check engine NISSAN PICK-UP 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 629 of 1306

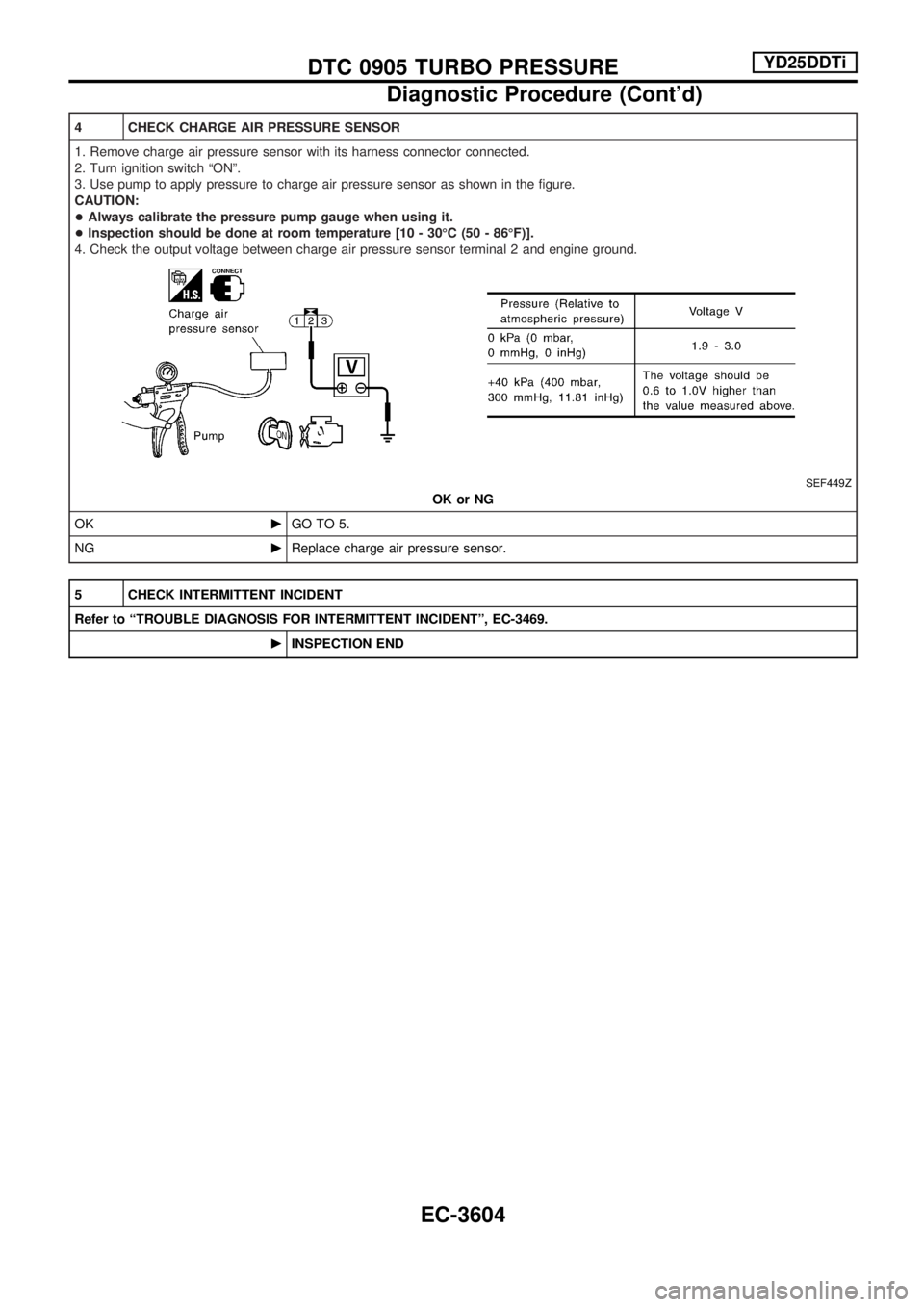

4 CHECK CHARGE AIR PRESSURE SENSOR

1. Remove charge air pressure sensor with its harness connector connected.

2. Turn ignition switch ªONº.

3. Use pump to apply pressure to charge air pressure sensor as shown in the figure.

CAUTION:

+Always calibrate the pressure pump gauge when using it.

+Inspection should be done at room temperature [10 - 30ÉC (50 - 86ÉF)].

4. Check the output voltage between charge air pressure sensor terminal 2 and engine ground.

SEF449Z

OK or NG

OKcGO TO 5.

NGcReplace charge air pressure sensor.

5 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

cINSPECTION END

DTC 0905 TURBO PRESSUREYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3604

Page 640 of 1306

CONSULT-II Reference Value in Data Monitor

Mode

Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

SPILL/V+Engine: After warm-

ing upIdle Approx. 13ÉCA

INJ TIMG C/V+Engine: After warming up,

idle the engine.Approx. 50 - 70%

DECELER F/CUT+Engine: After warm-

ing upIdle OFF

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62 kPa (1.0062 bar, 1.026 kg/cm

2, 14.59

psi)

Approx. 1,000 m (3,281 ft): Approx. 88.95 kPa (0.8895 bar, 0.907 kg/cm

2,

12.90 psi)

Approx. 1,500 m (4,992 ft): Approx. 83.16 kPa (0.8316 bar, 0.848 kg/cm

2,

12.06 psi)

Approx. 2,000 m (6,562 ft): Approx. 78.36 kPa (0.7836 bar, 0.799 kg/cm

2,

11.36 psi)

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

33 G/YElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.4V

40 PUElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.4V

52 L/WElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.1V

53 L/RElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.45V

Engine is running.

Engine speed is 2,000 rpmApproximately 0.7V

On Board Diagnosis Logic

Malfunction is detected when .... Check Items (Possible cause)

+Fuel cut control system does not function properly.+Harness or connectors

(Electronic control fuel circuit is open or shorted.)

+Electronic control fuel

DTC 1004 FUEL CUT SYSTEM1YD25DDTi

EC-3615

Page 645 of 1306

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E236, M278 (LHD models)

+Harness connectors E236, F35 (RHD models)

+Harness for open or short between electronic control fuel injection pump and engine ground

cRepair open circuit or short to ground or short to power in harness or connectors.

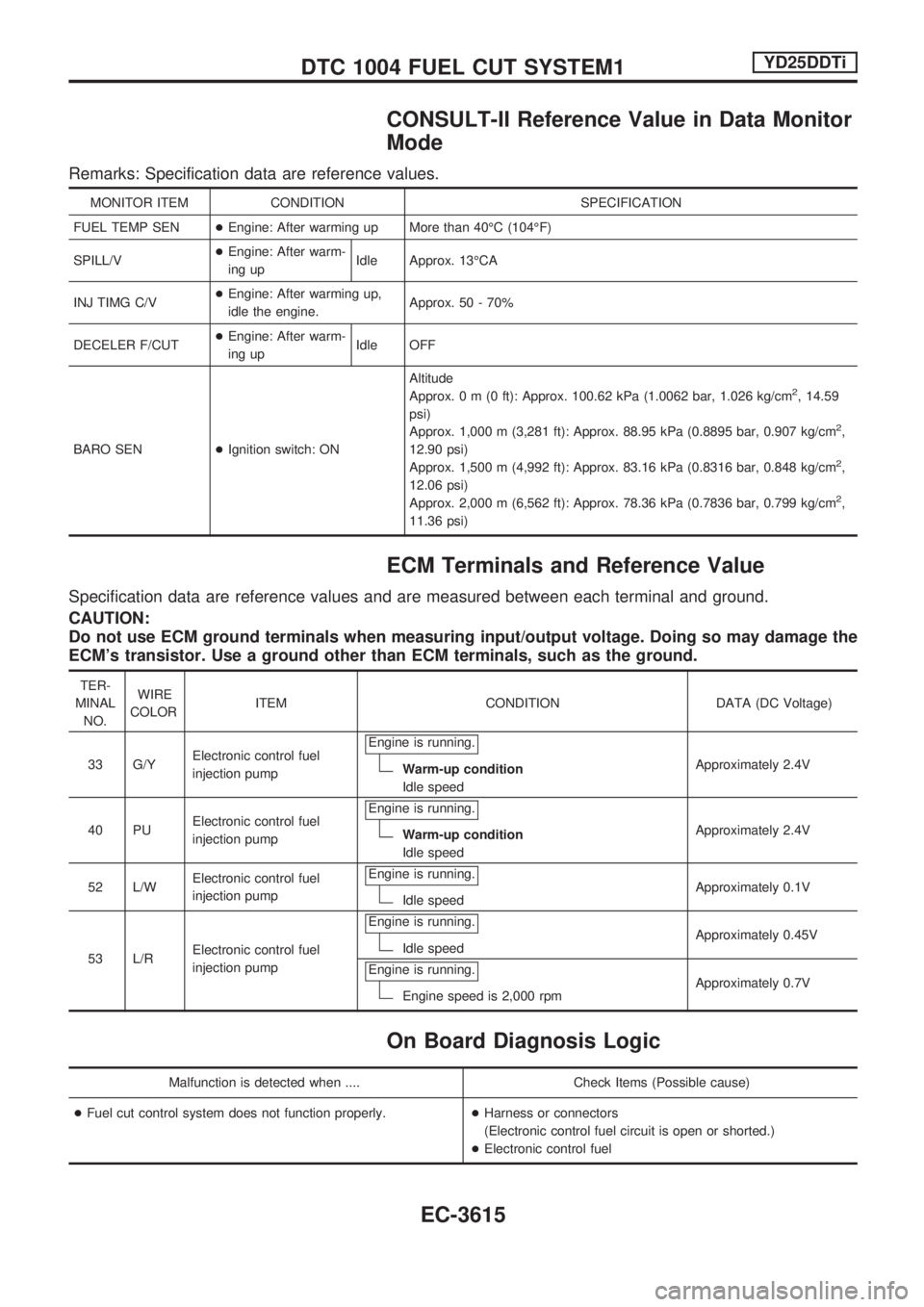

5 CHECK COMMUNICATION LINE FOR OPEN AND SHORT

1. Check continuity between the following terminals. Refer to Wiring Diagram.

MTBL0444

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 7.

NGcGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E237, M279 (LHD models)

+Harness connectors E237, F36 (RHD models)

+Harness for open or short between electronic control fuel injection pump and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

OK or NG

OKcReplace electronic control fuel injection pump.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

DTC 1004 FUEL CUT SYSTEM1YD25DDTi

Diagnostic Procedure (Cont'd)

EC-3620

Page 649 of 1306

Diagnostic Procedure

1 INSPECTION START

Check fuel level, fuel supplying system, starter motor, etc.

OK or NG

OKcGO TO 2.

NGcCorrect.

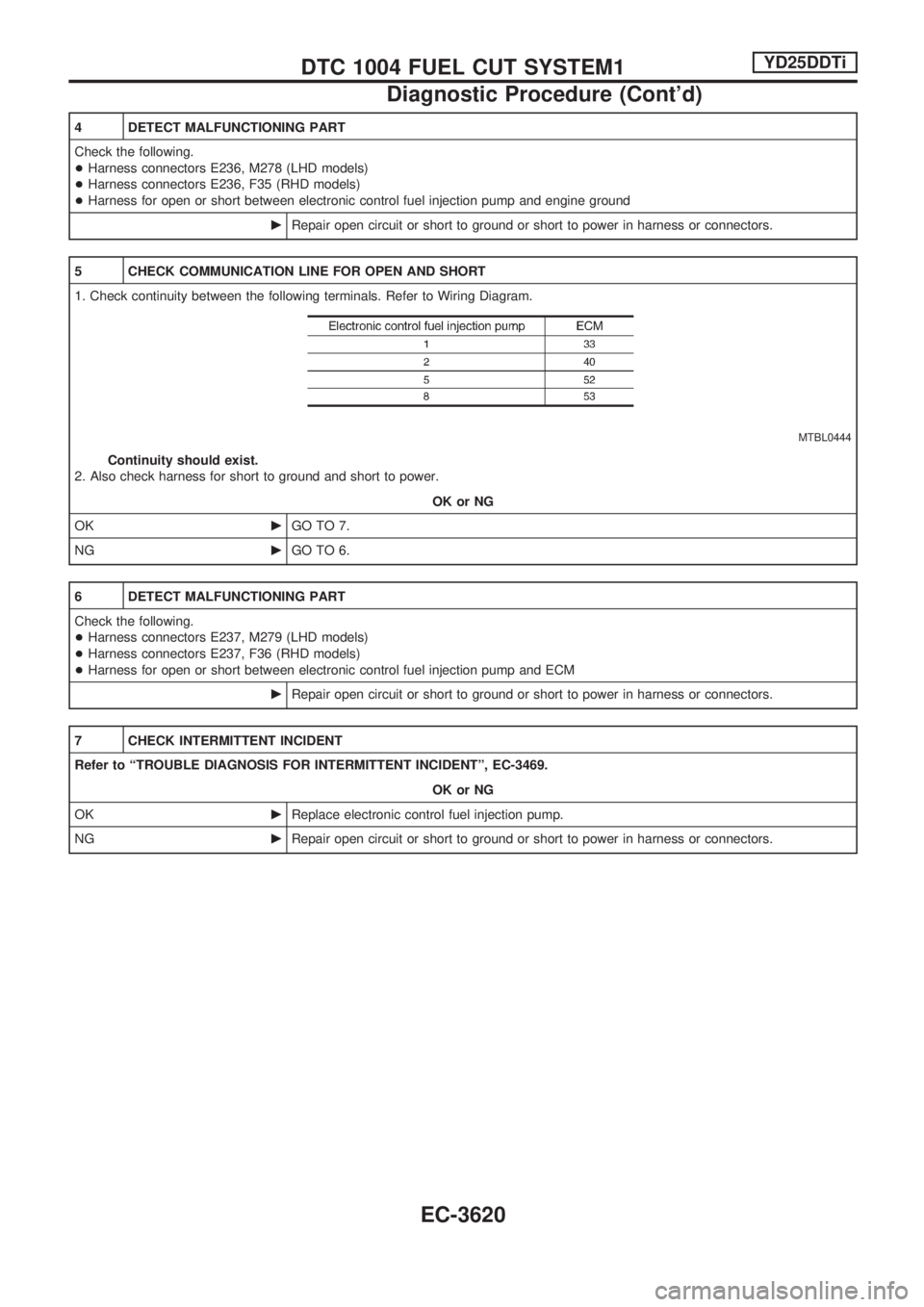

2 CHECK INSTALLATION

Check that all glow plug connecting plate nuts are installed properly.

SEC250D

OK or NG

OK (With CONSULT-II)cGO TO 3.

OK (Without CONSULT-II)cGO TO 4.

NGcInstall properly.

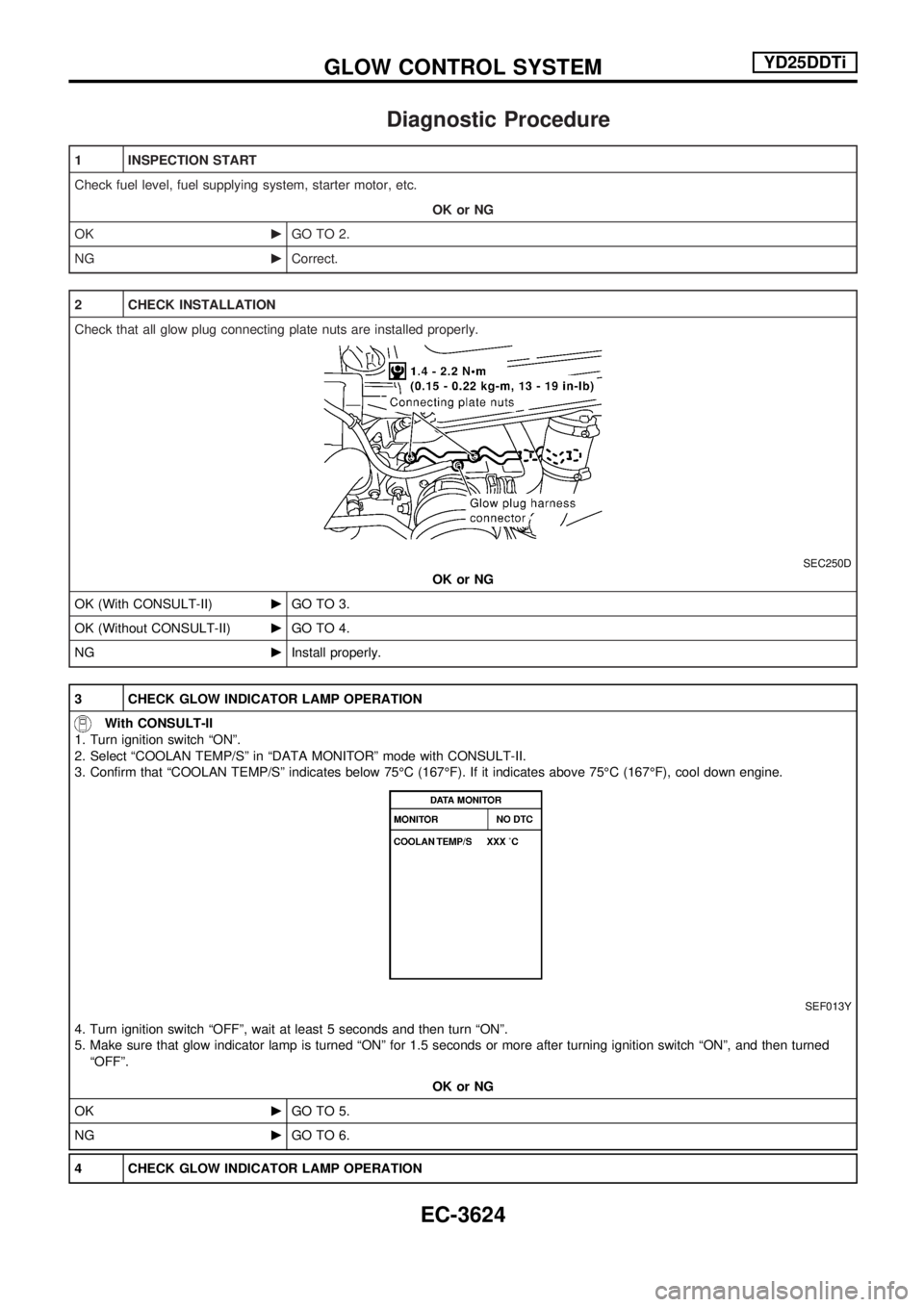

3 CHECK GLOW INDICATOR LAMP OPERATION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªCOOLAN TEMP/Sº in ªDATA MONITORº mode with CONSULT-II.

3. Confirm that ªCOOLAN TEMP/Sº indicates below 75ÉC (167ÉF). If it indicates above 75ÉC (167ÉF), cool down engine.

SEF013Y

4. Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

5. Make sure that glow indicator lamp is turned ªONº for 1.5 seconds or more after turning ignition switch ªONº, and then turned

ªOFFº.

OK or NG

OKcGO TO 5.

NGcGO TO 6.

4 CHECK GLOW INDICATOR LAMP OPERATION

GLOW CONTROL SYSTEMYD25DDTi

EC-3624

Page 650 of 1306

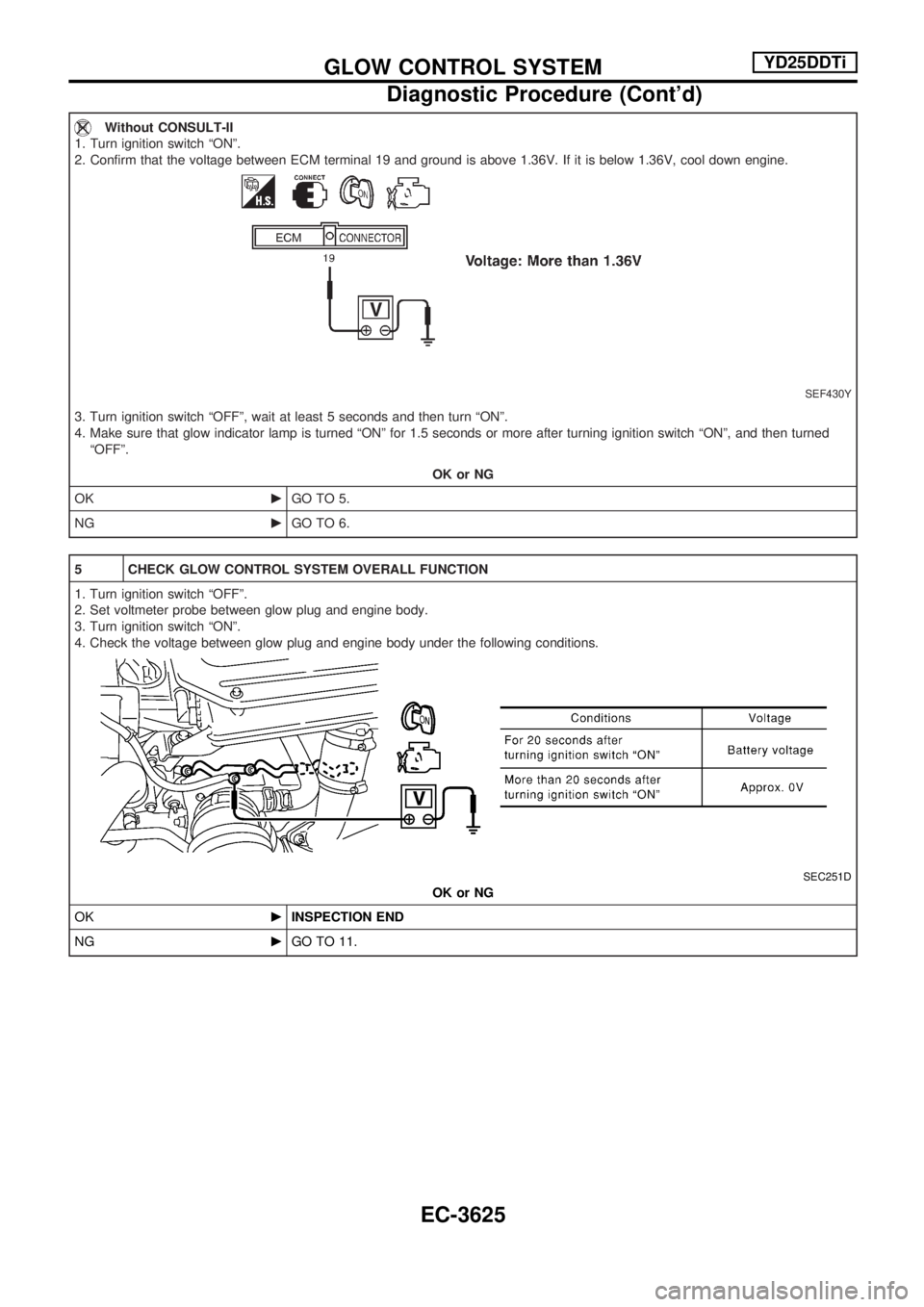

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Confirm that the voltage between ECM terminal 19 and ground is above 1.36V. If it is below 1.36V, cool down engine.

SEF430Y

3. Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

4. Make sure that glow indicator lamp is turned ªONº for 1.5 seconds or more after turning ignition switch ªONº, and then turned

ªOFFº.

OK or NG

OKcGO TO 5.

NGcGO TO 6.

5 CHECK GLOW CONTROL SYSTEM OVERALL FUNCTION

1. Turn ignition switch ªOFFº.

2. Set voltmeter probe between glow plug and engine body.

3. Turn ignition switch ªONº.

4. Check the voltage between glow plug and engine body under the following conditions.

SEC251D

OK or NG

OKcINSPECTION END

NGcGO TO 11.

GLOW CONTROL SYSTEMYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3625

Page 677 of 1306

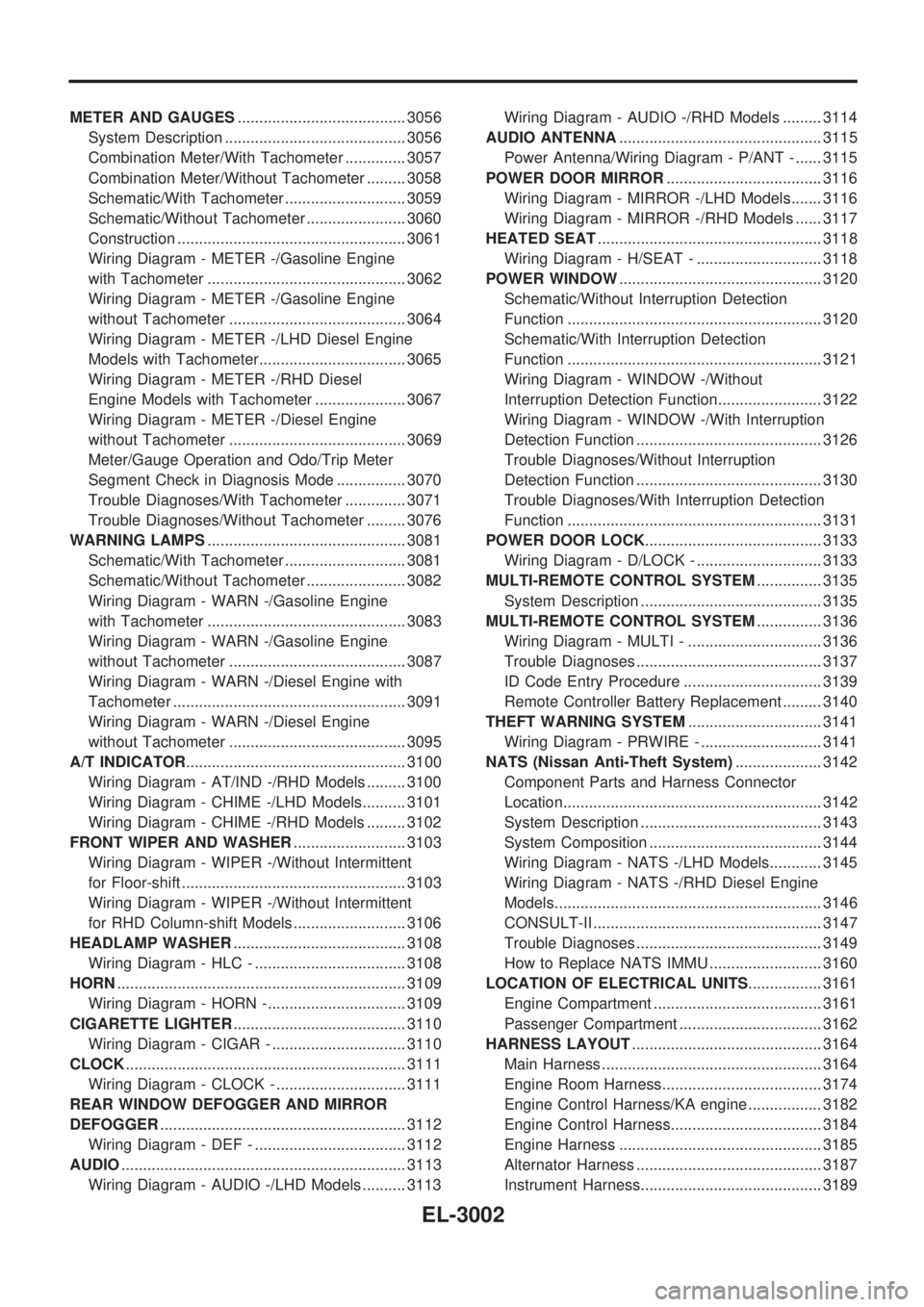

METER AND GAUGES....................................... 3056

System Description .......................................... 3056

Combination Meter/With Tachometer .............. 3057

Combination Meter/Without Tachometer ......... 3058

Schematic/With Tachometer ............................ 3059

Schematic/Without Tachometer ....................... 3060

Construction ..................................................... 3061

Wiring Diagram - METER -/Gasoline Engine

with Tachometer .............................................. 3062

Wiring Diagram - METER -/Gasoline Engine

without Tachometer ......................................... 3064

Wiring Diagram - METER -/LHD Diesel Engine

Models with Tachometer.................................. 3065

Wiring Diagram - METER -/RHD Diesel

Engine Models with Tachometer ..................... 3067

Wiring Diagram - METER -/Diesel Engine

without Tachometer ......................................... 3069

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode ................ 3070

Trouble Diagnoses/With Tachometer .............. 3071

Trouble Diagnoses/Without Tachometer ......... 3076

WARNING LAMPS.............................................. 3081

Schematic/With Tachometer ............................ 3081

Schematic/Without Tachometer ....................... 3082

Wiring Diagram - WARN -/Gasoline Engine

with Tachometer .............................................. 3083

Wiring Diagram - WARN -/Gasoline Engine

without Tachometer ......................................... 3087

Wiring Diagram - WARN -/Diesel Engine with

Tachometer ...................................................... 3091

Wiring Diagram - WARN -/Diesel Engine

without Tachometer ......................................... 3095

A/T INDICATOR................................................... 3100

Wiring Diagram - AT/IND -/RHD Models ......... 3100

Wiring Diagram - CHIME -/LHD Models.......... 3101

Wiring Diagram - CHIME -/RHD Models ......... 3102

FRONT WIPER AND WASHER.......................... 3103

Wiring Diagram - WIPER -/Without Intermittent

for Floor-shift .................................................... 3103

Wiring Diagram - WIPER -/Without Intermittent

for RHD Column-shift Models .......................... 3106

HEADLAMP WASHER........................................ 3108

Wiring Diagram - HLC - ................................... 3108

HORN................................................................... 3109

Wiring Diagram - HORN -................................ 3109

CIGARETTE LIGHTER........................................ 3110

Wiring Diagram - CIGAR - ............................... 3110

CLOCK................................................................. 3111

Wiring Diagram - CLOCK - .............................. 3111

REAR WINDOW DEFOGGER AND MIRROR

DEFOGGER......................................................... 3112

Wiring Diagram - DEF - ................................... 3112

AUDIO.................................................................. 3113

Wiring Diagram - AUDIO -/LHD Models .......... 3113Wiring Diagram - AUDIO -/RHD Models ......... 3114

AUDIO ANTENNA............................................... 3115

Power Antenna/Wiring Diagram - P/ANT - ...... 3115

POWER DOOR MIRROR.................................... 3116

Wiring Diagram - MIRROR -/LHD Models....... 3116

Wiring Diagram - MIRROR -/RHD Models ...... 3117

HEATED SEAT.................................................... 3118

Wiring Diagram - H/SEAT - ............................. 3118

POWER WINDOW............................................... 3120

Schematic/Without Interruption Detection

Function ........................................................... 3120

Schematic/With Interruption Detection

Function ........................................................... 3121

Wiring Diagram - WINDOW -/Without

Interruption Detection Function........................ 3122

Wiring Diagram - WINDOW -/With Interruption

Detection Function ........................................... 3126

Trouble Diagnoses/Without Interruption

Detection Function ........................................... 3130

Trouble Diagnoses/With Interruption Detection

Function ........................................................... 3131

POWER DOOR LOCK......................................... 3133

Wiring Diagram - D/LOCK - ............................. 3133

MULTI-REMOTE CONTROL SYSTEM............... 3135

System Description .......................................... 3135

MULTI-REMOTE CONTROL SYSTEM............... 3136

Wiring Diagram - MULTI - ............................... 3136

Trouble Diagnoses ........................................... 3137

ID Code Entry Procedure ................................ 3139

Remote Controller Battery Replacement ......... 3140

THEFT WARNING SYSTEM............................... 3141

Wiring Diagram - PRWIRE - ............................ 3141

NATS (Nissan Anti-Theft System).................... 3142

Component Parts and Harness Connector

Location............................................................ 3142

System Description .......................................... 3143

System Composition ........................................ 3144

Wiring Diagram - NATS -/LHD Models............ 3145

Wiring Diagram - NATS -/RHD Diesel Engine

Models.............................................................. 3146

CONSULT-II ..................................................... 3147

Trouble Diagnoses ........................................... 3149

How to Replace NATS IMMU .......................... 3160

LOCATION OF ELECTRICAL UNITS................. 3161

Engine Compartment ....................................... 3161

Passenger Compartment ................................. 3162

HARNESS LAYOUT............................................ 3164

Main Harness ................................................... 3164

Engine Room Harness..................................... 3174

Engine Control Harness/KA engine ................. 3182

Engine Control Harness................................... 3184

Engine Harness ............................................... 3185

Alternator Harness ........................................... 3187

Instrument Harness.......................................... 3189

EL-3002

Page 748 of 1306

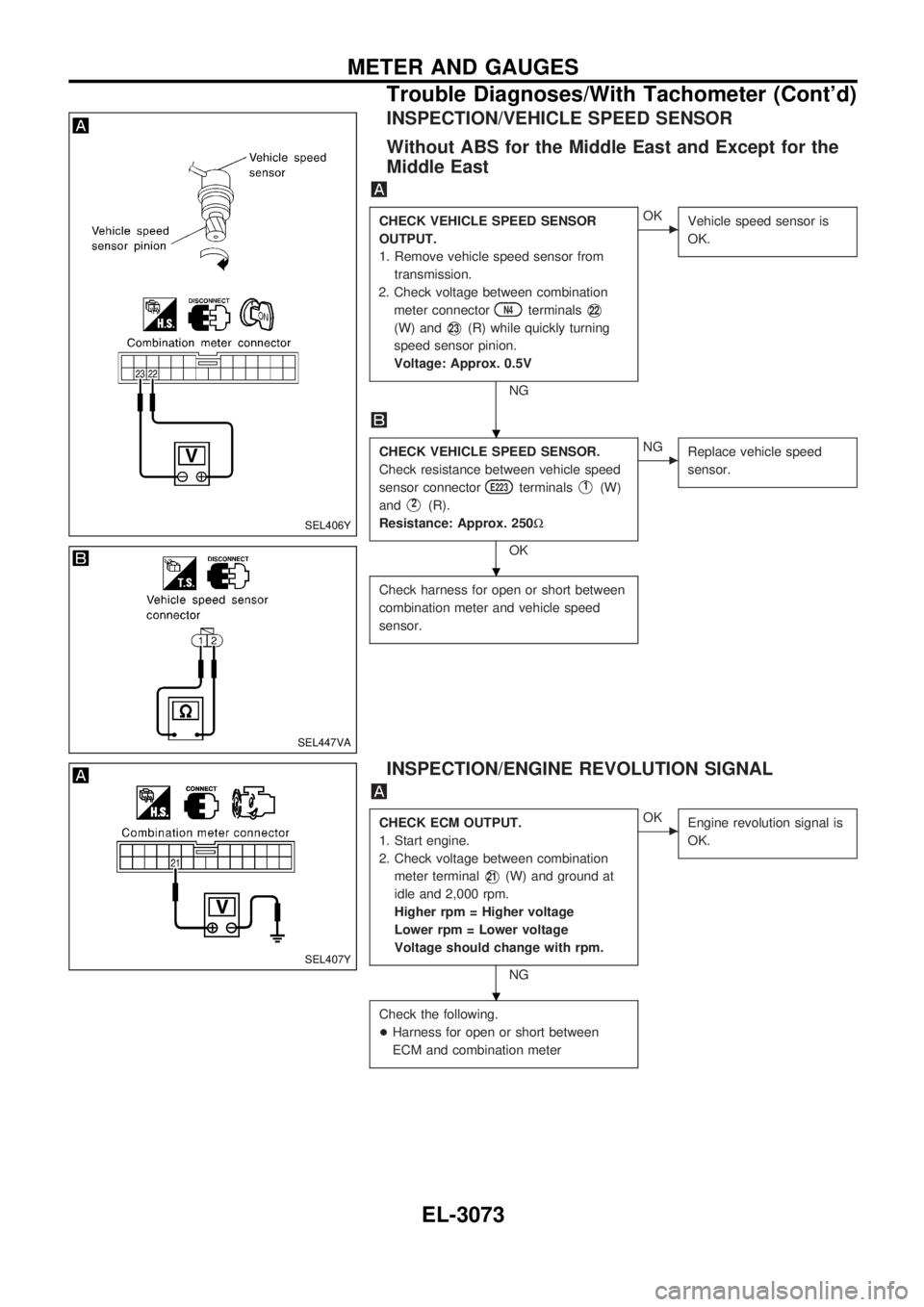

INSPECTION/VEHICLE SPEED SENSOR

Without ABS for the Middle East and Except for the

Middle East

CHECK VEHICLE SPEED SENSOR

OUTPUT.

1. Remove vehicle speed sensor from

transmission.

2. Check voltage between combination

meter connector

N4terminalsV22

(W) andV23(R) while quickly turning

speed sensor pinion.

Voltage: Approx. 0.5V

NG

cOK

Vehicle speed sensor is

OK.

CHECK VEHICLE SPEED SENSOR.

Check resistance between vehicle speed

sensor connector

E223terminalsV1(W)

and

V2(R).

Resistance: Approx. 250W

OK

cNG

Replace vehicle speed

sensor.

Check harness for open or short between

combination meter and vehicle speed

sensor.

INSPECTION/ENGINE REVOLUTION SIGNAL

CHECK ECM OUTPUT.

1. Start engine.

2. Check voltage between combination

meter terminal

V21(W) and ground at

idle and 2,000 rpm.

Higher rpm = Higher voltage

Lower rpm = Lower voltage

Voltage should change with rpm.

NG

cOK

Engine revolution signal is

OK.

Check the following.

+Harness for open or short between

ECM and combination meter

SEL406Y

SEL447VA

SEL407Y

.

.

.

METER AND GAUGES

Trouble Diagnoses/With Tachometer (Cont'd)

EL-3073

Page 823 of 1306

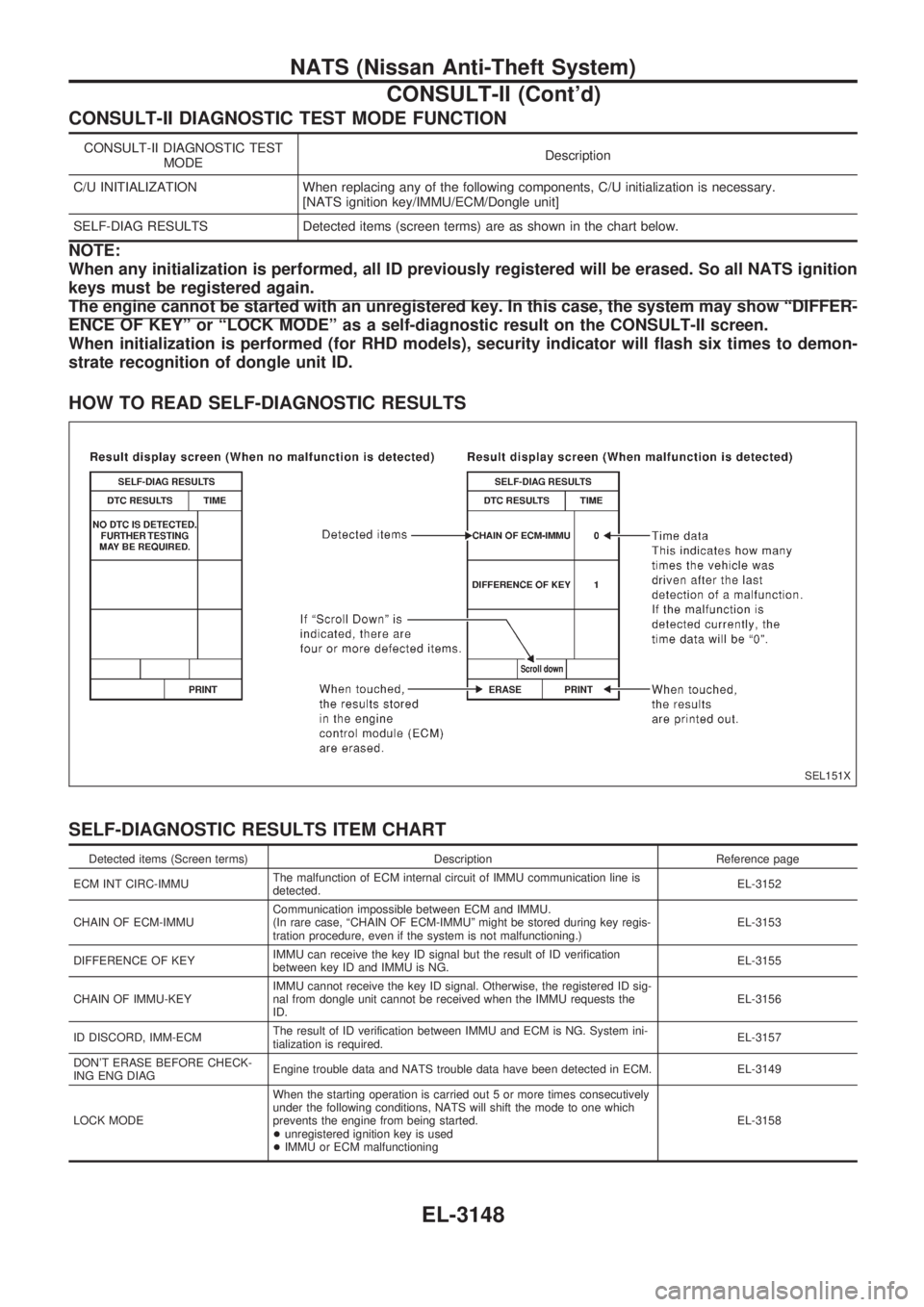

CONSULT-II DIAGNOSTIC TEST MODE FUNCTION

CONSULT-II DIAGNOSTIC TEST

MODEDescription

C/U INITIALIZATION When replacing any of the following components, C/U initialization is necessary.

[NATS ignition key/IMMU/ECM/Dongle unit]

SELF-DIAG RESULTS Detected items (screen terms) are as shown in the chart below.

NOTE:

When any initialization is performed, all ID previously registered will be erased. So all NATS ignition

keys must be registered again.

The engine cannot be started with an unregistered key. In this case, the system may show ªDIFFER-

ENCE OF KEYº or ªLOCK MODEº as a self-diagnostic result on the CONSULT-II screen.

When initialization is performed (for RHD models), security indicator will flash six times to demon-

strate recognition of dongle unit ID.

HOW TO READ SELF-DIAGNOSTIC RESULTS

SELF-DIAGNOSTIC RESULTS ITEM CHART

Detected items (Screen terms) Description Reference page

ECM INT CIRC-IMMUThe malfunction of ECM internal circuit of IMMU communication line is

detected.EL-3152

CHAIN OF ECM-IMMUCommunication impossible between ECM and IMMU.

(In rare case, ªCHAIN OF ECM-IMMUº might be stored during key regis-

tration procedure, even if the system is not malfunctioning.)EL-3153

DIFFERENCE OF KEYIMMU can receive the key ID signal but the result of ID verification

between key ID and IMMU is NG.EL-3155

CHAIN OF IMMU-KEYIMMU cannot receive the key ID signal. Otherwise, the registered ID sig-

nal from dongle unit cannot be received when the IMMU requests the

ID.EL-3156

ID DISCORD, IMM-ECMThe result of ID verification between IMMU and ECM is NG. System ini-

tialization is required.EL-3157

DON'T ERASE BEFORE CHECK-

ING ENG DIAGEngine trouble data and NATS trouble data have been detected in ECM. EL-3149

LOCK MODEWhen the starting operation is carried out 5 or more times consecutively

under the following conditions, NATS will shift the mode to one which

prevents the engine from being started.

+unregistered ignition key is used

+IMMU or ECM malfunctioningEL-3158

SEL151X

NATS (Nissan Anti-Theft System)

CONSULT-II (Cont'd)

EL-3148

Page 824 of 1306

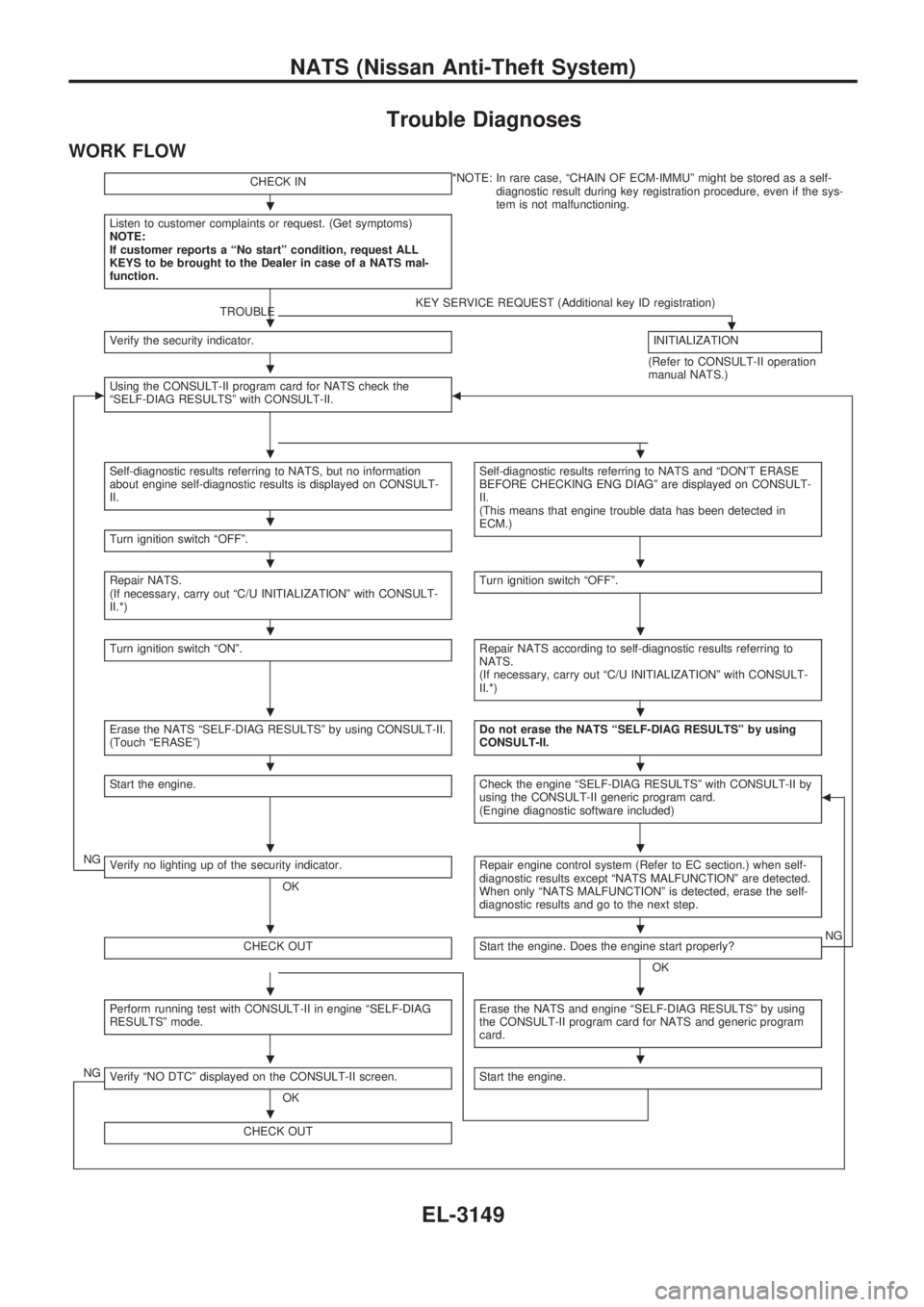

Trouble Diagnoses

WORK FLOW

CHECK IN*NOTE: In rare case, ªCHAIN OF ECM-IMMUº might be stored as a self-

diagnostic result during key registration procedure, even if the sys-

tem is not malfunctioning.

Listen to customer complaints or request. (Get symptoms)

NOTE:

If customer reports a ªNo startº condition, request ALL

KEYS to be brought to the Dealer in case of a NATS mal-

function.

TROUBLEKEY SERVICE REQUEST (Additional key ID registration).Verify the security indicator.INITIALIZATION

(Refer to CONSULT-II operation

manual NATS.)

cUsing the CONSULT-II program card for NATS check the

ªSELF-DIAG RESULTSº with CONSULT-II.b

Self-diagnostic results referring to NATS, but no information

about engine self-diagnostic results is displayed on CONSULT-

II.Self-diagnostic results referring to NATS and ªDON'T ERASE

BEFORE CHECKING ENG DIAGº are displayed on CONSULT-

II.

(This means that engine trouble data has been detected in

ECM.)

Turn ignition switch ªOFFº.

Repair NATS.

(If necessary, carry out ªC/U INITIALIZATIONº with CONSULT-

II.*)Turn ignition switch ªOFFº.

Turn ignition switch ªONº.Repair NATS according to self-diagnostic results referring to

NATS.

(If necessary, carry out ªC/U INITIALIZATIONº with CONSULT-

II.*)

Erase the NATS ªSELF-DIAG RESULTSº by using CONSULT-II.

(Touch ªERASEº)Do not erase the NATS ªSELF-DIAG RESULTSº by using

CONSULT-II.

Start the engine.Check the engine ªSELF-DIAG RESULTSº with CONSULT-II by

using the CONSULT-II generic program card.

(Engine diagnostic software included)b

NGVerify no lighting up of the security indicator.

OKRepair engine control system (Refer to EC section.) when self-

diagnostic results except ªNATS MALFUNCTIONº are detected.

When only ªNATS MALFUNCTIONº is detected, erase the self-

diagnostic results and go to the next step.

CHECK OUTStart the engine. Does the engine start properly?

OKNG

Perform running test with CONSULT-II in engine ªSELF-DIAG

RESULTSº mode.Erase the NATS and engine ªSELF-DIAG RESULTSº by using

the CONSULT-II program card for NATS and generic program

card.

NGVerify ªNO DTCº displayed on the CONSULT-II screen.

OKStart the engine.

CHECK OUT

.

.

.

..

.

..

..

..

..

..

..

..

..

.

NATS (Nissan Anti-Theft System)

EL-3149

Page 828 of 1306

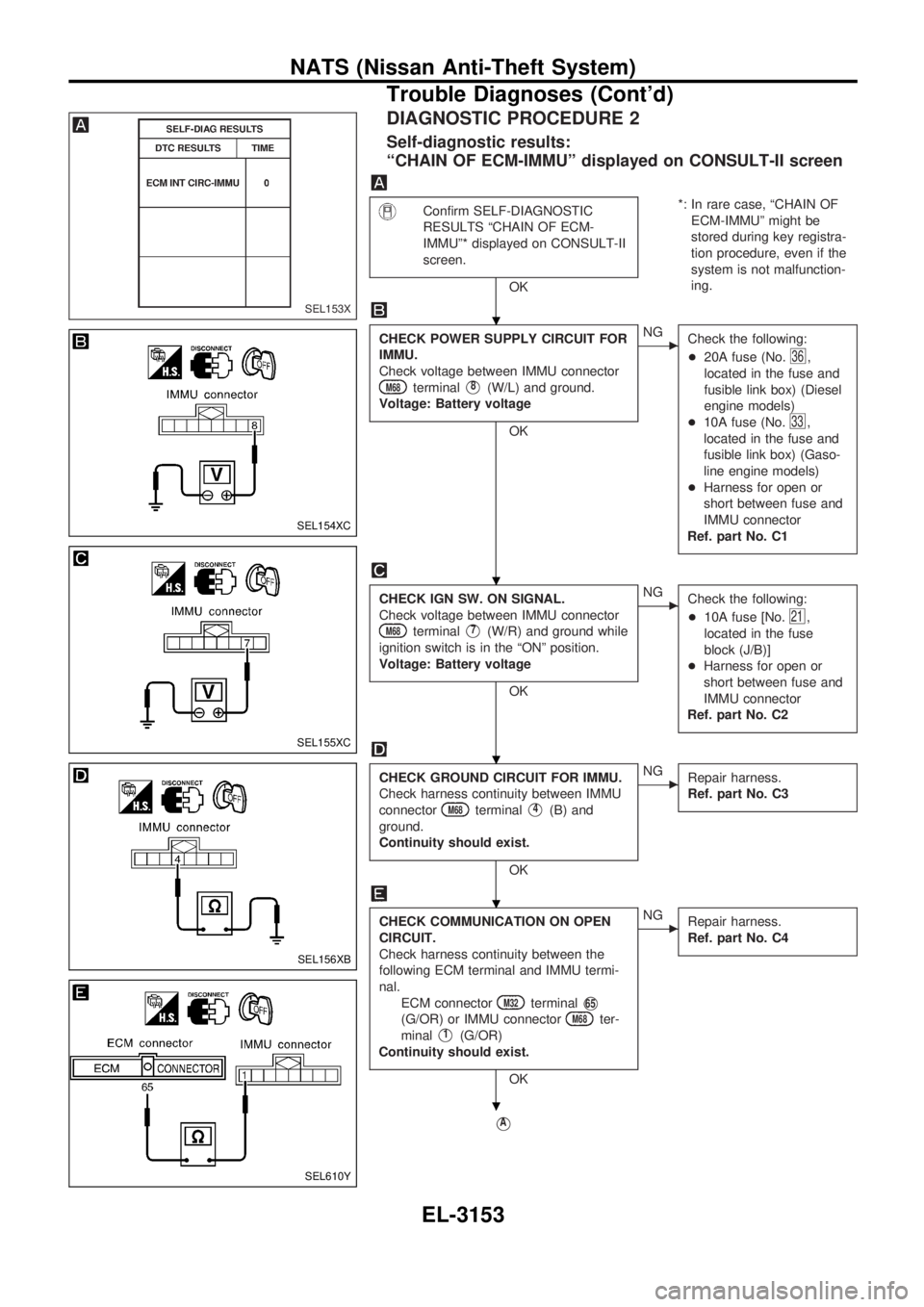

DIAGNOSTIC PROCEDURE 2

Self-diagnostic results:

ªCHAIN OF ECM-IMMUº displayed on CONSULT-II screen

Confirm SELF-DIAGNOSTIC

RESULTS ªCHAIN OF ECM-

IMMUº* displayed on CONSULT-II

screen.

OK*: In rare case, ªCHAIN OF

ECM-IMMUº might be

stored during key registra-

tion procedure, even if the

system is not malfunction-

ing.

CHECK POWER SUPPLY CIRCUIT FOR

IMMU.

Check voltage between IMMU connector

M68terminalV8(W/L) and ground.

Voltage: Battery voltage

OK

cNG

Check the following:

+20A fuse (No.

36,

located in the fuse and

fusible link box) (Diesel

engine models)

+10A fuse (No.

33,

located in the fuse and

fusible link box) (Gaso-

line engine models)

+Harness for open or

short between fuse and

IMMU connector

Ref. part No. C1

CHECK IGN SW. ON SIGNAL.

Check voltage between IMMU connector

M68terminalV7(W/R) and ground while

ignition switch is in the ªONº position.

Voltage: Battery voltage

OK

cNG

Check the following:

+10A fuse [No.

21,

located in the fuse

block (J/B)]

+Harness for open or

short between fuse and

IMMU connector

Ref. part No. C2

CHECK GROUND CIRCUIT FOR IMMU.

Check harness continuity between IMMU

connector

M68terminalV4(B) and

ground.

Continuity should exist.

OK

cNG

Repair harness.

Ref. part No. C3

CHECK COMMUNICATION ON OPEN

CIRCUIT.

Check harness continuity between the

following ECM terminal and IMMU termi-

nal.

ECM connector

M32terminalV65

(G/OR) or IMMU connectorM68ter-

minal

V1(G/OR)

Continuity should exist.

OK

cNG

Repair harness.

Ref. part No. C4

VA

SEL153X

SEL154XC

SEL155XC

SEL156XB

SEL610Y

.

.

.

.

.

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-3153