check engine NISSAN PICK-UP 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 504 of 1306

14 CHECK ECM POWER SUPPLY CIRCUIT-V

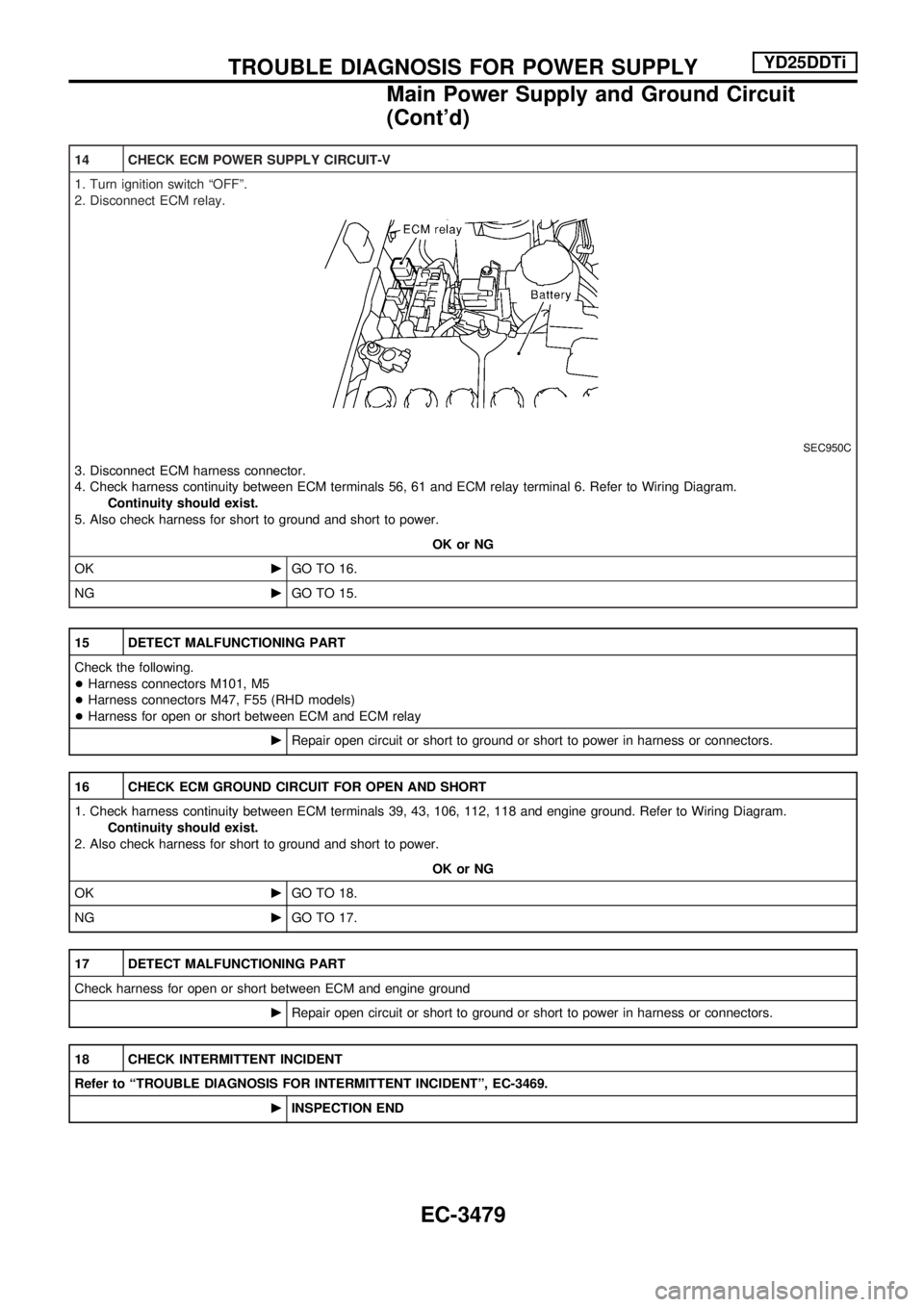

1. Turn ignition switch ªOFFº.

2. Disconnect ECM relay.

SEC950C

3. Disconnect ECM harness connector.

4. Check harness continuity between ECM terminals 56, 61 and ECM relay terminal 6. Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 16.

NGcGO TO 15.

15 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M101, M5

+Harness connectors M47, F55 (RHD models)

+Harness for open or short between ECM and ECM relay

cRepair open circuit or short to ground or short to power in harness or connectors.

16 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminals 39, 43, 106, 112, 118 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 18.

NGcGO TO 17.

17 DETECT MALFUNCTIONING PART

Check harness for open or short between ECM and engine ground

cRepair open circuit or short to ground or short to power in harness or connectors.

18 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

cINSPECTION END

TROUBLE DIAGNOSIS FOR POWER SUPPLYYD25DDTi

Main Power Supply and Ground Circuit

(Cont'd)

EC-3479

Page 505 of 1306

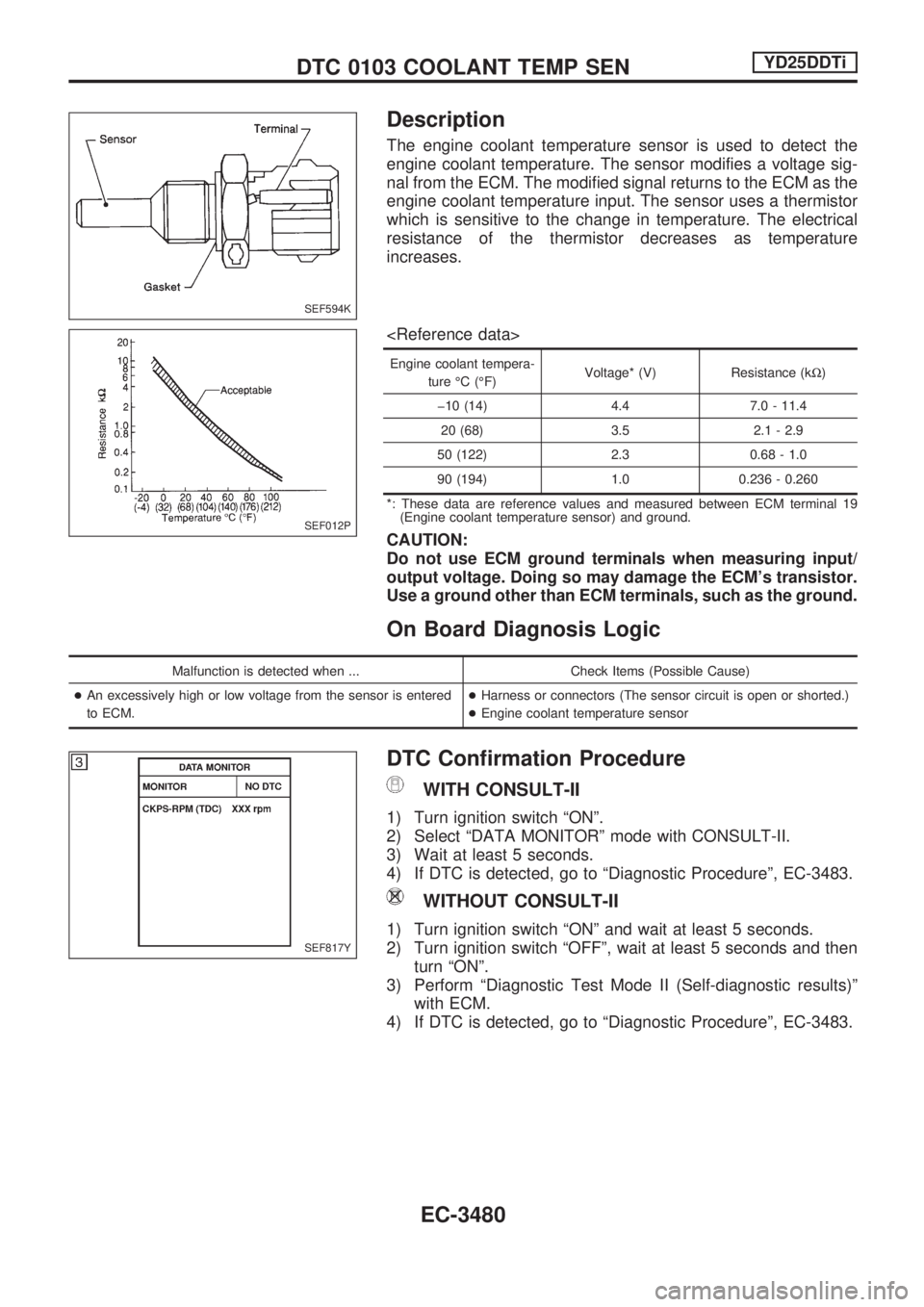

Description

The engine coolant temperature sensor is used to detect the

engine coolant temperature. The sensor modifies a voltage sig-

nal from the ECM. The modified signal returns to the ECM as the

engine coolant temperature input. The sensor uses a thermistor

which is sensitive to the change in temperature. The electrical

resistance of the thermistor decreases as temperature

increases.

Engine coolant tempera-

ture ÉC (ÉF)Voltage* (V) Resistance (kW)

þ10 (14) 4.4 7.0 - 11.4

20 (68) 3.5 2.1 - 2.9

50 (122) 2.3 0.68 - 1.0

90 (194) 1.0 0.236 - 0.260

*: These data are reference values and measured between ECM terminal 19

(Engine coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may damage the ECM's transistor.

Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

+An excessively high or low voltage from the sensor is entered

to ECM.+Harness or connectors (The sensor circuit is open or shorted.)

+Engine coolant temperature sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-3483.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 5 seconds.

2) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-3483.

SEF594K

SEF012P

SEF817Y

DTC 0103 COOLANT TEMP SENYD25DDTi

EC-3480

Page 507 of 1306

Diagnostic Procedure

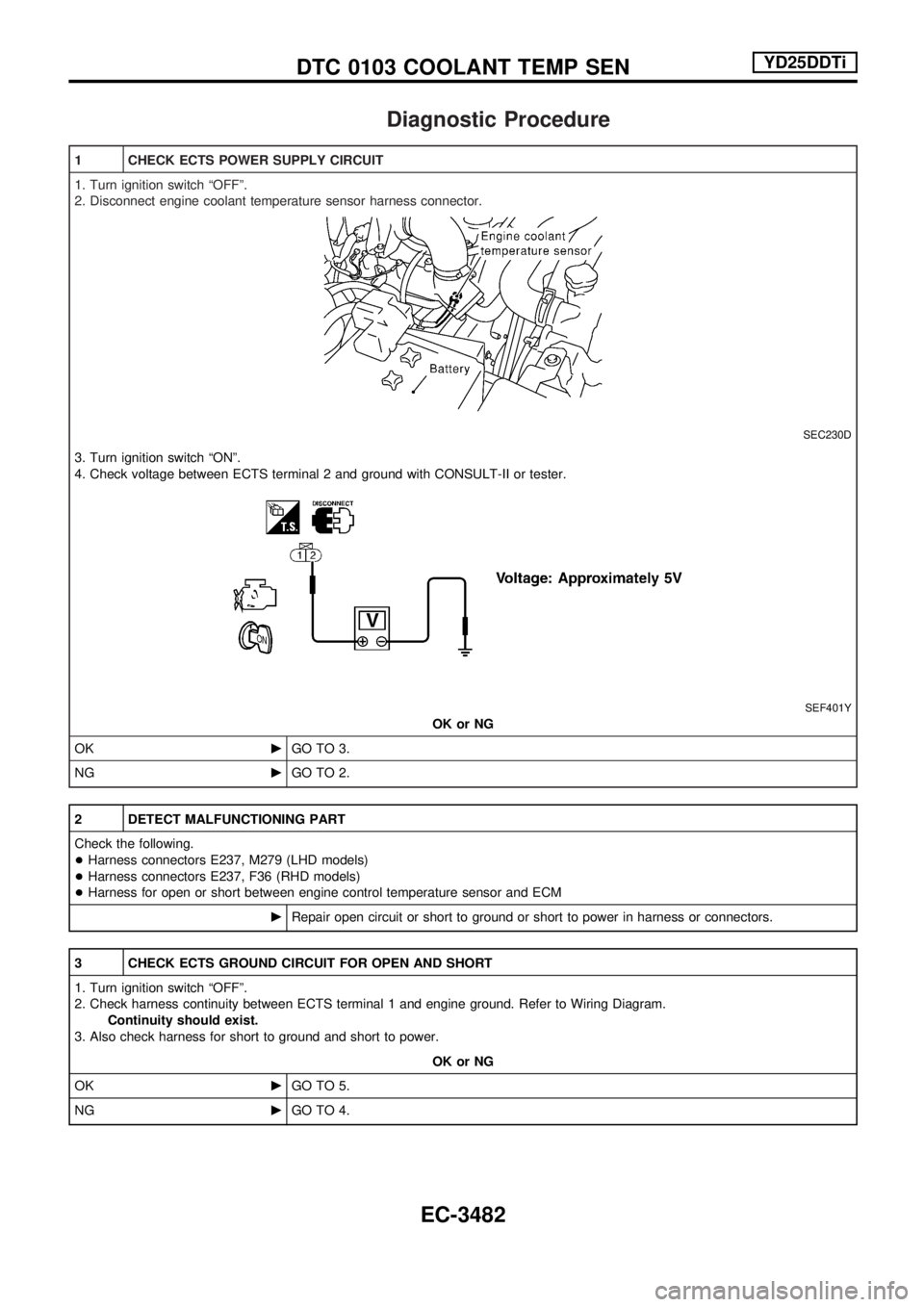

1 CHECK ECTS POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector.

SEC230D

3. Turn ignition switch ªONº.

4. Check voltage between ECTS terminal 2 and ground with CONSULT-II or tester.

SEF401Y

OK or NG

OKcGO TO 3.

NGcGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E237, M279 (LHD models)

+Harness connectors E237, F36 (RHD models)

+Harness for open or short between engine control temperature sensor and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ECTS GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between ECTS terminal 1 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 5.

NGcGO TO 4.

DTC 0103 COOLANT TEMP SENYD25DDTi

EC-3482

Page 508 of 1306

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E237, M279 (LHD models)

+Harness connectors E237, F36 (RHD models)

+Harness for open or short between engine coolant temperature sensor and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

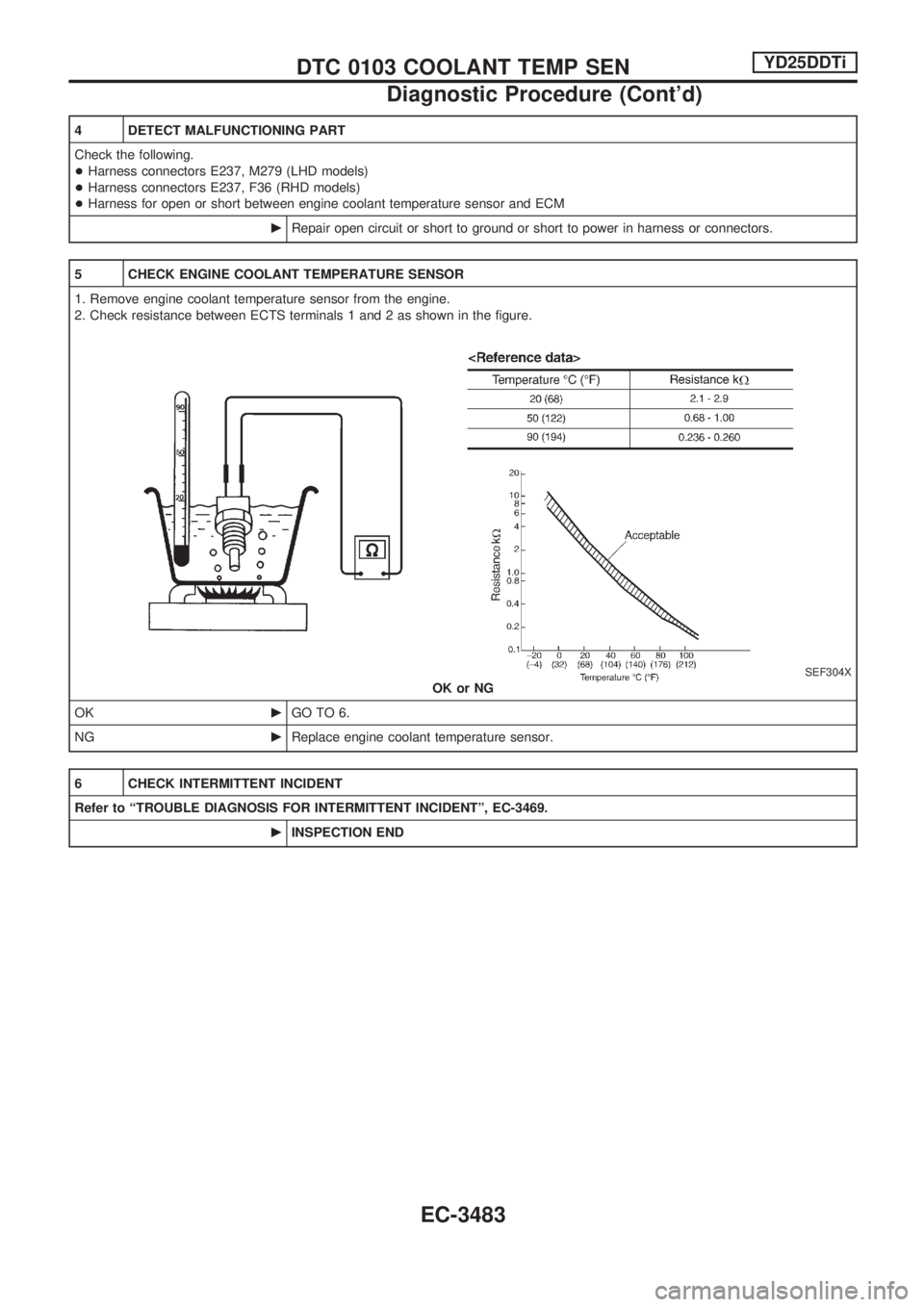

5 CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Remove engine coolant temperature sensor from the engine.

2. Check resistance between ECTS terminals 1 and 2 as shown in the figure.

SEF304X

OK or NG

OKcGO TO 6.

NGcReplace engine coolant temperature sensor.

6 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

cINSPECTION END

DTC 0103 COOLANT TEMP SENYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3483

Page 509 of 1306

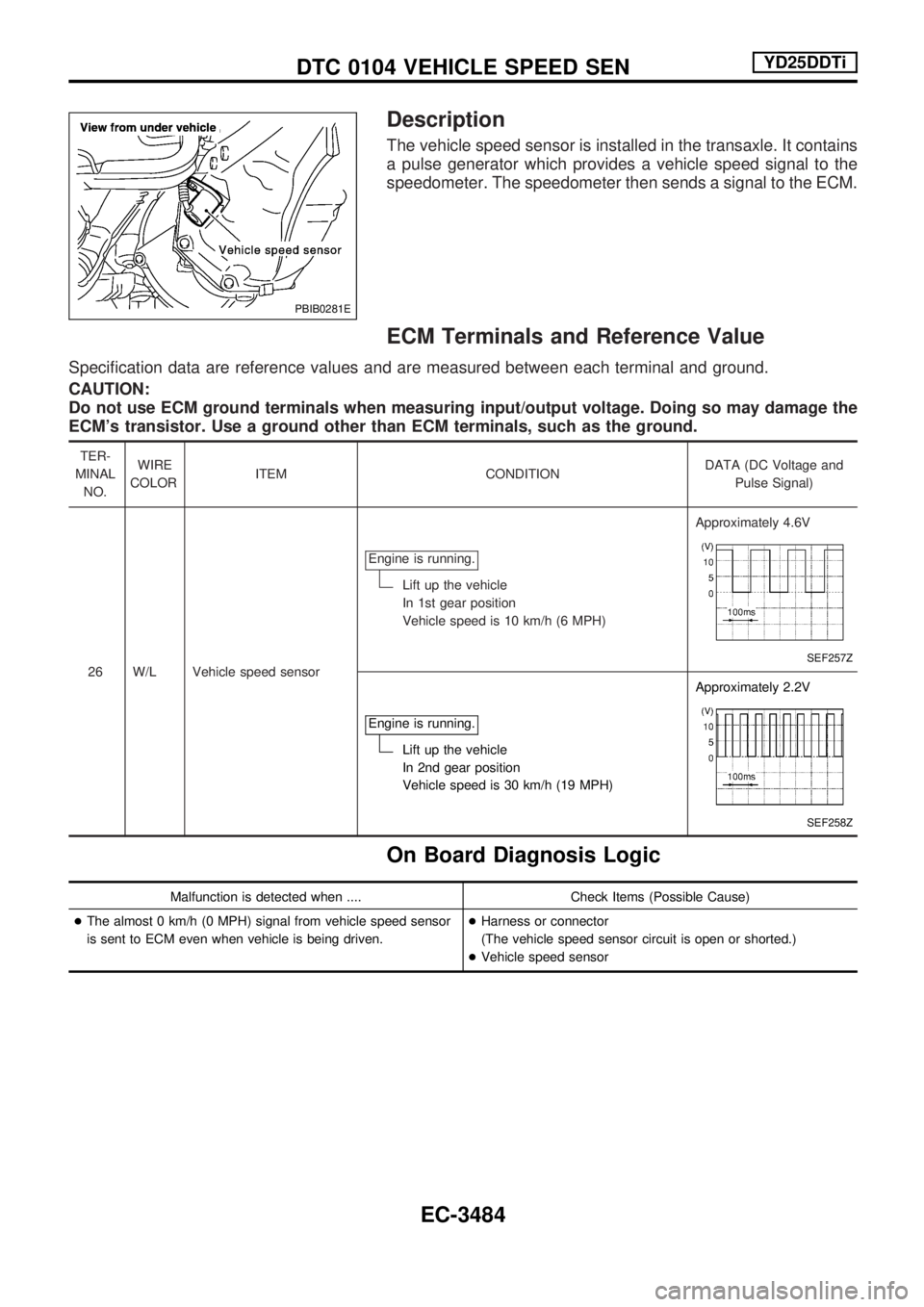

Description

The vehicle speed sensor is installed in the transaxle. It contains

a pulse generator which provides a vehicle speed signal to the

speedometer. The speedometer then sends a signal to the ECM.

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

26 W/L Vehicle speed sensorEngine is running.

Lift up the vehicle

In 1st gear position

Vehicle speed is 10 km/h (6 MPH)Approximately 4.6V

SEF257Z

Engine is running.

Lift up the vehicle

In 2nd gear position

Vehicle speed is 30 km/h (19 MPH)Approximately 2.2V

SEF258Z

On Board Diagnosis Logic

Malfunction is detected when .... Check Items (Possible Cause)

+The almost 0 km/h (0 MPH) signal from vehicle speed sensor

is sent to ECM even when vehicle is being driven.+Harness or connector

(The vehicle speed sensor circuit is open or shorted.)

+Vehicle speed sensor

PBIB0281E

DTC 0104 VEHICLE SPEED SENYD25DDTi

EC-3484

Page 510 of 1306

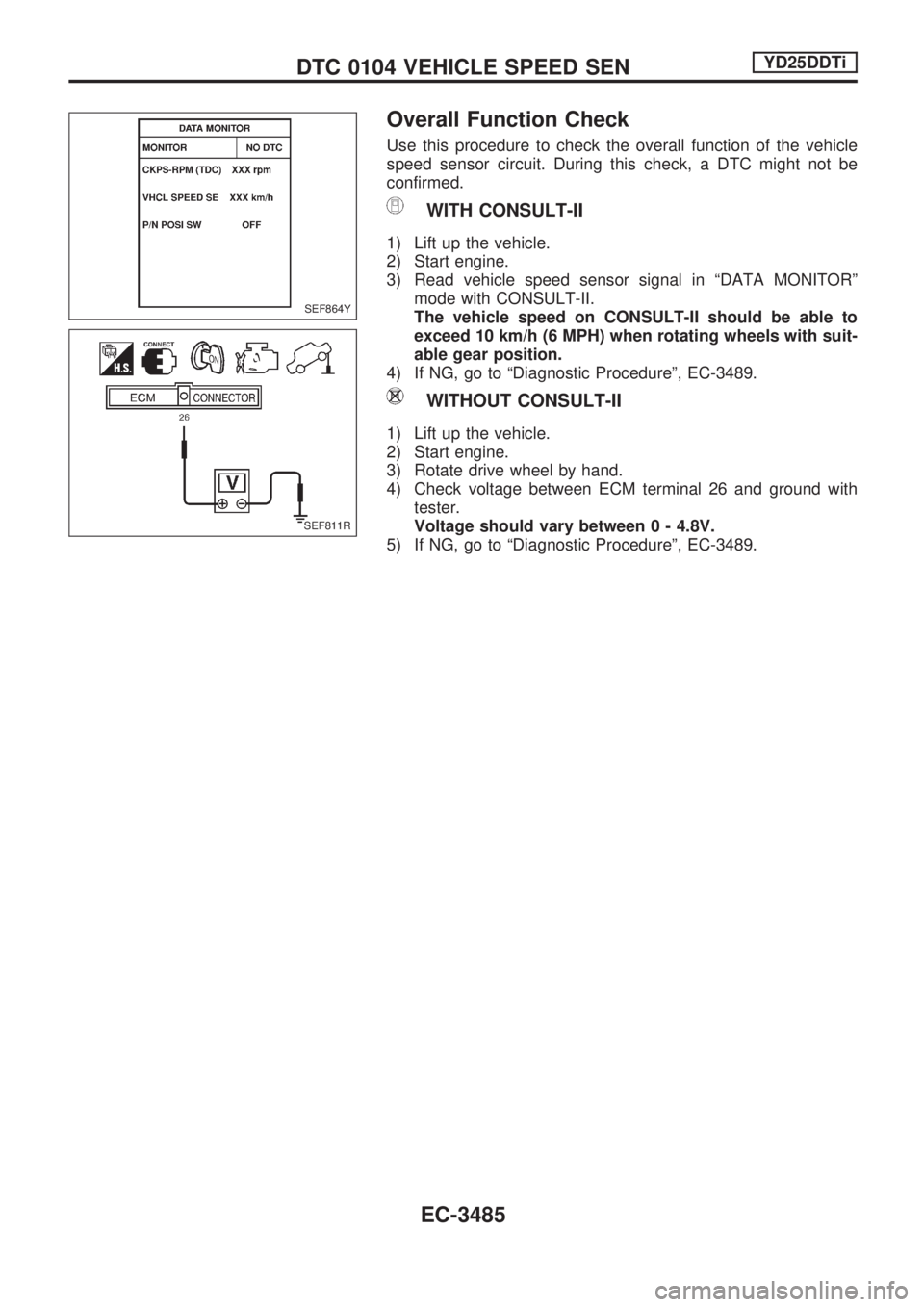

Overall Function Check

Use this procedure to check the overall function of the vehicle

speed sensor circuit. During this check, a DTC might not be

confirmed.

WITH CONSULT-II

1) Lift up the vehicle.

2) Start engine.

3) Read vehicle speed sensor signal in ªDATA MONITORº

mode with CONSULT-II.

The vehicle speed on CONSULT-II should be able to

exceed 10 km/h (6 MPH) when rotating wheels with suit-

able gear position.

4) If NG, go to ªDiagnostic Procedureº, EC-3489.

WITHOUT CONSULT-II

1) Lift up the vehicle.

2) Start engine.

3) Rotate drive wheel by hand.

4) Check voltage between ECM terminal 26 and ground with

tester.

Voltage should vary between 0 - 4.8V.

5) If NG, go to ªDiagnostic Procedureº, EC-3489.

SEF864Y

SEF811R

DTC 0104 VEHICLE SPEED SENYD25DDTi

EC-3485

Page 515 of 1306

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

14 G/B Cooling fan relayEngine is running.

Cooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

Engine is running.

Cooling fan is operatingApproximately 0.1V

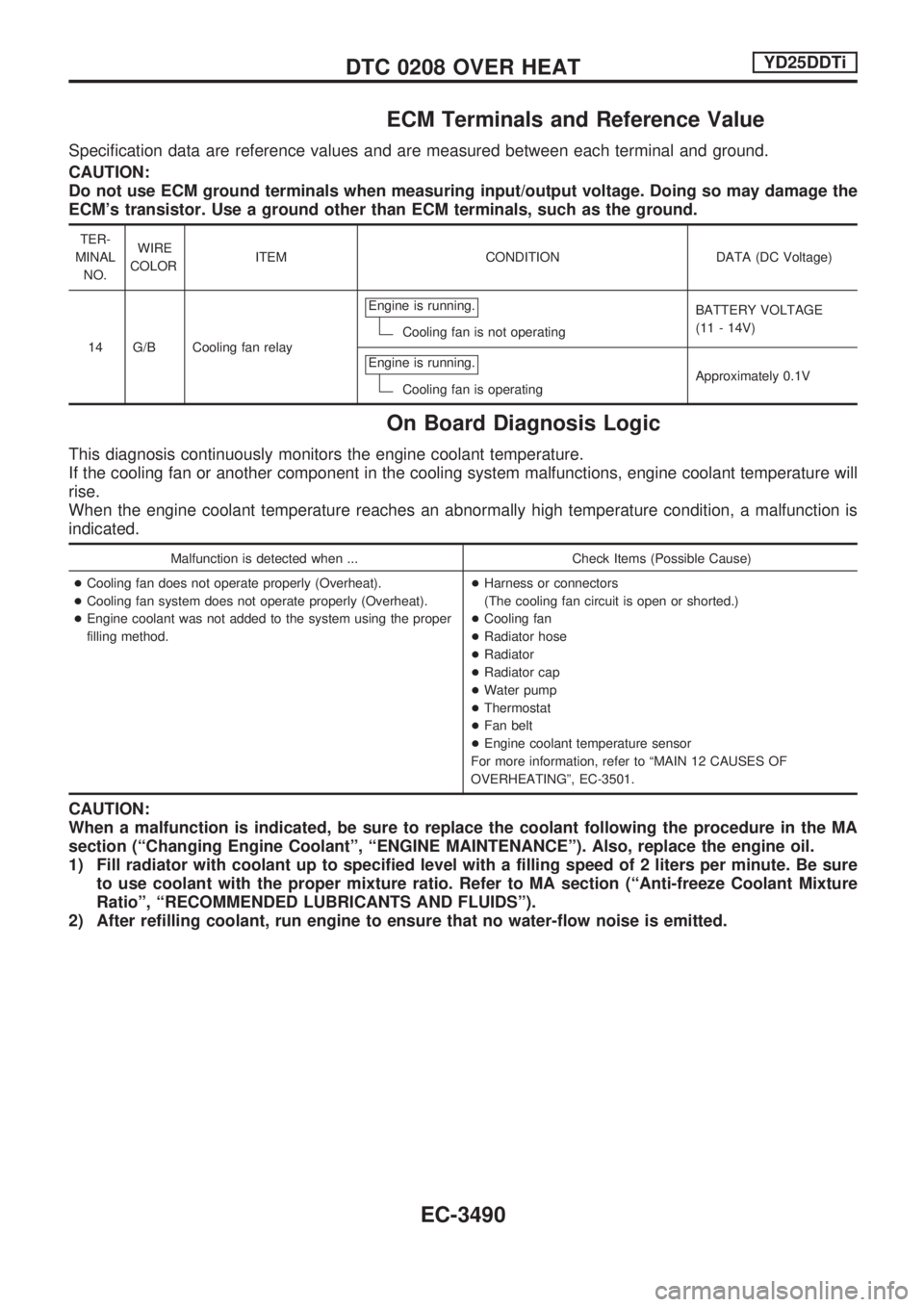

On Board Diagnosis Logic

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Malfunction is detected when ... Check Items (Possible Cause)

+Cooling fan does not operate properly (Overheat).

+Cooling fan system does not operate properly (Overheat).

+Engine coolant was not added to the system using the proper

filling method.+Harness or connectors

(The cooling fan circuit is open or shorted.)

+Cooling fan

+Radiator hose

+Radiator

+Radiator cap

+Water pump

+Thermostat

+Fan belt

+Engine coolant temperature sensor

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-3501.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure

to use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture

Ratioº, ªRECOMMENDED LUBRICANTS AND FLUIDSº).

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC 0208 OVER HEATYD25DDTi

EC-3490

Page 516 of 1306

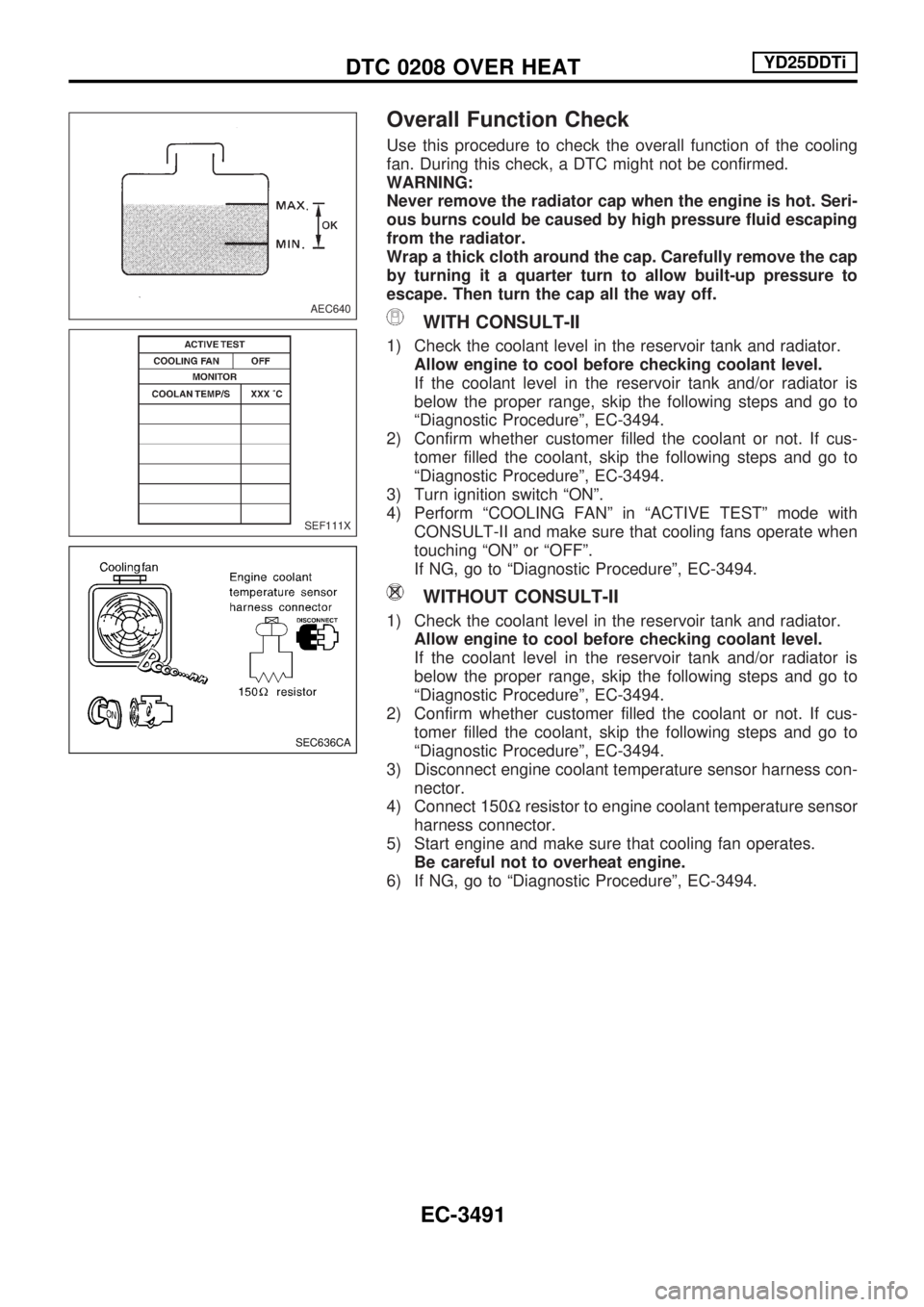

Overall Function Check

Use this procedure to check the overall function of the cooling

fan. During this check, a DTC might not be confirmed.

WARNING:

Never remove the radiator cap when the engine is hot. Seri-

ous burns could be caused by high pressure fluid escaping

from the radiator.

Wrap a thick cloth around the cap. Carefully remove the cap

by turning it a quarter turn to allow built-up pressure to

escape. Then turn the cap all the way off.

WITH CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is

below the proper range, skip the following steps and go to

ªDiagnostic Procedureº, EC-3494.

2) Confirm whether customer filled the coolant or not. If cus-

tomer filled the coolant, skip the following steps and go to

ªDiagnostic Procedureº, EC-3494.

3) Turn ignition switch ªONº.

4) Perform ªCOOLING FANº in ªACTIVE TESTº mode with

CONSULT-II and make sure that cooling fans operate when

touching ªONº or ªOFFº.

If NG, go to ªDiagnostic Procedureº, EC-3494.

WITHOUT CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is

below the proper range, skip the following steps and go to

ªDiagnostic Procedureº, EC-3494.

2) Confirm whether customer filled the coolant or not. If cus-

tomer filled the coolant, skip the following steps and go to

ªDiagnostic Procedureº, EC-3494.

3) Disconnect engine coolant temperature sensor harness con-

nector.

4) Connect 150Wresistor to engine coolant temperature sensor

harness connector.

5) Start engine and make sure that cooling fan operates.

Be careful not to overheat engine.

6) If NG, go to ªDiagnostic Procedureº, EC-3494.

AEC640

SEF111X

SEC636CA

DTC 0208 OVER HEATYD25DDTi

EC-3491

Page 519 of 1306

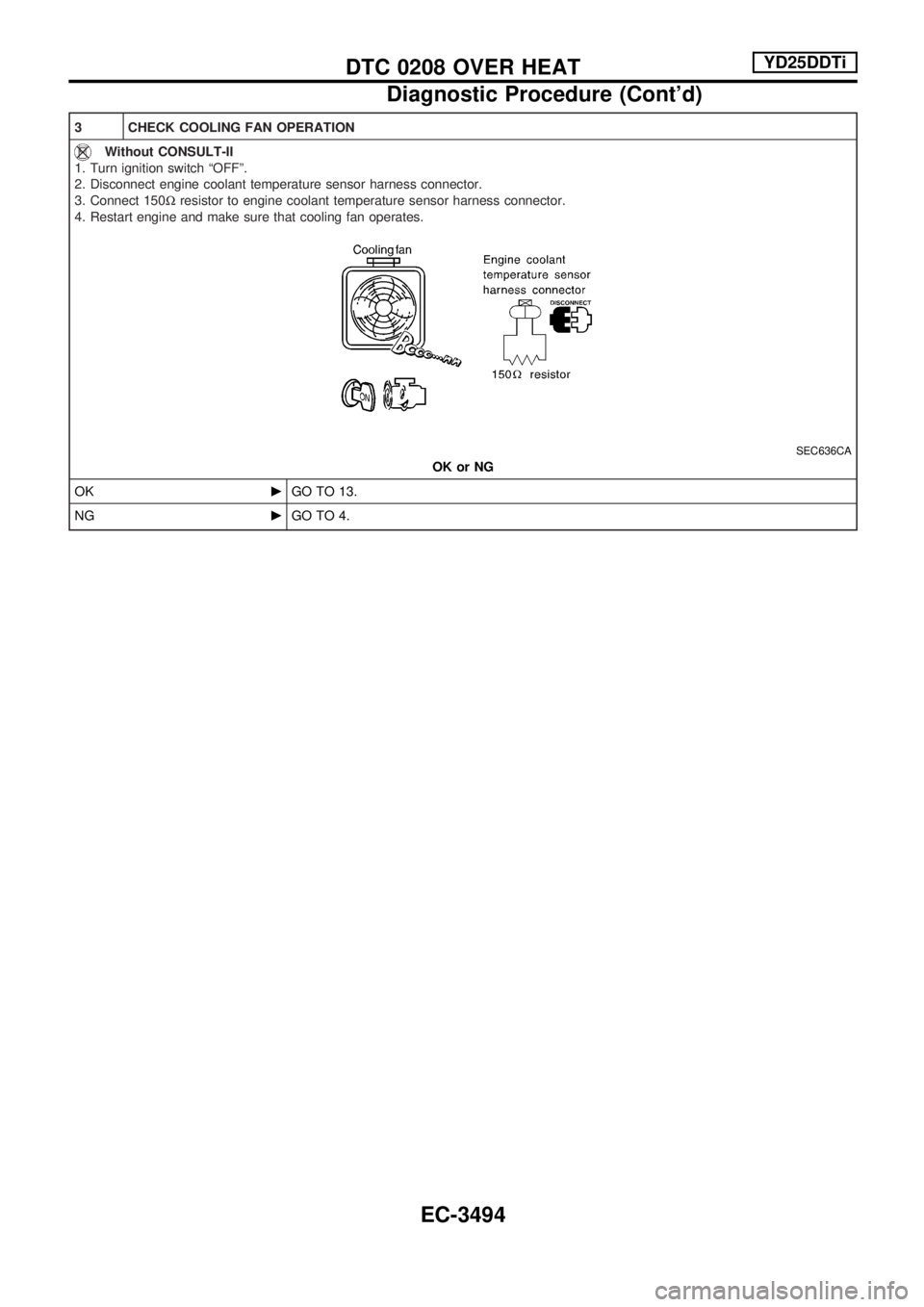

3 CHECK COOLING FAN OPERATION

Without CONSULT-II

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector.

3. Connect 150Wresistor to engine coolant temperature sensor harness connector.

4. Restart engine and make sure that cooling fan operates.

SEC636CA

OK or NG

OKcGO TO 13.

NGcGO TO 4.

DTC 0208 OVER HEATYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3494

Page 524 of 1306

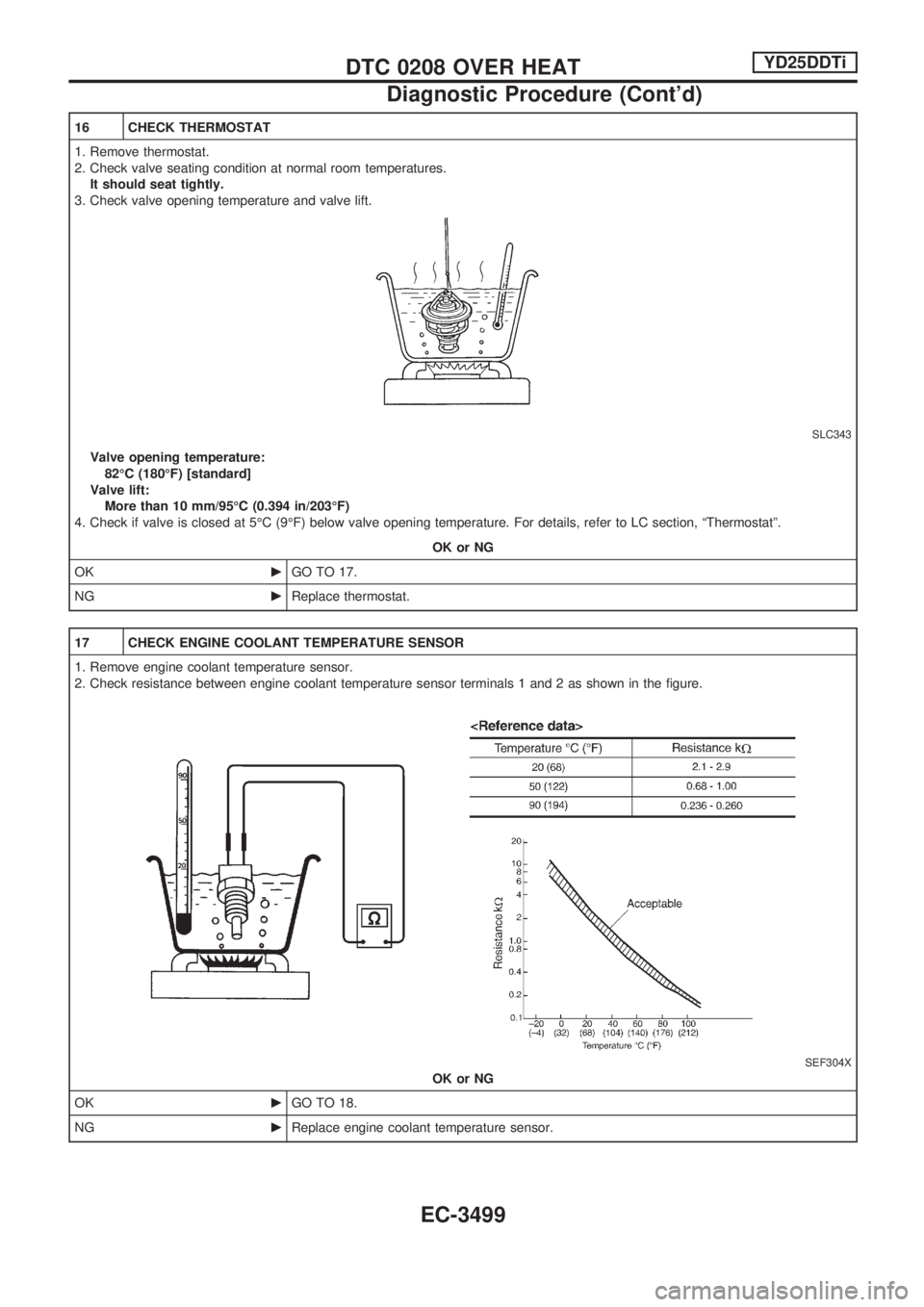

16 CHECK THERMOSTAT

1. Remove thermostat.

2. Check valve seating condition at normal room temperatures.

It should seat tightly.

3. Check valve opening temperature and valve lift.

SLC343

Valve opening temperature:

82ÉC (180ÉF) [standard]

Valve lift:

More than 10 mm/95ÉC (0.394 in/203ÉF)

4. Check if valve is closed at 5ÉC (9ÉF) below valve opening temperature. For details, refer to LC section, ªThermostatº.

OK or NG

OKcGO TO 17.

NGcReplace thermostat.

17 CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Remove engine coolant temperature sensor.

2. Check resistance between engine coolant temperature sensor terminals 1 and 2 as shown in the figure.

SEF304X

OK or NG

OKcGO TO 18.

NGcReplace engine coolant temperature sensor.

DTC 0208 OVER HEATYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3499