check engine NISSAN PICK-UP 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 557 of 1306

Diagnostic Procedure

1 CHECK INTAKE AIR SYSTEM

Listen for an intake air leak and clogging after the intake air temperature sensor.

OK or NG

OKcGO TO 2.

NGcRepair or replace.

2 CHECK CHARGE AIR PRESSURE SENSOR

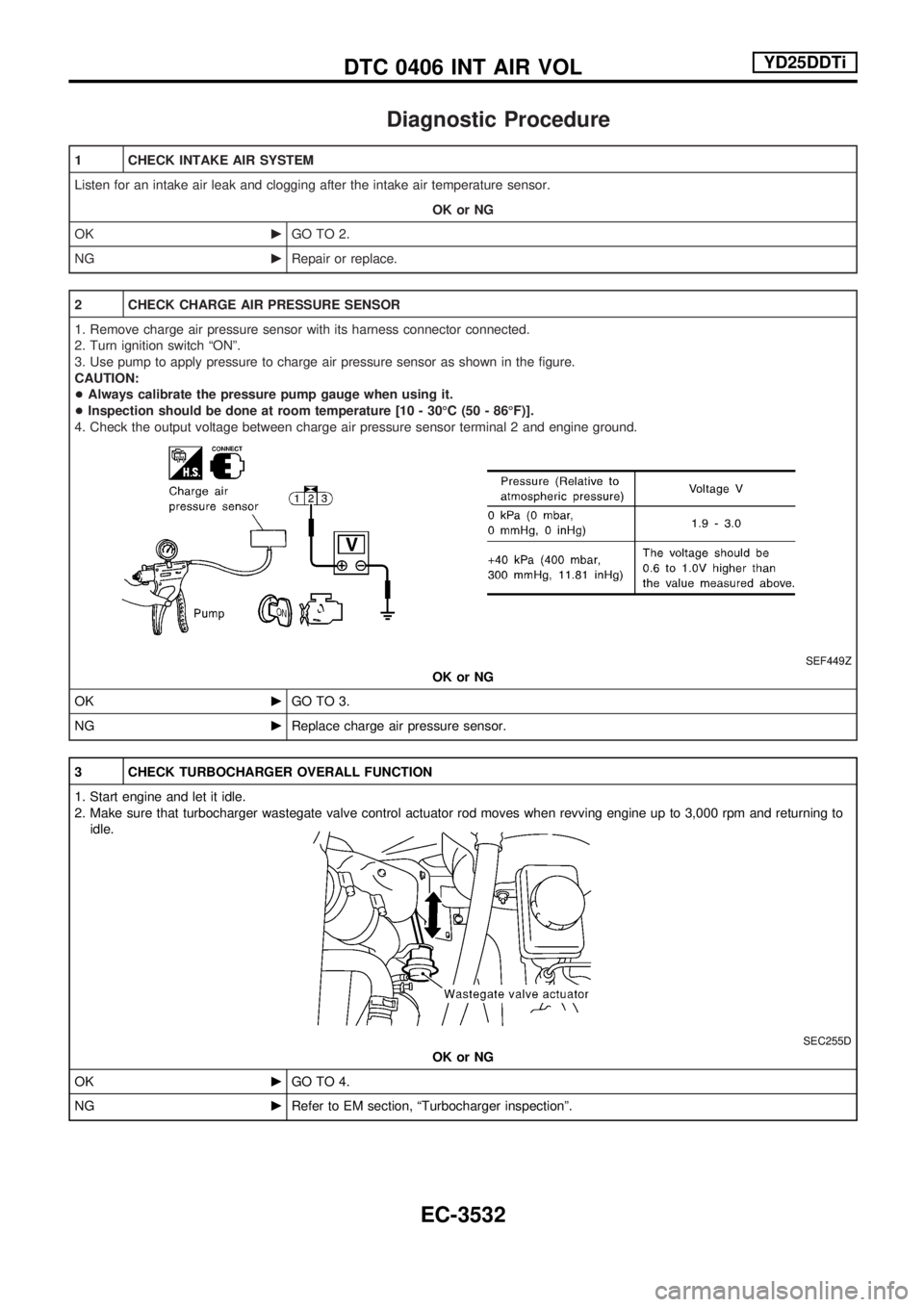

1. Remove charge air pressure sensor with its harness connector connected.

2. Turn ignition switch ªONº.

3. Use pump to apply pressure to charge air pressure sensor as shown in the figure.

CAUTION:

+Always calibrate the pressure pump gauge when using it.

+Inspection should be done at room temperature [10 - 30ÉC (50 - 86ÉF)].

4. Check the output voltage between charge air pressure sensor terminal 2 and engine ground.

SEF449Z

OK or NG

OKcGO TO 3.

NGcReplace charge air pressure sensor.

3 CHECK TURBOCHARGER OVERALL FUNCTION

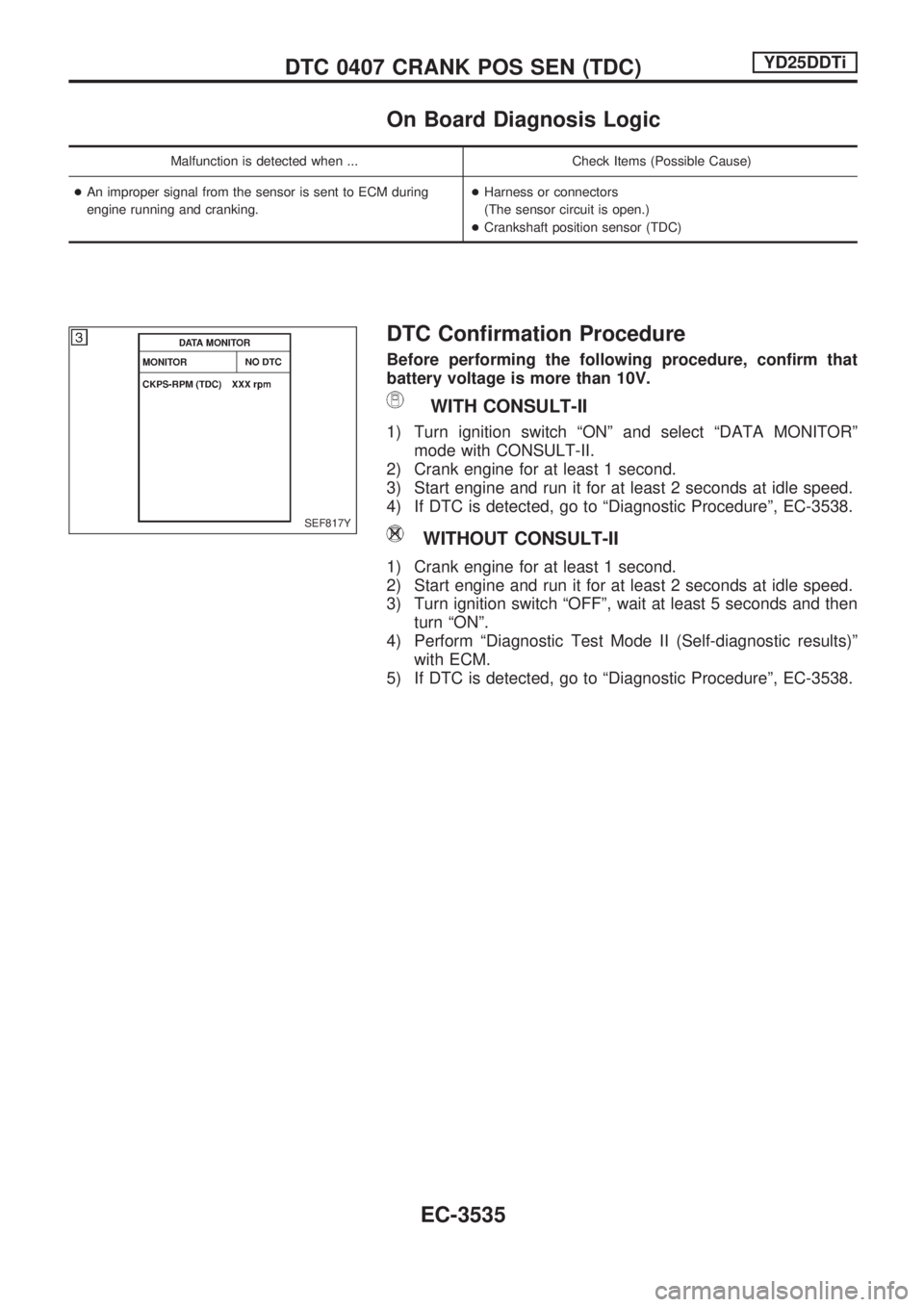

1. Start engine and let it idle.

2. Make sure that turbocharger wastegate valve control actuator rod moves when revving engine up to 3,000 rpm and returning to

idle.

SEC255D

OK or NG

OKcGO TO 4.

NGcRefer to EM section, ªTurbocharger inspectionº.

DTC 0406 INT AIR VOLYD25DDTi

EC-3532

Page 560 of 1306

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

+An improper signal from the sensor is sent to ECM during

engine running and cranking.+Harness or connectors

(The sensor circuit is open.)

+Crankshaft position sensor (TDC)

DTC Confirmation Procedure

Before performing the following procedure, confirm that

battery voltage is more than 10V.

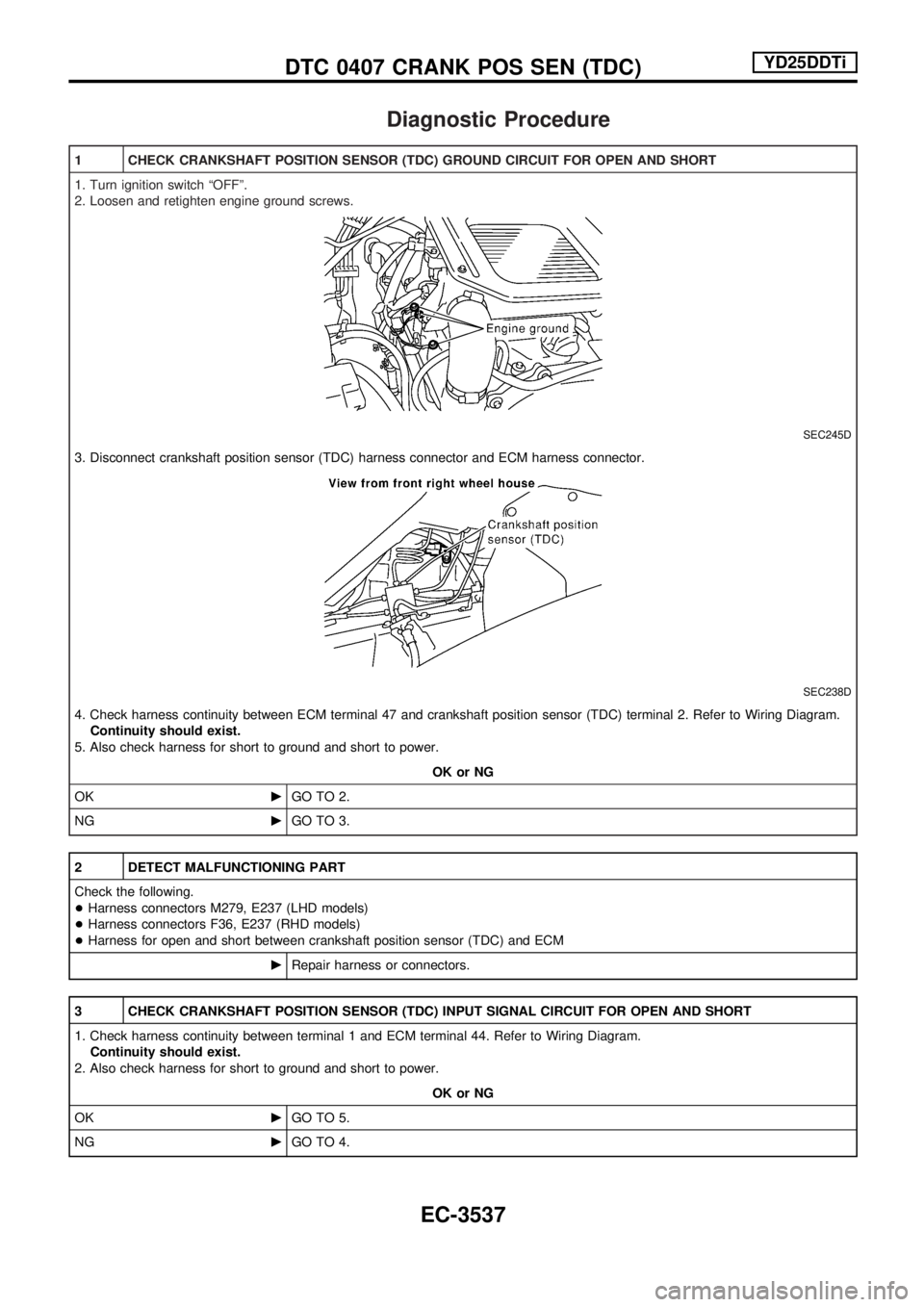

WITH CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº

mode with CONSULT-II.

2) Crank engine for at least 1 second.

3) Start engine and run it for at least 2 seconds at idle speed.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-3538.

WITHOUT CONSULT-II

1) Crank engine for at least 1 second.

2) Start engine and run it for at least 2 seconds at idle speed.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-3538.

SEF817Y

DTC 0407 CRANK POS SEN (TDC)YD25DDTi

EC-3535

Page 562 of 1306

Diagnostic Procedure

1 CHECK CRANKSHAFT POSITION SENSOR (TDC) GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEC245D

3. Disconnect crankshaft position sensor (TDC) harness connector and ECM harness connector.

SEC238D

4. Check harness continuity between ECM terminal 47 and crankshaft position sensor (TDC) terminal 2. Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 2.

NGcGO TO 3.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M279, E237 (LHD models)

+Harness connectors F36, E237 (RHD models)

+Harness for open and short between crankshaft position sensor (TDC) and ECM

cRepair harness or connectors.

3 CHECK CRANKSHAFT POSITION SENSOR (TDC) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between terminal 1 and ECM terminal 44. Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 5.

NGcGO TO 4.

DTC 0407 CRANK POS SEN (TDC)YD25DDTi

EC-3537

Page 565 of 1306

On Board Diagnosis Logic

The ECM checks if battery voltage is within the tolerance range for the engine control system.

Malfunction is detected when ... Check Items (Possible Cause)

+An abnormally high voltage from the battery is sent to ECM.+Incorrect jump starting

+Battery

+Alternator

+ECM

DTC Confirmation Procedure

With CONSULT-II

1)Check the following.

+Jumper cables are connected for jump starting.

+Battery or alternator has been replaced.

If the result is ªYesº for one item or more, skip the following steps and go to ªDiagnostic Procedureº,

EC-3541.

2) Check that the positive battery terminal is connected to battery properly. If NG, reconnect it properly.

3) Check that the alternator functions properly. Refer to EL section (ªCHARGING SYSTEMº).

4) Turn ignition switch ªONº and select ªDATA MONITORº mode with CONSULT-II.

5) Wait one minute.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-3541.

If DTC is not detected, go to next step.

7) Start engine and wait one minute at idle.

8) If DTC is detected, go to ªDiagnostic Procedureº, EC-3541.

Without CONSULT-II

1)Check the following.

+Jumper cables are connected for jump starting.

+Battery or alternator has been replaced.

If the result is ªYesº for one item or more, skip the following steps and go to ªDiagnostic Procedureº,

EC-3541.

2) Check that the positive battery terminal is connected to battery properly. If NG, reconnect it properly.

3) Check that the alternator functions properly. Refer to EL section (ªCHARGING SYSTEMº).

4) Turn ignition switch ªONº and wait one minute.

5) Turn ignition switch ªOFFº, wait 5 seconds and then turn ªONº.

6) Perform ªDiagnostic Test Mode II (Self-diagnostic result)º with ECM.

7) If DTC is detected, go to ªDiagnostic Procedureº, EC-3541.

If DTC is not detected, go to next step.

8) Start engine and wait one minute at idle.

9) Turn ignition switch ªOFFº, wait 5 seconds and then turn ªONº.

10) Perform ªDiagnostic Test Mode II (Self-diagnostic result)º with ECM.

11) If DTC is detected, go to ªDiagnostic Procedureº, EC-3541.

Diagnostic Procedure

1 INSPECTION START

Are jumper cables connected for the jump starting?

Yes or No

YescGO TO 3.

NocGO TO 2.

DTC 0502 BATTERY VOLTAGEYD25DDTi

EC-3540

Page 569 of 1306

On Board Diagnosis Logic

Malfunction is detected when .... Check Items (Possible cause)

+An improper voltage signal from cam position sensor (Built-

into electronic control fuel injection pump) is sent to injection

pump control unit.+Harness or connectors

(Electronic control fuel injection pump circuit is open or

shorted.)

+Electronic control fuel injection pump

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-3548.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-3548.

SEF817Y

DTC 0701 P1zCAM POS SENYD25DDTi

EC-3544

Page 573 of 1306

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E236, M278 (LHD models)

+Harness connectors E236, F35 (RHD models)

+Harness for open or short between electronic control fuel injection pump and engine ground

cRepair open circuit or short to ground or short to power in harness or connectors.

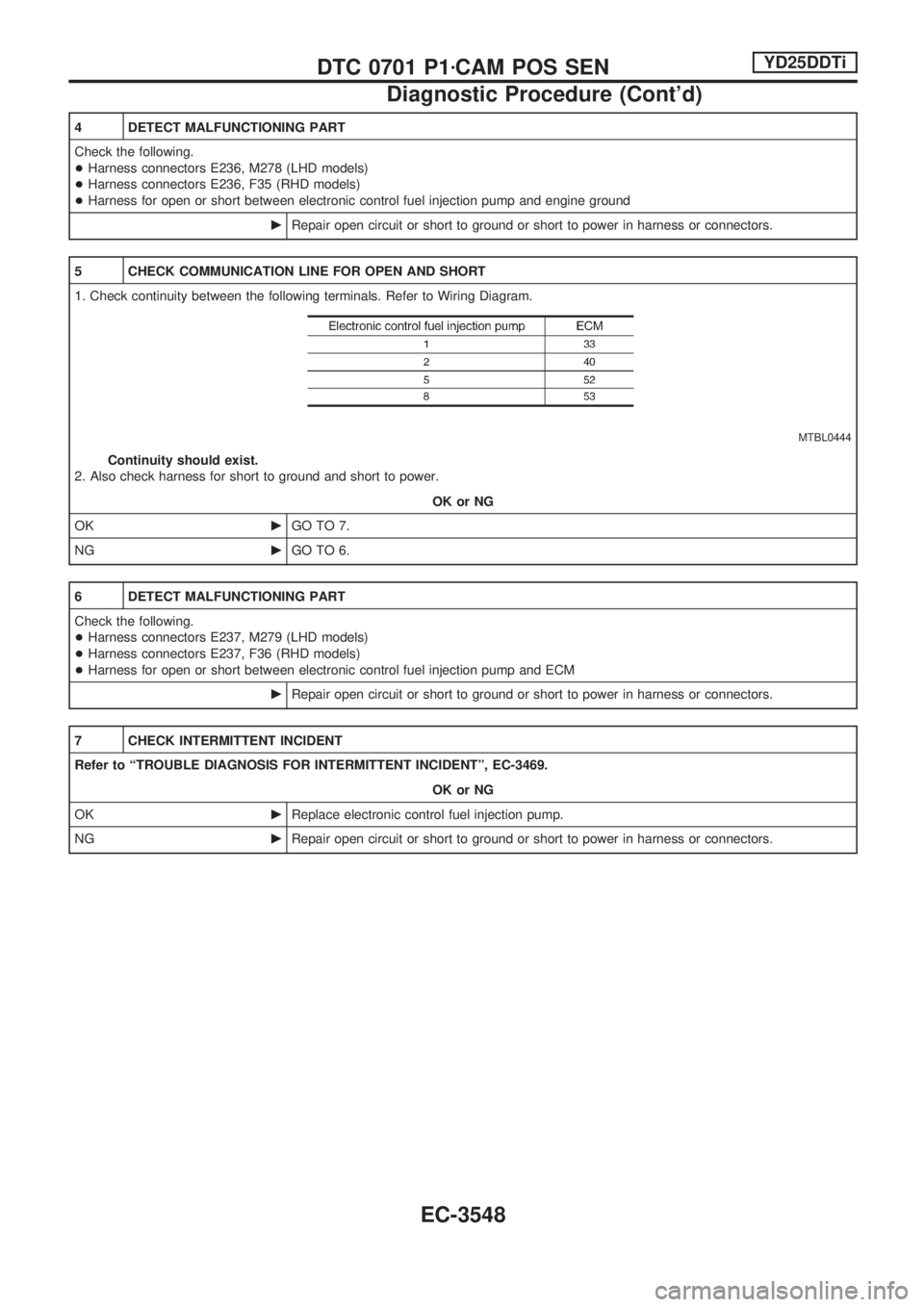

5 CHECK COMMUNICATION LINE FOR OPEN AND SHORT

1. Check continuity between the following terminals. Refer to Wiring Diagram.

MTBL0444

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 7.

NGcGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E237, M279 (LHD models)

+Harness connectors E237, F36 (RHD models)

+Harness for open or short between electronic control fuel injection pump and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

OK or NG

OKcReplace electronic control fuel injection pump.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0701 P1zCAM POS SENYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3548

Page 575 of 1306

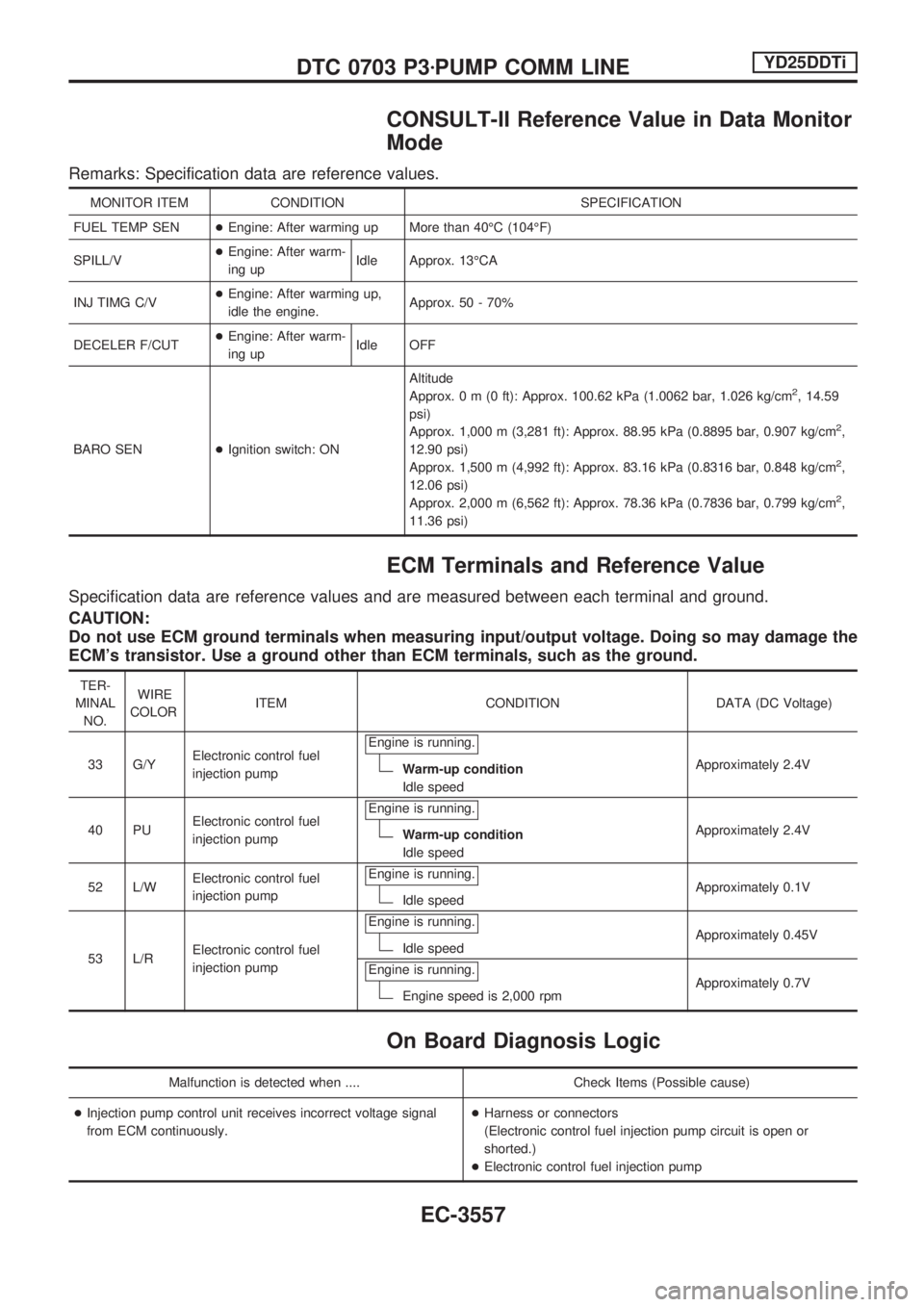

CONSULT-II Reference Value in Data Monitor

Mode

Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

SPILL/V+Engine: After warm-

ing upIdle Approx. 13ÉCA

INJ TIMG C/V+Engine: After warming up,

idle the engine.Approx. 50 - 70%

DECELER F/CUT+Engine: After warm-

ing upIdle OFF

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62 kPa (1.0062 bar, 1.026 kg/cm

2, 14.59

psi)

Approx. 1,000 m (3,281 ft): Approx. 88.95 kPa (0.8895 bar, 0.907 kg/cm

2,

12.90 psi)

Approx. 1,500 m (4,992 ft): Approx. 83.16 kPa (0.8316 bar, 0.848 kg/cm

2,

12.06 psi)

Approx. 2,000 m (6,562 ft): Approx. 78.36 kPa (0.7836 bar, 0.799 kg/cm

2,

11.36 psi)

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

33 G/YElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.4V

40 PUElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.4V

52 L/WElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.1V

53 L/RElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.45V

Engine is running.

Engine speed is 2,000 rpmApproximately 0.7V

On Board Diagnosis Logic

Malfunction is detected when .... Check Items (Possible cause)

+Injection pump control unit input signal [Crankshaft position

sensor (TDC) signal] processing function is malfunctioning.+Harness or connectors

(Electronic control fuel injection pump circuit is open or

shorted.)

+Electronic control fuel injection pump

DTC 0702 P2zTDC PULSE SIGYD25DDTi

EC-3550

Page 580 of 1306

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E236, M278 (LHD models)

+Harness connectors E236, F35 (RHD models)

+Harness for open or short between electronic control fuel injection pump and engine ground

cRepair open circuit or short to ground or short to power in harness or connectors.

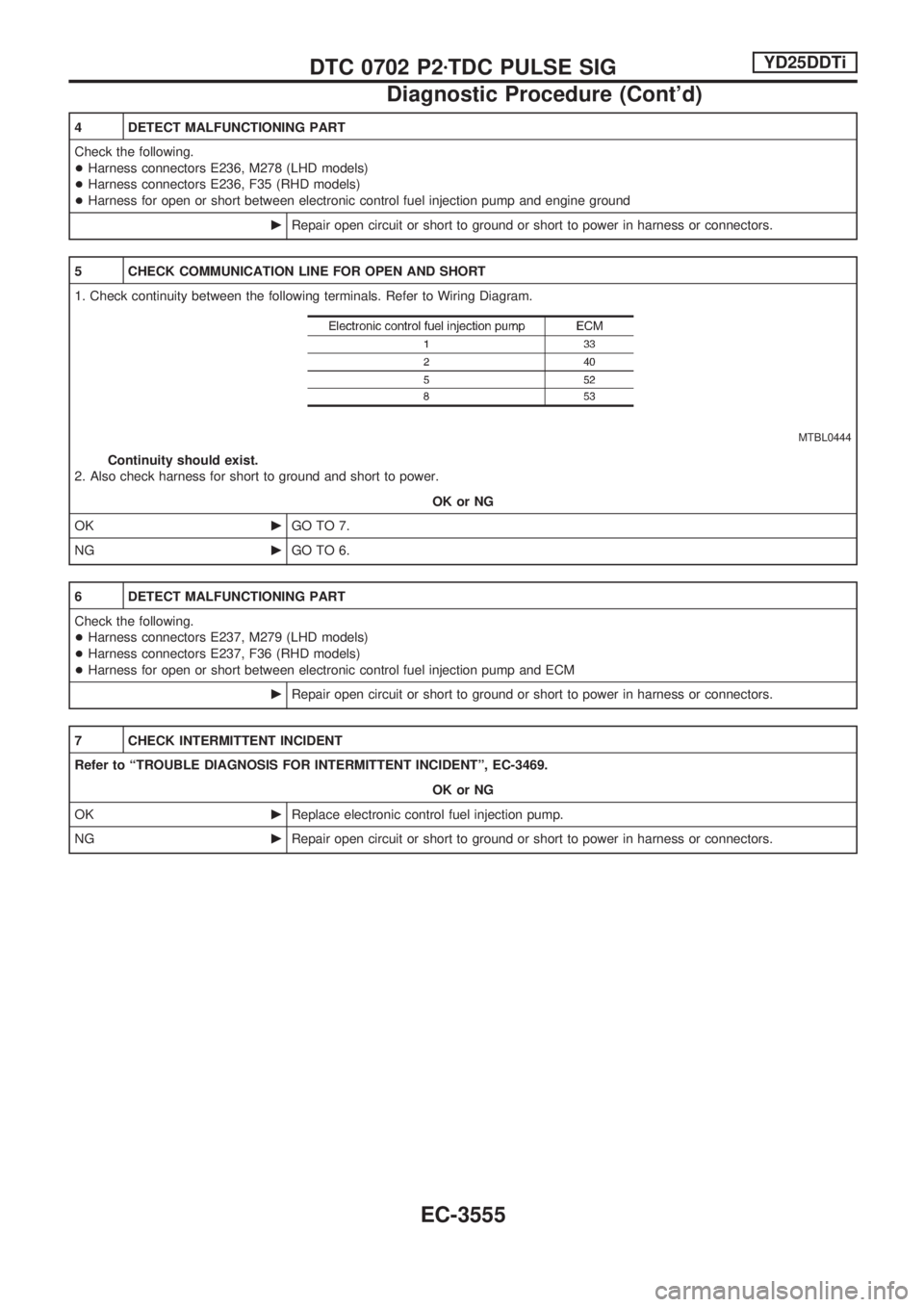

5 CHECK COMMUNICATION LINE FOR OPEN AND SHORT

1. Check continuity between the following terminals. Refer to Wiring Diagram.

MTBL0444

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 7.

NGcGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E237, M279 (LHD models)

+Harness connectors E237, F36 (RHD models)

+Harness for open or short between electronic control fuel injection pump and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

OK or NG

OKcReplace electronic control fuel injection pump.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0702 P2zTDC PULSE SIGYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3555

Page 582 of 1306

CONSULT-II Reference Value in Data Monitor

Mode

Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

SPILL/V+Engine: After warm-

ing upIdle Approx. 13ÉCA

INJ TIMG C/V+Engine: After warming up,

idle the engine.Approx. 50 - 70%

DECELER F/CUT+Engine: After warm-

ing upIdle OFF

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62 kPa (1.0062 bar, 1.026 kg/cm

2, 14.59

psi)

Approx. 1,000 m (3,281 ft): Approx. 88.95 kPa (0.8895 bar, 0.907 kg/cm

2,

12.90 psi)

Approx. 1,500 m (4,992 ft): Approx. 83.16 kPa (0.8316 bar, 0.848 kg/cm

2,

12.06 psi)

Approx. 2,000 m (6,562 ft): Approx. 78.36 kPa (0.7836 bar, 0.799 kg/cm

2,

11.36 psi)

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

33 G/YElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.4V

40 PUElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.4V

52 L/WElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.1V

53 L/RElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.45V

Engine is running.

Engine speed is 2,000 rpmApproximately 0.7V

On Board Diagnosis Logic

Malfunction is detected when .... Check Items (Possible cause)

+Injection pump control unit receives incorrect voltage signal

from ECM continuously.+Harness or connectors

(Electronic control fuel injection pump circuit is open or

shorted.)

+Electronic control fuel injection pump

DTC 0703 P3zPUMP COMM LINEYD25DDTi

EC-3557

Page 587 of 1306

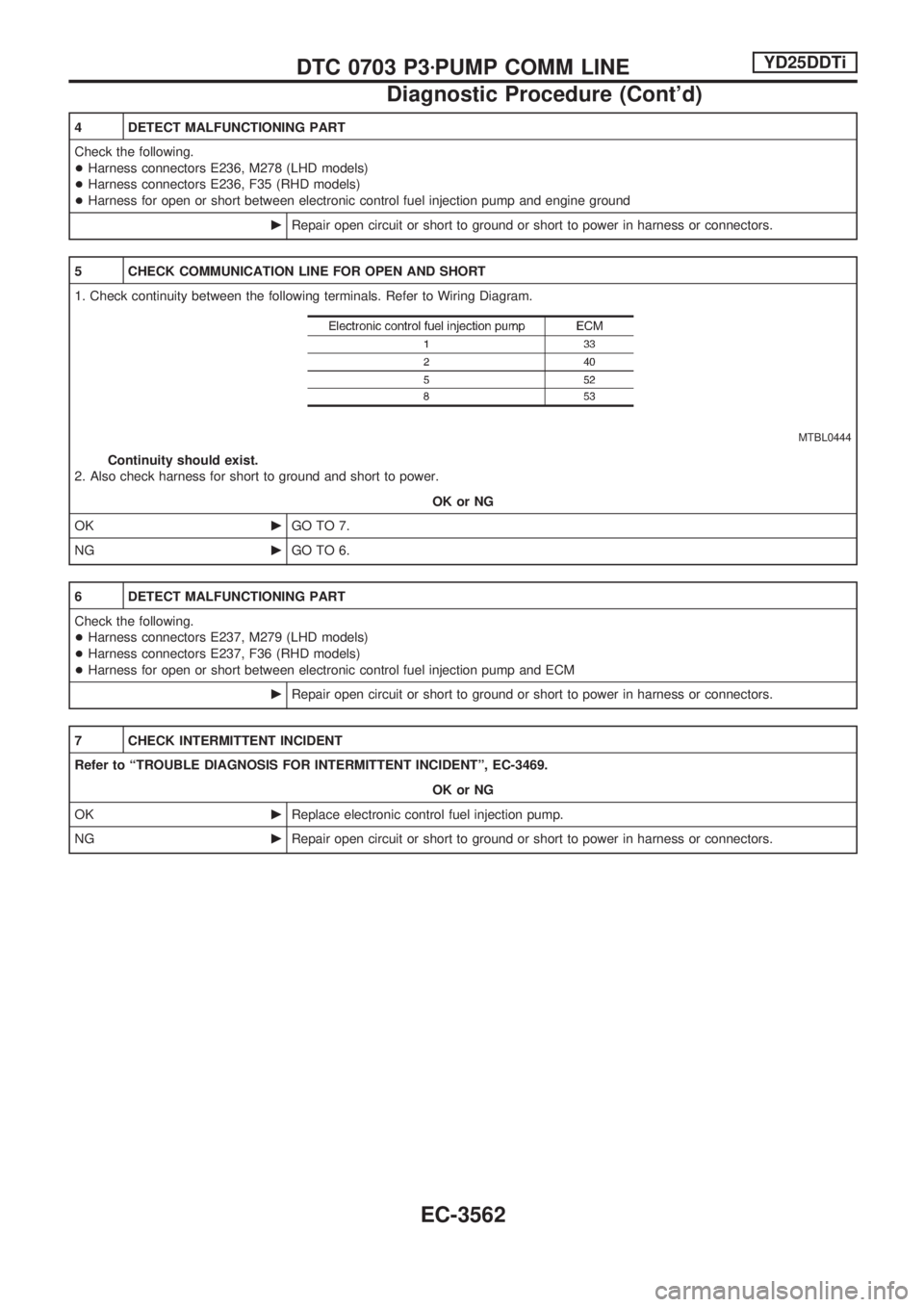

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E236, M278 (LHD models)

+Harness connectors E236, F35 (RHD models)

+Harness for open or short between electronic control fuel injection pump and engine ground

cRepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK COMMUNICATION LINE FOR OPEN AND SHORT

1. Check continuity between the following terminals. Refer to Wiring Diagram.

MTBL0444

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 7.

NGcGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E237, M279 (LHD models)

+Harness connectors E237, F36 (RHD models)

+Harness for open or short between electronic control fuel injection pump and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

OK or NG

OKcReplace electronic control fuel injection pump.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0703 P3zPUMP COMM LINEYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3562