check engine NISSAN PICK-UP 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 1040 of 1306

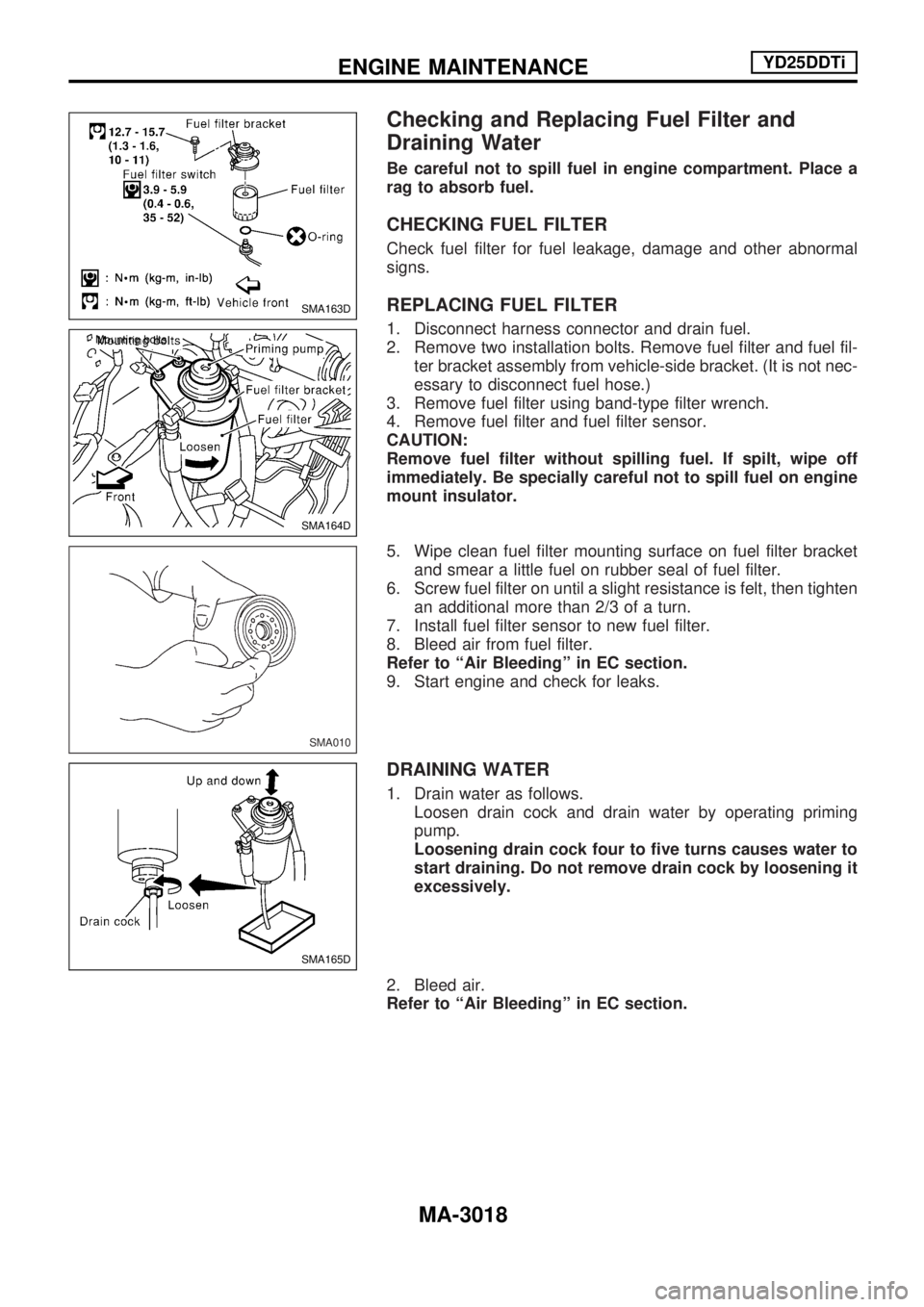

Checking and Replacing Fuel Filter and

Draining Water

Be careful not to spill fuel in engine compartment. Place a

rag to absorb fuel.

CHECKING FUEL FILTER

Check fuel filter for fuel leakage, damage and other abnormal

signs.

REPLACING FUEL FILTER

1. Disconnect harness connector and drain fuel.

2. Remove two installation bolts. Remove fuel filter and fuel fil-

ter bracket assembly from vehicle-side bracket. (It is not nec-

essary to disconnect fuel hose.)

3. Remove fuel filter using band-type filter wrench.

4. Remove fuel filter and fuel filter sensor.

CAUTION:

Remove fuel filter without spilling fuel. If spilt, wipe off

immediately. Be specially careful not to spill fuel on engine

mount insulator.

5. Wipe clean fuel filter mounting surface on fuel filter bracket

and smear a little fuel on rubber seal of fuel filter.

6. Screw fuel filter on until a slight resistance is felt, then tighten

an additional more than 2/3 of a turn.

7. Install fuel filter sensor to new fuel filter.

8. Bleed air from fuel filter.

Refer to ªAir Bleedingº in EC section.

9. Start engine and check for leaks.

DRAINING WATER

1. Drain water as follows.

Loosen drain cock and drain water by operating priming

pump.

Loosening drain cock four to five turns causes water to

start draining. Do not remove drain cock by loosening it

excessively.

2. Bleed air.

Refer to ªAir Bleedingº in EC section.

SMA163D

SMA164D Mounting bolts

SMA010

SMA165D

ENGINE MAINTENANCEYD25DDTi

MA-3018

Page 1041 of 1306

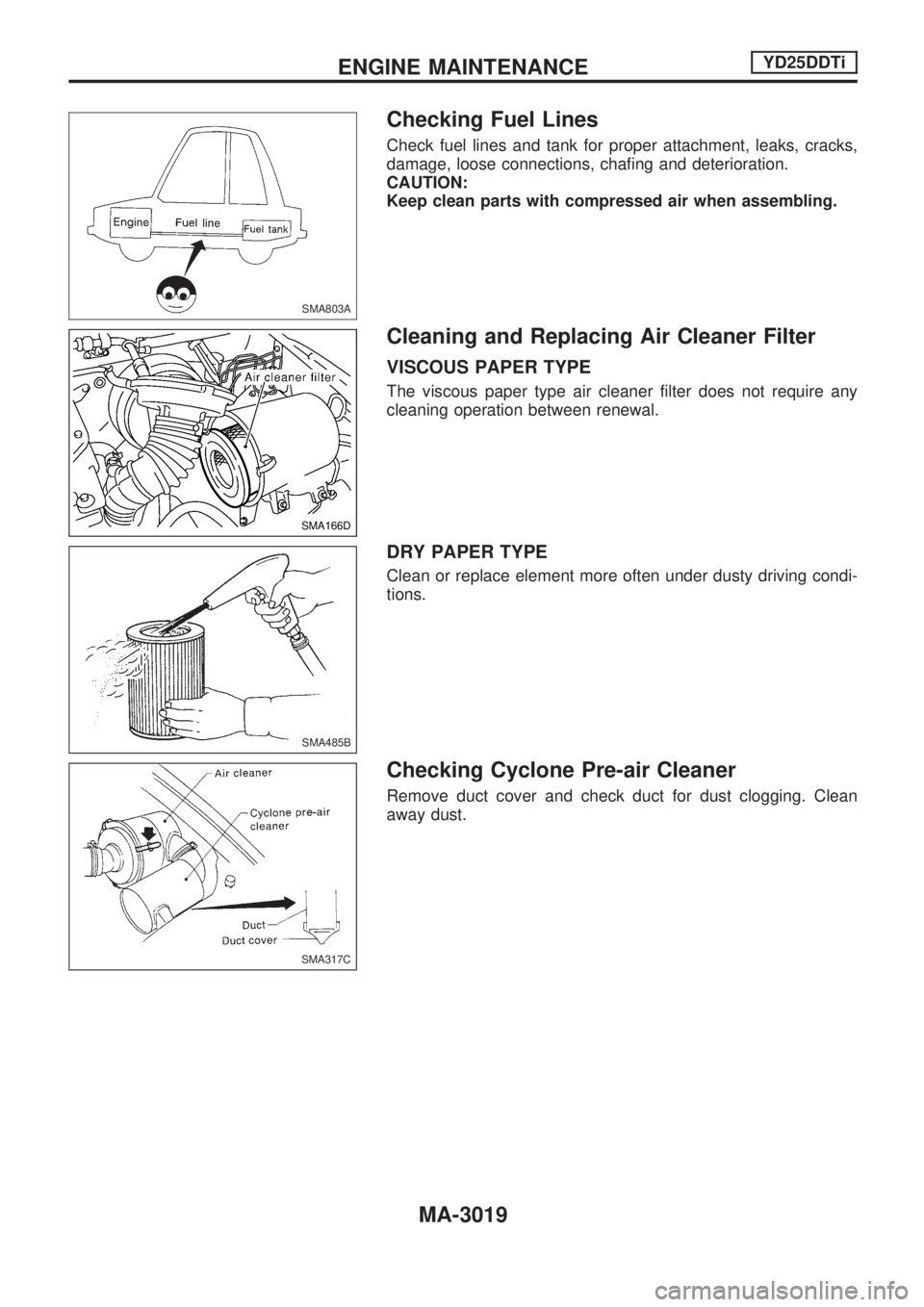

Checking Fuel Lines

Check fuel lines and tank for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CAUTION:

Keep clean parts with compressed air when assembling.

Cleaning and Replacing Air Cleaner Filter

VISCOUS PAPER TYPE

The viscous paper type air cleaner filter does not require any

cleaning operation between renewal.

DRY PAPER TYPE

Clean or replace element more often under dusty driving condi-

tions.

Checking Cyclone Pre-air Cleaner

Remove duct cover and check duct for dust clogging. Clean

away dust.

SMA803A

SMA166D

SMA485B

SMA317C

ENGINE MAINTENANCEYD25DDTi

MA-3019

Page 1042 of 1306

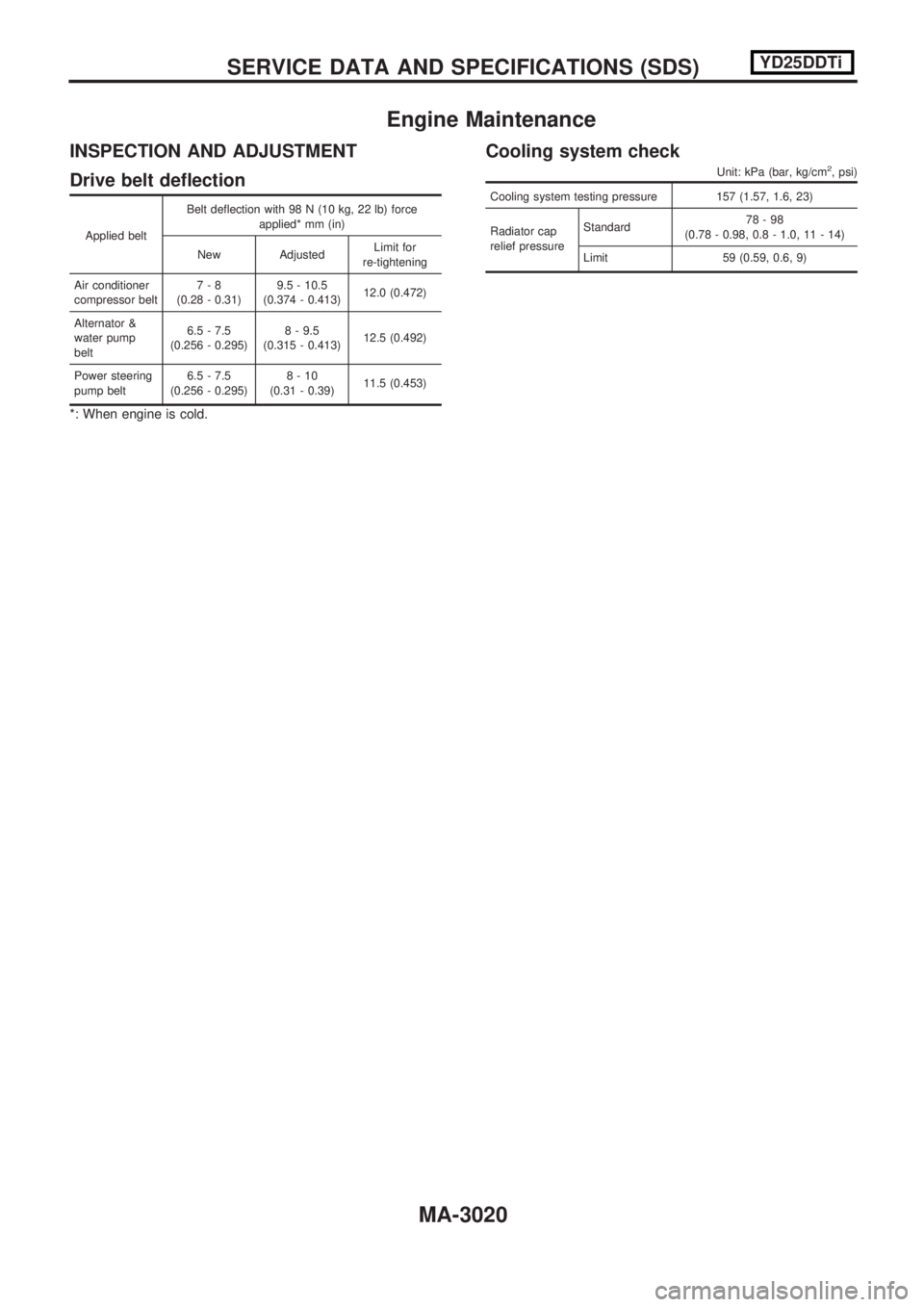

Engine Maintenance

INSPECTION AND ADJUSTMENT

Drive belt deflection

Applied beltBelt deflection with 98 N (10 kg, 22 lb) force

applied* mm (in)

New Adjusted Limit for

re-tightening

Air conditioner

compressor belt 7-8

(0.28 - 0.31) 9.5 - 10.5

(0.374 - 0.413) 12.0 (0.472)

Alternator &

water pump

belt 6.5 - 7.5

(0.256 - 0.295) 8 - 9.5

(0.315 - 0.413) 12.5 (0.492)

Power steering

pump belt 6.5 - 7.5

(0.256 - 0.295) 8-10

(0.31 - 0.39) 11.5 (0.453)

*: When engine is cold.

Cooling system check

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap

relief pressureStandard

78-98

(0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 (0.59, 0.6, 9)

SERVICEDATAANDSPECIFICATIONS(SDS) YD25DDTi

MA-3020

Page 1043 of 1306

ENGINE LUBRICATION &

COOLING SYSTEMS

SECTION

LC

MODIFICATION NOTICE:

+KA24DE engine information has been added. For specifications other than those described here, refer

to D22 Supplement-II Service Manual (SM9E-D22BE0E).

+YD25DDTi engine model has been added.

CONTENTS

KA24DE

ENGINE ROOM FAN MOTOR ELECTRICAL

CIRCUIT............................................................... 3002

Wiring Diagram ................................................ 3002

YD25DDTi

ENGINE LUBRICATION SYSTEM...................... 3003

Lubricating Circuit ............................................ 3003

Oil Pressure Check .......................................... 3004

Oil Pump .......................................................... 3004

Oil Filter Bracket .............................................. 3006

Oil Cooler ......................................................... 3006

ENGINE COOLING SYSTEM.............................. 3008Overheating Cause Analysis ........................... 3008

Cooling Circuit.................................................. 3010

System Check .................................................. 3011

Water Pump ..................................................... 3012

Thermostat and Water Piping .......................... 3014

Radiator............................................................ 3015

Cooling Fan (Crankshaft driven)...................... 3016

Cooling Fan (Motor driven) .............................. 3016

SERVICE DATA AND SPECIFICATIONS

(SDS).................................................................... 3018

Engine Lubrication System .............................. 3018

Engine Cooling System ................................... 3018

LC

Page 1046 of 1306

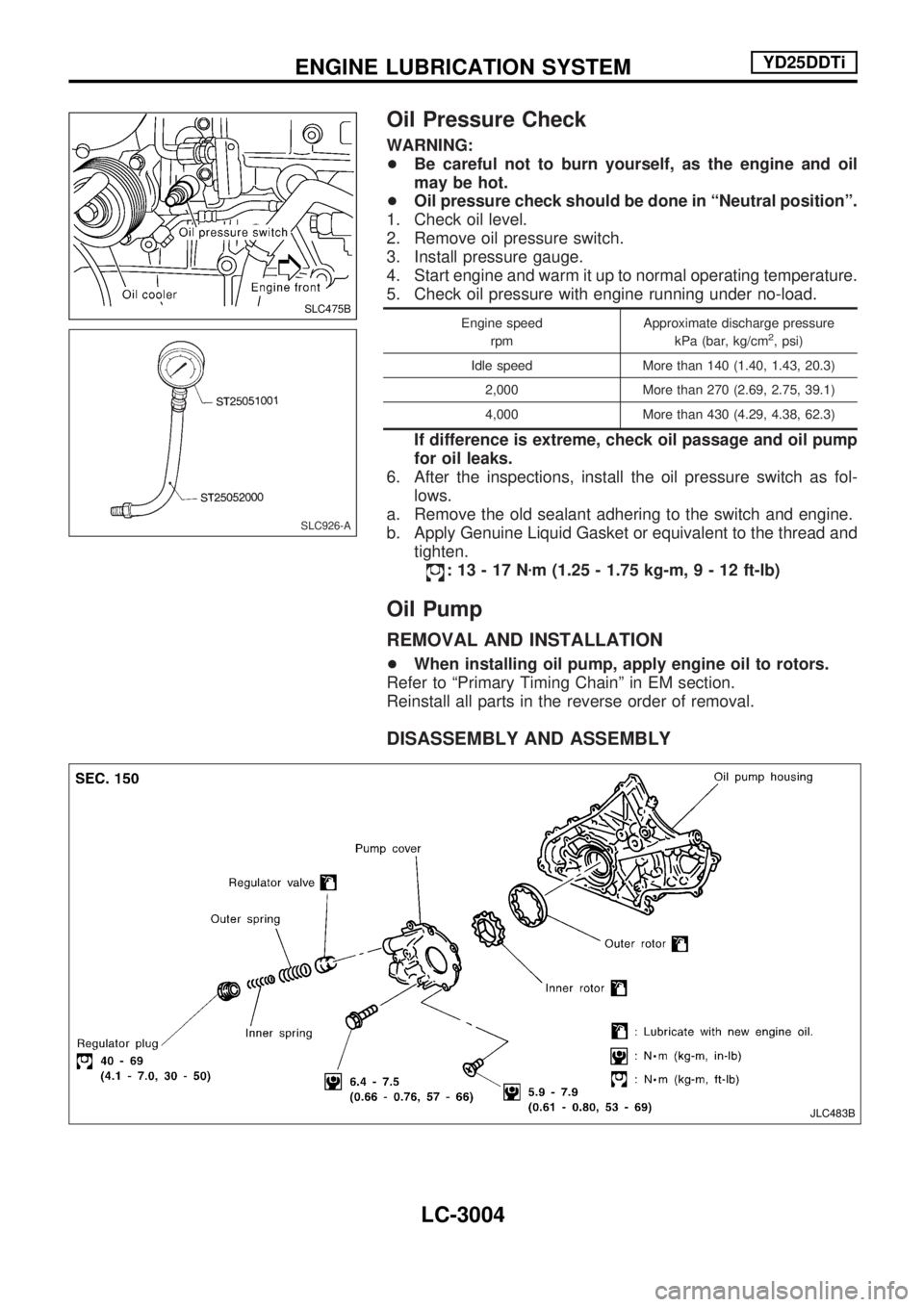

Oil Pressure Check

WARNING:

+Be careful not to burn yourself, as the engine and oil

may be hot.

+Oil pressure check should be done in ªNeutral positionº.

1. Check oil level.

2. Remove oil pressure switch.

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed More than 140 (1.40, 1.43, 20.3)

2,000 More than 270 (2.69, 2.75, 39.1)

4,000 More than 430 (4.29, 4.38, 62.3)

If difference is extreme, check oil passage and oil pump

for oil leaks.

6. After the inspections, install the oil pressure switch as fol-

lows.

a. Remove the old sealant adhering to the switch and engine.

b. Apply Genuine Liquid Gasket or equivalent to the thread and

tighten.

:13-17Nzm (1.25 - 1.75 kg-m,9-12ft-lb)

Oil Pump

REMOVAL AND INSTALLATION

+When installing oil pump, apply engine oil to rotors.

Refer to ªPrimary Timing Chainº in EM section.

Reinstall all parts in the reverse order of removal.

DISASSEMBLY AND ASSEMBLY

SLC475B

SLC926-A

JLC483B

ENGINE LUBRICATION SYSTEMYD25DDTi

LC-3004

Page 1047 of 1306

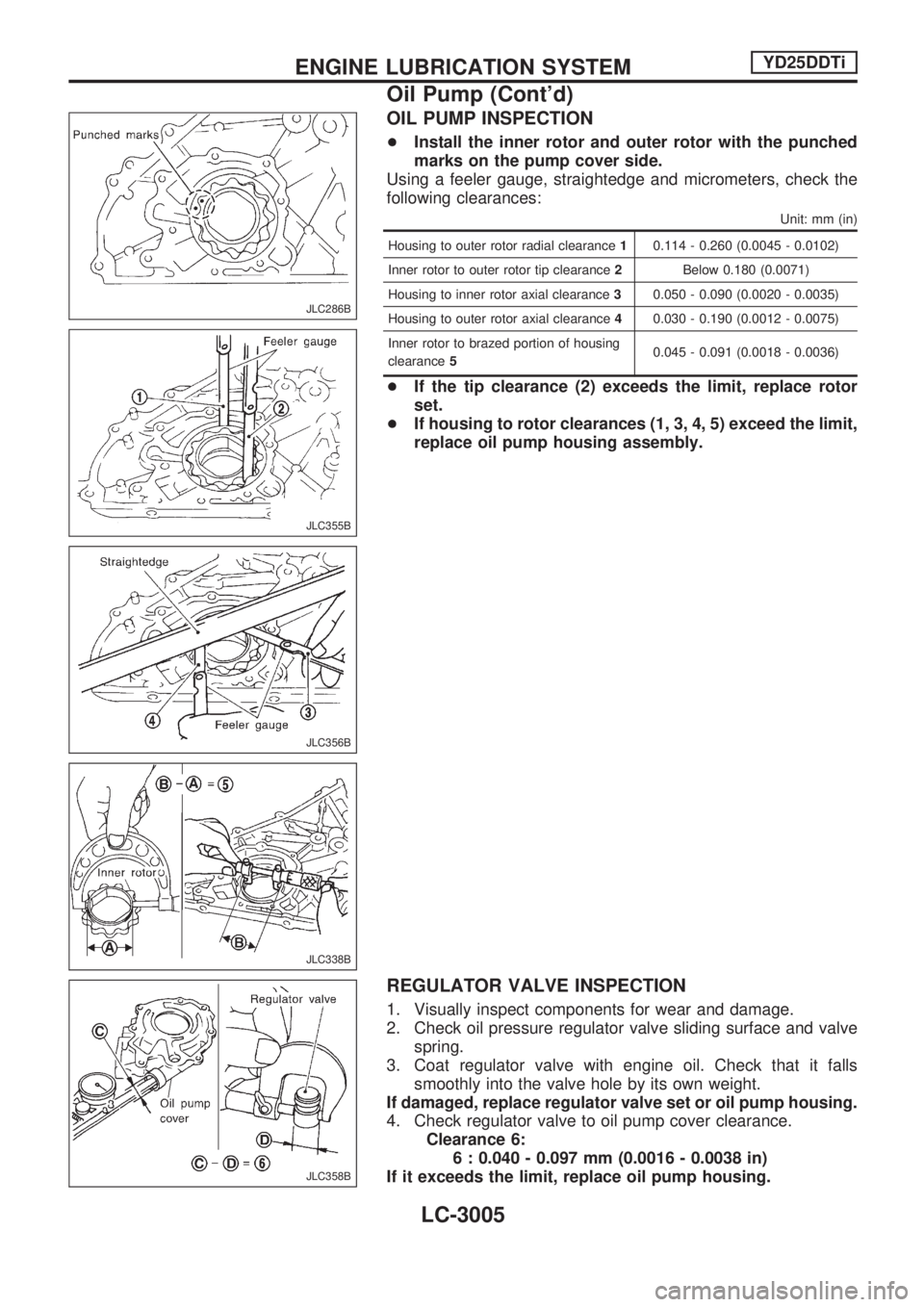

OIL PUMP INSPECTION

+Install the inner rotor and outer rotor with the punched

marks on the pump cover side.

Using a feeler gauge, straightedge and micrometers, check the

following clearances:

Unit: mm (in)

Housing to outer rotor radial clearance10.114 - 0.260 (0.0045 - 0.0102)

Inner rotor to outer rotor tip clearance2Below 0.180 (0.0071)

Housing to inner rotor axial clearance30.050 - 0.090 (0.0020 - 0.0035)

Housing to outer rotor axial clearance40.030 - 0.190 (0.0012 - 0.0075)

Inner rotor to brazed portion of housing

clearance50.045 - 0.091 (0.0018 - 0.0036)

+If the tip clearance (2) exceeds the limit, replace rotor

set.

+If housing to rotor clearances (1, 3, 4, 5) exceed the limit,

replace oil pump housing assembly.

REGULATOR VALVE INSPECTION

1. Visually inspect components for wear and damage.

2. Check oil pressure regulator valve sliding surface and valve

spring.

3. Coat regulator valve with engine oil. Check that it falls

smoothly into the valve hole by its own weight.

If damaged, replace regulator valve set or oil pump housing.

4. Check regulator valve to oil pump cover clearance.

Clearance 6:

6 : 0.040 - 0.097 mm (0.0016 - 0.0038 in)

If it exceeds the limit, replace oil pump housing.

JLC286B

JLC355B

JLC356B

JLC338B

JLC358B

ENGINE LUBRICATION SYSTEMYD25DDTi

Oil Pump (Cont'd)

LC-3005

Page 1050 of 1306

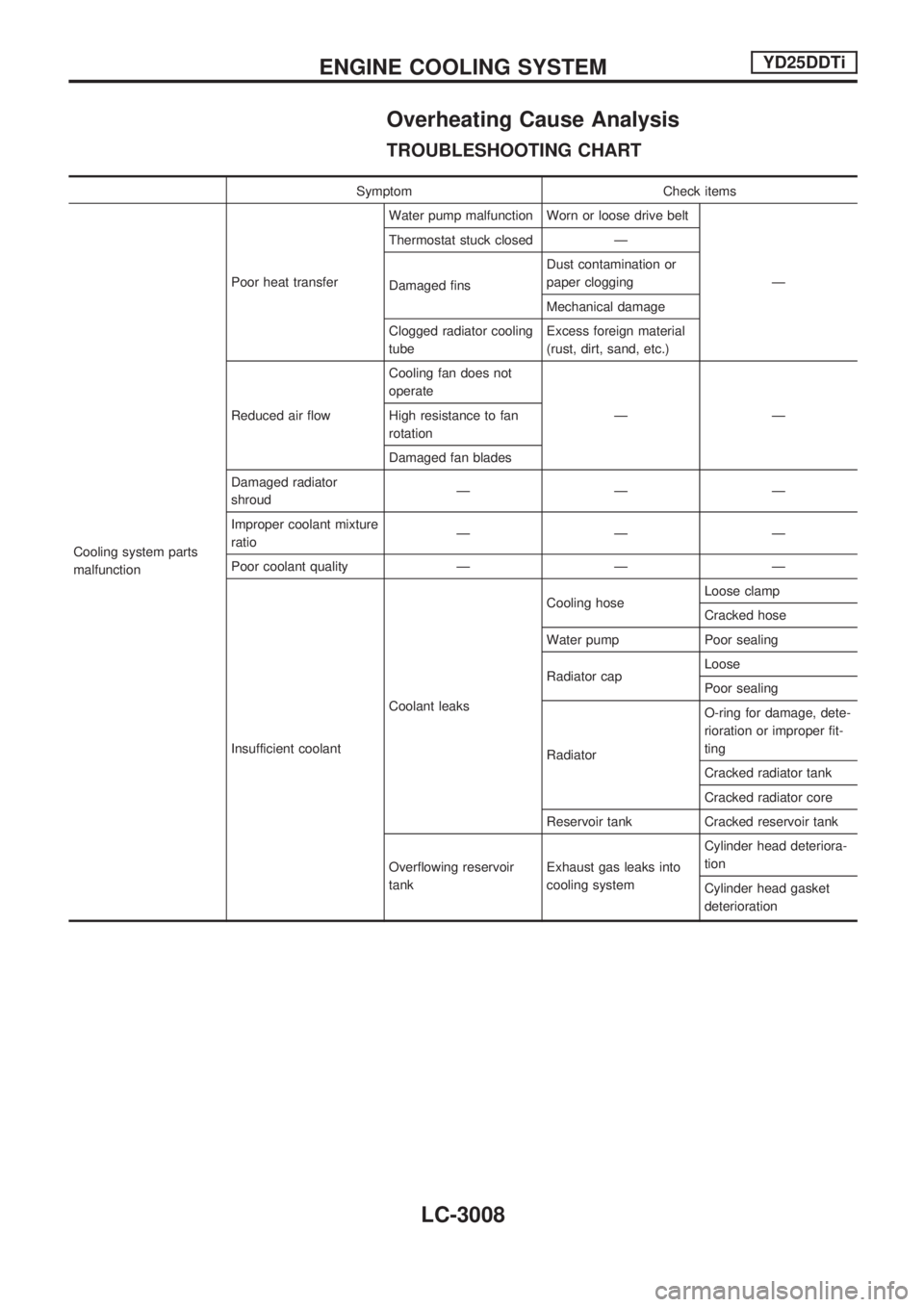

Overheating Cause Analysis

TROUBLESHOOTING CHART

Symptom Check items

Cooling system parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not

operate

ÐÐ High resistance to fan

rotation

Damaged fan blades

Damaged radiator

shroudÐÐÐ

Improper coolant mixture

ratioÐÐÐ

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, dete-

rioration or improper fit-

ting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir

tankExhaust gas leaks into

cooling systemCylinder head deteriora-

tion

Cylinder head gasket

deterioration

ENGINE COOLING SYSTEMYD25DDTi

LC-3008

Page 1051 of 1306

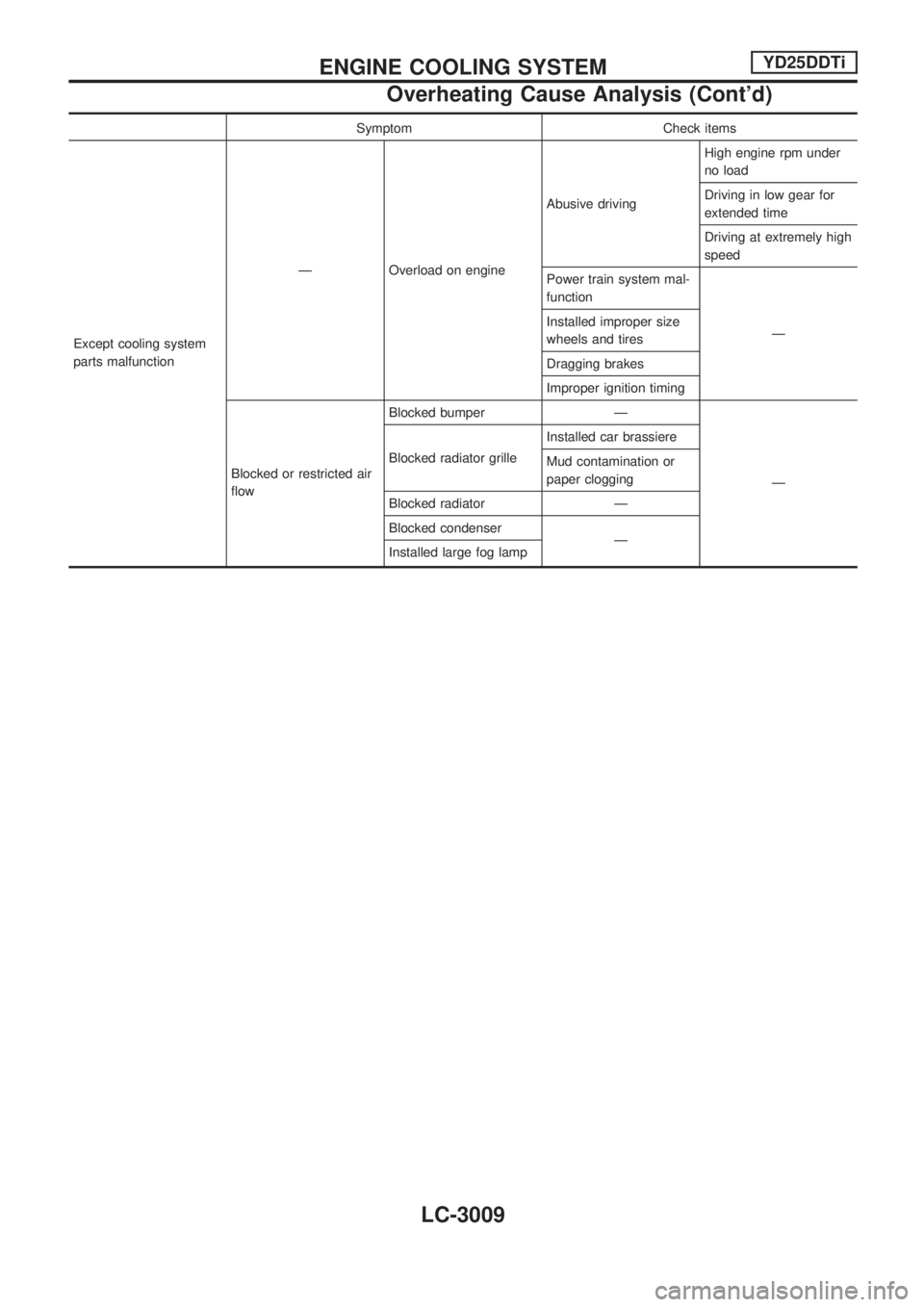

Symptom Check items

Except cooling system

parts malfunctionÐ Overload on engineAbusive drivingHigh engine rpm under

no load

Driving in low gear for

extended time

Driving at extremely high

speed

Power train system mal-

function

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

ENGINE COOLING SYSTEMYD25DDTi

Overheating Cause Analysis (Cont'd)

LC-3009

Page 1053 of 1306

System Check

WARNING:

Never remove the radiator cap when the engine is hot; seri-

ous burns could be caused by high pressure fluid escaping

from the radiator.

Wrap a thick cloth around the cap and carefully remove it by

turning it a quarter turn to allow built-up pressure to escape

and then turn the cap all the way off.

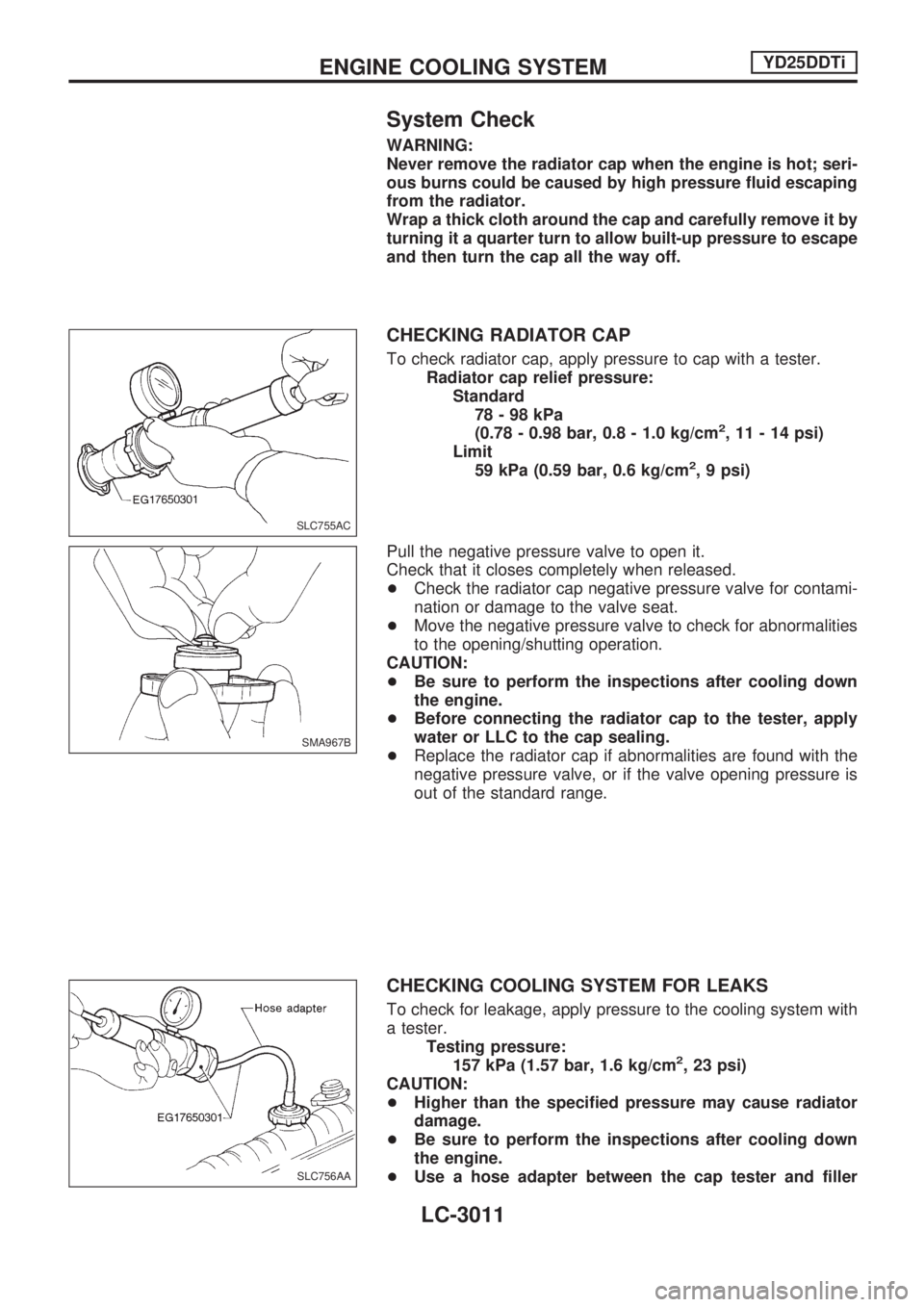

CHECKING RADIATOR CAP

To check radiator cap, apply pressure to cap with a tester.

Radiator cap relief pressure:

Standard

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Limit

59 kPa (0.59 bar, 0.6 kg/cm

2, 9 psi)

Pull the negative pressure valve to open it.

Check that it closes completely when released.

+Check the radiator cap negative pressure valve for contami-

nation or damage to the valve seat.

+Move the negative pressure valve to check for abnormalities

to the opening/shutting operation.

CAUTION:

+Be sure to perform the inspections after cooling down

the engine.

+Before connecting the radiator cap to the tester, apply

water or LLC to the cap sealing.

+Replace the radiator cap if abnormalities are found with the

negative pressure valve, or if the valve opening pressure is

out of the standard range.

CHECKING COOLING SYSTEM FOR LEAKS

To check for leakage, apply pressure to the cooling system with

a tester.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

CAUTION:

+Higher than the specified pressure may cause radiator

damage.

+Be sure to perform the inspections after cooling down

the engine.

+Use a hose adapter between the cap tester and filler

SLC755AC

SMA967B

SLC756AA

ENGINE COOLING SYSTEMYD25DDTi

LC-3011

Page 1054 of 1306

neck to prevent the radiator filler neck from deforming.

+If any abnormalities are found, repair or replace the malfunc-

tioning parts.

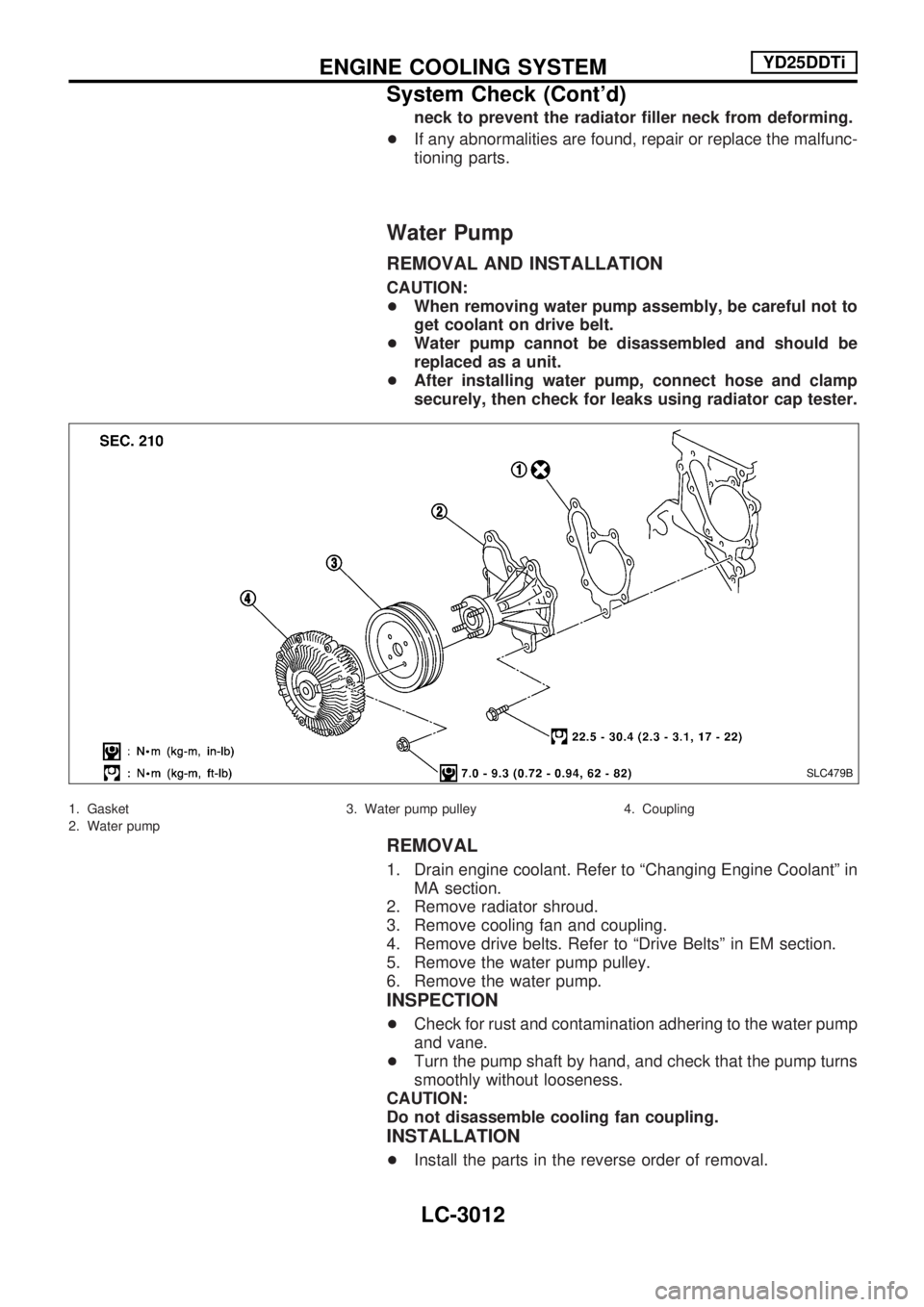

Water Pump

REMOVAL AND INSTALLATION

CAUTION:

+When removing water pump assembly, be careful not to

get coolant on drive belt.

+Water pump cannot be disassembled and should be

replaced as a unit.

+After installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

1. Gasket

2. Water pump3. Water pump pulley 4. Coupling

REMOVAL

1. Drain engine coolant. Refer to ªChanging Engine Coolantº in

MA section.

2. Remove radiator shroud.

3. Remove cooling fan and coupling.

4. Remove drive belts. Refer to ªDrive Beltsº in EM section.

5. Remove the water pump pulley.

6. Remove the water pump.

INSPECTION

+Check for rust and contamination adhering to the water pump

and vane.

+Turn the pump shaft by hand, and check that the pump turns

smoothly without looseness.

CAUTION:

Do not disassemble cooling fan coupling.

INSTALLATION

+Install the parts in the reverse order of removal.

SLC479B

ENGINE COOLING SYSTEMYD25DDTi

System Check (Cont'd)

LC-3012