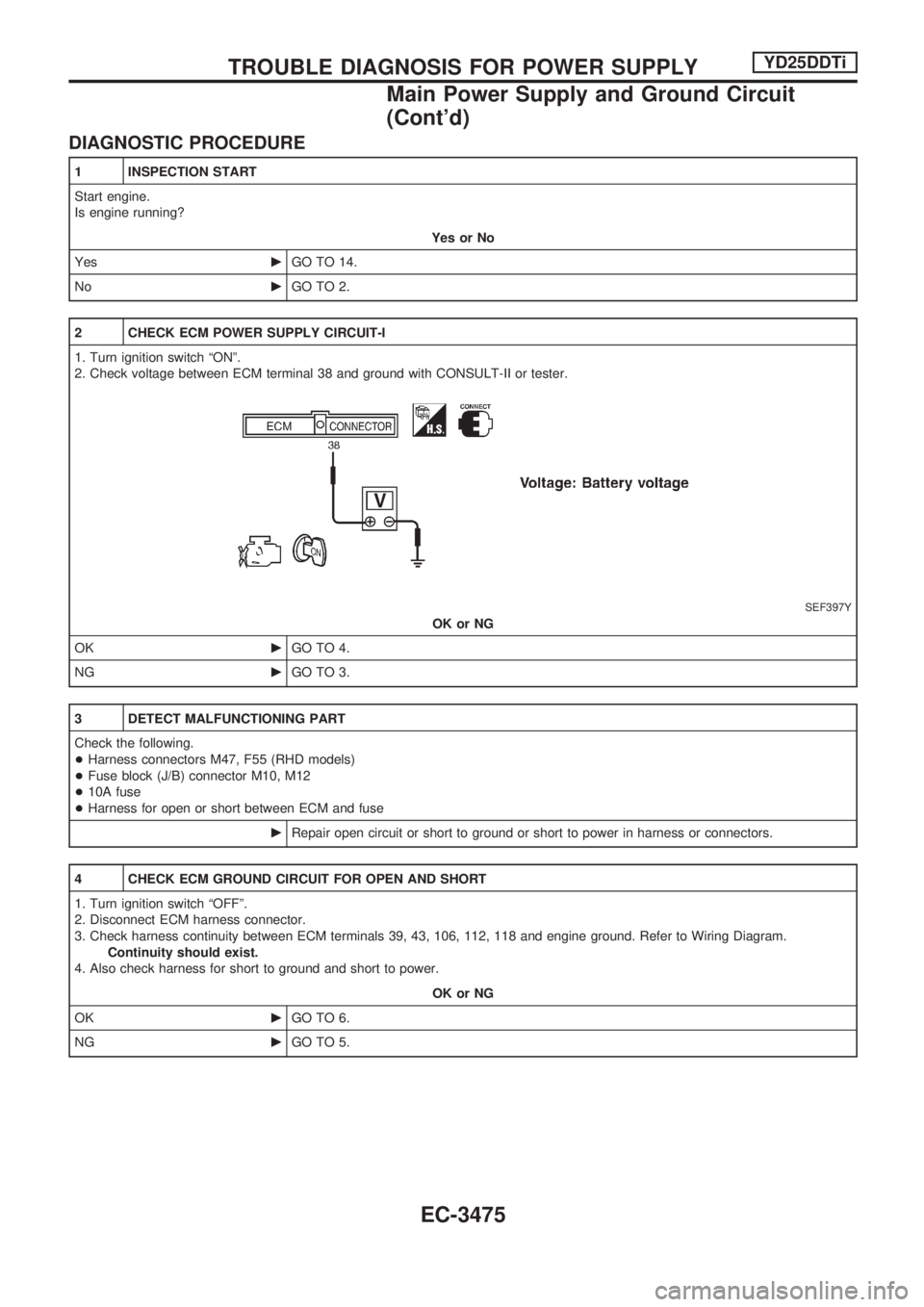

DIAGNOSTIC PROCEDURE

1 INSPECTION START

Start engine.

Is engine running?

Yes or No

YescGO TO 14.

NocGO TO 2.

2 CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 38 and ground with CONSULT-II or tester.

SEF397Y

OK or NG

OKcGO TO 4.

NGcGO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M47, F55 (RHD models)

+Fuse block (J/B) connector M10, M12

+10A fuse

+Harness for open or short between ECM and fuse

cRepair open circuit or short to ground or short to power in harness or connectors.

4 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 39, 43, 106, 112, 118 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 6.

NGcGO TO 5.

TROUBLE DIAGNOSIS FOR POWER SUPPLYYD25DDTi

Main Power Supply and Ground Circuit

(Cont'd)

EC-3475

Page 525 of 1306

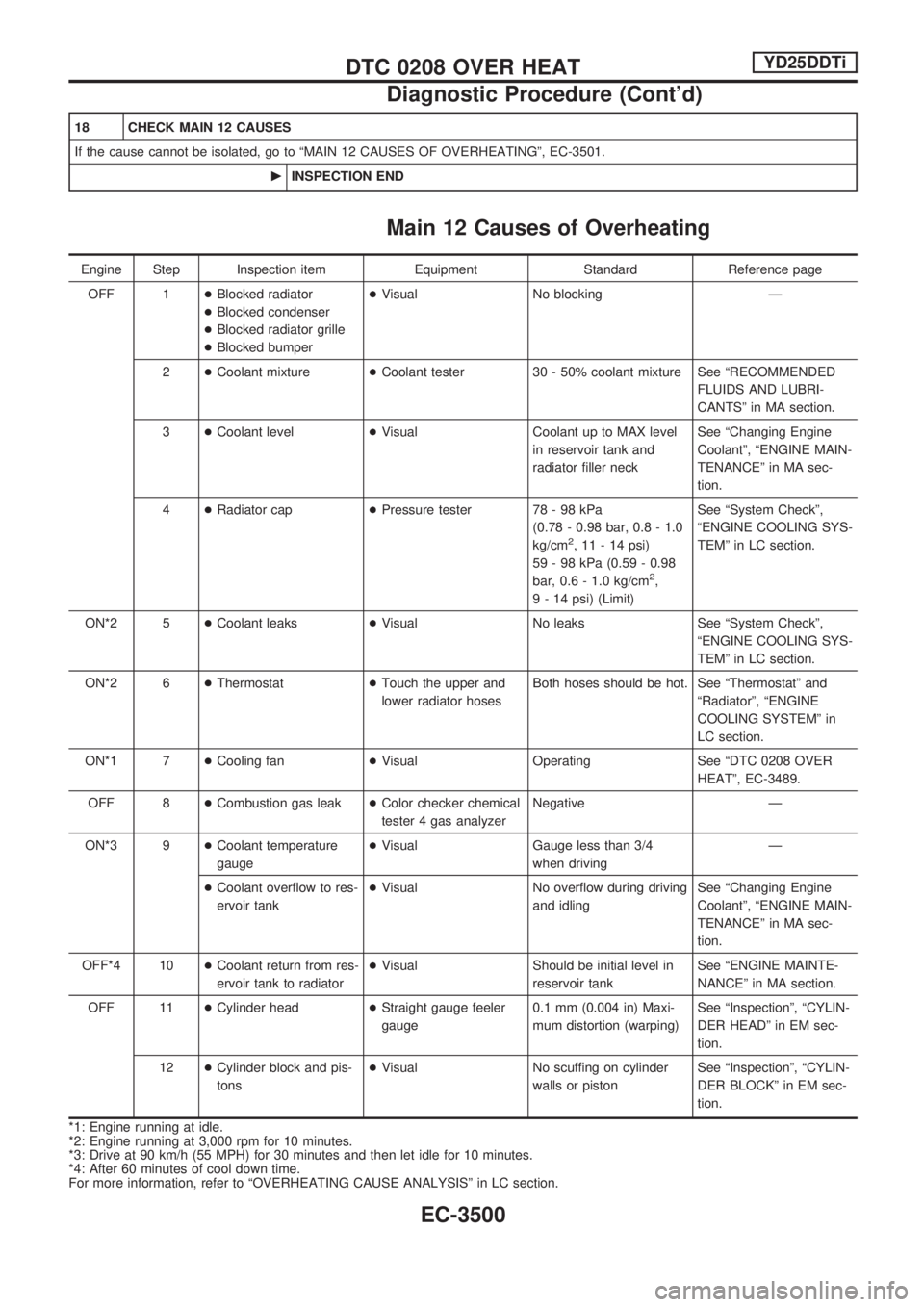

18 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-3501.

cINSPECTION END

Main 12 Causes of Overheating

Engine Step Inspection item Equipment Standard Reference page

OFF 1+Blocked radiator

+Blocked condenser

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 30 - 50% coolant mixture See ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

4+Radiator cap+Pressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit)See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 5+Coolant leaks+Visual No leaks See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 6+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be hot. See ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*1 7+Cooling fan+Visual Operating See ªDTC 0208 OVER

HEATº, EC-3489.

OFF 8+Combustion gas leak+Color checker chemical

tester 4 gas analyzerNegative Ð

ON*3 9+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to res-

ervoir tank+Visual No overflow during driving

and idlingSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

OFF*4 10+Coolant return from res-

ervoir tank to radiator+Visual Should be initial level in

reservoir tankSee ªENGINE MAINTE-

NANCEº in MA section.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ªInspectionº, ªCYLIN-

DER HEADº in EM sec-

tion.

12+Cylinder block and pis-

tons+Visual No scuffing on cylinder

walls or pistonSee ªInspectionº, ªCYLIN-

DER BLOCKº in EM sec-

tion.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

DTC 0208 OVER HEATYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3500

Page 564 of 1306

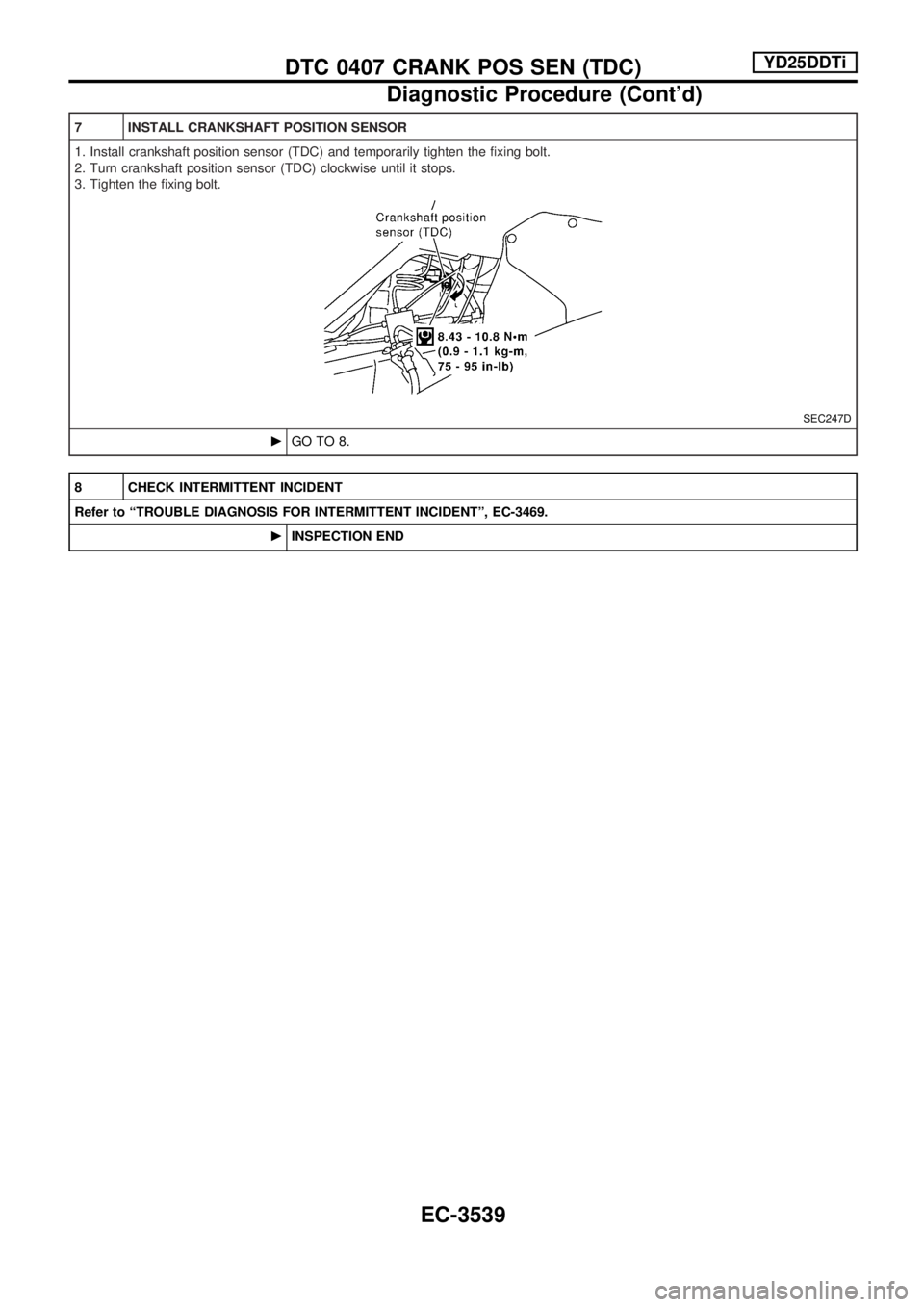

7 INSTALL CRANKSHAFT POSITION SENSOR

1. Install crankshaft position sensor (TDC) and temporarily tighten the fixing bolt.

2. Turn crankshaft position sensor (TDC) clockwise until it stops.

3. Tighten the fixing bolt.

SEC247D

cGO TO 8.

8 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

cINSPECTION END

DTC 0407 CRANK POS SEN (TDC)YD25DDTi

Diagnostic Procedure (Cont'd)

EC-3539

Page 657 of 1306

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M48, F54 (RHD models)

+10A fuse

+Fuse block (J/B) connectors M10, M12

+Harness for open or short between ECM and ignition switch

cRepair open circuit or short to ground or short to power in harness or connectors.

4 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

cINSPECTION END

START SIGNALYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3632

Page 677 of 1306

METER AND GAUGES....................................... 3056

System Description .......................................... 3056

Combination Meter/With Tachometer .............. 3057

Combination Meter/Without Tachometer ......... 3058

Schematic/With Tachometer ............................ 3059

Schematic/Without Tachometer ....................... 3060

Construction ..................................................... 3061

Wiring Diagram - METER -/Gasoline Engine

with Tachometer .............................................. 3062

Wiring Diagram - METER -/Gasoline Engine

without Tachometer ......................................... 3064

Wiring Diagram - METER -/LHD Diesel Engine

Models with Tachometer.................................. 3065

Wiring Diagram - METER -/RHD Diesel

Engine Models with Tachometer ..................... 3067

Wiring Diagram - METER -/Diesel Engine

without Tachometer ......................................... 3069

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode ................ 3070

Trouble Diagnoses/With Tachometer .............. 3071

Trouble Diagnoses/Without Tachometer ......... 3076

WARNING LAMPS.............................................. 3081

Schematic/With Tachometer ............................ 3081

Schematic/Without Tachometer ....................... 3082

Wiring Diagram - WARN -/Gasoline Engine

with Tachometer .............................................. 3083

Wiring Diagram - WARN -/Gasoline Engine

without Tachometer ......................................... 3087

Wiring Diagram - WARN -/Diesel Engine with

Tachometer ...................................................... 3091

Wiring Diagram - WARN -/Diesel Engine

without Tachometer ......................................... 3095

A/T INDICATOR................................................... 3100

Wiring Diagram - AT/IND -/RHD Models ......... 3100

Wiring Diagram - CHIME -/LHD Models.......... 3101

Wiring Diagram - CHIME -/RHD Models ......... 3102

FRONT WIPER AND WASHER.......................... 3103

Wiring Diagram - WIPER -/Without Intermittent

for Floor-shift .................................................... 3103

Wiring Diagram - WIPER -/Without Intermittent

for RHD Column-shift Models .......................... 3106

HEADLAMP WASHER........................................ 3108

Wiring Diagram - HLC - ................................... 3108

HORN................................................................... 3109

Wiring Diagram - HORN -................................ 3109

CIGARETTE LIGHTER........................................ 3110

Wiring Diagram - CIGAR - ............................... 3110

CLOCK................................................................. 3111

Wiring Diagram - CLOCK - .............................. 3111

REAR WINDOW DEFOGGER AND MIRROR

DEFOGGER......................................................... 3112

Wiring Diagram - DEF - ................................... 3112

AUDIO.................................................................. 3113

Wiring Diagram - AUDIO -/LHD Models .......... 3113Wiring Diagram - AUDIO -/RHD Models ......... 3114

AUDIO ANTENNA............................................... 3115

Power Antenna/Wiring Diagram - P/ANT - ...... 3115

POWER DOOR MIRROR.................................... 3116

Wiring Diagram - MIRROR -/LHD Models....... 3116

Wiring Diagram - MIRROR -/RHD Models ...... 3117

HEATED SEAT.................................................... 3118

Wiring Diagram - H/SEAT - ............................. 3118

POWER WINDOW............................................... 3120

Schematic/Without Interruption Detection

Function ........................................................... 3120

Schematic/With Interruption Detection

Function ........................................................... 3121

Wiring Diagram - WINDOW -/Without

Interruption Detection Function........................ 3122

Wiring Diagram - WINDOW -/With Interruption

Detection Function ........................................... 3126

Trouble Diagnoses/Without Interruption

Detection Function ........................................... 3130

Trouble Diagnoses/With Interruption Detection

Function ........................................................... 3131

POWER DOOR LOCK......................................... 3133

Wiring Diagram - D/LOCK - ............................. 3133

MULTI-REMOTE CONTROL SYSTEM............... 3135

System Description .......................................... 3135

MULTI-REMOTE CONTROL SYSTEM............... 3136

Wiring Diagram - MULTI - ............................... 3136

Trouble Diagnoses ........................................... 3137

ID Code Entry Procedure ................................ 3139

Remote Controller Battery Replacement ......... 3140

THEFT WARNING SYSTEM............................... 3141

Wiring Diagram - PRWIRE - ............................ 3141

NATS (Nissan Anti-Theft System).................... 3142

Component Parts and Harness Connector

Location............................................................ 3142

System Description .......................................... 3143

System Composition ........................................ 3144

Wiring Diagram - NATS -/LHD Models............ 3145

Wiring Diagram - NATS -/RHD Diesel Engine

Models.............................................................. 3146

CONSULT-II ..................................................... 3147

Trouble Diagnoses ........................................... 3149

How to Replace NATS IMMU .......................... 3160

LOCATION OF ELECTRICAL UNITS................. 3161

Engine Compartment ....................................... 3161

Passenger Compartment ................................. 3162

HARNESS LAYOUT............................................ 3164

Main Harness ................................................... 3164

Engine Room Harness..................................... 3174

Engine Control Harness/KA engine ................. 3182

Engine Control Harness................................... 3184

Engine Harness ............................................... 3185

Alternator Harness ........................................... 3187

Instrument Harness.......................................... 3189

EL-3002