sensor NISSAN PICK-UP 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 547 of 1306

Diagnostic Procedure

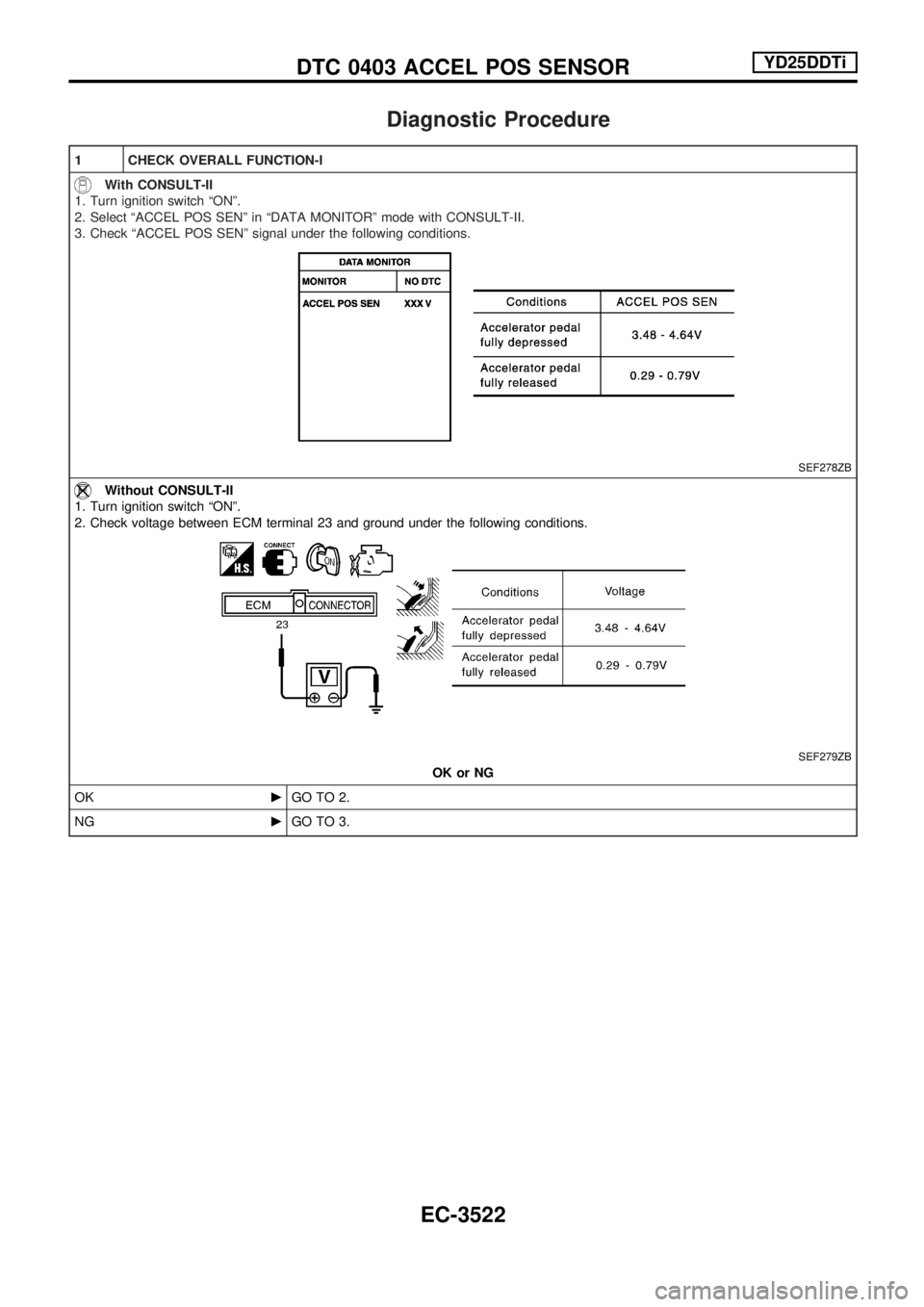

1 CHECK OVERALL FUNCTION-I

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªACCEL POS SENº in ªDATA MONITORº mode with CONSULT-II.

3. Check ªACCEL POS SENº signal under the following conditions.

SEF278ZB

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 23 and ground under the following conditions.

SEF279ZB

OK or NG

OKcGO TO 2.

NGcGO TO 3.

DTC 0403 ACCEL POS SENSORYD25DDTi

EC-3522

Page 548 of 1306

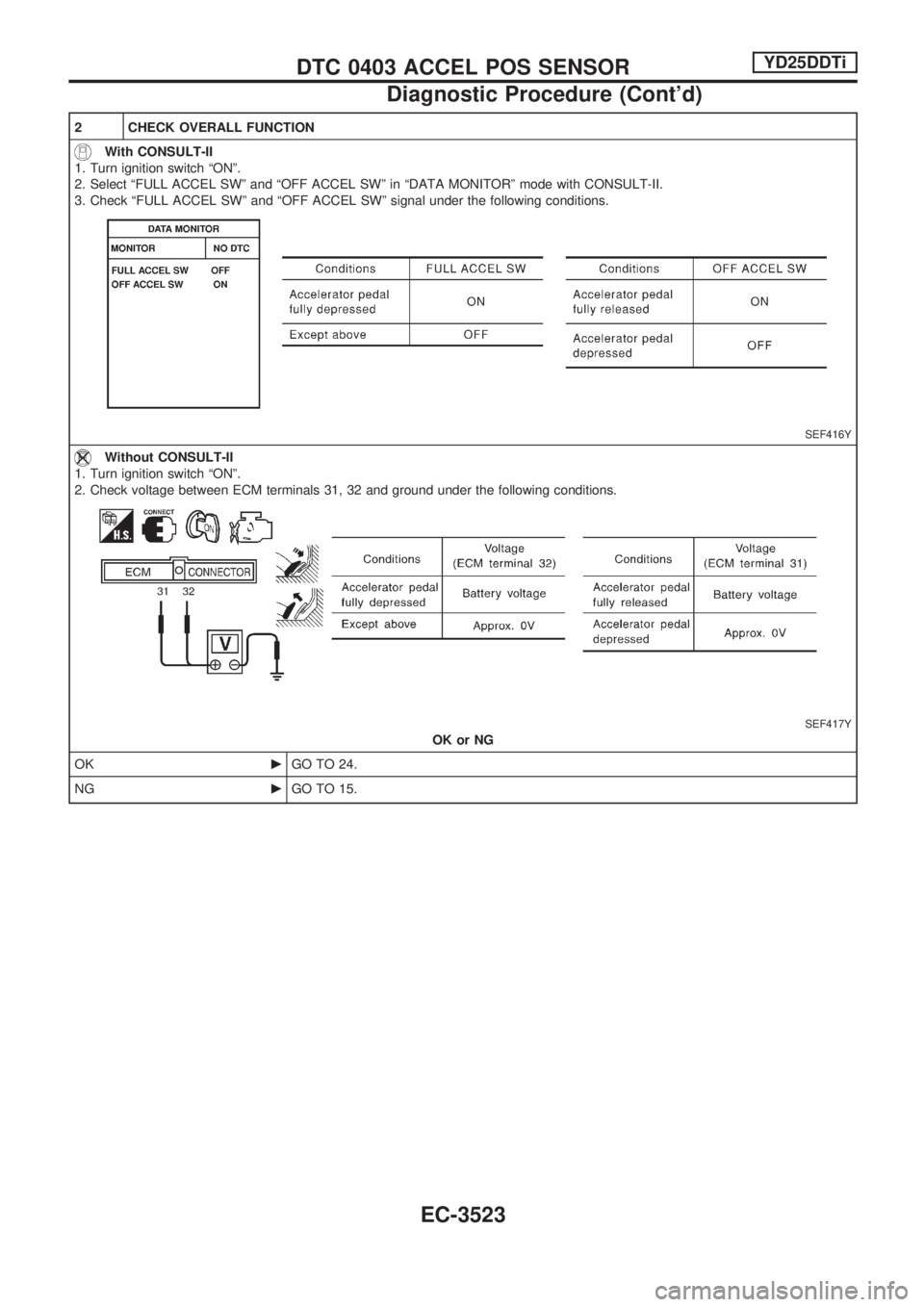

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªFULL ACCEL SWº and ªOFF ACCEL SWº in ªDATA MONITORº mode with CONSULT-II.

3. Check ªFULL ACCEL SWº and ªOFF ACCEL SWº signal under the following conditions.

SEF416Y

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminals 31, 32 and ground under the following conditions.

SEF417Y

OK or NG

OKcGO TO 24.

NGcGO TO 15.

DTC 0403 ACCEL POS SENSORYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3523

Page 549 of 1306

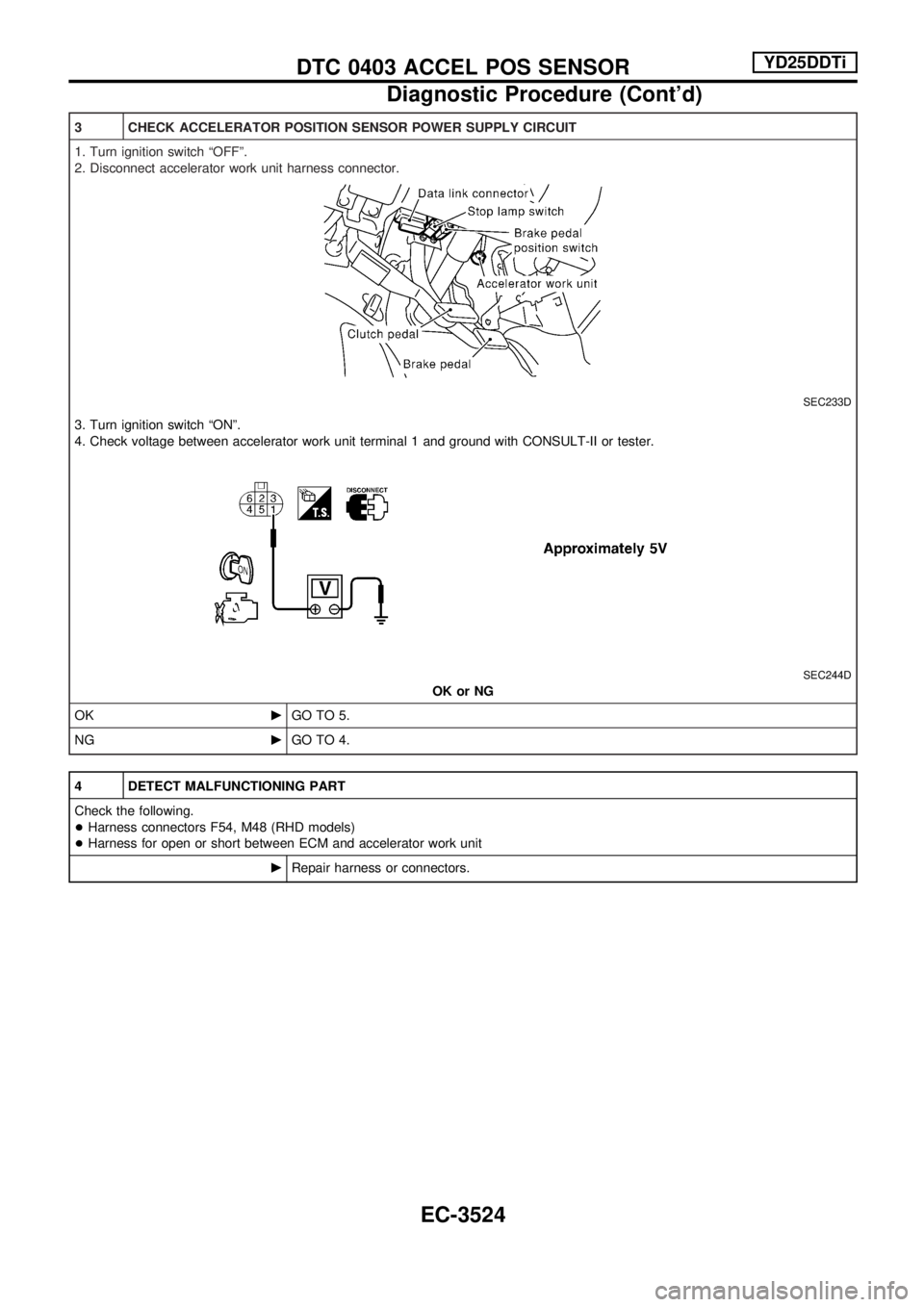

3 CHECK ACCELERATOR POSITION SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect accelerator work unit harness connector.

SEC233D

3. Turn ignition switch ªONº.

4. Check voltage between accelerator work unit terminal 1 and ground with CONSULT-II or tester.

SEC244D

OK or NG

OKcGO TO 5.

NGcGO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F54, M48 (RHD models)

+Harness for open or short between ECM and accelerator work unit

cRepair harness or connectors.

DTC 0403 ACCEL POS SENSORYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3524

Page 550 of 1306

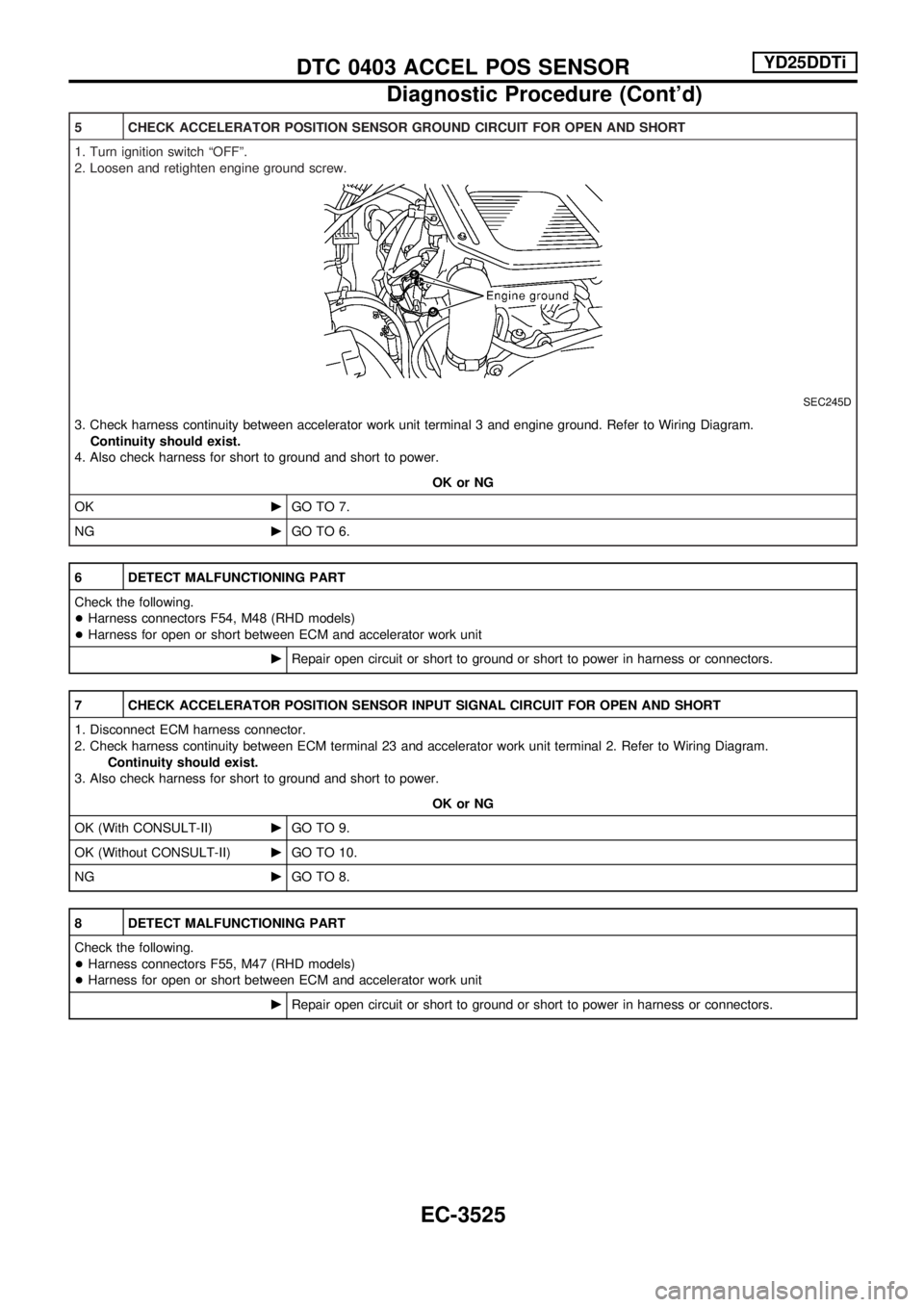

5 CHECK ACCELERATOR POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screw.

SEC245D

3. Check harness continuity between accelerator work unit terminal 3 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 7.

NGcGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F54, M48 (RHD models)

+Harness for open or short between ECM and accelerator work unit

cRepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK ACCELERATOR POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 23 and accelerator work unit terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK (With CONSULT-II)cGO TO 9.

OK (Without CONSULT-II)cGO TO 10.

NGcGO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F55, M47 (RHD models)

+Harness for open or short between ECM and accelerator work unit

cRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0403 ACCEL POS SENSORYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3525

Page 551 of 1306

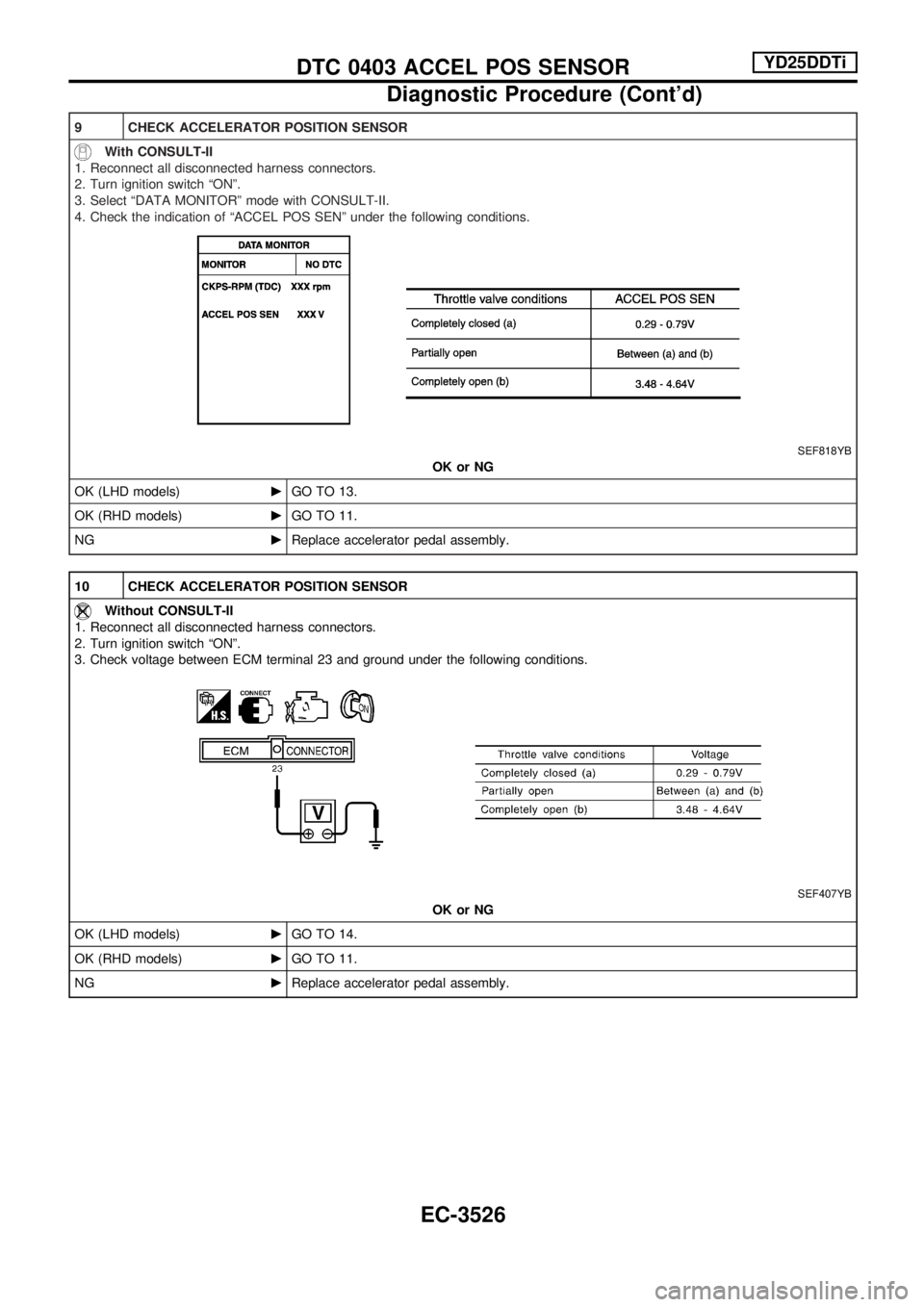

9 CHECK ACCELERATOR POSITION SENSOR

With CONSULT-II

1. Reconnect all disconnected harness connectors.

2. Turn ignition switch ªONº.

3. Select ªDATA MONITORº mode with CONSULT-II.

4. Check the indication of ªACCEL POS SENº under the following conditions.

SEF818YB

OK or NG

OK (LHD models)cGO TO 13.

OK (RHD models)cGO TO 11.

NGcReplace accelerator pedal assembly.

10 CHECK ACCELERATOR POSITION SENSOR

Without CONSULT-II

1. Reconnect all disconnected harness connectors.

2. Turn ignition switch ªONº.

3. Check voltage between ECM terminal 23 and ground under the following conditions.

SEF407YB

OK or NG

OK (LHD models)cGO TO 14.

OK (RHD models)cGO TO 11.

NGcReplace accelerator pedal assembly.

DTC 0403 ACCEL POS SENSORYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3526

Page 552 of 1306

11 CHECK ACCELERATOR POSITION SENSOR SHIELD CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between harness connector F55 terminal 13 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK (With CONSULT-II)cGO TO 13.

OK (Without CONSULT-II)cGO TO 14.

NGcGO TO 12.

12 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M47, F55

+Harness for open or short between harness connector F55 and engine ground

cRepair harness or connectors.

13 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªOFF ACCEL PO SIGº in ªACTIVE TESTº mode with CONSULT-II.

3. Touch ªCLEARº.

cGO TO 24.

14 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Let engine idle for 10 minutes.

cGO TO 24.

DTC 0403 ACCEL POS SENSORYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3527

Page 553 of 1306

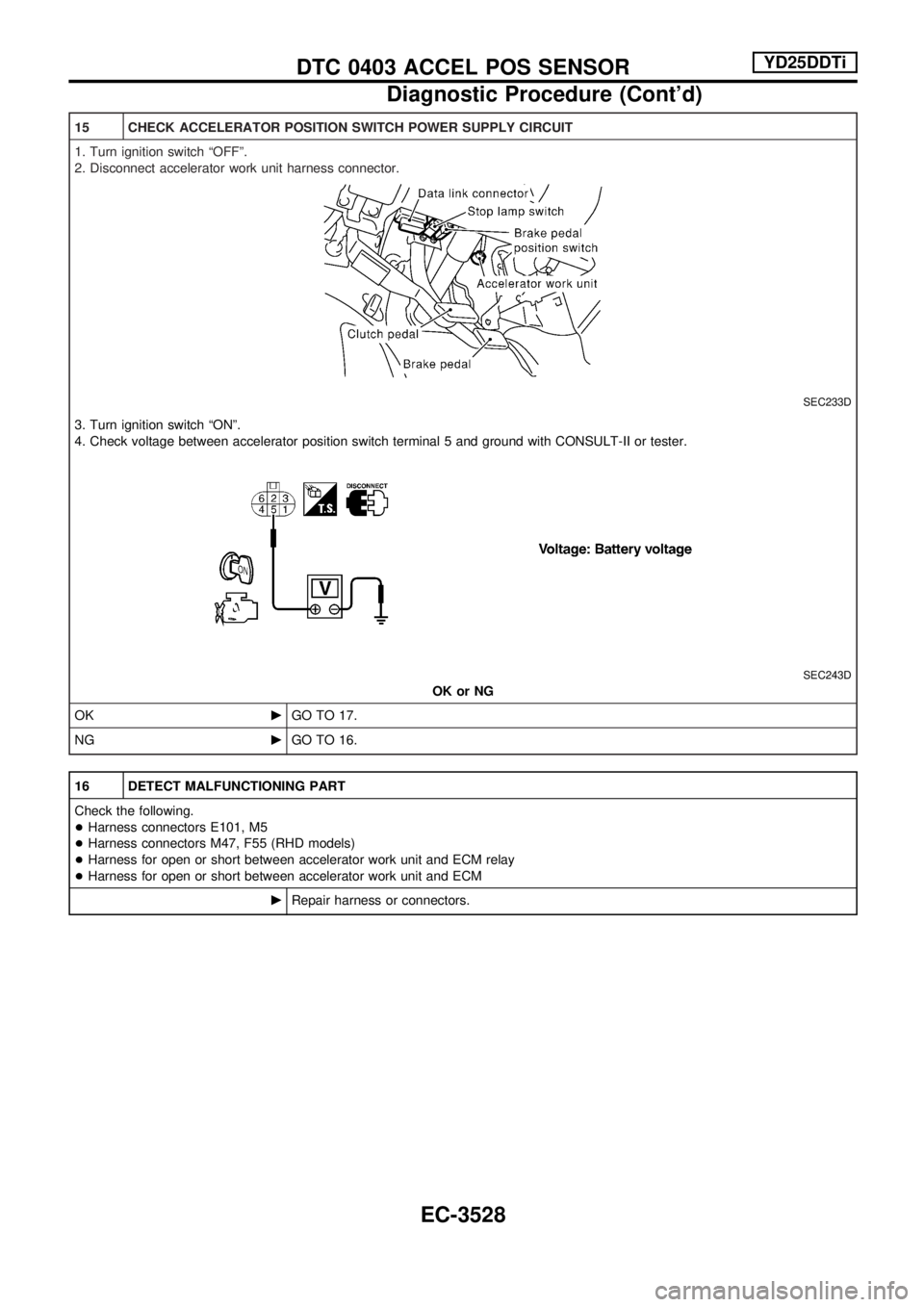

15 CHECK ACCELERATOR POSITION SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect accelerator work unit harness connector.

SEC233D

3. Turn ignition switch ªONº.

4. Check voltage between accelerator position switch terminal 5 and ground with CONSULT-II or tester.

SEC243D

OK or NG

OKcGO TO 17.

NGcGO TO 16.

16 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E101, M5

+Harness connectors M47, F55 (RHD models)

+Harness for open or short between accelerator work unit and ECM relay

+Harness for open or short between accelerator work unit and ECM

cRepair harness or connectors.

DTC 0403 ACCEL POS SENSORYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3528

Page 554 of 1306

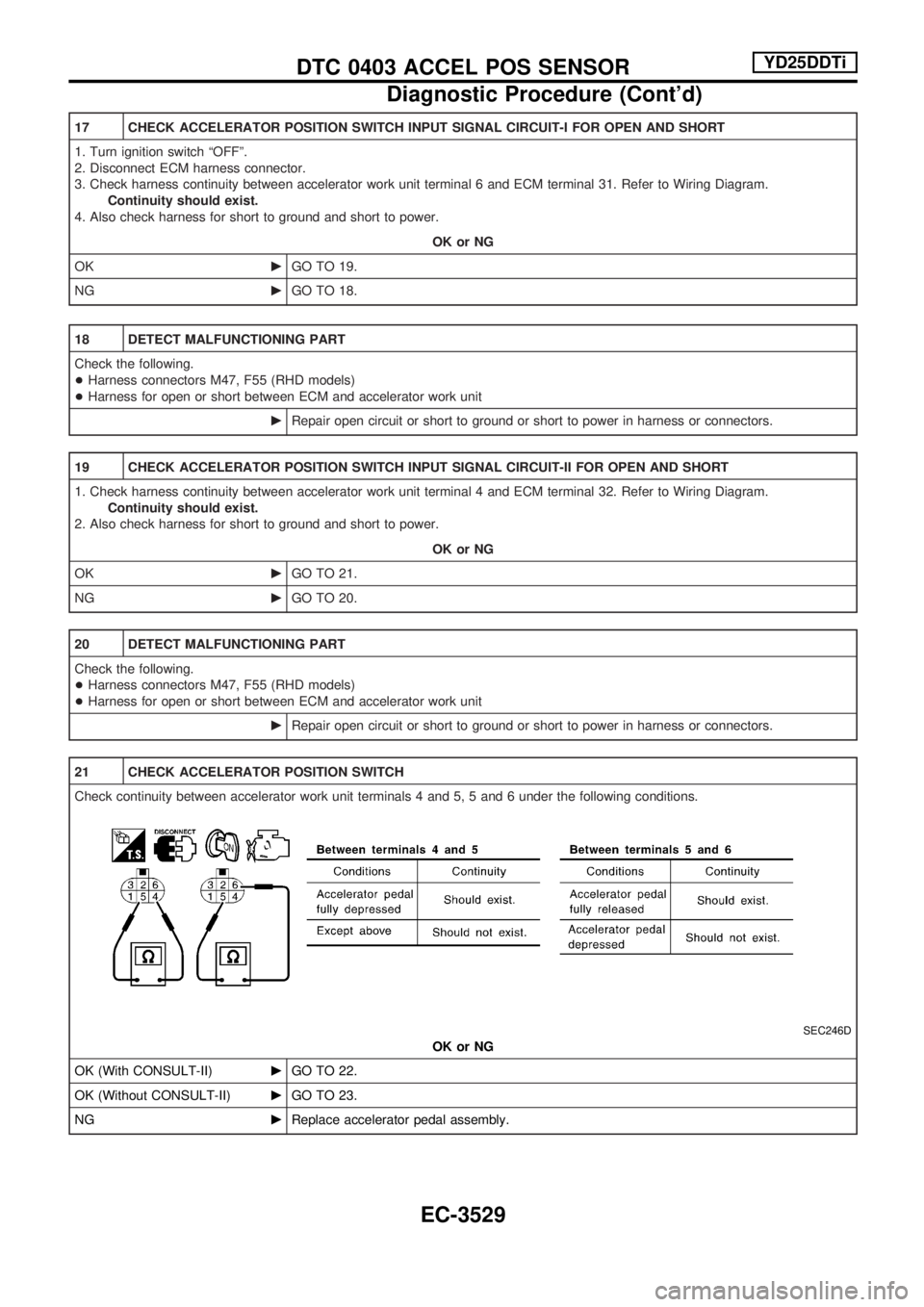

17 CHECK ACCELERATOR POSITION SWITCH INPUT SIGNAL CIRCUIT-I FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between accelerator work unit terminal 6 and ECM terminal 31. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 19.

NGcGO TO 18.

18 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M47, F55 (RHD models)

+Harness for open or short between ECM and accelerator work unit

cRepair open circuit or short to ground or short to power in harness or connectors.

19 CHECK ACCELERATOR POSITION SWITCH INPUT SIGNAL CIRCUIT-II FOR OPEN AND SHORT

1. Check harness continuity between accelerator work unit terminal 4 and ECM terminal 32. Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 21.

NGcGO TO 20.

20 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M47, F55 (RHD models)

+Harness for open or short between ECM and accelerator work unit

cRepair open circuit or short to ground or short to power in harness or connectors.

21 CHECK ACCELERATOR POSITION SWITCH

Check continuity between accelerator work unit terminals 4 and 5, 5 and 6 under the following conditions.

SEC246D

OK or NG

OK (With CONSULT-II)cGO TO 22.

OK (Without CONSULT-II)cGO TO 23.

NGcReplace accelerator pedal assembly.

DTC 0403 ACCEL POS SENSORYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3529

Page 555 of 1306

22 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

1. Reconnect all connectors disconnected.

2. Turn ignition switch ªONº.

3. Select ªOFF ACCEL PO SIGº in ªACTIVE TESTº mode with CONSULT-II.

4. Touch ªCLEARº.

cGO TO 24.

23 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

1. Reconnect all connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Let engine idle for 10 minutes.

cGO TO 24.

24 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

cINSPECTION END

DTC 0403 ACCEL POS SENSORYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3530

Page 556 of 1306

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

+An excessively high voltage from the charge air pressure sen-

sor is sent to ECM when engine is running.+Intake air system

+Turbocharger system

+Charge air pressure sensor

+Harness or connectors

(The charge air pressure sensor circuit is shorted.)

DTC Confirmation Procedure

NOTE:

If DTC 0406 ªINT AIR VOLº displayed with DTC 0905

ªTURBO PRESSUREº, perform trouble diagnosis for DTC

0905 ªTURBO PRESSUREº first. (See EC-3601.)

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and warm it up to normal operating temperature.

4) Drive vehicle.

5) Maintain the engine speed more than 4,000 rpm for at least

10 seconds.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-3533.

WITHOUT CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Drive vehicle.

3) Maintain the engine speed more than 4,000 rpm for at least

10 seconds.

4) Stop vehicle.

5) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

6) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

7) If DTC is detected, go to ªDiagnostic Procedureº, EC-3533.SEF817Y

DTC 0406 INT AIR VOLYD25DDTi

EC-3531