warning NISSAN PICK-UP 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 33 of 1306

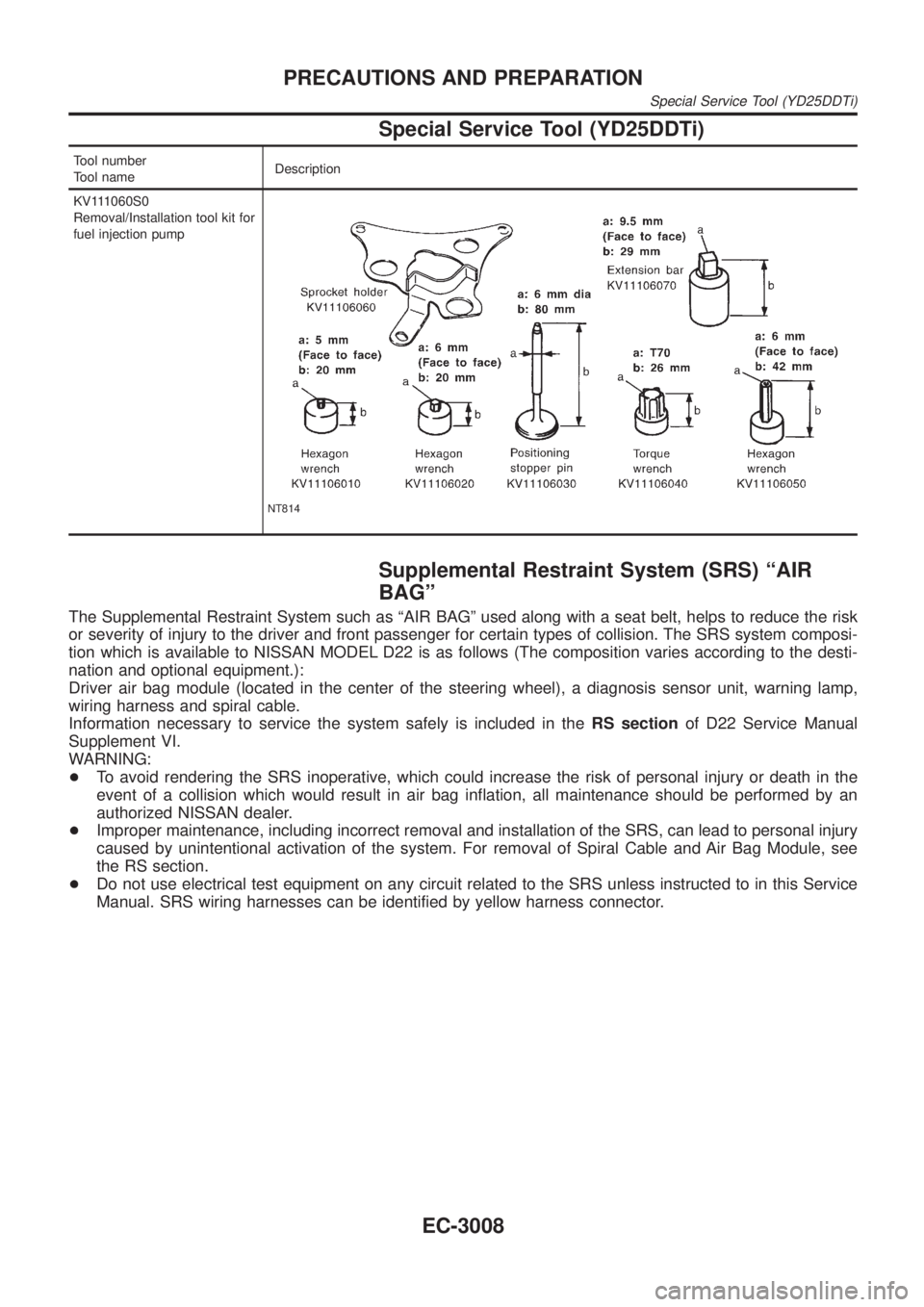

Special Service Tool (YD25DDTi)

Tool number

Tool nameDescription

KV111060S0

Removal/Installation tool kit for

fuel injection pump

NT814

Supplemental Restraint System (SRS) ªAIR

BAGº

The Supplemental Restraint System such as ªAIR BAGº used along with a seat belt, helps to reduce the risk

or severity of injury to the driver and front passenger for certain types of collision. The SRS system composi-

tion which is available to NISSAN MODEL D22 is as follows (The composition varies according to the desti-

nation and optional equipment.):

Driver air bag module (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof D22 Service Manual

Supplement VI.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in the

event of a collision which would result in air bag inflation, all maintenance should be performed by an

authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal injury

caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag Module, see

the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this Service

Manual. SRS wiring harnesses can be identified by yellow harness connector.

PRECAUTIONS AND PREPARATION

Special Service Tool (YD25DDTi)

EC-3008

Page 37 of 1306

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NEEC0002The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL D22 is as follows (The composition var-

ies according to the destination and optional equipment.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

Precautions for On Board Diagnostic (OBD)

System of Engine

NEEC0003The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver

of a malfunction causing emission deterioration.

CAUTION:

+Be sure to turn the ignition switch OFF and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

+Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

+Certain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector.

For description and how to disconnect, refer to EL section, ªHARNESS CONNECTORº.

+Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MI to light up due to the short circuit.

+Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the fuel injection system, etc.

+Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM before

returning the vehicle to the customer.

PRECAUTIONSKA24DE (EURO OBD)

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EC-3012

Page 86 of 1306

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, but

all of the data listed above, are cleared from the ECM memory during work procedures.

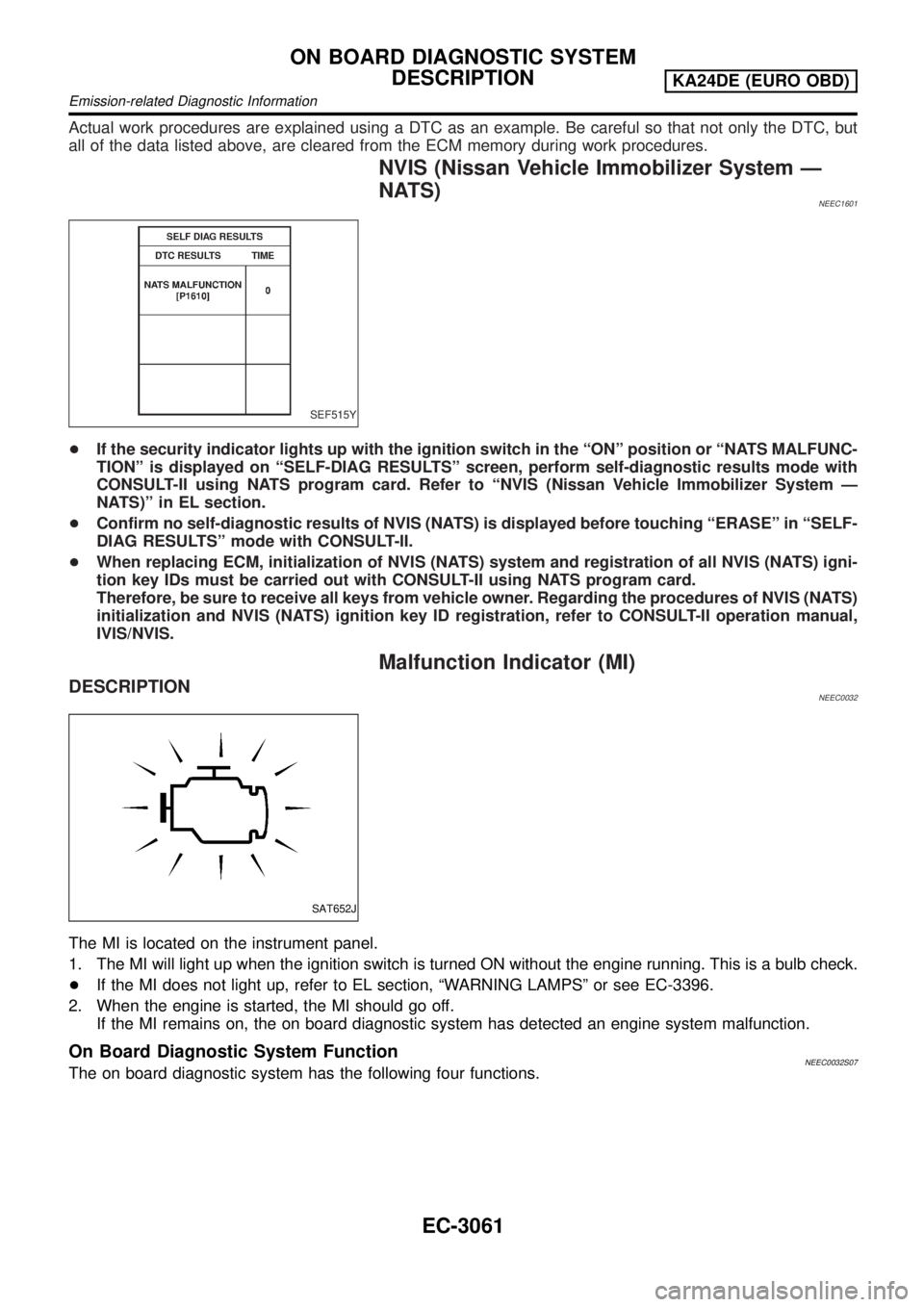

NVIS (Nissan Vehicle Immobilizer System Ð

NATS)

NEEC1601

SEF515Y

+If the security indicator lights up with the ignition switch in the ªONº position or ªNATS MALFUNC-

TIONº is displayed on ªSELF-DIAG RESULTSº screen, perform self-diagnostic results mode with

CONSULT-II using NATS program card. Refer to ªNVIS (Nissan Vehicle Immobilizer System Ð

NATS)º in EL section.

+Confirm no self-diagnostic results of NVIS (NATS) is displayed before touching ªERASEº in ªSELF-

DIAG RESULTSº mode with CONSULT-II.

+When replacing ECM, initialization of NVIS (NATS) system and registration of all NVIS (NATS) igni-

tion key IDs must be carried out with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner. Regarding the procedures of NVIS (NATS)

initialization and NVIS (NATS) ignition key ID registration, refer to CONSULT-II operation manual,

IVIS/NVIS.

Malfunction Indicator (MI)

DESCRIPTIONNEEC0032

SAT652J

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON without the engine running. This is a bulb check.

+If the MI does not light up, refer to EL section, ªWARNING LAMPSº or see EC-3396.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has detected an engine system malfunction.

On Board Diagnostic System FunctionNEEC0032S07The on board diagnostic system has the following four functions.

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION

KA24DE (EURO OBD)

Emission-related Diagnostic Information

EC-3061

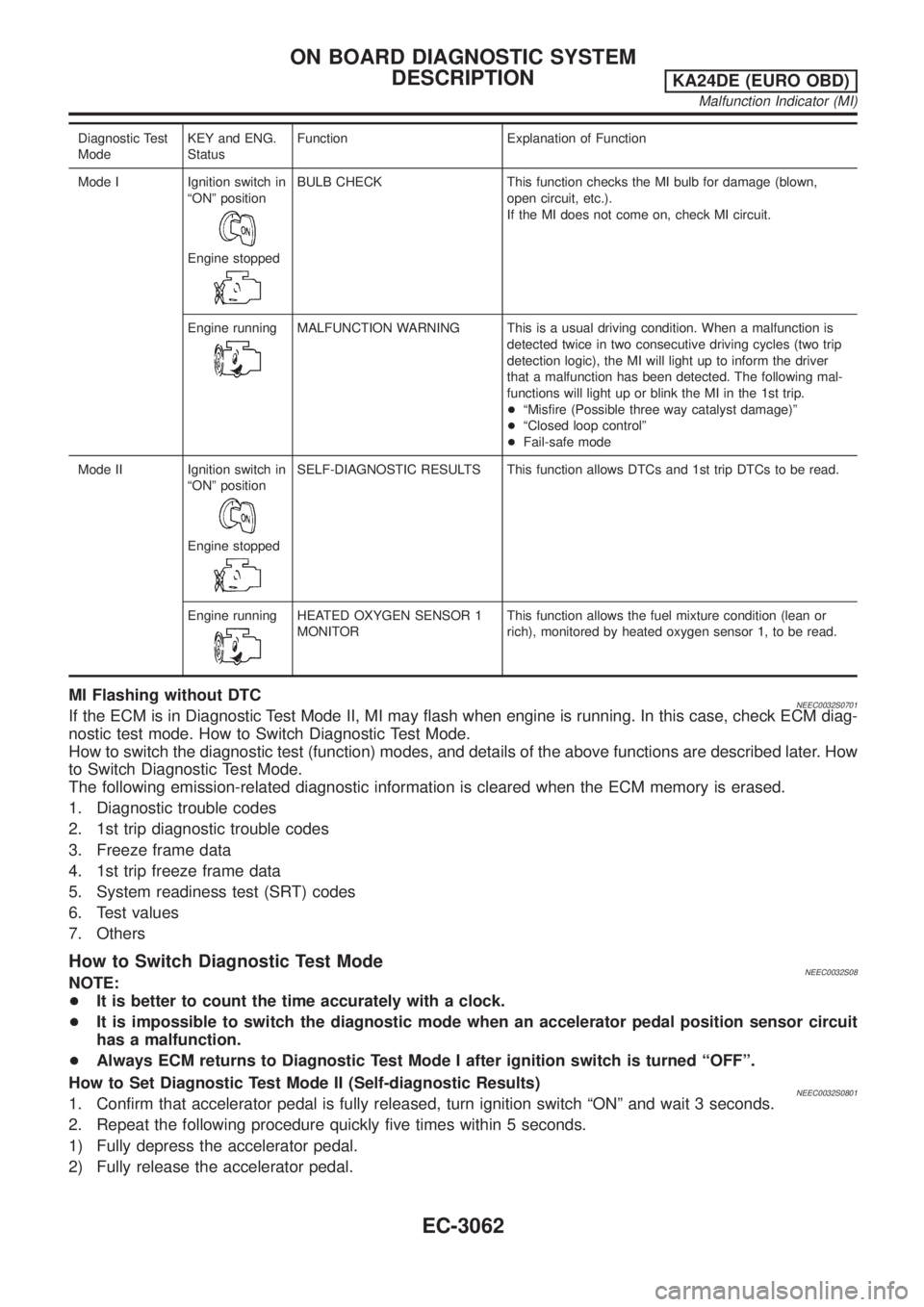

Page 87 of 1306

Diagnostic Test

ModeKEY and ENG.

StatusFunction Explanation of Function

Mode I Ignition switch in

ªONº position

Engine stopped

BULB CHECK This function checks the MI bulb for damage (blown,

open circuit, etc.).

If the MI does not come on, check MI circuit.

Engine running

MALFUNCTION WARNING This is a usual driving condition. When a malfunction is

detected twice in two consecutive driving cycles (two trip

detection logic), the MI will light up to inform the driver

that a malfunction has been detected. The following mal-

functions will light up or blink the MI in the 1st trip.

+ªMisfire (Possible three way catalyst damage)º

+ªClosed loop controlº

+Fail-safe mode

Mode II Ignition switch in

ªONº position

Engine stopped

SELF-DIAGNOSTIC RESULTS This function allows DTCs and 1st trip DTCs to be read.

Engine running

HEATED OXYGEN SENSOR 1

MONITORThis function allows the fuel mixture condition (lean or

rich), monitored by heated oxygen sensor 1, to be read.

MI Flashing without DTCNEEC0032S0701If the ECM is in Diagnostic Test Mode II, MI may flash when engine is running. In this case, check ECM diag-

nostic test mode. How to Switch Diagnostic Test Mode.

How to switch the diagnostic test (function) modes, and details of the above functions are described later. How

to Switch Diagnostic Test Mode.

The following emission-related diagnostic information is cleared when the ECM memory is erased.

1. Diagnostic trouble codes

2. 1st trip diagnostic trouble codes

3. Freeze frame data

4. 1st trip freeze frame data

5. System readiness test (SRT) codes

6. Test values

7. Others

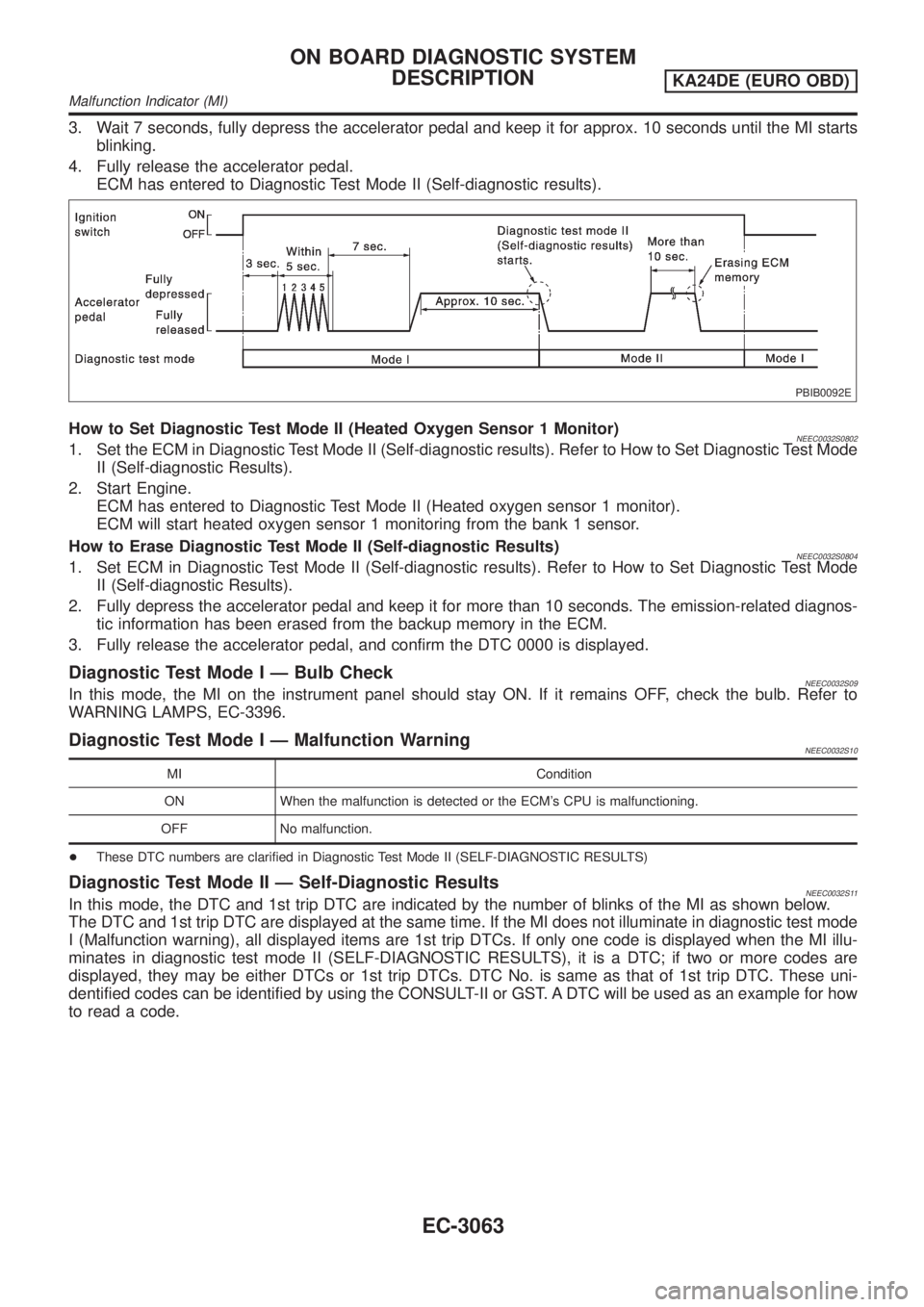

How to Switch Diagnostic Test ModeNEEC0032S08NOTE:

+It is better to count the time accurately with a clock.

+It is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit

has a malfunction.

+Always ECM returns to Diagnostic Test Mode I after ignition switch is turned ªOFFº.

How to Set Diagnostic Test Mode II (Self-diagnostic Results)

NEEC0032S08011. Confirm that accelerator pedal is fully released, turn ignition switch ªONº and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds.

1) Fully depress the accelerator pedal.

2) Fully release the accelerator pedal.

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION

KA24DE (EURO OBD)

Malfunction Indicator (MI)

EC-3062

Page 88 of 1306

3. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 10 seconds until the MI starts

blinking.

4. Fully release the accelerator pedal.

ECM has entered to Diagnostic Test Mode II (Self-diagnostic results).

PBIB0092E

How to Set Diagnostic Test Mode II (Heated Oxygen Sensor 1 Monitor)NEEC0032S08021. Set the ECM in Diagnostic Test Mode II (Self-diagnostic results). Refer to How to Set Diagnostic Test Mode

II (Self-diagnostic Results).

2. Start Engine.

ECM has entered to Diagnostic Test Mode II (Heated oxygen sensor 1 monitor).

ECM will start heated oxygen sensor 1 monitoring from the bank 1 sensor.

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

NEEC0032S08041. Set ECM in Diagnostic Test Mode II (Self-diagnostic results). Refer to How to Set Diagnostic Test Mode

II (Self-diagnostic Results).

2. Fully depress the accelerator pedal and keep it for more than 10 seconds. The emission-related diagnos-

tic information has been erased from the backup memory in the ECM.

3. Fully release the accelerator pedal, and confirm the DTC 0000 is displayed.

Diagnostic Test Mode I Ð Bulb CheckNEEC0032S09In this mode, the MI on the instrument panel should stay ON. If it remains OFF, check the bulb. Refer to

WARNING LAMPS, EC-3396.

Diagnostic Test Mode I Ð Malfunction WarningNEEC0032S10

MI Condition

ON When the malfunction is detected or the ECM's CPU is malfunctioning.

OFF No malfunction.

+These DTC numbers are clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC RESULTS)

Diagnostic Test Mode II Ð Self-Diagnostic ResultsNEEC0032S11In this mode, the DTC and 1st trip DTC are indicated by the number of blinks of the MI as shown below.

The DTC and 1st trip DTC are displayed at the same time. If the MI does not illuminate in diagnostic test mode

I (Malfunction warning), all displayed items are 1st trip DTCs. If only one code is displayed when the MI illu-

minates in diagnostic test mode II (SELF-DIAGNOSTIC RESULTS), it is a DTC; if two or more codes are

displayed, they may be either DTCs or 1st trip DTCs. DTC No. is same as that of 1st trip DTC. These uni-

dentified codes can be identified by using the CONSULT-II or GST. A DTC will be used as an example for how

to read a code.

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION

KA24DE (EURO OBD)

Malfunction Indicator (MI)

EC-3063

Page 141 of 1306

![NISSAN PICK-UP 2001 Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

49*1 WCamshaft position sen-

sor (Position signal)[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

SEF195T

[Engine is runni NISSAN PICK-UP 2001 Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

49*1 WCamshaft position sen-

sor (Position signal)[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

SEF195T

[Engine is runni](/img/5/57372/w960_57372-140.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

49*1 WCamshaft position sen-

sor (Position signal)[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

SEF195T

[Engine is running]

+Engine speed is 2,000 rpmApproximately 1.0V

SEF196T

49*2

53*2OR

ORCamshaft position sen-

sor (Reference signal)[Engine is running]

+Warm-up condition

+Idle speed0.2 - 0.5VSEF114V

[Engine is running]

+Engine speed is 2,000 rpm0 - 0.5V

SEF200T

50 WHeated oxygen sensor

1[Engine is running]

+After warning up to normal operating tempera-

ture and engine speed is 2,000 rpm.0 - Approximately 1.0V

SEF201T

54 L Mass air flow sensor[Engine is running]

+Warm-up condition

+Idle speed0.9 - 1.8V

[Engine is running]

+Warm-up condition

+Engine speed is 2,500 rpm1.9 - 2.3V

55 PMass air flow sensor

ground[Engine is running]

+Warm-up condition

+Idle speedApproximately 0V

TROUBLE DIAGNOSIS Ð GENERAL

DESCRIPTION

KA24DE (EURO OBD)

ECM Terminals and Reference Value

EC-3116

Page 369 of 1306

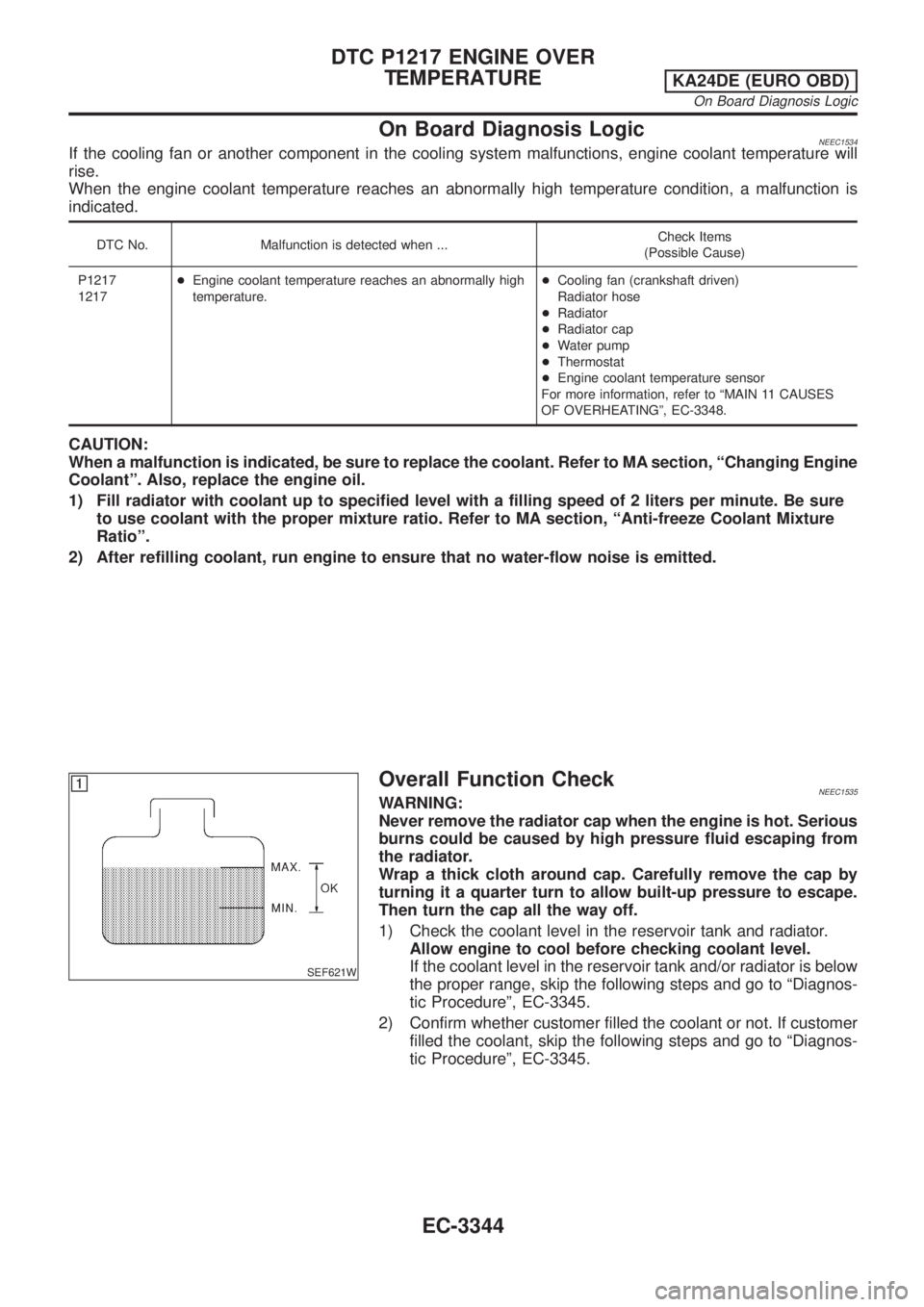

On Board Diagnosis LogicNEEC1534If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

DTC No. Malfunction is detected when ...Check Items

(Possible Cause)

P1217

1217+Engine coolant temperature reaches an abnormally high

temperature.+Cooling fan (crankshaft driven)

Radiator hose

+Radiator

+Radiator cap

+Water pump

+Thermostat

+Engine coolant temperature sensor

For more information, refer to ªMAIN 11 CAUSES

OF OVERHEATINGº, EC-3348.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant. Refer to MA section, ªChanging Engine

Coolantº. Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure

to use coolant with the proper mixture ratio. Refer to MA section, ªAnti-freeze Coolant Mixture

Ratioº.

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

SEF621W

Overall Function CheckNEEC1535WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high pressure fluid escaping from

the radiator.

Wrap a thick cloth around cap. Carefully remove the cap by

turning it a quarter turn to allow built-up pressure to escape.

Then turn the cap all the way off.

1) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-3345.

2) Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-3345.

DTC P1217 ENGINE OVER

TEMPERATURE

KA24DE (EURO OBD)

On Board Diagnosis Logic

EC-3344

Page 442 of 1306

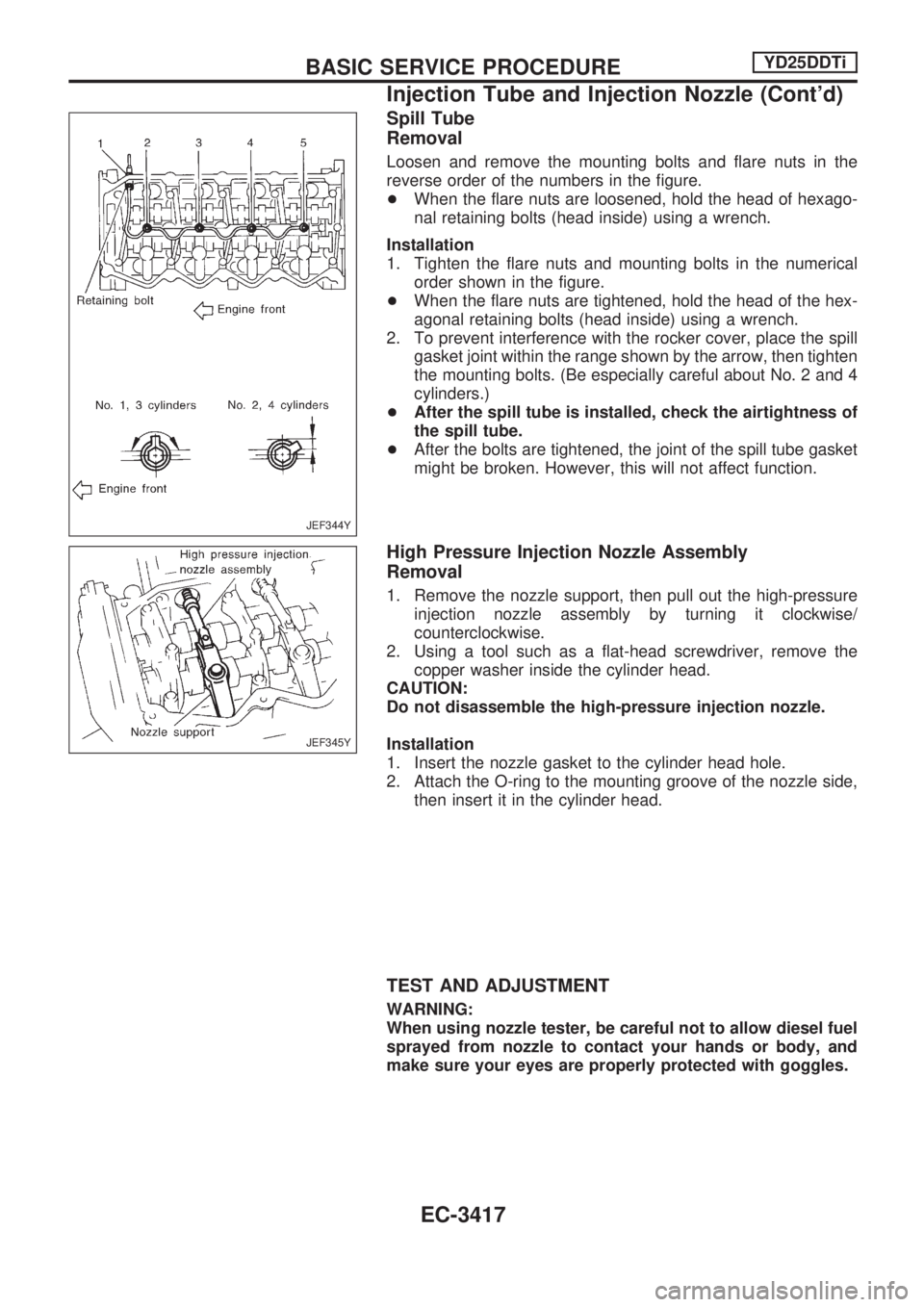

Spill Tube

Removal

Loosen and remove the mounting bolts and flare nuts in the

reverse order of the numbers in the figure.

+When the flare nuts are loosened, hold the head of hexago-

nal retaining bolts (head inside) using a wrench.

Installation

1. Tighten the flare nuts and mounting bolts in the numerical

order shown in the figure.

+When the flare nuts are tightened, hold the head of the hex-

agonal retaining bolts (head inside) using a wrench.

2. To prevent interference with the rocker cover, place the spill

gasket joint within the range shown by the arrow, then tighten

the mounting bolts. (Be especially careful about No. 2 and 4

cylinders.)

+After the spill tube is installed, check the airtightness of

the spill tube.

+After the bolts are tightened, the joint of the spill tube gasket

might be broken. However, this will not affect function.

High Pressure Injection Nozzle Assembly

Removal

1. Remove the nozzle support, then pull out the high-pressure

injection nozzle assembly by turning it clockwise/

counterclockwise.

2. Using a tool such as a flat-head screwdriver, remove the

copper washer inside the cylinder head.

CAUTION:

Do not disassemble the high-pressure injection nozzle.

Installation

1. Insert the nozzle gasket to the cylinder head hole.

2. Attach the O-ring to the mounting groove of the nozzle side,

then insert it in the cylinder head.

TEST AND ADJUSTMENT

WARNING:

When using nozzle tester, be careful not to allow diesel fuel

sprayed from nozzle to contact your hands or body, and

make sure your eyes are properly protected with goggles.

JEF344Y

JEF345Y

BASIC SERVICE PROCEDUREYD25DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-3417

Page 454 of 1306

+Erasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

NATS (Nissan Anti-Theft System)

+If the security indicator lights up with the ignition switch

in the ªONº position or ªNATS MALFUNCTIONº is dis-

played on ªSELF-DIAG RESULTSº screen, perform self-

diagnostic results mode with CONSULT-II using NATS

program card. Refer to ªNATS (Nissan Anti-Theft Sys-

tem)º in EL section.

+Confirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº

mode with CONSULT-II.

+When replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried

out with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle

owner. Regarding the procedures of NATS initialization

and NATS ignition key ID registration, refer to CON-

SULT-II operation manual, NATS.

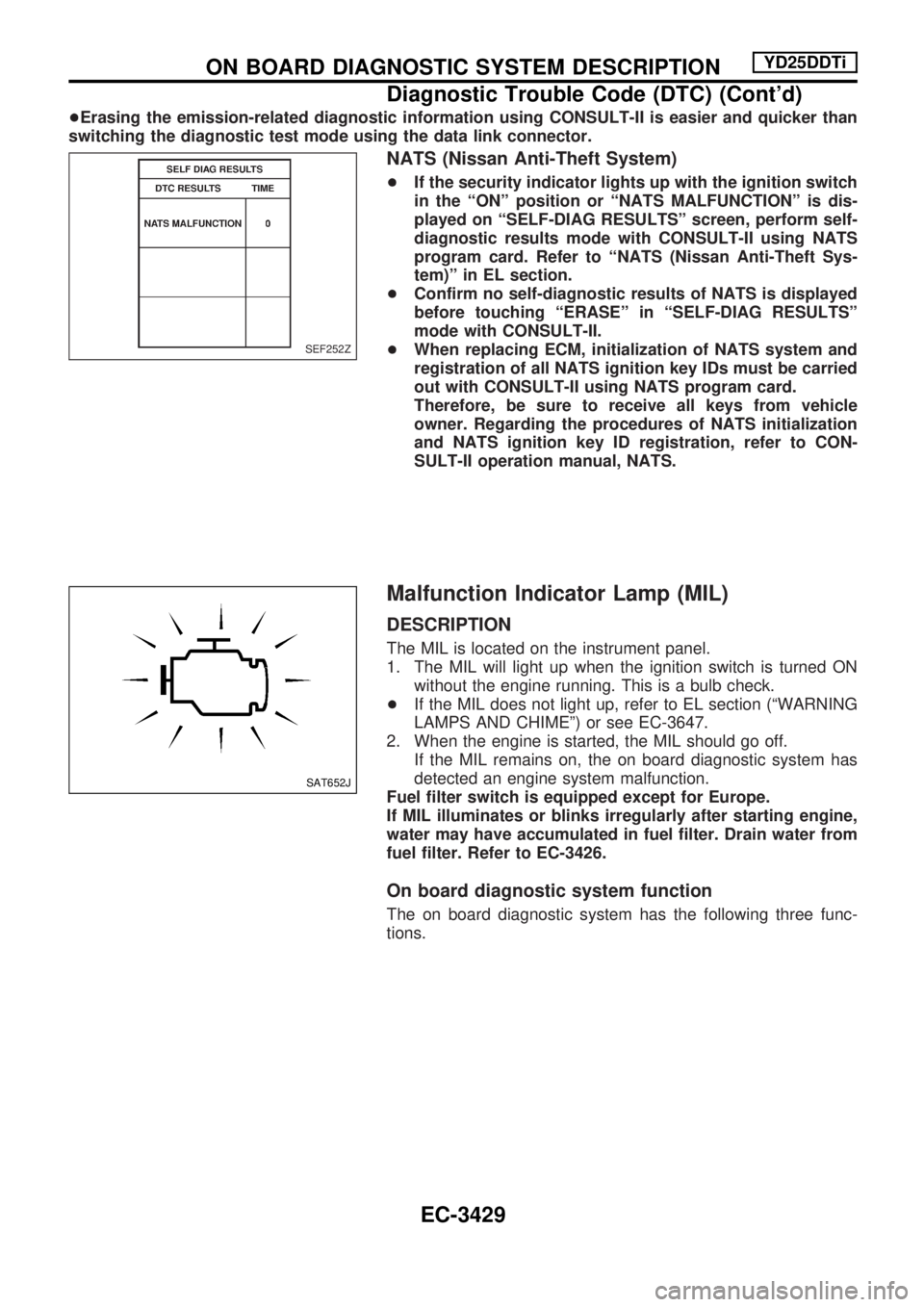

Malfunction Indicator Lamp (MIL)

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON

without the engine running. This is a bulb check.

+If the MIL does not light up, refer to EL section (ªWARNING

LAMPS AND CHIMEº) or see EC-3647.

2. When the engine is started, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

Fuel filter switch is equipped except for Europe.

If MIL illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter. Refer to EC-3426.

On board diagnostic system function

The on board diagnostic system has the following three func-

tions.

SEF252Z

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD25DDTi

Diagnostic Trouble Code (DTC) (Cont'd)

EC-3429

Page 455 of 1306

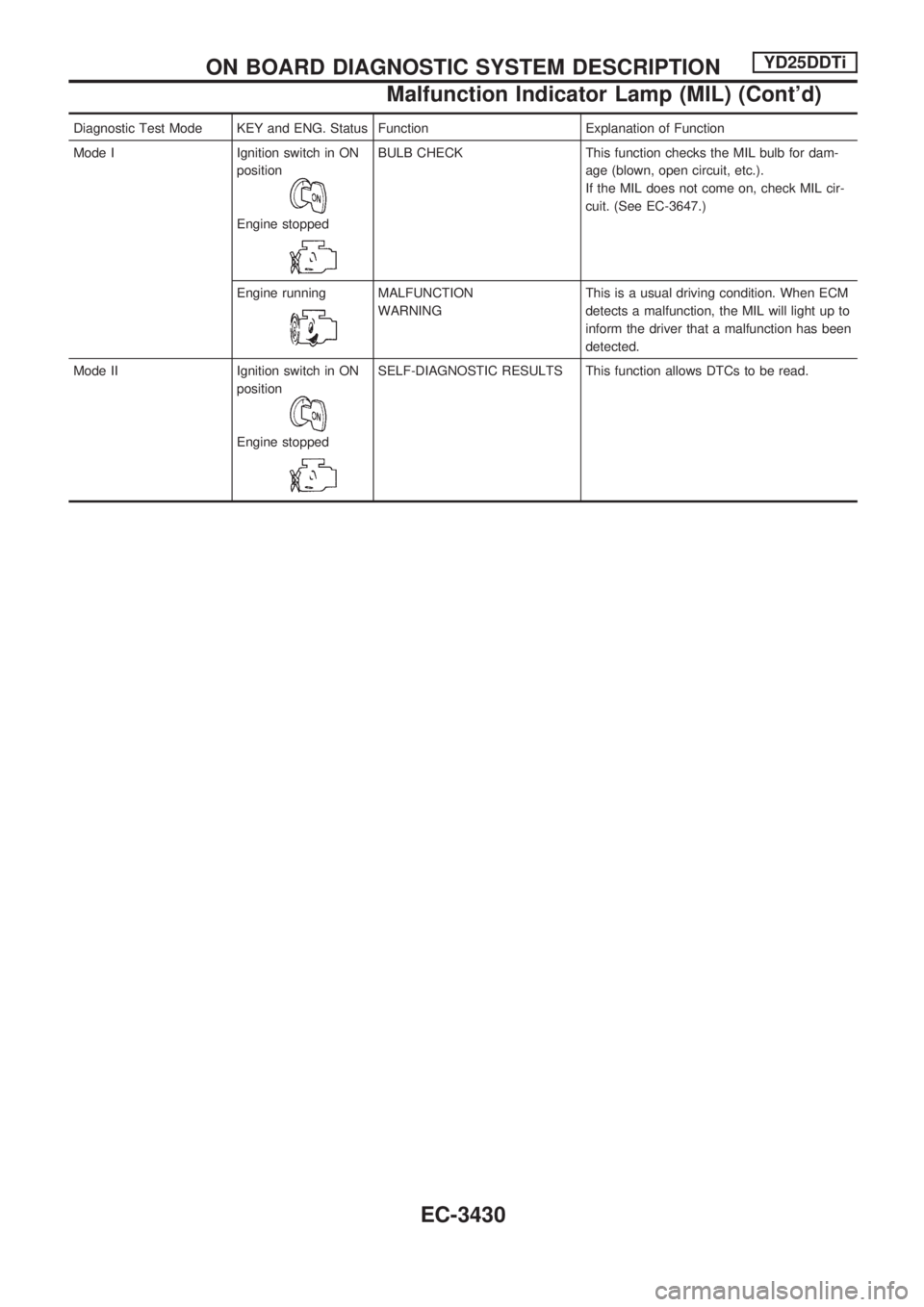

Diagnostic Test Mode KEY and ENG. Status Function Explanation of Function

Mode I Ignition switch in ON

position

Engine stopped

BULB CHECK This function checks the MIL bulb for dam-

age (blown, open circuit, etc.).

If the MIL does not come on, check MIL cir-

cuit. (See EC-3647.)

Engine running

MALFUNCTION

WARNINGThis is a usual driving condition. When ECM

detects a malfunction, the MIL will light up to

inform the driver that a malfunction has been

detected.

Mode II Ignition switch in ON

position

Engine stopped

SELF-DIAGNOSTIC RESULTS This function allows DTCs to be read.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD25DDTi

Malfunction Indicator Lamp (MIL) (Cont'd)

EC-3430