tires NISSAN PICK-UP 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 702 of 1306

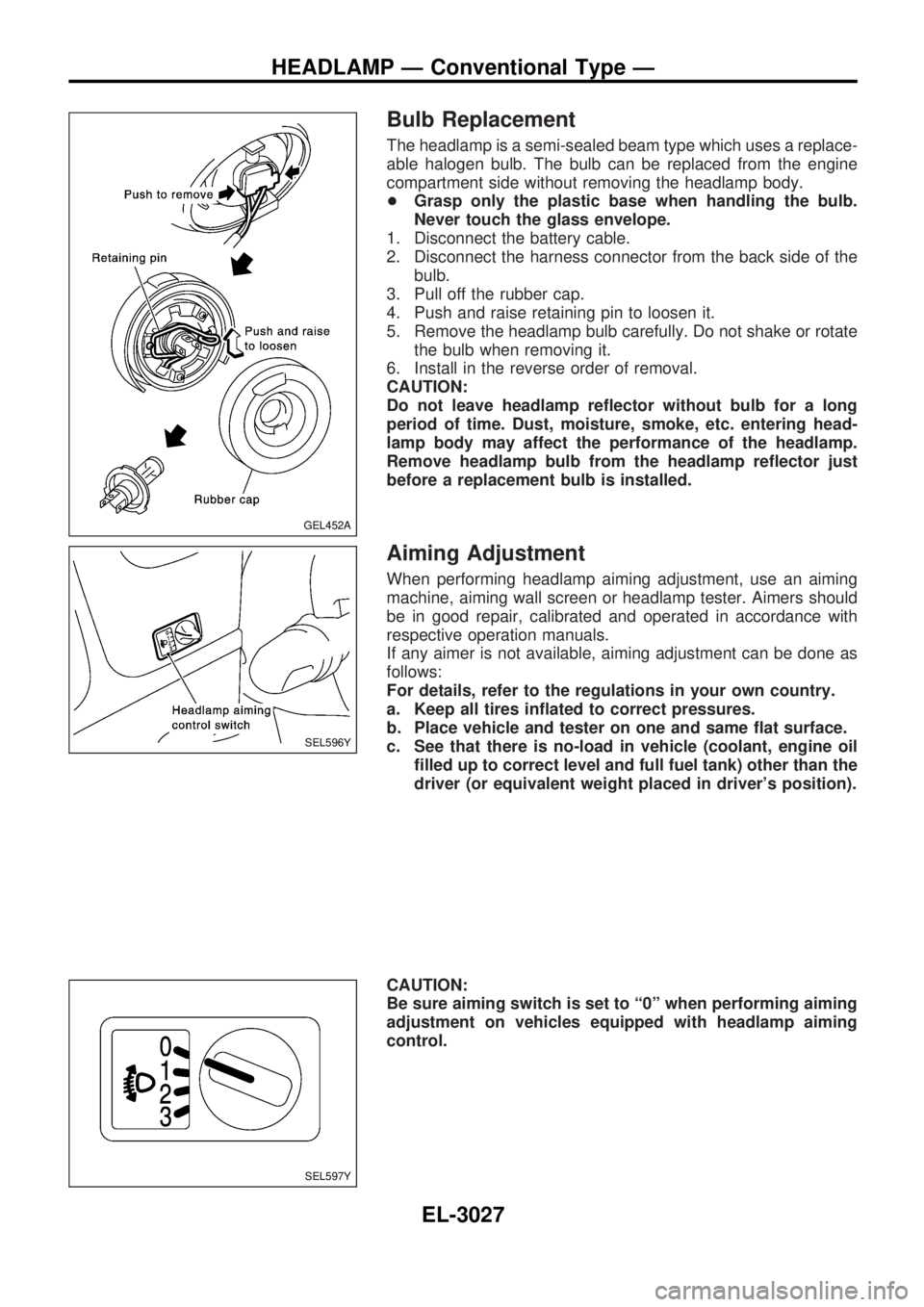

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replace-

able halogen bulb. The bulb can be replaced from the engine

compartment side without removing the headlamp body.

+Grasp only the plastic base when handling the bulb.

Never touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the

bulb.

3. Pull off the rubber cap.

4. Push and raise retaining pin to loosen it.

5. Remove the headlamp bulb carefully. Do not shake or rotate

the bulb when removing it.

6. Install in the reverse order of removal.

CAUTION:

Do not leave headlamp reflector without bulb for a long

period of time. Dust, moisture, smoke, etc. entering head-

lamp body may affect the performance of the headlamp.

Remove headlamp bulb from the headlamp reflector just

before a replacement bulb is installed.

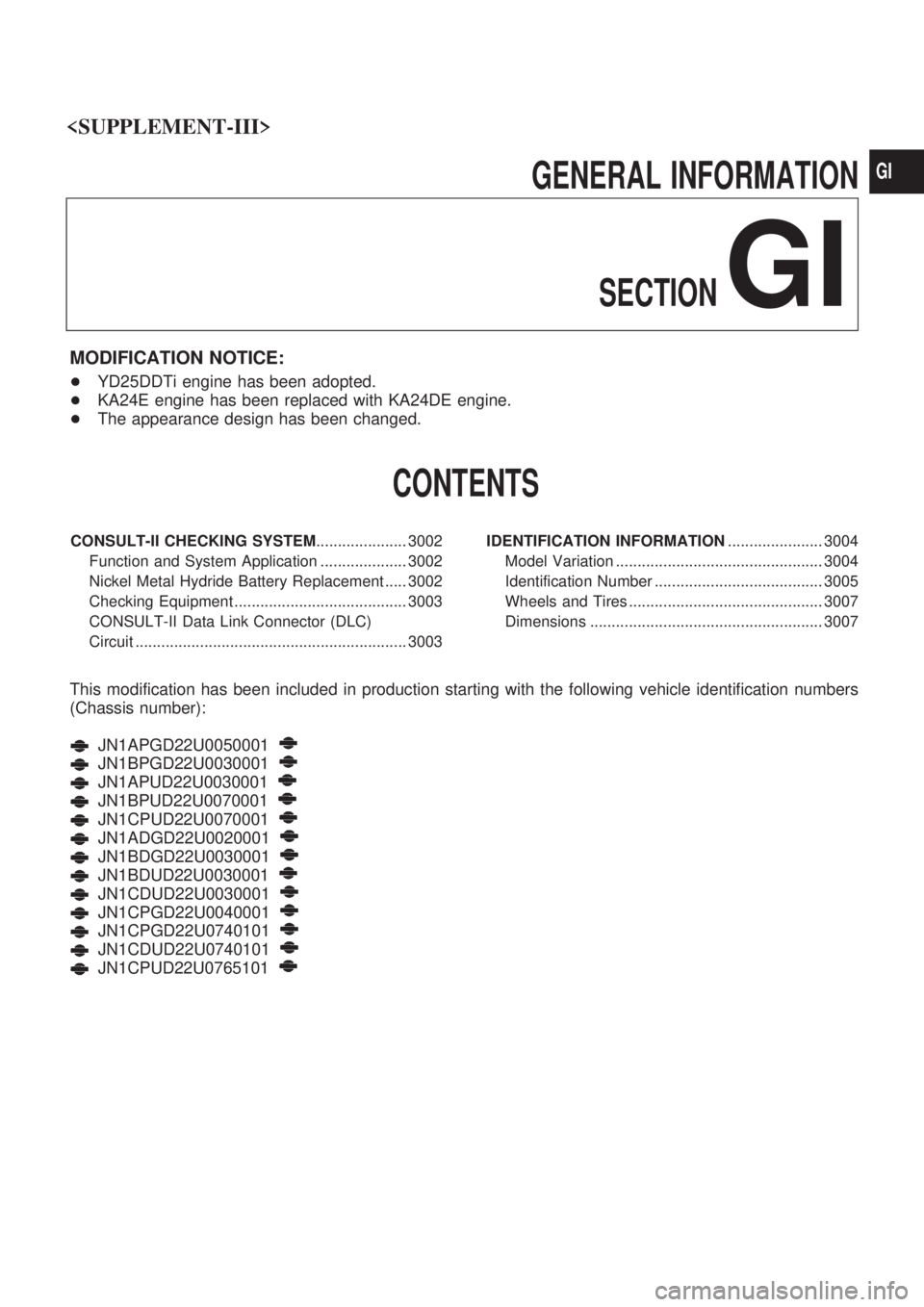

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. Aimers should

be in good repair, calibrated and operated in accordance with

respective operation manuals.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is no-load in vehicle (coolant, engine oil

filled up to correct level and full fuel tank) other than the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ª0º when performing aiming

adjustment on vehicles equipped with headlamp aiming

control.

GEL452A

SEL596Y

SEL597Y

HEADLAMP Ð Conventional Type Ð

EL-3027

Page 1008 of 1306

GENERAL INFORMATION

SECTION

GI

MODIFICATION NOTICE:

+YD25DDTi engine has been adopted.

+KA24E engine has been replaced with KA24DE engine.

+The appearance design has been changed.

CONTENTS

CONSULT-II CHECKING SYSTEM..................... 3002

Function and System Application .................... 3002

Nickel Metal Hydride Battery Replacement ..... 3002

Checking Equipment ........................................ 3003

CONSULT-II Data Link Connector (DLC)

Circuit ............................................................... 3003IDENTIFICATION INFORMATION...................... 3004

Model Variation ................................................ 3004

Identification Number ....................................... 3005

Wheels and Tires ............................................. 3007

Dimensions ...................................................... 3007

This modification has been included in production starting with the following vehicle identification numbers

(Chassis number):

JN1APGD22U0050001

JN1BPGD22U0030001

JN1APUD22U0030001

JN1BPUD22U0070001

JN1CPUD22U0070001

JN1ADGD22U0020001

JN1BDGD22U0030001

JN1BDUD22U0030001

JN1CDUD22U0030001

JN1CPGD22U0040001

JN1CPGD22U0740101

JN1CDUD22U0740101

JN1CPUD22U0765101

GI

Page 1014 of 1306

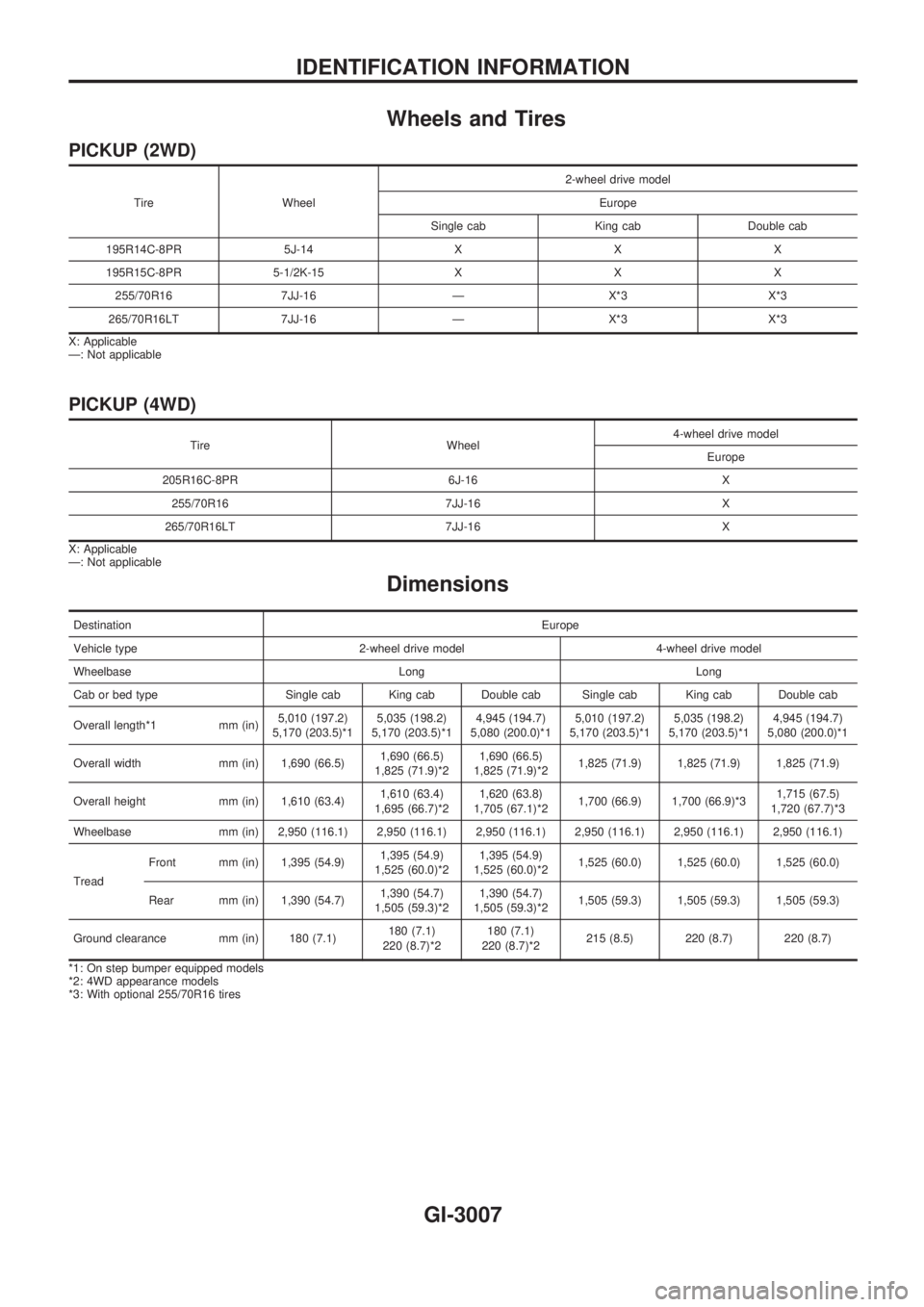

Wheels and Tires

PICKUP (2WD)

Tire Wheel2-wheel drive model

Europe

Single cab King cab Double cab

195R14C-8PR 5J-14 X X X

195R15C-8PR 5-1/2K-15 X X X

255/70R16 7JJ-16 Ð X*3 X*3

265/70R16LT 7JJ-16 Ð X*3 X*3

X: Applicable

Ð: Not applicable

PICKUP (4WD)

Tire Wheel4-wheel drive model

Europe

205R16C-8PR 6J-16 X

255/70R16 7JJ-16 X

265/70R16LT 7JJ-16 X

X: Applicable

Ð: Not applicable

Dimensions

DestinationEurope

Vehicle type 2-wheel drive model 4-wheel drive model

Wheelbase Long Long

Cab or bed type Single cab King cab Double cab Single cab King cab Double cab

Overall length*1 mm (in)5,010 (197.2)

5,170 (203.5)*15,035 (198.2)

5,170 (203.5)*14,945 (194.7)

5,080 (200.0)*15,010 (197.2)

5,170 (203.5)*15,035 (198.2)

5,170 (203.5)*14,945 (194.7)

5,080 (200.0)*1

Overall width mm (in) 1,690 (66.5)1,690 (66.5)

1,825 (71.9)*21,690 (66.5)

1,825 (71.9)*21,825 (71.9) 1,825 (71.9) 1,825 (71.9)

Overall height mm (in) 1,610 (63.4)1,610 (63.4)

1,695 (66.7)*21,620 (63.8)

1,705 (67.1)*21,700 (66.9) 1,700 (66.9)*31,715 (67.5)

1,720 (67.7)*3

Wheelbase mm (in) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1)

TreadFront mm (in) 1,395 (54.9)1,395 (54.9)

1,525 (60.0)*21,395 (54.9)

1,525 (60.0)*21,525 (60.0) 1,525 (60.0) 1,525 (60.0)

Rear mm (in) 1,390 (54.7)1,390 (54.7)

1,505 (59.3)*21,390 (54.7)

1,505 (59.3)*21,505 (59.3) 1,505 (59.3) 1,505 (59.3)

Ground clearance mm (in) 180 (7.1)180 (7.1)

220 (8.7)*2180 (7.1)

220 (8.7)*2215 (8.5) 220 (8.7) 220 (8.7)

*1: On step bumper equipped models

*2: 4WD appearance models

*3: With optional 255/70R16 tires

IDENTIFICATION INFORMATION

GI-3007

Page 1051 of 1306

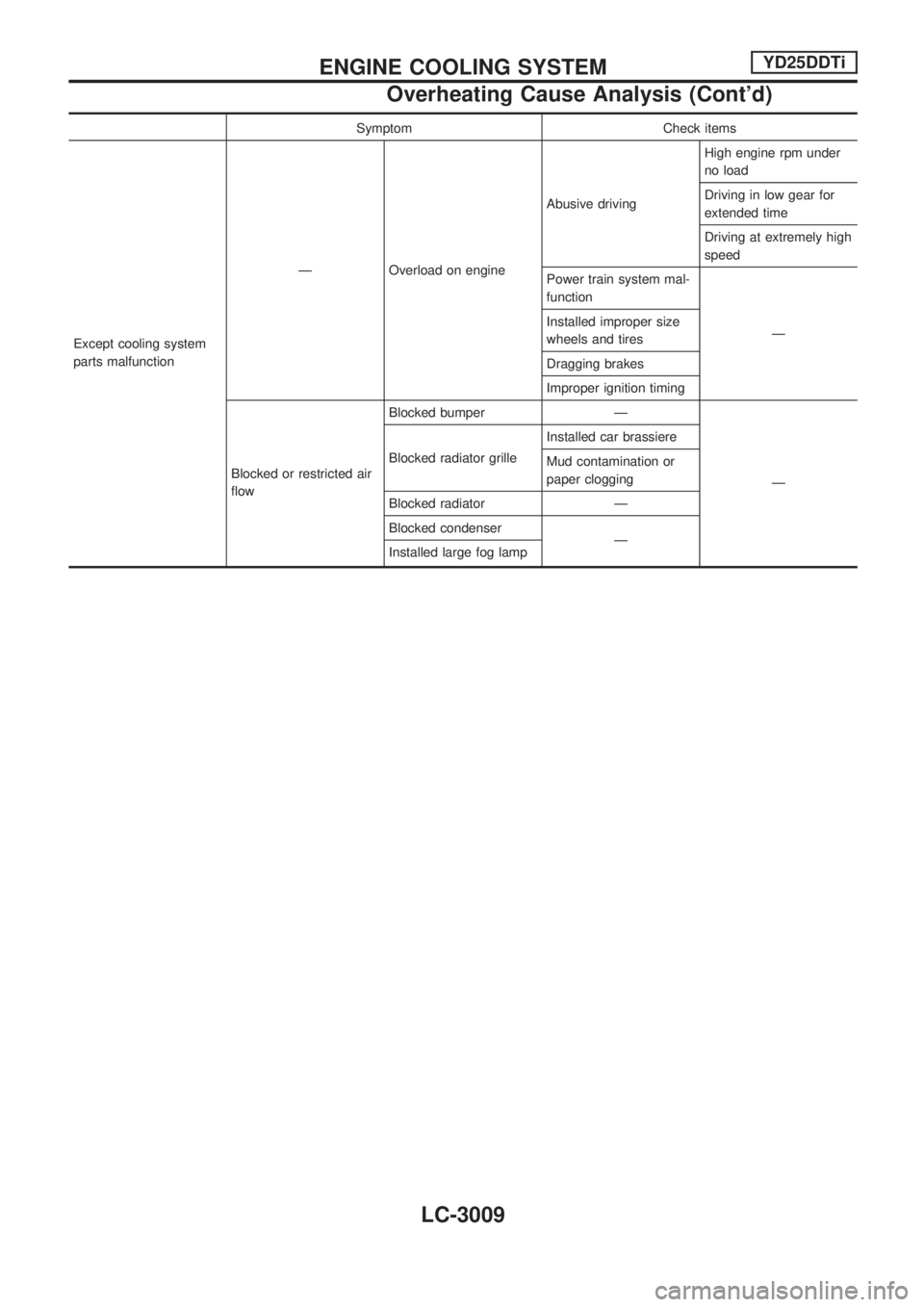

Symptom Check items

Except cooling system

parts malfunctionÐ Overload on engineAbusive drivingHigh engine rpm under

no load

Driving in low gear for

extended time

Driving at extremely high

speed

Power train system mal-

function

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

ENGINE COOLING SYSTEMYD25DDTi

Overheating Cause Analysis (Cont'd)

LC-3009

Page 1138 of 1306

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replace-

able halogen bulb. The bulb can be replaced from the engine

compartment side without removing the headlamp body.

+Grasp only the plastic base when handling the bulb.

Never touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the

bulb.

3. Pull off the rubber cap.

4. Push and raise retaining pin to loosen it.

5. Remove the headlamp bulb carefully. Do not shake or rotate

the bulb when removing it.

6. Install in the reverse order of removal.

CAUTION:

Do not leave headlamp reflector without bulb for a long

period of time. Dust, moisture, smoke, etc. entering head-

lamp body may affect the performance of the headlamp.

Remove headlamp bulb from the headlamp reflector just

before a replacement bulb is installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. Aimers should

be in good repair, calibrated and operated in accordance with

respective operation manuals.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is no-load in vehicle (coolant, engine oil

filled up to correct level and full fuel tank) other than the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ª0º when performing aiming

adjustment on vehicles equipped with headlamp aiming

control.

GEL452A

SEL596Y

SEL597Y

HEADLAMP Ð Conventional Type Ð

EL-3027